Page 1

®

TTi

Colorimeter Series

User’s Manual

Taylor Technologies, Inc.

800-TEST KIT (837-8548)

www.taylortechnologies.com

Page 2

Page 3

®

TTi

Colorimeter Series User’s Manual

Page 4

Page 5

®

TTi

Colorimeter Series User’s Manual

First Edition

last revision to this edition 6/12/2017

Taylor Technologies, Inc. Sparks, Maryland

Page 6

Taylor Technologies, Inc., Sparks, Maryland 21152

© 2012 Taylor Technologies, Inc.

All rights reserved. First edition published online 2012

For ready reference by the reader, the date of the last revision

to the manual is posted on the title page. The latest revision

date for each chapter or subsection is posted in parentheses

after its title in the table of contents. Check these periodically

to make sure your file copy is up to date.

Page 7

TABLE OF CONTENTS

PART 1 GENERAL INFORMATION

Safety and General Precautions (4/21/15 ) .............................................................................................1-3

Colorimeter Description ........................................................................................................................1-3

Features (10/19/12) ....................................................................................................................... 1-3

Optional Chemical Forms (4/19/13) ................................................................................................1-4

Components and Optional Accessories (6/12/17) ...................................................................................1-5

Colorimeter Reagent Packs (6/12/17) ....................................................................................................1-5

Supplementary Testing Supplies (4 /7/15 ) ...............................................................................................1-7

Registration (10/19/12) ........................................................................................................................1-7

Contacting Taylor Technologies (4 / 21/15) ..............................................................................................1-8

PART 2 TESTING PRIMER

Introduction to Colorimetric Absorption Analysis (10/19/12) ..................................................................... 2-3

Best Practices .....................................................................................................................................2-3

Sampling (10/19/12) ......................................................................................................................2-4

Filtering Samples (10/19/12) ..........................................................................................................2-4

Diluting Samples (10/19/12) ...........................................................................................................2-4

Pretreating Samples (4/14/16) ........................................................................................................2-5

Adding and Mixing Reagents (10/19/12) ..........................................................................................2-6

Storing Reagents (10/19/12) ..........................................................................................................2-6

Inserting and Aligning Sample Cells (4/ 2/13 ) ...................................................................................2-7

Performing a Test (10/19/12) .........................................................................................................2-8

Cleaning Sample Cells (10/19/12) ...................................................................................................2-8

PART 3 COLORIMETER OPERATION

The PC App (10/19/12) ........................................................................................................................3-3

Guide to Operating Parts and Controls (10/19/12) ..................................................................................3-3

Battery Installation/Connection to a Power Supply (10/19/12)..................................................................3-4

Keypad (10/19/12) ............................................................................................................................... 3-5

Display (10/19/12) ...............................................................................................................................3-6

Screen Format and Navigation (10/19/12) ..............................................................................................3-6

Icons and Symbols (10/19/12) ..............................................................................................................3-8

Main Menu (10/19/12) .........................................................................................................................3-9

Test Menus (10/19/12) .........................................................................................................................3-10

Initial Start-Up (10/19/12) .....................................................................................................................3-11

vTTi® Colorimeter User’s Manual

Page 8

PART 3 COLORIMETER OPERATION (cont’d)

Start Test ............................................................................................................................................3 -12

How to Perform a Test (10/19/12) ...................................................................................................3-12

Test Alerts (10/19/12) ....................................................................................................................3 -17

Test Timers and Auto-Read Option (10/19/12) .................................................................................3-17

Adjust Calibration (10/19/12) .......................................................................................................... 3-21

Access Test Data (10/19/12) ................................................................................................................3-24

Edit Favorites (10/19/12) ......................................................................................................................3-26

Edit Series (10/19/12) ..........................................................................................................................3-29

How to Perform a Series Test (10/19/12) ............................................................................................... 3-32

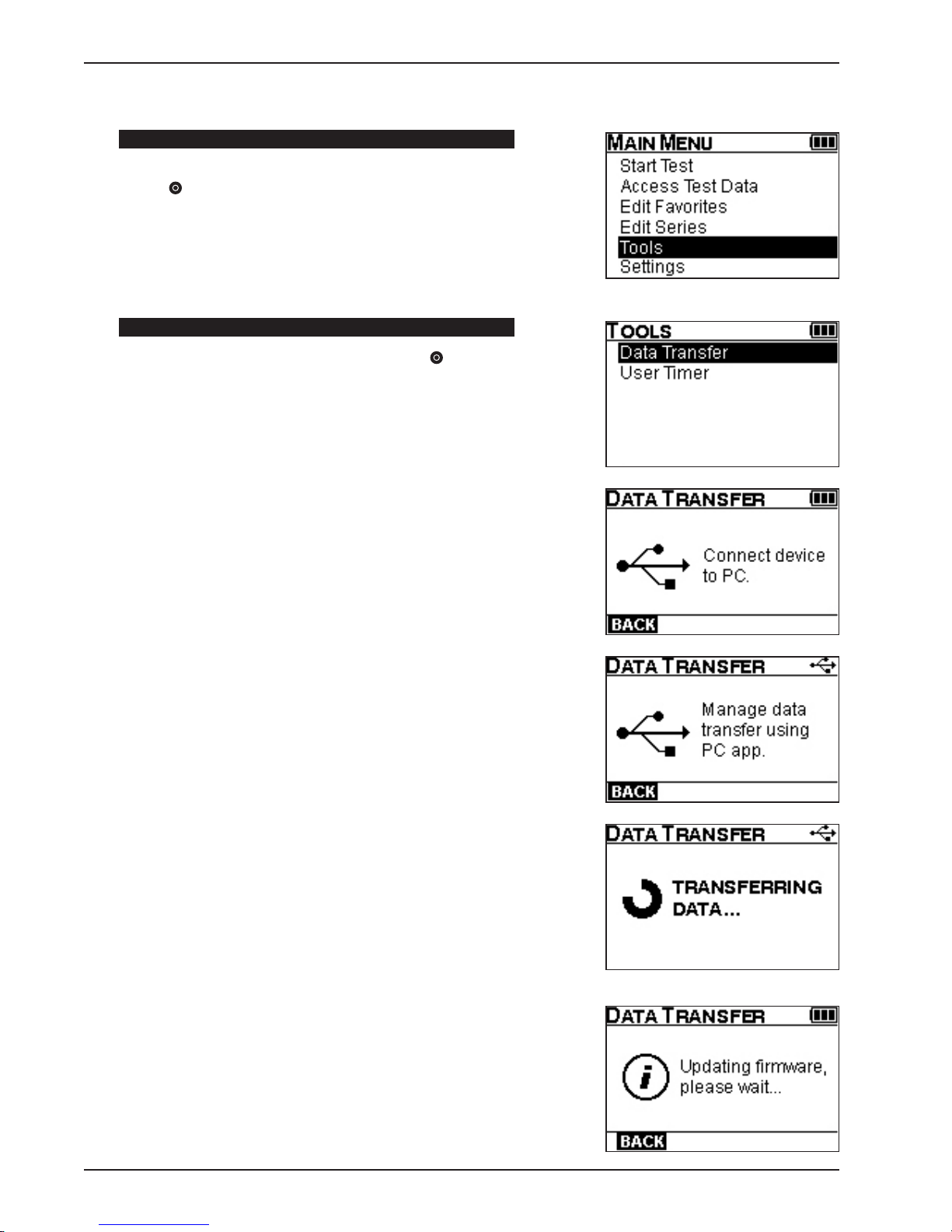

Tools ................................................................................................................................................... 3-35

Data Transfer (10/19/12) ................................................................................................................3-36

User Timer (10/19/12) ...................................................................................................................3-37

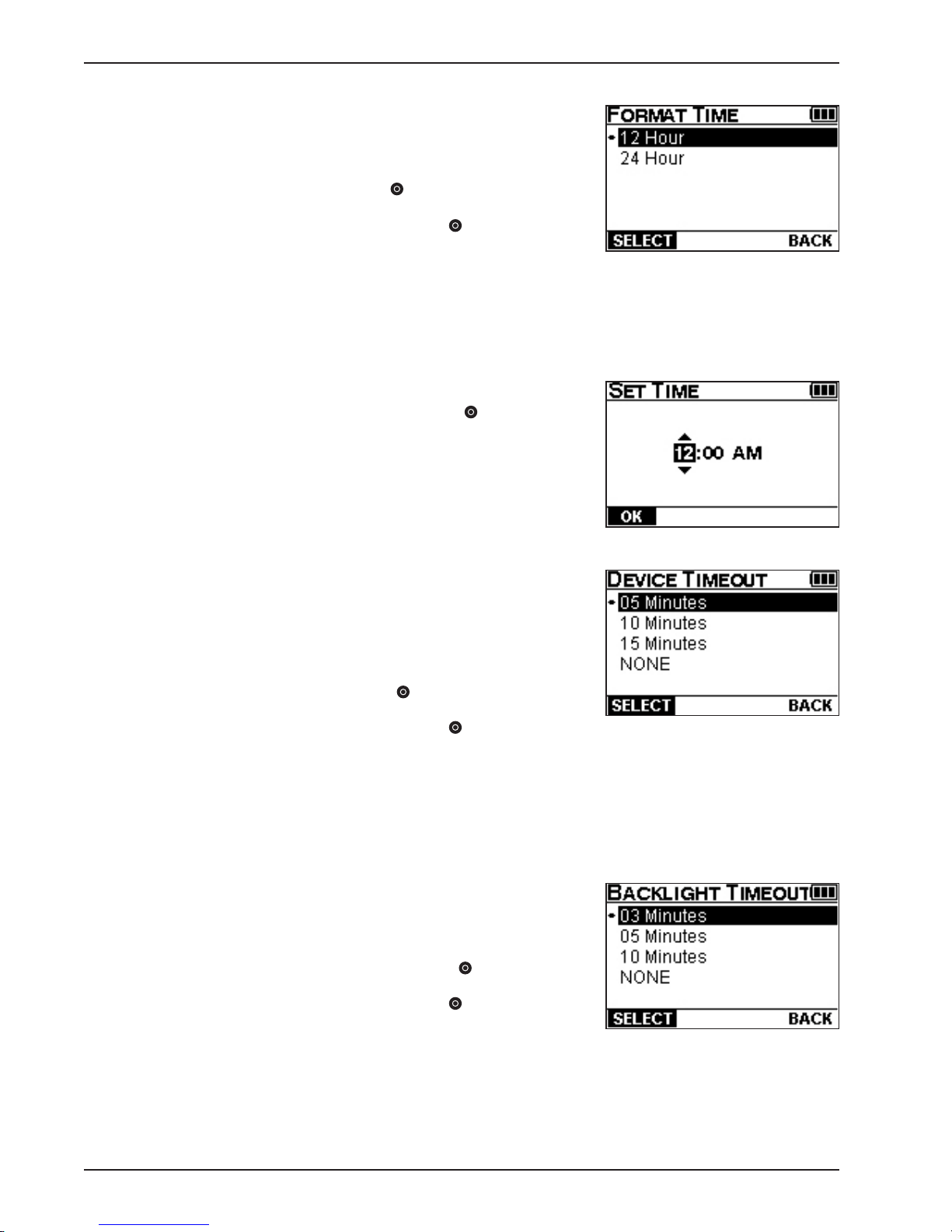

Settings (10/19/12) ..............................................................................................................................3-38

Absorbance and Transmittance Tests (10/19/12) ....................................................................................3-42

User-Developed Tests ...........................................................................................................................3-45

Program and Transfer a User-Developed Test (4/19/13) ....................................................................3-45

Edit a User-Developed Test (4/15/13) .............................................................................................. 3-48

Delete a User-Developed Test (4/15/13) ..........................................................................................3-48

Test Instruction Example (4 / 2/13 ) .........................................................................................................3-48

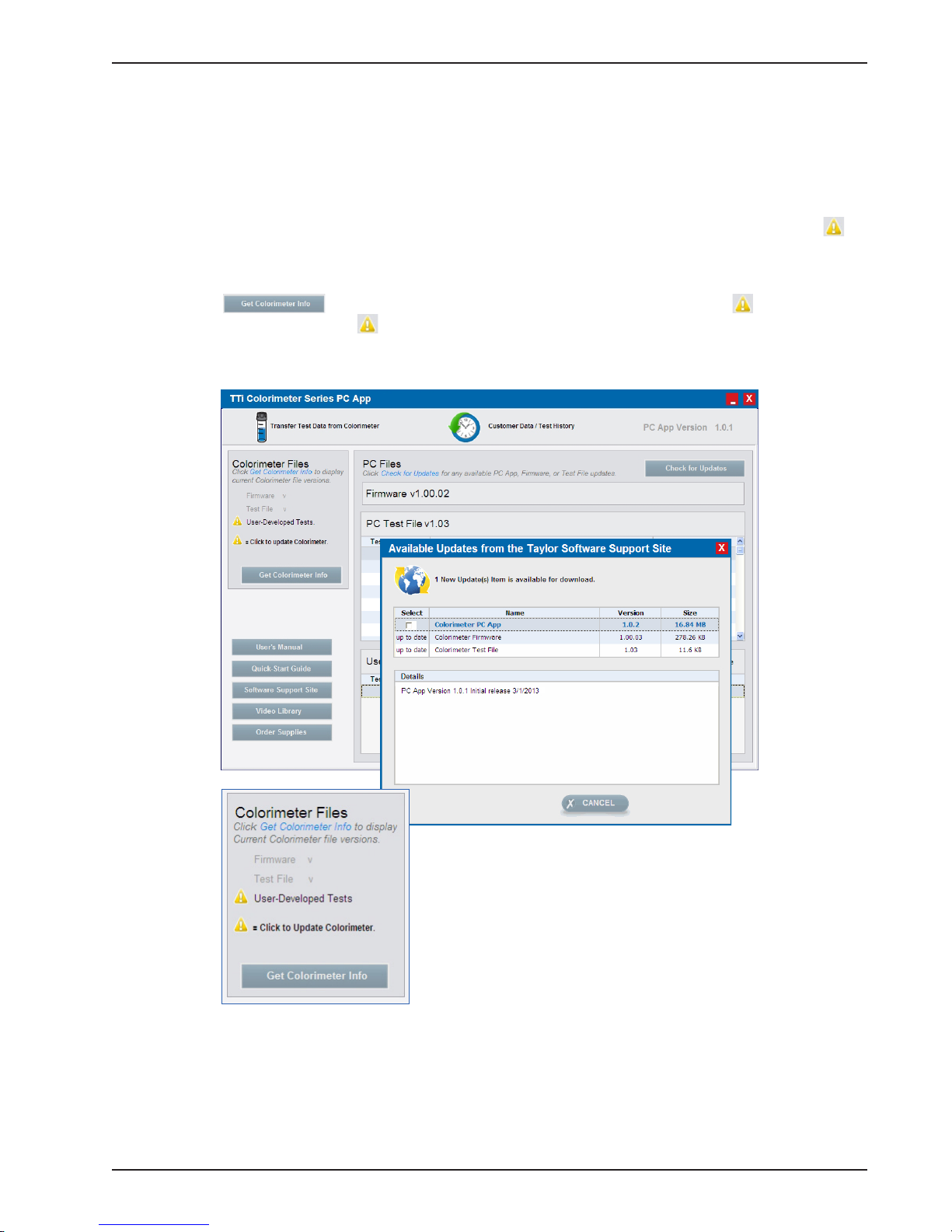

PART 4 USING THE PC APP

Transferring Test Data (4/15/13) ...........................................................................................................4-3

Maintaining a Customer Database (4 / 2/13 ) ...........................................................................................4-4

Updating the PC App, Firmware, and Test Files (4/15/13) ....................................................................... 4-5

Creating User-Developed Tests (4/19/13) ..............................................................................................4-6

Accessing Helpful Links (4 /2 / 13 ) .........................................................................................................4-6

PART 5 MAINTENANCE

Accuracy Check (10/19/12) ..................................................................................................................5-3

Routine Care (4 / 2/13 ) ..........................................................................................................................5-3

Waste Disposal (4 / 21/15) ..................................................................................................................... 5-3

Warranty Information (10/19/12) ........................................................................................................... 5-4

PART 6 BEFORE YOU CALL FOR SERVICE

Error Codes (10/19/12) ........................................................................................................................6-3

Return Policy (10/19/12) ......................................................................................................................6-5

vi TTi® Colorimeter User’s Manual

Page 9

PART 7 COLORIMETER SPECIFICATIONS

Specifications Summary (4/19/13) ........................................................................................................7-3

PART 8 COMPLIANCE SYNOPSIS

Certification (10/19/12) ........................................................................................................................8-3

Information to the User (10/19/12) ........................................................................................................8-3

viiTTi® Colorimeter User’s Manual

Page 10

1

Page 11

Part 1 General Information

Part 1

General

Information

1-1T Ti® Colorimeter User’s Manual

Page 12

Page 13

Part 1 General Information

SAFETY AND GENERAL PRECAUTIONS

he TTi® Colorimeter Series User’s Manual and actual test instruction(s) should be read in their entirety

T

before performing the initial setup, running any tests, or customizing the Colorimeter. We recommend

printing a hard copy of this manual for your files. The preprinted Quick-Start Guide supplied with the Colorimeter

summarizes key points in the User’s Manual and is intended to travel with the device for ready reference.

Observe the following precautions:

• Chemical safety:

Reagents for use with the instrument can be hazardous. Read and observe all information printed on reagent

labels and corresponding Safety Data Sheets (SDSs) prior to use. To view or print reagent SDSs, visit the

Product Info/Documents area of our website, www.taylortechnologies.com. You will need to know the

five-character product number signified by “R-XXXXX” on the reagent label and the test instruction. We

recommend printing file copies of the SDSs for all your reagents.

• Keep all reagents out of reach of children.

• Use only Taylor reagents for preprogrammed tests for operator safety and to avoid damage to the instrument.

• Operational requirements:

During operation place the instrument on a stable surface that is reasonably level, or hold in a horizontal

position if used as a handheld device.

• Environmental conditions:

Do not use or store the instrument in environments of extreme temperature or humidity.

Operational temperature range: 32°F–122°F (0°C–50°C)

Operational humidity limit: 90% @ 122°F (50°C) non-condensing

Do not immerse the instrument in water or use or store the instrument in environments with excessive

dust. The instrument has an IP67 environmental protection rating signifying that it is dust-tight and can

survive an accidental immersion in water of up to 1 meter for 30 minutes.

Do not leave the instrument exposed to direct sunlight for a prolonged period.

When not in use, keep the instrument stored in its carrying case.

• Voltage symbol indicates DC voltage. See instrument label.

COLORIMETER DESCRIPTION

The TTi® Colorimeter, manufactured by Taylor Technologies, Inc., is a handheld, multiwavelength,

microprocessor-controlled, menu-driven, direct-readout instrument that employs light-emitting diodes (LEDs)

as light sources. The instrument design combines technical performance with an intuitive user-interface, the

functional attributes most sought by water analysts, and durability. Its portability and data-logging capabilities

make it well suited for use in the field in addition to the laboratory.

FEATURES

• High performance spectral optics:

LEDs are durable and ideally suited for use in portable instruments.

Wavelength filters are used to narrow the bandpass of light emitted from LEDs to obtain accurate,

repeatable results. The instrument contains 6 wavelength filters (420, 470, 520, 570, 620, and 660 nm).

Wavelength filters are specified to provide a wavelength accuracy of ±1 nm and a wavelength bandwidth

of 10 nm ±1 nm. In addition, all filters are manufactured using a process that provides enhanced thermal,

environmental, and spectral stability.

1-3TTi® Colorimeter User’s Manual

Page 14

Part 1 General Information

• Preprogrammed tests for each model cover the most common tests sought by water analysts.

• Automatic wavelength selection for preprogrammed and user-developed tests.

• Integrated test timers (includes up to 4 preprogrammed test timers with AUTO-Read option) and 1 user

timer for general purposes.

• Test results displayed in concentration units (ppm, ppb, ppt, mg/L, µg/L, g/L), absorbance (ABS), or

transmittance (% T).

• Test results displayed in optional chemical forms (available for most preprogrammed tests).

• ADJUST CALIBRATION option allows adjustment of preprogrammed calibrations.

• Intuitive, easy to navigate user-interface.

• FAVORITES menu allows for a customized test menu to be created and edited.

• SERIES feature allows a group of selected tests to be chosen and performed consecutively in any order.

• Data storage and recall for 100 test results with time and date stamps.

• User-developed test capability allows users to program up to 8 proprietary tests of 12 data points each.

• Free PC App allows users to transfer test results, download test files and firmware, create user-developed

tests, and access helpful links.

• Custom graphical liquid crystal display (LCD) with anti-glare coating provides excellent contrast and

readability.

• Adjustable backlighting permits use in low-light environments; a timeout feature conserves battery life.

• Custom 8-button, silicone rubber keypad combines a soft, tactile feel with superior durability.

• Portable, rugged design that is waterproof and dust-tight.

• Powered by 4 AA batteries or an AC power adapter for connecting to a wall outlet, or a USB cable for

connecting to a PC or laptop (all power supply options are included with the instrument).

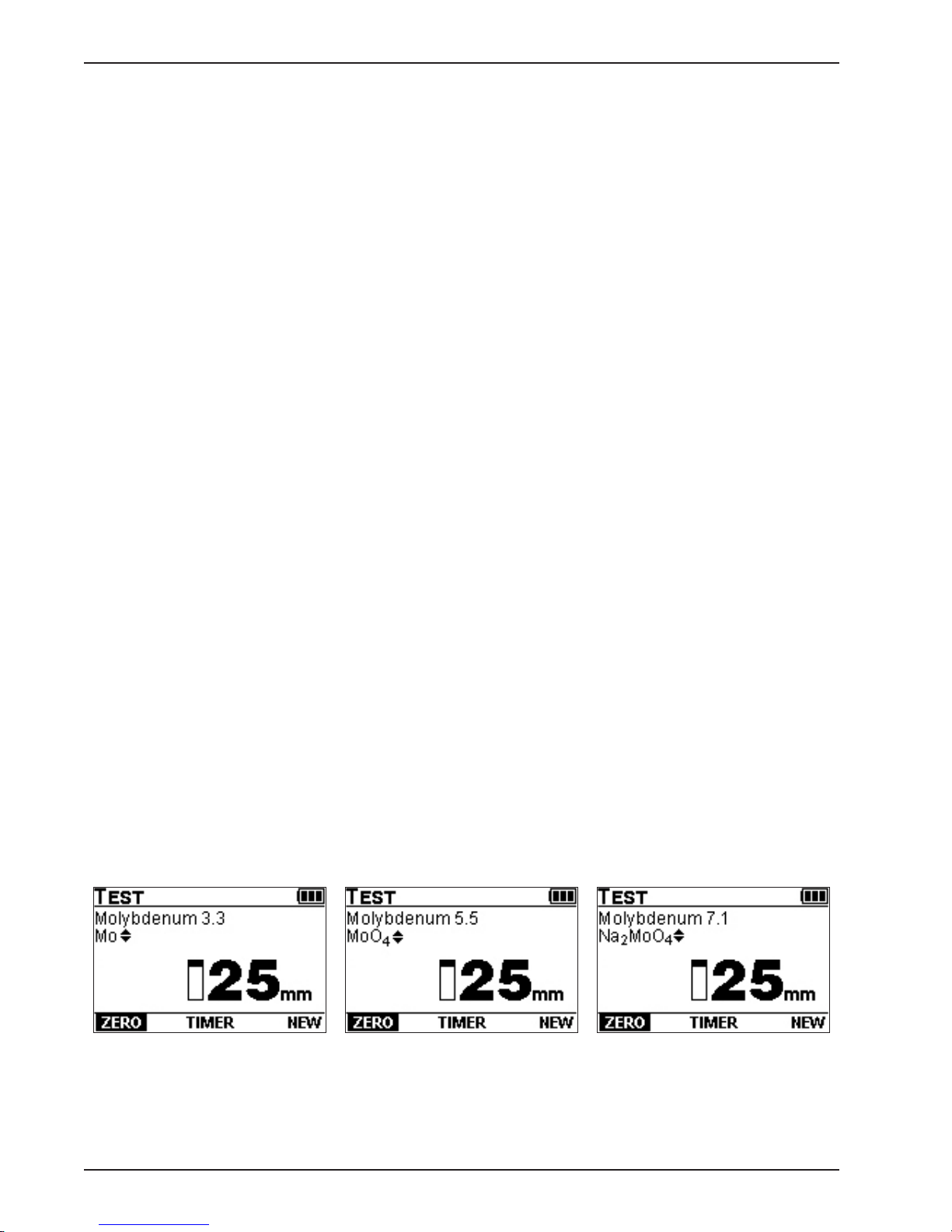

OPTIONAL CHEMICAL FORMS

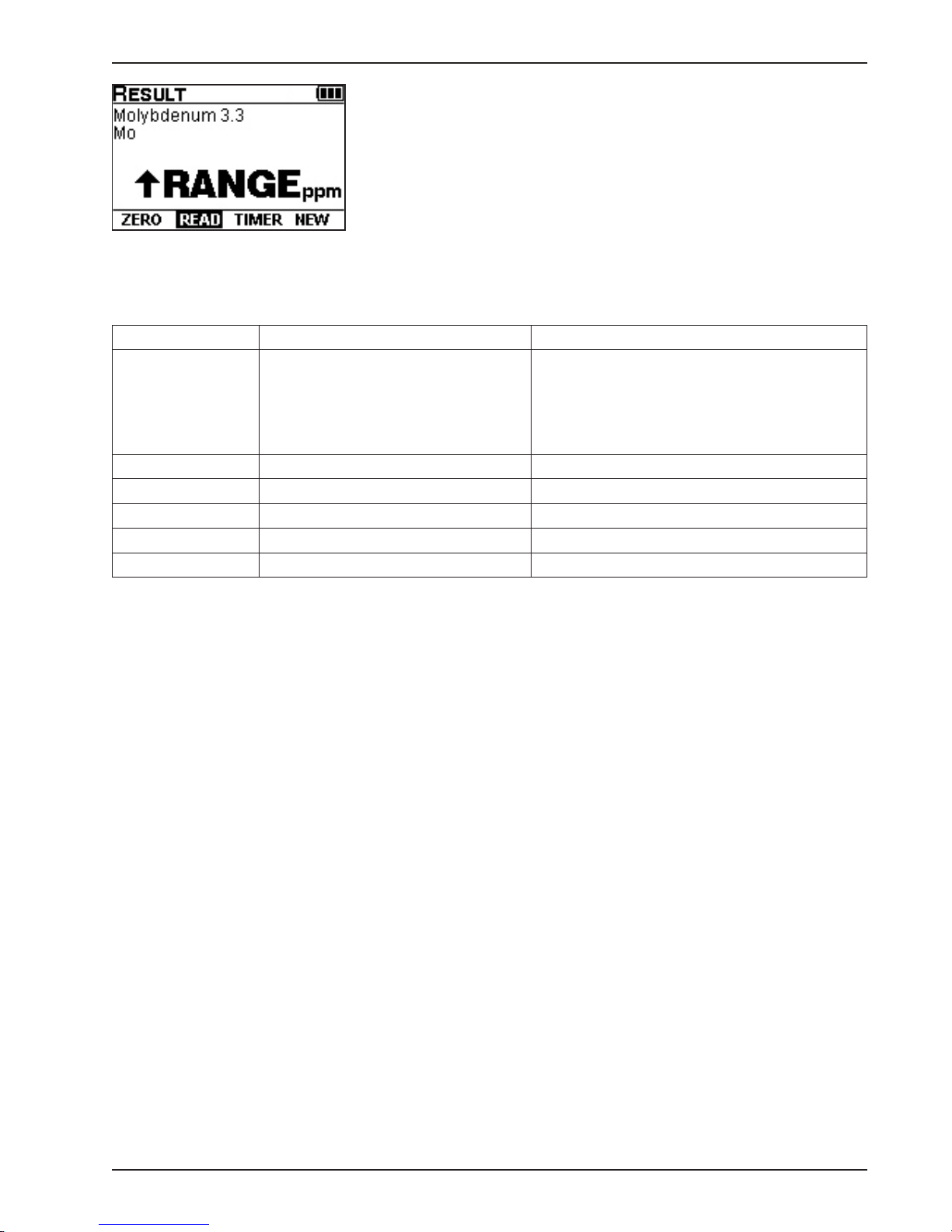

Optional chemical forms for expression of test results are available for most tests. If available, will appear

to the right of the chemical form. When an optional chemical form is selected within a test, the range (or range

upper limit) on the test screen will change to correlate with the selected chemical form, and all subsequent test

results and stored test data will be expressed in terms of the selected chemical form. The selected chemical

form will remain the default for that test until changed by the user.

NOTE: If a new Taylor test file is downloaded using the PC App, the optional chemical forms for all

tests will reset to the default chemical form.

Illustration of optional chemical forms available for testing molybdenum

1-4 TTi® Colorimeter User’s Manual

Page 15

Part 1 General Information

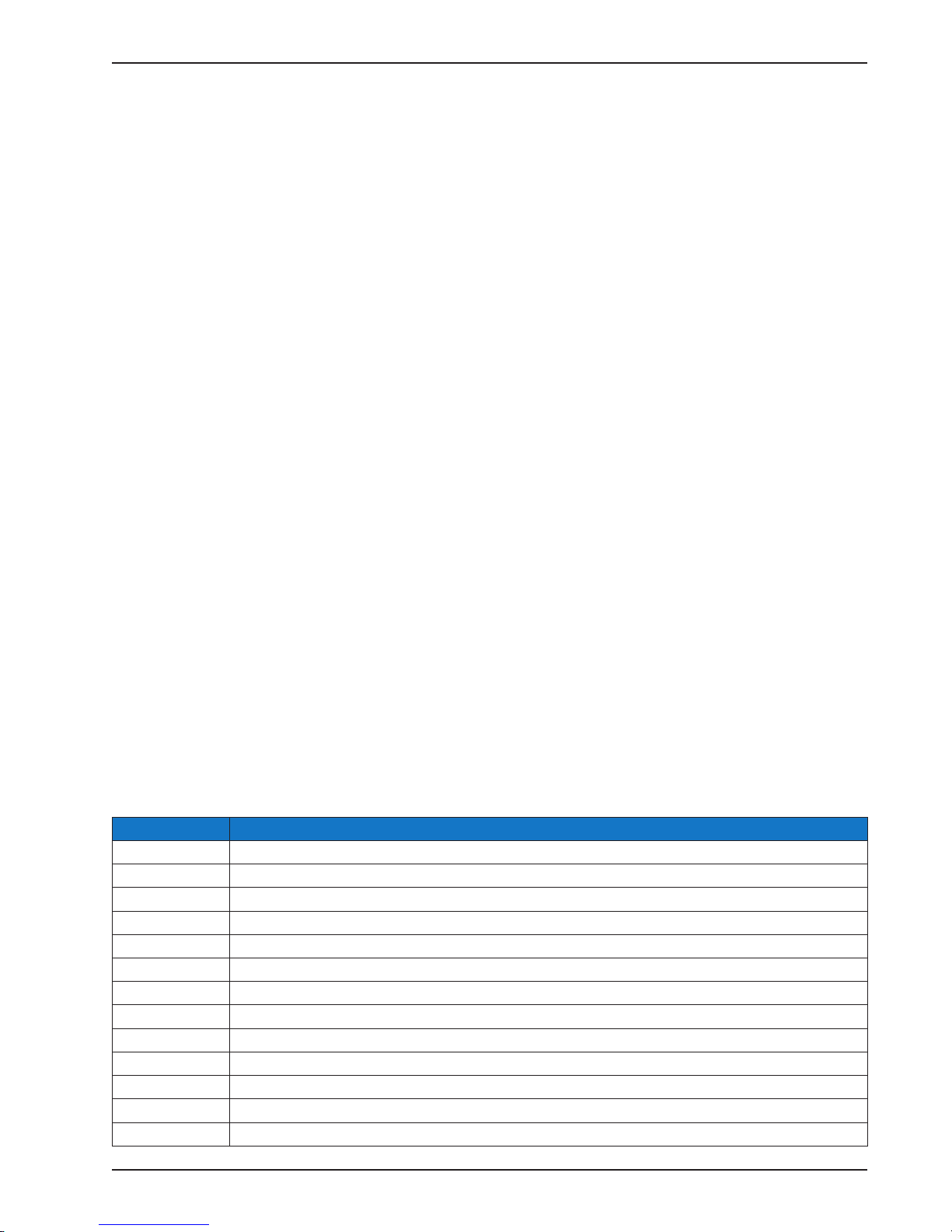

COMPONENTS AND OPTIONAL ACCESSORIES

Your meter purchase includes the following components:

Quantity Part Number Description

1 M-XXXX TTi® Colorimeter (model number on instrument faceplate)

1 5543 Quick-Start Guide

4 6105 AA Alkaline Battery

1 6535 AC Power Adapter

1 6551 Dilution Vial, 50 mL w/ cap

1 6552 USB Cable

4 6649 Foam Brush

2 9601 Sample Cell, 25 mm w/ cap

2 9602 Sample Cell, 15 mm w/ cap

The following optional accessories, viewable on www.taylortechnologies.com, may be purchased separately:

Part Number Description

K-8000 TTI® Colorimeter Series Accuracy Check Kit

714 6 Soft Carrying Case, gray (for use with TTi® 2000 or 3000), 11"w x 7"d x 4.625"h

7203 Replacement Foam Insert (for 7146)

9502 Hard Carrying Case, gray (for use with TTi® 3000), 20"w x 15.625"d x 5.5"h

9504 Hard Carrying Case, blue (for use with TTi® 2000), 20"w x 15.625"d x 5.5"h

9506 Hard Carrying Case, gray (for use with TTi® 2000), 10.75"w x 9"d x 7"h

All components and optional accessories, excluding batteries, as well as reagent packs (see next section), are

available directly from Taylor Technologies or authorized distributors. To order from Taylor, call toll-free

800-TEST KIT (837-8548).

COLORIMETER REAGENT PACKS

Currently available reagent packs for the TTi® 2000 Colorimeter are listed below. Each pack contains

an instruction and all the reagents needed to run the specified test, housed in a snap-fit kit of ABS plastic.

Instructions and kits are sized to fit securely in the optional Hard Carrying Case (#9504 or #9506).

Alternatively, the contents of the reagent packs may be transferred to your existing carrier.

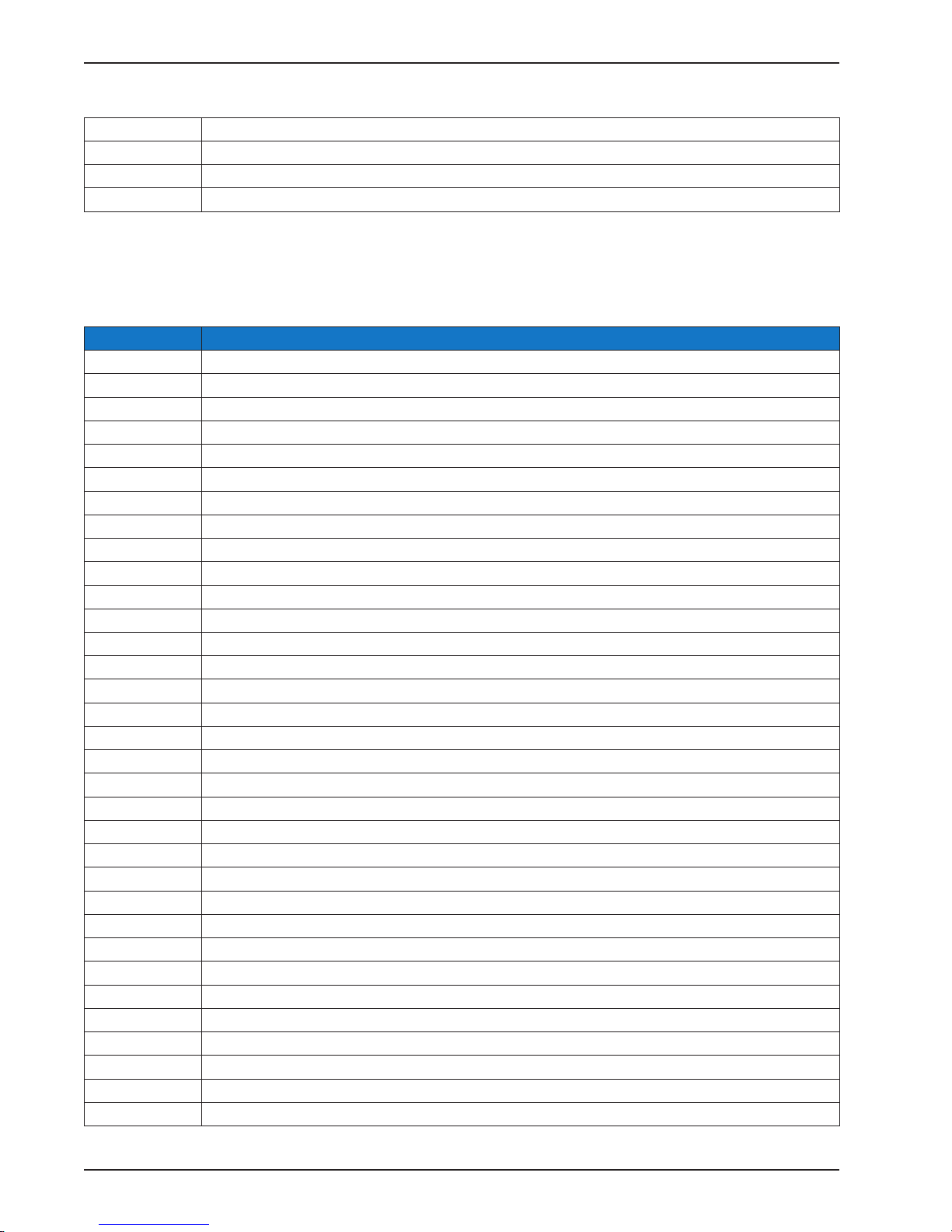

Part Number Description

K-8001 Reagent Pack, Colorimeter, Chlorine (free/total), DPD (powder), 0-4.00, 0-8.0, or 0-10.0 ppm

K-8002 Reagent Pack, Colorimeter, Bromine (total), DPD (powder), 0-10.00 or 0-20.0 ppm

K-8005 Reagent Pack, Colorimeter, Phosphate, 0-3.00 ppm (20-3000 ppb)

K-8009 Reagent Pack, Colorimeter, Iron, 0-4.00 ppm

K-8012 Reagent Pack, Colorimeter, Copper, 0-3.00 ppm

K-8020 Reagent Pack, Colorimeter, Hydrogen Peroxide, 0-2.00 ppm

K-8023 Reagent Pack, Colorimeter, Sodium Chloride (Salt), 0-80 ppm

K-8024 Reagent Pack, Colorimeter, Alkalinity (total), 0-250 ppm

K-8027 Reagent Pack, Colorimeter, pH, 6.50-8.50

K-80 27AB Reagent Pack, Colorimeter, pH (with Acid & Base Demand), 6.50-8.50

K-8029 Reagent Pack, Colorimeter, Hardness (total), 0-500 ppm

K-8030 Reagent Pack, Colorimeter, Hardness (calcium), 0-800 ppm

K-8031 Reagent Pack, Colorimeter, Monopersulfate, 0-10.0 ppm

1-5TTi® Colorimeter User’s Manual

Page 16

Part 1 General Information

Colorimeter Reagent Packs (cont’d)

K-8032 Reagent Pack, Colorimeter, Cyanuric Acid, 7-120 ppm

K-8034 Reagent Pack, Colorimeter, Manganese, 0-0.80 ppm

K-8035 Reagent Pack, Colorimeter, Nitrate, 0-44 ppm

K-8040 Reagent Pack, Colorimeter, Biguanide, 0-70 ppm

Currently available reagent packs for the TTi® 3000 Colorimeter are listed below. Each pack contains an

instruction and all the reagents needed to run the specified test, housed in a snap-fit kit of ABS plastic.

Instructions and kits are sized to fit securely in the optional Hard Carrying Case (#9502). Alternatively, the

contents of the reagent packs may be transferred to your existing carrier.

Part Number Description

K-8001 Reagent Pack, Colorimeter, Chlorine (free/total), DPD (powder), 0-4.00, 0-8.0, or 0-10.0 ppm

K-8002 Reagent Pack, Colorimeter, Bromine (total), DPD (powder), 0-10.00 or 0-20.0 ppm

K-8003 Reagent Pack, Colorimeter, Molybdenum, 0-3.30 ppm

K-8004 Reagent Pack, Colorimeter, Phosphate, 0-70.0 ppm

K-8005 Reagent Pack, Colorimeter, Phosphate, 0-3.00 ppm (20-3000 ppb)

K-8006 Reagent Pack, Colorimeter, Polymer, 0-20 or 20-500 ppm

K-8007 Reagent Pack, Colorimeter, Silica, 0-60.0 ppm

K-8008 Reagent Pack, Colorimeter, Silica, 0-4.00 ppm

K-8009 Reagent Pack, Colorimeter, Iron, 0-4.00 ppm

K-8 010 Reagent Pack, Colorimeter, Iron (ferrous), 0-3.00 ppm

K- 8 011 Reagent Pack, Colorimeter, Iron (total), 0-0.300 ppm

K-8012 Reagent Pack, Colorimeter, Copper, 0-3.00 ppm

K-8013 Reagent Pack, Colorimeter, Copper (free), 0-0.200 ppm

K-8014 Reagent Pack, Colorimeter, Phosphonate, 0-30.0 ppm

K-8014-A C Reagent Pack w/ accessories, Colorimeter, Phosphonate, 0-30.0 ppm

K-8015 Reagent Pack, Colorimeter, Hydrazine, 0-1.50 ppm

K-8 016 Reagent Pack, Colorimeter, Oxygen Scavenger, 0-1.000, 0-0.700, 0-2.450, 0-2.000, 0-3.000 ppm

K-8017 Reagent Pack, Colorimeter, Manganese, 0-30.0 ppm

K-8018 Reagent Pack, Colorimeter, Boron, 0-2.00 ppm

K-8019 Reagent Pack, Colorimeter, Zinc, 0-3.00 ppm

K-8020 Reagent Pack, Colorimeter, Hydrogen Peroxide, 0-2.00 ppm

K-8021 Reagent Pack, Colorimeter, Nitrite, 0-150 ppm

K-8022 Reagent Pack, Colorimeter, Hardness (total), 0-4.00 ppm

K-8023 Reagent Pack, Colorimeter, Sodium Chloride (Salt), 0-80 ppm

K-8024 Reagent Pack, Colorimeter, Alkalinity (total), 0-250 ppm

K-8025 Reagent Pack, Colorimeter, Sulfide, 0-1.00 ppm

K-8026 Reagent Pack, Colorimeter, Hardness (calcium), 0-4.00 ppm

K-8027 Reagent Pack, Colorimeter, pH, 6.50-8.50

K-80 27AB Reagent Pack, Colorimeter, pH (with Acid & Base Demand), 6.50-8.50

K-8028 Reagent Pack, Colorimeter, Molybdenum, 0-60.0 ppm

K-8029 Reagent Pack, Colorimeter, Hardness (total), 0-500 ppm

K-8030 Reagent Pack, Colorimeter, Hardness (calcium), 0-800 ppm

K-8031 Reagent Pack, Colorimeter, Monopersulfate, 0-10.0 ppm

1-6 TTi® Colorimeter User’s Manual

Page 17

Part 1 General Information

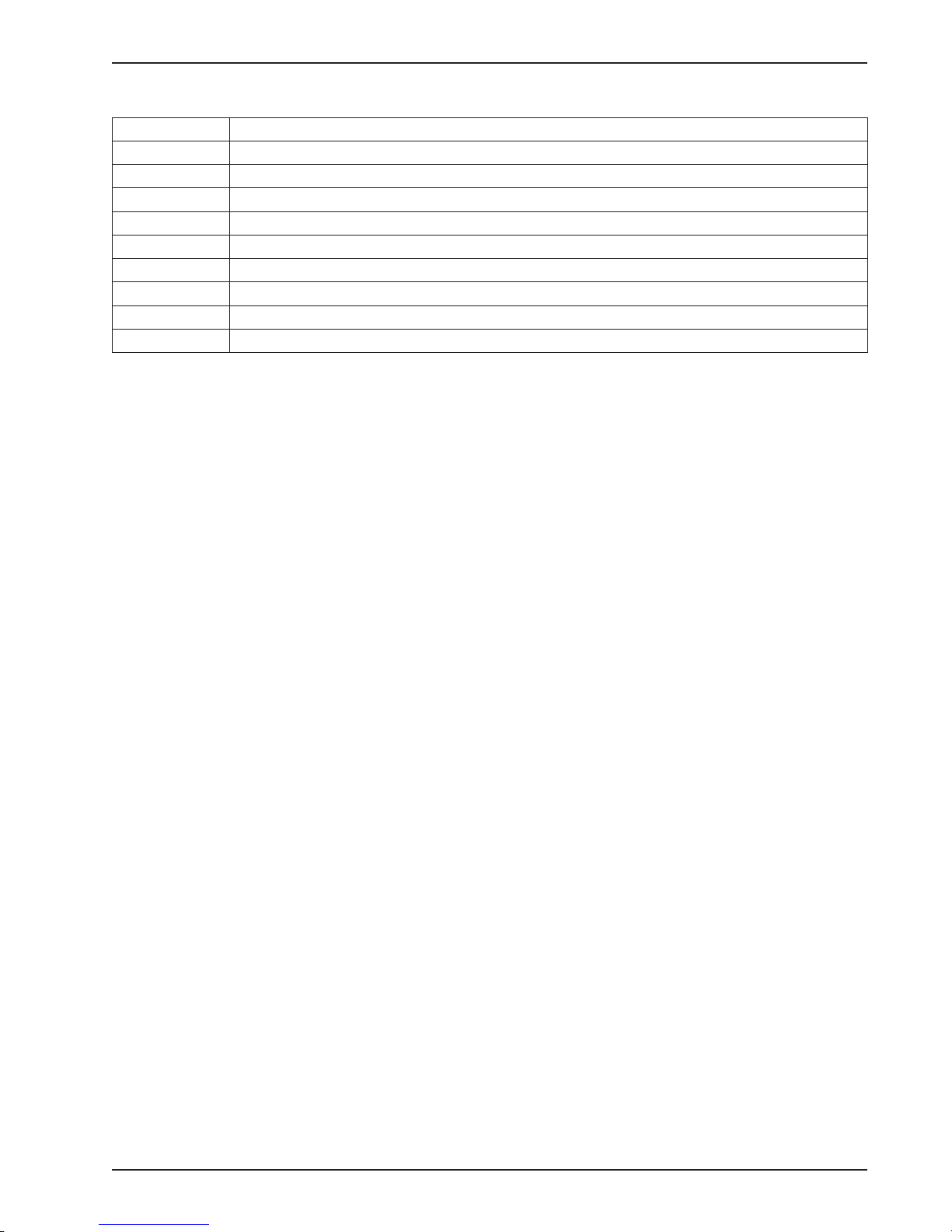

Colorimeter Reagent Packs (cont’d)

K-8032 Reagent Pack, Colorimeter, Cyanuric Acid, 7-120 ppm

K-8033 Reagent Pack, Colorimeter, Azole, 0-25.0 ppm

K-8033-AC Reagent Pack w/ accessories, Colorimeter, Azole, 0-25.0 ppm

K-8034 Reagent Pack, Colorimeter, Manganese, 0-0.80 ppm

K-8035 Reagent Pack, Colorimeter, Nitrate, 0-44 ppm

K-8036 Reagent Pack, Colorimeter, Turbidity, 10-400 FAU

K-8038 Reagent Pack, Colorimeter, Ammonia-Nitrogen, 0-1.00 ppm

K-8039 Reagent Pack, Colorimeter, Chlorine Dioxide, DPD, 0-8.0 ppm

K-8040 Reagent Pack, Colorimeter, Biguanide, 0-70 ppm

K-8041 Reagent Pack, Colorimeter, BlueTrace (6120), 0-10 mg/L

SUPPLEMENTARY TESTING SUPPLIES

4029 Pipet, Calibrated (0.5 & 1.0 mL), plastic

4078 Pipet, Graduated (3 mL w/ 0.5 mL div), plastic

9198 Sample Tube, Graduated (25 mL) w/ cap, plastic

96 01-3 Sample Cell, 25 mm, 3-pack

9602-3 Sample Cell, 15 mm, 3-pack

6649-4 Foam Brush, 4-pack

6656 UV Light, SteriPEN® (use with all tests requiring UV digestion)

9803 Syringe Filter Start-Up Pack (no filter discs), 60 mL, plastic (contains 6247, 6249, and instruction)

6247 Syringe Filter (no filter disc holder or filter discs), 60 mL, plastic

6260 Syringe Filter (no filter disc holder or filter discs), 30 mL, plastic

6249 Filter Disc Holder, 25 mm, Millipore™, (fits 6247 or 6260) use with filter discs 6261, 6248, 6257

6086-10

6261

6248

6257

6551 Dilution Vial, 50 mL w/ cap, plastic

Filter Discs (w/ individual filter disc holders), 0.45 µm, Millipore™, 10-pack

Filter Discs, 25 mm diameter, 0.45 µm, Millipore™, 100/box

Filter Discs, 25 mm diameter, 5.0 µm, Millipore™, 100/box

Filter Discs, 25 mm diameter, 2.5 µm, Whatman™, 100/box

REGISTRATION

To have full use of the TTi® Colorimeter’s features, you must first register as the owner of record. To begin the

process, go to www.taylorsoftwaresupport.com and enter the site through the TTi® Colorimeter portal. Be

prepared to enter the following information:

• Colorimeter serial number (S/N) - found on the product label on the bottom of the meter

• Owner’s (contact’s) name

• Business name

• Business mailing address

• Contact’s telephone number

• Contact’s e-mail – for notification about important news related to your meter model (e-mail addresses are

not shared with third parties)

Upon completion of the registration process, you will be able to download the TTi® Colorimeter Series PC App to

your computer. For complete information about this software, see Part 3, The PC App, and Part 4 in its entirety.

1-7TTi® Colorimeter User’s Manual

Page 18

CONTACTING TAYLOR TECHNOLOGIES

General Office: 410-472-4340

Our business hours are 8:00 a.m.–4:45 p.m. (Eastern Time), Monday through Friday,

except major holidays.

Customer Service: 800-TEST KIT (837-8548)

Customer service representatives are available 8:00 a.m.–5:00 p.m. for applicationspecific advice, to open an account, place an order, inquire about order status, or

report a problem with a shipment. If you require more advanced technical assistance,

your call or e-mail will be forwarded to the appropriate resource. You may also leave

us a voice-mail or e-mail message at anytime.

Exchanges and credits are only considered within 30 days of shipment. Please check

your order upon receipt and notify us immediately if there is any problem. To

assure the quality of our chemistries, we do not resell reagents returned to us. For this

reason they cannot be returned for credit, unless the reagents were shipped in error

by Taylor or their quality was compromised before they were shipped. To apply for an

exchange or credit under these mitigating circumstances, you will need to know the

lot number located on the lower left-hand corner of the reagent label.

Part 1 General Information

Technical 800-TEST KIT (837-8548)

Assistance: General assistance for TTi® Colorimeter owners is available Monday through Friday

from 8:00 a.m. – 4:45 p.m. Eastern Time, except major holidays, from Taylor Technologies’ customer service group by calling 800-TEST KIT (837-8548). Outside normal

business hours you may record a message for us by using the same toll-free number,

or you can leave an e-mail message using customerservice@taylortechnologies.com.

877-TEST KIT (837-8548)

Help specifically related to the TTi® Colorimeter Series PC App is available

9:00 a.m.–5:00 p.m. (Pacific Time), Monday through Friday (except major holidays),

from Taylor Technologies’ programmers. Online guidance may be found at

www.taylorsoftwaresupport.com. Enter through the TTi® Colorimeter portal.

E-mail: customerservice@taylortechnologies.com

Fax: 410-771-4291

Mailing Address: Taylor Technologies, Inc.

31 Loveton Circle

Sparks, Maryland 21152

USA

Corporate Website: www.taylortechnologies.com

Here you will find product descriptions, including test instructions, potential interferences, and Safety Data Sheets; video product demonstrations; high- and low-resolution

product photography; and articles of interest to water analysts. While online, you may

apply for an open-terms account, place an order, or post a question for our staff.

Software Website: www.taylorsoftwaresupport.com

This site is dedicated to supporting Taylor software products only. Enter through the

TTi® Colorimeter portal.

1-8 TTi® Colorimeter User’s Manual

2

Page 19

Part 2 Testing Primer

Testing Primer

Part 2

2-1T Ti® Colorimeter User’s Manual

Page 20

Page 21

Part 2 Testing Primer

INTRODUCTION TO COLORIMETRIC ABSORPTION ANALYSIS

Colorimetric absorption analysis, as used in this manual, refers to a technique for determining the concentration of various constituents of a water sample by adding reagents that selectively react with the substance being

analyzed to produce a color then measuring the absorbance of the resulting color to determine the substance

concentration.

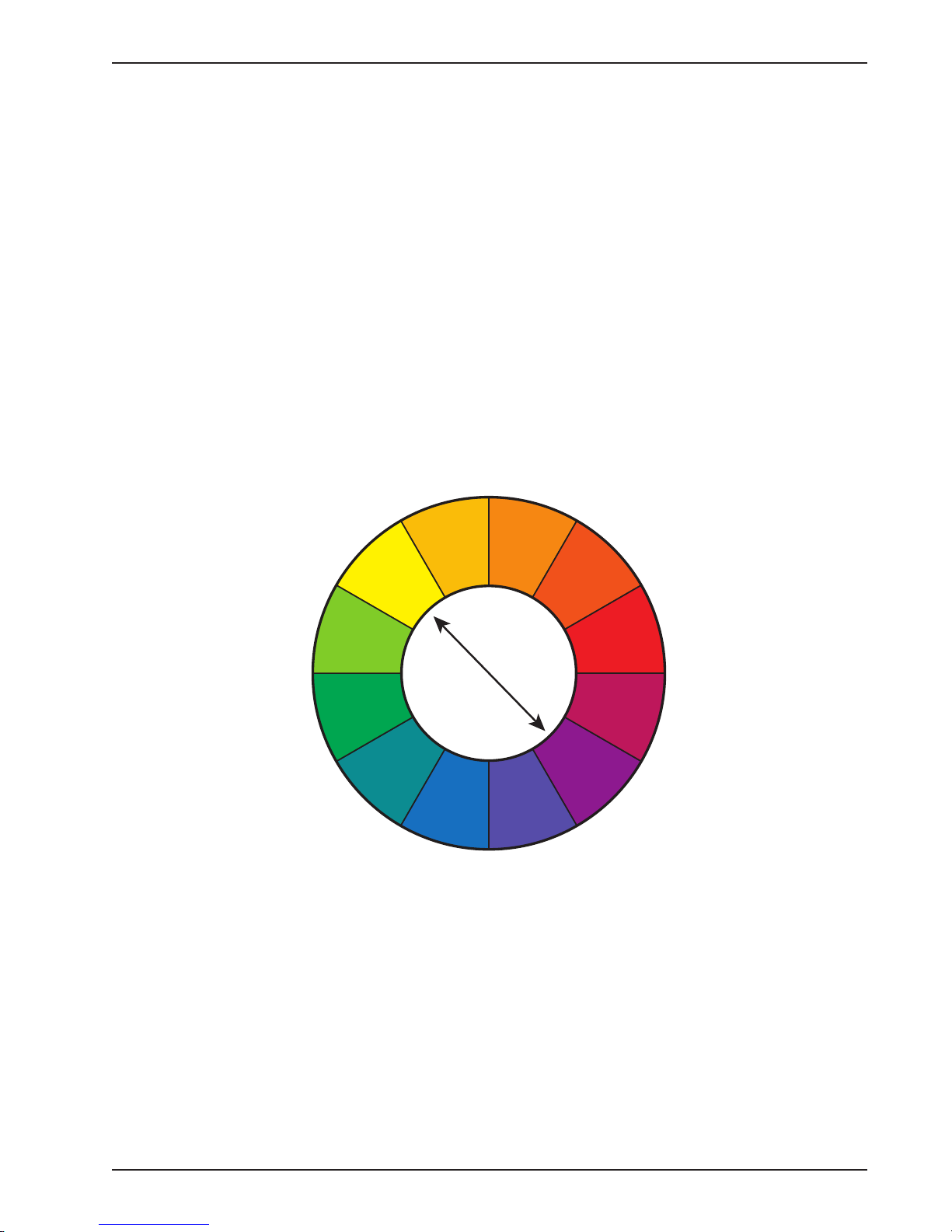

Visible light (as opposed to ultraviolet, infrared, etc.) is a type of electromagnetic radiation that can be seen

by the human eye. It consists of wavelengths ranging from approximately 400 to 700 nm. When visible light

passes through a colored solution, certain wavelengths are selectively and strongly absorbed while other

wavelengths pass through without being absorbed. This principle of absorption provides a means for quantification based on the Beer-Lambert Law, which states the concentration of a substance in solution is directly

proportional to both the absorbance and viewdepth of the solution. It is interesting to note the wavelengths

strongly absorbed by a colored solution correspond to colors which are complementary to the color of the

solution. For example, a yellow solution strongly absorbs violet wavelengths, a blue solution strongly absorbs

orange wavelengths, and a red solution strongly absorbs green wavelengths. Many substances in water samples

are colorless, so reagents must be added that selectively react with the analyte to produce a color that will

absorb specific wavelengths of visible light.

Illustration of complementary colors on a color wheel

YELLOW

GREEN

GREEN

YELLOW

BLUE

GREEN

YELLOW

ORANGE

BLUE

ORANGE

BLUE

VIOLET

RED

ORANGE

VIOLET

RED

RED

VIOLET

Taylo r’s T Ti® Colorimeter is an optical instrument for colorimetric absorption analysis which incorporates

light-emitting diodes (LEDs) to produce visible light, wavelength filters to isolate narrow bands of light that

pass through the sample, photoelectric detectors to convert light that passes through the sample into a useable

signal, a signal processor, and software to determine the concentration of a sample. In general, to perform an

instrumental absorption analysis, the instrument is first ZEROED with a blank (usually a sample containing

no reagents) to compensate for inherent color in the sample. Next, a sample containing all necessary reagents

is READ and the concentration is computed and displayed.

BEST PRACTICES

Proper technique is essential for obtaining accurate results when performing a water test. False test results can

lead the analyst into making an incorrect evaluation of the condition of the water, thereby applying the wrong

corrective actions to a system. The following practices will help you obtain reliable test results.

2-3TTi® Colorimeter User’s Manual

Page 22

Part 2 Testing Primer

SAMPLING

• Use dedicated sample bottles. These bottles should be labeled as such and not used for another purpose.

• Use a sample bottle of sufficient size. If too small, you will not have enough water to perform multiple

tests.

• Rinse the sample bottle and cap well (we recommend three times) with deionized water, distilled water, or

sample water.

• Take a sample that is representative of conditions in the whole system:

Closed Systems - Let the sample stream flow at a constant velocity for at least five minutes before beginning the collection process. If you blow out the line with a higher-than-normal flow, subsequently be sure

to reduce the flow to the normal rate for five minutes before proceeding with sampling.

Open Systems - Chemistry at the surface is atypical as the water is interacting with the air above and

oils and debris may be present. Samples taken near return lines, makeup water inlets, chemical feeders,

or in corners also can be different than in the body-at-large since the water may not have experienced the

same mixing action as in open areas. A sample taken downstream from a tributary or pollution source

will be different from a sample taken upstream. With these considerations in mind, select a representative

location, immerse the sample container bottomside up to about elbow depth, and then turn the container

upright to fill.

• Fill the sample bottle to overflowing. Do not leave any room for air in the bottle.

• Avoid contaminating the sample once collected. Immediately cap the bottle tightly to avoid contamination.

• Do not put any probe into a bottle of sample water that will be used for multiple tests.

• Do not let the sample sit before testing, or it may change its character. Boiler water samples that should be

at room temperature when beginning the test should be promptly cooled in a cold water bath to between

80°F– 90°F (27°C–32°C).

• Dispense sample water into the sample cell until the lowest point of the meniscus sits on the correct fill

mark when viewed at eye level.

• After a sample cell has been filled and capped, hold it by the cap and then wipe off any moisture or

fingerprints on the glass using a clean, lint-free cloth.

FILTERING SAMPLES

Unless otherwise specified, test methods are designed to determine dissolved substances in water samples.

If samples are turbid they may contain suspended solids, algae, or other substances that may interfere in the

test procedure. We recommend using a 0.45 µm membrane filter disc in a syringe-type filter to remove these

substances prior to testing.

DILUTING SAMPLES

Some test procedures specify diluting a sample to adjust the concentration of the analyte to fit the range of

the test. In such cases, the instruction will provide all details for performing the procedure with the dilution

vial supplied with the kit. When a test sample is diluted, the result displayed must be multiplied by a factor

to obtain the concentration of the undiluted analyte. This multiplication factor will be specified in the test

instruction.

Sample dilution also may be required even if a this procedure is not specified in the test instruction. When the

test result is above RANGE, the sample must be diluted using high-purity water and the dilution vial supplied

with the kit. See example display, following.

2-4 TTi® Colorimeter User’s Manual

Page 23

Part 2 Testing Primer

Illustration of above RANGE alert signaling dilution is necessary

Start with a small dilution and continue to increase the dilution as necessary to bring the concentration of the

analyte into the range of the test. (NOTE: Sample dilution should not be performed when testing pH or after

reagent addition, only before reagent addition.) The following table can be used as a guide.

Sample High-Purity Water Multiplication Factor

Add this volume of

sample to the dilution vial

33 mL 17 mL 1.5

25 mL 25 mL 2

10 mL 40 mL 5

5 mL 45 mL 10

2 mL 48 mL 25

Add this volume of high-purity water to the

dilution vial, cap, and mix thoroughly. Retest this

diluted sample according to the test instructions.

If the test result is now within the range of the test, multiply the result by the multiplication factor listed below to

determine the concentration of the analyte in the undiluted

sample. If the test result is still above RANGE, increase the

dilution and retest.

PRETREATING SAMPLES

Some samples may require digestion in order to test for total metals. To perform a digestion, rst

reduce the sample volume by gently heating and then reuxing to ensure all organometallic bonds

have been broken. Allow the sample to cool and then dilute to a specied volume with deionized

water. Sample digestion will require the following materials:

• ASTM Type I water

• Beaker, 250 mL

• Graduated cylinder, 100 mL

• Hotplate or steam bath

• Hydrochloric acid (high-purity grade)

• Hydrochloric acid solution 1:1

Add 50 mL hydrochloric acid (high-purity grade) to 40 mL ASTM Type I water. Dilute to 100 mL with

ASTM Type I water.

• Nitric acid (high-purity grade)

• Nitric acid solution 1:1

Add 50 mL nitric acid (high-purity grade) to 40 mL ASTM Type I water. Dilute to 100 mL with

ASTM Type I water.

• Ribbed watch glass, 75 mm

• Volumetric flask, 100 mL

• Watch glass, 75 mm

2-5TTi® Colorimeter User’s Manual

Page 24

Part 2 Testing Primer

Procedure:

1. Acidify entire sample using nitric acid solution 1:1 to a pH of less than 2.0. Mix well and let sit for 16

hours. Do not filter sample to remove insoluble materials.

2. Transfer 100 mL of acidified sample water to 250 mL beaker.

3. Working inside a fume hood, add 2 mL nitric acid solution 1:1 and 1 mL hydrochloric acid solution 1:1.

4. Place beaker on hotplate inside a fume hood and cover with ribbed watch glass.

5. Turn on hotplate and evaporate sample to approximately 20 mL being careful not to allow sample to

boil. (This step should take approximately 2 hours.)

6. Carefully remove ribbed watch glass and replace with smooth watch glass.

7. Continue heating and gently reflux sample for 30 minutes. Slight boiling may occur, but avoid vigorous

boiling.

8. After 30 minutes turn off hotplate, carefully remove beaker, and allow beaker to cool to room temperature.

9. Quantitatively transfer sample to 100 mL volumetric flask and dilute to the mark with ASTM Type I

water. Mix well. If insoluble materials remain, the sample may be filtered being careful not to introduce

contamination to the sample.

10. The sample is now ready for testing.

ADDING AND MIXING REAGENTS

A reagent is added to sample water using a dropper bottle with a precisely bored tip, a pipet, or a dipper spoon.

To assure the correct amount of liquid reagent is added to the sample when using a dropper bottle, hold it vertically when dispensing, not at a slant. If static builds up at the dropper tip making the drop size progressively

smaller, eliminate the static by wiping around the tip with a clean, damp cloth or paper towel. When using

a pipet, fill the pipet to the correct mark; then be sure to dispense the entire contents into the sample. When

using a dipper spoon, a gentle tapping action against the rim of the sample cell may be required to dislodge all

the powdered reagent. Cap the sample cell and then swirl the contents, using wrist action, to assure thorough

mixing. Do not shake or invert the sample cell unless specified in the test instruction.

Observe the following precautions:

• To prevent contamination, cap reagents tightly immediately after use and be careful not to exchange bottle

caps.

• Do not substitute another manufacturer’s reagents for Taylor’s.

• Replace reagents that are more than a year old.

• Wipe off spills and soil on the Colorimeter’s exterior with a soft, damp cloth as soon as possible.

• Remove stray fluid from the sample cell compartment with a clean cotton swab.

STORING REAGENTS

Reagents are perishables. The chemicals used with the TTi® Colorimeter will degrade over time, even under

optimum conditions. The process of deterioration speeds up when storage conditions are not ideal. Extremes

of heat and cold, as well as prolonged exposure to air, sunlight, humidity/moisture, and volatile treatment

chemicals, will diminish their useful life.

To preserve freshness, make sure reagent containers are kept tightly closed. When in storage, reagents do best

in a cool, dark place away from drums and bags of treatment chemicals, especially chlorine and bromine. If

you must choose between a hot warehouse (or vehicle trunk) and the refrigerator, opt for the latter for longerterm storage. Keeping reagents in the refrigerator will prolong shelf life; however, once they are taken out, they

2-6 TTi® Colorimeter User’s Manual

Page 25

Part 2 Testing Primer

should be used because subjecting them to constant fluctuations in temperature will cause them to degrade

faster. Ideal storage temperatures are between 36°F–85°F (2°C–29°C), preferably in an environment without

big temperature swings.

Generally speaking, a reagent’s suitability for testing is suspect if it is over one year old, if it is not its usual

color, if there are floating particles that do not dissolve when shaken, if it has begun to stain its container, or if

it has crusted around the tip of the dropper bottle.

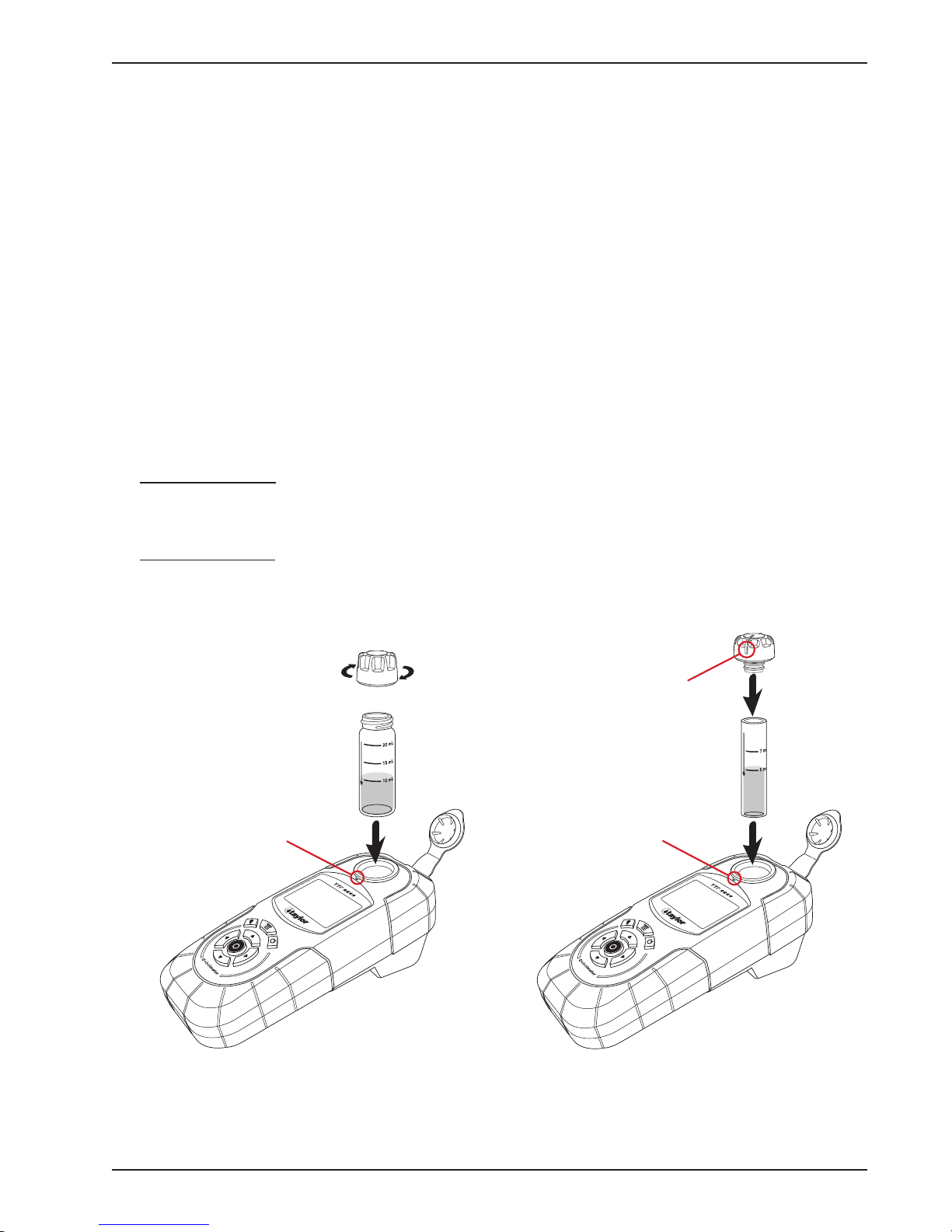

INSERTING AND ALIGNING SAMPLE CELLS

Taylor test procedures use either a 25 mm or 15 mm viewdepth sample cell, depending on which provides the

best combination of sensitivity and useable range. The 25 mm sample cell has greater viewdepth and employs

a screw thread cap. The 15 mm sample cell has less viewdepth and employs a plug cap. Test instructions specify

which sample cell to use.

For the most accurate result, align the sample cell correctly when inserting it in the sample cell compartment.

High-quality sample cells are supplied for use with the instrument but even minor variations in wall thickness

or diameter can cause slight variations in results if sample cells are not inserted in a consistent manner. Use the

following techniques to insert and align the 25 mm and 15 mm sample cells into the sample cell compartment:

25 mm Sample Cell - Partially insert the sample cell into the sample cell compartment. Align the arrow

on the sample cell with the notch on the meter; then gently push the sample cell down (without rotating)

until it rests on the base of the sample cell compartment.

15 mm Sample Cell - Align the raised line on the sample cell cap with the arrow on the sample cell. Insert

the sample cell into the sample cell compartment and align the raised line on the sample cell cap with the

notch on the meter.

raised line

25 mm Sample Cell

notch

15 mm Sample Cell

notch

2-7TTi® Colorimeter User’s Manual

Page 26

Part 2 Testing Primer

PERFORMING A TEST

• Carefully read test instructions before beginning a test. Instructions may change from time to time so it is

particularly important to review the procedure each time a reagent pack is purchased.

• Follow procedure exactly.

• For proper sample volume, be sure the low point of the meniscus sits on the correct fill mark when viewed

at eye level.

• Hold reagent bottles vertically when dispensing liquids.

• Add the precise amount of reagent specified.

• Before inserting a sample cell into the sample cell compartment, hold the sample cell by the cap and wipe

off any moisture or fingerprints on the glass using a clean, lint-free cloth.

• During operation, place the TTi® Colorimeter on a stable surface that is reasonably level. When using it as

a handheld device, keep the meter horizontal.

• Compare your results with the previous results from the sampling location. Do the results make sense?

If you get an inexplicable result, take a new sample and retest. We recommend graphing your data with

statistical process control software to facilitate comparisons.

CLEANING SAMPLE CELLS

Sample cells must be clean inside and out as well as scratch-free to prevent optical interference in the test

procedure.

• Use the foam brush (supplied) or a soft, nonabrasive cloth and water or mild detergent. Rinse thoroughly

with deionized or distilled water. NOTE: Test methods may recommend additional cleaning procedures.

• At least once a week, clean all sampling containers and sample cells with a 1:1 solution of hydrochloric

acid (Taylor reagent R-1305J) and high-purity water.

• Upon completing a test, flush out the sample cell with fresh sample water to avoid having residual

contaminate the next test.

2-8 TTi® Colorimeter User’s Manual

3

Page 27

Part 3 Colorimeter Operation

Part 3

Colorimeter

Operation

3-1TTi® Colorimeter User’s Manual

Page 28

Page 29

Part 3 Colorimeter Operation

THE PC APP

To use the TTi® Colorimeter to the fullest extent possible, it is necessary to install a special free software

application on your computer. This TTi® Colorimeter Series PC App is required to perform the following

functions:

• Transfer test results from the meter to the customer database you maintain on your PC or laptop

• Keep the meter’s operating software (i.e., firmware) up to date

• Obtain new and improved test files to add to your meter’s capabilities

• Access helpful links for further information and assistance

• Create proprietary (i.e., user-developed) test files

See Part 1, Registration, and Part 4 for complete information.

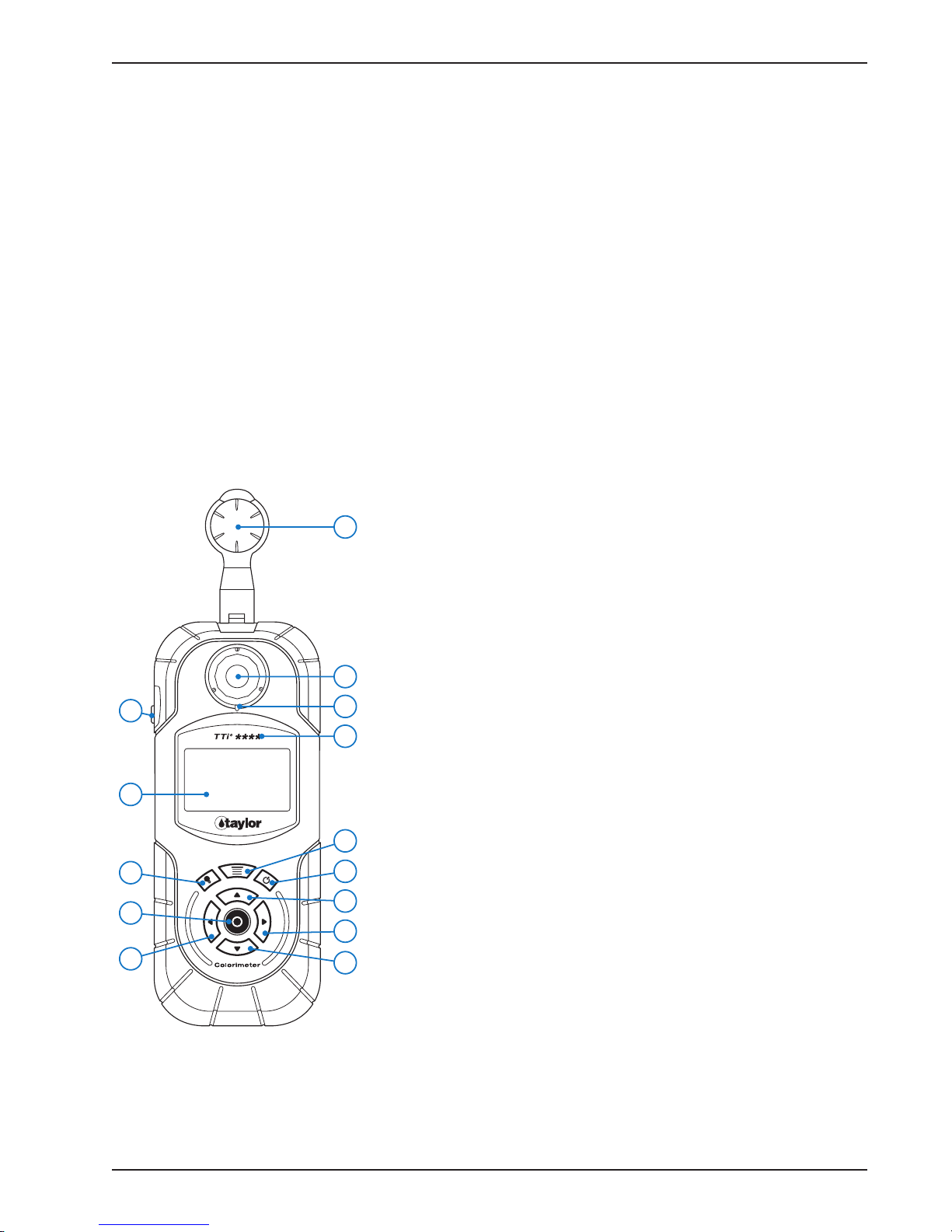

GUIDE TO OPERATING PARTS AND CONTROLS

Review the following illustrations to become familiar with parts and operating controls.

10

Top Vi ew

Top View

1. Power Button

14

2. Main Menu Button

3. Backlight Button

4. Enter Button, to enter the highlighted function

5. Scroll Up Arrow

6. Scroll Down Arrow

7. Scroll Right Arrow

12

13

11

8. Scroll Left Arrow

9. Liquid Crystal Display

10. USB Port Cover

11. Model Number

9

12. Sample Cell Compartment (shown open)

13. Alignment Notch

2

3

4

1

5

7

14. Sample Cell Compartment Cover

8

6

3-3TTi® Colorimeter User’s Manual

Page 30

Part 3 Colorimeter Operation

Bottom View

7

6

Side View

1

2

Bottom View

1. Product Label, shows model, part, and serial

3

numbers.

2. Timer Buzzer Opening

4

3. Battery Compartment Door Screw, total of 4

4. Battery Compartment Door

5

5. Battery Compartment (shown open)

Side View

6. USB Port (shown open)

7. USB Port Cover

BATTERY INSTALLATION/CONNECTION TO A POWER SUPPLY

The instrument can be powered by batteries, an AC power adapter, or a USB cable, described respectively as

Options A, B, and C below. Use Option A to replace the batteries, as well.

Option A - Battery Installation/Replacement

Turn the instrument off. Remove the battery compartment door and insert 4 AA alkaline (supplied) or lithium

batteries by matching the + and – ends on the batteries to the markings inside the battery compartment.

Replace the battery compartment door.

Replace batteries when the battery status icon indicates a low-battery status or when directed by an error code.

The battery status icon is displayed in the title bar on all screens when the instrument is powered by batteries.

To conserve battery life, adjust the following settings (see Part 3, Settings) to the lowest acceptable option:

• Device Timeout

• Backlight Timeout

• Backlight Level

• Adjust Contrast

3-4 TTi® Colorimeter User’s Manual

Page 31

Part 3 Colorimeter Operation

Option B - AC Power Adapter

Turn the instrument off. Connect the AC power adapter (supplied) to the USB port (located under the USB

port cover); then plug the AC power adapter into a 120V AC wall outlet. Always turn the instrument off

before disconnecting the AC power adapter.

Option C - USB Cable

Turn the instrument off. Connect the USB cable (supplied) to the USB port (located under the USB port cover);

then connect the USB cable to the corresponding USB port on a PC or laptop. Always turn the instrument

off before disconnecting the USB cable.

Option BOption A Option C

Colorimeter

Wall

USB Port

AC Power

Adapter

PC or Laptop

Colorimeter

USB Cable

KEYPAD

The 8-button keypad is designed for intuitive, rapid navigation. Silicone rubber enhances the user’s touch

perception. A custom coating provides resistance to chemical swelling and wear in a wide variety of environments.

Button Function

2

Keypad

3

4

8

1. Power Button Turns instrument On/Off

2. Main Menu Button Accesses Main Menu at any time

1

during operation

3. Backlight Button Turns display backlight On/Off

4. Enter Button Enters highlighted function on

5

display

5. Scroll Up Arrow Scrolls up through menus, selected

7

options, and data

6. Scroll Down Arrow Scrolls down through menus,

selected options, and data

7. Scroll Right Arrow Scrolls right through title bar, main

6

window, and footer options.

8. Scroll Left Arrow Scrolls left through title bar, main

window, and footer options.

3-5TTi® Colorimeter User’s Manual

Page 32

Part 3 Colorimeter Operation

DISPLAY

Display

The graphical liquid crystal display (LCD) provides excellent

viewing contrast and readability. An integrated backlight can

be set at either a 50% or 100% brightness level to provide easy

reading in low-light or no-light environments, and an adjustable

timeout feature can be utilized to conserve battery life. The

LCD is covered by a protective plastic window. An abrasion- and

chemical-resistant coating combined with an anti-glare coating

provide superior wear and chemical resistance while minimizing

surface glare.

NOTE: The protective plastic window has a temporary film

covering to provide additional scratch protection during

transit. Upon first use, this film should be gently peeled off

to provide maximum viewing clarity.

SCREEN FORMAT AND NAVIGATION

There are three designated sections of the screen where icons, menus, symbols, options, etc., are displayed.

These sections include the title bar (located at the top of the screen), the main window (located in the middle

of the screen), and the footer (located at the bottom of the screen). Screens may or may not contain all three

sections.

Screen navigation is simple and intuitive. The MAIN MENU button and the , and arrows are

used to access and navigate through all screens. The ENTER button is used to enter highlighted functions.

SCREEN SECTIONS

Title Bar

Identifies each screen, displays active icons and options. The

arrows on the keypad are used to scroll between options in the title

bar.

Main Window

Displays menus (lists), test information, symbols, and options. The

, and arrows on the keypad are used to scroll through

menus and between options in the main window.

Footer

Displays options. The arrows on the keypad are used to scroll

between options in the footer.

Title Bar

Icons

Main Window

Footer

Following are examples of various screen formats displayed when using the instrument. NOTE: Symbols for

directional arrows and and the ENTER button appear in test instructions, too.

3-6 TTi® Colorimeter User’s Manual

Page 33

Part 3 Colorimeter Operation

EXAMPLE 1

Title Bar + Main Window Sections

The title bar shows the screen name (ALL TESTS). Use the

arrows to scroll between options in the title bar. The battery status

icon is displayed.

The main window shows tests that are available in the ALL TESTS

screen. Use in combination with the highlight on the display to

select a test. All main window menus use a continuous scroll to

the end of the menu. When scrolling, the highlight starts at the top

of the menu and travels to the bottom. The highlight then remains

at the bottom as the menu travels up the screen. At the end of the

menu, the screen pages back to the beginning of the menu with

the first item highlighted. NOTE: You can access the bottom of a

list by scrolling up on any initial screen.

EXAMPLE 2

Title Bar + Main Window + Footer Sections

The title bar shows the screen name (TEST). The AC (Adjust

Calibration), timer, and battery status icons are displayed.

The main window shows test information (test name and upper

range, chemical form, test result, and units).

The footer shows four test options (ZERO, READ, TIMER, NEW).

Use the arrows on the keypad to scroll between options or to

access more options.

EXAMPLE 3

Title Bar +Main Window Sections

The title bar shows the screen name (TEST). The battery status

icon is displayed.

The main window shows a test procedure transition. This

animated graphic is displayed during a test procedure when the

instrument is zeroed. This type of screen format is used for

transitions, warnings, and errors. Text is displayed in the main

window, often with accompanying graphics. An animated graphic

is used when ZEROING the instrument and READING samples.

3-7TTi® Colorimeter User’s Manual

Page 34

EXAMPLE 4

Title Bar + Main Window + Footer Sections

The title bar shows the SET DATE screen. The battery status icon

is displayed.

The main window shows the date format and SET DATE prompt.

Use the , arrows on the keypad to set the date. This type

of screen format is used for setting the date and time. The left and

right scroll arrows move to the next unit, while the up and down

scroll arrows select the character. The numbers are highlighted

upon entering the screen.

The footer shows the OK option. After setting the date, OK is

selected.

ICONS AND SYMBOLS

ICONS

Part 3 Colorimeter Operation

AC (Adjust Calibration)

Displayed in the title bar when the test result has been adjusted to agree with a prepared standard. The adjusted calibration

icon will remain on for that specific test unless turned off by the user. The next time that specific test is selected from the

test menu, the adjust calibration icon will remain on.

Timer

Displayed in the title bar when the timer is started in a Taylor- or user-developed test. While the timer is running, the icon

will flash. When the timer expires, the icon will remain solid until a key is pressed, at which point it will be turned off. This

icon is not enabled or disabled by the User Timer, located in Tools.

Battery Status

Displayed in the title bar when the instrument is powered by batteries. Informs user how much power is remaining (3 bars

indicate a full charge; 0 bars indicate a very low charge).

USB

Displayed in the title bar when the instrument is powered by USB.

SYMBOLS

Action

Information

Indicates an action operation

Indicates relevant information

Error

Warning (flashing)

Sample Cell

3-8 TTi® Colorimeter User’s Manual

Indicates an operational error

Indicates an operational warning

Indicates sample cell viewdepth used in a test

Page 35

Part 3 Colorimeter Operation

MAIN MENU

The MAIN MENU contains six top-level options. It can be accessed anytime during operation by

pressing the MAIN MENU button on the keypad.

TOP LEVEL OPTIONS

Start Test

Select to access FAVORITES, RECENT TESTS, or ALL TESTS

menus. After initial start-up, the program will always open on the

current test menu.

Access Test Data

Select to recall or erase test data. The instrument will store the

results of the last 100 tests performed.

Edit Favorites

Select to create or edit (add, remove, sort) a Favorites menu to

establish a testing shortcut and save time when selecting tests.

A total of 120 Favorite tests can be created and arranged in any

order.

Edit Series

Select to create or edit (add, remove, sort) a Series test that allows

selected tests to be performed in rapid succession. A total of 10

Series tests can be created and arranged in any order. Each series

can encompass as many as 25 individual tests.

Too ls

Select to transfer data to a PC or laptop, update firmware and test

files, create user-developed tests using the TTi® Colorimeter

Series PC App, and to access the user timer to set an audible timer

for general purposes. The user timer beep can be distinguished

from the test timer beep. Both timers can run simultaneously.

Settings

Select to access About (displays current Firmware, Test File, and

Bootloader Versions), or to modify instrument settings (Format

Date, Set Date, Format Time, Set Time, Device Timeout, Backlight

Timeout, Backlight Level, Adjust Contrast, Language, and Factory

Restore).

3-9TTi® Colorimeter User’s Manual

Page 36

Part 3 Colorimeter Operation

TEST MENUS

Three separate test menus are available in the test mode (Start Test), namely ALL TESTS, RECENT TESTS,

and FAVORITES. Details are provided below. Use to select between menus. Menu priority is FAVORITES,

RECENT TESTS, and then ALL TESTS as long as one test resides in a menu. After initial start-up, the program

will always open in the current test menu.

THREE KINDS OF TEST MENUS

ALL TESTS

The ALL TESTS Menu contains all preprogrammed Taylor tests including absorbance and transmittance. In addition, all series tests,

user-developed tests, and test file updates will be stored in the ALL

TESTS Menu.

ALL TESTS GROUPING

• Preprogrammed Taylor tests in alphanumeric order

• Series tests in numeric order (see Part 3, Edit Series)

• Reserved tests (Absorbance and Transmittance; see Part 3,

Absorbance and Transmittance Tests)

• User-developed tests in alphanumeric order (see Part 3, UserDeveloped Tests)

RECENT TESTS

The RECENT TESTS menu contains the 10 most recent tests

performed.

RECENT TESTS GROUPING

The last test performed is moved to the top of the menu.

RECENT TESTS EMPTY

Displayed when the RECENT TESTS Menu is empty. This menu

can only be emptied by performing a Factory Restore (see Part 3,

Settings).

3-10 TTi® Colorimeter User’s Manual

Page 37

Part 3 Colorimeter Operation

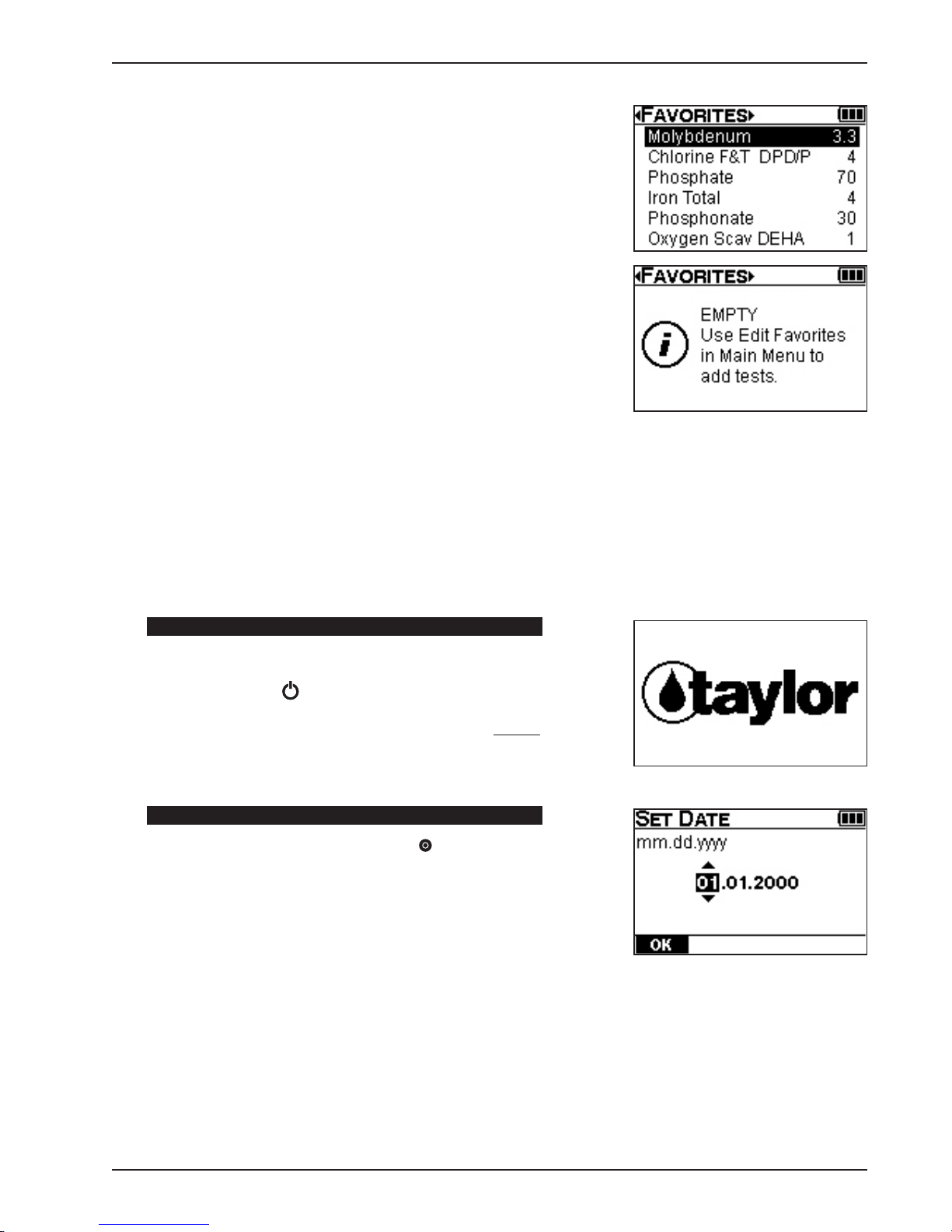

FAVORITES

The FAVORITES menu contains only tests added by the user (see

Part 3, Edit Favorites). A maximum of 120 favorites can be added.

FAVORITES GROUPING

Tests may be arranged in any order.

FAVORITES EMPTY

Displayed when the FAVORITES menu is empty.

INITIAL START-UP

Initial start-up consists of setting the date and time to allow the instrument to store, recall, and transfer test

data with the correct date and time stamps. It is performed the first time the instrument is turned on and after

a factory restore (see Part 3, Settings). Before initial start-up is performed, install the batteries or connect the

instrument to a power supply (see Part 3, Battery Installation/Connection to a Power Supply).

STEP 1

Turn on the Colorimeter.

Press POWER button for approximately 0.5 seconds.

The Taylor logo is displayed while the instrument performs start-up

tasks.

STEP 2

Set Date using , ; then press ENTER .

The default format for the date is mm.dd.yyyy. To change to

dd.mm.yyyy format, see Part 3, Settings.

Footer Option: OK

Accepts changes. Goes to the SET TIME screen.

3-11TTi® Colorimeter User’s Manual

Page 38

STEP 3

Set Time using , ; then press ENTER .

The default time is 12-Hour format. To change to 24-Hour format,

see Part 3, Settings.

Footer Option: OK

Accepts changes. Goes to the MAIN MENU screen.

Initial start-up completed.

The MAIN MENU screen is displayed.

Part 3 Colorimeter Operation

START TEST

Select Start Test to access the ALL TESTS, RECENT TESTS, and FAVORITES test menus and begin testing.

Instructions supplied with Taylor’s reagent packs provide all the information required to perform the particular

test. In general, the following steps are required:

• Select a test menu (ALL TESTS, RECENT TESTS, or FAVORITES) that contains the test to be

performed.

• Select the test from the test menu.

• Confirm test selection and sample cell size, and select a chemical form for expression of test results.

• Prepare a blank and ZERO the Colorimeter.

• Prepare sample and observe any timing steps.

• READ the sample.

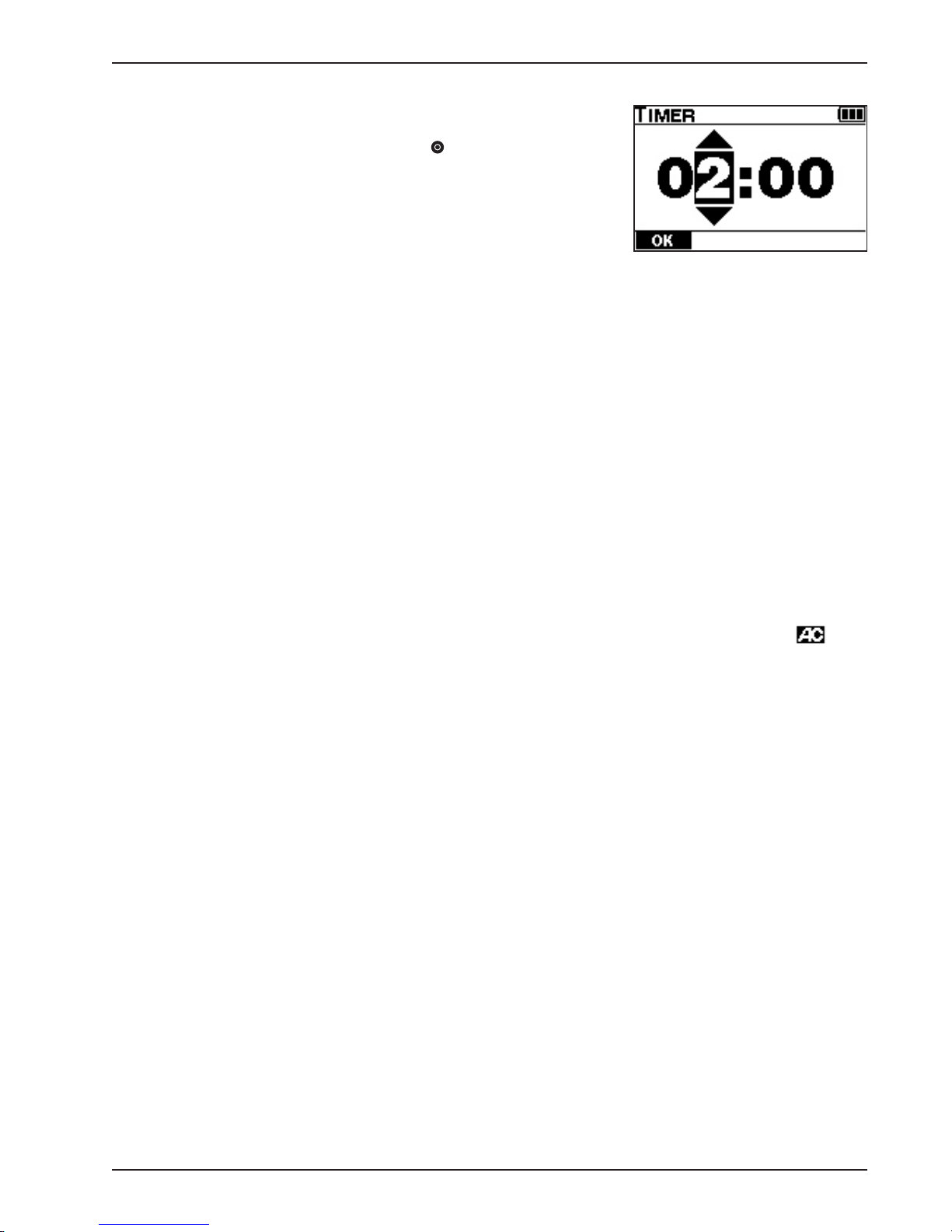

HOW TO PERFORM A TEST

The following example provides detailed information about test screens and test options while showing you

how to perform a test.

STEP 1

Select Start Test from the MAIN MENU using ; then press

ENTER .

NOTE: After initial start-up has been performed, the program will

skip the MAIN MENU and open in the current test menu when the

instrument is turned on.

3-12 TTi® Colorimeter User’s Manual

Page 39

Part 3 Colorimeter Operation

Select a Test Menu (ALL TESTS, RECENT TESTS, or FAVORITES)

containing the test to be performed using .

STEP 2

Select the test from the test menu using ; then press

ENTER .

STEP 3

Confirm test name and range, and sample cell size.

The test name, range, and sample cell size will be displayed.

Test name and range (or range upper limit).

Sample cell size (sample cell graphic, size, and unit).

AND

Select a chemical form for expression of test results using .

Optional chemical forms are available for most tests and can only

be selected on this screen. If available, will appear to the right

of the chemical form displayed. The test range (or range upper

limit) will change to correlate with the selected chemical form. The

selected form will remain the default for that test until changed

again by the user.

3-13TTi® Colorimeter User’s Manual

Page 40

STEP 4

Prepare blank.

A blank is used to ZERO the instrument and establish a reference

point for reading samples. A blank may or may not contain reagents

depending on specific test requirements. Instructions supplied with

each test will describe how to prepare the blank.

Here is a typical procedure for preparing a blank:

• Rinse and fill 25 mm sample cell to 10 mL mark with sample;

then cap.

• Insert sample cell into sample cell compartment. Align marks.

STEP 5

Part 3 Colorimeter Operation

Align ar row on

sample cell with

notch on meter.

Zero the Colorimeter.

Select ZERO using ; then press ENTER .

The ZEROING transition graphic will be displayed; then zero (0.00

for this example) will be displayed.

This zero reference point will be stored for all subsequent readings

until the test is exited. The instrument can be re-zeroed at any time

during the test procedure.

3-14 TTi® Colorimeter User’s Manual

Page 41

Part 3 Colorimeter Operation

STEP 6

Prepare sample.

Sample preparation varies for each test. Samples may need to be

filtered to remove turbidity or diluted to adjust the concentration

into a range that can be analyzed by the instrument. There may be

specific techniques or timing steps required for reagent addition.

Instructions supplied with each test specifically describe how to

prepare samples.

Here is a typical procedure for preparing a sample:

• Remove sample cell from sample cell compartment; then remove

cap.

• Add test reagents. Replace cap and swirl to mix thoroughly.

• Insert sample cell into sample cell compartment. Align marks.

Align

arrow on

sample

cell with

notch on

meter.

STEP 7

Read the sample.

Select READ using ; then press ENTER .

The READING transition graphic will be displayed and the instrument

will read the sample and display the result.

RESULT will be displayed in terms of the selected chemical form.

Re-zero/read more samples:

Select ZERO using ; insert blank; then press ENTER .

Select READ using ; insert sample; then press ENTER .

Return to current test menu:

Select NEW using ; then press ENTER .

3-15TTi® Colorimeter User’s Manual

Page 42

Result above or below range of test:

When the result is above or below the range of the test, either

↑

RANGE or ↓ RANGE will be displayed (see Part 3, Test Alerts).

Footer Options: Select using ; then press ENTER .

ZERO

Zeros the instrument on a blank and displays zero.

Part 3 Colorimeter Operation

READ

Reads the sample and displays a result.

TIMER

Goes to a preprogrammed timer if specified in the test procedure.

Goes to a nonprogrammed timer that can be set by the user if a

timing step is not specified in the test procedure. (See Part 3, Test

Timers and Auto-Read Option.)

NEW

Ends test and returns to the current test menu.

AC

Goes to the Adjust Calibration screen and turns on the Adjust

Calibration feature (see Part 3, Adjust Calibration).

AC/OFF

Turns off the Adjust Calibration feature. Only available if AC is

currently on (see Part 3, Adjust Calibration).

NEXT

Continues to the next test in a Series Test (see Part 3, How to

Perform a Series Test).

PREV

Returns to the previous test in a Series Test (see Part 3, How to

Perform a Series Test).

WL

Returns to the wavelength selection screen when in the

Absorbance and % Transmittance modes (see Part 3, Absorbance

and Transmittance Tests).

3-16 TTi® Colorimeter User’s Manual

Page 43

Part 3 Colorimeter Operation

TEST ALERTS

Test alerts are noncritical messages displayed during normal operation when certain test mode parameters are

not met. If a test alert is triggered, refer to the table below to determine the cause and appropriate response.

Display Message Cause User Response

↑

RANGE and result

alternately flash

↑

RANGE Sample concentration greatly exceeds upper

↓

RANGE and result

alternately flash

↓

RANGE Sample concentration greatly exceeds lower range

↑

LIMIT The Adjust Calibration upper limit has been reached. Make sure the concentration of the calibration

↓

LIMIT The Adjust Calibration lower limit has been reached. Make sure the concentration of the calibration

ZERO ? A zero was not performed before starting the

↑

LIGHT Too much ambient light. Retest. Make sure the sample cell is capped and

Sample concentration exceeds upper range of

the test. An approximate result is calculated and

displayed.

range of the test. An approximate result cannot be

calculated.

Sample concentration exceeds lower range of

the test. An approximate result is calculated and

displayed.

of the test. An approximate result cannot be

calculated.

timer’s auto-read feature.

Dilute the sample. Retest; then multiply result by

the dilution factor (see Part 2, Diluting Samples for

Test Procedures).

Dilute the sample. Retest; then multiply result by

the dilution factor (see Part 2, Diluting Samples for

Test Procedures).

Clean the sample cells and retest to verify. Make

sure the sample cells are capped and correctly

aligned in the sample cell compartment.

Clean the sample cells and retest to verify. Make

sure the sample cells are capped and correctly

aligned in the sample cell compartment.

standard (prepared standard of known concentration) is between 70%–80% of the upper test range

provided in the test instruction. (See Part 3, Adjust

Calibration.)

standard (prepared standard of known concentration) is between 70%–80% of the upper test range

provided in the test instruction. (See Part 3, Adjust

Calibration.)

Retest. Zero before the timer expires when using

the auto-read feature. (See Part 3, Test Timers and

Auto-Read Option.)

correctly aligned in the sample cell compartment.

TEST TIMERS AND AUTO-READ OPTION

Test timers are included in the test screen footer for all tests. Test timers are either preprogrammed or

nonprogrammed. Preprogrammed timers are used when a test requires timing steps between addition of

reagents or to assure full color development of reagents. Up to four preprogrammed timers may be used in a

test. Preprogrammed timers can be accessed and edited at any time during the test procedure. Test instructions

will inform the user when to use a preprogrammed timer. If a preprogrammed timer is not required in a test, a

nonprogrammed (general use) timer will be available in the footer. When a test timer expires, the device emits

three sets of beeps. Each set consists of one long beep followed by two short beeps. The timer icon remains

solid until a key is pressed.

The timer will count down as long as the user does not exit the test or move to the next test in a series. It will

continue to count down during ZERO and READ operations.

AUTO-Read Option: The final preprogrammed timer in a test will include the AUTO-Read option in the

test screen footer. When this option is selected, the device will automatically READ the sample when the

timer countdown expires. The AUTO-Read option is not available for nonprogrammed timers.

3-17TTi® Colorimeter User’s Manual

Page 44

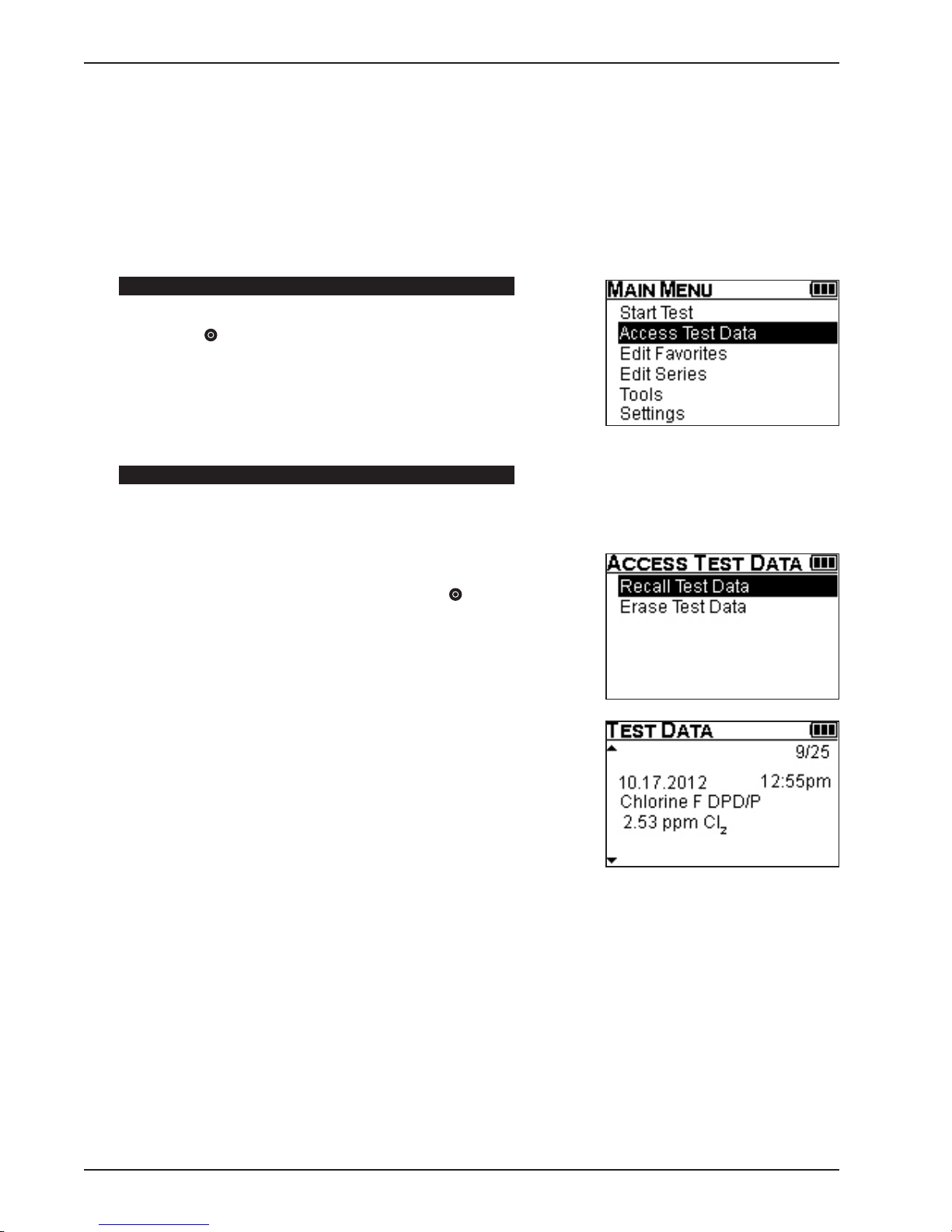

STEP 1

Select TIMER using ; then press ENTER .

The TIMER 1 screen will be displayed.

The timer will open to the preprogrammed time, even if the timer

was previously set to a different time.

If multiple timers are used in a test, will appear to the right of

each timer. Use to scroll between timers. All preprogrammed

timers can be accessed and edited at any time during a test. If a

test does not require a timed step, a nonprogrammed timer will be

available for use.

Part 3 Colorimeter Operation

Footer Options: Select using ; then press ENTER .

START

Starts the timer. The timer icon will be enabled and flash in the title

bar until the timer countdown expires.

EXIT

Returns to the previous test screen:

• When the timer is exited while it is stopped, the timer resets to

the preprogrammed time.

• When the timer is exited while it is running, the timer will

continue to count down when the timer screen is reentered.

• When the timer is exited (using either AUTO or EXIT) and a ZERO

has already been performed, the display returns to the test

screen with READ highlighted.

• When the timer is exited (using either AUTO or EXIT) and a ZERO

has not been performed, the display returns to the test screen

with ZERO highlighted.

SET

Goes to editing mode (see Timer Edit below).

RESET

Resets the timer to the preprogrammed time. When the timer is

RESET while it is running, the timer stops and then resets to the

preprogrammed time.

3-18 TTi® Colorimeter User’s Manual

Page 45

Part 3 Colorimeter Operation

STEP 2

St art timer.

Select START using ; then press ENTER .

Footer Options: Select using ; then press ENTER .

EXIT

Returns to the previous test screen:

• When the timer is exited while it is stopped, the timer resets to

the preprogrammed time.

• When the timer is exited while it is running, the timer will

continue to count down when the timer screen is reentered.

STOP

Stops the timer.

RESET

Resets the timer to the preprogrammed time. When the timer is

RESET while it is running, the timer stops and then resets to the

preprogrammed time.

STEP 3

Proceed with timer countdown.

After START is selected, the timer will begin the countdown. When

the countdown expires, the device will beep. Select a preferred

option to proceed.

When the timer is exited, it will continue to count down until the

countdown expires, the timer is stopped, or the test is exited.

When the timer expires before the TIMER screen is exited, the

timer remains on the TIMER screen and resets to the preprogrammed time.

3-19TTi® Colorimeter User’s Manual

Page 46

NOTE: If the timer is the final preprogrammed timer in a test

(TIMER 2 in this example), AUTO will be available in the footer

after starting the timer.

Select AUTO using ; then press ENTER .

AUTO

Enables the AUTO-read option and returns to the previous test

screen; the timer icon will flash.

The display returns to the previous test screen and the timer icon

continues to flash. The device will automatically READ the sample

when the timer countdown expires.

Part 3 Colorimeter Operation

• When AUTO is selected and ZERO has not been performed,

ZERO? will be displayed. A ZERO will need to be performed

before the sample can be read.

• To see the timer countdown when AUTO has been selected,

select TIMER using ; then press ENTER . The display will

return to the timer screen and the device will automatically READ

the sample when the timer countdown expires.

• When AUTO is selected and the test is exited, the timer will stop

and reset to the preprogrammed time. No AUTO-read will occur.

3-20 TTi® Colorimeter User’s Manual

Page 47

Part 3 Colorimeter Operation

To edit the timer:

Edit Timer using , ; then press ENTER .

The upper limit of the timer is 99:59 minutes.

Footer Option: OK

Saves changes and returns to TIMER screen.

ADJUST CALIBRATION

The Adjust Calibration option can be used to adjust preprogrammed calibrations when required by regulations,

quality control protocol, or in rare circumstances where all samples show a consistent bias. This option is

allowed for most, but not all, preprogrammed tests and there is a limit to the allowed adjustment. This option

is not available for absorbance and transmittance tests.

An Adjust Calibration is performed by analyzing a prepared standard of known concentration (calibration

standard). If the concentration displayed on the instrument differs from the calibration standard, the concentration displayed on the instrument is adjusted to agree with the calibration standard. The magnitude of

the adjustment is used to calculate an adjustment factor that is applied to all subsequent test results until the

feature is disabled. The same adjustment factor will be applied to all chemical forms selected for that particular test. If a preprogrammed calibration is adjusted for a particular test, then the range, estimated detection

limit, and precision provided in the test instruction may not apply to the adjusted calibration. After performing

an Adjust Calibration, the acceptability of the adjusted calibration should be determined by testing several

standards of known concentration at various intervals covering the range of the test.

When an Adjust Calibration is performed and entered for a specific test, the Adjust Calibration icon will

be enabled and displayed in the title bar on all test screens for that test. The AC icon indicates test results are

being calculated using the adjust calibration factor, not the preprogrammed calibration. The Adjust Calibration

option and the AC icon will remain enabled until disabled by the user.

To adjust the calibration of a test, prepare a standard of known concentration (calibration standard) which is

between 70%–80% of the upper test range provided in the test instruction. Using the calibration standard as

the sample, follow the test instruction to obtain a result. If the displayed result does not equal the concentration

of the calibration standard, use the adjust calibration option to adjust the displayed result to agree with the

concentration of the calibration standard.

The following example shows how to use the Adjust Calibration option to adjust the preprogrammed calibration of the Chlorine F&T DPD/P 4 test. Since the range of this test is 0–4.00 ppm Cl2, a calibration standard

is prepared with a concentration of 3.00 ppm Cl2 (i.e., between 70%–80% of the upper test range). A test is

performed following the Chlorine F&T DPD/P 4 test instruction using the calibration standard as the sample.

The result displayed is 2.90 ppm Cl2.

3-21TTi® Colorimeter User’s Manual

Page 48

STEP 1

Select AC using ; then press ENTER .

STEP 2

Adjust the displayed result (2.90 ppm Cl2) to the known

concentration of the calibration standard (3.00 ppm Cl2) using

; then press ENTER . The numbers will continuously scroll

when arrows are held down.

Part 3 Colorimeter Operation

The display will return to the RESULT screen and the displayed

result will agree with the concentration of the calibration standard