Models QS11/23

Modular Grills

Operating Instructions

074606-M

5/24/04

Complete this page for quick reference when service is required:

Taylor Distributor:

Address:

Phone:

Service:

Parts:

Date of Installation:

Information found on the data label:

Model Number:

Serial Number:

Electrical Specs: Voltage Cycle

Phase

Maximum Fuse Size: A

Minimum Wire Ampacity: A

E May, 2004 Taylor

All rights reserved.

074606-M

Taylor Company

The word Taylor and the Crown design

are registered trademarks in the United States

of America and certain other countries.

a division of Carrier Commercial Refrigeration, Inc.

750 N. Blackhawk Blvd.

Rockton, IL 61072

Table of Contents

Section 1 To the Installer 1............................................

Air Clearance 1.........................................................

Electrical Connections 1.................................................

Installation of Cable Kit 2................................................

Ventilation and Clearance 2..............................................

Leveling Procedures 3...................................................

Section 2 To the Operator 6...........................................

Section 3 Safety 7....................................................

Section 4 Operator Parts Identification 9...............................

QS11 9................................................................

QS23 10................................................................

QS11 Accessories 11.....................................................

QS23 Accessories 13.....................................................

Section 5 Important: To the Operator 15.................................

Operating Screen and Controls 16.........................................

Maintenance Menu 18....................................................

Maintenance Menu F lowchart 21...........................................

Section 6 Operating Procedures 22.....................................

Opening Procedures 22...................................................

Cooking Procedures 24...................................................

Table of Contents Models QS11 & QS23

Table of Contents -- Page 2

r

Cleaning Between Product Runs 25........................................

Cleaning the Grease Tray Partition 26......................................

Closing Procedures 27...................................................

Weekly Cleaning Procedures 28...........................................

Section 7 Troubleshooting Guide 29....................................

Section 8 Warranty Explanation 31......................................

Parts 31................................................................

Labor 31................................................................

Section 9 Parts List 32.................................................

Wiring Diagram 38.......................................................

Note: Continuing research results in steady improvements; t h erefore, in fo rmation

in this manual is subject to change without notice.

E May, 2004 Taylo

All rights reserved.

074606-M

Taylor Company

The word Taylor and the Crown design

are registered trademarks in the United States

of America and certain other countries.

Models QS11 & QS23 Table of Contents

a division of Carrier Commercial Refrigeration, Inc.

750 N. Blackhawk Blvd.

Rockton, IL 61072

Section 1 To the Installer

This machine is designed for indoor use only.

DO NOT install the machine in an area where

a water jet could be used to clean or rinse the machine.

Failure to follow this instruction may result in serious

electrical shock.

Air Clearance

Clearances from the grill to other surfaces are required

for adequate air circulation:

Rear: 3 inches (76 mm) minimum.

Sides: 3 inches (76 mm) to combustible

surfaces;

0 inches (0 mm) to non‐combustible

surfaces;

0 inches (0 mm) between grills in

multiple installations.

Failure to comply with these minimum

clearance requirements will hinder grill perfor‐

mance and cause damage to its components.

In all other areas of the world, equipment should be

installed in accordance with the existing local codes.

Please contact your local authorities.

Stationary appliances which are not equipped with a

power cord and a plug or other device to disconnect

the appliance from the power source must have an

all-pole disconnecting device with a contact gap of at

least 3 mm installed in the external installation.

This equipment is provided with a grounding lug

that is to be properly attached to the rear of the frame

by the authorized installer. The installation location is

marked by the equipotential bonding symbol (5021 of

IEC 60417-1) on the removable panel and the frame.

The proper wire size and fused circuit should be

selected according to grill data label information.

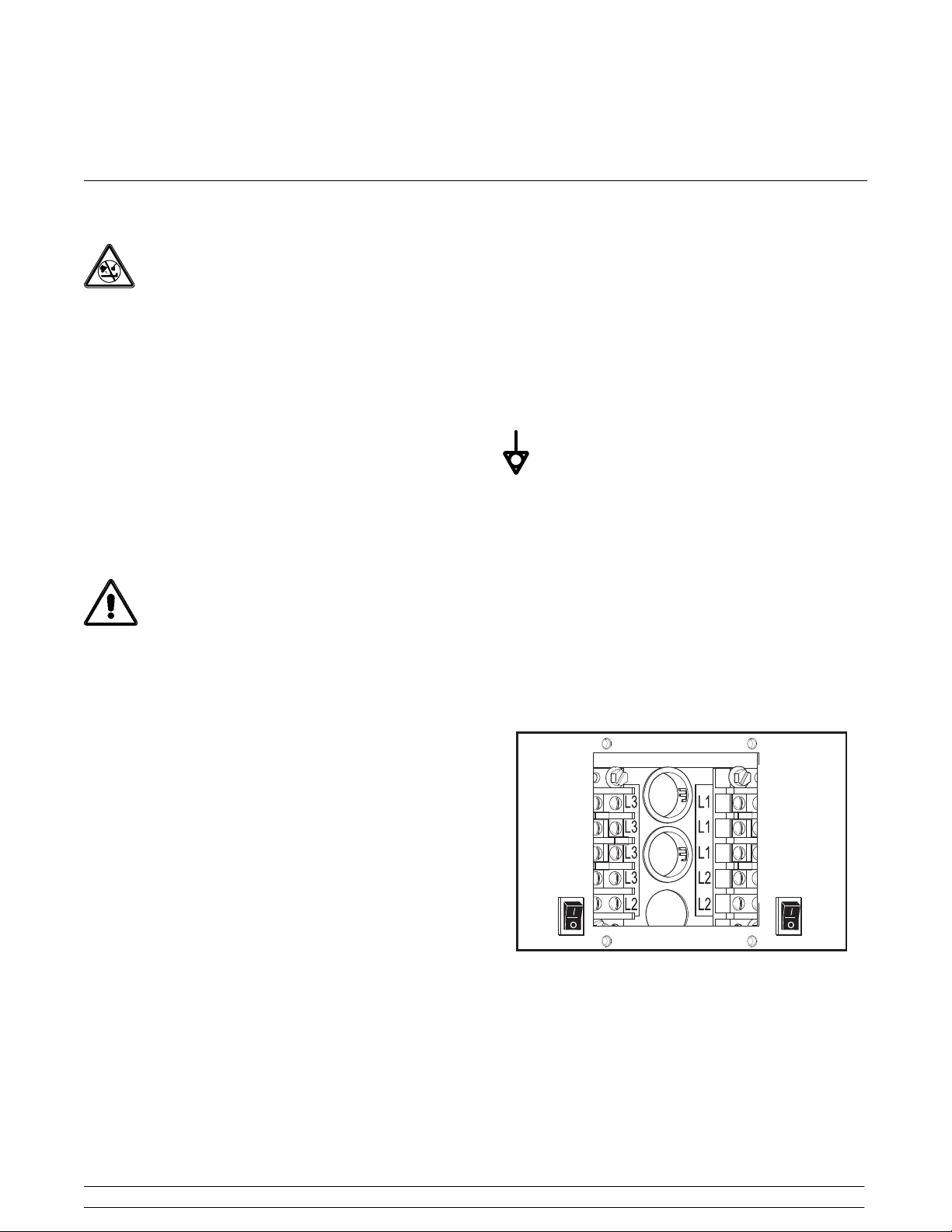

Incoming power must be connected to the terminals

with black characters on a white background, as

shown:

Electrical Connections

The QS series grills have one electrical connection.

Check the data plate on the grill for voltage, cycle,

phase and electrical specifications. Refer to the wiring

diagram, provided inside the protective control panel

door at the front of the grill, for proper power

connections. The power connection is located behind

the access line cover on the front of the grill.

In the United States, this equipment is intended to be

installed in accordance with the National Electrical

Code (NEC), ANSI/NFPA 70-1987. The purpose of

the NEC code is the practical safeguarding of persons

and property from hazards arising from the use of

electricity. This code contains provisions considered

necessary for safety. Compliance therewith and

proper maintenance will result in an installation

essentially free from hazard!

14092

Figure 1

071102

Models QS11 & QS23 To the Installer

1

Installation of Cable Kit

Ventilation and Clearance

Kit A.-3 Ft. Restrain Cable (part no. 074948) must be

installed to limit the movement of the grill. This is

necessary in order to protect the electrical conduit

from stress. The cable is made of flexible conduit.

To install the kit, look at the back of the unit. There is

a 1/2” hole on the left side of the frame, about half way

down. Remove the plug and attach the cable.

To ensure proper operation of this appliance it must be

installed so that products of combustion are efficiently

removed. Do not store anything on top of the grill.

Most service can be performed from the front of the

grill. When inspecting heating elements, the unit must

be disconnected and pulled out of the hood enclosure.

Allow four feet in front of the appliance for this purpose.

060504

To the Installer

2

Models QS11 & QS23

Leveling Procedures

Step 1

The leveling adjustment needs to be performed when

the grill is properly gapped and at operating

temperature. Level the grill without the release

material sheets in place.

Step 2

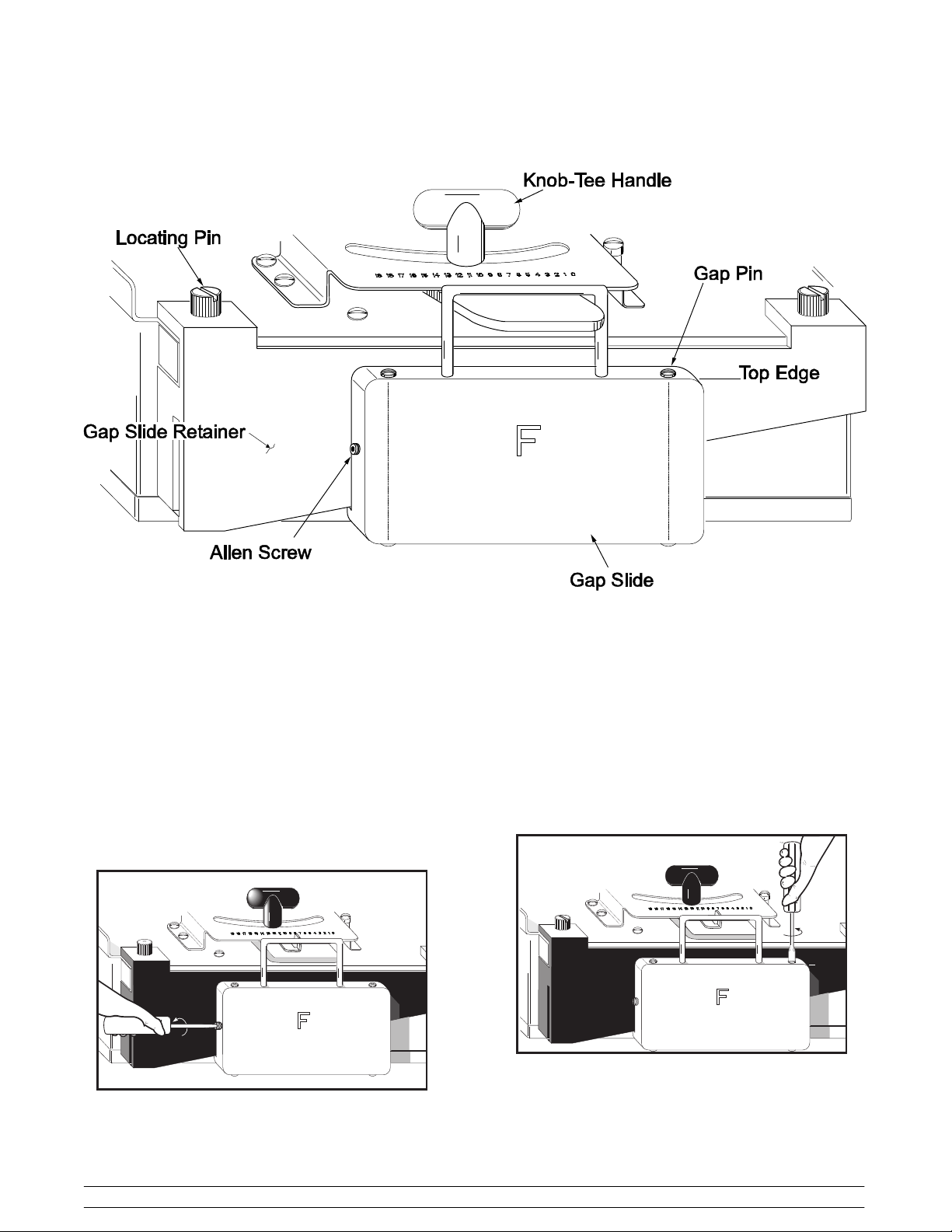

To allow adjustment of the gap pins, loosen the two

1/8” allen screws located on the sides of the front and

rear gap slides.

14110

Figure 2

Step 3

Raise both gap pins on the front gap slide until the

bottom of the screwdriver slot is flush with the top edge

of the gap slide. Repeat this step for the rear gap slide.

Slide the gap slide to the right.

14111

FLUSH

WITH

TOP

Figure 3

Models QS11 & QS23 To the Installer

3

Figure 4

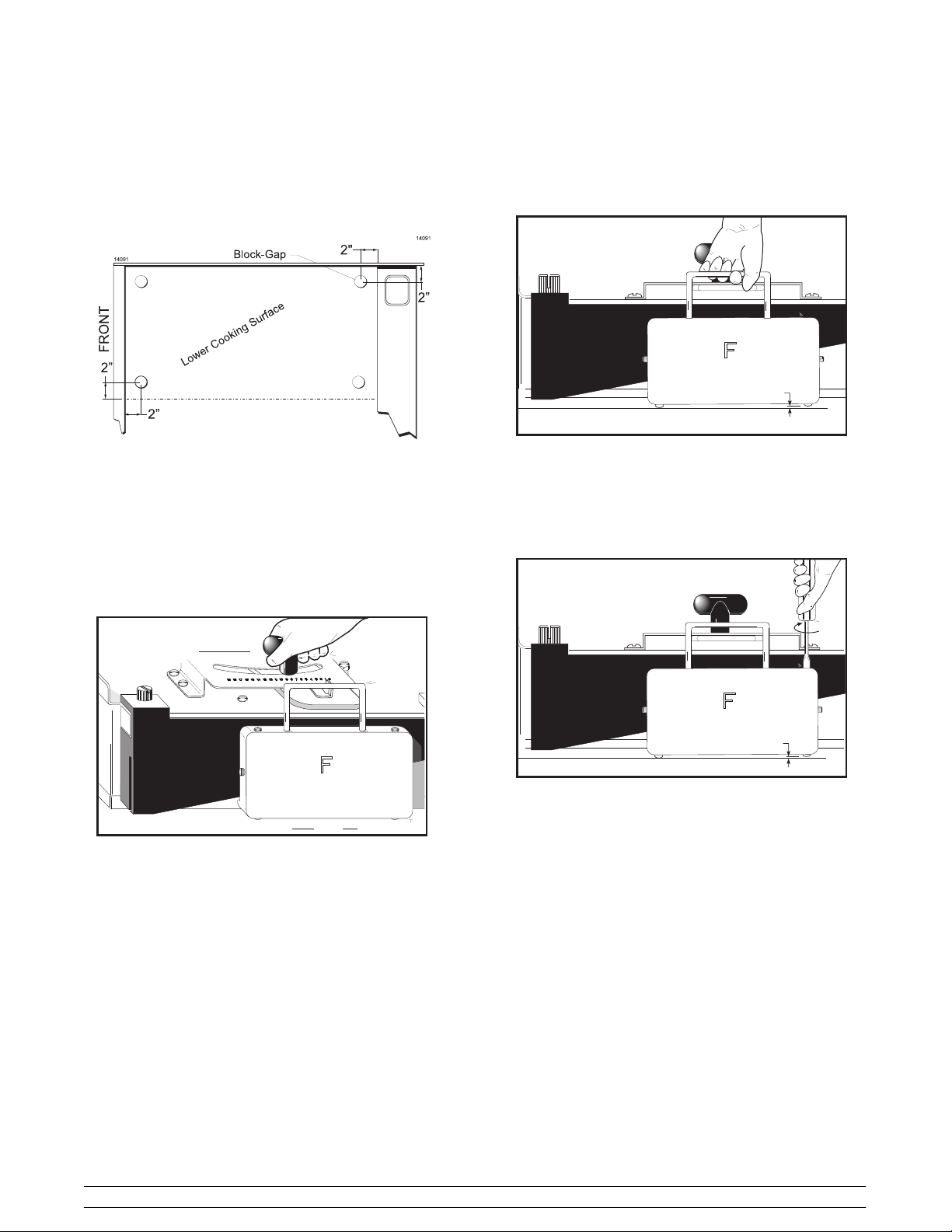

Step 4

For each cook surface requiring adjustment, place the

four gap blocks on the cook surface, approximately 2”

(51 mm) in from each corner. (Figure 5)

Step 6

Wearing proper protection, carefully attempt to raise

the gap slide to evaluate which gap pin is in need of

adjustment.

14113

GAP

Figure 5

Step 5

Lower the cook surface assembly. Loosen and slowly

move the T‐handle to the left until the gap

indicator/pointer is at #8 on the gap indicator plate, and

tighten the T‐handle.

14112

SLIDE

Figure 6

Figure 7

With the gap slide raised, slowly turn the gap pin

needing adjustment until it makes contact with the

cook surface. Note: Do not use force to adjust the pins.

Repeat these steps for both gap slides.

14114

GAP

Figure 8

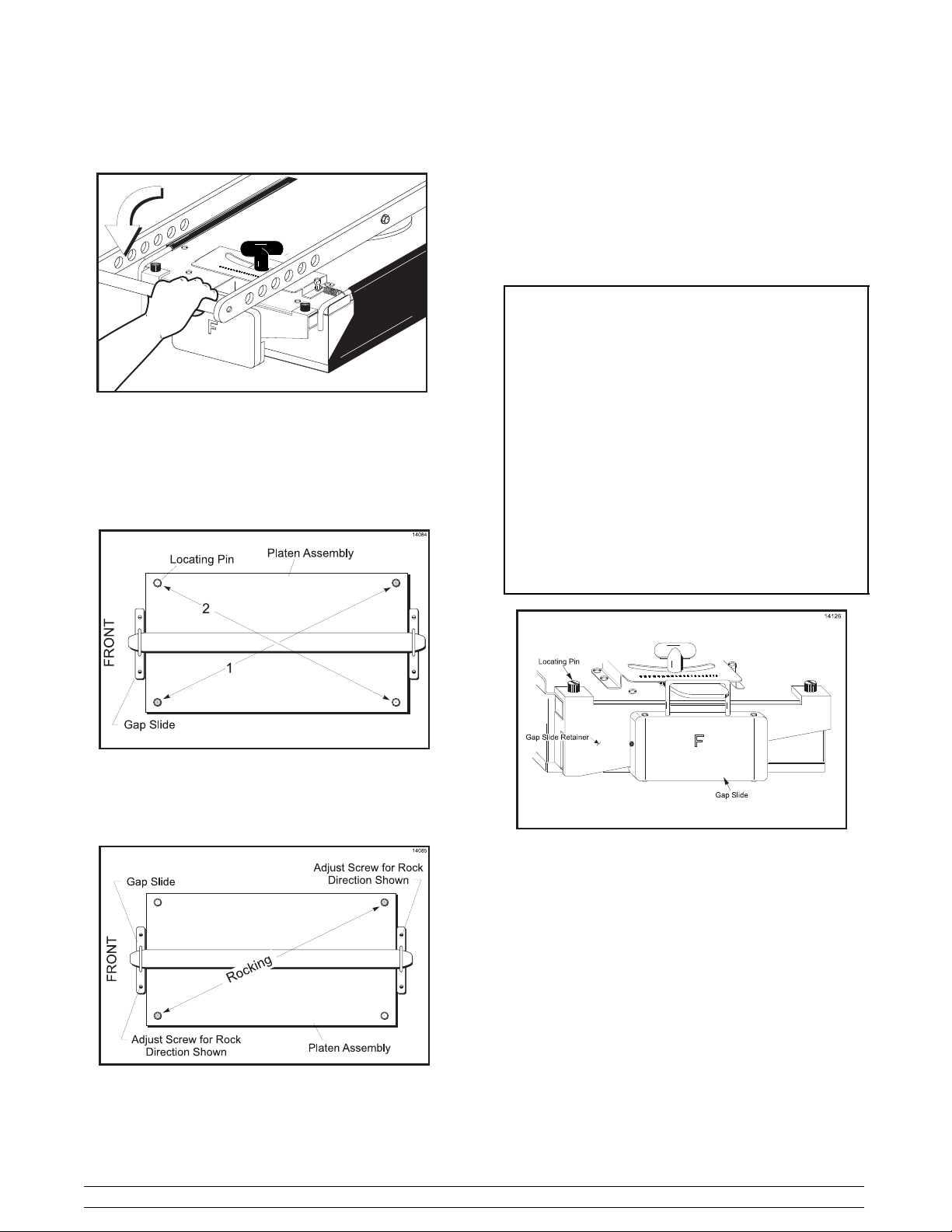

Step 7

Raise the upper cook surface and remove the four gap

blocks.

To the Installer

4

Models QS11 & QS23

Step 8

Lower the upper cook surface into the COOK position.

14115

Figure 9

Step 9

Wearing proper protection, attempt to rock the cook

surface assembly. Apply slight pressure on the

locating pins at opposite corners to each other as

shown in Figure 10.

Step 11

After adjusting, verify the unit for stability/rock.

Step 12

If all adjustments on the cook surface are correct, and

no rocking occurs, tighten the two allen screws located

on the sides of the front and rear gap slides to lock all

adjustments from moving.

IMPORTANT: It is highly recommended

that the gap slides and the gap slide

retainers (as shown in Figure 12) be

removed at least weekly for cleaning these

parts and the cook surface shroud behind

these parts.

These parts are easily removed by removing

the locating pins and holding both parts,

because they are not attached together, and

pulling them from the cook surface.

Take the gap slides and the gap slide retainers

to the sink for cleaning. (Be sure to re-install

the gap slides as they were removed, i.e., “F”

front.) See Weekly Cleaning Procedures

on page 28.

Figure 10

Step 10

If the unit rocks, split the adjustment for gap pins

across the uneven corners, as shown in Figure 11.

Figure 12

Figure 11

090401

Models QS11 & QS23 To the Installer

5

Section 2 To the Operator

The grill you have purchased has been carefully

engineered and manufactured to provide dependable

operation. The QS series grills are designed to deliver

“cook‐to‐order” menu items. The two‐sided cooking

method increases speed of service and assures safe

product integrity.

These grills, when properly operated and maintained,

will produce a consistent quality product. Like all

mechanical products, they require cleaning and

maintenance. A minimum amount of care and

attention is necessary if the operating procedures in

this manual are followed closely.

This Operator's Manual should be read before

operating or performing any maintenance on your

equipment.

It is strongly recommended that all personnel

responsible for the equipment's operation and

cleaning, review these procedures for proper training

and assurance that no misunderstandings exist.

In the event that you require technical assistance,

please contact your local authorized Taylor Distributor.

affixed to this product, it signifies that this product is

compliant with the EU Directive as well as other similar

legislation in effect after August 13, 2005. Therefore,

it must be collected separately after its use is

completed, and cannot be disposed as unsorted

municipal waste.

The user is responsible for returning the product to the

appropriate collection facility, as specified by your local

code.

For additional information regarding applicable local

laws, please contact the municipal facility and/or local

distributor.

If the crossed out wheeled bin symbol is

050831

To the Operator

6

Models QS11 & QS23

Section 3 Safety

We at Taylor Company are deeply concerned about

the safety of the operator when he or she comes in

contact with the grill and its parts. Taylor has gone to

extreme efforts to design and manufacture built‐in

safety features to protect both you and the service

technician. As an example, warning labels have been

attached to the grill to further point out safety

precautions to the operator.

To Operate Safely:

3” (76 mm) from all combustible materials

(0” to non-combustible materials).

Failure to comply could result in a fire hazard.

All grills require 3” (76 mm) of air clearance in the rear.

Failure to comply will hinder grill performance.

Grill clearance must be maintained at least

DO NOT operate the grill without reading this

operator's manual. This manual should be kept in a

safe place for future reference.

This equipment is provided with a grounding lug

that is to be properly attached to the rear of the frame

by the authorized installer. The installation location is

marked by the equipotential bonding symbol (5021 of

IEC 60417-1) on the removable panel and the frame.

S DO NOT operate the grill unless it is

properly grounded.

S DO NOT use the cord if it is frayed.

S DO NOT attempt any repairs unless the

power supply to the grill has been

disconnected.

S DO NOT operate the grill unless all service

panels are restrained with screws.

S Stationary appliances which are not

equipped with a power cord and a plug or

other device to disconnect the appliance

from the power source must have an

all-pole disconnecting device with a contact

gap of at least 3 mm installed in the external

installation.

Failure to follow these instructions may result in

electrocution. Contact your local Taylor Distributor for

authorized service.

DO NOT use a water jet to clean or rinse the

grill. Failure to follow this instruction may result in the

following:

S serious electrical shock

S burns from hot steam

S liquid collecting inside the grill and

destroying electrical components.

S DO NOT prepare or remove product without

proper equipment.

S DO NOT allow untrained personnel to

operate this grill.

S USE EXTREME CAUTION when cleaning

the grill.

Failure to follow these instructions may result in severe

burns from high temperatures.

040408

Models QS11 & QS23 Safety

7

This grill must be placed on a level surface.

Failure to comply may result in personal injury or

equipment damage.

CAUTION: DO NOT attempt to use the grill

during a power outage. Grills require electrical

power for operation. In the event of a prolonged power

outage, place the unit in the “OFF” position.

DO NOT slide the grill with the legs attached.

Failure to follow this instruction may damage the grill.

NOISE LEVEL: Airborne noise emission does not

exceed 70 dB(A) when measured at a distance of 1.0

meter from the surface of the machine and at a height

of 1.6 meters from the floor.

040210

Safety

8

Models QS11 & QS23

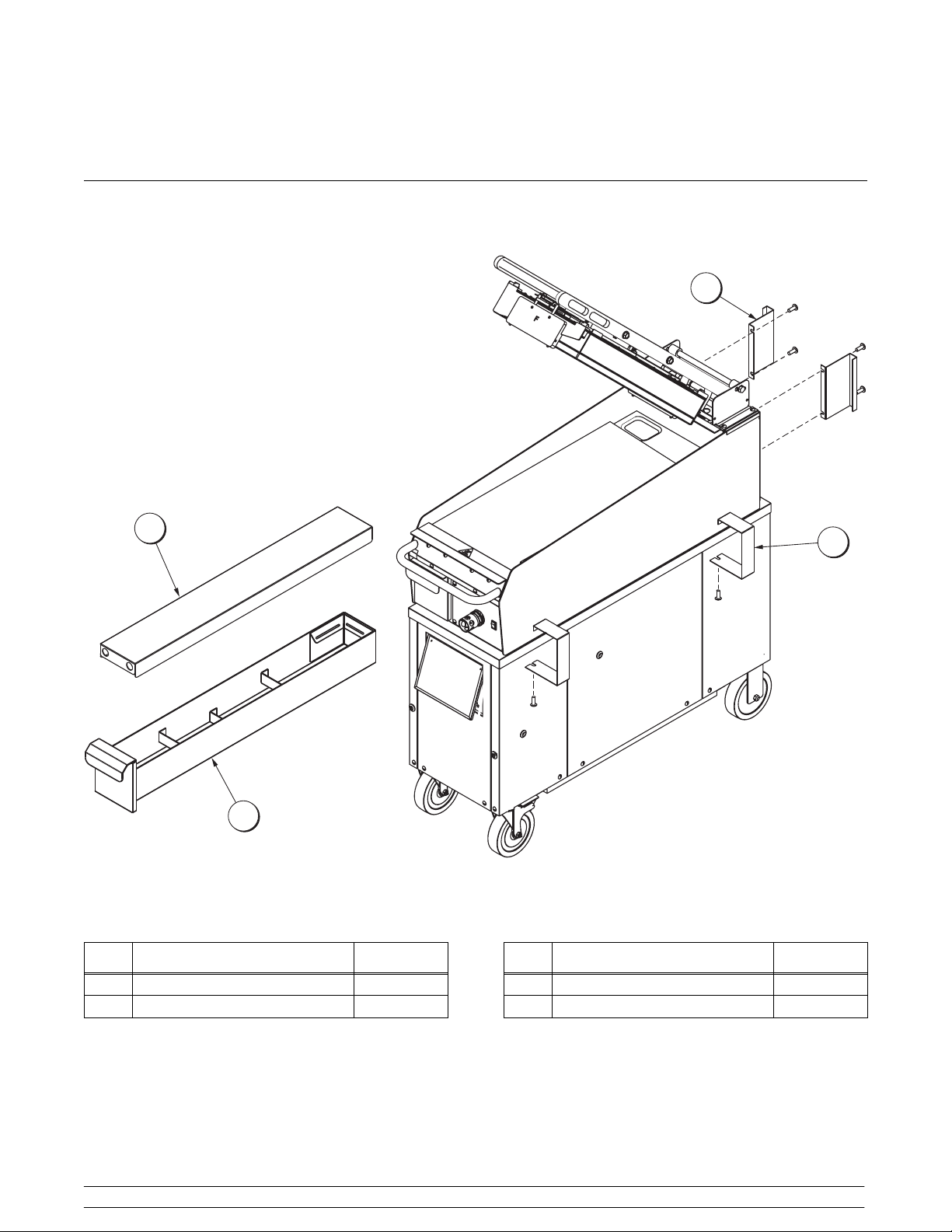

Section 4 Operator Parts Identification

QS11

3

1

2

ITEM DESCRIPTION PART NO.

4

Figure 13

ITEM DESCRIPTION PART NO.

1 COVER-TOP 079969

2 TRAY A.-GREASE X79940-SER

Models QS11 & QS23 Operator Parts Identification

9

3 STANDOFF-REAR 079288

4 STANDOFF-FRONT 079289

071102

Loading...

Loading...