MANUAL OF USE AND

MANUEL D’UTILISATION

MANUAL DE USO Y

MANUALE D’USO E

ELECTRONIC PASTEURIZERS WITH BAIN-MARIE

PASTEURISATEURS ELECTRONIQUES BAIN-MARIE

PASTORIZADORES ELÉCTRONICOS CON BAŇO MARIA

PASTORIZZATORI ELETTRONICI A BAGNOMARIA

MAINTENANCE

ET D’ENTRETIEN

MANUTENCION

MANUTENZIONE

Series-Série-Serie

CH03 05

CH04 04

CH05 04

1 - ENGLISH

We recommend to carefully and fully read the present manual before using your

TAYLOR machine.

In your own interest, pay particular attention to the following warnings:

IMPORTANT

The non-observance of this warning can jeopardize the user’s health and the

correct operation of the machine.

The machine is covered by guarantee according to the conditions reported in the Seller’s

In the following field, please write your machine serial number in capital letters

Serial number

Distributor’s stamp

ENGLISH - 2

Congratulations on purchasing a machine TAYLOR.

The present manual, enclosed to the machine, is integrant and essential part of the

machine and shall be delivered to the final user. Before performing any kind of operation, it

is recommended to carefully study the reported instructions, as only a careful reading

allows you getting the highest performance from your machine. The following pages report

all information necessary to correctly install, commission, adjust and service your machine.

TAYLOR reserves the right to carry out all changes necessary to improve its product or

manual without prior notice and to insert them in the subsequent issues.

INDEX

1. TRANPORT, HANDLING AND STORAGE .…………………….…………. 4

2. MARKINGS AND GRAPHICS ………………………………………… 5

3. INSTALLATION ………………………………………… 7

3.1 Field of use ………………………………………… 7

3.2 Limits of use ………………………………………… 7

3.3 Machine outfit ………………………………………… 7

3.4 Commissioning ………………………………………… 7

4. SAFETY DEVICES ………………………………………… 10

5. OPERATION ………………………………………… 11

5.2.1CH03 – CH04 operation ………………………………… 15

5.2.2 CH05 operation ………………………………… 17

6. MAINTENANCE ………………………………………... 18

6.1 Routine maintenance ………………………………………… 18

6.1.1 Cleaning and sanitization ………………………………… 18

6.2 Extraordinary maintenance ………………………………………… 20

6.2.1 Refrigeration plant ………………………………………… 20

6.2.2 Electric system ………………………………………… 20

7. TROUBLE-SHOOTING …………………….………………… 21

7.1 Alarm management ………………………………………… 21

7.2 Trouble-shooting ………………………………………… 22

8. APPENDICES ………………………………………… A1

1.1 Preliminary inspection ………………………………………… 4

1.2 Machine unpacking ………………………………………… 4

1.3 Packing dimensions ………………………………………… 4

5.1 Control panel ………………………………………… 11

5.2 Use of programs ………………………………………… 15

8.1 Technical data ………………………………………… A1

3 - ENGLISH

1 TRANSPORT, HANDLING AND STORAGE.

1.1 PRELIMINARY INSPECTION

The machine travels at the customer’s risk. In case packing is damaged, immediately

inform the carrier.

Immediately inform the carrier also in case of damage to the machine, even if you open

the packing a few days after the delivery.

It is always advisable to accept the goods SUBJECT TO INSPECTION.

The equipment shall be assembled with great care: falls and shocks can damage it without

showing external damages.

1.2 MACHINE UNPACKING

For a correct machine unpacking, carefully follow the instructions hereunder reported:

in case of packing carton on wooden frame:

• Remove the strap fixing the carton to the bottom and take the packing off from the top.

In case of wood case:

• Remove the case upper side and the side walls by means of a nail drawer, pay

attention not to disperse the nails and the wood splinters;

• Remove the plastic bag and put it in a safe place;

• Unscrew the machine side panels by means of a cross and/or cut screw-driver;

• Turn out the screws fixing the packing lower side to the machine by means of a 17mm

wrench;

• Remove the packing lower part, lift the machine and hook it up to the lifting points

specified on the frame with the symbols;

• Reposition the side panels.

The packing shall be stored in a dry place, out of the children’s reach. It can be used

again, if correctly preserved, for a possible transfer of the machine.

The storing temperature shall range between -13°F and +131 °F.

Humidity shall range between 30 and 95%.

Packing elements such as plastic bags, nails, expanded polystyrene, cartons, etc. must be

left out of the children’s reach.

1.3 Packing dimensions

MODEL

CH03

CH04

CH05

SIZES (CM) WEIGHT N- L (KG)

50X90X130 159-190

50X113X130 200-248

90X113X130 335-410

CASE

ENGLISH - 4

2. MARKINGS AND GRAPHICS

Never touch the machine with hands and tools during production or maintenance and

cleaning operations, without making sure that the machine is in STOP position, the master

switch is off and/or the multipolar plug disconnected.

TAYLOR declines any liability for accidents deriving from an improper use of the machine

due to the non-compliance with the above-mentioned recommendations.

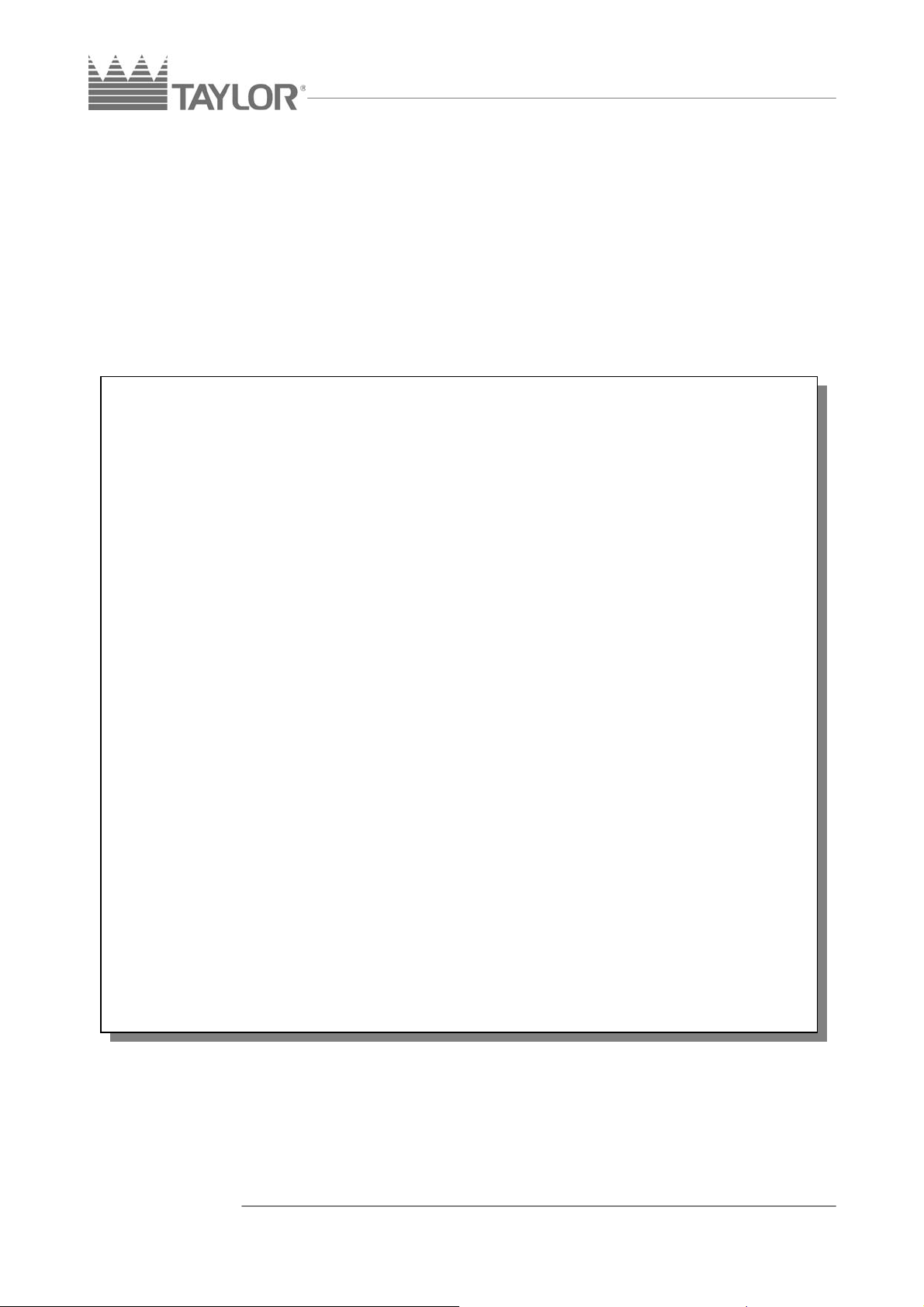

The machine is provided with a plate and some pictograms, which together with the

present manual allow using the machine in safer conditions.

Machine data plate

The adhesive label located on the back of the

machine allows identifying the model and reports the

following indications:

Manufacturer’s name and address; Machine model

and version; Serial number; Rated electrical

characteristics; Type and weight of employed Freon;

Manufacturing year.

Indication

Points of application of lifting devices.

The following plate is placed on the four sides of the

frame lower part and shows the points where lifting

hooks shall be positioned in order to perform this

operation in safe conditions. By means of a cross

screw-driver unscrew the two side panels and then

position the lifting devices into the apposite points.

Make sure that they cannot accidentally come out

during lifting operations.

Warning!

Maintenance allowed to qualified personnel only.

The following plate placed on the machine back panel

forbids extraordinary maintenance operations and/or

repairs delegating them to authorized people only,

whose address is indicated in the provided space.

5 - ENGLISH

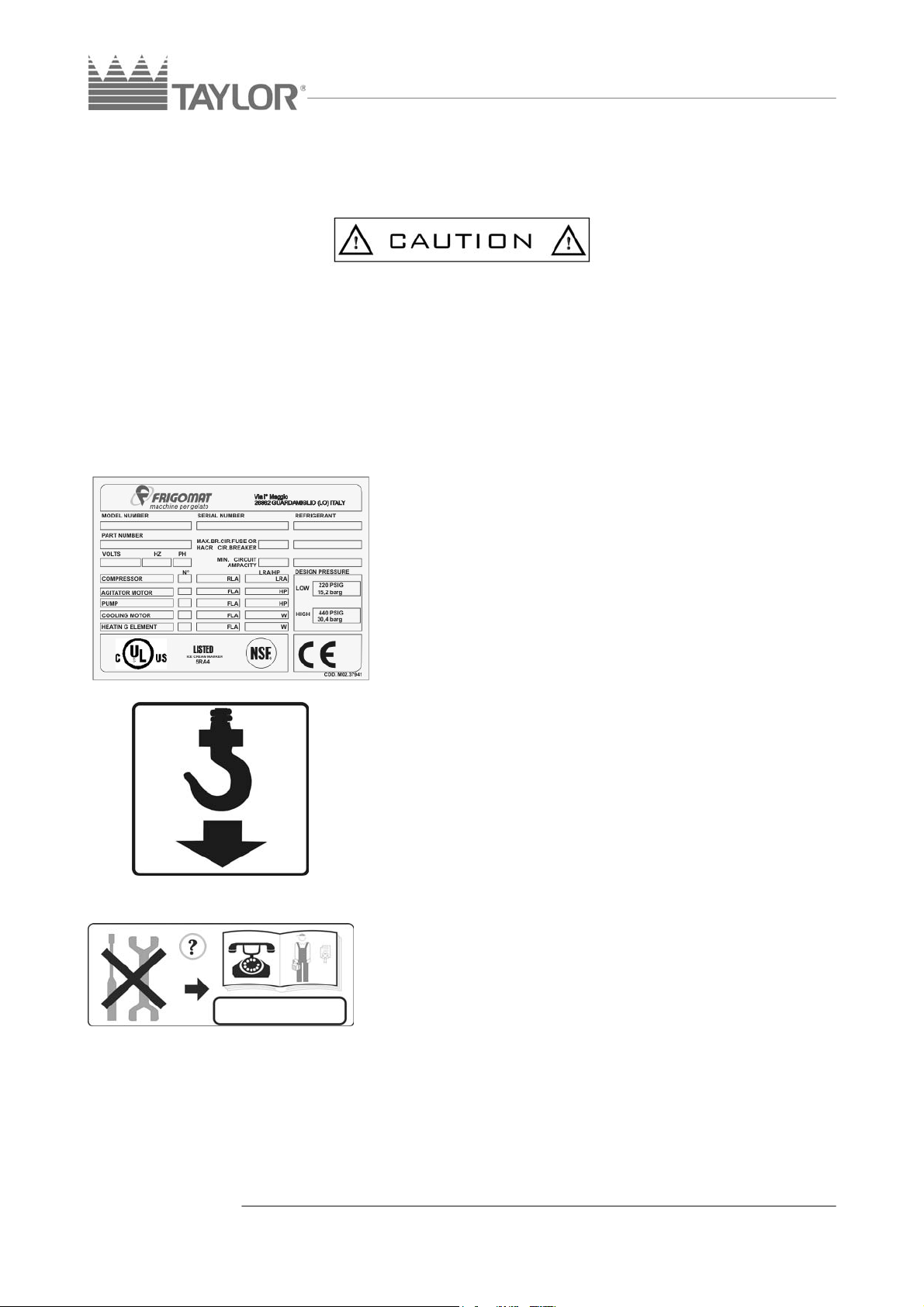

Warning!

Do not touch with hands.

The following plate placed on the back of air-cooled

machines shows that cleaning operations on the heat

exchanger shall be carried out only by means of a

brush or an exhauster.

Warning!

High voltage inside, danger of fulguration.

The following plate is placed on the electric box cover

and warns the operator that in no case the cover must

be removed avoiding this way the risk of lethal

fulguration. Also in this case, maintenance operations

on internal components must be performed by

authorized personnel only.

Warning!

Risk of crashing.

The following plate is applied on the upper panel on

the tank cover right side and shows that it is

necessary to pay attention to the cover both during

cleaning and loading operations. In fact it can fall

down if accidentally knocked causing injuries to the

operator.

All CH pasteurizers are equipped with an advanced

shearing-prevention system able to stop moving

elements when the cover is opened. Nevertheless, all

cleaning and maintenance operations shall be carried

out when the machine is in “STOP” position and the

master switch turned off.

ENGLISH - 6

3. INSTALLATION

3.1 FIELD OF USE

Equipment suitable to the preservation and low and high pasteurization of food mixture for

ice-cream for appropriate legal purposes.

3.2 LIMITS OF USE

Never use the machine with variable supply voltage and/or more than +/- 10% of the value

showed in the nameplate or when the feeder is damaged;

Do not use the machine for purposes different from the ones indicated in the present

manual;

Do not use the machine in explosive environment;

Do not wash the machine with high-pressure jets of water or poisonous substances;

Do not expose the machine to excessive heat or humidity;

Do not use completely unbalanced mixtures and/or quantities not in compliance with the

specifications reported on the packing.

3.3 MACHINE OUTFIT

- Disk wheel

- Cleaning rod

- Gasket dismantling tool

- Stiff paddle

- Packing screw

- Packing washer

- Flat packing washer

- Cock O-Ring 3112

- Cock O-ring 3075

3.4 COMMISSIONING

Bring the machine to the place of employment and check that everything is all right as far

as installation concerns:

A. Power supply;

B. Water supply (only in case of water condensing);

C. Suitable run-off pit for water (only in case of water condensing).

• Lock the machine by means of the apposite lever located on the front wheels;

• Place the machine far from walls or other obstacles (at least 10 cm sideways and 30 on

the back). In case the machine is provided with water-cooled condenser, the distance

between the wall and the back panel can be reduced to 10 cm.

• Make sure that the supply voltage and power comply with the values reported on the

rating plate placed on the back panel;

• Connect the machine to the mains; upstream the machine, arrange an omnipolar

master switch with minimum contact opening equal to 3 mm and adequate power,

interlocked with fuses to allow plugging and unplugging at open circuit.

- Cock O-ring 121

- Cock O-ring 4087

- Pivot O-ring 2018

- Lubricant

- Squeese bottle

- Use and maintenance manual

- Declaration of conformity

- Certificate of guarantee

7 - ENGLISH

• Connect the feeder to a type-approved plug: the feeder shall be well stretched, to avoid

rolling and overlapping. It shall not be exposed to possible shocks or tampering

attempts and far from liquids, water and heat sources. It shall not be damaged,

otherwise make it be replaced by qualified personnel with another section and type

5G4 H07RN-F (for version 400 V), before connecting the machine to the mains.

• Arrange the connection of the yellow-green wire to a good earth connection.

• Put the machine metallic parts to earth by means

of the apposite equipotent fastening screw located

on the back under the frame and marked by the

symbol showed on the left.

• Make sure that the water supply system is

provided with sufficient pressure for a correct

operation of the condensing plant. A residual

pressure ranging between 1 bar and 3 bar is

considered suitable.

• Connect the condensing water inlet hose to the

inlet showed in the picture by means of a rubber

hose Ø1/2”. Interpose a cut-off cock at the

operator’s reach.

• Connect the condensing water outlet hose to the

outlet showed in the picture by means of a hose

connector Ø1/2” and bring it to the discharge.

• Both for inlet and outlet connections it is advisable

to make use of linenized hoses suitable to

withstand pressures up to 10 bar and apposite

hose clamps DIN 3017.

• The water outlet hose shall have a min. inclination

of 3 cm for each meter of length.

• In case of water condensing it is necessary to

check that the water valve correctly works.

• After both inlet and outlet hoses have been

connected, open the cut-off cock and make sure

that the discharge does not leak liquid when the

machine is not working. If this is the case, apply to

a qualified customer service.

• After the master switch has been turned on, press

pushbutton 5 to start up the compressor motor.

After a few seconds the condensing water shall

regularly come out of the outlet hose end at a

temperature of 35°C. Press pushbutton 10 STOP

to stop the machine. In case of troubles, apply to

the customer service.

• For the three-phase version only, check that the

mixer sense of rotation is clockwise:

• Close the tank cover and start up mixing by means

of pushbutton 9. Check that the disk wheel inside

ENGLISH - 8

the tank clockwise rotates as showed in the

picture.

• Press pushbutton 10 STOP to stop the machine.

• In case the sense of rotation is not clockwise,

remove voltage and exchange the two wires of the

feeder between themselves.

• The ideal temperature shall range between

15°(59°F) and 35°C (95°F);

• The ideal humidity shall range between 30 and

60%.

TAYLOR declines any liability for damages to persons and/or things due to a wrong

installation and/or the non-compliance with the industrial accident prevention standards.

Never touch the machine with hands, both when it is on duty and during cleaning and

maintenance operations, without making sure that the machine has been stopped by

means of pushbutton 10 STOP and the master switch has been turned off. Never clean

the machine by means of high pressure jets of water. Never close the cut-off cock while

the machine is running. Pay attention not to damage the feeder. In case of necessity,

make it be replaced.

In case the machine provided with water-cooling is left at a room temperature inferior to

0°C (32°F), it is necessary to run off all water present inside the condenser before starting

up the machine.

9 - ENGLISH

4. SAFETY DEVICES

Shearing prevention system: realized by means of a NO micro-switch in conformity with

the European standard. It stops the mixer motor when the tank cover is opened;

Motor reliability of service: realized by means of overload relays, which can be manually

reset. They protect the machine motors against overloads and the pushbuttons STOP and

TER contemporarily light up. An acoustic signal (beep) is issued every 10 seconds. To

reach the overload relay, press the reset pushbutton once or twice at the most to avoid

burning the motor winding.

Auxiliary circuit supply safety system (24 V): realized by means of an insulating

transformer according to the European Standards in force. In case of trouble it prevents

the primary circuit voltage from being present on the auxiliary elements (probes, logic unit,

solenoid valves, etc.).

Protection against auxiliary equipment short-circuit: realized by means of modular

magneto-thermal circuit-breakers, that trip in case of short-circuit on the logic unit or on the

auxiliary power supply.

The cut-off function is automatically restored after removing the problem making the safety

system trip.

Glycol circuit alarm: when the machine is in STOP position and the FLU led is lighted up,

the glycol circuit is in trouble (opened water valve and blocked pump).

Fluid level alarm: when the FLU led blinks the level of fluid has reached the bottom and it

is necessary to check the circuit.

Safety thermostat alarm: when the machine is in STOP position and the TER led is

lighted up, the fluid safety thermostat or one of the motor protection has tripped.

Temperature probe alarm: when the machine is in STOP position and the TEM led is

lighted up, the temperature probe circuit does not correctly work.

In any case the machine carries out a series of tests during production:

Logic unit self-reset in case of lack of power supply

• Diagnosis of control panel flashing signal lights: all leds present on the panel light up for

10 seconds at each current reset and show the operator their functions. Press any key

to exit this function.

• Automatic reset of the previously set-up function.

Logic unit self-diagnosis (watch-dog)

• Microprocessor diagnosis and maintenance of program data: it controls possible

internal troubles and stops the card in case of failure.

ENGLISH - 10

5. OPERATION

5.1 CONTROL PANEL

Digital display

Switching on the machine, the display shows an abbreviation

composed of a letter followed by two figures: for example the

abbreviation P1.3 shows the program type P = PASTEURIZER and

1.3 NUMBER OF SOFTWARE VERSION.

Possible indications:

¾ 32-210: temperature in °F of the mixture inside the tank;

¾ 86-194°F: set-up value of temperature in SEMI-AUTOMATIC

0-120 minutes: set-up value of pause time in SEMI-AUTOMATIC

mode (pasteurizer only).

1. Digital display

2. Water-cock pushbutton

3. STOP/VALUE CONFIRMATION

pushbutton

4. Pushbutton for the introduction of water

into the tank / VALUE CANCELLATION

5. Fluid alarm

6. Overload relays alarms

7. Temperature alarm

8. “SEMIAUTOMATIC” pushbutton

9. “HIGH PASTEURIZATION” pushbutton

10. “LOW PASTEURIZATION” pushbutton

11. “COOLING” and “PRESERVATION”

pushbutton

12. “LOW MIXING” pushbutton

cycle (pasteurizer only);

11 - ENGLISH

Water-cock pushbutton

This pushbutton carries out two functions:

1. press it to introduce water into the cock and wash it. The delivery

of water keeps on as long as the pushbutton is pressed.

2. if the pushbutton is lighted up this means that programming of

heating temperature or preservation time is active. Press it to

decrease the value showed by the display. Once the desired

value has been selected, press STOP pushbutton to confirm and

save it.

The water-cock function is active with any other function in progress,

STOP included.

STOP/VALUE CONFIRMATION pushbutton

This pushbutton carries out 3 functions:

1. press the pushbutton to cancel the function in progress and stop

the machine;

2. if the SEMI-AUTOMATIC pushbutton has been pressed and the

cock-washing led and the water-tank led are lighted up, press this

pushbutton to confirm both storage of the program and the

parameter showed on the display, the mixture heating

temperature in °F or this temperature preservation time expressed

in minutes for pasteurizers;

3. It restores the machine functions after the machine has been

stopped due to an alarm signal.

Pushbutton WATER – TANK/ VALUE CANCELLATION

This pushbutton carries out 2 functions:

1. Press it and the flexible shower delivers water for a preset time of

2’ and 30”. To stop delivery press the pushbutton again;

2. if the pushbutton is lighted up, press it to increase the numerical

value showed by the display (heating temperature and

preservation time). Once the desired value has been selected,

press stop to confirm and save it. The function water-tank is active

with any other function in progress, STOP included.

“SEMIAUTOMATIC” pushbutton

This pushbutton gives the operator the possibility to select the

desired cycle and to have the correct pause time indication for a

perfect pasteurization. In case it is necessary to change this time,

due to special requirements, the operator can do it by directly

programming on the pushbutton panel, with machine in STOP

position.

ENGLISH - 12

By pressing the SEMI-AUTOMATIC pushbutton the water-cock and water-tank

pushbuttons light up and the STOP pushbutton remains lighted up to show that the

pushbutton panel is ready for programming.

The digital display shows the heating temperature value programmed for the last SEMIAUTOMATIC cycle.

If this value is suitable to the kind of mixture, which is going to be processed, it is sufficient

to press the STOP pushbutton to confirm the value and save it. The display will

automatically show the time required for a correct pasteurization.

On the contrary, if it is necessary to program a different value, press the water-cock

pushbutton to decrease the value or water-tank pushbutton to increase it.

Once the desired value has been set up, press the STOP pushbutton to confirm and save

it. The SEMI-AUTOMATIC pushbutton starts up blinking to show that the pushbutton panel

is ready to program the heating temperature preservation time.

If this value is suitable to the mixture requirements, press the STOP pushbutton to start up

the selected pasteurization cycle, which is automatic. To each cooking temperature

corresponds a defined preservation time. All preservation times necessary to carry out a

correct pasteurization from 60°C(140°F) to 85°C (185°F), arranged degree by degree, are

stored in the machines CH series.

We recommend the operators not to modify these times, which moreover automatically

appear on the display without being necessary to remember it.

However, in case the operator intends to process some ingredients at his will, it is possible

to change both temperature and aging time, it will be sufficient to press the water-cock and

the water-tank pushbuttons to decrease or increase the values.

Once the desired combination has been fixed, press the STOP pushbutton again to

confirm it and start up the desired mixing and/or heating cycle. Remember that

pasteurization is carried out in memorized programs only.

In LOW and HIGH PASTEURIZATION or SEMI-AUTOMATIC mode, the tank cover

opening makes the mixer motor, the heating resistor and the refrigeration compressor

immediately stop, but not the glycol circulation pump

During all these phases it is possible to wash the cock and introduce water into the tank,

always with the display showing the mixture temperature.

“HIGH PASTEURIZATION” pushbutton

185°F

Press this pushbutton to start up heating with switched-on mixer

motor, glycol pump and heating resistor until the temperature reaches

the value of 85°C (185°F).

Once the preset value of 85°C (185°F) has been reached, the cooling

cycle begins until the mixture preservation temperature of 4°C (39°F) is reached. At the

end of the cooling cycle the preservation cycle begins.

.

13 - ENGLISH

149°F

39°F

“LOW PASTEURIZATION” pushbutton

Press this pushbutton to start up the mixer motor, the heating resistor

and the glycol pump until the temperature of 65°C (149°F) is reached

and showed on the display.

Once the temperature of 65°C (149°F) is reached the preservation

cycle of 30 minutes begins, at the end of which the cooling cycle

begins until the preservation temperature of 4°C (39°F) is reached.

At the end of the cooling phase, the preservation cycle begins.

COOLING/PRESERVATION pushbutton

Press this pushbutton to start up cooling the mixture with working

mixer motor, refrigeration compressor and glycol circulation pump,

until the mixture inside the tank reaches a temperature of 4°C (39°F),

stopping all machine functions.

Subsequently, the compressor (if necessary) and the mixer will

automatically start up running for 15” every 4 minutes.

During the entire cycle, the display shows the temperature value of

the mixture inside the tank.

“LOW MIXING” pushbutton

When the machine is in STOP position, press the MIXING

pushbutton to start up the mixer and allows mixing. If the tank cover

is open, the mixer motor does not start up until the cover is

closed.

The display shows the temperature of the product inside the tank.

Before introducing the mixture or the ingredients, it is advisable to

accurately wash and sanitize the machine. It is also advisable to

check that the piston gaskets are correctly placed and close it.

ENGLISH - 14

5.2 HOW TO USE THE PROGRAMS

“Beep” switching off

In case the buzzer is enabled, a short pressure of the pushbutton corresponding to the

cycle in progress, allows switching the buzzer off until it is enabled again.

“SKIP” function

During the pause times set up in cycles, normally indicated by the display blinking, to reset

the time of current “STEP”, keep the pushbutton corresponding to the cycle in progress

pressed for at least 5 seconds.

TIME SET display

Press the pushbutton corresponding to the cycle in progress to display the time set of the

“STEP” in progress.

The pushbutton shall be released after 5” otherwise the “SKIP” function of pause time

reset automatically intervenes.

Energy-saving mode

A minute after one of the pushbutton has been pressed, the display brightness is reduced

to lower the electronic card. The correct brightness degree is restored as soon as a

pushbutton is pressed.

5.2.1 CH03-CH04 OPERATION

Before preparing the mixture, it is advisable to accurately wash and sanitize the machine.

Pour some liquid (milk or water) into the tank covering the mixer disk wheel for at least 10

cm.

Press the MIXING pushbutton.

Add the solid components such as sugar, eggs, flavours and powdered ingredients and

avoid introducing solid fats which shall be add warm.

Add the remaining liquid raw materials to complete the recipe, then press STOP.

Select the desired working cycle among the available ones:

HIGH PASTEURIZATION AT 85°C (185°F)

It is suitable for mixtures with ingredients (fats, chocolate, etc.) requiring high temperatures

for a complete melting.

Pour some liquid (milk or water) into the tank and press the MIXING pushbutton, then add

the solid components: sugar, flavours, eggs, powdered ingredients, etc...

Add the remaining liquid to complete the recipe, fats excluded. Then press pushbutton

HIGH PASTEURIZATION. The heating cycle starts up until a temperature of 85°C (185°F)

is reached.

Once a temperature of 85°C (185°F) has been reached, the cooling cycle begins to cool

the mixture down to 4°C (39°F). The mixture preservation cycle begins at 4°C (39°F), with

the automatic intervention of the mixer, every 4 minutes, for about 15” and, in case of

necessity of the compressor.

15 - ENGLISH

In case during pasteurization, a voltage failure occurs, the machine restarts the cycle from

the beginning.

LOW PASTEURIZATION AT 65°C (149°F)

It is suitable for mixtures whose characteristics can be altered at higher temperatures.

Follow the same procedure as for high pasteurization. Then press the pushbutton LOW

PASTEURIZATION. The low pasteurization cycle begins until a temperature of 65°C

(149°F) is reached.

The mixture shall be kept at 65°C (149°F) for 30 minutes. the cooling cycle begins to

cool the mixture down to 4°C (39°F).

SEMI-AUTOMATIC CYCLE OF PASTEURIZATION

It allows selecting the heating temperature suitable to special mixtures (the corresponding

pause time is automatically selected).

See SEMI-AUTOMATIC pushbutton operation.

SEMI-AUTOMATIC CYCLE FOR OTHER TREATMENTS

Composing both the temperature values and the pause times it is possible to meet all

requests (zabaglione, invert sugar, etc...).

Independently from the selected cycle:

- the mixture is delivered through the cock, whose grip shall be counter-clockwise turned to

open and clockwise turned to close it;

- after the mixture has been delivered and the cock well closed, it is sufficient to press the

water-cock pushbutton to wash the cock and remove mixture residues.

ENGLISH - 16

5.2.2 CH05 OPERATION

The machine is equipped with two

microprocessor and two pushbutton panels, one

for each tank. Working with a single tank, CH05

operation is the same as CH04.

Working with two tanks, it is necessary to

proceed as follows:

1. prepare the mixture in tank A, then press the

selected pasteurization cycle (or the SEMIAUTOMATIC cycle), to start up the AUTOMATIC

cycle;

2. prepare the mixture in B, then press the

desired pasteurization pushbutton on the

pushbutton panel located on this tank (or the

SEMI-AUTOMATIC cycle), which intermittently

lights up to show that tank B is in STAND-BY.

3. when tank A has reached the programmed temperature and started up the cooling

phase, the selected pasteurization cycle led in tank B will light up and remain fixed,

to show the beginning of the heating cycle for tank B, while tank A continues

cooling.

4. when tank A has completed the pasteurization cycle (or AUTOMATIC cycle), the

compressor and the mixer in tank B keep on working until the selected cycle for this

tank is completed.

17 - ENGLISH

6. MAINTENANCE

6.1 ROUTINE MAINTENANCE (ADDRESSED TO THE USER)

During production, cleaning and maintenance operations, never touch the machine with

hands or tools without making sure that the machine has been disconnected from mains.

In case of troubles, make sure that they are not caused by a lack of servicing. On the

contrary, ask for the intervention of a TAYLOR customer service. In case it is necessary to

replace a piece, always ask a distributor or an authorized retailer for ORIGINAL spare

parts.

It is advisable to make the machine be checked by a Customer Service every 6/8 months.

6.1.1 CLEANING AND SANITIZATION

Bacteria and moulds easily proliferate due to the presence of fats in cream, that is why it is

necessary to carefully wash and clean all parts in contact with the product, such as tank,

tank cover, mixer and cock.

Rustless materials and/or made of plastic for food industry used for our machines, in

conformity with the most severe international standards, make washing operations easier,

however they cannot prevent mould proliferation, etc. caused by insufficient cleaning.

TAYLOR recommends to clean the tank and the parts in contact with the product after the

employment and in any case in compliance with the sanitary standards in force in the

country of installation.

It is advisable to periodically remove the O-rings by means of a drawer and thoroughly

wash them.

To clean your CH correctly, proceed as follows:

1. To wash the tank, fill it with a suitable quantity of

water, without removing the mixer and with the

machine in STOP position. To this purpose, make

use of a flexible shower started up by the watertank pushbutton for a programmed time of 2

minutes and 30”. To stop the programmed flow,

press the pushbutton a second time. Add a nonaggressive and non-corrosive cleanser.

2. Close the tank cover and press pushbutton 9

MIXING to start up the mixer motor.

3. At washing completion, press pushbutton 10

STOP to stop mixing, completely run off the tank

and in case of necessity repeat the cycle. Lift the

cover, take the mixer out and accurately clean the

tank with a wet cloth.

ENGLISH - 18

4. To clean the cock proceed as follows:

- Unscrew the cock ring nut (Pos. A)

- Take the spring from the cock body (pos. B) off,

then counterclockwise rotate the knob until the

entire stopper is drawn out from body C

- Thoroughly wash and reassemble.

5. Take the hinge pin off to remove the cover and

wash it.

6. Thoroughly clean the mixer.

7. Spray sanitising liquid into the tap hole in the

cleaning water inlet hole, using the squeeze bottle.

8. Reassemble the cock, the mixer and the tank, add

a sanitizer and warm up at the temperature

indicated by the sanitizer’s manufacturer as long

as it is necessary.

9. Run off the sanitizing water and rinse.

- To preserve plastic components and gaskets,

never use solvents and/or diluents during washing.

- Sanitizing chemicals shall be used according to

laws in force and with the utmost caution.

- After any sanitizing operation, it is indispensable

not to touch the sterilized parts either with hands

or with towels, sponges or other.

- Avoid making the mixer run empty, as the machine

can be damaged. Even during washing operations,

never make the mixer run for more than two

minutes.

- After cleaning, it is indispensable to lubricate all

rubber gaskets with glycerin for food industry and

replace them with the ones provided as standard.

19 - ENGLISH

6.2 EXTRAORDINARY MAINTENANCE (ADDRESSED TO QUALIFIED PERSONNEL)

6.2.1 REFRIGERATION PLANT

In case of machine with water-cooled condenser it is necessary to run off the water

present in the condenser if temperature is expected to fall beneath 0° C (32°F). Disconnect

the water inlet pipes after the delivery of water has been interrupted by means of the cutoff cock. Remove the right side panel to reach the condensing water drain plug and open it

until water is completely run off. Screw the plug again and replace the panel.

6.2.2 ELECTRIC SYSTEM

The functional wiring diagram

and the electric box lay-out,

different for each model are

located on the box cover.

OMG electronic card

ENGLISH - 20

7. TROUBLE-SHOOTING

7.1 ALARM MANAGEMENT

MESSAGE DESCRIPTION REMEDIES

EME

EMERGENCY

L-F

FLUID LEVEL

ALARM

P-F

FLUIDE PRESSURE

SWITCH ALARM

TER

MOTOR

OVERLOAD RELAY

ALARM

EPO

STORED DATA

ALARM

EPI

MEMORY ALARM

LI

POWER SUPPLY

ALARM

OUT

OUTPUT MODULE

ALARM

The cover is open or a protection device stopping

mixing is active.

The buzzer releases a beep every 10”

Followed by led FLU (fluid alarm) blinking and by a

beep from the buzzer every 10” if the glycol level is

low.

Followed by led FLU (fluid alarm) lighted up and by

a beep from the buzzer every 10” if the glycol

pressure is low. It can be caused by the opening of

glycol pressure switch.

Followed by led TER blinking and a beep from the

buzzer every 10” in case a motor overload relay has

tripped, or the thermostat has intervened due to

glycol temperature over 110°C (230°F).

At each machine start-up, the microprocessor

checks the data in EPROM memory. If they are not

correct, the display visualizes the writing EPO

followed by a beep from the buzzer every 10”.

If memory is not recognized, during operation the

display visualized the writing EPI followed by a beep

from the buzzer every 10”.

If during operation voltage is too low, the display

visualizes the writing LI followed by a beep from the

buzzer every 10”.

If during operation the output control module breaks

down or it is not recognized, the display visualizes

the writing OUT followed by a beep from the buzzer

every 10”.

Make sure that the cover

is closed and correctly

positioned.

Check pump operation

and the level of glycol

inside the tank. Then

press STOP.

Check pump operation

and level of glycol inside

the tank. Then press

STOP.

After a check on the

machine, press STOP to

restore the correct

operation.

Send for a technician

Send for a technician

Check mains voltage and

machine power supply

Send for a technician

Temperature probe alarm

Unlike the above-mentioned messages, the temperature probe alarm is a message

composed as follows:

P=PROBE 1= TANK 2=FLUID O=OPEN (open) C=CLOSED (short-circ.)

For example, if the display visualizes message P10 followed by led TEM (temperature

alarm) blinking and by a beep from the buzzer every 10”, it means that the tank probe is

broken down. In this case send for a technician.

21 - ENGLISH

7.2 TROUBLESHOOTING

TROUBLE POSSIBLE CAUSES REMEDIES

The machine does not start

(STOP pushbutton ON without

active alarms)

Electric trouble Send for a technician

The machine does non start

(STOP pushbutton OFF)

While cooling a layer of ice form

on the tank walls.

The mixing disc disengages itself

during the operation

While cooling the machine works

intermittent

Master switch OFF Close the switch

Blown fuses Check and replace them

Insufficient quantity of product

Insufficient mixing inside the tank

The mixing disc has been

assembled in the opposite

direction

Wrong sense of rotation of the

mixing shaft (counterclockwise).

Lack of consending water

Work with at least 1/3 of the

max. quantity of mixture suitable

for each CH model

CH04-CH05: Require the

double-finned mixing disc

(optional)

CH03: Remove the mixing disc

central part.

Correctly install the mixing disc

Remove voltage and reverse the

two phase wires of the feeder

between themselves.

Check the presence of water in

the water system to which the

machine is connected. Check

cocks.

Mixing inside the tank is very

noisy.

The machine does not wait the

end of the pasteurizing cycle and

begins all over again.

Insufficient lubrication of bronze

bushings

Worn-out bronze bushings Send for a technician

Electric black-out

Assess the causes of the electric

Lubricate.

black-out.

ENGLISH - 22

Loading...

Loading...