Page 1

D22

DIGITAL BROADCAST DELAY

USER’S MANUAL

Page 2

Page 3

a

IMPORTANT SAFETY INSTRUCTIONS

1 Read these instructions.

2 Keep these instructions.

3 Heed all warnings.

4 Follow all instructions.

5 Do not use this apparatus near water.

6 Clean only with dry cloth.

7 Do not block any ventilation openings.

Install in accordance with the manufacturer's

instructions.

8 Do not install near any heat sources such as radiators,

heat registers, stoves, or other apparatus (including

amplifiers) that produce heat.

9 Do not defeat the safety purpose of the polarized or

grounding-type plug. A polarized plug has two blades

with one wider than the other. A grounding type plug

has two blades and a third grounding prong. The wide

blade or the third prong are provided for your safety. If

the provided plug does not fit into your outlet, consult

an electrician for replacement of the obsolete outlet.

10 Protect the power cord from being walked on or

pinched particularly at plugs, convenience receptacles,

and the point where they exit from the apparatus.

11 Only use attachments/accessories specified by the

manufacturer.

12 Unplug this apparatus during lightning storms or when

unused for long periods of time.

13 Refer all servicing to qualified service personnel.

Servicing is required when the apparatus has been

damaged in any way, such as power-supply cord or

plug is damaged, liquid has been spilled or objects

have fallen into the apparatus, the apparatus has been

exposed to rain or moisture, does not operate normally,

or has been dropped.

• This equipment should be installed near the socket

outlet and disconnection of the device should be easily

accessible.

• Do not install in a confined space.

• Do not open the unit - risk of electric shock inside.

Caution:

You are cautioned that any change or modifications not

expressly approved in this manual could void your authority

to operate this equipment.

Service

• There are no user-serviceable parts inside.

• All service must be performed by qualified personnel.

WARNING

• To reduce the risk of fire or electric shock, do not

expose this apparatus to rain or moisture.

• This apparatus must be earthed.

• Use a three wire grounding type line cord like the one

supplied with the product.

• Be advised that different operating voltages require the

use of different types of line cord and attachment plugs.

• Check the voltage in your area and use the

correct type. See table below:

Voltage Line plug according to

standard.

110-125V UL817 and CSA C22.2 no 42.

220-230V CEE 7 page VII, SR section

107-2-D1/IEC 83 page C4.

240V BS 1363 of 1984.

Specification for 13A fused

plugs and switched and

unswitched socket outlets.

The lightning flash with an arrowhead symbol

within an equilateral triangle, is intended to alert

the user to the presence of uninsulated

"dangerous voltage" within the product's enclosure

that may be of sufficient magnitude to constitute a

risk of electric shock to persons.

The exclamation point within an equilateral

triangle is intended to alert the user to the

presence of important operating and maintenance

(servicing) instructions in the literature

accompanying the product.

Page 4

b

NOTE

Certificate Of Conformity

TC Electronic A/S, Sindalsvej 34, 8240 Risskov, Denmark,

hereby declares on own responsibility that following

product:

D22 - Digital Broadcast Delay

That is covered by this certificate and marked with CE-label

conforms with following standards:

EN 60065 Safety requirements for mains

(IEC 60065) operated electronic and related

apparatus for household and similar

general use

EN 55103-1 Product family standard for audio,

video, audio-visual and entertainment

lighting control apparatus for

professional use.

Part 1: Emission.

EN 55103-2 Product family standard for audio,

video, audio-visual and entertainment

lighting control apparatus for

professional use.

Part 2: Immunity.

With reference to regulations in following directives:

73/23/EEC, 89/336/EEC

Issued in Risskov, December 2002

Anders Fauerskov

Managing Director

EMC / EMI.

This equipment has been tested and found to comply with

the limits for a Class B Digital device, pursuant to part 15 of

the FCC rules.

These limits are designed to provide reasonable protection

against harmful interference in residential installations. This

equipment generates, uses and can radiate radio

frequency energy and, if not installed and used in

accordance with the instructions, may cause harmful

interference to radio communications. However, there is no

guarantee that interference will not occur in a particular

installation. If this equipment does cause harmful

interference to radio or television reception, which can be

determined by turning the equipment off and on. The user

is encouraged to try to correct the interference by one or

more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and

receiver.

• Connect the equipment into an outlet on a circuit

different from that to which the receiver is connected.

• Consult the dealer or an experienced radio/TV

technician for help.

For the customers in Canada:

This Class B digital apparatus complies with Canadian

ICES-003.

Cet appareil numérique de la classe B est conforme à la

norme NMB-003 du Canada.

Page 5

3

TABLE OF CONTENTS

INTRODUCTION

Important Safety Instructions &

Certificate of conformity . . . . . . . . . . . a-b

Table of Contents . . . . . . . . . . . . . . . . . 3

Introduction . . . . . . . . . . . . . . . . . . . . . . 5

Front Panel . . . . . . . . . . . . . . . . . . . . . . 6

Rear Panel . . . . . . . . . . . . . . . . . . . . . . 8

Signal Flow Diagram . . . . . . . . . . . . . . . 9

Setups. . . . . . . . . . . . . . . . . . . . . . . . . 10

BASIC OPERATION

The Controls . . . . . . . . . . . . . . . . . . . . 12

Recall . . . . . . . . . . . . . . . . . . . . . . . . . 14

Store . . . . . . . . . . . . . . . . . . . . . . . . . . 16

I/O - Setup . . . . . . . . . . . . . . . . . . . . . 17

Utility . . . . . . . . . . . . . . . . . . . . . . . . . . 20

APPENDIX

Troubleshooting . . . . . . . . . . . . . . . . . . 21

Technical Specifications . . . . . . . . . . . 22

Self Test . . . . . . . . . . . . . . . . . . . . . . . 23

Glossary . . . . . . . . . . . . . . . . . . . . . . . 24

Soldering Instructions . . . . . . . . . . . . . 25

Frequently Asked Questions . . . . . . . . 27

Optional Master fader . . . . . . . . . . . . . 28

TC Electronic, Sindalsvej 34, DK-8240 Risskov - tcdk@tcelectronic.com

Rev 3.2 - SW - V 2.50

Prod. No. 606090015

Page 6

Page 7

5

Congratulations on your purchase of the TC Electronic D22 broadcast delay.

Researching the broadcast scene, TC Electronic found demands for a “state of the art” broadcast delay dedicated to sync audio to motion

pictures. With TC’s experience on Digital Delay we found it natural to comply with a product in this category.

Therefore TC now proudly presents the D22 broadcast delay unit with Seamless Update, adding no clicks, pitch changes or noise,

as one of the main features.

Main Features

- Seamless Delay update:

No clicks, pitch changes or noise.

- 5200ms* Delay pr. Channel (two channels).

- 24 bit A/D-D/A converters.

- Digital I/O's: AES/EBU, S/PDIF,

Wordclock BNC 75ohm.

- Sample Rates: Internal 44.1, 48kHz,

External 32, 44.1 and 48kHz.

- Total recall via programmable setups/presets.

- Tap Delay time - Instant or Preview.

INTRODUCTION

- Delay time in: Frames, Fields, Milliseconds, Meters

or Feet.

- Separate Dial and Nudge keys for Delay time adjustment.

- Independent resolution for Dial wheel and Nudge keys.

- Built in Digital Output fader (remote controllable).

- Remote capabilities: RS-485 (Input only) for Recall Setup,

Delay time adjustment.

- GPI (General Purpose Impulse) for External control of digital

fader, Tap Delay time and Bypass.

- User Interface Lock mode for "Set & Forget" purposes.

- Sample Rate Converter.

* The extension allowing a Delay time of 5200ms is installed from serial number 2000912 and up.

Max Delay time is now 5200 ms at all sampling frequencies (32K or 44.1K or 48K)(D22 cannot run 96K!)

Max number of Delay frames is now 157 frames (@30fps).

Please contact you local dealer or TC Electronic for information on upgrade procedure if you own a unit with a serial no below 2000912.

Page 8

6

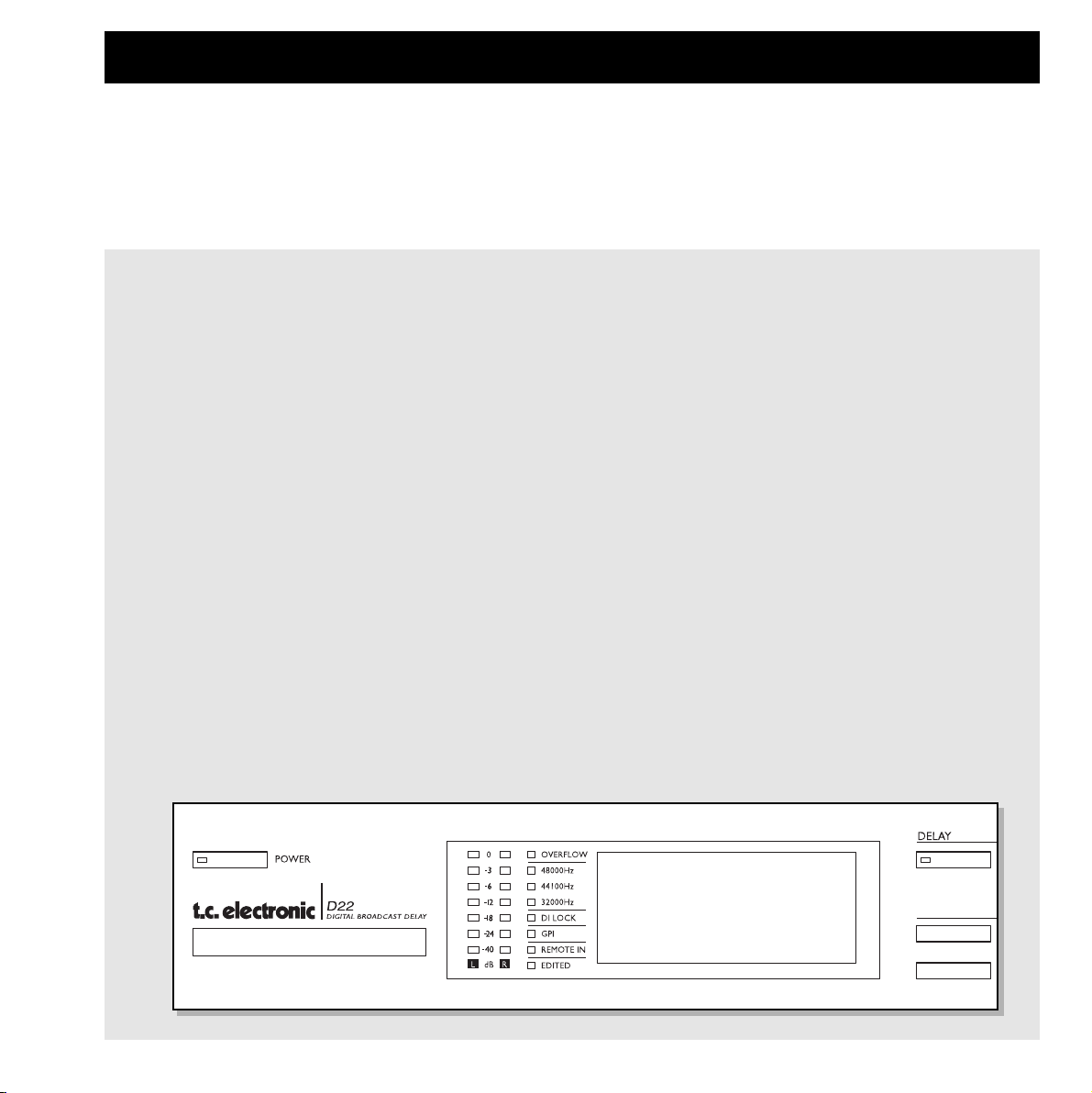

FRONT PANEL

POWER &

MEMORY CARD

Electronic POWER switch

»Easy touch«

Turn on the unit with a single

light touch. To turn off the unit

you must press and hold

down the POWER key

approx. 3 seconds until the

display reads “D22”.

PCMCIA MEMORY CARD

Copy presets to/from a

standard memory card.

CARD TYPES

S-RAM Type 1 PCMCIA

cards, with a minimum of

64KB and a maximum of

2MB memory.

LED INDICATORS

LEVEL

Shows the Input or

Output level for left and

right channels.

Select Input or Output

metering in Utility.

OVERFLOW

Indicates excessive

Input level or internal

DSP owerflow.

SAMPLE RATE

Indicates at which external

Sample Rate the unit is

locked to when set to

Sync In or Wordclock.

Flashing LEDs indicates

“no lock”.

DI LOCK

Digital Lock Indicator.

GPI

Incoming pulse detection.

REMOTE IN

Indicates incoming

Serial Remote Data.

EDITED

Indicates that the current

preset has been edited.

TAP KEY

Tap the desired Delay time.

Instant (destructive) or Preview

(non-destructive) mode can be

selected in the Utility menu.

Key LED red:

Indicates Instant mode is used

Key LED green:

Indicates Preview mode is selected.

NUDGE KEYS

Increases or decreases the

Delay time in increments specified in

the Utility menu.

ADJUST WHEEL - DELAY SECTION

Increases or decreases the Delay time

in increments specified in the Utility

menu.

Page 9

7

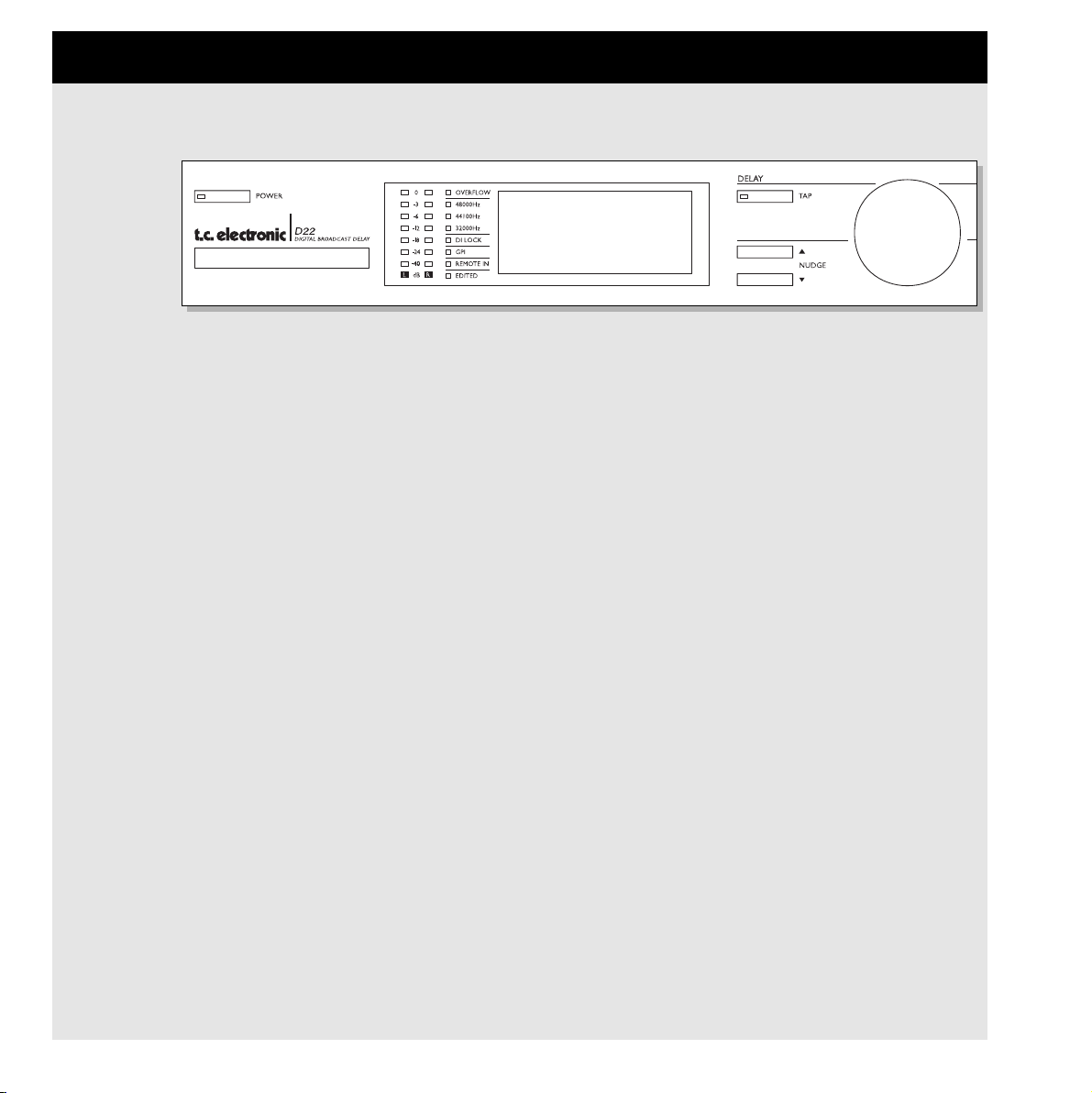

FRONT PANEL

OK

Confirms operations.

CURSOR

Used to change the position of the

cursor in the display.

ADJUST WHEEL - CONTROL SECTION

Changes parameter values.

RECALL

Recalls/loads RAM or ROM presets.

Preview the presets using the

CONTROL ADJUST wheel and press

OK to confirm/enter your choice.

STORE

For storing and naming presets.

I/O

Input/Output settings.

UTILITY

Setup global parameters here.

- Display - Viewing angle

- Time resolution

- Control Resolution

- Tap Delay

- RS485 CTRL

- External Input

- Meter - Input/Output.

REMOTE ENABLE

Use a RS-485 remote for:

- Recalling presets

- Delay time adjustments.

Use a momentary pedal for:

- Tap Delay time via pulse.

Signal is given at every tap.

Use an alternating pedal for

Bypass.

Use a TC Master Fader as a

digital Master Output fader.

BYPASS

Bypasses the unit.

Page 10

8

REAR PANEL

IN

PIN2+/PIN3- PIN2+/PIN3-

LEFTLEFT

DI

RIGHTRIGHT

DO

DI

DO

S/PDIF

BALANCED OUTPUTS

BALANCED INPUTS DIGITAL AUDIO

AES/EBU

2

1

3

RS485 GPI

IN

SYNC

SERIAL NO.

TYPE: V002-B

MADE IN DENMARK

CAUTION

RISK OF ELECTRIC SHOCK

DO NOT OPEN

WARNING

TO REDUCE THE RISK OF FIRE OR ELECTRIC

SHOCK DO NOT EXPOSE THIS EQUIPMENT TO

RAIN OR MOISTURE

AVIS:

RISQUE DE CHOC ELECTRIQUE-NE PAS

THIS CLASS B DIGITAL DEVICE MEETS ALL REQUIREMENTS OF THE

CANADIAN INTERFERENCE-CAUSING EQUIPMENT REGULATIONS AND

COMPLIES WITH PART 15 OF THE FCC RULES.

OPERATION SUBJECT TO CONDITIONS STATED IN THE MANUAL.

OUVRIR.

100-240V 50-60Hz 20W~AC

R

NRTL/C

UL1419

EN 60065

PROFESSIONAL

AUDIO

EQUIPMENT

Main

Power

Switch

Power

Input

Balanced

XLR

Analog

Inputs

Balanced

XLR

Analog

Outputs

Serial

no.

Digital

In/Out

AES/EBU

S/PDIF

Wordclock

BNC

RS 485

1, 2, 3

External

Control

Input

(GPI)

Pin 2 is »hot« on all XLR’s (IEC and AES standards).

Unbalanced Input:

If you are connecting unbalanced equipment to the D22, pins 1 and 3 must be tied together in the cable

ends away from the D22. (see fig. 1)

Unbalanced Output:

If the D22’s Outputs are connected to unbalanced equipment pin 3 should not be connected. (see fig 2).

If you are using cable types, where pins 1 and 3 are connected (fig. 1), the maximum analog Output will

be reduced by 6dB from 26dBu to 20dBu.

Sleeve - Pin 1 (Ground)

Tip - Pin 2 (Hot)

Sleeve - Pin 3 (Cold)

Jack (unbalanced) - XLR - Input

Fig. 1

Sleeve - Pin 1 (Ground)

Tip - Pin 2 (Hot)

Jack (unbalanced) - XLR - Output

Fig. 2

Pin 1 (Ground)

Pin 2 (Hot)

Pin 3 (Cold)

Balanced XLR - XLR

Fig. 3

Page 11

9

SIGNAL FLOW

The signal path is 24 bit.

If the digital gains are set to 0dB and dither is set to off, the full 24 bit digital signal is

preserved on the bit level.

The De-Emphasis on the analog Output is automatically set based on the digital Input when

applicable.

Signal is always present on all Outputs.

ANALOG

INPUTS

[balanced]

ANALOGIN

GAIN

ANALOGOUT

GAIN

AN

OU

[b

A/D

DigitalInputSelect

INPUT/OUTPUTPPM

Left

Left

Right

Bypass

Right

Input

Selector

Dig

DigitalInput

[AES]

AES

S/PDIF

Dig

DigitalInput

[S/PDIF]

D/A

D22

24bit

DigitalDela y

24bit

Fader

Dither

Digital

Out

Gain

Digital

OutGain

Digital

InGain

L Trim

R Trim

L Trim

R Trim

De-

Emphasis

Page 12

10

SETUPS

Input: Analog

Sample Rate: 48kHz or 44.1kHz

(internal generated clock)

Output: Analog

Input: Analog

Sample Rate: Must be 48kHz or 44.1kHz

(internal generated clock).

Output: AES or S/PDIF

Dither: Same as the resolution on the device

after the D22.

Input: Analog

Sample Rate: EXT DI (AES/EBU or AES 11).

Output: AES or S/PDIF.

Dither: Same as the resolution on the device

after the D22.

Installation note:

A House-clock connected to the Wordclock

Inputs of the D22 and the downstream devices

will enhance jitter rejection.

Fig 1

Fig 2

Fig 3

D22

Analog Device

ANALOG

ANALOG

IN

D22

DIGITAL

Digital Device

AES 11

D22

DIGITAL

Digital Device

ANALOG

ANALOG

IN

IN

Page 13

11

SETUPS

Input: Analog

Sample Rate: Sync.

Output: AES or S/PDIF

Dither: Same as the resolution on the device

after the D22.

Installation note:

Wordclock Inputs on the D22 and the downstream device may be used to enable jitter

rejection.

Input: Digital

Sample Rate: EXT DI

Output: AES or S/PDIF

Dither: Same as the resolution on the device

after the D22.

Installation note:

Wordclock Inputs on the D22 and the downstream device may be used to enable jitter

rejection.

Input: Digital

Sample Rate: Sync.

Sample Rate Conversion: On

Output: AES or S/PDIF

Dither: Same as the resolution on the device

after the D22.

If using both the digital Input and the Sync

Input, these must be syncronized.

The Sample Rate on the device after the D22

must be taken from its digital Input unless the

Sync Input on this device is used.

Fig 4

Fig 5

Fig 6

SYNC IN

D22

DIGITAL

Digital Device

D22

Digital Device

ANALOG

DIGITAL

DIGITAL

IN

IN

Local Wordclock

SYNC IN

Digital Device

D22

SYNC IN

DIGITAL

DIGITALREF

fr om Remote Clock

IN

Page 14

12

BASIC OPERATION

PPM Meter

Shows Input/Output level of selected source Input.

Select whether the meters should show the Input level or the

Output level in the Utility menu.

Range/Colors:

0 - Red

-3 - Yellow

-6 - Yellow

-12 - Green

-18 - Green

-24 - Green

-40 - Green

OVERFLOW LED

This LED can indicate two different level problems.

- Overload due to excessive Input level. To compensate reduce

the Output level of the sending device or the Input level on the

D22. If the meters are set up to indicate the Output level, you

might not be aware of an Input clipping. The Overflow LED

will bring your attention to this problem.

A single clipped sample will invoke the Overflow LED.

- Internal DSP overload, which will not occur under normal

operating conditions.

SAMPLE RATE LEDs

Indicating the current internal Sample Rate.

The D22 can lock to 48kHz, 44.1kHz or 32kHz.

If a "No Lock" situation should occur, the three LEDs will blink.

DI Lock

Indicates when the unit is locked to an incoming Digital signal

or an external clock.

GPI LED

General Purpose Impulse LED.

Indicates the incoming pulse from an external on/off switch such

as a hold pedal or a DC pulse.

REMOTE IN

Indicates incoming Serial Remote data.

EDITED LED

Indicates that the current preset has been edited but not yet stored.

DELAY TAP key

Tap the Delay time in a "Destructive" or "Non-destructive" way.

The Tap mode is set in the Utility menu.

Instant (destructive):

When Instant mode is selected the TAP key LED will be red.

Tap the desired Delay time and the D22 will instantly update the

Delay time.

Preview (non-destructive):

When Preview mode is selected the TAP key LED will be green.

Tap the desired Delay time. The Delay time will be displayed and

blink, indicating that the displayed Delay time is not yet recalled.

Press the OK key to activate the tapped previewed Delay time.

The Tapped Delay time is always rounded to nearest increment

setup in the Utility menu.

NUDGE keys

Increases or decreases the Delay time in increments specified in

the Utility menu. The possible ranges are:

0.1, 0.5, 1.0, 2.0, 5.0 or 10.0 milliseconds, fields, frames, feet or

meters.

In the Utility menu you setup whether the Recall display should

show the Delay time in fields (flds), frames pr. second (fps),

milliseconds (ms), feet or meters.

Note! The NUDGE keys are always functional no matter what

menu is active (except when the keyboard is locked).

DELAY ADJUST wheel

Increases or decreases the Delay time in increments

specified in the Utility menu. The possible ranges are:

0.1, 0.5, 1.0, 2.0, 5.0 or 10.0 milliseconds, fields,

frames, feet or meters.

In the Utility menu you setup whether the Recall display should

show the in fields (flds), frames pr. second (fps) or

milliseconds (ms), feet or meters.

Note! The DELAY ADJUST wheel is always functional no matter

what menu is active (except when the keyboard is locked).

Use either the NUDGE keys or the DELAY ADJUST

wheel for major Delay time adjustments and the other for

fine adjustments.

This chapter explains all the controls and LEDs on the front panel.

The following chapters will explain operations in details.

Page 15

13

BASIC OPERATION

REMOTE ENABLE

Activates remote control capabilities.

Use a RS-485 remote for:

- Recalling presets

- Delay time adjustments

Please see description on page 20.

Use a momentary pedal for:

- Tap Delay time via pulse.

Signal is given at every tap.

Use an alternating pedal for Bypass.

Use a TC Master Fader as a digital Master Output fader.

Please see the description on page 28.

The GPI function is setup in the Utility menu.

BYPASS

Bypasses the unit.

I/O levels are kept as well as 24 bit A/D-D/A conversion.

The Bypass key LED will be red when the unit is bypassed.

The Bypass is a true 24 bit type.

RECALL

Press the RECALL key to enter the Recall display, if you are not

already there. The Recall display is the homepage of the D22.

Please see the explanation of the Recall display on page 14.

STORE

Press the STORE key to enter the Store page. Pressing the Store

key again disables the Store page and exits to the "Recall page".

Please see explanation of the Store display on page 16.

I/O

The I/O section hold two pages. Press the I/O key once to enter

I/O page 1, and once more to enter I/O page 2. Pressing the I/O

key a third time will return you to the Recall page.

The I/O page is where you setup :

- Input Source

- Sample Rate Converter On/Off

- Master Clock selection

- Dither

Please refer to page 18 for further information.

UTILITY

Setup global parameters here.

- Display - Viewing angle

- Time resolution

- Control Resolution

- Tap Delay

- RS485 CTRL

- Memory backup

- External Input

- Meter - Input/Output

Please refer to page 19 for further information.

OK

Confirms various operations like Recalling presets, Store and

Tapped Delay time (when in non-destructive mode).

CURSOR

Used to change the position of the cursor in the display.

CONTROL ADJUST wheel

Changes parameter values.

Keyboard Lock Function

Press and hold the RECALL key for approx. 3 seconds to lock all

keys on the front panel. This includes the POWER key.

Keyboard lock is remembered as a "Current setting" meaning

that the lock state still remains after a hard power off. The Lock

mode is indicated in the upper line of the Mainpage display,

stating "Keyboard Locked" and a Padlock symbol is displayed.

The Lock mode can only be activated in Recall mode.

To disable the Lock mode - press and hold the RECALL key for

approx. 3 seconds.

Page 16

14

RECALL

Recalling a preset

Press the RECALL key to enter the Recall page.

The Recall page is your homepage and this is where

you return to whenever you exit the Store, I/O or the

Utility menu.

Tap Mode - Instant or Preview

The tap mode is setup in the Utility menu. (Please see page 17).

Instant (destructive):

When Instant mode is selected the TAP key LED will be red.

Tap the desired Delay time and the D22 will instantly update the

Delay time.

Preview (non-destructive):

When Preview mode is selected the TAP key LED will be green.

The Delay time will be displayed and blink, indicating that the

displayed Delay time is not yet recalled.

Press the OK key to activate the tapped previewed Delay time.

The Tapped Delay time is always rounded to nearest increment

setup in the Utility menu.

I/O Delay

Any A/D or D/A conversion implements a small amount of Delay

time. When D22 analog Inputs or Outputs are used,

compensation for the conversion delay is calculated, and the

displayed Delay time is the total and correct Delay time*.

However this requires correct setting of the Output mode according to the Output you actually are using.

The Outmode is setup in the I/O page 1.

* Note! This is only correct when the set Delay time is 2 ms

or above.

To recall/activate a preset:

- Use the CONTROL ADJUST wheel to scroll through the

presets. Until you confirm your choice you are previewing the

presets. At this stage the OK LED will be blinking.

- When you find the desired preset press OK to recall/confirm.

A preset contains settings of all parameters except Bypass,

RS 485 address and RAM protect, enabling the user to make a

total recall

of a specific setup.

The preset includes:

- All I/O settings

- Current Delay time

- All Utility settings except RS485 address and RAM protect.

- Remote on/off.

All current settings are saved at power off, meaning that D22

"wakes up" in the exact same state as when powered off.

Presets - In General

The D22 holds 4 factory presets.

The presets hold no Delay time but are meant as four basic

relevant setups including I/O settings and Status bits.

Preset #1 : Analog I/O AES

Preset #2 : Analog I/O NTSC

Preset #3 : Digital I/O AES/EBU

Preset #4 : Digital I/O S/PDIF

Presets 1-4 are write-protected.

You can store presets on locations 5-127.

Preset name

Preset number

Tap Mode

Instant/Preview

Delay Time Line

Page 17

15

RECALL

Fader

By connecting a TC Master Fader to the External Control In,

on the rear panel you are able to remote control the digital

Output fade. When the fader pot is moved the Recall display will

instantly show you the fader position in the lower half.

When the fader has not been moved for approx. 3 seconds the

fader indication will disappear.

When Fader is set to 0dB, an Arrow indicator appears to confirm

maximum level.

Locked mode

To avoid accidental changes in parameter values you are able to

lock all keys on the front panel. A padlock symbol will appear

instead of the Tap mode.

This function is activated by pressing and holding the RECALL

key for approx. 3 seconds.

To release the unit from the locked mode, press the RECALL key

again for approx. 3 seconds.

Seamless preset changes

To obtain perfectly seamless update when changing presets, I/O

and Utility settings must be the same in both presets.

Page 18

16

STORE

Storing User Presets

Basic operation

Press the STORE key to enter the Store display. Use the cursor

keys and the CONTROL ADJUST wheel to select between:

- Overwrite/Delete mode

- RAM location

- Name Edit line

Upper line - Delay time

This line shows the current Delay time. The Delay time is shown

in either milliseconds, frames, fields, meters or feet specified in

the Utility menu.

Overwrite/Delete

Two modes are available in the Store display. Use the Overwrite

mode as a regular storing mode, where you overwrite the preset

present in any selected RAM space.

In the Delete mode you are able to erase an entire preset from the

selected RAM space.

Place the cursor next to the Overwrite/Delete line and use the

CONTROL ADJUST wheel to select mode.

Overwrite mode

- Press STORE followed by the OK key to store the preset in the

same location or; place the cursor at the RAM location line,

and use the CONTROL ADJUST wheel to select a new

RAM location.

- Press the OK key to confirm.

Warning! All previous information on the selected RAM position

will be destroyed.

Delete mode

- Use the CONTROL ADJUST wheel to select the preset you

wish to delete.

- Press the OK key to confirm.

Storing presets

- Press the STORE key.

- Press the OK key to store the preset with the same name at

the same location or:

- Place the cursor at the RAM location line and select a new

location for your preset using the CONTROL ADJUST wheel.

(You can store your preset in the RAM bank or the Card bank,

when a RAM card is available).

- Press OK and the preset is stored with the same name at the

selected location or - to change name:

- Place the cursor at the Name Edit line.

- Use the CURSOR keys to select letter position and the

ADJUST wheel to select letter.

- Confirm entire Store/naming operation by pressing

the OK key.

Using a Memory card

Insert the card. The D22 will now autodetect your card and you

are able to dump the entire RAM bank to the card for backup.

The card will automatically be formatted the first time you save

or dump information to the card.

Warning: This will destroy all existing information on the card.

Card types

S-RAM Type 1 PCMCIA cards, with a minimum of 64KB and a

maximum of 2MB memory.

Delay time

Preset Name

Name Edit line

RAM location

Overwrite/Delete mode

Page 19

17

I/O - SETUP

I/O page 1

The I/O section holds two pages. Press the I/O key

once to enter I/O page 1, and once more to enter I/O

page 2. Pressing the I/O key a third time will return you

to the Recall page.

Input:

Select Input source: Analog, AES or S/PDIF.

- Analog defaults to 48kHz internal clock.

Out status bit defaults to AES.

- AES defaults to AES clock.

- S/PDIF defaults to S/PDIF clock.

Sample Rate Conversion

Determines whether the Sample Rate Converter is On or Off.

The SRC works according to the selected clock.

Clock

Selects master clock: Int 44.1, Int 48, Ext. Sync, AES, S/PDIF.

Dither

Selects Output dither: 8, 12, 16, 18, 20, 22 or 24 bit (Off).

Dither is only present on Digital outputs.

Output

Selects the Output status of the D22. Select between:

Analog, AES, S/PDIF or Thru.

I/O page 1

Analog

When analog Outputs are used in combination with analog Inputs

the Output status bit defaults to AES/EBU.

When analog Outputs are used in combination with a digital

Input format, the digital Input format will also be Output.

AES/EBU

When AES/EBU is selected the D22 will send out its own

professional set of status bits, meaning that any incoming ID will

be lost. However, in order to take full advantage of the D22’s

24 bit resolution you should select AES/EBU to make sure that

the receiving device after the D22 will accept all 24 bits.

S/PDIF

When S/PDIF is selected, the D22 will send its own consumer

status bits out, meaning that any incoming ID will be lost. The

D22’s S/PDIF Output carries up to 24 bits.

Thru

When this setting is selected the D22 will send out the same

information as it received.

I/O Delay

Any A/D or D/A conversion implements a small amount of Delay

time. When D22 analog Inputs or Outputs are used,

compensation for the conversion delay is calculated, and the

displayed Delay time is therefore the total and correct Delay

time*. To obtain this please set Output mode according to the

Output are you actually using.

* Note! This is only correct when the set Delay time is 2ms

or above.

Input

type

select

Sample Rate

Conversion

On/Off

Clock

select

Dither

select

Output

type

select

Page 20

18

In page 2

I/O page 2

Press the I/O key twice to enter this page

Analog In

Sensitivity : -4 to 28dBu Default: 18dBu

Left Trim : -2 to 0dB in 0.1 increments Default: 0

Right Trim : -2 to 0dB in 0.1 increments Default: 0

Please note that setting sensitivity to e.g. 18dBu means that you

need + 18dBu from your mixing console’s Output to reach

0dBFS on the D22 Input.

Analog Out

Range : -4 to +28dBu Default: 18dBu

Fine Out Left : -2 to 0dB in 0.1 increments Default: 0

Fine Out Right : -2 to 0dB in 0.1 increments Default: 0

Please note that setting the Analog Out parameter to e.g.

+18dBu means that 0dBFS on the D22 Output is the equivalent

of +18dBu on your mixing console’s Input.

Digital I/O

Input Gain : -18 to +6 dB in 1dB increments Default: 0

Output Gain : -18 to 0 dB in 1dB increments Default: 0

I/O - SETUP

Page 21

19

UTILITY

Basic operation

- Use the CURSOR keys to select parameter.

- Use the ADJUST wheel to change values.

Display

Viewing Angle

Adjust for best contrast on the LCD display.

_____________________________________________________

Time Resolution

Unit

Frames, fields, milliseconds, meters or feet.

(1 field is 1/2 frame)

Format

24fps, 25fps, 29.97fps, 30DF or 30fps.

_____________________________________________________

Control Resolution

Nudge Step : 0.1, 0.5, 1.0, 2.0, 5.0 or 10.0

Dial Step : 0.1, 0.5, 1.0, 2.0, 5.0 or 10.0

The value of the steps depends on the format set

in the Time resolution section. (see above)

_____________________________________________________

Tap Delay

Tap Mode

Instant : The Delay time is updated instantly.

Preview : The tapped Delay time is displayed but must be

confirmed by pressing the OK key to take effect.

Page 22

UTILITY

20

RS485 CTRL.

Remote control of Preset change, Delay time and Bypass is

implemented in the D22 by using a RS485 controller.

All remote control capabilities are enabled/disabled by the

REMOTE key. All displays and key states are updated according

to incoming remote control info, i.e. the Delay time on the Recall

page is always indicating the actual Delay.

The command structure for a Program change is:

#AA,<PRE>,<NUM><CR>

The command structure for changing Delay time is:

#AA,<DEL>,<delay in current mode><CR>

The command structure for changing Bypass mode is:

#AA,<BYP>,<0/1><CR>

CR=ASCII 13

Pinout of the 5-pin DIN connector:

(All three connectors carry the same RS485 I/O capability)

Data + : Pin no 3

Data - : Pin no 1

Common : Pin no 2 (Only on Thru and output connectors.)

Program Change

The RS485 implementation in the D22 is a

“command receive only” type.

On : Program changes from a RS485 controller will be

recognized.

Off : Program changes from a RS485 controller will be

ignored.

Address

The D22 unit RS485 address number.

Memory Backup

RAM to Card - Press OK

This action will dump all presets to the RAM card.

WARNING ! All previous information on the card will be

destroyed.

RAM Protect - ON/OFF

Turn the ADJUST wheel to activate the RAM protect function.

With the RAM protect function activated you can not delete or

overwrite RAM presets.

Card to RAM - Press OK

Copies all presets from the PCMCIA card to the internal RAM

bank.

Note! All presets in the internal RAM bank will be deleted.

_____________________________________________________

GPI - (External Input)

Use a:

Digital Fader - for digital fade on the Output.

Momentary switch - for tap Delay time

Alternating switch - for activating/deactivating Bypass mode.

_____________________________________________________

Meter

Selects whether the meters should show Input or Output levels.

Page 23

21

Preset changes are not seamless

- To obtain perfect seamless update when changing presets, I/O

and Utility settings must be the same in both presets.

You press the POWER switch but there is no light.

- The POWER switch on the rear panel is switched off.

The Input PPM meters do not peak out.

- You are using Analog Inputs, but the Input selector in the I/O

menu is set to Digital in.

- The Analog Input level is set too low.

No sound through the D22.

- You are using Analog Inputs, but the Input selector in the I/O

menu is set to Digital in.

You cannot turn the power off.

- Hold the POWER key pressed for at least 3 seconds.

APPENDIX - Troubleshooting

Page 24

22

APPENDIX - Technical specifications

Digital Inputs and Outputs

Connectors:

Formats:

Output Dither:

Word Clock Input:

Sample Rates:

Processing Delay:

Frequency Response DIO:

Sample Rate Conversion

Type:

Dynamic Range:

THD+N:

Input Rate Range:

Analog Inputs

Connectors:

Impedance:

Max. Input Level:

Min Input Level (for 0 dBFS):

A to D Conversion:

A to D Delay:

Dynamic Range:

THD:

Frequency Response:

Crosstalk:

Analog Outputs

Connectors:

By-pass:

Impedance:

Max. Output Level:

Full Scale Output Range:

D to A Conversion:

D to A Delay:

Dynamic Range:

THD:

Frequency Response:

Crosstalk:

EMC

Complies with:

Safety

Certified to:

Environment

Operating Temperature:

Storage Temperature:

Humidity:

PCMCIA Interface

Connector:

Standards:

Card Format:

Control Interface

RS485:

GPI, Pedal, Fader:

General

Finish:

LCD:

Dimensions:

Weight:

Mains Voltage:

Power Consumption:

Backup Battery Life:

Warranty parts and labor:

XLR (AES/EBU), RCA Phono (S/PDIF)

AES/EBU (24 bit), S/PDIF(24 bit), EIAJ CP-340, IEC 958

HPF TPDF dither 8-24 bit

BNC, 75 Ohm, 0.6 to 10 Vpp

32 kHz, 44.1 kHz, 48 kHz

0.2 ms @ 48 kHz

DC to 23.9 kHz ± 0.01 dB @ 48 kHz

Asynchronous

120 dB

-106 dB 44.1 to 48 kHz @ 1 kHz, -2 dBFS

31 kHz to 49 kHz

XLR balanced (pin 2 hot)

20 kOhm (balanced)

+27 dBu (balanced)

-4 dBu (balanced)

24 bit (1 bit, 128 times oversampling)

0.8 ms @ 48 kHz

>103 dB (unweighted), >106 dB(A)

-95 dB (0.0018 %) @ 1 kHz, -6 dBFS (FS @ +18 dBu)

10 Hz to 20 kHz: +0/-0.2 dB

<-80 dB, 10 Hz to 20 kHz, typical -100 dB @ 1 kHz

XLR balanced (pin 2 hot)

Through relay

40 Ohm (balanced)

+26 dBu (balanced)

-4 dBu to +26 dBu (balanced)

24 bit (1 bit, 128 times oversampling)

0.57 ms @ 48 kHz

>100 dB (unweighted), >104 dB(A)

-86 dB (0.005 %) @ 1 kHz, -6 dBFS (FS @ +18 dBu)

10 Hz to 20 kHz: +0/-0.5 dB

<-60 dB, 10 Hz to 20 kHz, typical -90 dB @ 1 kHz

EN 55103-1 and EN 55103-2, FCC part 15 class B, CISPR 22 class B

IEC 65, EN 60065, UL 1419 and CSA E65

32° F to 122° F (0° C to 50° C)

-22° F to 167° F (-30° C to 70° C)

Max. 90% non-condensing

PC Card, 68 pin type 1 cards

PCMCIA 2.0, JEIDA 4.0

Supports up to 2 MB SRAM

5 Pin DIN

¼ inch phone jack

Anodized aluminum face and top plate. Plated and painted steel chassis

56 x 128 dot graphic LCD-display

19" x 1.75" x 8.2" (483 x 44 x 208 mm)

5.2 lb. (2.35 kg)

100 to 240 VAC, 50 to 60 Hz (auto-select)

<20 W

>10 years

1 year

Due continuous development these specifications are

subject to change without notice.

Page 25

23

APPENDIX - Self test

Press the BYPASS key while powering up to access

the self-test and select “ RUN TEST PROGRAM” using

the CURSOR keys.

Use the CONTROL ADJUST wheel to scroll through the different

self tests.

Key test

Select Keys test by pressing OK.

The keys must be pressed in the order they are requested by the

D22 to pass the test.

Power off to exit test.

DELAY + CONTROL wheel test

Select ADJUST wheel test by pressing OK.

Turn the ADJUST wheels to 30 and back to 0 to pass test.

Power off to exit test.

LED test

Select LED test by pressing OK.

Turn the CONTROL ADJUST wheel to test the LEDs one by

one. The test is “ok” when all LEDs are lit.

Power off to exit test.

Display test

Select Display test by pressing OK.

Press OK to check that all pixels are lit. Press any key to leave

the pixel test.

Power off to exit test.

Analog I/O test

Select analog I/O test by pressing OK

Connect a D22 analog Output to a D22 analog Input and

press OK. Use a balanced cable.

PPM must show -12 dB to pass test.

Power off to exit test.

Digital I/O test

Select digital I/O test by pressing OK.

Connect the D22’s AES/EBU Output to the D22’s AES/EBU

Input and press OK.

PPM must show 0dB to pass test.

Connect the D22’s S/PDIF Output to the D22’s S/PDIF Input and

press OK.

PPM must show 0dB to pass test.

Power off to exit test.

RS485 test

Select RS485 test by pressing OK.

Confirm that result is ok

Power off to exit test.

GPI test

Select GPI test by pressing OK.

Connect a momentary switch to the GPI socket.

When pressing the switch, the result should be OK.

When released, the result should be NOT OK.

Power off to exit test.

PCMCIA Card test

Select PC Card test by pressing OK.

Insert PC Card.

Note that all data on the PC Card will be destroyed.

Press OK to test.

Result reads:

- Low battery - Time to change battery in your PC Card.

- Not Ok - Try the test using another PCMCIA card.

Power off to exit test.

Battery test

Select Battery test by pressing OK.

Confirm that result is OK.

Power off to exit test.

System test

Select System test by pressing OK.

Confirm that result is OK.

Result reads:

- EEPROM Not OK - The unit will most likely work ok, the

message is for service matters only.

- DSP Not OK - Contact your local dealer.

Power off to exit test.

Power Off - On to start standard software.

Buit In test v. 3.09

Service note

In case of the unlikely event that the unit needs to be send in for

service, please use the original box AND an outer box.

Page 26

24

APPENDIX - Glossary

Dithering

When going from one type of bit resolution to a lower, e.g. from

24 bit to 16 bit, you actually loose 8 bits of information.

The process of cutting of bits is called truncation and it introduces

digital distortion of low level signals, due to the lack of complete

signal information. To compensate for this, dithering must be

applied. Dithering is a small amount of filtered noise, shaped and

optimized for the human ear, and when added to the truncated

signal the effect is a less distorted low level signal.

Dithering is only relevant on digital Outputs and it is always the

receiving device that determines the number of bits you must

dither to.

A DAT or CDR recorder should always be dithered to 16 bit.

TC Products do not perform truncation on digital Outputs.

Truncation is left to be done by the receiving device.

House Clock

A separate piece of equipment used only to generate a common

standard clock keeping all the attached digital equipment in sync.

Master Clock

If you don’t use a separate House Clock you can use most digital

units for the same purpose. In this case the unit you sync to is

called the Master Clock.

Sample Rate

The quality of sound depends on how precise you can measure

the analog signal. This is done by taking “pictures” of the wave

at a given rate: The Sample Rate.

The maximum frequency that can be successfully reproduced is

the Sample Rate divided by two since you need two points to

define a sinus curve. E.g. the max frequency that can be

successfully reproduce with a Sample Rate of 48kHz is 24kHz.

Sys-Ex - System Exclusive MIDI Commands

Device dependent MIDI commands normally used for remote

control.

AES/EBU

Professional digital In/Out standard, using balanced XLR cables.

The AES/EBU format outputs 24 bit.

S/PDIF

Consumer digital In/Out standard, using coaxial phono-type

cables. This format can generally output 20 bit.

TC products outputs all 24 bits on S/PDIF.

Tos-link

Also called optical S/PDIF. 24 bits can be transferred with this

format.

ADAT/TDIFF

Format capable of transferring 8 channels of 24 bit 48kHz using

optical cables.

Bits & Bytes

1 bit is the smallest unit for information in the digital world. Its

value can be can be 0 or 1 or you could say on/off. 1 byte=8 bit.

Compressor Overshoot

When slow attack times are used overshoots might occur. This

causes an unwanted click/distortion. To prevent compressor

overshoots you can use a brickwall type limiter.

Cross-over point

Splitpoint indicating where the different bands begins/stops

working

dBFS

dB full scale. 0dBFS is the absolute max in the digital world.

Any signal above 0dBFS will cause serious unwanted distortion.

dBu

Measuring unit in the analog world.

0dBu=0,775V in 600ohm

Page 27

25

APPENDIX Soldering instructions

MIDI Cable

Pedal Cable

Fader Cable

DIN CONNECTOR

5POLE - MALE

45 degrees

DIN CONNECTOR

5POLE - MALE

45 degrees

max. 10m

JACK PLUG

Mono - male

Ø 6.35mm, 1/4”

max. 100m

Shield/ground

Tip

Switch must be

momentary type

PEDAL SWITCH or similar

JACK PLUG

Mono - male

Ø 6.35mm, 1/4”

max. 100m

MASTER FADER or similar

2 wires

SHIELDED CABLE (3 or 5 wires + screen)

NOTE!

On TC units with RS485 interface pins 1 and 3 on the DIN connectors are reserved for RS485 connection. Therefore, if you are connecting the

unit to other equipment that use these pins, please make sure to use 3-wire standard MIDI type cable (not a five wire MIDI-PLUS type).

Note

Note

Page 28

26

Sleeve - Pin 1 (Ground)

Tip - Pin 2 (Hot)

Jack (unbalanced) - XLR - Output

APPENDIX Soldering instructions

Sleeve - Pin 1 (Ground)

Tip - Pin 2 (Hot)

Ring - Pin 3 (Cold)

Pin 1 - Pin 1 (Ground)

Pin 2 - Pin 2 (Hot)

Pin 3 - Pin 3 (Cold)

Sleeve - Pin 1 (Ground)

Tip - Pin 2 (Hot)

Sleeve - Pin 3 (Cold)

XLR - XLR Jack (unbalanced) - XLR - Input

Jack (balanced) - XLR

TIP

RING

GND

TIP

GND

TIP

GND

Page 29

27

FREQUENTLY ASKED QUESTIONS

Question: What parameters can be set using serial remote

control of the D22?

Answer

: Preset change, Delay time and Bypass using an

RS485/422/232 controller.

Question:

What serial protocol is used?

Answer

: The serial protocol is 9600, N, 8, 1.

This means 9.6 kbaud, no parity, 8 bit, 1 stop.

Question:

What is the command structure for the remote

protocol?

Answer

: #AA,CMD,VALUE<CR>

AA is Unit Address number as set on the Utility page.

CMD is command:

PRE for preset change,

BYP for Bypass,

DEL for delay.

VALUE is (RAM) Preset number, 0 for Not Bypass, 1 for

Bypass or amount of Delay.

<CR> is carriage return, the same as Enter or hex 0D.

Examples:

#05,PRE,10<CR> =Recall RAM preset no. 10 on D22 address 5.

#03,BYP,1<CR> =Bypass D22 address 3.

All commands and numbers are shown as ASCII.

Question: What is the data length of the delay time?

Answer

: The delay is always a decimal number related to the

given delay unit of the D22. It is not posible to change delay unit

via the RS-485, so you must set this manually before you send

the command lines.

Example 1:

The delay unit is ms and you would like to set the delay to 10.5 ms:

#05,DEL,10.5<CR>

Example 2:

The delay unit is frames and you would like to set the delay to

10.5 frames: #05,DEL,10.5<CR>

As you can see there is no difference between example 1 and 2.

Example 3:

The delay unit is ms and you would like to set the

delay to 10.5 frames:

You have to calculate the delay in ms yourself based on the fps

setting and then send a command-line.

Question:

What ASCII characters should be sent for Recall of

RAM preset no. 10 on D22 address 5?

Answer

: #05,PRE,10<CR> means these values (hex) actually

transmitted 23 30 35 2C 50 52 45 2C 31 30 0D

Page 30

28

MASTER FADER

Why make a Master Fader?

The Master Fader makes it possible to perform a manual fade on the very Output of the D22 enabling you to keep your fade in the

Digital domain to ensure perfect tracking of left and right.

Connecting and Calibrating the Master Fader

In order to work the Master Fader accurately, the D22 must be calibrated:

- Connect the Master Fader to the “GPI” Input.

- Press and hold the BYPASS key of the D22 while powering up.

- Scroll down to “Fader Calibration” using the MENU keys, and press the OK key.

- Move the Master Fader to maximum position. To compensate for mechanical tolerances draw back the Master Fader slightly.

- Press OK.

- Move the Master Fader to minimum position. To compensate for mechanical tolerances raise the Master Fader slightly.

- Press OK.

- The Master Fader is now Calibrated. Power On/Off.

Activating the Master Fader

To activate the Master Fader, enter the Utility menu and scroll down to “GPI External Input” using the MENU keys.

Dial the ADJUST wheel to choose “FADER”.

The Master Fader is now controlling the Digital fader of the D22. The Fader located in the D22 output section will now

follow and display the movement of the Master Fader.

Cables and Lengths

The Master Fader uses standard mono jack cables. The cable can be extended using the jack to jack adapter, and can run at cable

lengths up to 100 meters. Remember to recalibrate after extending the cable.

Loading...

Loading...