Item No. _______________________________

CH04

Batch Heat Treatment

Features

Allows the operator to incorporate a hot process to mix, heat,

refrigerate, hold, and age gelato or other frozen dessert

mixes. Using a hot process improves mix stability, assures a

rich, creamy texture, and maintains quality frozen product in

the display case. Flexible equipment may also be used for

specialty recipes, like pudding, inverted sugar, slush base,

syrup toppings or hot chocolate. Manufactured in Italy by

Frigomat to ensure European equipment quality and

technology.

Reservoir

One, 63.4 quart (60 liter) vat. Clear cover allows operator to watch

the mixing action. If cover is raised, heating and agitation will stop

for safety purposes, but refrigeration continues.

Controls

Touch pads control mixing, refrigeration, faucet, rinsing the spout,

two automatic and one programmable heat cycles.

CH04

Heat Cycles

Two automatic heating temperature cycles are pre-programmed to

heat and cool within specified time periods to assure food safety.

The high temperature cycle heats to 185ºF. (85ºC.) and immediately

begins cooling the mix to maintain safe product temperatures below

41ºF (5ºC). The lower temperature cycle heats to 150ºF. (65ºC.),

holds the mix at that temperature for 30 minutes, before cooling,

The heating and cooling cycle is completed within two hours. One

semi-automatic cycle allows the operator to personalize their recipe

by selecting the proper temperatures for specific ingredients.

Delicate ingredients such as cream or chocolate are typically added

during the cool down phase.

Bain-Marie

Indirect heat surrounds the vat for cooking delicate ingredients like

custards or melting chocolate. Heat transfers through the entire

tank surface, instead of only where heating elements are located.

Also aids in refrigerating product without the possibility of ice

crystal formation.

Easy Cleaning

With both hot and cold water attached, cleaning is simple.

Independent rinse cycle for the spout maintains strictest hygiene

between batches, and eliminates flavor carryover. Agitator and

spout disassemble easily without tools.

Drip Tray

Clear drip tray and stainless steel holder may be removed as needed

for filling large containers.

Rockton, Illinois 61072

800-255-0626

Phone 815-624-8333 Fax 815-624-8000

www.taylor-company.com

e-mail: info@taylor-company.com

International Office

Taylor Company S.r.l.

Roma, Italy

Tel: +39-06-420-12002 Fax: +39-06-420-12034

e-mail: romeoff@taylor-company.com

CH04Batch Heat Treatment

CH04

Weights lbs. kgs.

Net 441 200.0

Crated 529 240.0

cu. ft. cu. m.

Volume 25.7 0.73

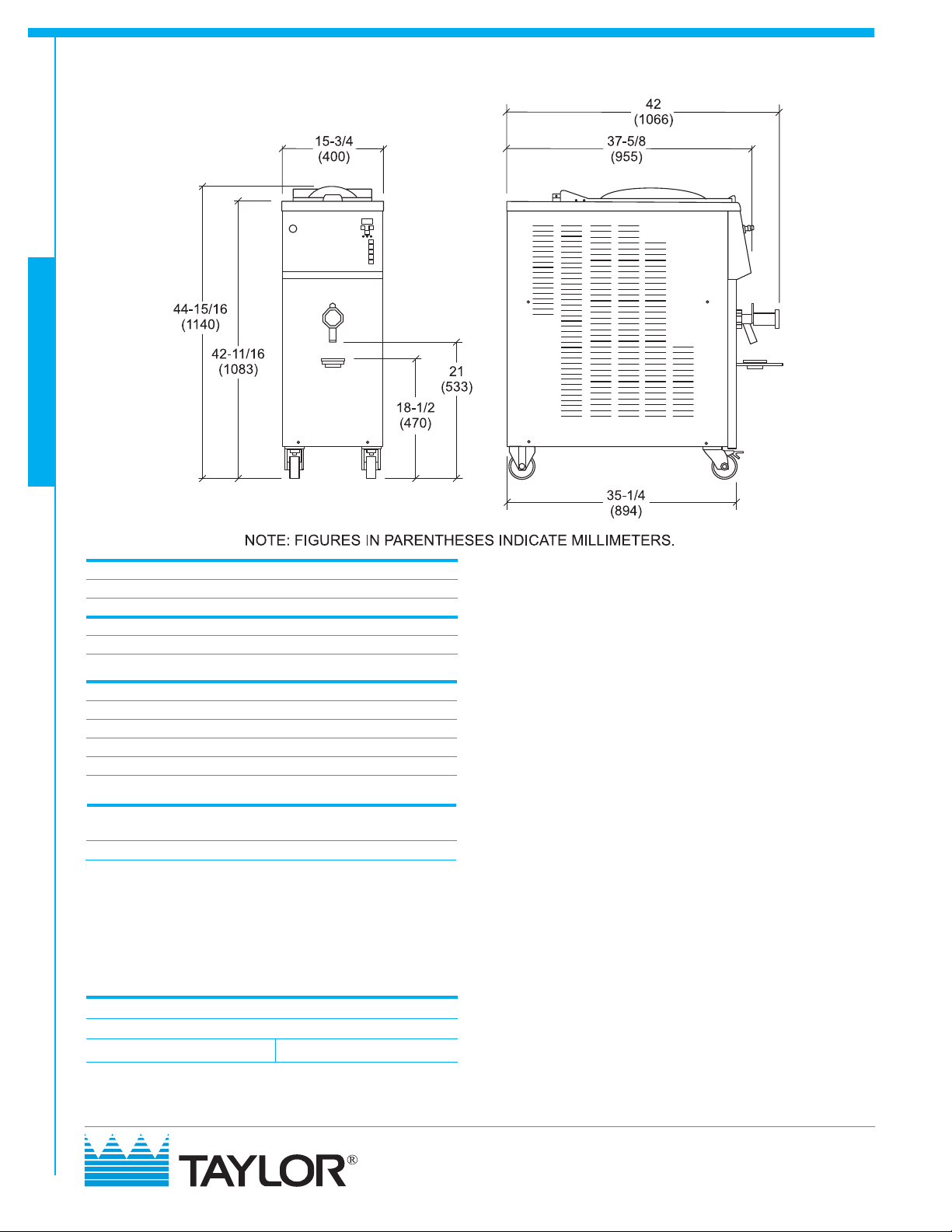

Dimensions in. mm.

Width 15-3/4 400

Depth 42 1066

Height 44-15/16 1140

Floor Clearance* 4 102

Mounted on standard casters

Electrical Maximum Minimum Poles (P)

Fuse Size Circuit Ampacity Wires (W)

208-230/60/3 Water 30 22 3P 4W

This unit may be manufactured in other electrical and cooling characteristics.

Refer to the local Taylor Distributor for availability.

(For exact electrical information, always refer to the data label of the unit.)

Bidding Specs

Electrical: Volt ___________________ Hz__________ ph _________

Neutral: Yes No Cooling: Air Water NA

Options:_________________________________________________

_________________________________________________________

Specifications

Electrical

One dedicated electrical connection is required. See the Electrical chart for

the proper electrical requirements. Manufactured to be permanently

connected. Consult your local Taylor distributor for cord & receptacle

specifications as local codes allow.

Heater

One, 6 kW.

Refrigeration System

One, approximately 46,300 BTU/hr. R404A.

(BTUs may vary depending on compressor used.)

Agitator Motor

One, 3/4 HP.

Water Cooled

Water inlet and drain connections at rear, 1/2” FPT.

Taylor Company,

A Division of Carrier Commercial Refrigeration, Inc.

Rockton, Illinois 61072

815-624-8333 800-255-0626 Fax 815-624-8000

www.taylor-company.com

Printed in U.S.A.

063085-ADV

6/06

Loading...

Loading...