Taylor Freezer QS22 General Manual

Item No. _______________________________

QS22

Electric Grill

Features

Cook-to-order menu items are served FAST!! With the

optional platen(s) lowered, the top and bottom of the product

are cooked simultaneously. With the addition of innovative

Auto Lift technology, the platen raises automatically at the

completion of the product cook cycle, assuring product

quality and product safety every time. Foods maintain

natural juiciness, and your customers are served food hot off

the grill, in less than half the time of standard grills.

Even temperatures across the entire cooking surface assures

safe product integrity and fast recovery. Holding cooked food

products for busy times is virtually unnecessary, reducing

product waste. Multiple grills may be installed side-by-side

to increase cooking surface and capacities.

Lower Cooking Surface

Two, 12” (30.5 cm) wide, by 24” (61.0 cm) deep cooking zones with

three independent heating elements per zone. Assures even

temperatures and quick recovery.

QS22

Shown with two platens (optional)

Controls

Programmable microprocessor controls make menu selection

simple. Includes a self-diagnostic feature for serviceability. Clear

plastic door protects control from splashes or spills. Separate

durable start button is provided to activate cooking cycle.

Temperature Control

Grill surface temperature may be set from 150 to 400ºF (65 to

205ºC). Optional upper platen temperature may be set from 150 to

425ºF (65 to 218ºC).

Indicator Lights

Lights illuminate when heaters are on.

Utility Box

For grill scraper & release sheet wiper.

Rockton, Illinois 61072

800-255-0626

Phone 815-624-8333 Fax 815-624-8000

www.taylor-company.com

e-mail: info@taylor-company.com

Optional grooved lower cooking

surface and/or grooved upper

platen

International Office

Taylor Company S.r.l.

Roma, Italy

Tel: +39-06-420-12002 Fax: +39-06-420-12034

e-mail: romeoff@taylor-company.com

QS22Electric Grill

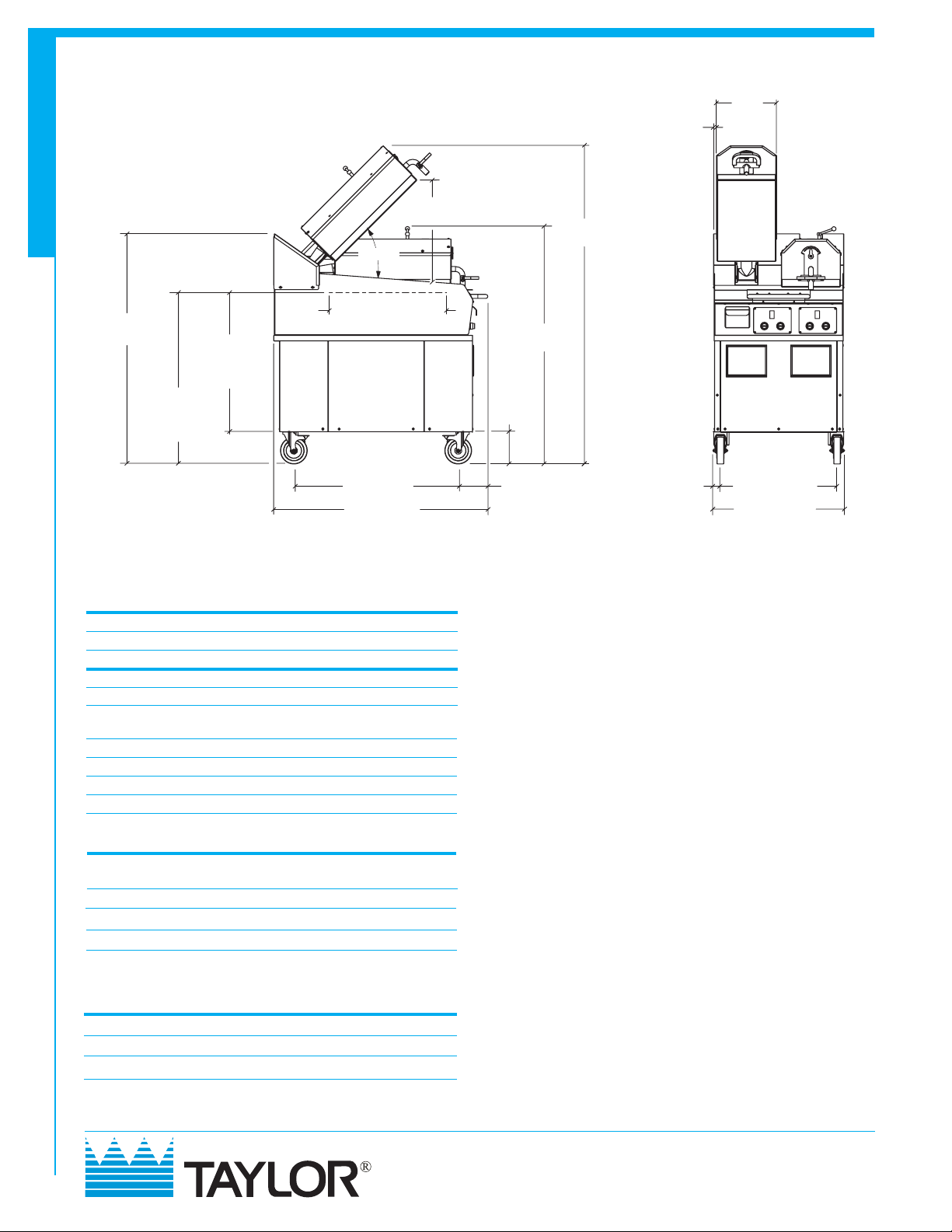

NOTE: FIGURES IN PARENTHESES INDICATE MILLIMETERS.NOTE: FIGURES IN PARENTHESES INDICATE MILLIMETERS.

21-13/16 (554)

24-3/16 (615)

1-3/16 (31)

11-1/8

(283)

11-1/8

(283)

1/

(13)

1/

(13)

2

24 (610)

DEEP COOK SURFACE

24 (610)

DEEP COOK SURFACE

32

(813)

COOKING

SURFACE

32

(813)

COOKING

SURFACE

26

(660)

COOKING

SURFACE

26

(660)

COOKING

SURFACE

42-7/8

(1089)

42-7/8

(1089)

32-1/4 (820)

6

(152)

6

(152)

39-7/8 (1013)

3-3/4 (95)

18-13/16

(478)

18-13/16

(478)

59-1/2

(1511)

59-1/2

(1511)

44-3/8

(1127)

44-3/8

(1127)

30 -60°°30 -60°°

QS22

Weights shown are for single platen. Add 84 lbs (38.6 kgs) for

second platen, or subtract for no platens.

Weights lbs. kgs.

Net 560 254.0

Crated 686 311.2

cu. ft. cu. m.

Volume 38.0 1.07

Dimensions in. mm.

Width 25-1/8 638

Depth 39-7/8 1013

Height 42-7/8 1089

Floor Clearance 6 152

*Mounted on standard casters

Electrical Total Total Requires

Amps KW 60 Amp Cord

208/60/3 with One Platen 40 14.4 IEC309-1 & 2

208/60/3 with Two Platens 53 18 IEC309-1 & 2

230/400/50/3N~ with Two Platens 28 19.6 IEC309-1 & 2

This unit may be manufactured in other electrical characteristics. Refer to the

local Taylor Distributor for availability.

(For exact electrical information, always refer to the data label of the unit.)

Bidding Specs

Electrical: Volt ___________________ Hz__________ ph _________

Options:_________________________________________________

_________________________________________________________

Neutral: Yes No

Specifications

Electrical

One dedicated electrical connection is required. See the Electrical chart for

the proper electrical requirements.

Clearance

Grill clearance must be maintained at least 3” (76 mm) from all combustible

materials, and 3” (76 mm) of air clearance in the rear.

Options

Grease Tray Drain

Grooved Lower Cooking Surface

Upper Platen, Grooved Cooking Surface

Upper Platen, Smooth Cooking Surface

Upper Platen

Platen(s) raise automatically at the completion of the product cook cycle.

Each upper platen has a cooking surface of 11” X 20” (279 X 508 mm) with

three individually controlled heaters. An infinite gap adjustment will

accommodate varying product thicknesses from zero to 1” (25.4 mm).

Release Material

Completely covers and protects upper platen surface, prevents product from

sticking and minimizes carbon build-up. Attachment method ensures that the

release material stays in place throughout the day for easy cleaning.

Continuing research results in steady improvements; therefore, these

specifications are subject to change without notice.

Taylor Company,

A Division of Carrier Commercial Refrigeration, Inc.

Rockton, Illinois 61072

815-624-8333 800-255-0626 Fax 815-624-8000

www.taylor-company.com

Printed in U.S.A.

065267-ADV

1/09

Loading...

Loading...