Page 1

TW-357 REV E

LABS

(Laboratory Archival Biological Storage)

CRYOSTORAGE SYSTEM

OPERATING AND MAINTENANCE INSTRUCTION

REVIEW AND UNDERSTAND ALL SAFETY PROCEDURES IN FORM # TW-10 P/N 7950-8052

BEFORE ATTEMPTING TO INSTALL, OPERATE OR PERFORM MAINTENANCE ON THIS

CRYOSTORAGE SYSTEM.

DO NOT ATTEMPT TO USE OR MAINTAIN THIS UNIT UNTIL YOU READ AND UNDERSTAND

THESE INSTRUCTIONS. DO NOT PERMIT UNTRAINED PERSONS TO USE OR

MAINTAIN THIS UNIT. IF YOU DO NOT FULLY UNDERSTAND THESE INSTRUCTIONS,

CONTACT YOUR SUPPLIER FOR FURTHER INFORMATION.

1

Page 2

TW-357 REV E

2

Page 3

TW-357 REV E

Table of Contents

WARNING 4

Safety Precautions for Liquid Nitrogen 4

GENERAL INFORMATION 6

Text Format Notation 6

LABS Cryostorage Specifications 7

INSTALLATION 9

Unpacking and Inspection 9

Liquid Nitrogen Supply Connection 9

Power Supply Connection 10

KRYOS Control Field Installation 10

OPERATION 11

Initial Fill 11

Control Components 12

Operating Parameters 14

Adding an Inventory Control System 15

Control Operation 20

Control On Battery Backup Version 31

Solenoid Valve 31

INTERFACE SOFTWARE 32

MAINTENANCE 33

Strainer Cleaning Instructions 33

Defrosting Your LAB-Series CryoStorage System 33

Cleaning Your Taylor-Wharton CryoStorage System 34

Making Adjustments to the LABS KRYOS Sensor Assembly 35

Removing/Installing the Solenoid Valve 37

Sensor Plug Schematic 38

LABS Plumbing Assembly 39

TROUBLESHOOTING 40

Symptoms 40

Factory Settings 44

Replacement Parts 45

3

Page 4

TW-357 REV E

WARNING

The following safety precautions are for your protection. Before installing, operating, or maintaining this unit

read and follow all safety precautions in this section and in reference publications. Failure to observe all

safety precautions can result in property damage, personal injury, or possibly death.

Safety Precautions for Liquid Nitrogen

Nitrogen is an inert, colorless, odorless, and tasteless gas making up four-fifths of the air you breathe. Liquid

nitrogen is obtained by cooling air until it becomes a liquid and then removing the oxygen. Air is roughly

one-fifth oxygen. Liquid nitrogen is at a temperature of -320°F (-196°C) under normal atmospheric pressure.

Extreme Cold - Cover Eyes and Exposed Skin

Accidental contact of liquid nitrogen or cold issuing gas with the skin or eyes may cause a freezing injury

similar to frostbite. Handle the liquid so that it won't splash or spill. Protect your eyes and cover the skin

where the possibility of contact with the liquid, cold pipes and cold equipment, or cold gas exists. Safety

goggles or a face shield should be worn when operating this equipment. Insulated gloves that can be easily

removed and long sleeves are recommended for arm protection. Trousers without cuffs should be worn

outside boots or over the shoes to shed spilled liquid.

Keep Equipment Area Well Ventilated

Although nitrogen is non-toxic and non-flammable, it can cause asphyxiation in a confined area without

adequate ventilation. Any atmosphere not containing enough oxygen for breathing can cause dizziness,

unconsciousness, or even death. Nitrogen, a colorless, odorless, and tasteless gas, cannot be detected by the

human senses and will be inhaled normally as if it were air. Without adequate ventilation, the expanding

nitrogen will displace the normal air resulting in a non-life-supporting atmosphere.

Liquid Nitrogen System

The liquid nitrogen supply pressure at the inlet to the refrigerator should be in the range of 10 psig (0.7bar/69

kPa) to 20 psig (1l4bar/138 kPa) for optimum performance. Higher operating pressures will increase transfer

losses and create excessive turbulence of the liquid in the refrigerator which can generate false signals to the

liquid level controller causing the refrigerator to under-fill. In “liquid phase” storage applications, excessive

turbulence can cause splashing which could result in personal injury and/or damage to the refrigerator. When

installing piping or fill hose assemblies, make certain a suitable safety relief valve is installed in each section

of plumbing between shut-off valves. Trapped liquefied gas will expand greatly as it warms and may burst

hoses or piping causing damage or personal injury. A relief valve is installed in the refrigerator plumbing to

protect the line between the customer supplied shut-off valve and the refrigerator solenoid valve.

CAUTION: When installing field fabricated piping, make certain a suitable safety valve is installed

in each section of piping between shut-off valves.

For more detailed information concerning safety precautions and safe practices to be observed when handling

cryogenic liquids consult CGA pamphlet P-12 "Handling Cryogenic Liquids" available from the Compressed

Gas Association, 1235 Jefferson Davis Highway, Arlington, VA 22202.

Warning: Inlet pressure should not exceed 22 psig (1.5bar/152 kPa). Higher pressures could result in

damage to equipment.

4

Page 5

TW-357 REV E

Dispose of Waste Liquid Nitrogen Safely

Dispose of waste liquid nitrogen out-of-doors where its cold temperature cannot damage floors or driveways

and where it will evaporate rapidly. An outdoor pit filled with clean sand or gravel will evaporate liquid

nitrogen safely and quickly.

Electrical

Electrical Shock Can Kill – the liquid level controllers used with these refrigerators operate from 16.5VAC.

However, the external transformer does have an 110/220VAC primary.

Do not attempt any service on these

units without disconnecting the electrical power cord.

Note: Units are supplied with Taylor-Wharton approved controllers. If other liquid level controllers

are used, please contact Taylor-Wharton before putting the refrigerator into service.

Freight Damage Precautions

Any Freight damage claims are your responsibility. Cryostorage systems are delivered to your carrier from

Taylor-Wharton’s dock in new condition. When you receive our product you may expect it to be in that same

condition. For your own protection, take time to visually inspect each shipment in the presence of the carrier’s

agent before you accept delivery. If any damage is observed, make an appropriate notation on the freight bill.

Then, ask the driver to sign the notation before you receive the equipment. You should decline to accept

containers that show damage, which might affect serviceability.

5

Page 6

TW-357 REV E

GENERAL INFORMATION

Thank you for purchasing this product. This state of the art CRYOSTORAGE SYSTEM can control either the

liquid level and/or the vapor temperature range. The features are designed to provide a safe environment for

samples while at the same time tracking all relevant information associated with the freezer. This control

provides a complete historical record of the environment in your freezer and therefore, the environment in

which your samples have been stored.

Text Format Notation

In this owner’s manual we use some special text formats to denote certain portions of the system. These are

listed below:

• Menu is indicated in ALL CAPS BOLD.

• Actual Menu Choices are indicated in ALL CAPS.

• Start Fill and Stop Fill sensor are indicated in ALL CAPS ITALICS.

• Specific Menu Descriptions under a main category are listed in Italics.

.

Taylor-Wharton LABS CryoStorage Systems are designed for applications where extremely low temperature

storage of biological products is required. They are also appropriate for industrial or other applications where

liquid nitrogen temperatures and high capacity are needed.

The LABS style refrigerator covered by this publication is designed for, but not limited to, the laboratory

environment. Each model is supplied with casters to enable limited mobility for cleaning and positioning

purposes.

The standard model is also equipped with the KRYOS electronic liquid level controller that will monitor and

control the supply of liquid nitrogen to the unit. The controller features a vacuum fluorescent display. The

addition of a liquid nitrogen supply and inventory control racks for systematic retrieval of stored product

completes the total cryostorage system.

6

Page 7

TW-357 REV E

LABS Cryostorage Specifications

Liquid nitrogen at atmospheric pressure weighs 1.78 lb./liter (0.8 kg/liter). All Taylor-Wharton Gas

Equipment cryostorage systems are designed to support the full weight of liquid nitrogen and a complete

stainless steel or aluminum inventory control system with boxes and specimens.

Dimensions 80K 40K 20K

External Operating Height in 42.5 42.5 42.5

(Top of Step to Lid opening) mm 1080 1080 1080

Step Height in 11 11 11

mm 279 279 279

Overall Height in. 60 60 60

(Top of Control Interface) mm 1524 1524 1524

Usable Height, Internal in. 30.0 30.0 30.0

mm 762.0 762.0 762.0

Outside Diameter in 59.5 45.0 34.0

mm 1511 1143 863.6

Internal Working Diameter in 55.0 40.5 29.5

mm 1397 1029 750

Neck Opening in 24.5 18.0 13.0

mm 622 457 330

Capacity

LN2 Capacity L 1350 606 407

Power Supply

Evaporation Rate1 L/day 15.0 9.0 8

Weight, Empty lb 1550 920 650

kg 703 417 295

Maximum Gross Weight2 lb. 3956 2000 1375

kg 1794 907 624

Inventory Control System Specifications

No 5.0 x 5.0 Racks

No. Shelves/Rack 13 13 13

No. 3.0 x 3.0 Racks

No. Shelves/Rack 13 13 13

Vial Capacity, 2 ml

Blood Bag (Fenwall 4R9951) 2100 1204 560

Blood Bag (Fenwall 4R9953) 1505 820 400

Blood Bag (Fenwall 4R9955) 1050 590 290

Footnotes:

0

This is the power supply for the standard battery backup version. The Kryos version (No Battery) uses a 24 VAC power supply.

For power outlets other than North American 110 VAC contact Taylor-Wharton Customer Service.

1

Evaporation rate is nominal. Actual rate may be affected by the nature of the contents, atmospheric

conditions, container history, and manufacturing tolerances.

2

Includes the empty weight and total LN2 capacity weight.

3

5.0 in. x 5.0 in. (127 mm x 127 mm) 100 cell box.

4

3.0 in. x 3.0 in. (76 mm x 76 mm) 25 cell box.

5

2 ml vial size; 12.5 mm O.D. internal thread.

0

VAC 16.5 16.5 16.5

3

58 30 14

4

12 8 4

5

79300 41600 19500

7

Page 8

TW-357 REV E

KRYOS Specifications

Configurations: Designed exclusively for all Taylor-Wharton LABS CryoStorage

Systems

Power Supply: 16.5 VAC, 40 Voltamps – Standard Battery Backup Version

24 VAC, 40 Voltamps (No Battery)

(For power outlets other than North American 110 VAC contact

Taylor-Wharton Customer Service.)

Sensor Assembly: Freeze-Guard Assembly – Standard

8-Thermistor Assembly– Optional

4-Thermistor Assembly – Optional

Thermocouples: Operates with none, 1 or 2 Type T

Thermocouples (1 piece standard)

Solenoid Valve: 12 VDC cryogenic solenoid valve – Standard

Control Type: Liquid Level Control or Liquid Level Control with Temperature

Control

Security: User Access via 2-digit password

Power On/Off Password

Menu access Password

Alarms: Audible

Visual red LED

Alarm description

Remote alarm relay

Diagnostics: Circuit diagnostics at start-up

Sensor diagnostics from front panel

Thermocouple diagnostics from front panel

Manual Test for audible, visual and remote alarms

Temp. Calibration: Automated calibration from the front panel

Communications: RS-232 Serial Port for 2-way communications capable

Logging Capacity: System Logs (4096 events)

Alarm Logs (4096 events)

Temperature Logs (32,768 events)

Battery: A CR2032 coin cell battery is used to back up time/date

8

Page 9

TW-357 REV E

INSTALLATION

Unpacking and Inspection

Inspect shipping containers for external damage. All claims for damage (apparent or concealed) or partial loss

of shipment must be made in writing within five (5) days from receipt of goods. If damage or loss is apparent,

please notify the shipping agent immediately.

Open the shipping containers; a packing list is included with the system to simplify checking that all

components, cables, accessories, and manuals were received. Please use the packing list to check off each item

as the system is unpacked. Inspect for damage. Be sure to inventory all components supplied before discarding

any shipping materials. If there is damage to the system during transit, be sure to file proper claims promptly

with the carrier and insurance company. Please advise Taylor-Wharton of such filings. In case of parts or

accessory shortages, advise Taylor-Wharton immediately. Taylor-Wharton cannot be responsible for any

missing parts unless notified within 60 days of shipment.

Repackaging for Shipment

If it is necessary to return any part of the system for repair or replacement, a Material Return Authorization

(MRA) number must be obtained from an authorized factory representative before returning the instrument to

our service department. Contact your distributor for return authorization. When returning an instrument for

service, the following information must be provided before obtaining an MRA:

A. System model and serial number, and controller serial number

B. User’s name, company, address, and phone number

C. Malfunction symptoms

D. Description of System

If possible, the original packing material should be retained for reshipment. If not available, consult TaylorWharton for shipping and packing instructions. It is the responsibility of the shipper to assure that the goods

are adequately packaged for return to the factory.

Liquid Nitrogen Supply Connection

The package included with the refrigerator includes a strainer. The liquid fill hose from a low pressure source

of liquid nitrogen must be connected to the inlet through this fitting. This liquid nitrogen source must have a

shut-off valve, and may be any portable liquid cylinder or a bulk supply. The liquid nitrogen supply pressure

at the inlet to the refrigerator should be in the range of 10 psig (0.7 bar/69 kPa) to 20 psig (1.4 bar/38 kPa) for

optimum performance. Higher operating pressures will increase transfer losses and create excessive turbulence

of the liquid in the refrigerator which can generate false signals to the liquid level controller causing the

refrigerator to under-fill. In “liquid phase” storage applications, excessive turbulence can cause splashing

which could result in personal injury and/or damage to the refrigerator. If the liquid nitrogen supply pressure

at the inlet to the refrigerator rises above the opening pressure of the relief valve on the refrigerator, liquid

nitrogen will be discharged into the surrounding area which can cause a rapid and very dangerous depletion of

oxygen in the atmosphere. Once this pressure relief device has opened and cooled to liquid nitrogen

temperature, it will not reseat until it has warmed to near ambient temperature.

ENTIRE CONTENTS OF THE LIQUID NITROGEN SUPPLY SYSTEM TO BE DISCHARGED INTO

THE IMMEDIATE AREA OF THE REFRIGERATOR(S) .

WARNING: In order to prevent the relief device on the nitrogen refrigerator(s) from opening when the

system is in operation, the liquid nitrogen supply system must be protected by a pressure relief device

that will open when the pressure at the inlet to the refrigerator(s) is approximately 22 psig (1.5 bar/152

kPa). Never install the supply system pressure relief device onto a liquid service line.

THIS COULD PERMIT THE

9

Page 10

TW-357 REV E

Power Supply Connection

Connect the 16.5 Volt AC power supply to the control of the LABS cryostorage system; then plug the power

supply into a surge protected 110/120 VAC outlet.

KRYOS Control Field Installation

1. Unplug power from old unit.

2. Close liquid nitrogen supply at valve.

3. Remove 4 Phillips head screws from rear of interface display box.

4. Remove controller face from interface display box.

5. Finish face removal by disconnecting plug and ground wire.

6. Remove 2 Phillips head screws from the old control located underneath the tabletop.

7. Withdraw old controller from underneath table top, noting how the controller body has been

resting on outer upper head.

8. Unplug all connectors and wires and set panel aside.

9. Disconnect supply hose from solenoid valve.

10. Remove old solenoid.

11. Remove spiral wire wrap.

12. Mark old sensor locations with electrical tape

13. Measure and make note of the “Start Fill”, “Stop Fill” and temperature sensors from the bottom

of the appropriate sensor tube. You will need this information to set up the new controller.

14. Remove old sensor wires.

15. Calibrate new KRYOS control to new temperature sensor.

16. Reverse procedure to install KRYOS control.

10

Page 11

TW-357 REV E

OPERATION

These instructions are for operators experienced with cryogenic equipment. Before operating the system,

become familiar with the safety precautions in this manual and in reference publications. Make certain all

applicable provisions set forth in the Installation Section have been followed before placing a system in

operation. Study this manual thoroughly. Know the location and function of all system components.

Initial Fill

The LABS cryostorage system using the KRYOS controller, comes preset from the factory. The liquid

nitrogen supply pressure at the inlet to the refrigerator should be in the range of 10 psig (0.7 bar/69 kPa) to 20

psig (1.4 bar/138 kPa) for optimum performance. Higher operating pressures will increase transfer losses and

create excessive turbulence of the liquid in the refrigerator which can generate false signals to the liquid level

controller causing the refrigerator to under fill. In “liquid phase” storage applications, excessive turbulence

can cause splashing which could result in personal injury.

WARNING: Maintain adequate ventilation to prevent asphyxiation hazard (see Safety Precautions).

WARNING: If the fill fails to stop for any reason, quickly close the liquid supply valve to prevent

overfilling until the cause of the problem can be determined.

11

Page 12

TW-357 REV E

Control Components

Interface Panel

The KRYOS Interface panel, which the user will interact with, contains the vacuum fluorescent display as

well as the number keypad, power button, help button and the soft-key control buttons. (See figure 1.0 below.)

Figure 1.0 KRYOS Interface Panel

Main Control

The “brain” for the control system “talks” to the interface unit and makes all decisions regarding liquid levels,

temperatures, valve opening/closing, etc. It is located away from the Interface Panel on the upper outer head.

(See figure 2.0 below.)

Main Control

Figure 2.0 KRYOS Main Control

Sensor Assembly

A standard 7+1 thermistor assembly, includes the Freeze-Guard over-fill sensor. Optional 4-thermistor, or 8thermistor sensor assemblies can be ordered. The 4-thermistor assembly maintains the liquid level between 2

middle sensors. The 8-thermistor assembly maintains the liquid level between the high sensor and the low

sensor assigned by the user. The standard 7-thermistor assembly is similar to an 8 sensor assembly in that the

user can select the START FILL and STOP FILL positions. The eighth position on this assembly is tied into

an inline plumbing thermistor, which detects if the solenoid valve fails to close.

12

Page 13

TW-357 REV E

Lid Switch

Is attached to the hinge and determines whether or not the lid is open on the freezer. This also allows the

control to determine whether to activate the Quickchill, Auto Defog or Lid Alarm features.

Lid Switch

Figure 3.0 Lid Switch

Solenoid Valve

Designed to work with 12 VDC solenoid valves manufactured by Valcor, Parker-Hannifin, ASCO or Alcon.

(See plumbing assembly Figure 10.0 on page 37 of this manual.)

Thermocouples

Type T thermocouples determine the temperature in the freezer. The user may choose to use NONE, 1 or 2

thermocouples with this control at any time. (The unit comes complete with one Thermocouple)

Wall Transformer

A 16.5 VAC, 40 VA wall transformer is a standard option on the LABS cryostorage system with battery

backup. A 24 VAC, 40 VA wall transformer is supplied for the Kryos version (No Battery). The system is

supplied with a transformer compatible with common household (North American) 110VAC. (For other

power outlets contact Taylor-Wharton Customer Service.) These wall transformers have UL approval. UL

approval for the system as a whole is not required since the control operates on low voltage. If your power

source differs, or is subject to disruption or line surges due to other equipment on line, consult your TaylorWharton representative.

Battery Backup

The LABS cryostorage system with the battery backup option has a 12VDC battery installed underneath the

unit's tabletop.

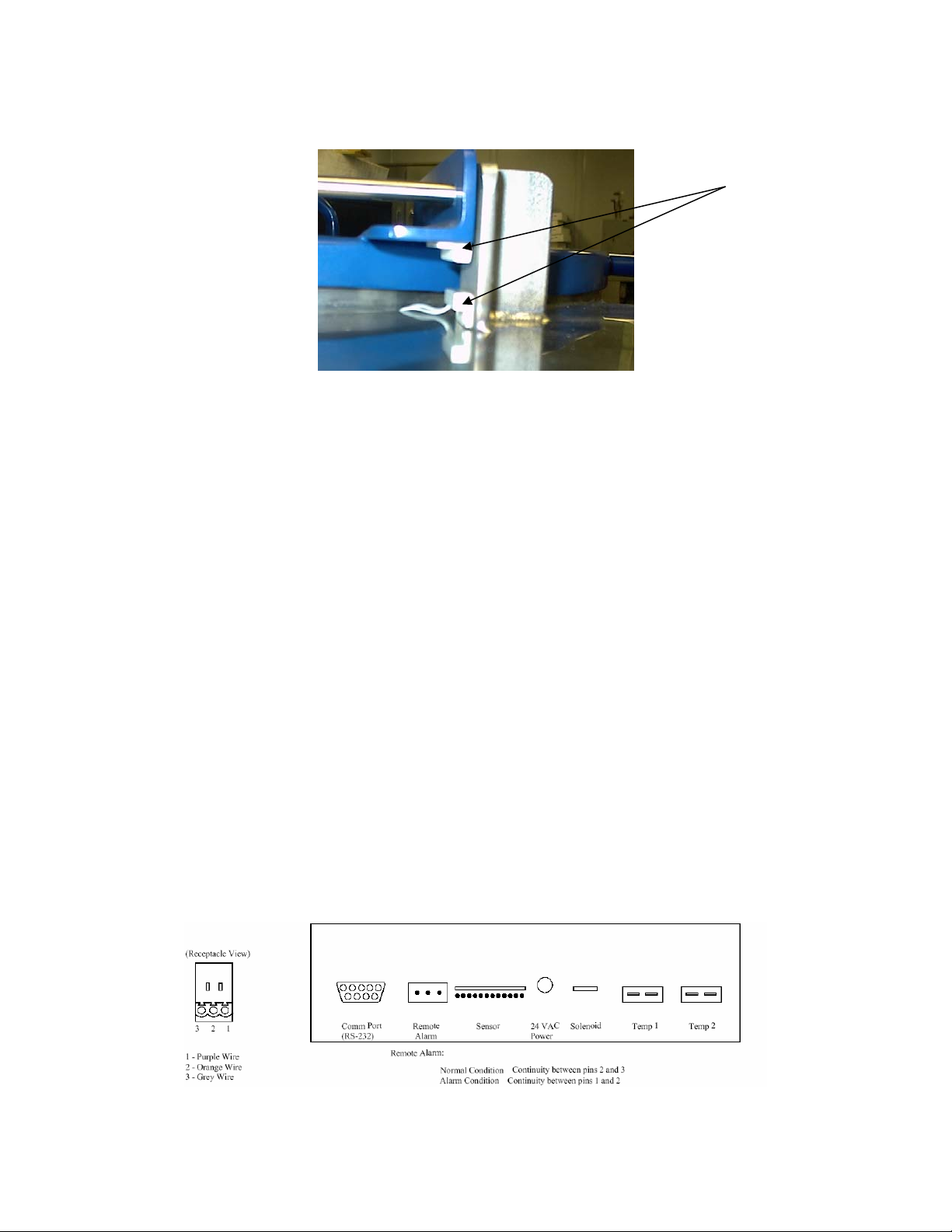

Remote Alarm

If an error condition occurs after a user defined period of time a remote alarm circuit can be initiated. This is

accomplished by connecting a remote device to the remote alarm jack on the rear electrical panel. The 3-pin

jack on the back of the unit provides continuity between pin #2 (common) and pin #3 in the normal condition.

Continuity between pin #1 and pin #2 is provided in an error condition. (See Figure 4.0 below.)

Figure 4.0 Remote Alarm Plug Connection

13

Page 14

TW-357 REV E

Operating Parameters

When materials are immersed in liquid nitrogen, they will assume the temperature of the liquid -196ºC (320ºF). When material is stored in the vapor phase over the liquid, the liquid nitrogen is still a very cold

refrigerant, but the refrigerator’s interior temperature increases somewhat as product is stored higher over the

liquid. This temperature differential is not significant in many biological storage applications, and is affected

by the amount of product stored in the refrigerator, the type and size of inventory control system, and the

liquid level in the unit.

The liquid level in the refrigerator is determined by the position of the sensor probes in the tube located to the

right of the refrigerator. These probes are set at installation to maintain a specific liquid level. The controller

operates a fill cycle that adds liquid at a low level, fills to a predetermined high level, then stops the fill. The

cycle repeats when the liquid level drops to the low level sensor over time. Sensor probe assignments may be

changed on the controller keypad to define new high and low levels, and these levels may be set

independently to vary the liquid level differential between fills. Prior to the initial fill of the refrigerator, a

determination should be made whether vapor phase or liquid phase storage will be utilized.

The sensor probe contains seven thermistors that can be preprogrammed for any liquid level application. The

separate sensor in the sensor tube is the temperature thermocouple. The thermocouple is normally positioned

at the top of the storage rack. The factory sensor positions will maintain a liquid level within a distance of 2 in.

(50.8 mm) from the bottom of the operating tray.

Liquid Phase Storage

Liquid phase storage is normally utilized when liquid nitrogen temperatures are required to maintain stored

product viability and the storage medium is adequate for storage in liquid nitrogen.

In a typical liquid phase storage system, the liquid level sensors are positioned to maintain the liquid level at

or below the top level of the inventory control system. During operation, the upper levels of the inventory

control system will at times become exposed as the liquid level fluctuates.

Care must be taken to ensure that the liquid level remains below the bottom of the refrigerator lid. Exposure to

liquid nitrogen may result in physical damage to the lid. Additionally, operating the refrigerator with high

liquid levels characteristic of liquid phase storage may result in turbulence during fill cycles. Caution must be

exercised if the refrigerator lid is opened during a fill, and appropriate safety equipment should always be

worn.

The LABS cryostorage system is set at the factory for vapor phase storage. To reconfigure the system's

settings for liquid phase, the following steps should be used.

1. Power up the unit.

2. Remove the “Start Fill”, “Stop Fill” (Thermistor) sensors.

3. Allow the unit to fill to your desired “Stop Fill” elevation.

4. Stop the fill by closing the supply line valve.

5. On the interface panel, push (MENU, 2, 1).

6. Insert the “Start Fill”, “Stop Fill” (Thermistor) sensors until the #6 sensor changes on the display

from G (gas) to L (liquid).

7. Return to the main (MENU).

8. Dress wires and seal with stopper.

14

Page 15

TW-357 REV E

Thermocouple Positioning

The thermocouple is a separate sensor used to monitor and control the temperature within the refrigerator. The

factory-supplied thermocouple in the LABS cryostorage system is positioned to monitor the temperature 30”

above the tray.

Adding an Inventory Control System

The purpose of the inventory control system is to bring order to the storage of many small samples, and to

allow direct retrieval of the particular sample you need at any time. It is important to be aware that when you

lift an ICS rack from the refrigerator it is in a warmer environment. Learn to locate your sample quickly to

avoid unnecessary warming of your stored product. Keep ICS inserts (drawers or boxes) and dividers in good

repair. Replacement inserts and dividers are available from your Taylor-Wharton distributor to keep your

system as efficient as possible.

Always wear gloves when handling ICS racks or stored product, as they are very cold – read the precautions

in the Safety section of these instructions, and in Taylor-Wharton publication TW-10 “Handle With Care”, for

more detail on handling product stored in liquid nitrogen.

When removing ICS racks to retrieve product, protect the labels, plastic, and electronic areas of the

refrigerator from liquid nitrogen that may spill from the rack inserts. These parts of the refrigerator are subject

to damage from the extreme low temperature of the refrigerant.

Do not let ice or debris collect in the bottom of the freezer. Schedule periodic clean out if racks no longer

stand upright.

15

Page 16

Inventory Control System Layouts (LABS Cryostorage System)

Typical 13-2 Rack

100 Vial Polycarbonate

100 Vial Aluminum Boxes

81 Vial Polycarbonate, Cardboard, or

Stainless Steel Boxes

NOTE:

RACKS ARE NOT SQUARE.

ORIENTATION IS IMPORTANT.

TW-357 REV E

LABS-20K

LABS-80K LABS-40K

2ml vial storage – ask about other Box types

Part

Number

Racks

13 x 2 x 100

R23K-8C35

Racks

13 x 2 x 25

R10K-9C44

BOXES-100

N-374187-92

(Case of 24

Polycarbonate)

BOXES-25

N-374180

(Case of 36

Polycarbonate)

VIAL

CAPACITY

Max. allowable

LABS-80K 58 12 754 156 79300

LABS-40K 30 8 390 104 41600

LABS-20K 14 4 182 52 19500

Figure 5.0 Vial Storage on Racks

16

Page 17

TW-357 REV E

Blood Bag Cassette

Blood Bag Storage in Cassette

LABS-20K

LABS-80K LABS-40K

Fenwal 4R9951 Blood Bags – ask about other Bag types

PART NUMBER CAPACITY FRAMES CASSETTES

LABS-80K 2100 300 2100

LABS-40K 1204 172 1204

LABS-20K 560 80 560

Figure 6.0 Fenwal 4R59951 Blood Bag Rack Arrangements

17

Page 18

TW-357 REV E

Blood Bag Cassette

Blood Bag Storage in Cassette

LABS-20K

LABS-80K LABS-40K

Fenwal 4R9953 Blood Bags – ask about other Bag types

PART NUMBER CAPACITY FRAMES CASSETTES

LABS-80K 1505 301 1505

LABS-40K 820 164 820

LABS-20K 400 80 400

Figure 7.0 Fenwal 4R59953 Blood Bag Rack Arrangements

18

Page 19

Blood Bag Cassette

Blood Bag Storage in Cassette

TW-357 REV E

LABS-20K

LABS-80K LABS-40K

Fenwal 4R5462 – 9955 Blood Bags – ask about other Bag types

PART NUMBER CAPACITY FRAMES CASSETTES

LABS-80K 1050 210 1050

LABS-40K 590 118 590

LABS-20K 290 58 290

Figure 8.0 Fenwal 4R5462 – 9955 Blood Bag Rack Arrangements

19

Page 20

TW-357 REV E

Control Operation

This section of the operating manual is for Taylor-Wharton approved equipment that uses the

KRYOS controller.

Introduction

The KRYOS temperature and LN2 level controller is designed for easy operation and uninterrupted,

reliable service. This controller will maintain the selected temperature and liquid level range of LN2

in your refrigerator as well as provide audible and visual alarms for any alarm conditions that may

occur. An “alarm” is any off-normal condition, such as a sensor short or open circuit, a temperature

outside of the limit set by the user, or any other condition that would cause the controller to enter the

ALARM mode. “Events” are lid openings and closings, solenoid valve openings and closing, and

operation of the controller’s relay for remote alarm indication. “Data” refers to periodic alarm and

event logging available at the “Data Output” connection.

The KRYOS controller should require no additional attention to control temperature and maintain

liquid level if an adequate supply source of liquid nitrogen is maintained. If your protocol calls for

you to “top-off” the cryostorage system at the end of a workday or workweek, press the FILL

button. The unit will fill to the upper allowable liquid level and stop automatically. You may choose

to manually stop the fill by pressing the STOP button at anytime during the fill.

Normal Fill Cycle

When the refrigerator is filled and the controller is operating, the LOW LEVEL and LOW ALARM

sensors are immersed in liquid nitrogen. Their resistance values are interpreted by the controller as

“in liquid”. At the same time, the FULL LEVEL and the HIGH ALARM sensors are above the

liquid pool, sending the controller an “above liquid” signal. As liquid nitrogen evaporates, the liquid

level in the refrigerator drops slowly until the LOW LEVEL sensor is above the liquid and sends a

different signal to the controller. After a delay sufficient to ensure the signal, the controller interprets

this condition as low liquid and opens the fill solenoid, admitting more liquid nitrogen from the

supply source.

The refrigerator will fill slowly. The fill continues until the STOP FILL sensor sends the controller a

signal that it is now in liquid. The controller will close the liquid supply solenoid to stop the fill. As

liquid evaporates, the display will indicate the liquid is at a normal level as the cycle begins again.

The KRYOS temperature and liquid level controller is designed to support a remote alarm.

Connections are provided on the back of the controller chassis.

Power

The control can be turned on and off by pressing the Power button followed by “42”, as instructed

on the display panel. The two-step shutdown is a precaution against accidental shutdown. Shutdown

can also be password protected to prevent users from turning the system on and off under the

security section of this manual.

20

Page 21

TW-357 REV E

Main Display Screen

The main display screen consists of 4 lines of information.

Line 1: Displays the current status of the control. It indicates if all systems are normal or if any errors have

been detected. Error messages disappear when the error is corrected.

Line 2: Displays the level sensing in the control. If the 7-thermistor or 8-thermistor assembly is being used, the

control will indicate actual liquid level in the freezer. If a 4-thermistor assembly is being used, the control will

indicate LOW if the liquid level is below sensor #2, NORMAL if the liquid level is between sensor #2 and

sensor #3, and HIGH if the liquid level is above sensor #3. In addition, LOW LEVEL ALARM is indicated

when the liquid level is below sensor #1 and HIGH LEVEL ALARM is indicated when liquid level is above

sensor #4.

Line 3: Displays the temperature indicated by thermocouple #1 and #2. If either thermocouple is disabled by

the user through the menu system, it is no longer displayed on the front panel. If both thermocouples are

disabled by the user, line 3 is blank.

Line 4: Used to annotate (or label) the soft-key buttons and to provide information about the valve and the lid

status. In the center of the line, a rotating “baton” provides a visual indication that the control is running and

functioning properly.

The Menu System

Pressing the Soft Key labeled MENU on the front right side of the control will access the menu system.

Choose a menu option by pressing the appropriate number of your menu choice. If more menu choices are

available than will fit on 1 screen (more than 4 choices in this menu section), the left-hand soft-key button will

give the “More” choice Pressing this button will give the user the additional menu choices. A shortcut is

available to get to the proper menu choice by pressing the appropriate number button. The menu choice need

not be visible on the screen to select it.

When the menu is accessed, all control functions cease until the control returns to the main status screen.

Therefore, if a fill is occurring and the menu is accessed, the solenoid valve will close until the menu system is

exited and the control is again displaying the main screen. If the menu system is accessed but not interacted

with for 3 minutes, it will automatically revert to the main screen and all functions will resume.

Please note that the menu system can vary slightly depending on the configuration of the control. Menu

choices will be included or excluded depending on the selected features in the control. This is illustrated in the

menu system when the 4-sensor or the 8-sensor probe assembly is being used. The START FILL and STOP

FILL sensor must be physically set when the 4-sensor probe is in use, so the START FILL level and STOP

FILL level menu items are not displayed. When the control is operated with the 8-sensor assembly, the user

can assign the START FILL and STOP FILL levels with the control key pad without physical intervention to

the sensors in the storage chamber unless you want to change from vapor phase storage to liquid phase

storage. (See Menu Table 1.0 on page 21 of this manual.)

21

Page 22

Table 1.0 Menu System

1. Temperature

1.1 Thermocouple Select

1.2 Calibrate Temperature

1.3 Test Temperature System

2. Level Sensing

2.1 Test Level Sensors

2.2 Set Sensor Offset

2.3 Sensor Positions

2.3.1 Start Set Point

2.3.2 Stop Set Point

2.4 Sensor Type

2.5 Inch/Metric

3. Alarms

3.1 High-Temp Alarm #1

3.2 High-Temp Alarm #2

3.3 System Alarms

3.3.1 LN2 Supply Alarm

3.3.2 Sensor Error Alarm

3.3.3 Remote Alarm Timer

3.3.4 Lid Open Too Long

3.3.5 Thermocouple Alarm

3.4 Test Alarms

3.4.1 Test Audible

3.4.2 Test Visual

3.4.3 Test Remote

4. Logging

4.1 Dump Logs

4.1.1 Dump System Logs

4.1.2 Dump Error Logs

4.1.3 Dump Temp Log #1

4.1.4 Dump Temp Log #2

4.2 Error Logs

4.2.1 Sensor Error Logging

4.2.2 Low Supply Logging

4.2.3 Remote Alarm Logging

4.2.4OpenThermocouple logging

4.2.5 High Temperature

Alarm Logging #1

4.2.6 High Temperature

Alarm Logging #2

4.3 System Logs

4.3.1 Fill Logging

4.3.2 Lid Action

Logging

4.3.3 User Access Logs

TW-357 REV E

4.4 Temperature Logs

4.4.1 Thermocouple #1 Log Rate

4.4.2 Thermocouple #2 Log Rate

4.5 Erase Logs

4.5.1 Erase System Logs

4.5.2 Erase Error Logs

4.5.3 Erase Temperature Log #1

4.5.4 Erase Temperature Log #2

5. Security

5.1 Power-On Password

5.2 Menu Password

6. User Options

6.1 RS-232 Settings

6.1.1 Disable RS-232

6.1.2 Set up RS-232

6.1.2.1Toggle

Handshaking

6.1.2.2 19200 Baud (Sets

the baud rate)

6.2 Control Options

6.2.1 Date & Time

6.2.2 Lid/Defog Settings

6.2.2.1 Defog Timer

6.2.2.2 Lid Switch Setup

6.2.2.3 Auto Defog

6.2.2.4 Quick-Chill

6.2.3 Control By Temperature

6.2.3.1Disable

Temperature

Control

6.2.3.2Temperature

Control settings

6.2.3.2.1Control

Temperature

6.2.3.2.2 Control

Range

6.2.4 Freeze-Guard Options

6.2.4.1 Valve Open

Duration

6.2.4.2 Frozen Valve

Sensor

6.2.4.3 Valve De-icing

6.3 Display Brightness

6.4 About this Control

22

Page 23

TW-357 REV E

Help Screens

The Help button provides help to the user at any point in the menu system. The help message is displayed and

the user is then prompted to press a button to return to the menu system.

Temperature

Thermocouple Select

The chamber temperature is monitored with 1 or 2 Type T thermocouples. The thermocouple is placed in the

chamber to monitor temperature level with the top rack. Factory installation includes one thermocouple inside

of the thermocouple tube at an elevation to match the height of standard racks. A second Type T thermocouple

may be added to monitor another location inside the chamber. Both thermocouples can be

activated/deactivated through the menu system. (MENU, 1, 1)

Calibrate Temperature

KRYOS provides easy calibration of the thermocouples. To calibrate, the user should enter the menu system

(MENU, 1,2). Remove the thermocouple from the thermocouple tube and dip thermocouple #1 into an ice

water bath. The fourth line of the control display will indicate “Wait” and will give a reading on the proximity

of the temperature to 0ºC. When the temperature reaches equilibrium the control will indicate “OK” and the

user can press the left soft-key button. Dry the thermocouple thoroughly. Next, the control will prompt you to

dip thermocouple #1 into LN2. Wait while the control reaches equilibrium at -196ºC (-320ºF). When it does,

the control will again indicate “OK” and the user can again press the left soft-key button. The control is now

calibrated. The thermocouple is now ready to be repositioned inside the thermocouple tube. Please note that

both thermocouples are calibrated by going through this process with Thermocouple #1.

Test Temperature System

The temperature circuitry can be checked at any time through the menu system (MENU, 1,3). This check will

tell if the thermocouples are working or if they are “open” (broken or unplugged). If a thermocouple is not

connected to the control it will check as “open.” If a thermocouple is “Disabled” through the menu system, it

will not show up on the check.

Level Sensing

The level sensing in the system is determined through the use of thermistor-based sensor assemblies.

Thermistors are thermal resistors whose resistances change as temperature changes. Their use in liquid level

control is a time-tested method to provide accurate results. The KRYOS uses a 7-, 8- or a 4-thermistor

assembly to measure liquid level in the freezer. The 4-sensor assembly provides general information about

liquid level (high, normal, and low alarm) while the 7- and 8-thermistor assemblies provide liquid level

readings accurate to within one inch. When the LN2 level drops below the START FILL sensor, the control

opens the solenoid valve to commence the fill process. This process continues until the LN2 level reaches the

STOP FILL sensor. When the control “senses” that the LN2 has reached the upper level, it flashes “Check” on

the display while the KRYOS insures that it has not received false signals and then allows the fill to stop. The

fill process can be halted at any time before it reaches the STOP FILL sensor by manually pressing the STOP

FILLING button.

Test Level Sensors

The sensor assembly can be tested through the menu system as well (MENU, 2, 1). The sensor diagnostics

indicates the sensor number and the status (whether in liquid or gas) of that sensor. If the control is set for an

eight-thermistor or Freeze-Guard sensor it will indicate 8 sensors in the diagnostics. Likewise, if it is set for a

four-sensor assembly, it will indicate 4 sensors. The status is indicated with either an “O” for open, a “G” for

gas or an “L”

for liquid. This is an easy means to tell if sensors are in or out of liquid or if a new sensor

assembly is needed (open sensors).

23

Page 24

TW-357 REV E

Sensor Type

The sensor type can be set through the menu system (MENU, 2, 4). The sensor type selection should match

the sensor type that is being used in the system. This is a 4-sensor, a 7-sensor (Freeze-Guard) or an 8-sensor

array. If the sensor assembly is unplugged and the main control is still on, the display will indicate that a

sensor error has occurred. In addition the level indicated would be 8” on an 8-sensor assembly, 7” on a FreezeGuard assembly or “High Alarm” on a 4-sensor assembly. This occurs because the control cannot differentiate

between a very high resistance (when a thermistor is in LN2 ) and an infinite resistance (when an open circuit

appears in the level sensing circuitry).

Alarms and Error Conditions

The KRYOS control tracks many different conditions in the freezer and therefore, has a full complement of

alarms associated with these different conditions. As alarms occur, they cause an audible beep as well as a

flashing red light. A remote alarm relay is also triggered following a user-designated period of time, after the

error condition occurs, if it is not corrected. In addition, the error condition is displayed on the top line until

the error condition is corrected. When an error does occur, the audible alarm may be muted by pressing the

designated button. The audible alarm will then be silent until activated by a new error condition. The red light

will continue to flash until all errors are corrected. The remote alarm will be activated if the power is

interrupted.

The High Temperature Alarm for Thermocouple #1 can be set through the menu system (MENU, 3, 1). This

alarm is activated if the temperature rises above the designated temperature. The alarm temperature can range

from 0ºC to -190ºC. It can also be disabled.

The High Temperature Alarm for Thermocouple #2 can be set through the menu system (MENU, 3, 2). This

alarm is activated if the temperature rises above the designated temperature. The alarm temperature can range

from 0ºC to -190ºC and it can also be disabled.

24

Page 25

TW-357 REV E

System Alarms

The Low LN2 Supply Alarm can be set through the menu system (MENU, 3, 3, 1). This alarm is activated if

the solenoid valve is not closed within a designated time period after a fill starts. The solenoid valve can be

closed either automatically (the LN2 level reaches the STOP FILL sensor) or manually (the stop fill button is

pressed) to stop the timer which activates this alarm. The possible choices for this alarm are None, 15, 30, 45,

60 minutes, 2 or 3 hours. This alarm does not correct itself until the fill is stopped (the solenoid closes).

The Sensor Error Alarm can be set through the menu system (MENU, 3, 3, 2). This alarm is activated if the

control detects a sensor error such as an open sensor. The possible choices are ENABLE or DISABLE. An

open sensor can be confirmed through the TEST LEVEL SENSORS option in the menu system (MENU, 2,1).

The Remote Alarm Timer can be set through the menu system (MENU, 3, 3, 3). This is the amount of time

allowed to pass before the remote alarm relay is triggered if an error condition is not corrected. The possible

choices are None, Immediate, 30 minutes, 60 minutes or 2 hours.

The Lid Open Too Long Alarm can be set through the menu system (MENU, 3, 3, 4). This is the amount of

time the lid can be open before it triggers an alarm condition. The possible choices are None, 1, 2, 5 or 10

minutes.

The Thermocouple Alarm can be set through the menu system (MENU, 3, 3, 5). This alarm is activated if

either thermocouple experiences an open circuit. The possible choices are ENABLE or DISABLE.

Test Alarms

The audible, visual and remote alarms can be tested at any time by the user through the menu system

(MENU, 3, 4). Follow the instructions on the display to hear the audible “chirping” indicator of an alarm or to

see the red LED flash or to trigger an immediate relay closure of the remote alarm.

Logging

The on board memory logging function is one of the most powerful and useful features of the KRYOS

control. It provides a historical record for not only your freezer but also a complete record of the environment

in which specimens were stored. Four separate logs are kept in the control:

1. Sy stem log – System logs are events that occur in the system such as lid opening/closing, LN2 filling

Quick-Chill, Defog, etc.

2. Error log - Error logs are off-normal conditions detected by the system.

3. Temperature #1 log and Temperature #2 log - The two temperature logs are simply records of the

temperatures recorded by the two thermocouples in the system.

The system and the error log each hold 4096 events while the combined temperature logs hold an additional

32,765 temperature events. All the logs are kept in non-volatile memory, meaning that the information is

saved regardless of whether the control has power.

When an event (system, error or temperature) occurs, the control does two things with the data:

1. It enters the beginning or the conclusion of an event in the internal memory of the controller.

2. It sends the event data out the serial port of the freezer.

25

Page 26

TW-357 REV E

The control consolidates the events in the internal log (combining “start event” / ”conclude event” information

to provide one event with duration), however, when the data is sent out the serial port no consolidation of data

occurs.

As an example, a fill would provide one log entry in the internal log of the control, indicated as follows: Fill

occurred on 9/28/98 @ 8:07 for 24 minutes. The same data coming out of the serial port would cause two

entries in a computer or printer and would be indicated as follows:

Fill Started on 9/28/98 @ 8:07

… (elapsed time)

Fill occurred on 9/28/98 @ 8:07 for 24 minutes

Menu Access causes the control to make some decisions on logging an event and they are handled in the

following manner: Temperature is immediately logged (if it is enabled) and then a fresh time period is started

when the Menu system is exited. System and error logs are placed in a suspended state until the control exits

the menu system and timing is started again. Duration of system and error logs then are total time of the event

less any time that the user was in the menu system.

When logs are dumped to the serial port, the oldest events are sent first. The control operates on the FIFO

(First In First Out) method. If the maximum number of entries is reached, the oldest are lost to make way for

the newest entries.

Dump Logs

Dump SYSTEM LOGS is accessible through the menu system of the control (MENU, 4, 1, 1). This option

sends data from the system logs out the serial port of the freezer. When this option is chosen, the display

reports how many system logs are stored. While the data is being sent to the serial port, it can be paused or

completely cancelled through the menu system.

DUMP ERROR LOGS is accessible through the menu system of the control (MENU, 4, 1, 2). This option

sends data from the error logs to the serial port of the freezer. When this option is chosen, the display reports

how many error logs are in the system. While the data is being sent out the serial port, it can be paused or

completely cancelled through the menu system.

DUMP TEMP LOG #1 and TEMP LOG #2 are accessible through the menu system of the control (MENU, 4,

1, 3 or MENU, 4, 1, 4). This option sends data from the temperature logs to the serial port of the freezer.

When this option is chosen, the display reports how many temperature logs are in the system. While the data

is being sent out the serial port, it can be paused or completely cancelled through the menu system.

Error Logs

SENS. ERR. LOGGING is accessible through the menu system of the control (MENU, 4, 2, 1). This menu

choice turns on/off the logging of all sensor errors. The choices are ENABLE or DISABLE. Records data in

the error log.

LOW SUPPLY LOGGING is accessible through the menu system of the control (MENU, 4, 2, 2). This menu

choice turns on/off the logging of the low LN2 supply error. The choices are ENABLE or DISABLE. Records

data in the error log.

REMOTE ALARM LOGGING is accessible through the menu system of the control (MENU, 4, 2, 3). The

menu choice turns on/off the logging of the remote alarm activation. The choices are ENABLE OR

DISABLE. Records data in the error log.

26

Page 27

TW-357 REV E

OPEN THERMOCOUPLE LOGGING is accessible through the menu system of the control (MENU, 4, 2,

4). This menu choice turns on/off the logging of the thermocouple open alarm. The choices are ENABLE and

DISABLE. Records data in the error log.

HIGH TEMP #1 LOG is accessible through the menu system of the control (MENU, 4, 2, 5). This menu

choice turns on/off the logging of the high temperature alarm for Thermocouple #1. The choices are ENABLE

and DISABLE. Records data in the error log.

HIGH TEMP #2 LOG is accessible through the menu system of the control (MENU, 4, 2, 6). This menu

choice turns on/off the logging of the high temperature alarm for Thermocouple #2. The choices are ENABLE

and DISABLE. Records data in the error log.

System Logs

FILL LOGGING is accessible through the menu system of the control (MENU, 4, 3, 1). This menu choice

turns on/off the logging of tank filling operations. The choices are ENABLE or DISABLE. Records data in

the system log.

LID ACTION LOGGING is accessible through the menu system of the control (MENU, 4, 3, 2). This menu

choice turns on/off the logging of lid openings and closings. The choices are ENABLE or DISABLE. Records

data in the system log.

USER ACCESS LOGGING is accessible through the menu system of the control (MENU, 4, 3, 3). This

menu choice turns on/off the logging of user access codes, which are requested when the lid is opened.

Records data in the system log.

Temperature Logs

Temperature Logging Rates for thermocouple #1 (T/C #1 LOGGING) and thermocouple #2 (T/C #2

LOGGING) are accessible through the menu system of the control (MENU, 4, 4, 1 or MENU, 4, 4, 2). This

menu choice adjusts the rate at which temperatures are logged for the two thermocouples. The possible

choices are Disabled, 15, 30 minutes, 1, 2, 4, 6, 12 or 24 hours. Records data in the temperature logs.

Erase Logs

ERASE LOGS is accessible through the menu system of the control (MENU, 4, 5). This menu choice erases

any of the four logs found in the control.

Please note that once a log has been erased, it is gone forever.

ERASE SYSTEM LOGS (MENU, 4, 5, 1).

ERASE ERROR LOGS (MENU, 4, 5, 2).

ERASE TEMPERATURE LOG #1 (MENU, 4, 5, 3).

ERASE TEMPERATURE LOG #2 (MENU, 4, 5 ,4).

Security

KRYOS security features restrict access to certain key features such as power and the menu system.

The POWER-ON PASSWORD can be set through the menu system of the control (MENU, 5, 1). The poweron password requires entry of a 4-digit password before turning on or turning off the control. Follow the

directions on the display to set a new password or disable a password. Codes 0000 & 9999 are invalid choices.

Code 9999 is used to access a procedure to clear passwords should they be forgotten.

27

Page 28

TW-357 REV E

The MENU PASSWORD can be set through the menu system of the control (MENU, 5, 2). The menu

password requires entry of a 4-digit password before allowing access to the menu system to change any

control settings. Follow the directions on the display to set a new password or to disable a password.

Codes 0000 & 9999 are invalid choices. A code of 9999 is used to access a procedure to clear passwords

should they be forgotten.

User Options

The user options menu choice covers all other control settings not already covered. These include serial port

settings, date and time settings, Lid Settings, Defog, Quick-Chill, Temperature Control, Valve Freeze-Guard,

Display brightness and Control Information.

Lid Switch Setup

LID SWITCH SETUP can be accessed through the menu system of the control (MENU 6, 2, 2, 2). This

option enables or disables the lid switch.

Manual Defog

DEFOG TIMER can be changed through the menu system of the control (MENU, 6, 2, 2, 1). This is the time

interval that the valve is opened when the user manually presses the defog button. The possible choices are

disabled through 90 seconds.

Auto Defog

The AUTO DEFOG (MENU, 6, 2, 2, 3) feature provides a burst of gaseous N2 to the freezer to clear the fog

when the lid is opened. This is activated through the lid switch. If the lid switch is deactivated this feature will

be disabled. The choices for auto defog time are disabled through 90 seconds.

Quick-Chill

The QUICK-CHILL (MENU, 6, 2, 2, 4) feature provides a burst of N2 gas to the freezer to lower the

temperature each time the lid has been opened and then closed. This is activated through the lid switch. If the

lid switch is deactivated this feature will be disabled. The choices for quick-chill time are disabled through 90second purge of gaseous nitrogen.

Control By Temperature

CONTROL BY TEMP can be set through the menu system of the control (MENU, 6, 2, 3). By enabling this

option KRYOS will control by temperature around Thermocouple #1. The Temperature Control menu choices

are only available if Thermocouple #1 is enabled.

Temperature Control Settings

TEMP CTRL SETTINGS can be set through the menu system of the control (MENU, 6, 2, 3, 2, 1). The user

can set the temperature that must be maintained in the freezer around Thermocouple #1. The set-point can be

set from -180º to -100ºC.

Control Temperature

KRYOS can also provide a vapor chamber temperature control for specimens that must be stored in a

particular vapor temperature range. The temperature control function operates in addition to the level control

function. The level control always takes precedence. If the liquid level of LN2 is maintained between the

START FILL sensor and the STOP FILL sensor, the control attempts to maintain a selected temperature

around Thermocouple #1.

28

Page 29

TW-357 REV E

Menu Password

When the menu password is active, it is possible to review all of the control settings without having the

password. When a password is activated and the user presses the menu key, two choices are available:

1) MENU (PASSWORD REQ)

2) CONTROL SETTINGS

By selecting choice #2 the user can go through the menu system and see all of the settings in the control but in

this mode, the user cannot change any settings. If either the power-on or the menu passwords are forgotten, the

user can reset the password by typing in 9999 when asked for the password. The KRYOS will display an 8digit number. Call your distributor or Taylor-Wharton with the 8-digit number to obtain a unique 8-digit

number to type into the control. When this number is entered, all passwords are cleared.

Serial Communications and RS-232 Settings

The KRYOS control system is designed with a 2-way serial communication feature. RS-232 (MENU, 6, 1)

allows the user to configure the serial port to “talk” with other Data Terminal Equipment (DTE). The control

can send data through it’s serial port to a computer, a printer or a modem. System logs, error logs or

temperature logs are always available for download. In addition to downloading data, the control can accept

commands through the serial port. Control settings can be viewed or changed at any time. Also remote

diagnostics can be performed.

If the RS-232 is enabled the handshaking can be turned on and off. This feature allows two devices to

communicate when sending data. Also the baud rate can be set for the following speeds: 300, 1200, 2400,

4800, 9600 or 19200 baud.

Time and Date Set

TIME AND DATE SET can be changed through the menu system. (MENU, 6, 2, 1). The date and time will be

set at the factory to Central Time, USA.

User Access Logs

The USER ACCESS LOGS (MENU, 4, 3) track all personnel who enter the freezer by asking for an

identification number when the lid is opened. When this feature is enabled, the control asks for an

identification number any time the lid is opened. An entry is then recorded in the log indicating the time, date

and identification of the person entering the freezer. The user has 30 seconds to enter an ID code (the 30

seconds is counted down on the screen). If an ID is not entered within the 30-second time frame, the log

indicates that an unidentified user accessed the freezer. Identification numbers range from 00 to 99.

29

Page 30

TW-357 REV E

Control Range

CONTROL RANGE can be accessed through the menu system of the control (MENU, 6, 2, 3, 2, 2). KRYOS

maintains a temperature range around the user-selected temperature. A tighter range maintains a temperature

very close to the selected temperature at the cost of greater LN2 usage. A broad range provides more

temperature variability but the LN2 usage is less. The range can be varied from +1º to +15ºC above and below

the selected temperature. The total range therefore, is between 2ºC (1º below and 1º above the selected

temperature) and 30ºC (15º below and 15º above the selected temperature). When the KRYOS is attempting

to control by temperature, it flashes “T.Recov” (Temperature Recovery) in the center of the bottom line.

Freeze-Guard Options

Ice crystals introduced through the supply line are the primary cause of an overfill. Freeze-Guard is a process

designed to reduce the risk of an overfill. Freeze-Guard consists of two options to reduce the risk of a frozen

valve: 1) The maximum valve open duration can be set by the user. (VALVE OPEN DURATION) 2) The valve

can be rapidly turned on and off trying to free it up (VALVE DE-ICING). Option 2 occurs if either the Freeze-

Guard sensor detects that the valve is not fully closed. The special “Freeze-Guard” sensor assembly includes a

plumbing “T” with an in-line thermistor which is placed in the plumbing directly downstream from the

solenoid valve. KRYOS monitors the “Freeze-Guard”

thermistor and detects if the flow of LN2 is stopped when the valve has been commanded to close.

Valve Monitoring

If KRYOS detects that a flow of LN2 is occurring even when the solenoid valve is supposedly closed, an error

message will appear on the screen indicating “Valve Stuck Open.” To confirm, the control waits for 10

seconds after it determines that the valve should be closed before it will indicate that the valve is stuck open.

Valve Open Duration

Valve Open Duration can be accessed through the menu system (MENU, 6, 2, 4, 1). This allows the user to

set the maximum amount of time, which the valve will stay open at any one time. If a fill operation exceeds

the valve open duration time set by the user, the valve closes for 15 seconds and then opens again for another

cycle. This 15 second rest period allows the solenoid valve to warm. The allowable settings are Disabled and

1-15 minutes.

Valve De-icing

Valve De-Icing can be accessed through the menu system (MENU, 6, 2, 4, 2). This feature can be turned on

or off. If enabled, the control will try to free up the valve by rapidly turning it on and off. This feature is

triggered when the Freeze-Guard sensor detects a stuck valve condition. KRYOS will attempt to free up the

valve by De-icing 5 times with a two-minute delay between tries.

Splash-Guard

Splash Guard is a process to reduce or eliminate false signals detected by the thermistor sensor assembly. In

particular this reduces sporadic valve operation when the sensor assembly is splashed with LN2 . When a fill

operation has completed because the level has reached the STOP FILL sensor, the display will flash “Check”

and the control will check the validity of the signals received from the sensor assembly. The splash-guard

check occurs for 20 seconds and the bottom line of the display indicates this by flashing “Check”.

30

Page 31

TW-357 REV E

Display Brightness

DISPLAY BRIGHTNESS can be set through the menu system of the control (MENU, 6, 3). This option

changes the intensity of the display. The possible choices are 25%, 50%, 75% and 100%.

About this Control

ABOUT THIS CONTROL can be accessed in the menu system (MENU, 6, 4). This option provides

information about the control. In particular it tells the serial number of the control and the software version

that the control is running.

Control On Battery Backup Version

This controller is similar to the AC Kryos Controller. The menu system and all features are identical. The

only operational difference is if a power failure occurs, the control goes into battery backup mode. The Kryos

control operates on 24 VAC power. As an option, however, the control can also operate on battery power to

provide up to 72 hours of continuous service without AC power. The system is designed for full operational

service during a power failure, including full solenoid valve operation. The battery backup system can be

ordered from Taylor-Wharton and should be factory installed.

Differences between the regular Kryos and the battery backed Kryos:

Please see the chart below for the differences between the two systems.

SOLENOID VALVE

Wall Transformer

Battery

Battery Extension Cable

Software

Control Board (1)

Regular Kryos Battery Backed Kryos

24 VAC solenoid 12 VDC solenoid

24 VAC/ 40 Voltamps output 16.5 VAC/ 40 Voltamps output

None 17amp-hour

None Connects battery to control board

V4.0 V4.0

Black 2-pin solenoid valve

plug

Red 2-pin solenoid valve plug &

Red 3-pin battery plug.

(1) The control board for the battery backup is quite different than the control board for the regular Kryos in

that a number of parts are either removed or changed. The best way to tell if the control is a battery

backed unit or a regular unit is to look at the valve connector.

Operation

The software is designed such that if power is lost and a battery-backed control is in place, the control detects

the loss of power and continues to operate from the battery. If power is lost, a “Battery Backup” message

appears on the display, the alarm beeper sounds and the red LED starts to flash. After a short period of time

(approximately 10 seconds) the display will go dark to conserve power, however the red LED will continue to

flash and the beeper will continue to sound until it is muted. The display can be brought back at any time by

pressing any button on the front panel.

The control will continue to monitor the system, record logs and operate the valve until the battery runs too

low. Original specifications required that the battery run, fully operational, for at least 72 hours. Battery

backup mode is treated by the control as an alarm condition. This means that the remote alarm will be

triggered after a period of time as defined by the user.

Note: We strongly recommend that all Cryo-Storage systems be connected to a redundant alarm, a

building alarm system or a dialer. This insures that someone is notified if an error condition persists.

31

Page 32

TW-357 REV E

The DC solenoid valve requires that the battery be connected for the system to work properly. If the battery is

disconnected or completely discharged the valve operation and the control operation may be affected. In

particular, if the control is calling for a fill, the solenoid will be called to open. Opening the solenoid takes a

substantial inflow current, which the solenoid may “steal” from the control if it cannot get sufficient power

from the battery. This in turn will “fool” the control into believing that a power failure has occurred, which

will cause the control to reset and the valve to close. This will occur over and over again. If a battery-backed

control keeps turning itself on and then off, try recharging the battery by following the steps below.

Battery Charging: The Kryos control has a circuit that trickle charges the battery. This provides a fully

charged battery for the times when it is needed yet keeps it from being damaged by overcharging. If the

battery should become discharged, the following steps should be followed to charge it.

Turn the control off using the Power button on the front panel of the Kryos. Even though the control is turned

off, the battery will still be recharged.

Check all connections to the Kryos, especially the harness plug, the wall transformer and the battery extension

cable. The wall transformer should be plugged into the wall.

Wait for 30-60 minutes. After this time period, the battery should have enough power to run the control and

continue charging the battery.

Battery Life

The life of the battery will vary according to many factors including use and storage temperature. The leadacid batteries have an expected life of 3 to 5 years. For full functionality of your Cryo-Storage system we

recommend that the lead-acid battery be changed every 3 years.

INTERFACE SOFTWARE

Optional software (CRYOCOM) is available which allows a computer system to communicate with KRYOS

through the serial port on the freezer. The software provides the capability to download the logs, review

control settings, change control settings and perform system functions such as open/close the solenoid valve,

mute the alarm, etc. Contact Taylor-Wharton for details. Please have your Cryostorage System serial number,

KRYOS serial number and version number as it appears in ABOUT THIS CONTROL (MENU, 6, 4).

The Kryos control is also compatible with the SQR-1 Sequence that provides sequence filling at multiple

freezer locations.

32

Page 33

TW-357 REV E

MAINTENANCE

Strainer Cleaning Instructions

The container will not fill properly if the strainer is clogged with ice or dirt. To clean the strainer, first close

the supply valve to the refrigerator. Vent the fill line of all pressure. Remove and warm the strainer to ambient

temperature. Purge the strainer from both directions with dry nitrogen gas or dry oil-free air. Rinse the strainer

with alcohol and purge it again with dry nitrogen gas or dry oil-free air to clear contaminants. If the cleaning

process doesn’t clear the blockage, replace with a new filter (P/N 7631-1080).

Defrosting Your LAB-Series CryoStorage System

All liquid nitrogen storage systems are subject to ice and frost buildup over time. Regular preventive

maintenance programs should be instituted to remove ice and frost from the sensor and fill tubes and from the

refrigerator lid. Ice and frost buildup in the sensor tube may result in false readings being relayed to the

controller from the sensors. Ice can form a thermal barrier around a level sensor, rendering it insensitive to the

temperature differences between vapor and liquid. Sensors and thermocouples should be carefully removed

regularly and inspected for ice and frost buildup.

Ice and frost buildup in the fill tube may block the flow of liquid nitrogen into the refrigerator during fill. This

blockage can result in the liquid level dropping to dangerously low levels, and may result in the Low Alarm

sensor being activated. In addition, a fill line blockage may cause the Low LN2 Supply Alarm to be activated.

If the fill line becomes blocked, it must be warmed until the ice blockage is cleared. Ice blockage would

typically form in the fill tube at the point at which water will form ice. This location may be just inside the

storage chamber, near the top. Warm the fill line with a hair dryer or other safe low heat source with the

solenoid in the open position. If this is not successful in 2 minutes, the refrigerator should be allowed to thaw

to room temperature, and purge with dry nitrogen to remove all traces of moisture within the storage chamber

before re-filling.

Excessive ice and frost buildup may occur on the refrigerator lid if the lid is left open or the liquid level is too

close to the underside of the lid. To defrost the lid, open the lid to the fully open position. Clean the ice and

frost from the underside of the lid by allowing it to thaw slightly and wiping with a clean, lint-free cloth. Care

must be taken to insulate the inventory control system from high temperatures, which may affect the

viability of the stored product.

If it is determined that defrosting is necessary the following procedure must be followed. Cryogenic freezers

of these types must be carefully warmed to ambient temperatures to avoid the ingress of water. As long as

liquid nitrogen is present in the unit, the evaporation of the liquid nitrogen provides slightly positive gas

pressure in the unit, preventing the entrance of moisture laden air. When all of the liquid nitrogen has

evaporated but the unit temperature is still below the dew point of the surrounding atmosphere, condensation

will start to collect in the unit. When frost and condensation collect in the unit, staining of the carousel or

damage to the level sensors will occur. If one of these units is to be taken out of service for any reason the

following steps must be performed to avoid damaging the unit.

1. Disconnect power and liquid nitrogen source.

2. Remove all stored product and inventory control system components.

3. A source of nitrogen gas must be found and used to purge the unit as the temperature rises to

ambient. The purge gas can be installed on the thermocouple tube, sensor tube, or fill line after

the appropriate components have been removed. The purge gas may also simply be delivered to

the unit through a bent metal tube under the lid. A flow rate of 5 to 10 SCFM is sufficient to

prevent water from collecting inside the unit. This flow of purge gas will also speed the warming

of the unit to ambient temperature.

33

Page 34

TW-357 REV E

Cleaning Your Taylor-Wharton CryoStorage System

The cryogenic vessel of all LABS CryoStorage Systems may need to be cleaned, and sterilized if the type of

stored product is changed or the unit is taken out of service.

sterilized regardless of the type of stored product, prior to return to Taylor-Wharton for repair or maintenance.

Prior to cleaning, the unit must be warmed and defrosted following the defrosting procedure described above.

To clean and sterilize your defrosted LABS CryoStorage System, Spray the entire inner vessel surface with

ample amounts of an approved disinfectant. Allow surface contact to be maintained for a minimum of five

minutes. Rinse the inner vessel with water, remove all water and debris through the access opening located in

the carousels bottom tray, and vacuum or towel dry the surface. Spray the inner vessel surface with a 70%

alcohol to water solution and maintain surface contact for fifteen minutes. Rinse the inner vessel surface with

water and vacuum or towel dry excess water. Final dry the inner container, sensor line, and fill line using a

nitrogen gas purge.

The vessel must be defrosted, cleaned, and

34

Page 35

TW-357 REV E

WARNING: Never use chlorine-based disinfectants to clean a LABS CryoStorage System.

Normal Evaporation Rate (NER) Test

Nitrogen consumption is an accumulation of all system components and user introduced evaporation. The

storage chamber is a double walled, vacuum insulated vessel and contributes to the daily consumption of

liquid nitrogen. The liquid nitrogen supply vessel and transfer hose also contribute greatly to the daily

consumption rate. Choosing to control the vapor temperature, combined with the liquid level and temperature

specified, will affect the overall nitrogen consumption. In addition to these variables, opening the lid to

retrieve product, and adding new product into the storage chamber will pay a role in the accumulative liquid

nitrogen consumption.

If the nitrogen consumption of your CryoStorage system seems excessive, it may be appropriate to perform an

estimated Normal Evaporation Rate (NER) test on the CryoStorage chamber. To perform an NER test:

1. Fill the CryoStorage unit to the “High Level” sensor.

2. Measure the liquid nitrogen level with a plastic or wooden measuring rod.

WARNING: Never use hollow rods or tubes as dipsticks. When a warm tube is inserted into liquid

nitrogen, liquid will spout from the top of the tube and may cause personal injury.

3. Close and lock the lid of the LABS CryoStorage System for forty-eight (48 hours).

4. Open the LABS CryoStorage System and measure the liquid nitrogen level. Typically, liquid nitrogen

levels will drop approximately 3/8 in. (9.53 mm) per day. If your measurement indicates a drop in excess of

3/4 in. (19 mm) per day, please contact your Taylor-Wharton distributor or Taylor-Wharton for further

information. Please have your serial number, this manual and service history available.

WARNING: The source power supply at 110/120VAC can cause a lethal electrical shock. Unplug the

power cord before proceeding with any repairs.

The KRYOS has been designed for easy setup and maintenance. All connectors on the controller are uniquely

identified snap-on plugs. The thermocouple, sensor assembly, solenoid valve, power, remote alarm,

temperature recorder and data lines can be connected or disconnected in seconds.

Making Adjustments to the LABS KRYOS Sensor Assembly

The factory settings for the LABS control system are as follows:

• Low Level Alarm = 2 (Always 1” below the start fill)

• Start Fill Sensor = 3 (1 5/8” below the carousel tray)

• Stop Fill Sensor = 5 (Just below the carousel tray)

• High Level Alarm = 6 (Always 1” above the stop fill)

The sensor assembly is pushed to the bottom of the refrigerator as delivered from the factory. If adjustments

need to be made, the following procedure will simplify the process.

35

Page 36

TW-357 REV E

The Kryos Control installed on the Taylor-Wharton LABS80K refrigerator operates with software version 9.0

(regular operation) or 9.0B (battery backup). This control software has been specially designed to match the

design characteristics of the LABS 80K refrigerator. The differences between the versions are in the table

below

Table: Software version differences

Level Readings

Default Start Fill / Stop Fill

Default Auto Defog

Offset Value

Units of measure

Kryos V4.0 Kryos V9.0 & Kryos V9.0B

1" increments (linear) Level Range (nonlinear)

3" / 6" 3" / 5"

15 seconds 20 seconds