Page 1

METAL CUT OFF SAW

355mm (14”) Wheel

TST16-355

0807

Page 2

GENERAL SAFETY RULES

WARNING!

Read all instructions Failure to follow all instructions listed below may result in electric

shock, fire and/or serious injury. The term ’’power tool’’ in all of the warnings listed below

refers to your mains-operated (corded) power tool or battery-operated (cordless) power

tool.

SAVE THESE INSTRUCTIONS

1) Work area

a) Keep work area clean and well lit. Cluttered and dark areas invite accidents.

b) Do not operate power tools in explosive atmospheres, such as in the presence of

flammable liquids, gases or dust. Power tools create sparks which may ignite the

dust or fumes.

c) Keep children and bystanders away while operating a power tool. Distractions can

cause you to lose control.

2) Electrical safety

a) Power tools plugs must match the outlet. Never modify the plug in any way. Do not use

any adapter plugs with earthed (grounded) power tool. Unmodified plugs and matching

outlets will reduce risk of electric shock.

b) Avoid body contact with earthed or grounded surfaces such as pipes, radiators, ranges

and refrigerators. There is an increased risk of electric shock if your body is earthed or

grounded.

c) Do not expose power tools to rain or wet conditions. Water entering a power tool will

increase the risk of electric chock.

d) Do not abuse the cord. Never use the cord for carrying, pulling or unplugging the power

tool. Keep cord away from heat, oil, sharp edges or moving parts. Damaged or entangled

cords increase the risk of electric shock.

e) When operating a power tool outdoors, use an extension cord suitable for outdoor use.

Use of a cord suitable for outdoor use reduces the risk of electric shock.

f) For added protection against accidental electrocution use a residual current device (RCD or

Safety Switch) in conjunction with power tools. If not already fitted to the domestic electricity

supply board, portable power boards with built-in Safety Switches can be purchased from

most reputable hardware stores.

3) Personal safety

a) Stay alert, watch what you are doing and use common sense when operating a power

tool. Do not use a power tool while you are tired or under the influence of drugs, alcohol

or medication. A moment of inattention while operating power tools may result in serious

personal injury.

b) Use safety equipment. Always wear eye protection. Safety equipment such as dust mask,

non-skid safety shoes, hard hat, or hearing protection used for appropriate conditions will

reduce personal injuries.

c) Avoid accidental starting. Ensure the switch is in the off-position before plugging in.

Carrying power tools with your finger on the switch or plugging in power tools that have

the switch on invites accidents.

Page 3

d) Remove any adjusting key or wrench before turning the power tool on. A wrench or a key

left attached to rotating part of the power tool may result in personal injury.

e) Do not overreach. Keep proper footing and balance at all times. This enables better

control of the power tool in unexpected situations.

f) Dress properly. Do not wear loose clothing or jewellery. Keep your hair, clothing and gloves

away from moving parts. Loose clothes, jewellery or long hair can be caught in moving

parts.

g) If devices are provided for the connection of dust extraction and collection facilities,

ensure these are connected and properly used. Use of these devices can reduce dust

related hazards.

4) Power tool use and cars

a) Do not force the power tool. Use the correct power tool for your application. The correct

power tool will so the job better and safer at the rate for which it was designed.

b) Do not use the power tool if the switch does not turn it on and off. Any power tool that

cannot be controlled with the switch is dangerous and must be repaired.

c) Disconnect the plug from the power source and/or the battery pack from the power tool

before making any adjustments, changing accessories, or storing power tools. Such

preventive safety measures reduce the risk of starting the power tool accidentally.

d) Store idle power tools out of the reach of children and do not allow persons unfamiliar

with the power tool or these instructions to operate the power tool. Power tools are

dangerous in the hands of untrained users.

e) Maintain power tools. Check for misalignment or binding of moving parts, breakage of

parts and any other condition that may affect the power tools operation. If damaged, have

the power tool repaired before use. Many accidents are caused by poorly maintained

power tools.

f) Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp cutting

edges are less likely to bind and are easier to control.

g) Use the power tool, accessories and tool bits etc. in accordance with these instructions

and in the manner intended for the particular type of power tool, taking into account

the working conditions and the work to be performed. Use of the power tool for

operations different from those intended could result in a hazardous situation.

5) Service

a) Have your power tool serviced by a qualified repair person using only identical replacement

parts. This will ensure that the safety of the power tool is maintained.

Page 4

Precautions on using Metal Cut Off Machine

The Cut off Machine is for light duty home use for cutting metal.

Disconnect power supply plug before replacing wheels or covers.

Ensure abrasive wheel rotates freely before switching on the power.

Do not operate the machine with the wheel guard off.

Never allow material to jam between the wheels and the rests.

Never strike the wheels, as they are brittle and may crack.

Never use a wheel that has been cracked.

Before installing the abrasive wheel, check its direction of rotation with the arrow

indicated on the safety guard.

If the power is reduced and more sparks occur by the commutator during the

operation, check the carbon brush. Change the brush if worn out.

Maintain and oil tools frequently and with care. Keep cutting tools sharp and clean

for better and safer performance. Follow instruction for lubrication and changing

accessories. Inspect tool cord periodically and if damaged have it repaired or

changed by an authorized service facility. Inspect extension cords frequently and

replace if damaged. Please use only original spare parts for replacement.

Ensure switch is in off-position when plugging in.

The temperature of the machine will increase during the operation. Keep the

working area well ventilated to decrease the temperature. Allow machine to cool if

it becomes too hot.

Do not use the cutting-off machine without guards in position.

Use only abrasive wheels recommended by the manufacturer which have marked

speed equal or greater to that marked on the machine.

Page 5

OPERATION

1. Make sure that the supply voltage matches that specified on the

rating plate.

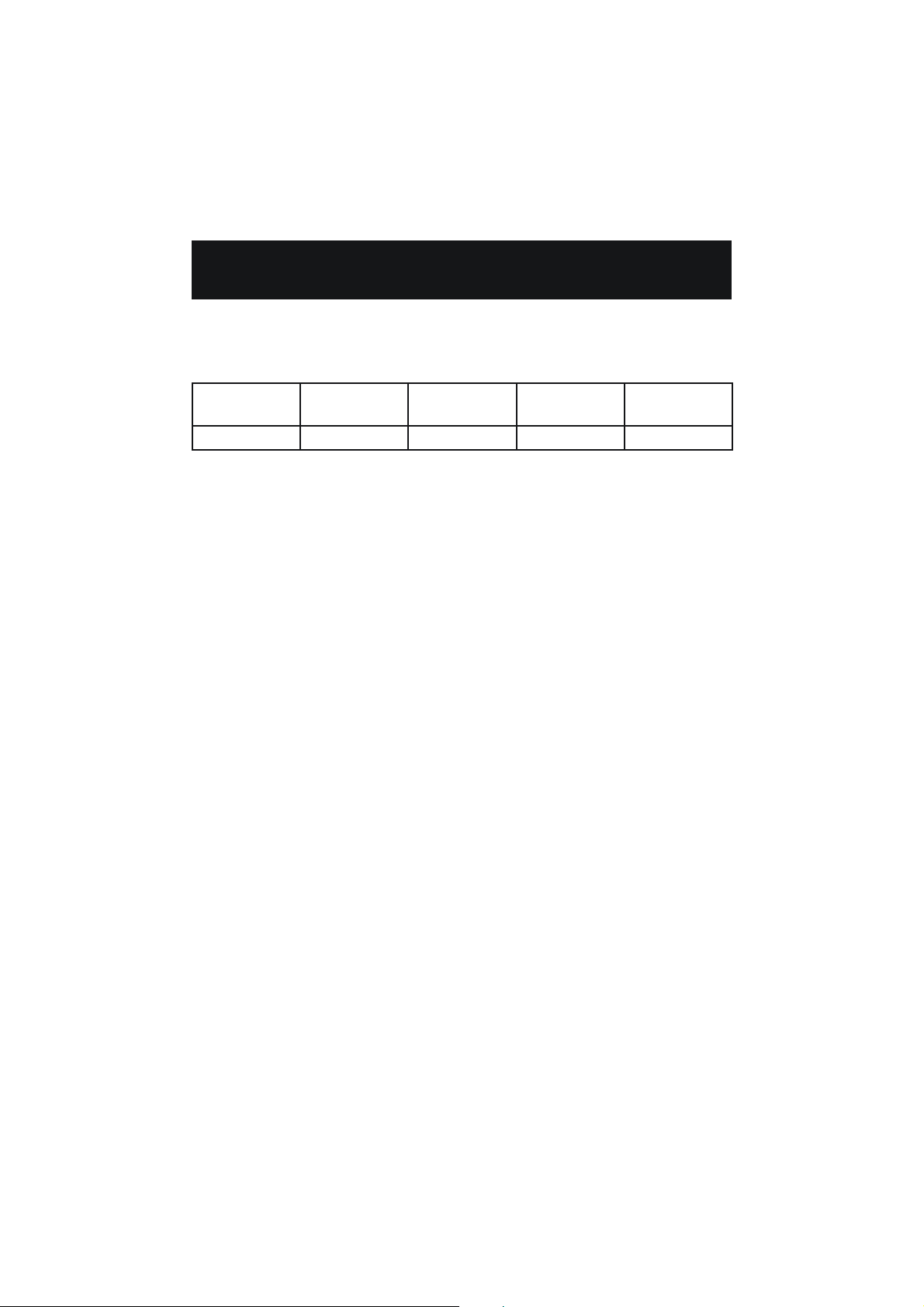

2. Specifications for abrasive wheel:

Type Outer

Diameter

TS16-355 355 254mm 32mm * 80 m/s

3. Use only abrasive wheels in good condition.

4. An abrasive wheel that has been stored for more than one year should be

strength tested. It can be only used after it has passed the test.

5. Before carrying out any work, allow the motor to run idle for one minute.

Make sure there is no oscillation caused by improper installation of the

abrasive wheel. Unusual oscillation may cause unusual noises and the

installation should be adjusted.

6. Secure the work-piece properly with vice before starting to cut. Maintain

appropriate wheel speed by varying the downward pressure applied

during cutting, depending on the profile, material and diameter of the

object being cut.

Adjustment of the vice

The auxiliary stopper of the vice can be tilted to an angle of –30° to 45°.

To Adjust the angle of the vice loosen the two fixing screws on the auxiliary stopper

and tilt it to the desired angle, then tighten the fixing screws again.

Inner

Diameter

Thickness Operating

Linear Velocity

Page 6

Loosen and Tighten the vice

Tighten

Turn the vice rod clockwise to secure the work-piece with the vice.

Loosen

Turn the vice rod anti-clockwise to release the work-piece (see Figure 1).

• When a large work-piece is to be processed, move the auxiliary stopper

forward 3.5 mm (see Figure 2).

• Raise the section bar with a supporting block, if you want to continuously

use a worn abrasive wheel. Check the size of the supporting block first.

Ensure that it is smaller than the size of the section bar, so that the section

bar can be secured by the vice.

Figure 1

Supporting Block

3.5mm

Figure 2

Page 7

CLEANING AND MAINTENANCE

1. Keep the motor-outlet well ventilated and clean. Compressed air can be

used to blow off the dust in the motor.

2. Check the bearing housing and the gearbox periodically and lubricate

them occasionally.

3. After the cutting-off machine has been operated for 40 hours, check the

carbon brush for replacement. The carbon brush should be changed, when

its length is shortened to only 5-6 mm by abrasion (see Figure 3).

4. Disconnect the plug from the power source then remove the brush lid with

a screwdriver for checking and replacing the brush. Take away the worn

brushes, and insert a new pair. Let the motor run for 10 minutes.

Figure 3

Figure 6

Specification of the cutting-off machine

D: Outer Diameter D1: Inner Diameter t: Thickness

Type TS16-355

D0 (mm) 355

Dimension of the

wheel

Power Voltage (V) 230

Nominal input

capacity

Idling speed (r/min) 3900

Dimension (mm) 600X330X430

Net weight (kg) 18

Vibration (m/s2) 1.109

Noise (dB(A)) Lp=89.6, Lw=102.6

Max. cutting depth (mm) 90

D1 (mm) 25.4

t (mm) 3.2

Frequency (Hz) 50

(W ) 2000

Page 8

Cutting Capability

Cutting

Capability

Type 90° / 45° 90° 45° 90° 90°

TS16-355 115 mm 120 mm 106 mm 102 mm x

197 mm

Main components of metal cut off saw

Switch on grip

Side covers

Moveable Hood

139 mm

Vice Rod

Abrasive Wheel

Work table

Page 9

Page 10

Page 11

Page 12

Page 13

ALDI STORES

1 SARGENTS ROAD

MINCHINBURY NSW 2770

AUSTRALIA

www.aldi.com.au

Page 14

taurus warranty.pdf 14/5/07 11:09:53 AM

Page 15

Page 16

639

Metal Cut Off Saw

2000Watt

1

T

T

A

W

0

0

0

2

m

m

m

m

5

5

5

5

3

3

/

/

”

”

4

4

1

TST16-355

1

639

N15151

355mm

Metal Cut Off Saw

2000Watt

0807

TST16-355

AUSTRALIA

this product, please return it to

If you are not entirely satified with

our stringent quality specifications.

your nearest ALDI store for a full

refund or replacement.

ALDI STORES

1 SARGENTS ROAD

MINCHINBURY NSW 2770

www.aldi.com.au

20-25 kg

• Blade: 355mm x 25.4mm x 3mm

• 230VAC~50Hz 2,000W

• 3900rpm

• 0-45° angle blade adjustment

• Max. cutting depth round material: 115mm

• Max. cutting depth square material: 110mm

• Max. cutting depth flat material: 175mm

• Spindle lock system

• Vice system for quick feeding and easy tightening

• Blade safety shield

• One year warranty

TM

TAURUS is a tradmark of ALDI Stores

Made in China

Specially made for ALDI Stores to

639

Metal Cut Off Saw

2000Watt

1

T

T

A

W

0

0

0

2

m

m

m

m

5

TST16-355

5

5

5

3

3

/

/

”

”

4

4

1

1

639

355mm

Metal Cut Off Saw

2000Watt

355mm Blade

Used for general purpose cutting of steel.

Fitted with safety spark deflector.

639

Quick Feed Vice

For quick and easy tightening of material.

Includes 45° adjustment for angled cutting.

2000W Motor

Powerful motor to ensure job is done properly.

Equipped with a safety trigger switch.

Page 17

Metal Cut Off Saw

Model No: TST16-355

N15151

230V~50Hz 2000W

3900rpm Ø355mm

MADE IN CHINA

08/07

Nameplate3800 .pdf 28/5/07 11:52:17 AM

Loading...

Loading...