Page 1

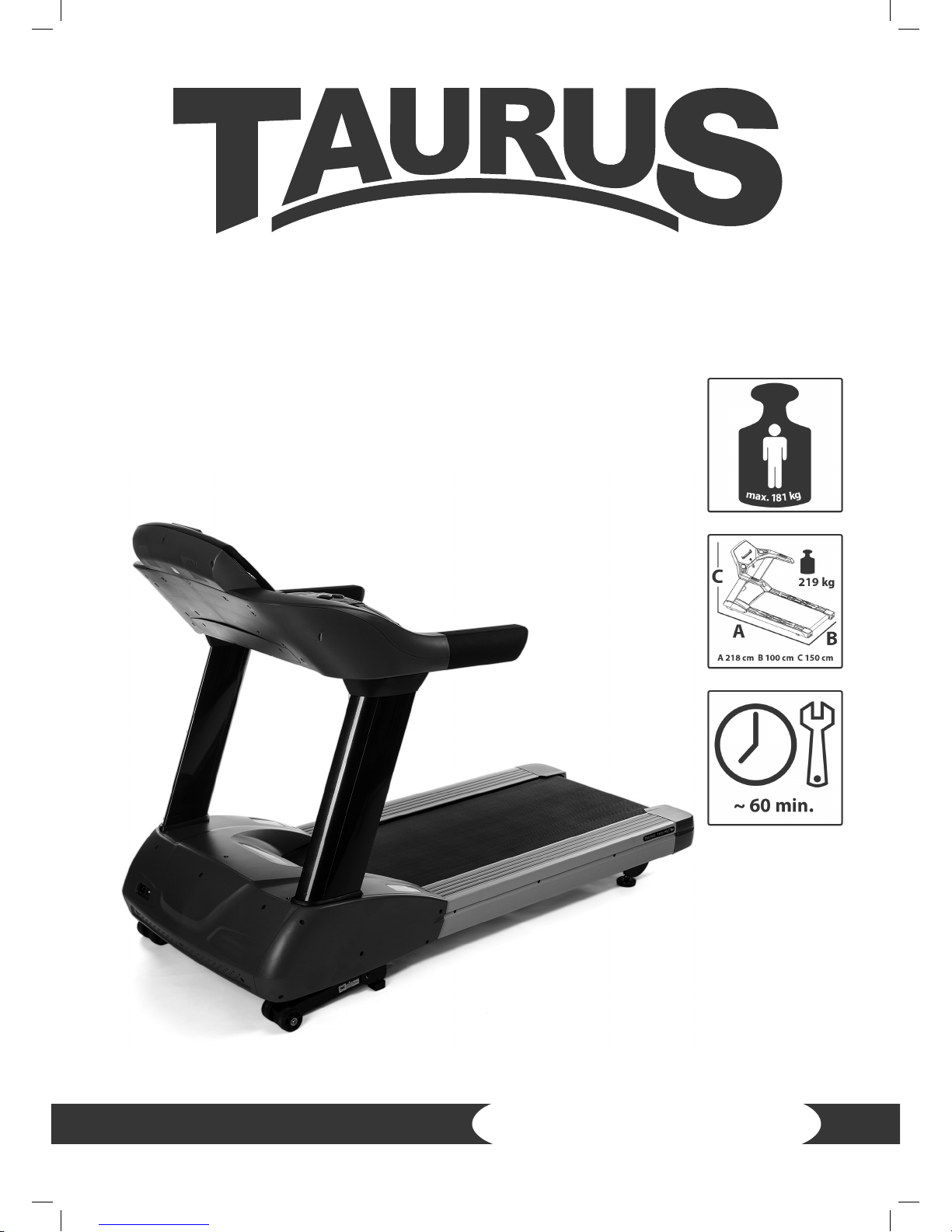

Assembly and operating instructions

Treadmill T10.5 Pro

Art. No. TF-T10.5

Page 2

T10.5PRO

2

Page 3

3

Dear Customer,

Thank you for deciding for a high-quality training equipment of the brand Taurus,

the brand that makes athlete‘s hearts beat faster. Taurus oers a wide range of home

tness equipment like elliptical cross trainers, ergometers, treadmills and rowing

machines. Taurus equipment is the optimal equipment for all those who want to train

at home independent of goals and tness level. For further information please visit

www.sport-tiedje.com or www.taurus-tness.de.

SAFETY NOTICE

Please read all of the instructions carefully before assembly and rst

use. These instructions are intended to ensure speedy assembly and

explain safe usage. Make sure that all people exercising with the

equipment (in particular children and persons with limited physical, sensory, mental or

motor capabilities) are informed about these instructions and its content in advance.

In case of doubt, a responsible person must supervise the use of the equipment.

This equipment has been manufactured according to the latest safety knowledge. As

far as possible, potential safety hazards which could cause injury have been eliminated.

Make sure to follow the instructions carefully and that all parts are securely in place. If

required, read through the instructions again to correct any mistakes.

Please pay close attention to the safety and maintenance instructions given here.

The contract partner cannot be held liable for damage to health, accidents or

damage to the equipment when it is not used in accordance with these instructions.

The equipment is suitable for home use, semi-professional use (e. g., hospitals, clubs,

hotels, schools, etc.) as well as for commercial or professional use (e. g., commercial

gyms).

Retain these instructions in a safe place for future reference, maintenance or when

ordering replacement parts.

Page 4

T10.5PRO

4

CONTENTS

1 GENERAL INFORMATION 6

1.1 Technical data 6

1.2 Personal safety 7

1.3 Electrical safety 8

1.4 Set-up place 9

2 ASSEMBLY INSTRUCTIONS, MAINTENANCE AND CARE 10

2.1 General instructions 10

2.2 Errors and error diagnosis 11

2.3 Care and maintenance 12

2.4 Maintenance and service calendar 14

3 ASSEMBLY 15

3.1 Package contents 15

3.2 Assembly instructions 16

4 OPERATING INSTRUCTIONS 22

4.1 Console display 22

4.2 Button functions 24

4.3 Turning on the equipment 25

4.4 Programs 26

4.4.1 Manual program 26

4.4.2 Weight reduction 28

4.4.3 5k RUN 30

4.4.4 Interval program 32

4.4.5 Cardio program 35

4.4.6 User-dened training program 37

5 WORKOUT INSTRUCTIONS 40

5.1 Heart rate measuring 40

5.2 10 tips for eective running training 43

5.3 Designing a workout 44

Page 5

5

5.4 Stretching exercises for leg & chest muscles 46

5.5 Workout journal 48

6 WARRANTY INFORMATION 49

7 DISPOSAL 51

8 ORDERING ACCESSORIES 52

9 ORDERING SPARE PARTS 53

9.1 Service hotline 53

9.2 Serial number and model name 53

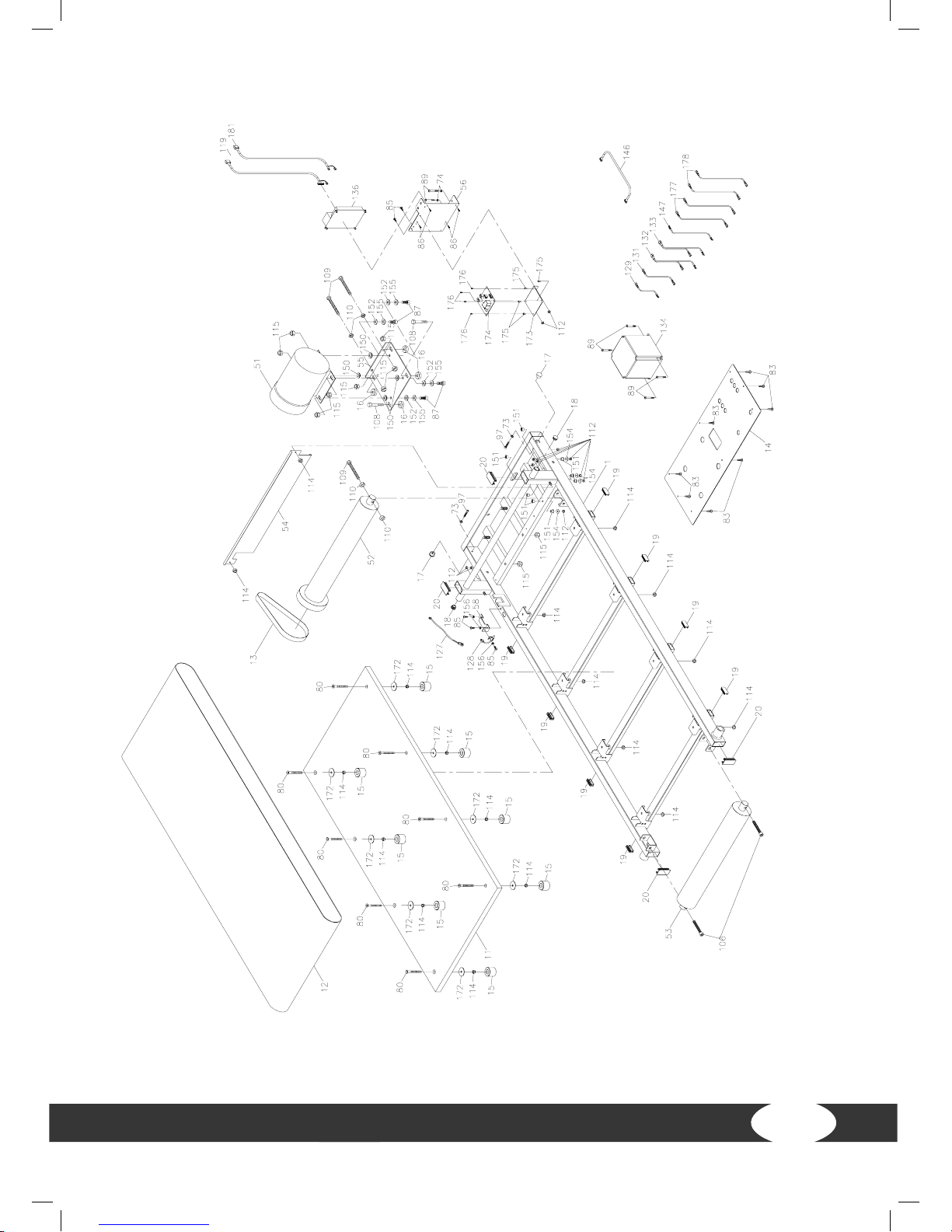

9.3 Parts list 54

9.4 Exploded drawing 57

Page 6

T10.5PRO

6

1 GENERAL INFORMATION

1.1 Technical data

LCD display of

+ speed in km/h

+ training time in min

+ training distance in km

+ calories burnt in kcal

+ heart rate (when using the hand sensors or a chest strap)

+ incline in %

+ Watt

+ METs

+ cadence (rotations per minute)

+ resistance level

Motor output: 3 HP continuous output (AC motor)

Max. motor continuous output: 2.2 kW / 3 HP

Max. motor peak rating: 4.1 kW / 6 HP

Speed range: 0.8 - 25 km/h

Incline range: 0 - 15 %

Total number of training programs: 6

Pre-set programs: 4

Heart rate controlled programs: 1

User-dened programs: 1

Running surface size (L x W): 158 x 56 cm

Wheel diameter: 89 mm

Running belt thickness: 3.3 mm (orthopedic running belt)

Running deck thickness: 25.4 mm

Weight and dimensions:

Article weight (gross, including packaging): 244 kg

Article weight (net, without packaging): 219 kg

Packaging dimensions (L x W x H): approximately 2210 mm x 940 mm x 520 mm

Set-up dimensions (L x W x H): approximately 2180 mm x 1000 mm x 1500 mm

Maximum user weight: 181 kg / 399 lbs

Page 7

7

1.2 Personal safety

+ Before you start using the equipment, you should consult your physician that

this type of exercise is suitable for you from a health perspective. Particularly

aected are persons who: have a hereditary disposition to high blood pressure

or heart disease, are over the age of 45, smoke, have high cholesterol values, are

overweight and/or have not exercised regularly in the past year.

+ Please note that working out excessively can seriously damage your health. Please

also be aware that heart rate monitoring systems might be imprecise.

+ The equipment may only be used for its intended purpose; that means for running

training by adults.

+ Any other usage is prohibited and potentially dangerous. The contract partner

cannot be held liable for damage resulting from improper use.

+ The equipment is strictly for use by one person at a time.

+ Children should not be allowed unsupervised access to the equipment.

+ Before starting your training, make yourself familiar with all of the equipment‘s

functions and setting options. Have an expert explain the correct usage of the

product to you.

+ Make sure that nobody is in the range of motion of the equipment while exercising.

+ Keep your hands, feet and other body parts, hair, clothing, jewelry and other

objects well clear of moving parts.

+ During use, wear suitable sports clothing rather than loose or baggy clothing.

When selecting sports shoes, think about the suitability of the sole – preferably

this should be made of rubber or other non-slip materials. Shoes with heels,

leather soles, studs or spikes are not suitable. Never work out in bare feet.

+ It is also important to take note of the information given in the workout instructions

for creating a workout plan.

+ At the rst signs of weakness, nausea, dizziness, pain, diculty in breathing or

other abnormal symptoms, stop your workout immediately and, if necessary,

consult your physician.

+ Without prior agreement from your authorized contract partner, opening the

equipment is prohibited.

+ The equipment has stable steps on the sides that you can stand on in case of an

emergency and leave the equipment.

+ The safety key should be inserted during all training.

+ The safety key and the power cable should be removed when you are not present

in order to rule out improper usage by third parties.

Page 8

T10.5PRO

8

Safety Key

+ The equipment has an EMERGENCY STOP mechanism for your safety. The

equipment may only be operated when the safety key is properly attached to the

contact point of the cockpit. The equipment will automatically stop immediately if

the safety key is no longer on the contact point. That is why you should attach the

safety key string with the clip to your clothing before training. Remove the safety

key from the cockpit with the help of the string if you would like to quickly stop

the treadmill, you can no longer handle the speed or an emergency occurs.

+ In order for the safety key to be released from the cockpit contact point in the

event of a fall, the clip from the safety key must be attached to your clothing!

+ An uncontrolled usage of the equipment by third parties can be avoided by

removing and storing the safety key.

+ Prevent children from having access to the safety key.

1.3 Electrical safety

+ The equipment requires a 220 - 240V / 50 Hertz mains power supply.

+ The equipment should be connected directly to a grounded plug socket only by

means of the power cable supplied. The use of multi-socket adapters or similar

is not recommended. Extension leads must comply with local electrical safety

guidelines. Always fully unwind the power cable.

+ The outlet should be secured with a fuse with a minimum value of „16 amperes,

slow“.

+ In order to reduce the risk of an electric shock, always unplug the equipment from

the mains socket immediately after your workout, before assembly or dismantling,

and before maintenance or cleaning. Do not pull on the cable.

+ When plugged in, do not leave the equipment unattended at any time. To avoid

use by anyone unfamiliar with the operating instructions, the power cable should

be removed when the equipment is not in use.

+ Keep the power cable away from heat, oil and sharp edges. Do not route the power

cable underneath the equipment or under a carpet or rug, and do not place any

objects on top of it.

+ Make no modications to either the power cable or the mains plug.

+ If the power cable or the plug are damaged or defective, contact your authorized

contract partner. Do not use the equipment in the meantime.

+ Do not keep electrical devices (e. g., mobile phones) in close proximity to the

console or the control electronics, otherwise display values (e. g., pulse measuring)

could be inaccurate.

Page 9

9

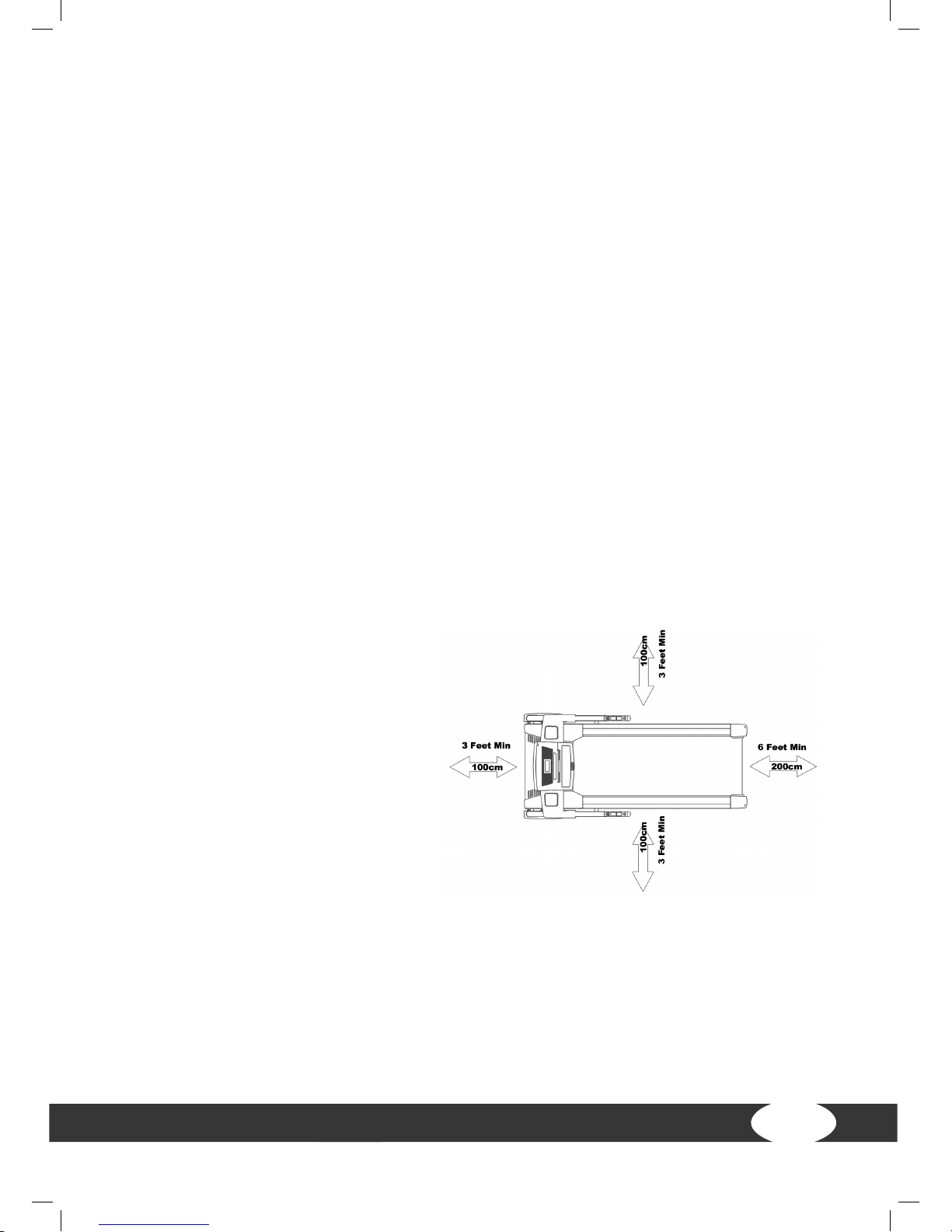

1.4 Set-up place

+ The equipment should only be used indoors, in a suciently heated and dry area

(ambient temperature between 10°C and 35°C). The equipment should not be

used outdoors or in rooms with high humidity (over 70%) like swimming pools. The

equipment should only be stored in surroundings with an ambient temperature

between 5°C and 45°C.

+ The training room should be well ventilated during training and not be exposed to

any draughts.

+ Choose a location in which to place the equipment such that there is enough free

space/clearance to the front, the rear and to the sides of the equipment (at least

1.50 m). Furthermore, the equipment should not be set up in main entrances or on

escape routes.

+ Always keep the power cable away from hot surfaces and grounds and make sure

that the cable is not stuck somewhere or becomes a „trip hazard“.

+ No objects of any type should be inserted into the openings of the equipment.

+ The equipment should be placed on a level and solid surface, any unevenness in

the oor should be leveled out.

+ A oor protective mat / equipment underlay can help to protect high-quality oor

coverings (parquet, laminate, cork, carpets) from dents and sweat and can help to

level out slight unevenness.

2

Page 10

T10.5PRO

10

2 ASSEMBLY INSTRUCTIONS, MAINTENANCE AND CARE

2.1 General instructions

+ Please check if all parts and tools belonging to the equipment are included in the

delivery and if there is any transport damage. If there are any complaints, please

contact your contract partner directly.

+ Some of the nuts and bolts to be used in assembly are already pre-mounted in

order to make set-up as easy as possible.

+ The equipment must be assembled by adults. In case of doubt, ask for assistance

from another person with technical skills.

+ Keep children away from the equipment during assembly, because small parts are

included in the delivery and may be swallowed.

+ Make sure that you have enough space (at least 1.50 m) in every direction during

assembly.

+ Do not leave any tools and packaging materials like plastic sheeting laying around

to avoid danger of suocation for children.

+ Assemble the equipment on an underlay mat or on the cardboard packaging in

order to avoid damage to the equipment and to the oor (scratches).

+ Before starting assembly, all individual parts should be placed on the oor next to

each other.

+ Read the assembly instructions carefully and assemble the equipment according

to the illustrations. Proceed carefully and cautiously.

+ First loosen all parts and check for their correct tting. Then tighten the screws

using a tool.

+ Modications to the design or improper repairs may pose a hazard to the user and

should not be carried out. The product warranty may be void as a result.

+ Only authorized service technicians are permitted to carry out all servicing and/or

repairs – it excludes maintenance and care.

+ Damaged or worn components may impair your safety and the lifespan of

the equipment. You should therefore immediately replace damaged or worn

components. Please contact your contract partner in such a case. The equipment

should no longer be used until it has been repaired. When needed, only use

original Taurus spare parts.

+ Check the tightness of all screw connections once a month.

+ In order to be able to guarantee the constructively dened safety level of this

equipment, we recommend having the equipment regularly maintained (at least

once a year) by specialists (service technicians of your contract partner).

Page 11

11

+ The equipment may be cleaned of dust, dirt and sweat using a damp cloth. The

use of solvents should be strictly avoided. Also, make sure that no liquids (e. g.

sweat) get into the openings of the equipment (e. g. console).

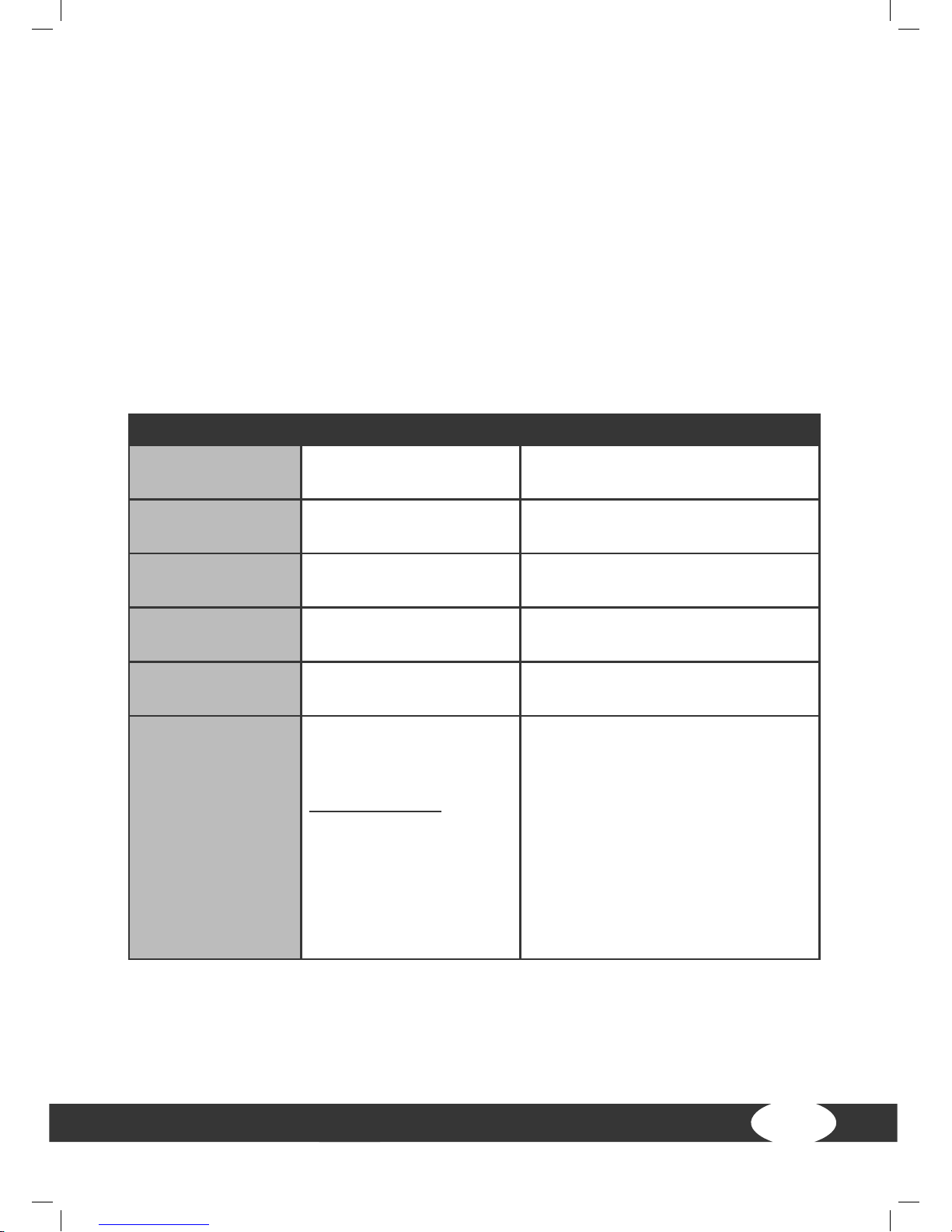

2.2 Errors and error diagnosis

The equipment runs through regular quality controls during production. Nevertheless,

errors or malfunctions on the equipment may occur. Individual parts are often the

cause of faults and replacement is usually sucient. Please use the following overview

to see the six most common errors and how to repair them. If the equipment still does

not work properly, please contact your contract partner.

Error Cause Repair

Console only

shows lines

Safety key missing Check if the safety key is inserted

and place it in

Running belt tilted

Running belt not

aligned

Align running belt in accordance

with the instructions

Running belt slips

through/stops

Belt tension/lubrication

not ok

Check belt tension/lubrication in

accordance with the instructions

Scraping noises

Running belt scrapes,

because it is not aligned

Align running belt in accordance

with the instructions

Display does not

show anything

Check plug connections

(cables)

Mains switch on “on”, make sure

that the safety key is inserted

No pulse display

Sources of interference

in the room

With chest strap

Unsuitable chest strap

Position of the chest

strap incorrect

Batteries empty

Remove sources of interference (e.

g. mobile phone, speakers, etc.)

Use suitable chest strap (see

recommended accessories)

Reposition chest strap and/or

moisten electrodes

Change batteries

Page 12

T10.5PRO

12

2.3 Care and maintenance

The most important maintenance measure is taking care of the running belt. It

includes the adjustment, tensioning and lubrication of the running belt. Damage

caused due to a lack of care or negligence will not be covered by the warranty. Thus,

check for maintenance in regular intervals. Be extremely careful when adjusting and

tensioning the belt, because a strong over or under tension may cause damages. The

running belt is set properly in the factory before delivery. However, the running belt

may get out of place during transport.

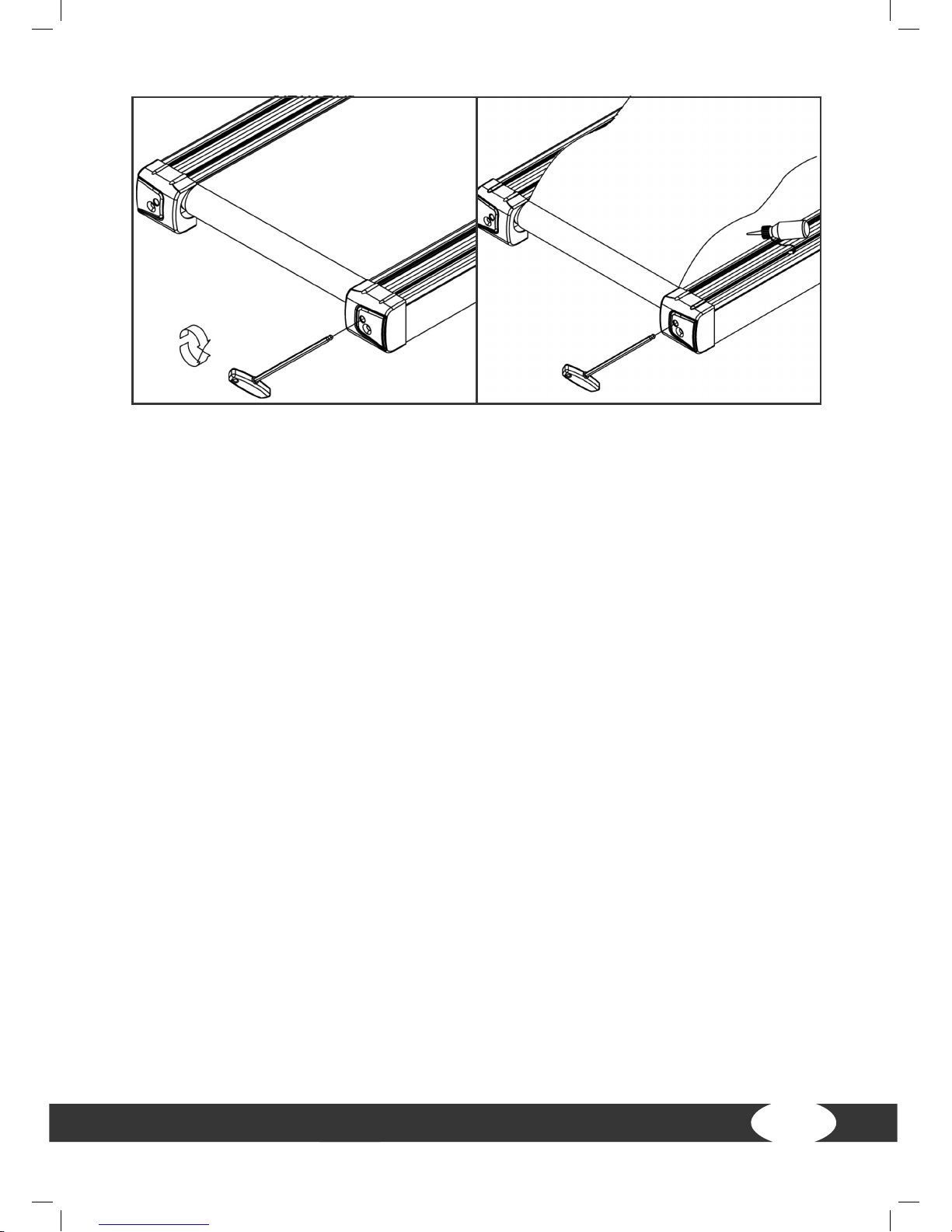

Aligning the running mat

+ During training, the running belt should run as centered and straight as possible.

The alignment of the running belt may change depending on the stress and load.

Another reason can be the positioning of the equipment on an uneven surface.

+ While adjusting the belt, let the equipment run with a speed of approximately

5km/h. Nobody may be on the equipment during this process.

+ If the running belt is oset to the left, turn the left setting screw on the rear end of

the equipment at most 1/4 rotation clockwise and the right setting screw at most

1/4 rotation counterclockwise (g. C).

+ If the running belt is oset to the right, turn the right setting screw on the rear end

of the equipment at most 1/4 rotation clockwise and the left setting screw at most

1/4 rotation counterclockwise (g. D).

+ Then watch how the belt runs for approximately 30 seconds, because the change

will not be visible immediately.

+ Repeat the process until the running belt runs straight again. If the running belt

cannot be adjusted, please contact your contract partner.

Page 13

13

Tensioning the belt

+ If the running belt slips over the rollers during operation (if this is the case, a

noticeable jerking will be noticed while running), the running belt must be

tightened again. In most cases, the cause for the slipping is a straining of the belt

through usage. This is completely normal.

+ It can be tightened through the same setting screws that were used during

alignment.

+ While tensioning the belt, let the equipment run with a speed of 5km/h.

+ Turn the left and right setting screws directly after each other a max. of 1/4 rotation

clockwise.

+ Then check if the running belt is still slipping. If this is still the case, the described

process needs to be repeated.

Lubricating the running belt

+ If the running belt is inadequately lubricated, the friction will increase signicantly

and this leads to strong wear of the endless belt, running panel, motor and circuit

board.

+ If you feel an increase in friction from the running belt, this is an indicator that you

should lubricate the belt (however, a lubrication should be done at least every

three months).

+ The treadmill has a reminder for lubricating the treadmill: A symbol is displayed on

the console every 100 operating hours. The symbol appears on the display for ve

minutes and then turns o. In order to turn o the symbol prematurely, press the

INCLINE up and INCLINE down buttons at the same time.

Page 14

T10.5PRO

14

+ In order to be able to optimally lubricate the treadmill, the running belt must be

lifted slightly. Then apply some silicone spray on the entire running deck. Apply

three short (approximately 1 second) sprays of silicone lubricant between the belt

and the running deck.

+ The spraying tube should be held sideways in order to guarantee a moistening of

the entire underside of the belt. Continue to rotate the belt by hand so that the

entire area between the endless belt and running deck is lubricated. Wipe o the

excess lubricant.

+ This maintenance must also be executed after the equipment has not been used

for a longer period of time.

2.4 Maintenance and service calendar

The cockpit, casing, handrails and entire frame must be cleaned after every training

session with a moist towel (no solvent!) in order to avoid damage caused by sweat.

After 150 hours of operation, the maintenance symbol reminds you to clean the

treadmill. After you have cleaned the treadmill and checked all components, turn o

the symbol by simultaneously pressing the INCLINE up and INCLINE down buttons.

The following routine work must be done in the specied time intervals:

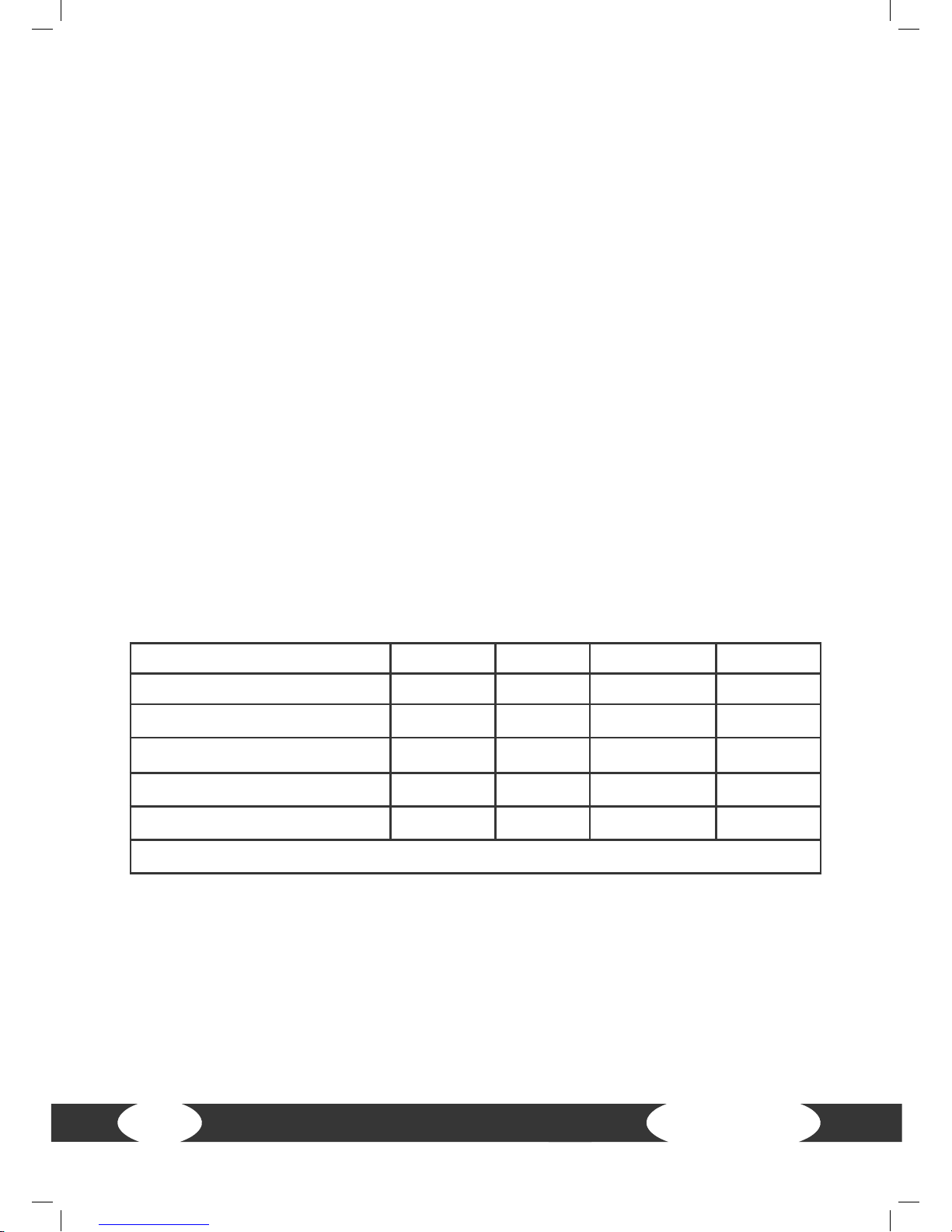

Part Weekly Monthly 2x annually Annually

Display console c I

Belt tension

I

Belt lubrication

I

Plastic covers

c I

Screws & cable connections

I

Legends: C = cleaning; I = inspect

Page 15

15

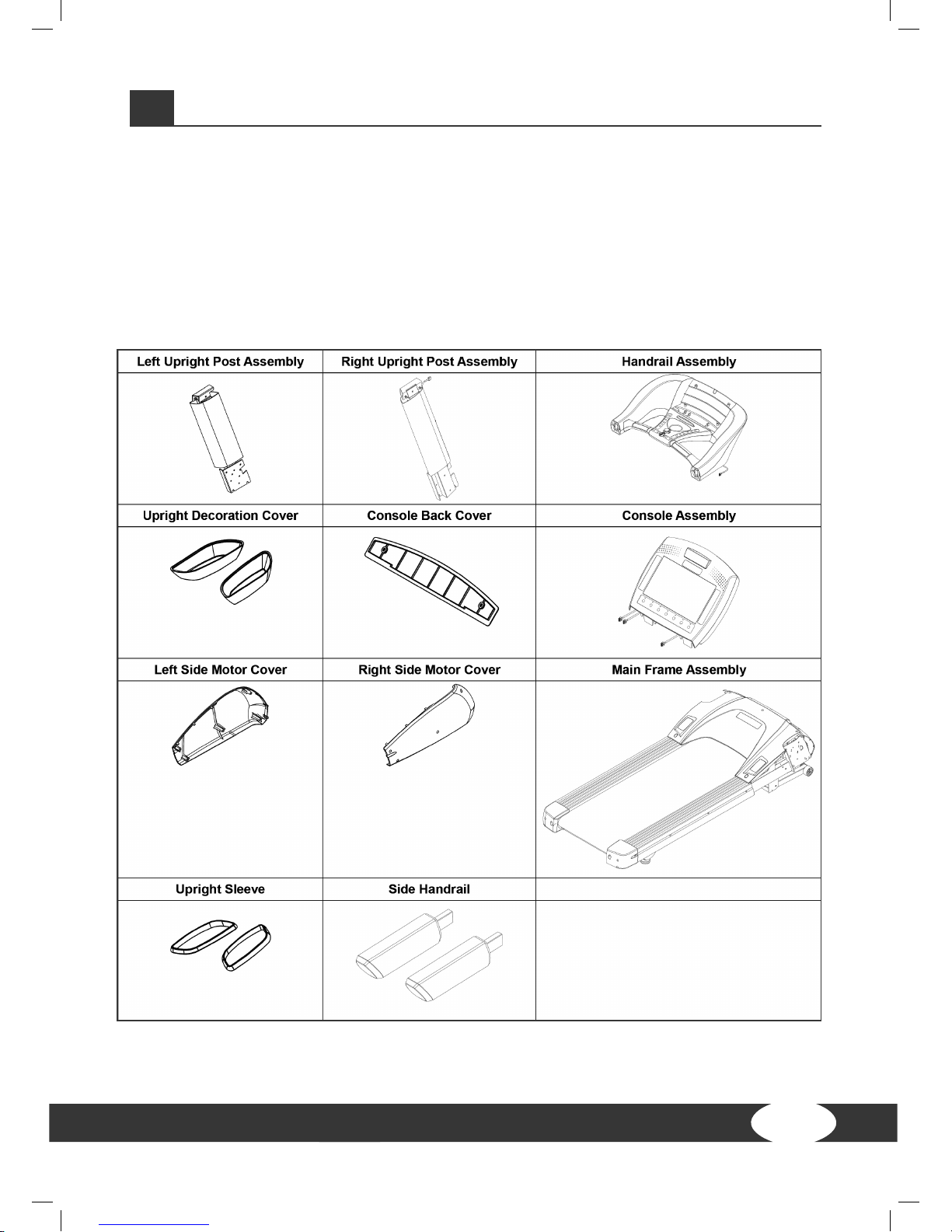

3 ASSEMBLY

3.1 Package contents

The package contains the parts represented in the illustration, including a power

cable with mains plug. If one of the illustrated parts is missing, please contact your

contract partner.

Page 16

T10.5PRO

16

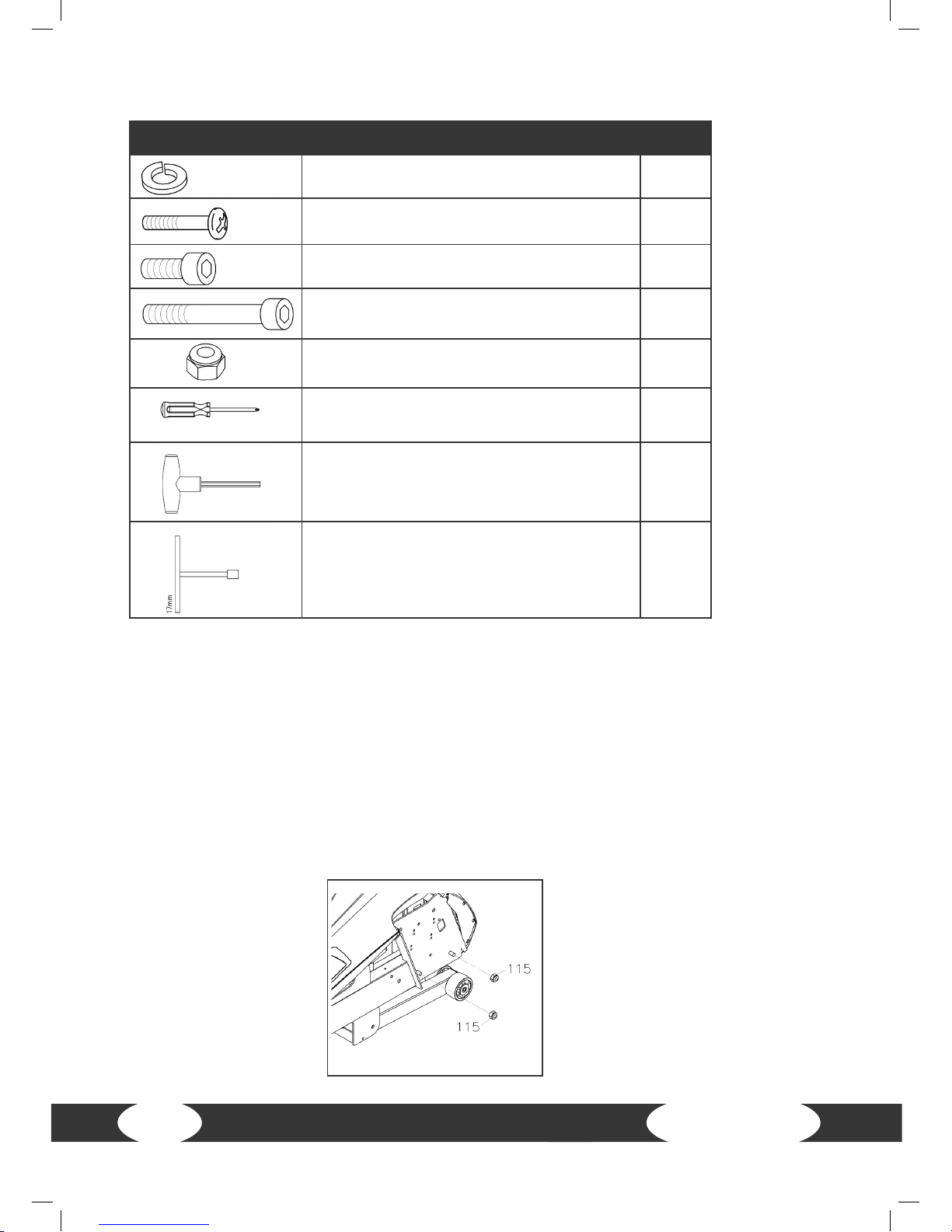

Drawing Part no. and description Qty.

75) Spring washer (M10) 4

76) Bolt (M5x15mm) 16

102) Bolt (M10x20mm) 4

105) Bolt (M10x65mm) 2

115) Nylon nut (M10xp1.5) 2

Screwdriver 1

Allen wrench (6mm / 8mm) 1

T-hand socket wrench (17mm) 1

Tools and screw sets

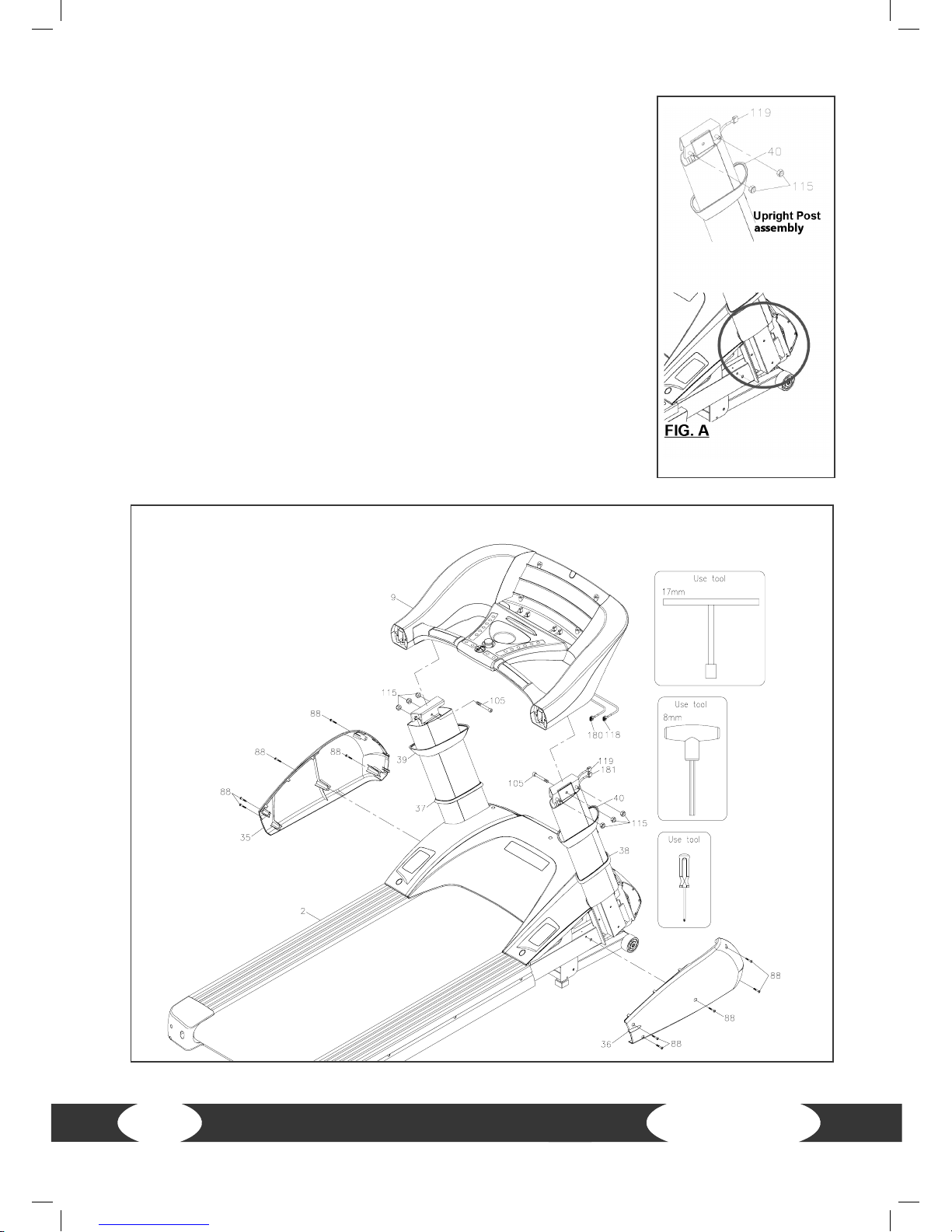

3.2 Assembly instructions

Before starting assembly, look carefully through the individual assembly steps shown

and assemble the equipment in the order indicated.

Step 1: Assembly of the console mast

Note: Two nylon nuts (M10xp1.5)(115) were pre-mounted on each front side of the

frame (2); a total of four nylon nuts (115) are pre-mounted.

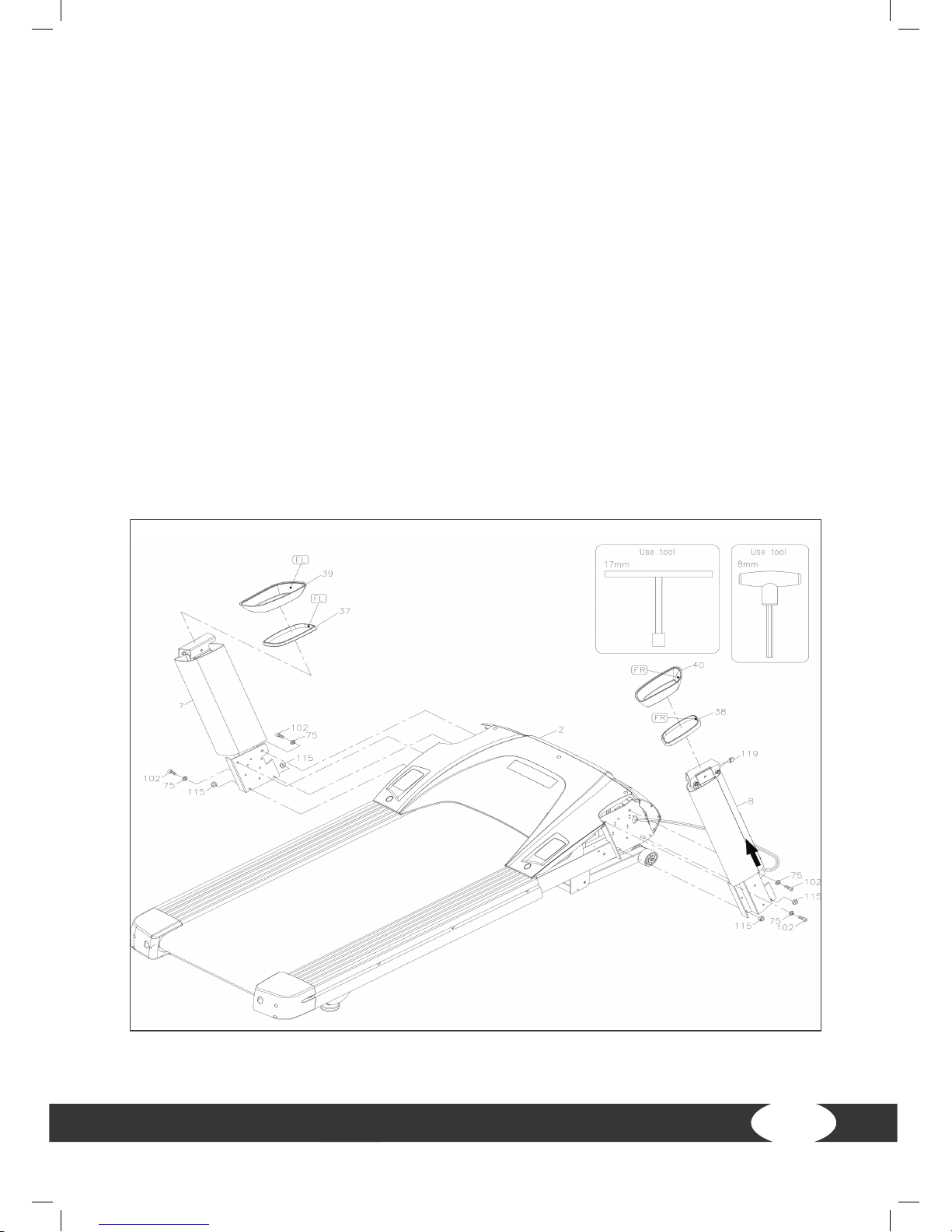

Page 17

17

Step 1: Assembly of the console mast

a. Remove two nylon nuts (M10xp1.5)(115) on the right of the frame assembly (2).

b. Mount the right console mast assembly (8) on the frame (2) with two shims (M10)

(75), two bolts (M10x20mm)(102) and two nylon nuts (M10xp1.5)(115).

Note: Tighten the shims, bolts and nylon nuts later (see point d in Step 2).

c. Carefully pull the rear connecting cable (119) through the right console mast

assembly (8).

Warning: Do not bend the cable.

d. Determine the correct direction of the right sleeve (38) and the right decorative

cover (40). “FR” is engraved on the inner side of the right sleeve (38) and the right

decorative cover (40).

e. Carefully push the right sleeve (39) and the right decorative cover (40) on the right

console mast assembly (8).

f. Repeat the step for the left side.

Page 18

T10.5PRO

18

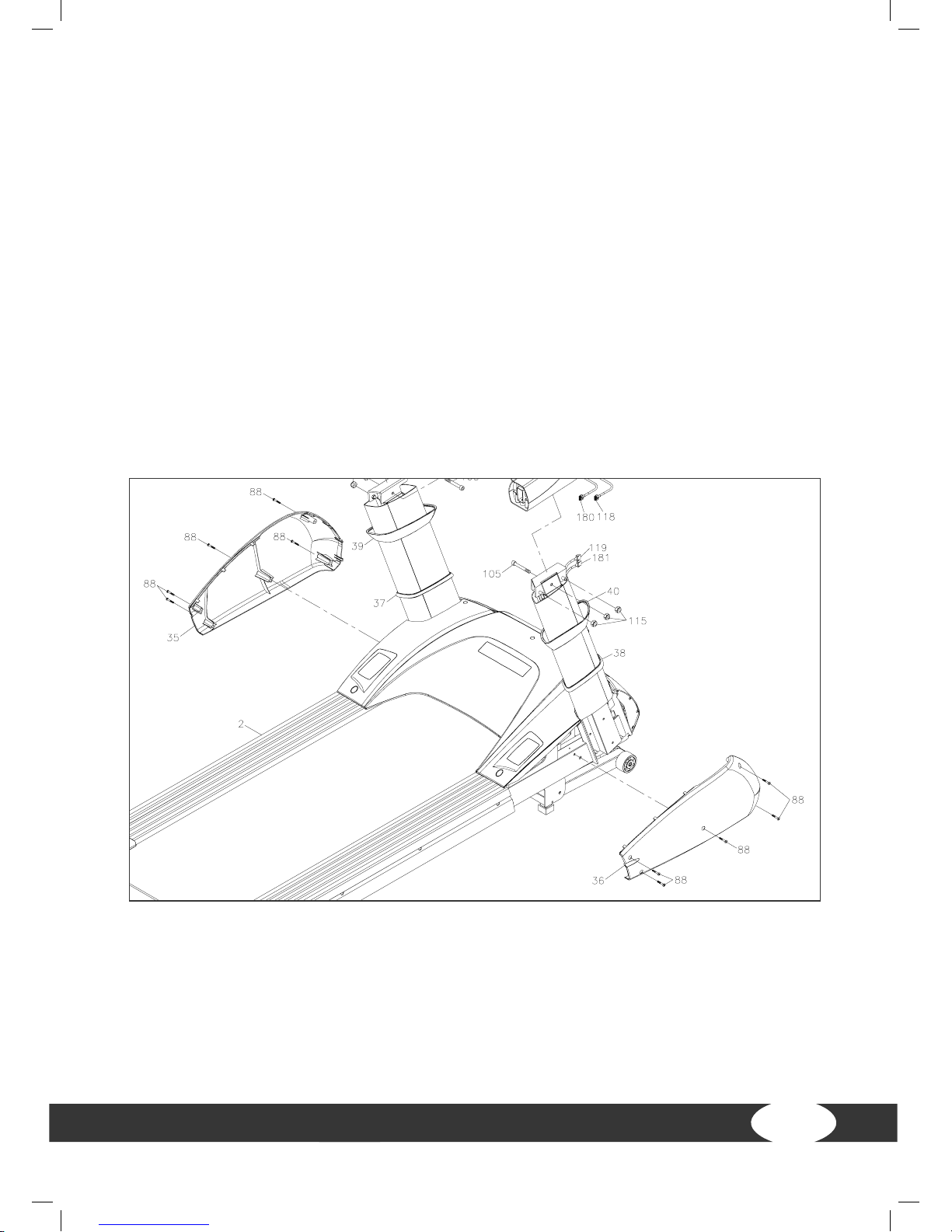

Step 2: Assembly of the handrail

Note: Two nylon nuts (M10xp1.5)(115) were pre-mounted on

each side of the upper console mast assembly; a total of four

nylon nuts (115) are pre-mounted.

a. Remove two nylon nuts (M10xp1.5)(115) on the right of the

console mast assembly.

b. Mount the handrail assembly (9) on the frame assembly (2)

with three nylon nuts (M10xp1.5)(115) and a bolt (M10x65mm)

(105).

c. Slide the sleeve (38) down until it meets the upper motor

cover (22).

d. Follow FIG. A, tighten the two shims (M10)(75), two bolts

(M10x20mm)(102) and two nylon nuts (M10xp1.5)(115), which

connect the console mast assembly and the frame.

e. Repeat the step on the left side.

Page 19

19

Step 3: Assembly of the motor covers

a. Mount the right side motor cover (36) on the frame assembly (2) with ve bolts

(M5x15mm)(88).

b. Repeat the step for the left side.

c. Connect the middle connecting cable (118) with the rear connecting cable (119).

Do not bend the cable.

d. Connect the ERP middle connecting cable (180) with the ERP connecting cable

(181). Do not bend the cable.

e. Move the right decorative cover (40) up and slide the right decorative cover (40)

carefully into the cavities behind the handrail assembly (9).

f. Repeat the step on the left side.

Note: Make sure that the upper parts are tightened before you go to the next step.

Page 20

T10.5PRO

20

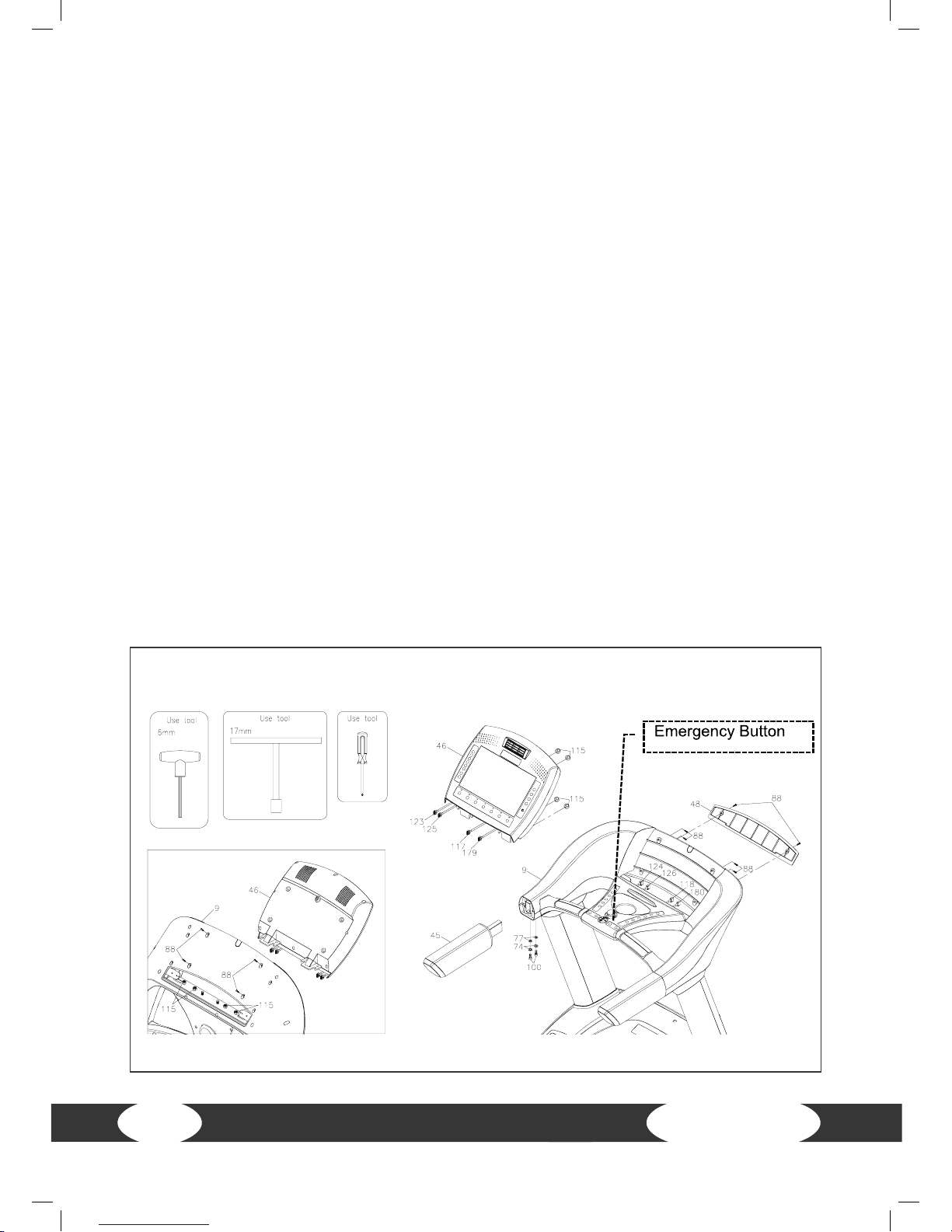

Step 4: Assembly of the console

Note: The handrail assembly (9), rear console cover (48) and two bolts (M5x15mm)

(88) are pre-mounted together.

a. Remove the rear console cover (48) from the handrail assembly (9) by loosening

and removing the two bolts (M5x15mm)(88).

Note: Four nylon nuts (M10xp1.5)(115) are already pre-mounted on the backside of

the handrail assembly (9).

b. Pay attention to FIG. B (see below) and remove the four nylon nuts (M10xp1.5) (115)

from the handrail assembly (9).

c. Connect the middle front handle cable (124) with the upper front handle cable

(123). Do not bend the cable.

d. Connect the middle handle cable (126) with the upper handle connecting cable

(125). Do not bend the cable.

e. Connect the middle connecting cable (118) with the upper connecting cable (117).

Do not bend the cable.

f. Connect the ERP middle connection cable (180) to the ERP upper connection cable

(179). Do not bend the cable.

g. Pay attention to FIG. B. and mount the console (46) on the handrail assembly (9)

with four nylon nuts (M10xp1.5)(115) and four bolts (M5x15mm)(88).

h. Mount the rear console cover (48) on the console (46) with two bolts (M5x15mm)

(88).

Page 21

21

Step 5: Assembly of the side handrails

Note: Two shims (M8)(74), two washers (M8x16x2.0t)(77) and two bolts (M8x20mm)

(100) are already pre-mounted on the left side handrail (45).

a. Remove the two shims (M8)(74), two washers (M8x16x2.0t)(77) and two bolts

(M8x20mm)(100) from the left side handrail (45).

b. Mount the left side handrail (45) on the left side of the handrail assembly (9) with

two shims (M8)(74), two washers (M8x16x2.0t)(77) and two bolts (M8x20mm)(100).

c. Repeat the steps for the assembly of the right side handrail (45).

d. Loosen the emergency button to the normal setting by pulling it slightly upwards,

see gure below.

e. Finish the assembly. Make sure that all parts are tightened before you use the

equipment.

Step 6: Attaching the power cable

a. Connect the power cable (145) with the power

switch (30) on the front right side of the frame.

b. Connect the power cable (145) to an outlet in order

to turn on the console.

c. Turn on the main power switch (A) in the front of

the equipment at the power cable.

Step 7: Transportation of the treadmill

Note: We recommend transporting the equipment with two persons.

The treadmill has four wheels for transportation. Grab the rear frame tightly and

carefully lift up the treadmill. Then you can transport it comfortably.

Page 22

T10.5PRO

22

4 OPERATING INSTRUCTIONS

4.1 Console display

Page 23

23

TIME

Count up: If no target time was selected, the TIME will count up

from 0:00 to a maximum of 99:99 minutes.

Count down: If you entered a target time (10:00 to 99:00; 1 min.

increments), the console will count down from the selected time

to 0:00.

INCLINE

Press INCLINE up or DECLINE down in order to increase or decrease

the incline from 0% to 15%; 1% increments.

SPEED

Press SPEED (+) or SPEED (-) in order to increase or decrease

the speed from 0.8 to 25 km/h/0.5 to 15 mph; 0.1 km/h/mph

INCREMENTS.

PULSE

Wear a compatible chest strap or grab the hand pulse sensors

with both hands. Your pulse will be displayed after a few seconds.

If you do not wear a compatible chest strap or your hands do not

correctly grab the sensors and a few seconds pass without a pulse,

the console will turn o the pulse circuit. The console will then

show the error message “P”. If you grab the pulse sensors correctly

again with both hands, the pulse will be displayed.

AGE

During setting, the value here stands for “AGE”. Please look at each

instruction from the console programs for detailed information.

Display range: 10 to 99 years; 1 year increments.

NOTE: Even though the console allows a minimum age of 10 years,

the equipment is not recommended for usage by children.

CALORIES Indicates the estimated number of calories burnt.

WEIGHT

During setting, the value here stands for “WEIGHT”. Please look

at each instruction from the console programs for detailed

information.

30 to 180kg/40 to 400 lbs; 1 kg/lbs increments; After you pressed

ENTER to conrm the desired value for WEIGHT, the desired value

for WEIGHT will become a “default” when the user starts again.

DISTANCE The distance is calculated based on your speed.

Turn on

a. Make sure that the power cable is inserted correctly in an outlet.

b. Turn on the main power switch located in the front on the treadmill.

c. Insert the safety key to turn on the console.

Turn o

After 20 minutes of no usage, the console will automatically change into SLEEP MODE.

Press any button to turn the console back on.

Page 24

T10.5PRO

24

START

Press START to start the exercise.

In order to continue the program, press START again to

continue having all values displayed until the program is

complete.

If you have not made a selection and press START directly, the

MANUAL program will be selected.

STOP/PAUSE/

HOLD TO RESET

Press STOP (PAUSE/HOLD TO RESET) in order to stop/

interrupt all functions during a training program. All data on

the display will freeze.

Note: After 5 minutes, the console will return to the start

menu if the console is in the STOP (PAUSE/HOLD TO RESET)

mode.

Press STOP (PAUSE/HOLD TO RESET) twice to end the workout.

Press STOP (PAUSE/HOLD TO RESET) three times to return to

the start mode.

Continue to press STOP (PAUSE/ HOLD TO RESET) and all data

will be set to 0 and the console returns to the start mode.

ENTER/MODE

Press ENTER to conrm the entered values for TIME, WEIGHT,

SPEED, AGE, TARGET PULSE and INCLINE.

SPEED+

Press SPEED (+), to select your desired program (MANUAL,

WEIGHT REDUCTION, 5K RUN, INTERVAL, CARDIO, USER

PROGRAM).

Press SPEED (+), to increase the entered values for TIME,

WEIGHT, SPEED, AGE, TARGET PULSE.

During the workout, press SPEED (+) to increase the SPEED.

SPEED-

Press SPEED (-), to select your desired program (MANUAL,

WEIGHT REDUCTION, 5K RUN, INTERVAL, CARDIO, USER

PROGRAM).

Press SPEED (-), to decrease the entered values for TIME,

WEIGHT, SPEED, AGE, TARGET PULSE.

During the workout, press SPEED (-) to decrease the SPEED.

4.2 Button functions

Page 25

25

INCLINE up

Press INCLINE up to select a desired program (MANUAL,

WEIGHT REDUCTION, 5K RUN, INTERVAL, CARDIO, USER

PROGRAM).

Press INCLINE up to increase the entered values for TIME,

WEIGHT, SPEED, AGE, TARGET PULSE and INCLINE. During the

workout, press INCLINE up to increase the INCLINE.

DECLINE down

Press DECLINE down to select a desired program (MANUAL,

WEIGHT REDUCTION, 5K RUN, INTERVAL, CARDIO, USER

PROGRAM).

Press DECLINE down to decrease the entered values for TIME,

WEIGHT, SPEED, AGE, TARGET PULSE and INCLINE.

During the workout, press DECLINE down to decrease the

INCLINE.

4.3 Turning on the equipment

Console display - start menu

Once you have turned on the console (short beep), the console shows the “WELCOME”

notication. After a few minutes, the console will go to the start menu.

The display in the main LED window runs through all programs as shown below and

allows the user to select the desired individual program.

Note: The console has metric and imperial system dierences due to usage in dierent

countries.

Page 26

T10.5PRO

26

4.4 Programs

You can select one of the following program categories:

• Manual program

• Weight reduction program

• 5K RUN program

• Interval program

• Heart rate controlled program

• User program

• Dene

4.4.1 Manual program

Press INCLINE up or DECLINE down / SPEED (+) or SPEED (-) in order to select the

MANUAL PROGRAM (P1).

After a few seconds, the LED window will display the notication “PRESS ENTER TO

MODIFY OR START TO BEGIN WORKOUT” (press ENTER in order to change or start the

workout).

The notication above informs the user to press the button to continue.

Select your desired button for the next step:

START: Press this button in order to immediately start the exercise without entering

TIME and WEIGHT.

ENTER: Press this button in order to enter the desired TIME and WEIGHT.

STOP: Press this button to return to the start menu.

ENTER: Press ENTER in order to enter the time.

TIME illuminates on the display with “00:00”.

Select TIME (10:00 to 99:00; 1 min. increments) with INCLINE up or DECLINE down /

SPEED (+) or SPEED (-).

COMMENT on TIME

Count up: If no target time was selected, the TIME will count up from 0:00

to a maximum of 99:99 minutes.

Count down: If you entered a target time, the console will count down from

the selected time to 0:00.

ENTER: Press ENTER in order to conrm the TIME.

CALORIES lights up. Now the value means “WEIGHT”. After this, the main LED window

Page 27

27

will display the notication “ADJUST BODYWEIGHT THEN PRESS ENTER MODE”.

Select WEIGHT (30 to 180kg/40 to 400 lbs; 1 kg/lbs increments) with INCLINE up or

DECLINE down / SPEED (+) or SPEED (-).

ENTER: Press ENTER to conrm the WEIGHT. Make sure that you have selected the

correct values for TIME and WEIGHT.

START: Press START to start the exercise.

“3 2 1 GO” appears on the main LED window as the countdown for your workout.

After a long beep, the MANUAL (400meter/0.25 mile) PROGRAM prole (see below)

will appear in the main LED window.

Manual Training (P1) Comment on the manual during the workout

No pulse signal

You must either wear a compatible chest strap or grab the pulse sensors on the

handles. Your pulse will be displayed after a few seconds.

If you do not wear a compatible chest strap or your hands do not correctly grab the

sensors and a few seconds pass without a pulse, the console will turn o the pulse

circuit. The console will then show the error message “P”.

If you place your hands on the pulse sensors again, the pulse display will light up

again.

Enter INCLINE

While training, the INCLINE can be adjusted at any time in order to achieve your

training goal.

Press INCLINE up or DECLINE down in order to increase or decrease the incline from

0% to 15% in 1% increments.

Enter SPEED

During training, the SPEED can be adjusted at any type in order to achieve your

training goal.

Press SPEED (+) or SPEED (-) in order to increase or decrease the speed from 0.8 to 25

km/h/0.5 to 15 mph; 0.1 km/h/mph increments.

Press STOP (PAUSE/HOLD TO RESET) in order to stop/interrupt all functions during a

training program. All data on the display froze.

NOTE: After ve minutes, the console will return to the start menu if the console is in

the STOP (PAUSE/HOLD TO RESET) mode.

If you enter an INCLINE, INCLINE will automatically return back to 0%. In order to

continue the program, press START so that all data is displayed again. INCLINE

Page 28

T10.5PRO

28

automatically returns to the previously entered position.

Press STOP (PAUSE/HOLD TO RESET) twice to end the workout.

Now the user can select other programs (MANUAL, WEIGHT REDUCTION, 5K RUN,

INTERVAL, CARDIO, USER-DEFINED) in order to continue with the workout.

Press STOP (PAUSE/HOLD TO RESET) three times to return to the start menu.

If you press STOP (PAUSE/ HOLD TO RESET), all data will return to zero and the console

goes back to the start menu.

4.4.2 Weight reduction (P2)

Press INCLINE up or DECLINE down / SPEED (+) or SPEED (-) in order to select the

PROGRAM WEIGHT LOSS (P2).

After a few seconds, the main LED window will display the notication “PRESS ENTER

TO MODIFY OR START TO BEGIN WORKOUT” (press ENTER in order to change or start

the workout).

The notication above informs the user to press the button to continue.

Select one of the following buttons:

START: Press the button to immediately start training without entering the TIME,

WEIGHT and SPEED.

ENTER: Press the button in order to enter the TIME, WEIGHT and SPEED.

STOP: Press this button to return to the start menu.

ENTER: Press ENTER in order to enter the time.

TIME illuminates on the display with “30:00”.

Select the TIME (10:00 to 99:00; 1 min. increments) with INCLINE up or DECLINE down

/ SPEED (+) or SPEED (-).

COMMENT on TIME

Count up: If no target time was selected, the TIME will count up from 0:00

to a maximum of 99:99 minutes.

Count down: If you entered a target time, the console will count down from

the selected time to 0:00.

ENTER: Press ENTER in order to conrm the TIME.

CALORIES lights up. Now the value means “WEIGHT”. After this, the main LED window

will display the notication “ADJUST BODYWEIGHT THEN PRESS ENTER MODE”.

Page 29

29

Select WEIGHT (30 to 180 kg/40 to 400 lbs; 1 kg/lbs increments) with INCLINE up or

DECLINE down / SPEED (+) or SPEED (-).

COMMENT on WEIGHT

30 to 180kg/40 to 400lbs; 1 kg/lbs increments; The equipment is not recommended

for usage by children.

If you conrmed the desired value for WEIGHT with ENTER, this desired value for

WEIGHT will become the “default” when the user restarts the program.

ENTER: Press ENTER to conrm the WEIGHT.

SPEED lights up.

Select the max. SPEED 5 (5 to 25 km/h/3 to 15 mph; 0.1 km/h/mph increments) with

INCLINE up or DECLINE down / SPEED (+) or SPEED (-)

ENTER: Press ENTER to conrm the SPEED. Make sure that the TIME, WEIGHT and

SPEED were entered correctly.

START: Press START to start the training.

“3 2 1 GO” appears on the main LED window as the countdown for your workout. After

a long beep, the WEIGHT REDUCTION PROGRAM prole will appear in the main LED

window.

Weight reduction (P2) Comment on the manual during the workout

No pulse signal

You must either wear a compatible chest strap or grab the pulse sensors on the

handles. Your pulse will be displayed after a few seconds.

If you do not wear a compatible chest strap or your hands do not correctly grab the

sensors and a few seconds pass without a pulse, the console will turn o the pulse

circuit. The console will then show the error message “P”.

If you place your hands on the pulse sensors again, the pulse display will light up

again.

Enter INCLINE

While training, the INCLINE can be adjusted at any time in order to achieve your

training goal.

Press INCLINE up or DECLINE down in order to increase or decrease the incline from

0% to 15% in 1% increments.

Page 30

T10.5PRO

30

Enter SPEED

During training, the SPEED can be adjusted at any type in order to achieve your

training goal.

Press SPEED (+) or SPEED (-) in order to increase or decrease the speed from 0.8 to 25

km/h/0.5 to 15 mph; 0.1 km/h/mph increments.

Press STOP (PAUSE/HOLD TO RESET) in order to stop/interrupt all functions during a

training program. All data on the display froze.

NOTE: After ve minutes, the console will return to the start menu if the console is in

the STOP (PAUSE/HOLD TO RESET) mode.

If you enter an INCLINE, INCLINE will automatically return back to 0%. In order to

continue the program, press START so that all data is displayed again. INCLINE

automatically returns to the previously entered position.

Press STOP (PAUSE/HOLD TO RESET) twice to end the workout.

Now the user can select other programs (MANUAL, WEIGHT REDUCTION, 5K RUN,

INTERVAL, CARDIO, USER-DEFINED) in order to continue with the workout.

Press STOP (PAUSE/HOLD TO RESET) three times to return to the start menu.

If you press STOP (PAUSE/ HOLD TO RESET), all data will return to zero and the console

goes back to the start menu.

4.4.3 5k RUN (P3)

Press INCLINE up or DECLINE down / SPEED (+) or SPEED (-) in order to select the

PROGRAM 5K (P3).

After a few seconds, the main LED window will display the notication “PRESS ENTER

TO MODIFY OR START TO BEGIN WORKOUT” (press ENTER in order to change or start

the workout).

The notication above informs the user to press the button to continue.

Select one of the following buttons:

START: Press the button to immediately start training without entering the WEIGHT.

ENTER: Press the button in order to enter the WEIGHT.

STOP: Press this button to return to the start menu.

ENTER: Press ENTER in order to enter the time.

TIME illuminates on the display with “30:00”.

Select the TIME (10:00 to 99:00; 1 min. increments) with INCLINE up or DECLINE down

/ SPEED (+) or SPEED (-).

Page 31

31

COMMENT on TIME

Count up: If no target time was selected, the TIME will count up from 0:00

to a maximum of 99:99 minutes.

Count down: If you entered a target time, the console will count down from

the selected time to 0:00.

ENTER: Press ENTER in order to conrm the TIME.

CALORIES lights up. Now the word means “WEIGHT”. After this, the main LED window

will display the notication “ADJUST BODYWEIGHT THEN PRESS ENTER MODE”.

Select WEIGHT (30 to 180 kg/40 to 400 lbs; 1 kg/lbs increments) with INCLINE up or

DECLINE down / SPEED (+) or SPEED (-).

COMMENT on WEIGHT

30 to 180 kg/40 to 400 lbs; 1 kg/lbs increments; The equipment is not recommended

for usage by children.

If you conrmed the desired value for WEIGHT with ENTER, this desired value for

WEIGHT will become the “default” when the user restarts the program.

ENTER: Press ENTER to conrm the WEIGHT.

SPEED lights up.

Select the max. SPEED 5 (5 to 25 km/h/3 to 15 mph; 0.1 km/h/mph increments) with

INCLINE up or DECLINE down / SPEED (+) or SPEED (-).

ENTER: Press ENTER to conrm the SPEED. Make sure that the TIME, WEIGHT and

SPEED were entered correctly.

START: Press START to start the training.

“3 2 1 GO” appears on the main LED window as the countdown for your workout. After

a long beep, the 5K RUN/3.1 MILE PROGRAM will appear in the main LED window.

5k RUN (P3) Comment on the manual during the workout

No pulse signal

You must either wear a compatible chest strap or grab the pulse sensors on the

handles. Your pulse will be displayed after a few seconds.

If you do not wear a compatible chest strap or your hands do not correctly grab the

sensors and a few seconds pass without a pulse, the console will turn o the pulse

circuit. The console will then show the error message “P”.

If you place your hands on the pulse sensors again, the pulse display will light up

again.

Page 32

T10.5PRO

32

Enter INCLINE

While training, the INCLINE can be adjusted at any time in order to achieve your

training goal.

Press INCLINE up or DECLINE down in order to increase or decrease the incline from

0% to 15% in 1% increments.

Enter SPEED

During training, the SPEED can be adjusted at any type in order to achieve your

training goal.

Press SPEED (+) or SPEED (-) in order to increase or decrease the speed from 0.8 to 25

km/h/0.5 to 15 mph; 0.1 km/h/mph increments.

Press STOP (PAUSE/HOLD TO RESET) in order to stop/interrupt all functions during a

training program. All data on the display froze.

NOTE: After ve minutes, the console will return to the start menu if the console is in

the STOP (PAUSE/HOLD TO RESET) mode.

If you enter an INCLINE, INCLINE will automatically return back to 0%. In order to

continue the program, press START so that all data is displayed again. INCLINE

automatically returns to the previously entered position.

Press STOP (PAUSE/HOLD TO RESET) twice to end the workout.

Now the user can select other programs (MANUAL, WEIGHT REDUCTION, 5K RUN,

INTERVAL, CARDIO, USER-DEFINED) in order to continue with the workout.

Press STOP (PAUSE/HOLD TO RESET) three times to return to the start menu.

If you press STOP (PAUSE/ HOLD TO RESET), all data will return to zero and the console

goes back to the start menu.

4.4.4 Interval program (P4)

Press INCLINE up or DECLINE down / SPEED (+) or SPEED (-) in order to select the

PROGRAM interval (P4).

After a few seconds, the main LED window will display the notication “PRESS ENTER

TO MODIFY OR START TO BEGIN WORKOUT” (press ENTER in order to change or start

the workout).

The notication above informs the user to press the button to continue.

Select one of the following buttons: START: Press the button to immediately start

training without entering the TIME, WEIGHT and SPEED.

Page 33

33

ENTER: Press the button in order to enter the TIME, WEIGHT and SPEED.

STOP: Press this button to return to the start menu.

ENTER: Press ENTER in order to enter the time.

TIME illuminates on the display with “30:00”.

Select the TIME (10:00 to 99:00; 1 min. increments) with INCLINE up or DECLINE down

/ SPEED (+) or SPEED (-).

COMMENT on TIME

Count up: If no target time was selected, the TIME will count up from 0:00

to a maximum of 99:99 minutes.

Count down: If you entered a target time, the console will count down from

the selected time to 0:00.

ENTER: Press ENTER in order to conrm the TIME.

CALORIES lights up. Now the value means “WEIGHT”. After this, the main LED window

will display the notication “ADJUST BODYWEIGHT THEN PRESS ENTER MODE”.

Select WEIGHT (30 to 180 kg/40 to 400 lbs; 1 kg/lbs increments) with INCLINE up or

DECLINE down / SPEED (+) or SPEED (-).

COMMENT on WEIGHT

30 to 180 kg/40 to 400 lbs; 1 kg/lbs increments; The equipment is not recommended

for usage by children.

If you conrmed the desired value for WEIGHT with ENTER, this desired value for

WEIGHT will become the “default” when the user restarts the program.

ENTER: Press ENTER to conrm the WEIGHT.

SPEED lights up.

Select the max. SPEED 5 (5 to 25 km/h/3 to 15 mph; 0.1 km/h/mph increments) with

INCLINE up or DECLINE down / SPEED (+) or SPEED (-)

ENTER: Press ENTER to conrm the SPEED. Make sure that the TIME, WEIGHT and

SPEED were entered correctly.

START: Press START to start the training.

“3 2 1 GO” appears on the main LED window as the countdown for your workout. After

a long beep, the INTERVAL PROGRAM (P4) will appear in the main LED window.

Page 34

T10.5PRO

34

Interval program (P4) Comment on the manual during the workout

No pulse signal

You must either wear a compatible chest strap or grab the pulse sensors on the

handles. Your pulse will be displayed after a few seconds.

If you do not wear a compatible chest strap or your hands do not correctly grab the

sensors and a few seconds pass without a pulse, the console will turn o the pulse

circuit. The console will then show the error message “P”.

If you place your hands on the pulse sensors again, the pulse display will light up

again.

Enter INCLINE

While training, the INCLINE can be adjusted at any time in order to achieve your

training goal.

Press INCLINE up or DECLINE down in order to increase or decrease the incline from

0% to 15% in 1% increments.

Enter SPEED

During training, the SPEED can be adjusted at any type in order to achieve your

training goal.

Press SPEED (+) or SPEED (-) in order to increase or decrease the speed from 0.8 to 25

km/h/0.5 to 15 mph; 0.1 km/h/mph increments.

Press STOP (PAUSE/HOLD TO RESET) in order to stop/interrupt all functions during a

training program. All data on the display froze.

NOTE: After ve minutes, the console will return to the start menu if the console is in

the STOP (PAUSE/HOLD TO RESET) mode.

If you enter an INCLINE, INCLINE will automatically return back to 0%. In order to

continue the program, press START so that all data is displayed again. INCLINE

automatically returns to the previously entered position.

Press STOP (PAUSE/HOLD TO RESET) twice to end the workout.

Now the user can select other programs (MANUAL, WEIGHT REDUCTION, 5K RUN,

INTERVAL, CARDIO, USER-DEFINED) in order to continue with the workout.

Press STOP (PAUSE/HOLD TO RESET) three times to return to the start menu.

If you press STOP (PAUSE/ HOLD TO RESET), all data will return to zero and the console

goes back to the start menu.

Page 35

35

4.4.5 Cardio program (P5)

Press INCLINE up or DECLINE down / SPEED (+) or SPEED (-) in order to select the

CARDIO (P5) program.

After a few seconds, the main LED window will display the notication “PRESS ENTER

TO MODIFY OR START TO BEGIN WORKOUT” (press ENTER in order to change or start

the workout).

The notication above informs the user to press the button to continue.

Select one of the following buttons:

START: Press the button to immediately start training without entering the TIME,

WEIGHT and TARGET PULSE.

ENTER: Press the button in order to enter the TIME, WEIGHT and TARGET PULSE.

STOP: Press this button to return to the start menu.

ENTER: Press ENTER in order to enter the time.

TIME illuminates on the display with “30:00”.

Select the TIME (10:00 to 99:00; 1 min, increments) with INCLINE up or DECLINE down

/ SPEED (+) or SPEED (-).

COMMENT on TIME

Count up: If no target time was selected, the TIME will count up from 0:00

to a maximum of 99:99 minutes.

Count down: If you entered a target time, the console will count down from

the selected time to 0:00.

ENTER: Press ENTER in order to enter the time.

PULSE (pulse/heart rate) value lights up. Now the value means “AGE”.

After this, the main LED window will display the notication “ADJUST AGE THEN PRESS

ENTER MODE”.

Select the AGE (10 to 99 years; 1 year increments) with INCLINE up or DECLINE down

/ SPEED (+) or SPEED (-).

COMMENT about the AGE

Even though the console allows a minimum age of 10 years, the equipment is not

recommended for usage by children.

ENTER: Press ENTER to conrm the AGE.

PULSE LED lights up.

Page 36

T10.5PRO

36

Select the target pulse (60-220 BPM (beats per minute); 1 BPM increments) with

INCLINE up or DECLINE down / SPEED (+) or SPEED (-)

ENTER: Press ENTER to conrm the TARGET PULSE. Make sure that the TIME, WEIGHT

and TARGET PULSE were entered correctly.

START: Press START to start the training.

“3 2 1 GO” appears on the main LED window as the countdown for your workout. After

a long beep, the CARDIO PROGRAM (P5) will appear in the main LED window.

Cardio program (P5) Comment on the manual during the workout

No pulse signal

You must either wear a compatible chest strap or grab the pulse sensors on the

handles. Your pulse will be displayed after a few seconds.

If you do not wear a compatible chest strap or your hands do not correctly grab the

sensors and a few seconds pass without a pulse, the console will turn o the pulse

circuit. The console will then show the error message “P”.

If you place your hands on the pulse sensors again, the pulse display will light up

again.

Enter SPEED

During training, the SPEED can be adjusted at any type in order to achieve your

training goal.

Press SPEED (+) or SPEED (-) in order to increase or decrease the speed from 0.8 to 25

km/h/0.5 to 15 mph; 0.1 km/h/mph increments.

Press STOP (PAUSE/HOLD TO RESET) in order to stop/interrupt all functions during a

training program. All data on the display froze.

NOTE: After ve minutes, the console will return to the start menu if the console is in

the STOP (PAUSE/HOLD TO RESET) mode.

If you enter an INCLINE, INCLINE will automatically return back to 0%. In order to

continue the program, press START so that all data is displayed again. INCLINE

automatically returns to the previously entered position.

Press STOP (PAUSE/HOLD TO RESET) twice to end the workout.

Now the user can select other programs (MANUAL, WEIGHT REDUCTION, 5K RUN,

INTERVAL, CARDIO, USER-DEFINED) in order to continue with the workout.

Press STOP (PAUSE/HOLD TO RESET) three times to return to the start menu.

If you press STOP (PAUSE/ HOLD TO RESET), all data will return to zero and the console

goes back to the start menu.

Page 37

37

4.4.5 User-dened training program (P6)

Press INCLINE up or DECLINE down / SPEED (+) or SPEED (-) in order to select the

DEFINE USER PROGRAM (P6) program.

After a few seconds, the main LED window will display the notication “PRESS ENTER

TO MODIFY OR START TO BEGIN WORKOUT” (press ENTER in order to change or start

the workout).

The notication above informs the user to press the button to continue.

Select one of the following buttons:

START: Press the button to immediately start training without entering the TIME,

WEIGHT and SPEED during every time interval.

ENTER: Press the button to enter the TIME, WEIGHT and SPEED or INCLINE during

every time interval.

STOP: Press this button to return to the start menu.

ENTER: Press ENTER in order to enter the time.

Select the TIME (10:00 to 99:00; 1 min. increments) with INCLINE up or DECLINE down

/ SPEED (+) or SPEED (-).

COMMENT on TIME

Count up: If no target time was selected, the TIME will count up from 0:00

to a maximum of 99:99 minutes.

Count down: If you entered a target time, the console will count down from

the selected time to 0:00. The input value is saved as the “default” for the

next user-dened training.

ENTER: Press ENTER to conrm the weight.

CALORIES lights up. Now the word means “WEIGHT”. After this, the main LED window

will display the notication “ADJUST BODYWEIGHT THEN PRESS ENTER MODE”.

Select WEIGHT (30 to 180 kg/40 to 400 lbs; 1 kg/lbs increments) with INCLINE up or

DECLINE down / SPEED (+) or SPEED (-).

COMMENT on WEIGHT

30 to 180 kg/40 to 400 lbs; 1 kg/lbs increments; The equipment is not recommended

for usage by children.

If you conrmed the desired value for WEIGHT with ENTER, this desired value for

WEIGHT will become the “default” when the user restarts the program.

Page 38

T10.5PRO

38

ENTER: Press ENTER to conrm the WEIGHT.

SPEED appears for the rst time interval in the LED window.

Select SPEED (0.8 to 25 km/h/0.5 to 15 mph; 0.1 km/h/mph increments) for the rst

time interval with SPEED (+) or SPEED (-)

Then press INCLINE up or DECLINE down to enter the incline for the rst time interval.

Select INCLINE up or DECLINE down in order to enter the desired INCLINE (0% to 15%;

1% increments).

ENTER: Press ENTER in order to conrm the selected SPEED and INCLINE in the rst

time interval. Then SPEED will light up in the LED window again.

Repeat the steps above in order to select SPEED and INCLINE for the seconds and the

other time intervals (max. 21 time intervals).

START: Press START to start the training.

“3 2 1 GO” appears on the main LED window as the countdown for your workout. After

a long beep, the created USER PROGRAM prole will appear in the main LED window.

User program (P6) Comment on the manual during the workout

No pulse signal

You must either wear a compatible chest strap or grab the pulse sensors on the

handles. Your pulse will be displayed after a few seconds.

If you do not wear a compatible chest strap or your hands do not correctly grab the

sensors and a few seconds pass without a pulse, the console will turn o the pulse

circuit. The console will then show the error message “P”.

If you place your hands on the pulse sensors again, the pulse display will light up

again.

Enter SPEED

During training, the SPEED can be adjusted at any type in order to achieve your

training goal.

Press SPEED (+) or SPEED (-) in order to increase or decrease the speed from 0.8 to 25

km/h/0.5 to 15 mph; 0.1 km/h/mph increments.

Press STOP (PAUSE/HOLD TO RESET) in order to stop/interrupt all functions during a

training program. All data on the display froze.

NOTE: The console returns to the start menu after ve minutes if the console is still in

the STOP (PAUSE/HOLD TO RESET) mode.

If you enter an INCLINE, INCLINE will automatically return back to 0%. In order to

continue the program, press START so that all data is displayed again. INCLINE

automatically returns to the previously entered position.

Page 39

39

Press STOP (PAUSE/HOLD TO RESET) twice to end the workout. Now the user can

select other programs (MANUAL, WEIGHT REDUCTION, 5K RUN, INTERVAL, CARDIO,

USER-DEFINED) in order to continue with the workout.

Press STOP (PAUSE/HOLD TO RESET) three times to return to the start menu.

If you press STOP (PAUSE/ HOLD TO RESET), all data will return to zero and the console

goes back to the start menu.

Page 40

T10.5PRO

40

5 WORKOUT INSTRUCTIONS

5.1 Heart rate measuring

Pulse measuring through hand sensors

The hand sensors integrated in the handles allow you to determine your heart rate.

You can measure your heart rate by lightly grasping the sensors with both hands at the

same time. Blood pressure changes occur due to the heartbeat. The sensors measure

the changes to the electric skin resistance caused by it. These values are then used to

create an average and are displayed on the screen of the console as a heart rate.

Note:

For some people, the skin resistance change caused by the heart rate is so minimal

that the measurements do not allow for usable values. Strong callus or sweat on the

hands may also impair a correct measurement. In such cases, the heart rate will not be

shown at all or only incorrectly.

If the measurement is incorrect or not taken at all, please check if it happens to only

one person or to several people. If the pulse display only does not work in a single

case, the equipment is not defective. In this case, we recommend using a chest strap

to achieve a permanently correct heart rate display.

CAUTION: Your training equipment is not a medical device. Dierent factors

may inuence the accuracy of the heart rate display. The heart rate display only

serves as a training aid.

Telemetric heart rate measuring

This treadmill is already equipped with a heart rate receiver as standard. Using a chest

strap makes it possible for you to have a wireless heart rate measuring. This optimal

and ECG-precise type of measuring reads the heart rate directly from the skin through

a transmitting chest strap. The chest strap then sends the impulse to the receiver

integrated in the console.

Positioning the chest strap and moistening the electrodes:

Place the belt directly below the chest, while the transmitter should be placed on the

middle of the chest. The chest strap should sit comfortably, but not too loose. If the

belt is too loose, the contact to the electrodes may be disrupted or the belt may slip

while exercising. The transmitter turns on automatically once it is put on. In order to

allow for a precise measuring, you should moisten the rubber electrodes. This is best

done with a special chest strap contact gel, which is also used for ultrasound scans.

Page 41

41

Note:

If you have not been active in doing sports for a longer period of time, you should

rst go to your physician in order to discuss your training with them. You should also

contact your physician in advance in the event of heart problems, high/low blood

pressure and obesity.

Training with heart rate orientation

Heart rate orientation guarantees an extremely eective and healthy training. Through

your age and the following table, you can quickly and easily read and determine the

optimal pulse for your training. An alarm will sound if your heart rate exceeds the set

target heart rate. Which target heart rate is important for which training goal can be

found out in the following.

Fat burning (weight management): The main goal here is to burn deposits of fat. In

order to achieve this training goal, a low training intensity (approximately 55% of the

maximum heart rate) and a longer training period are required.

Cardiovascular training (cardio training): The primary goal is to increase stamina

and tness through an improved provision of oxygen through the cardiovascular

system. In order to achieve this training goal, medium intensity (approximately 75%

of the maximum heart rate) with a medium training period is required.

Anaerobic (maximum) load training: The main goal of maximum load training is to

improve recovery after short, intense loads in order to be able to quickly return to the

aerobic zone. In order to achieve this training goal, a high intensity (approximately

90% of the maximum heart rate) with short, intense load is required, which is followed

by a recovery phase in order to prevent muscle fatigue.

Page 42

T10.5PRO

42

Example:

For a 45-year-old man or woman, the maximum heart rate is 175 (220 - 45 = 175).

• The fat burning target zone (55%) is at approximately 96 beats/min.

= (220 - age) x 0.55.

• The cardio target zone (75%) is at approximately 131 beats/min.

= (220 - age) x 0.75.

• The maximum heart rate for an anaerobic load training (90%) is at approximately

157 beats/min. = (220 - age) x 0.9.

20

80

100

120

140

160

180

200

220

65 7060555045403525 30

200

195

190

185

180

175

170

180

150

110

146

107

175

171

166

162

157

153

148

143

139

135

131

128

124

105

102

99

96

94

91

88

85

83

113

116

120

144

139

136

150

155

160

165

Heart rate diagram for training intensity

Maximum pulse (220-age)

90% of maximum pulse - anaerobic (maximum) intensity training

75% of maximum pulse - cardiovascular training (cardio training)

55% of maximum pulse - fat burning (weight control)

Heartbeats

Age

Page 43

43

5.2 10 tips for eective running training

1. Set goals

What would you like to achieve with your training? Weight regulation, improved

stamina, prevent risk of disease, more mobility, cardiovascular training, etc. In order

to achieve your long-term training goal, set individual partial goals, e. g., weekly or

monthly goals.

2. Concentration on training

Try to only dedicate yourself to your training session and do not be distracted.

3. Position yourself correctly while exercising

When you execute the movement, you should start with a moderate speed and hold on

if needed. The speed can then be increased gradually. The adjustment of your natural

running style will occur relatively quickly. Beginners and overweight people should

start with a walking program in order to not overload their joints in the beginning.

4. Correct breathing / appropriate resistance level

Do not overexert yourself physically and mentally by starting with resistance levels

that are too high. Start slowly and increase the resistance steadily. Aim for regular and

calm breathing.

5. Keep yourself properly hydrated

Drink, drink, drink! Have a drinking bottle close by during your workout.

6. Sucient recovery periods

Allow your body and your muscles enough time to recover after your workout. Only a

relaxed muscle will be fully operational again.

7. Choose a diversied program

Dierent program functions from your training console support you in doing this. For

example, you can complete an interval, incline or step number training unit.

8. Creating the right workout

Every training session should have a warm-up phase, a cool-down phase and a

targeted stretching. It increases physical and mental performance and prevents

injuries and sore muscles.

Page 44

T10.5PRO

44

9. Workout journal

Keep a record of your training sessions. Note the date, resting pulse, active pulse,

recovery pulse, resistance level, time, distance, calories burnt and tness level.

10. Reward yourself

Do something good for you and your body after training or after achieving a partial

goal. Go to the sauna or a swimming pool. Mix a protein shake or enjoy a delicious

salad.

5.3 Designing a workout

We recommend two or three workouts per week. Warm up for about ve minutes

before starting each workout. Finish the workout with a cool-down and targeted

stretching.

Warm-up approx. ve min. Dynamic movement of large muscle groups at a

low intensity. Core body temperature increases

and the metabolic process is speeded up.

WEEK 1 + 2

Beginner Advanced

Days Duration Intensity Duration Intensity

Mon 20 min. Brisk walking 30 min. Running at a slow speed

Wed 20 min. Brisk walking 30 min. Running at a slow speed

Fri 20 min. Brisk walking 30 min. Running at a slow speed

Increased speed for two to three

minutes in between in the rst week.

Maintain your heart rate.

Increase the speed in between in the

second week. Maintain your heart rate.

WEEK 3 + 4

Beginner Advanced

Days Duration Intensity Duration Intensity

Mon 25 min. After every 10 min.

run for 1 min.

35 min. Running at a moderate

speed

Wed 25 min. After every 10 min.

run for 1 min.

35 min. Running at a moderate

speed

Page 45

45

Fri 25 min. After every 10 min. run

for 1 min.

35 min. Running at a moderate

speed

In the third week, run for two minutes after

every 10 minutes. Maintain your heart rate.

In the fourth week, increase the speed

for one minute each. Maintain your

heart rate.

WEEK 5 + 6

Beginner Advanced

Days Duration Intensity Duration Intensity

Mon 30 min. Alternate walking and

running

40 min. Running according to

heart rate

Wed 30 min. Alternate walking and

running

40 min. Running according to

heart rate

Fri 30 min. Alternate walking and

running

40 min. Running according to

heart rate

In the fth week, run for three minutes after

every eight minutes. In the sixth week, run

for three minutes after every six minutes.

Maintain your heart rate.

Pay attention to your heart rate.

WEEK 7 + 8

Beginner Advanced

Days Duration Intensity Duration Intensity

Mon 35 min. Walk 8 minutes, run 5

minutes

45 min. Running according to

heart rate

Wed 35 min. Walk 8 minutes, run 5

minutes

45 min. Running according to

heart rate

Fri 35 min. Walk 8 minutes, run 5

minutes

45 min. Running according to

heart rate

Increase in the eight week: Walk ve minutes, run seven minutes. Maintain your heart

rate.

If you feel comfortable, then include a

few steps or hills in your training.

Cool-down approximately ve min. Finish your training at low resistance and

at slow speed. Allow your body to gently

slow back down.

Page 46

T10.5PRO

46

5.4 Stretching exercises for leg & chest muscles

1. Exercise: Stretching of front thigh / leg extension (quadriceps)

• Stable position, grab arches of feet

• Pull heel towards buttocks, knee points downwards

(no abduction)

• Straight upper body, avoid tilting the pelvic forward

(hollow back) by tensing the abdominal muscles

• Change legs

2. Exercise: Stretching the back thigh / leg curl (hamstring)

• Pull thigh towards upper body with both

hands

• Stretch through increased stretching in

the knee joint

• The lower leg maintains contact with the

oor, keep hips bent

• Change legs

Page 47

47

3. Exercise: Stretching the calf muscles (gastrocnemius)

• Place feet parallel to each other pointing forward,

the heels touch the oor

• Support yourself on a chair coming from a lunge

• Move your body weight to the front leg, press

your heel from the rear leg towards the oor and

hold the contact

• Slowly stretch your knee of the rear leg until you

feel the stretch in your calves

• Change legs

4. Exercise: Stretching the chest muscles (pectoralis major)

• Stand parallel to a wall

• Place your forearm at 90° to the wall with the elbow

just above shoulder height

• Turn your head and upper body gradually to the

opposite sides until you feel a stretch in the front

chest, of the shoulder being leaned on

• Pay attention to tension in your abdominal and

gluteal muscles

• Your weight is on your front leg

• Change legs

All recommendations of these instructions apply solely to healthy persons and

are not suitable for those with heart or cardiovascular problems. All of the tips

are intended only as a guide to help you create a workout. Your physician can

oer appropriate advice for particular, personal requirements.

We hope you enjoy your workout and have a lot of success!

Page 48

T10.5PRO

48

5.5 Workout journal

Date

Training weight

Time (min.)

Calories burnt Body weight

Distance

Ø Pulse

Resistance level

I feel ...

(Copy template)

Page 49

49

6 WARRANTY INFORMATION

Taurus training tness equipment is subject to strict quality controls. However, if a

tness equipment purchased from us does not work perfectly, we take it very seriously

and ask you to contact our customer service as indicated. We are happy to help you by

phone via our service hotline.

Error descriptions

Your tness equipment is developed for long-term, high-quality training. However,

should a problem arise, please rst read the operating instructions. For further

assistance, please contact your contract partner or call our service hotline. To ensure

your problem is solved as quickly as possible, please describe the defect as exactly as

possible.

In addition to the statutory warranty, we provide a warranty for every tness

equipment purchased from us according to the following provisions.

Your statutory rights are not aected.

Warrantee

The warrantee is the rst/original buyer and/or any person who received a newly

purchased product as a gift from the original buyer.

Warranty periods

The following warranty periods begin on delivery of the tness equipment.

Model Use Full warranty Frame Motor

T10.5 Pro

Home use 24 months 30 years 10 years

Semi-professional use 24 months

Professional use 12 months

Repair costs

According to our choice, there will either be a repair, a replacement of individual

damaged parts or a complete replacement. Spare parts, that have to be mounted

while assembling the equipment, have to be replaced by the warrantee personally

and are not a part of repair. After the expiration of the warranty period for repair costs,

a pure parts warranty applies, which does not include the repair, installation and

delivery costs.

Page 50

T10.5PRO

50

The terms of use are dened as follows:

• Home use: solely for private use in private households up to 3 hours per day

• Semi-professional use: up to 6 hours per day (e. g. rehabilitation centers, hotels,

clubs, company gyms)

• Professional use: more than 6 hours per day (e. g. commercial gyms)

Warranty service

Within the warranty period, equipment which develops faults as a result of material

or manufacturing defects, will be repaired or replaced at our discretion. Ownership

of equipment or parts of equipment which have been replaced is transferred to us.

The warranty period is not extended nor does a new warranty period begin following

repair or replacement under the warranty.

Warranty conditions

For the warranty to be valid, the following steps must be taken:

Please contact our customer service by email or phone. If the product under warranty

has to be sent in for repair, the seller bears costs. After expiry of the warranty, the buyer

bears the costs of transport and insurance. If the fault is covered by our warranty, you

will receive a new or repaired equipment in return.

Warranty claims are invalid in case of damage resulting from:

• misuse or improper handling

• environmental inuences (moisture, heat, electrical surge, dust, etc.)

• failure to follow the current safety measures for the equipment

• failure to follow the operating instructions

• use of force (e. g. hitting, kicking, falling)

• interventions which were not carried out by one of our authorized service centers

• unauthorized repair attempts

Proof of purchase and serial number

Please make sure that you are able to provide the appropriate receipt when claiming

on your warranty. So that we can clearly identify the model of your equipment, and

for the purposes of our quality control, you will need to give the serial number of

your equipment, when contacting the service team. Where possible please have your

serial number and your customer number ready when you call our service hotline. It

will help us to deal with your request swiftly.

Page 51

51

7 DISPOSAL

At the end of its operational life, this equipment cannot be disposed

of in normal household waste. Instead, it must be disposed of via an

electricals recycling centre. Further information can be obtained from

your local authority‘s recycling service.

The materials can be recycled as per their symbols. Through the reuse, recycling of

materials or other forms of recovery of old equipment, you make an important contribution to the protection of the environment.

If you have trouble nding the serial number on your tness equipment, our service

team is at your disposal to oer further information.

Service outside the warranty period

We are also happy to issue an individual cost estimate if there is a problem with your

tness equipment after the warranty has expired, or in cases which do not fall under

the terms of the warranty, e. g. normal wear and tear. Please contact our customer

service team to nd a quick and cost-eective solution to your problem. In such a case

you will be responsible for the delivery costs.

Communication

Many problems can be solved just by speaking to us as your contract partner. We

know how important it is to you as a user of the tness equipment to have problems

solved quickly and simply, so you can enjoy working out with minimal interruption.

For that reason, we also want to resolve your queries quickly and in a straightforward

manner. Thus, please always keep your customer number and the serial number of the

faulty equipment handy.

Page 52

T10.5PRO

52

8 ORDERING ACCESSORIES

Sport-Tiedje oor mat size XXL

Art. No. ST-FM-XXL

Polar transmitter chest strap T34

uncoded

Art. No. T34

Togu Senso Walking Trainer

Art. No. TOGU-470501

Chest strap

contact gel

250ml

Art. No. BK-250

Sport-Tiedje

silicone spray

Art. No. ST-1003

Fitness equipment care set

Art. No. HF-500

Page 53

53

9 ORDERING SPARE PARTS

9.1 Service hotline

So that we can give you the best possible service, please have your model name, part

number, serial number, exploded drawing and parts list ready.

SERVICE-HOTLINE

9.2 Serial number and model name

Before assembling your equipment, nd the serial number on the white sticker and

enter it in the appropriate space.

Serial number:

Brand / category: Model name:

Taurus treadmill T10.5 Pro

+31 172 619961

info@tshop.nl

Mon - Thu 9 am - 5 pm

Fri 9 am - 9 pm

Sat 10 am - 5 pm

NL

+44 141 876 3972

orders@powerhousetness.co.uk

Mon - Fri 9 am - 5 pm

UK

+49 4621 4210-0

+49 4621 4210-699

service@sport-tiedje.de

Mon - Fri 8:00 am - 6:00 pm

Sat 9:00 am - 6:00 pm

DE

Page 54

T10.5PRO

54

9.3 Parts list

No. Description Qty. No. Description Qty.

1 Running Deck Frame 1 34 Square Plug (38x50mm) 2