Page 1

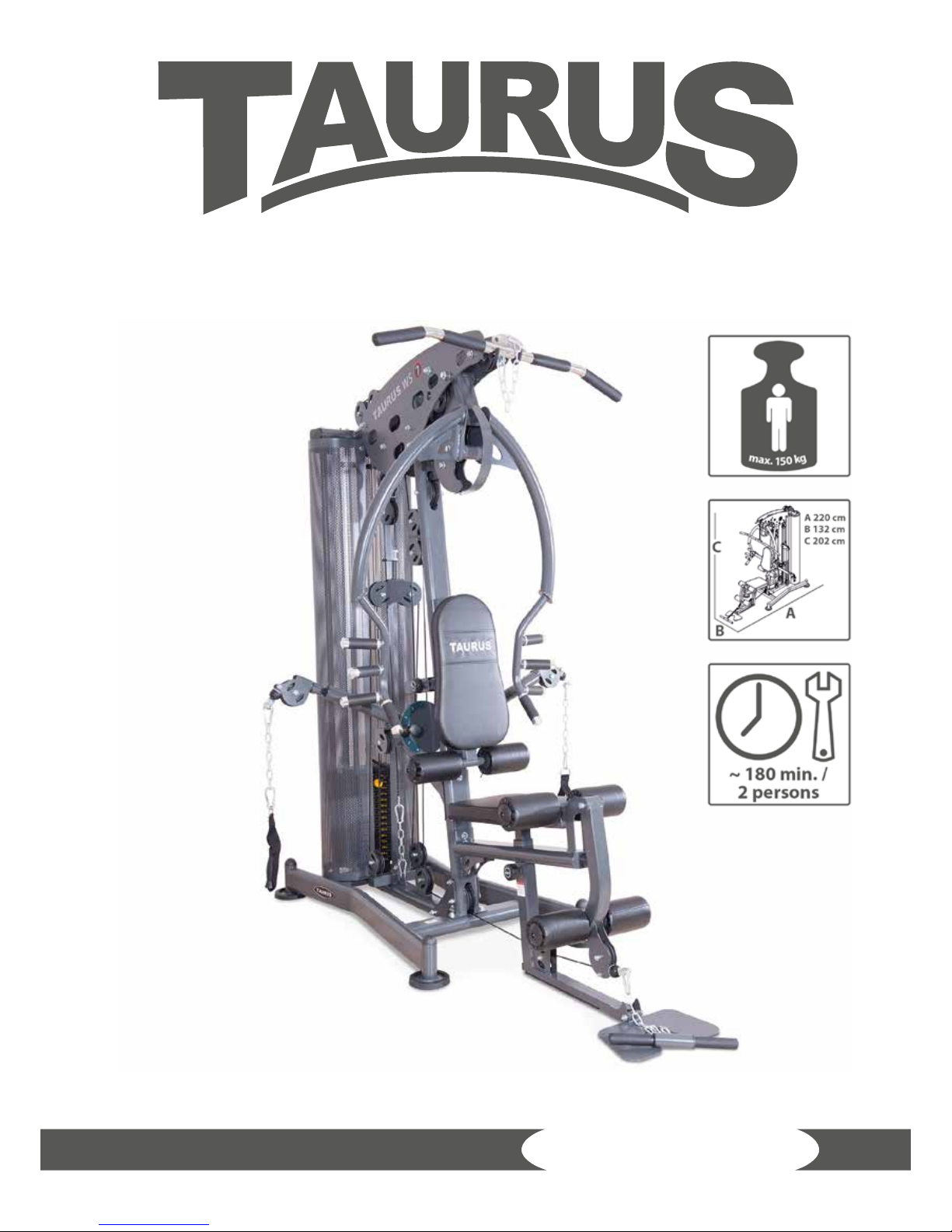

Assembly and operating instructions

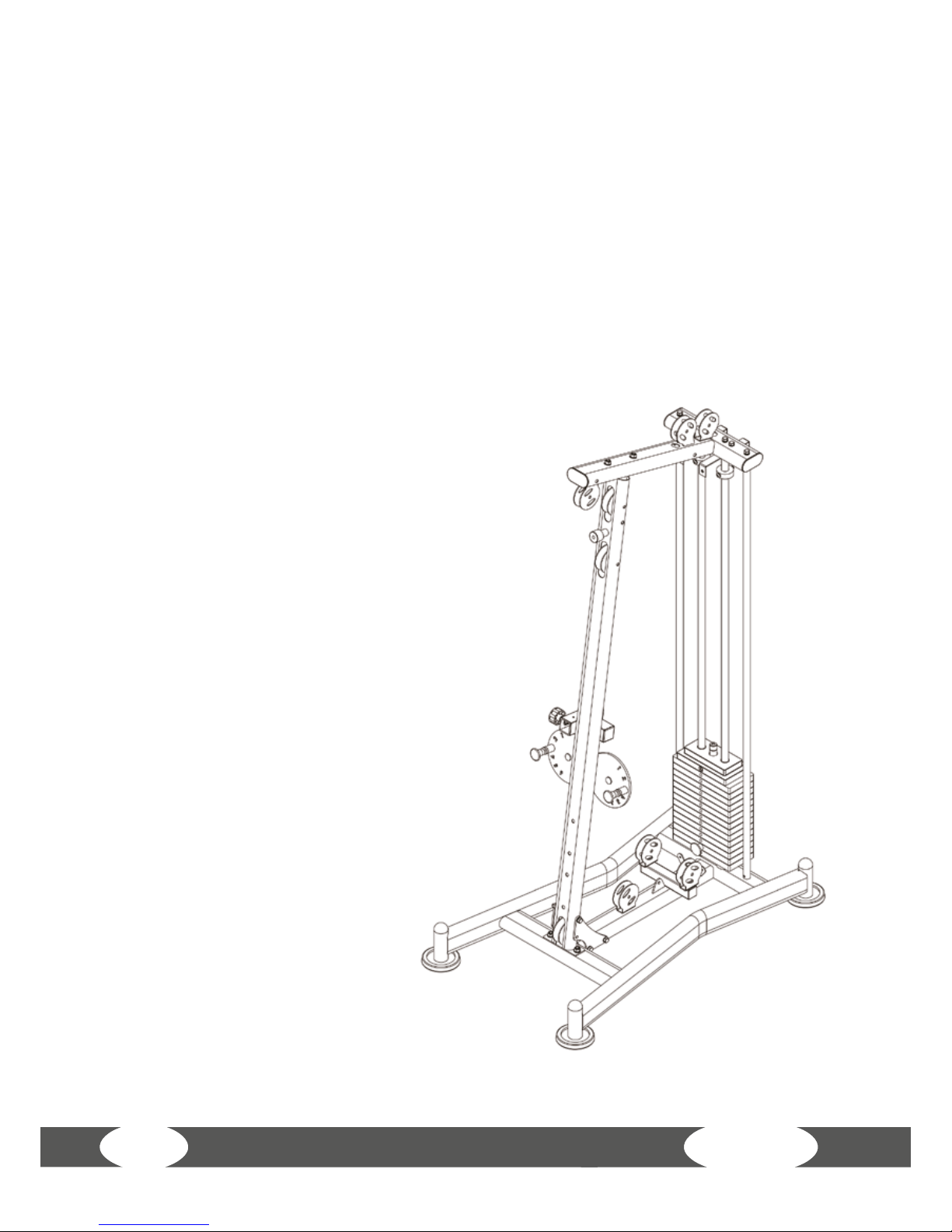

Multi-gym WS7

TF-WS7-2

Page 2

WS7

2

Page 3

3

Dear Customer,

Thank you for deciding for a high-quality training equipment of the brand Taurus,

the brand that makes athlete‘s hearts beat faster. Taurus oers a wide range of home

tness equipment like elliptical cross trainers, ergometers, treadmills and rowing

machines. Taurus equipment is the optimal equipment for all those who want to train

at home independent of goals and tness level. For further information please visit

www.sport-tiedje.com or www.taurus-tness.de.

SAFETY NOTICE

Please read all of the instructions carefully before assembly and rst

use. These instructions are intended to ensure speedy assembly and

explain safe usage. Make sure that all people exercising with the

equipment (in particular children and persons with limited physical, sensory, mental or

motor capabilities) are informed about these instructions and its content in advance.

In case of doubt, a responsible person must supervise the use of the equipment.

This equipment has been manufactured according to the latest safety knowledge. As

far as possible, potential safety hazards which could cause injury have been eliminated.

Make sure to follow the instructions carefully and that all parts are securely in place. If

required, read through the instructions again to correct any mistakes.

Please pay close attention to the safety and maintenance instructions given here. The

contract partner cannot be held liable for damage to health, accidents or damage to

the equipment when it is not used in accordance with these instructions.

The equipment is only suitable for use at home. The equipment is not suitable for

semi-professional (e. g., hospitals, clubs, hotels, schools, etc.) and commercial or

professional use (e. g., health clubs).

Retain these instructions in a safe place for future reference, maintenance or when

ordering replacement parts.

Page 4

WS7

4

Page 5

5

CONTENTS

1 GENERAL INFORMATION 6

1.1 Technical data 6

1.2 Personal safety 7

1.3 Set-up place 8

2 ASSEMBLY INSTRUCTIONS, MAINTENANCE AND CARE 9

2.1 Workout exercises 9

2.2 Faults and Troubleshooting 10

2.3 Maintenance and service calendar 11

3 ASSEMBLY 12

4 WORKOUT INSTRUCTIONS 50

4.1 Workout exercises 50

4.2 Stretching exercises for leg and chest muscles 54

4.3 Workout journal 56

5 WARRANTY INFORMATION 57

6 DISPOSAL 59

7 ORDERING ACCESSORIES 60

8 ORDERING SPARE PARTS 61

8.1 Service hotline 61

8.2 Serial number and model name 61

8.3 Parts list 62

8.4 Exploded drawing 65

Page 6

WS7

6

1 GENERAL INFORMATION

1.1 Technical data

Weight and dimensions:

Weight and dimensions:

Item weight (gross, incl. packaging): 249 kg

Item weight (net, without packaging): 233 kg

Weight stack in kg: 90 kg

Packed dimensions boxes (length x width x height):

No. 1 approx. 195 cm x 47 cm x 22 cm

No. 2 approx. 139 cm x 93 cm x 28.5 cm

No. 3 approx. 181.5 cm x 30 cm x 20 cm

No. 4 approx. 28.5 cm x 13 cm x 13.5 cm

No. 5 approx. 28.5 cm x 13 cm x 13.5 cm

No. 6 approx. 28.5 cm x 13 cm x 13.5 cm

Set-up dimensions (length x width x height): approx. 220 cm x 132 cm x 202 cm

Maximum user weight: 150 kg/330 lbs

Page 7

7

1.2 Personal safety

+ Before you start using the equipment, you should consult your physician that this

type of exercise is suitable for you from a health perspective. Particularly aected

are persons who: have a hereditary disposition to high blood pressure or heart

disease, are over the age of 45, smoke, have high cholesterol values, are overweight

and/or have not exercised regularly in the past year.

+ Please note that working out excessively can seriously damage your health.

+ The equipment may only be used for its intended purpose; this means for strength

training for adults.

+ Any other usage is prohibited and potentially dangerous. The contract partner

cannot be held liable for damage resulting from improper use.

+ The equipment may not be used by several persons at the same time.

+ Children should not be allowed unsupervised access to the equipment.

+ Before starting your training, make yourself familiar with all of the equipment‘s

functions and setting options. Have an expert explain the correct usage of the

product to you.

+ Make sure that nobody is in the range of motion of the equipment while exercising.

+ Keep your hands, feet and other body parts, hair, clothing, jewelry and other

objects well clear of moving parts.

+ During use, wear suitable sports clothing rather than loose or baggy clothing.

When selecting sports shoes, think about the suitability of the sole – preferably

this should be made of rubber or other non-slip materials. Shoes with heels, leather

soles, studs or spikes are not suitable. Never work out in bare feet.

+ It is also important to take note of the information given in the workout instructions

for creating a workout plan.

+ At the rst signs of weakness, nausea, dizziness, pain, diculty in breathing or

other abnormal symptoms, stop your workout immediately and, if necessary,

consult your physician.

+ Before each training session, check all cables for any possible damage. Immediately

replace defective cables and do not use the equipment until it has been repaired.

Also pay attention to any material fatigue.

+ Never let go of the handlebars or grips as long as there is resistance in order to

avoid crushing and similar injuries.

+ Make sure that the cables are always in the wheel guide. If the cables are stuck

while you are training, stop training immediately and check the cable run.

+ If you adjust the seat, make sure that it fully locks in its new position, because

otherwise it may slide and lead to injuries.

Page 8

WS7

8

1.3 Set-up place

+ The equipment should only be used indoors, in a suciently heated and dry area

(ambient temperature between 10°C and 35°C). The equipment should not be

used outdoors or in rooms with high humidity (over 70%) like swimming pools. The

equipment should only be stored in surroundings with an ambient temperature

between 5°C and 45°C.

+ The training room should be well ventilated during training and not be exposed to

any draughts.

+ Choose a location in which to place the equipment such that there is enough free

space/clearance to the front, the rear and to the sides of the equipment (at least

1.50 m). Furthermore, the equipment should not be set up in main entrances or on

escape routes.

+ No objects of any type should be inserted into the openings of the equipment.

+ The equipment should be placed on a level and solid surface, any unevenness in

the oor should be leveled out.

+ A oor protective mat / equipment underlay can help to protect high-quality oor

coverings (parquet, laminate, cork, carpets) from dents and sweat and can help to

level out slight unevenness.

2

Page 9

9

2 ASSEMBLY INSTRUCTIONS, MAINTENANCE AND CARE

2.1 General instructions

+ Please check if all parts and tools belonging to the equipment are included in the

delivery and if there is any transport damage. If there are any complaints, please

contact your contract partner directly.

+ Some of the nuts and bolts to be used in assembly are already pre-mounted in

order to make set-up as easy as possible.

+ The equipment must be assembled by adults. In case of doubt, ask for assistance

from another person with technical skills.

+ Keep children away from the equipment during assembly, because small parts are

included in the delivery and may be swallowed.

+ Make sure that you have enough space (at least 1.50 m) in every direction during

assembly.

+ Do not leave any tools and packaging materials like plastic sheeting laying around

to avoid danger of suocation for children.

+ Assemble the equipment on an underlay mat or on the cardboard packaging in

order to avoid damage to the equipment and to the oor (scratches).

+ Before starting assembly, all individual parts should be placed on the oor next to

each other.

+ Read the assembly instructions carefully and assemble the equipment according

to the illustrations. Proceed carefully and cautiously.

+ First loosen all parts and check for their correct tting. Then tighten the screws

using a tool.

+ Modications to the design or improper repairs may pose a hazard to the user and

should not be carried out. The product warranty may be void as a result.

+ Only authorized service technicians are permitted to carry out all servicing and/or

repairs – it excludes maintenance and care.

+ Damaged or worn components may impair your safety and the lifespan of

the equipment. You should therefore immediately replace damaged or worn

components. Please contact your contract partner in such a case. The equipment

should no longer be used until it has been repaired. When needed, only use

original Taurus spare parts.

+ Check the tightness of all screw connections once a month.

+ In order to be able to guarantee the constructively dened safety level of this

equipment, we recommend having the equipment regularly maintained (at least

once a year) by specialists (service technicians of your contract partner).

Page 10

WS7

10

+ The equipment may be cleaned of dust, dirt and sweat using a damp cloth. The

use of solvents should be strictly avoided. Also, make sure that no liquids (e. g.

sweat) get into the openings of the equipment.

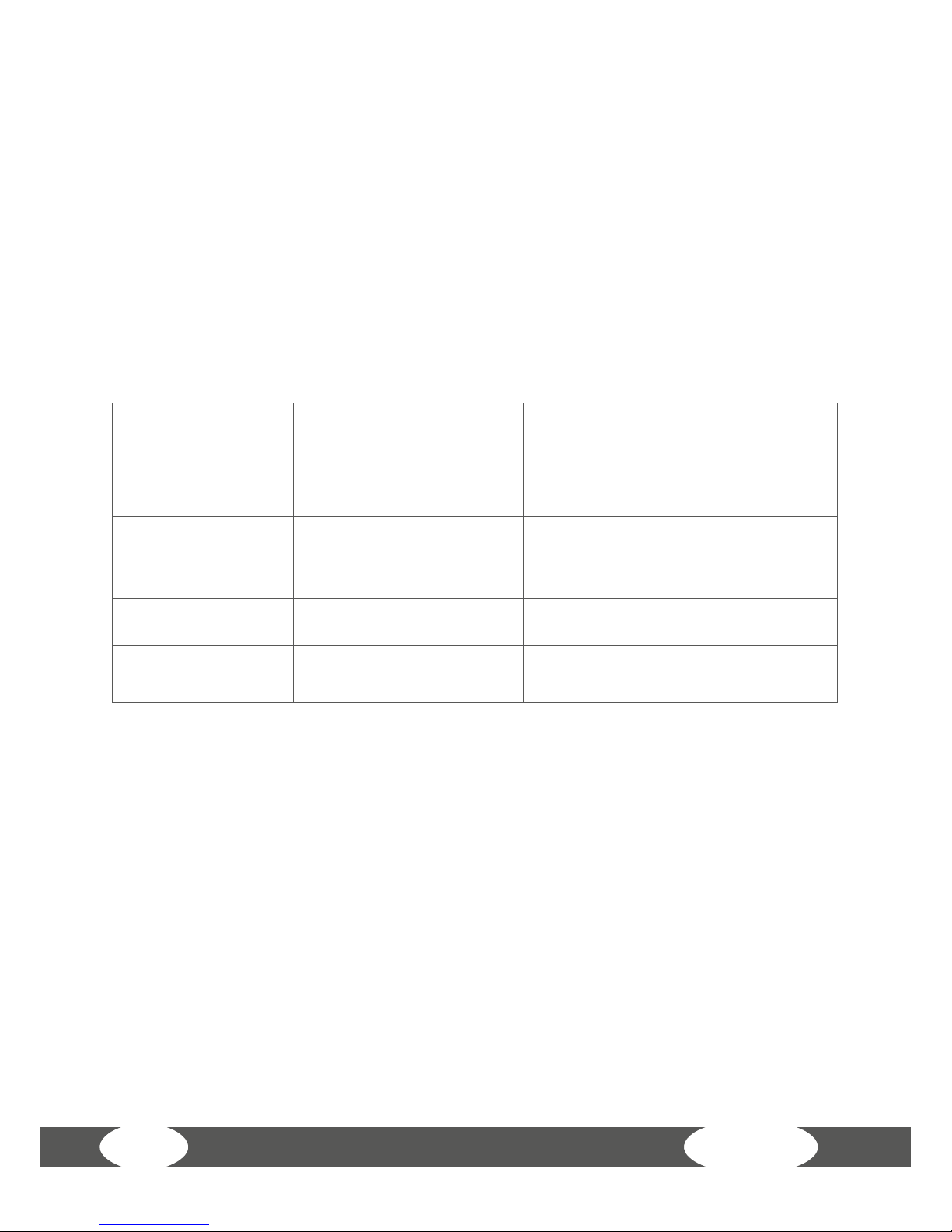

2.2 Faults and Troubleshooting

The equipment runs through regular quality controls during production. Nevertheless,

errors or malfunctions on the equipment may occur. Individual parts are often the

cause of faults and replacement is usually sucient. Please use the following overview

to see the four most common errors and how to repair them. If the equipment still

does not work properly, please contact your contract partner.

Problem Cause Solution

Scraping noises

Cable or pulleys not

running smoothly or are

damaged

Perform a visual check of the route

of the cable or of the pulley or of

the pulley guide

Weight is

suspended in the

air

Cable is too tightly

stretched

Readjust cable tension

Cable is not taut Cable is too slack Readjust cable tension

Squeaking &

cracking noises

Screws are either too

loose or too tight

Check that screws are correctly

tightened or lubricate

Page 11

11

2.3 Maintenance and service calendar

The multi-gym needs to be cleaned after every training session with a moist towel (no

solvent!) in order to avoid damage caused by sweat.

The following routine work must be done in the specied time intervals:

Part Weekly Weekly 2x annually Annually

Pulling ropes and rollers C / I

Bolts

I

Pulleys and cable guide

I

Legends: C = cleaning; I = inspect

Page 12

WS7

12

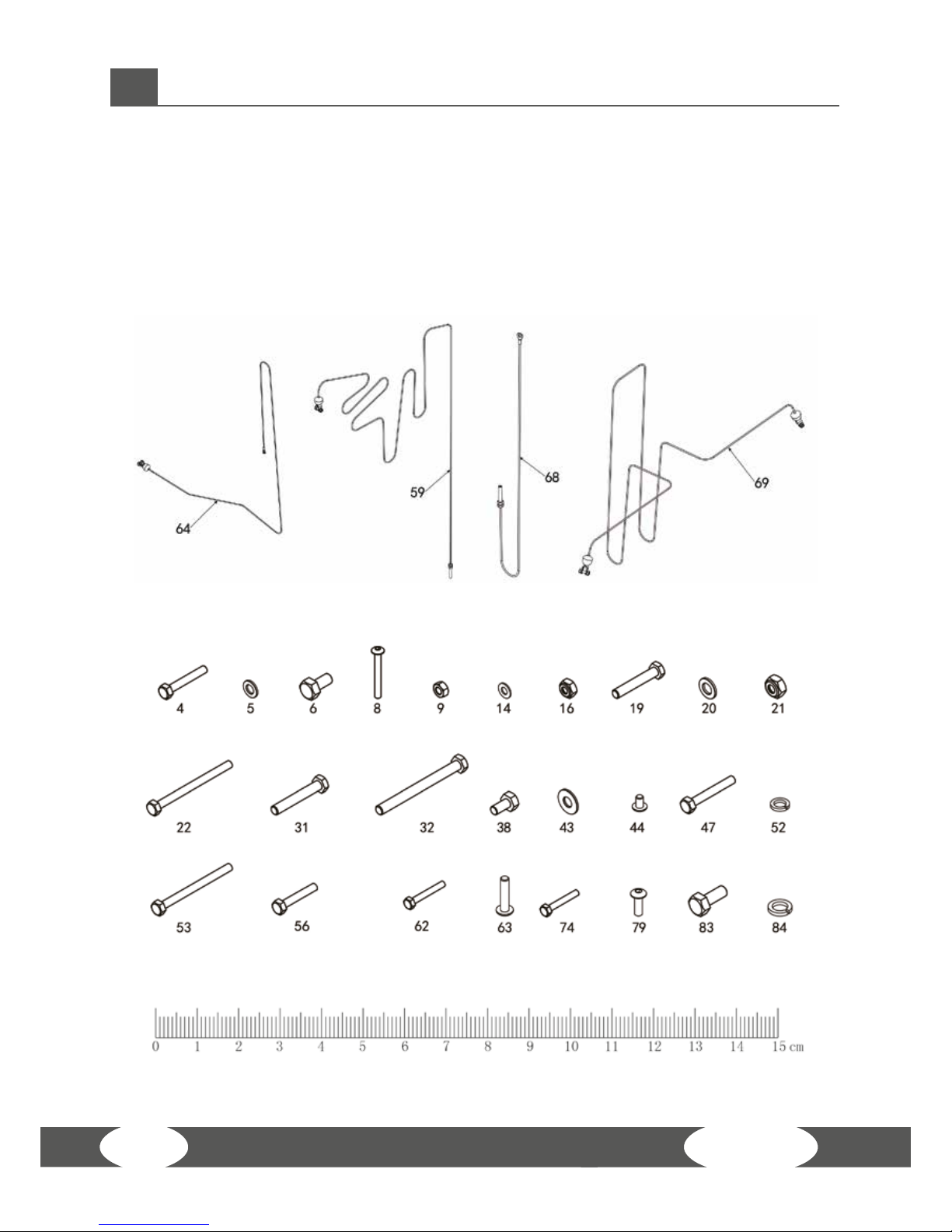

3 ASSEMBLY

In order to make the assembly of the equipment easier, we recommend that you

do not initially fully tighten the screws and bolts. However, you should make

sure that all screws and bolts are rmly tightened after assembly.

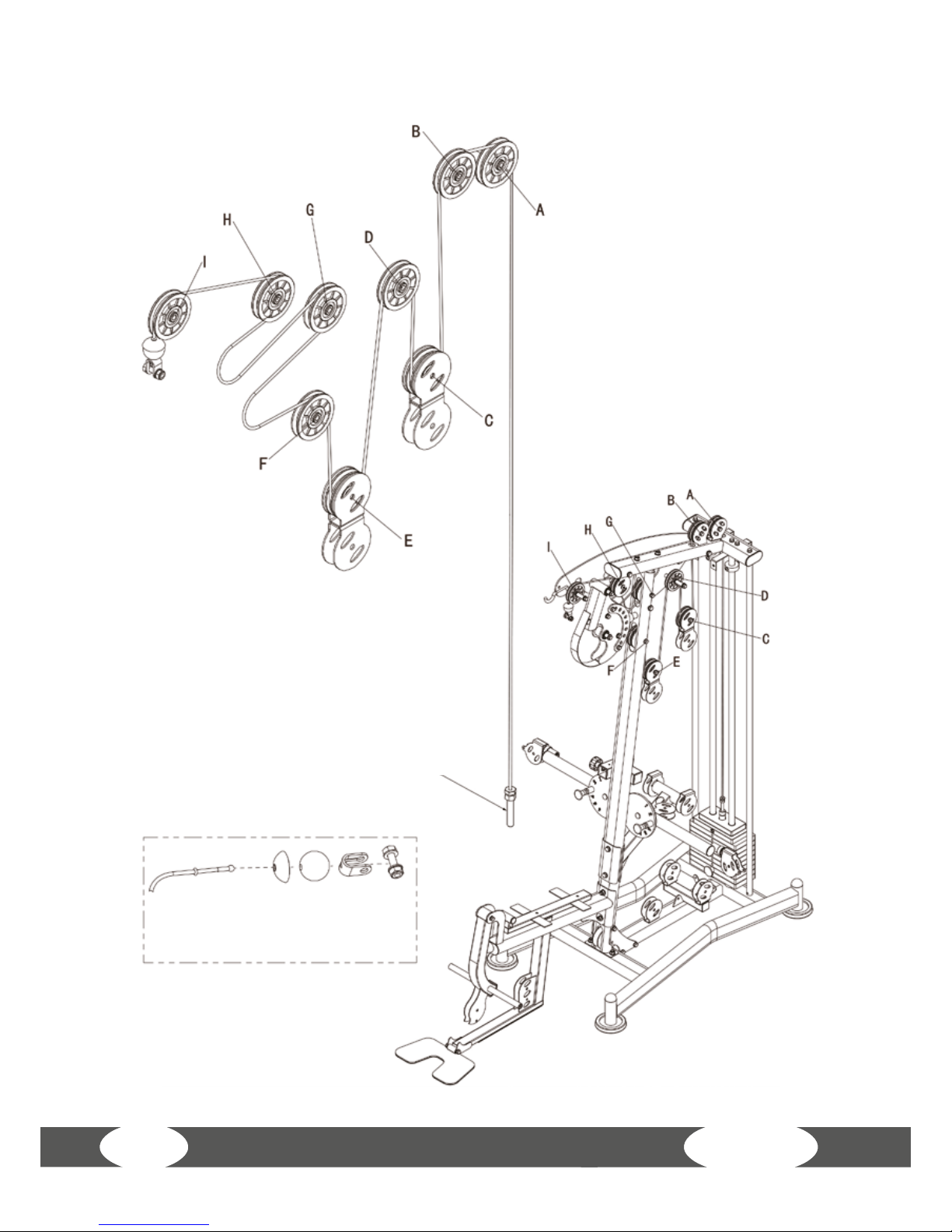

Screws and cables overview

Page 13

13

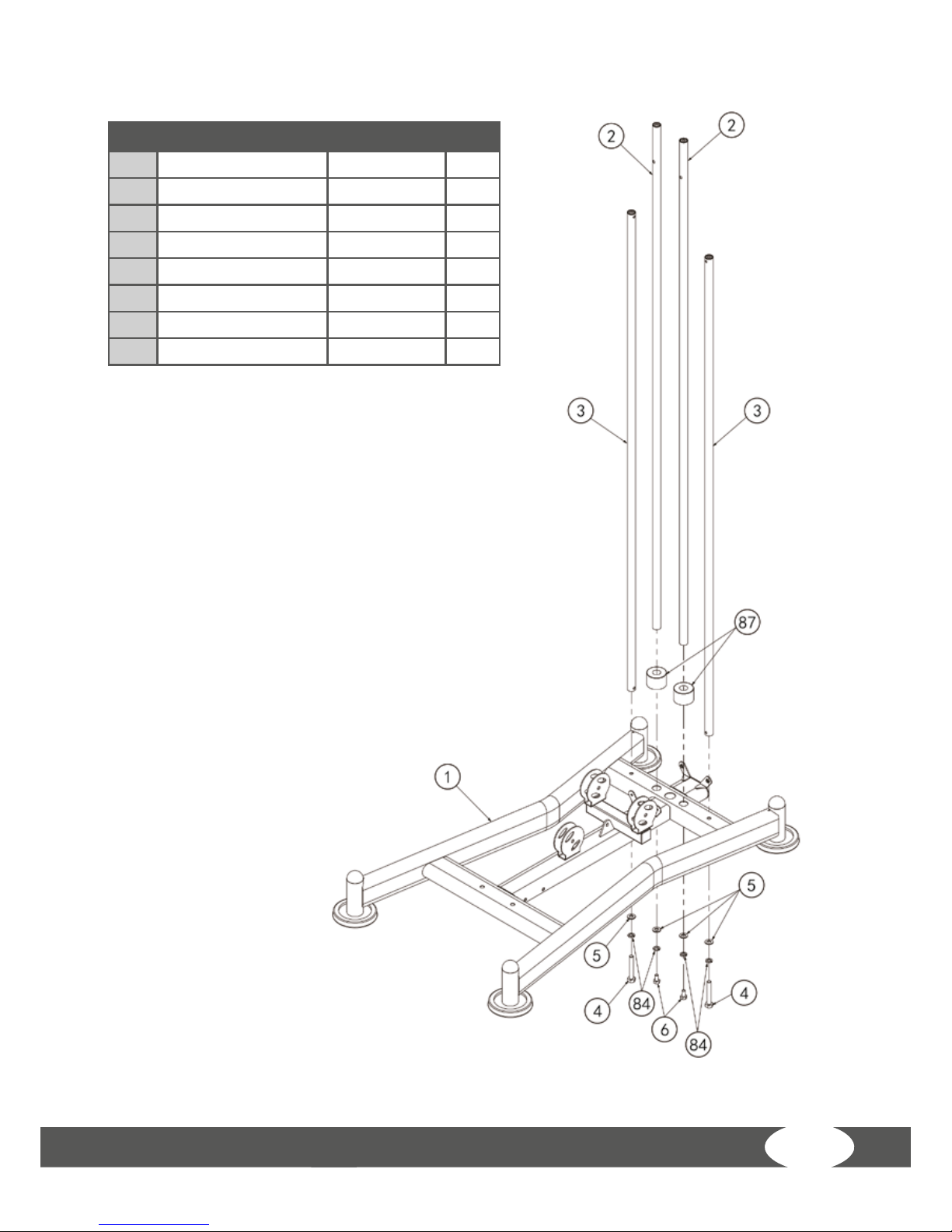

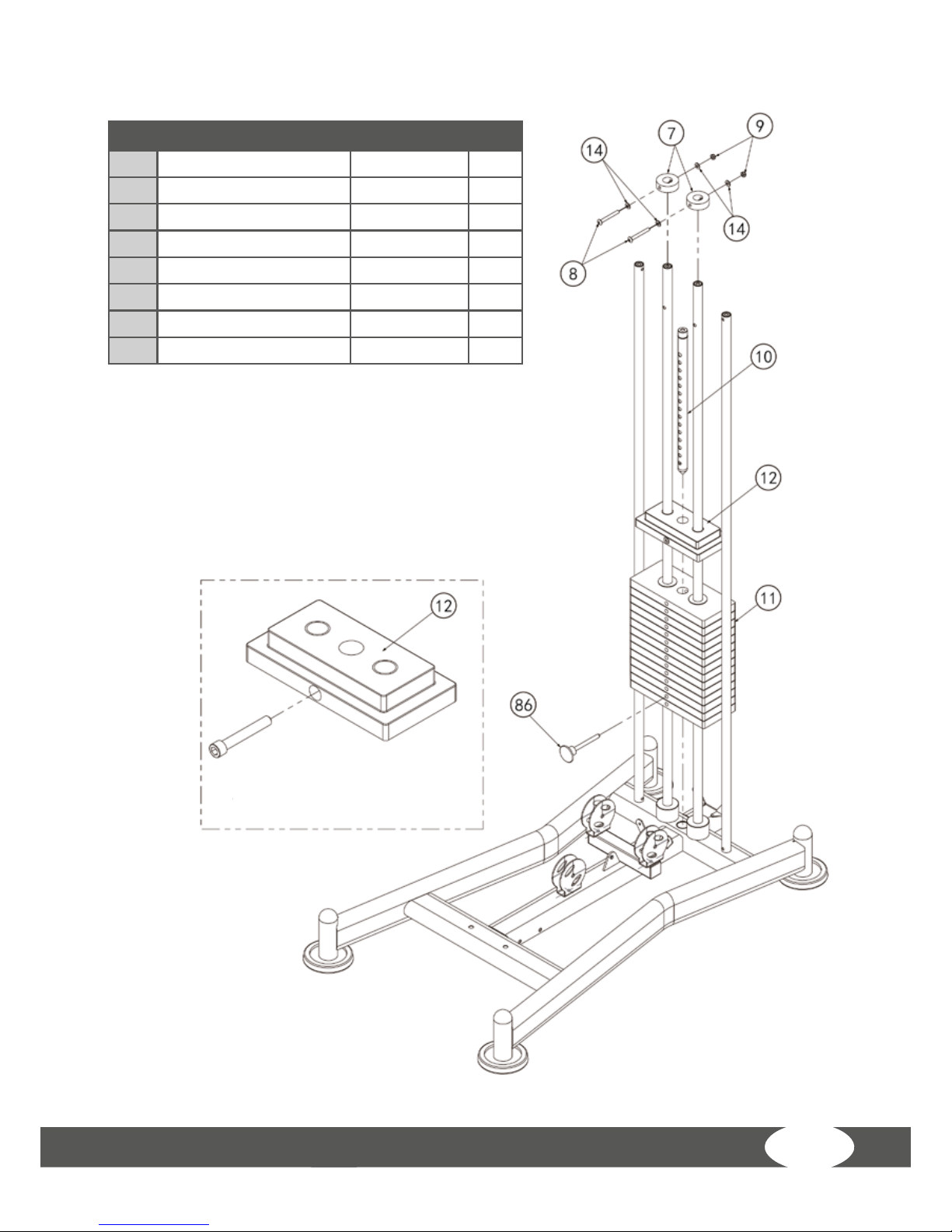

Step 1: Exploded drawing

No. Description Note

Qty.

1 ground frame 1

2 guide bar Φ25*1853 2

3 back support tube Φ259*1757.5 2

4 outer hexagon bolt M10*65 2

5 shim Φ10 4

6 outer hexagon bolt M10*20 2

84 spring shim Φ10 4

87 cushion Φ60*Φ26*42 2

Page 14

WS7

14

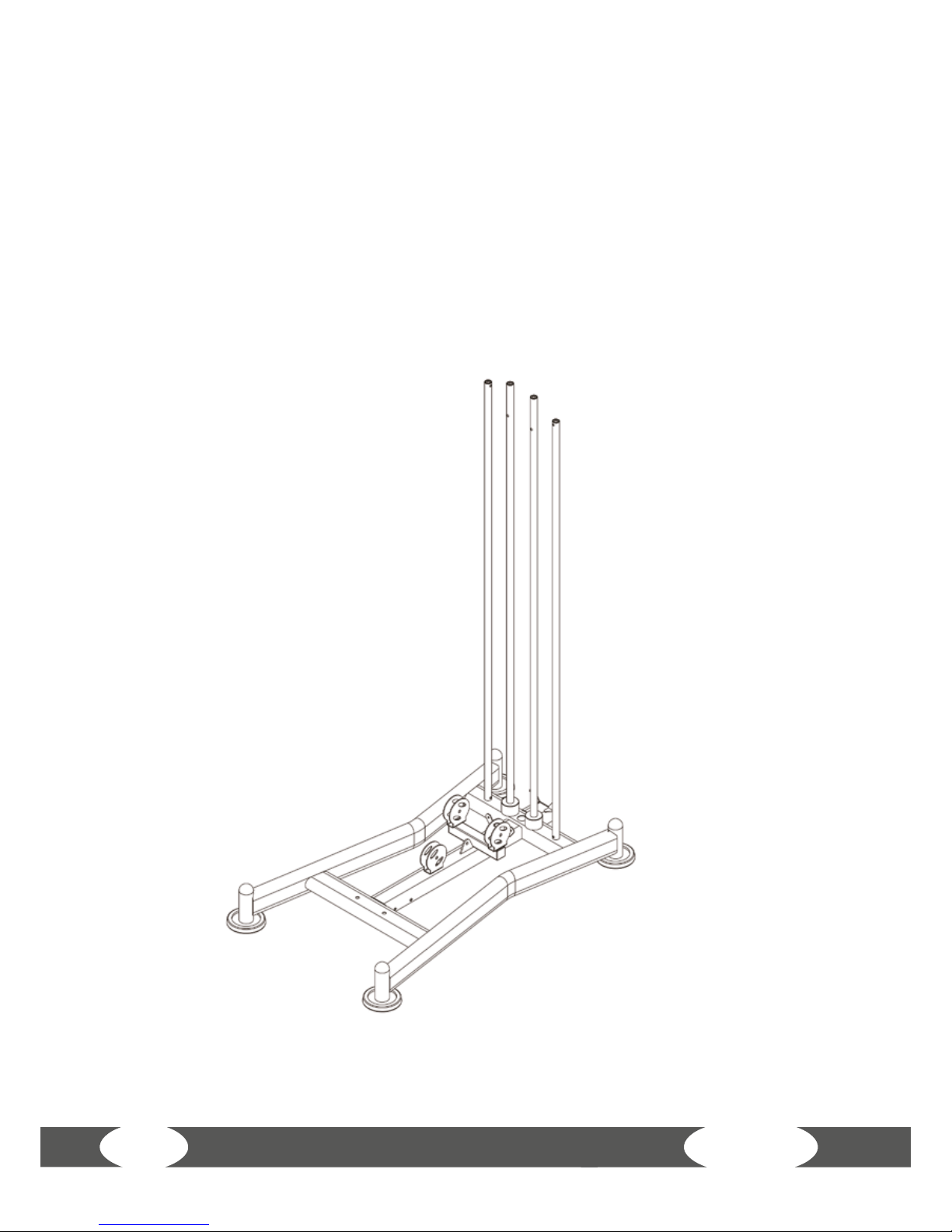

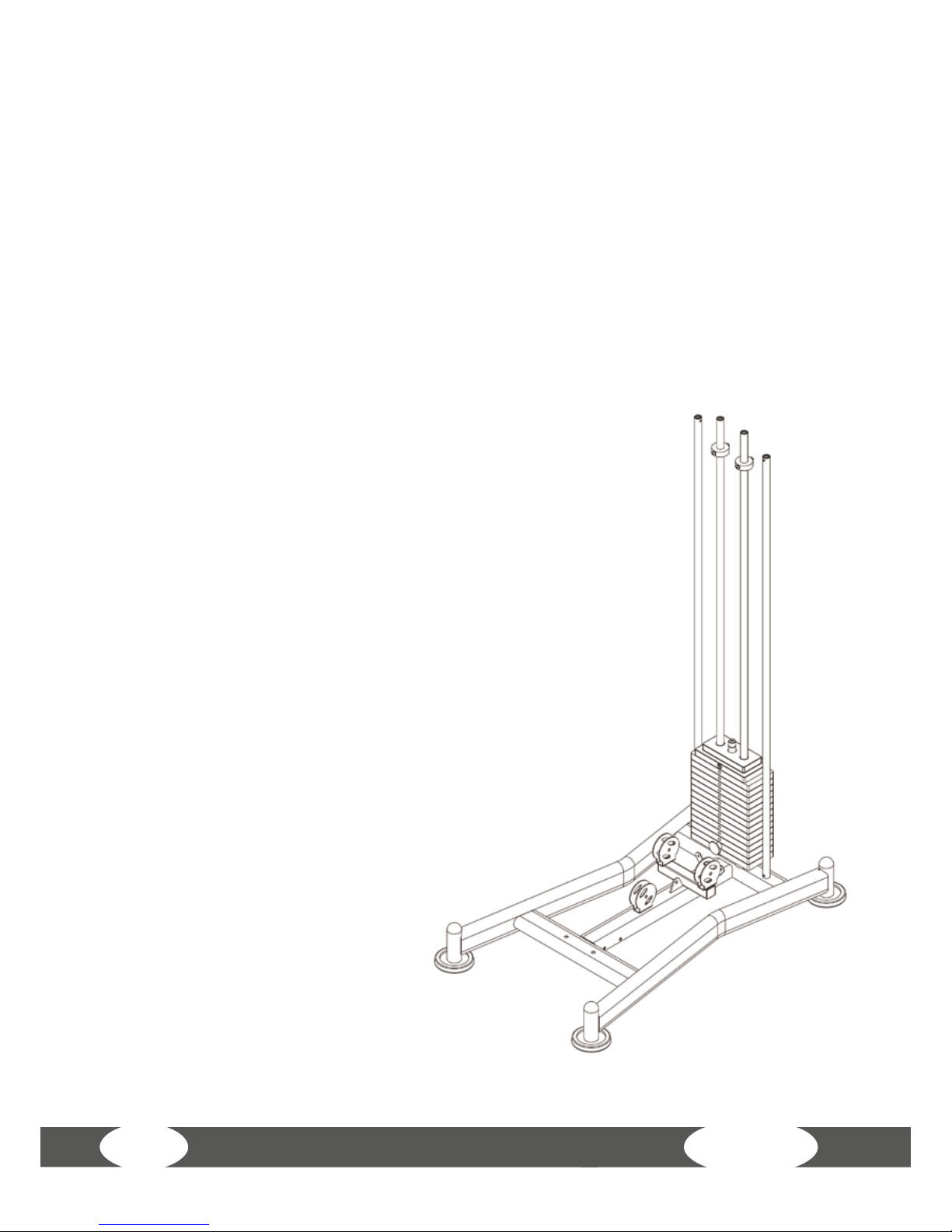

Step 1: Assembly

1. Mount the rear support struts (3) to the base frame (1) using hexagon bolts M10*65

(4), (4), spring washers Φ10 (84) and washers Φ10 (5).

2. Secure the guide rods (2) to the base frame (1) using hexagon bolts M10*20 (6),

spring washers Φ10 (84) and washers Φ10 (5).

3. Slide the rubber dampers (87) on the guide rods (2) from the top down to the very

bottom.

Page 15

15

Step 2: Exploded drawing

No. Description Note

Qty.

7 weight stack rubber crash Φ60*Φ26*20 2

8 hexagon sock button head M8*70 2

9 lock nut M8 2

10 weight stack lift bar 92 KG 1

11 below steel weight stack 6 KG 14

12 top steel weight stack 8 KG 1

14 shim Φ8 4

86 magnetic pin Φ10*100 1

Upper steel weight stack (12)

Partially enlarged drawing

Page 16

WS7

16

Step 2: Assembly

1. Guide the 14 6-kg weight plates (11) carefully down the two guide rods (2); nally

set the single 8-kg weight stack (12) on the top.

Ideally, the weight stacks should be labeled before they are put in place; arrange

the stacks so that the heaviest weight is at the bottom. The writing should be

visible from the front.

2. Remove the screw from the topmost weight stack (12), lower the steel lifting

rod/strut (10) into the central opening in the weight stack and secure it in place by

screwing the screw back into the upper weight stack (12).

3. Secure the two upper rubber stoppers (7) in the topmost hole in the guide rods

(2) using – in each case – one hexagon bolt M8* (8), two

washers Φ8 (14) and one locking nut (9).

4. Insert the magnetic safety pin (86) into the front of the

second-to-bottom weight plate.

Page 17

17

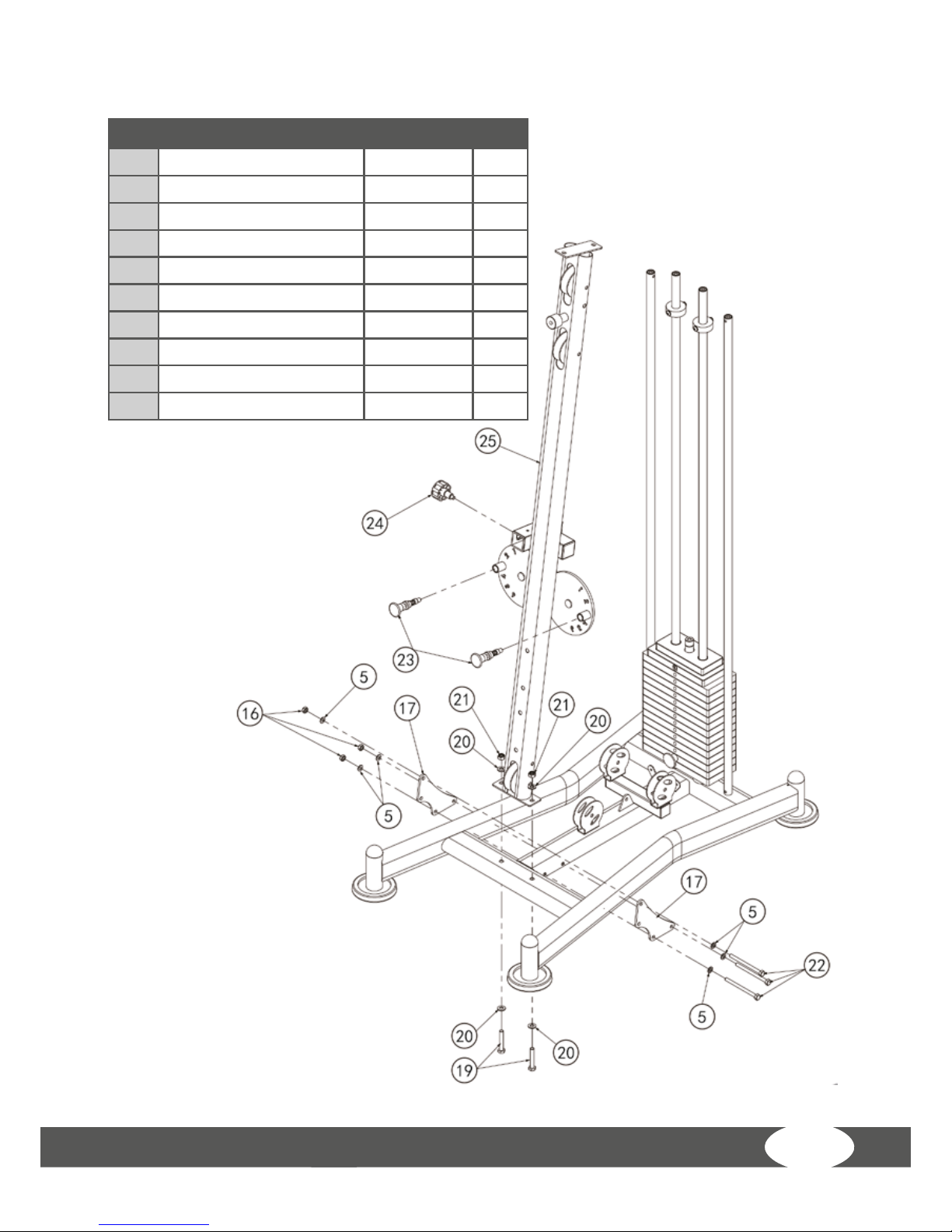

Step 3: Exploded drawing

No. Description Note

Qty.

5 shim Φ10 6

16 luck out M10 3

17 side support xing plate 2

19 outer hexagon bolt M12*70 2

20 shim Φ12 4

21 luck out M12 2

22 outer hexagon bolt M10*130 3

23 umbrella shape lock pin 2

24 plum ower pull pin M18*1.5 Φ10 1

25 inclined support frame 1

Page 18

WS7

18

Step 3: Assembly

1. Mount the diagonal, front frame section (25) to the base frame (1) using hexagon

bolts M12*70 (19), washers Φ12 (20) and locking nuts M12 (21).

2. Mount the two side mounting plates (17) to the diagonal, front frame section (25)

and to the base frame (1) using three hexagon bolts M10*130 (22), six washers Φ10 (5)

and three locking nuts M10 (16).

3. Mount the two locking pins (23) to the two circular plates on the front of the frame

section (25).

4. Mount the pull pin/retaining pin (24) to the diagonal, front frame section (25).

Page 19

19

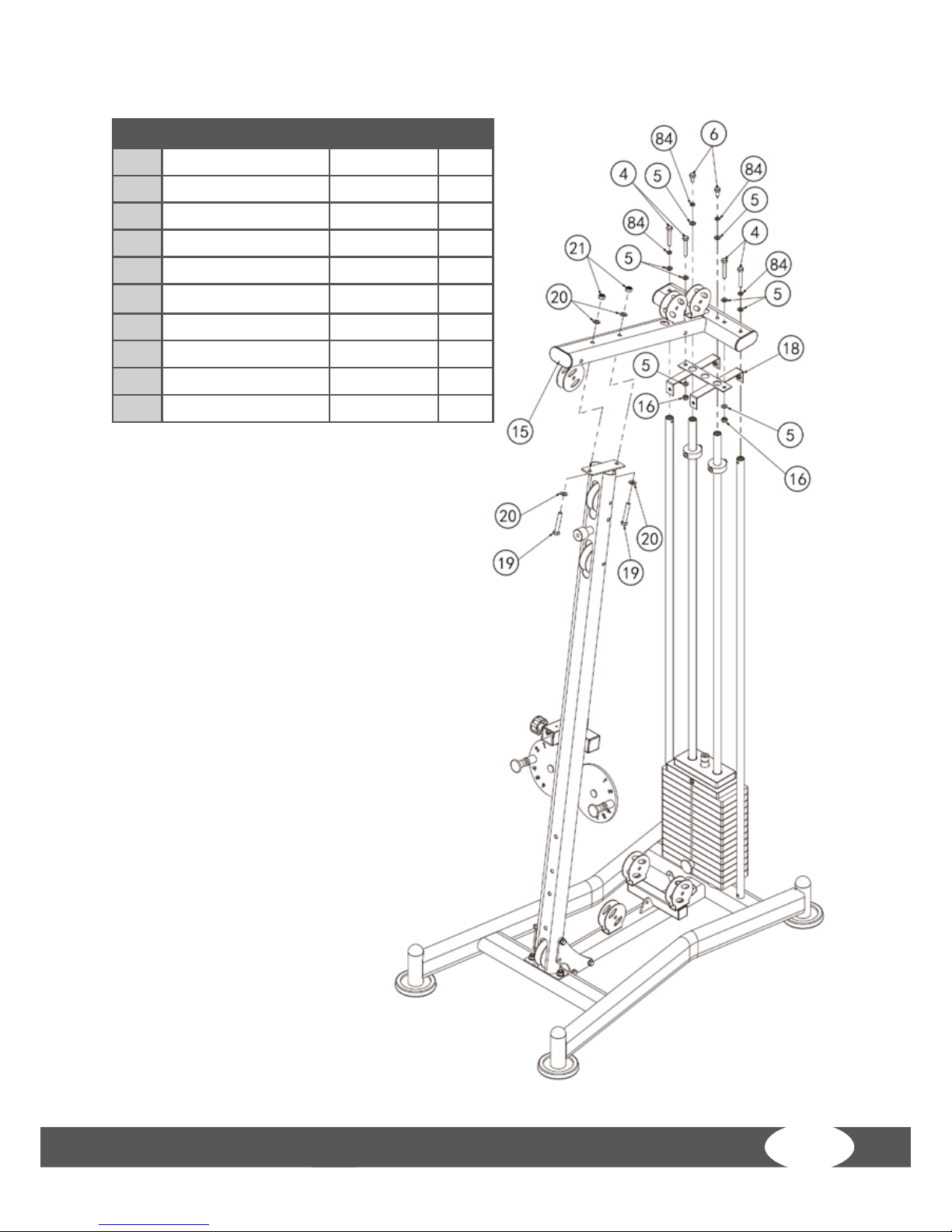

Step 4: Exploded drawing

No. Description Note

Qty.

4 outer hexagon bolt M10*65 4

5 shim Φ10 8

6 outer hexagon bolt M10*20 2

15 upper frame weldment 1

16 luck out M10 2

18 sheild support frame 1

19 outer hexagon bolt M12*70 2

20 shim Φ12 4

21 luck out M12 2

84 spring shim Φ10 4

Page 20

WS7

20

Step 4: Assembly

1. Push the mounting for the weight stack cover (18) onto the guide rods.

2. Place the upper connecting frame (15) on the guide rods and the front, diagonal

frame. Mount the upper frame to the guide rods using two hexagon bolts M10*20 (6),

two washers Φ10 (5) and two spring washers Φ10 (84).

3. Mount the upper frame (15) to the front frame using two hexagon bolts M12*70

(19), two washers Φ12 (20) and two locking nuts M12 (21).

4. Mount the upper frame (15) to the rear support struts (3) using two hexagon bolts

M10*65 (4), two washers Φ10 (5) and two spring washers Φ10 (84).

5. Mount the holder for the weight stack cover

(18) to the upper frame (15) using two hexagon

bolts M10*65 (4), two washers Φ10 (5) and two

locking nuts M10 (16).

Page 21

21

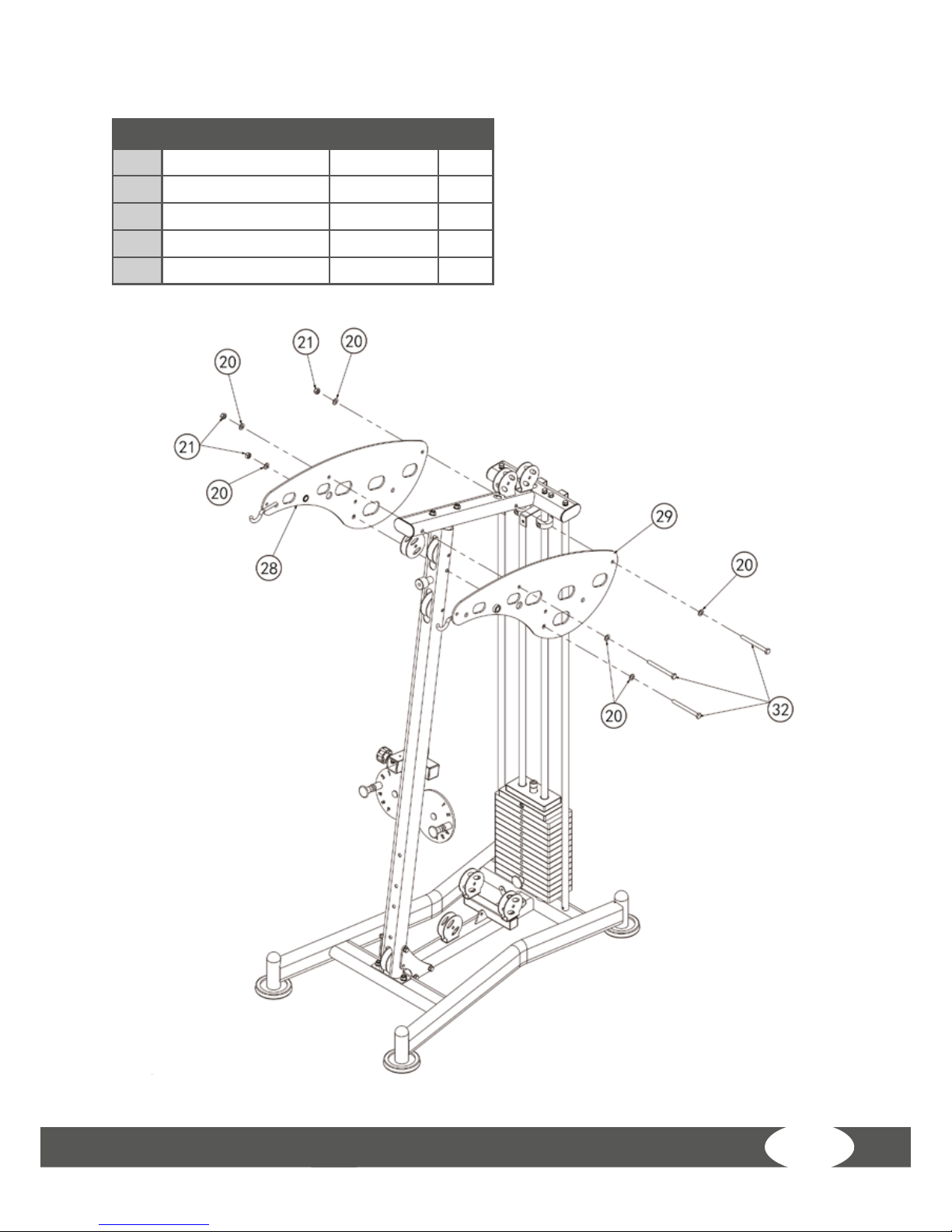

Step 5: Exploded drawing

No. Description Note

Qty.

20 shim Φ12 6

21 luck out M12 3

28 right decorative plate M10*20 1

29 left decorative plate 1

32 outer hexagon bolt M12*130 3

Page 22

WS7

22

Step 5: Assembly

Mount the right cover (28) and the left cover (27) onto the upper frame using three

hexagon bolts M12*130 (32), six washers Φ12 (20) and three locking nuts M12 (21).

Page 23

23

Step 6: Exploded drawing

No. Description Note

Qty.

5 shim Φ10 2

20 shim Φ12 4

21 luck out M12 2

24 plum ower pull pin

M18*1.5

Φ10 1

26 saet cushion adjust

frame

1

27 leg curl bending tube 1

30 axis of rotation Φ17*57 1

31 outer hexagon bolt M12*75 2

33 seat cushion tube 1

83 outer hexagon bolt M10*25 2

84 spring shim Φ10 2

Page 24

WS7

24

Step 6: Assembly

1. Mount the seat upholstery holder (33) to the front frame using hexagon bolts

M12*75 (31), washers Φ12 (20) and locking nuts M12 (21).

2. Push the bushing (30) into the leg-curl holder (27).

3. Insert the leg-curl sloping bar (27) into the seat upholstery holder (33) using

hexagon bolts M10*25 (83), spring washers Φ10 (84) and washers Φ10 (5).

4. Mount the seat upholstery adjustment frame (26) to the seat upholstery holder (33)

using the locking screw (24).

Page 25

25

Step 7: Exploded drawing

No. Description Note

Qty.

6 outer hexagon bolt M10*20 4

14 shim Φ8 1

36 front push frame holder 1

37 front push holder axle Φ17*134 1

38 outer hexagon bolt M8*16 1

39 front push arm 1

40 front push frame axle Φ17*100 1

41 labeling arc plate 1

43 big shim Φ25*10*2.0 4

82 plum ower pull pin-M18*1.5 Φ12 1

84 spring shim Φ10 2

Page 26

WS7

26

Step 7: Assembly

1. Using the shaft (37), connect chest-press mount (36) to the covers and, using

hexagon bolts M10*20 (6), spring washers Φ10 (84) and the large washers Φ10 (43),

x both ends to the front mount shaft (37).

2. Connect chest-press module (39) to chest-press mount (36) using the front bushings

(40). Secure to the bushing (40) on both sides using the hexagon bolts M10*20 (6) and

large washers Φ10 (43). Fix retaining pin (82) to the chest-press module (39).

3. Mount guard plate (41) to the chest-press mount (36) using the hexagon bolt

M8*16 (38) and washer Φ8 (14).

Page 27

27

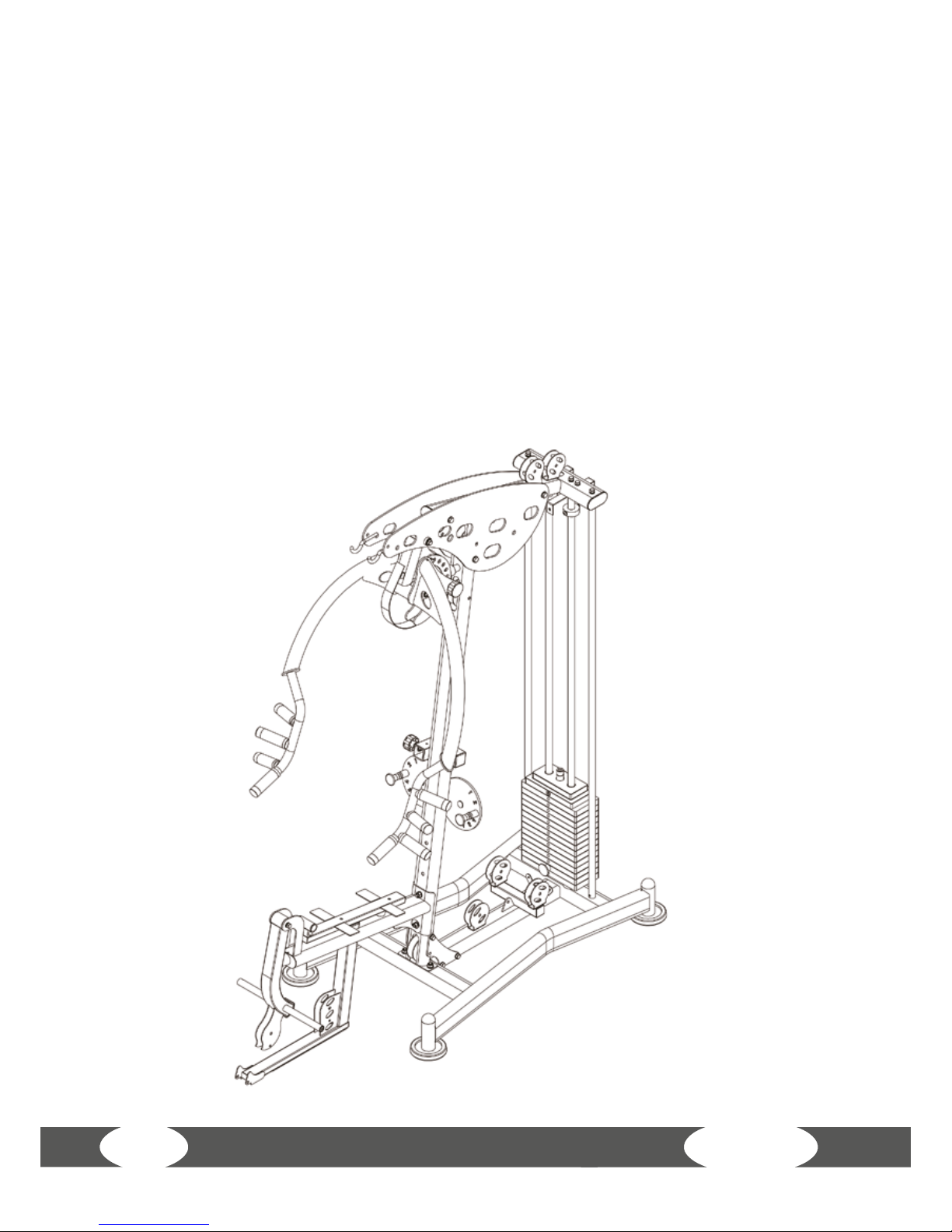

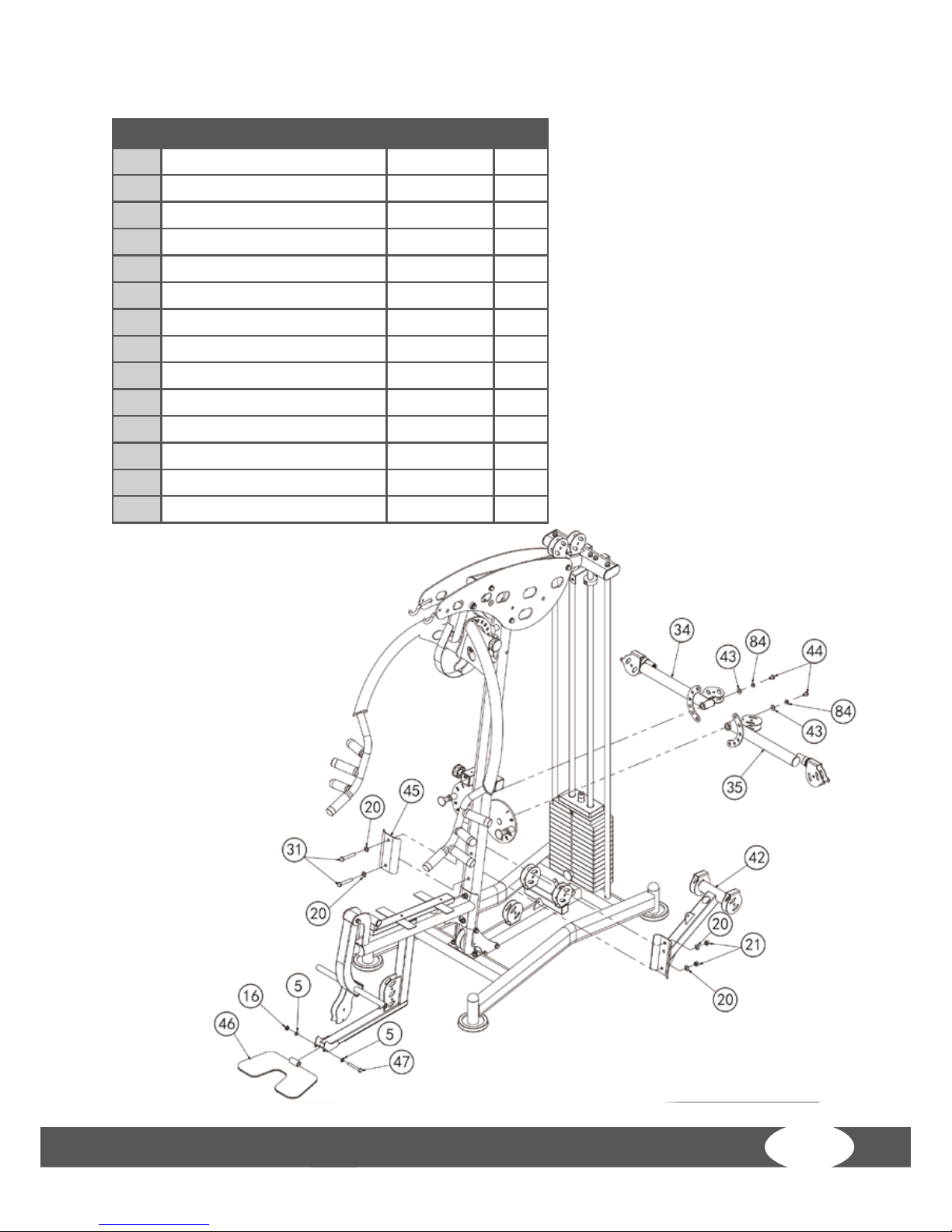

Step 8: Exploded drawing

No. Description Note

Qty.

5 shim Φ10 2

16 luck out M10 1

20 shim Φ12 4

21 luck out M12 2

31 outer hexagon bolt M12*75 2

34 buttery arm-right 1

35 buttery arm-left 1

42 pulley support frame 1

43 big shim Φ25*10*2.0 2

44 hexagon sock button head bolt M10*16 2

45 long semicircle plate 1

46 feet pad 1

47 outer hexagon bolt M10*70 1

84 spring shim Φ10 2

Page 28

WS7

28

Step 8: Assembly

1. Mount the left buttery arm (35) to the front frame using hexagon bolt M10*16

(44), spring washer Φ10 (84) and large washer Φ10 (43).

2. Mount the right buttery arm (34) to the front frame using hexagon bolt M10*16

(44), spring washer Φ10 (84) and large washer Φ10 (43).

3. Mount the reinforcing plate (45) to the front of the frame using hexagon bolts

M12*75 (31) and washers Φ12 (20). On the other side, place the supporting frame on

the guide-pulley mount (42) and secure using washers Φ12 (20) and locking nuts Φ12

(21).

4. Mount the footplate (46) to the front

of the seat frame using hexagon bolt

M12*70 (47), washer Φ10 (5) and locking

nut M10 (16).

Page 29

29

Step 9: Exploded drawing

No. Description Note

Qty.

5 shim Φ10 2

16 luck out M10 31

22 outer hexagon

bolt

M10*130 8

48 “-” shape pulley

frame

2

49 pulley Φ95*26 25

50 link sleeve Φ14*100 1

53 outer hexagon

bolt

M10*115 1

56 outer hexagon

bolt

M10*45 19

58 pulley spacer

sleeve

Φ22*Φ10.5*

45.5

4

59 lat pull cable L:4540mm 1

63 hexagon sock

button head bolt

M10*45 1

Page 30

WS7

30

Step 9: Exploded drawing

Lat-pull cable end

Lat-pull cable drawing

Page 31

31

Step 9: Assembly

1. Mount two guide pulleys A, B (49) in the guide-pulley frames (48) using hexagon

bolts M10*45 (56), washers Φ10 (5) and locking nuts M10 (16). Likewise mount two

guide pulleys C, E (49) in the guide-pulley frames using hexagon bolts M10*45 (56),

washers Φ10 (5) and locking nuts M10 (16).

2. Mount two guide pulleys I, D (49) to the frame using hexagon bolts M10*130 (22),

guide-pulley spacers (58), washers Φ10 (5) and nuts M10 (16).

3. Mount the guide pulley G (49) to the front frame using hexagon bolt M10*130 (22),

washers Φ10 (5) and locking nuts M10 (16).

4. Mount the guide pulley H (49) to the frame using hexagon bolt M10*45 (63),

washers Φ10 (5) and locking nuts M10 (16).

5. Mount the guide pulley F (49)

to the frame using hexagon bolt

M10*115 (53), washers Φ10 (5) and

locking nut M10 (16).

6. Attach one hexagon bolt

M10*130 (22) to the left cover (near

point I) using connecting tube (50),

washer Φ10 (5) and nut M10 (16).

7. Connect the lat-pull cable (59)

with the end of the lifting rod /strut.

8. Pull the lat-pull cable (59) over

the guide pulleys (49) in the order

A, B, C, D, E, F, G, H, I; and attach the

end of the lat-pull cable to guide

pulley I (49) (see detail drawing).

Page 32

WS7

32

Step 10: Exploded drawing

No. Description Note

Qty.

5 shim Φ10 12

9 lock nut M8 2

14 shim Φ8 4

16 luck out M10 6

22 outer hexagon bolt M10*130 1

49 pulley Φ95*26 5

56 outer hexagon bolt M10*45 4

60 9 hooks chain 1

62 outer hexagon bolt M8*45 2

64 low pull cable L:3365mm 1

65 short bar 1

83 outer hexagon bolt M10*25 1

Page 33

33

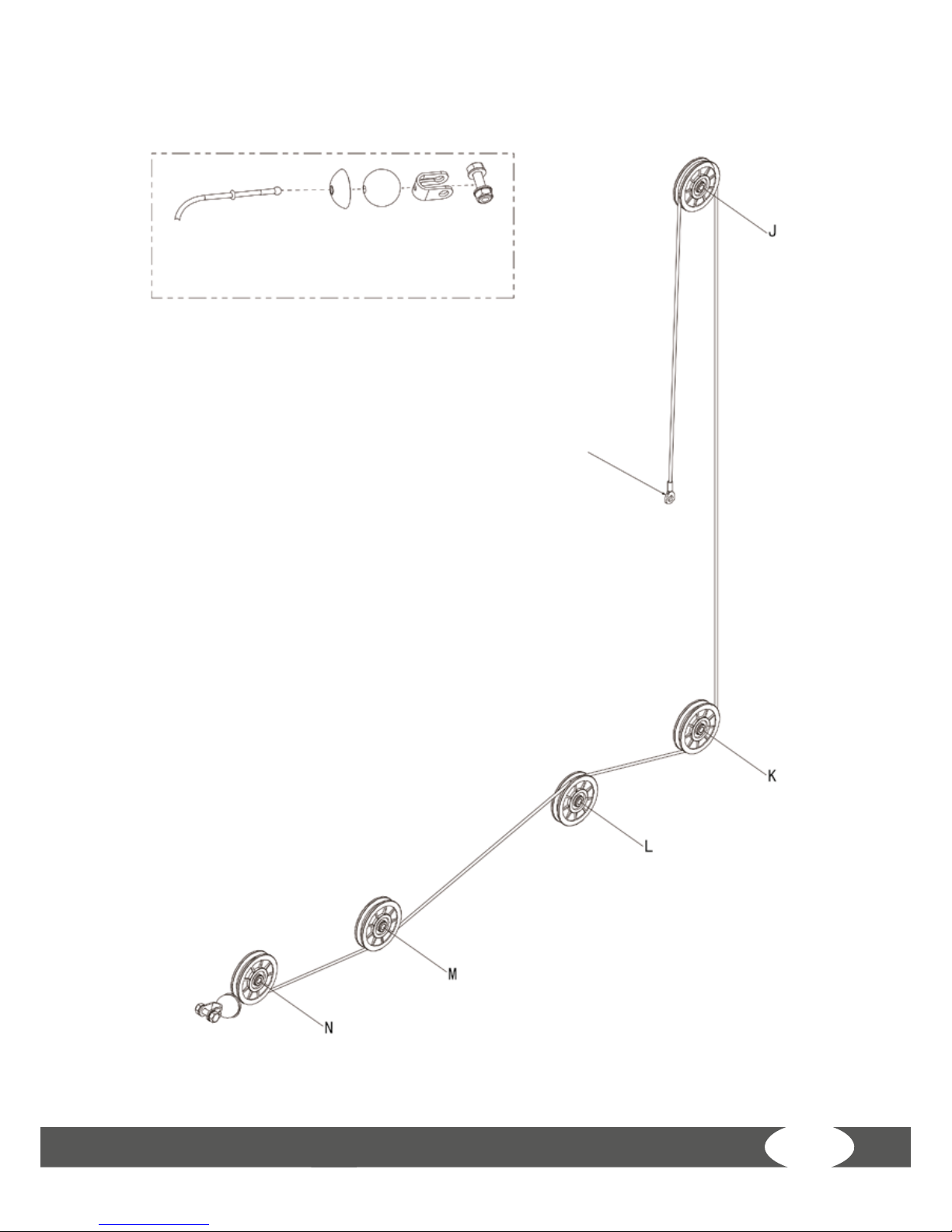

Step 10: Cable run drawing

Lower pull cable end

Lower pull cable drawing

Page 34

WS7

34

Step 10: Assembly

1. Mount the guide pulleys J, K, M, N (49) in the brackets on the frame intended for

that purpose, using hexagon bolts M10*45 (56), washers Φ10 (5) and nuts M10 (16)

in each case.

2. Mount the guide pulley L (49) to the frame using hexagon bolt M10*130 (22),

washer Φ10 (5) and nut M10 (16).

3. Mount the upper pull cable end to the guide-pulley supporting frame using

hexagon bolt M10*25 (83), washer Φ10 (5) and nut M10 (16).

4. Pull the lower pull cable end over the guide pulley J, under K, over L and under M

and N; then mount the head end on the cable (see detail drawing).

5. Connect one end of the chain (60) to the head end of the cable using the snap

hook, and the other end to the pull bar (65).

Page 35

35

Step 11: Exploded drawing

No. Description Note

Qty.

5 shim Φ10 6

16 luck out M10 3

49 pulley Φ95*26 3

51 double pulley guide plate 1

56 outer hexagon bolt M10*45 3

60 9 hooks chain 1

66 double pulley plate 1

68 middle cable L:1500mm 1

Page 36

WS7

36

Step 11: Assembly

1. Mount two guide pulleys (49) to the double guide-pulley mount (66) using hexagon

bolts M10*45 (56), washers Φ10 (5) and locking nuts M10 (16).

2. Mount one end of the chain (60) to the pull cable (68) and the other end low down

on the base frame.

3. Guide the pull cable through the opening in the small plate/spacer (51) on the

double guide-pulley mount (66) and then connect the screw end of the pull cable

(66) to the double guide-pulley mount (66). Secure the spacer (51) onto the double

guide-pulley mount (66) using the pre-mounted nut.

4. Place the pull cable (68) between the spacer (51) and the screw end of the cable

via the guide pulley (49). Now secure the guide pulley (49) in 0 position in the guidepulley mount using hexagon bolt M10*45 (56), four washers Φ10 (5) and nut M10 (16).

Page 37

37

Step 12: Exploded drawing

Page 38

WS7

38

Step 12: Exploded drawing

No. Description Note

Qty.

5 shim Φ10 14

9 lock nut M8 2

14 shim Φ8 4

16 luck out M10 6

49 pulley Φ95*26 8

56 outer hexagon bolt M10*45 8

62 outer hexagon bolt M8*45 2

69 buttery arm cable L:5375mm 1

Buttery-arm cable drawing

Page 39

39

Step 12: Assembly

1. Mount the six guide pulleys P, Q, S, U, X, Y (49) in the pulley mounts intended for

that purpose, using hexagon bolts M10*45 (56), washers Φ10 (5) and nuts M10 (16).

2. Mount the two guide pulleys R, W (49) in the pulley mounts intended for that

purpose (nal pulleys on the guide-pulley (42) supporting frame, see page 26), using

hexagon bolts M10*45 (56) and washers Φ10 (5).

3. Starting from point P, guide the pull cable (69), over the guide pulleys in the order:

P, Q, R, S, T, U, W, X, Y. The diagram on page 37 shows the sequence. The pull cable head

end should be removed, where necessary, beforehand (see detail drawing). Points T, U

can be found on the double guide pulley (66) in assembly step 11.

4. Re-attach the pull cable head end.

5. Mount one hexagon bolt M8*45 (62), two washers Φ8 (14) and one nut M8 (9) on

the mounts intended for this purpose on

the end of each of the two buttery arms,

near P and Y.

Page 40

WS7

40

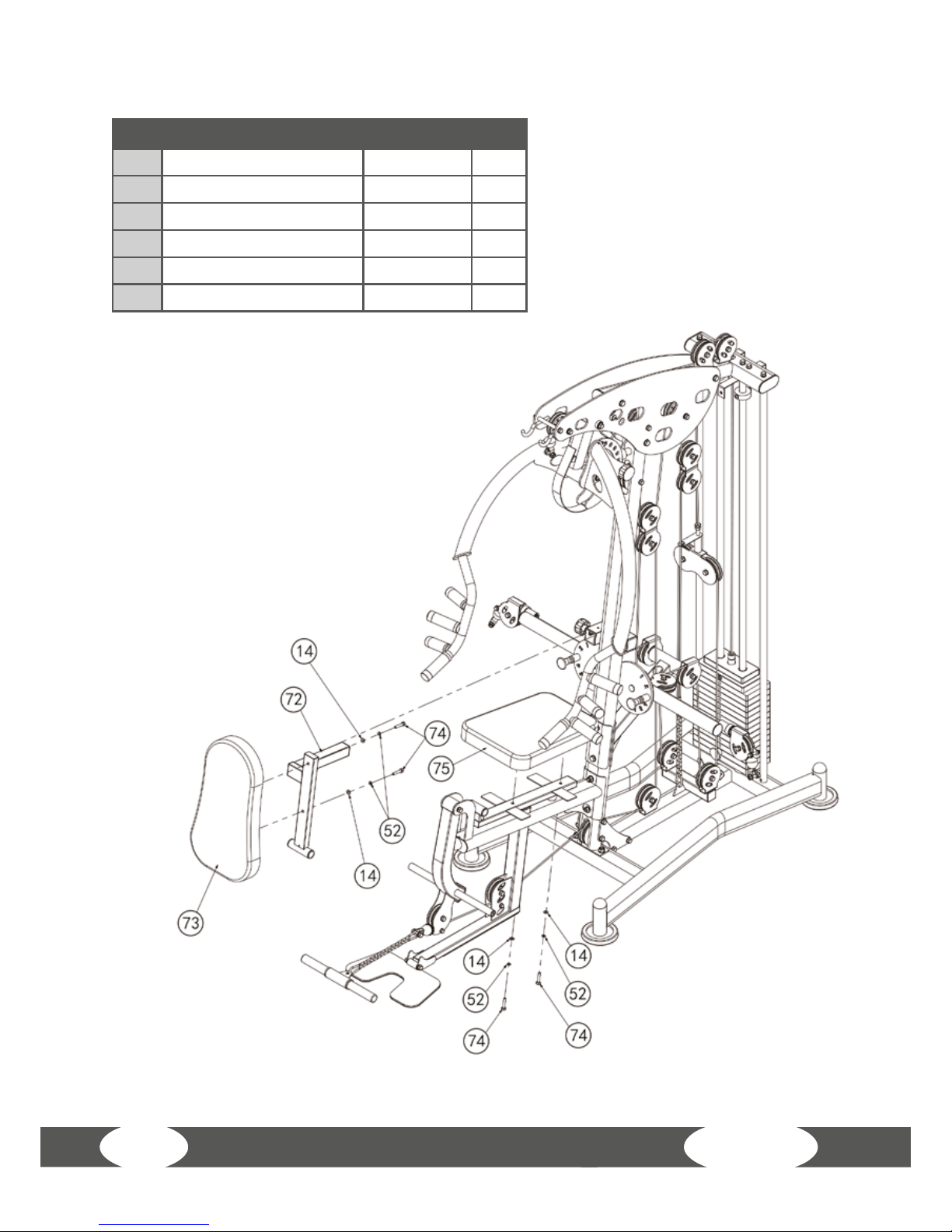

Step 13: Exploded drawing

No. Description Note

Qty.

14 shim Φ8 4

52 spring shim Φ8 4

72 back cushion adjust frame 1

73 back cushion 1

74 outer hexagon bolt M8*40 4

75 seat cushion 1

Page 41

41

Step 13: Assembly

1. Using hexagon bolts M8*40 (74), spring washers Φ8 (52) and washers Φ8 (14),

mount the seat upholstery (75) to the seat upholstery adjustment frame (26) from

page 23.

2. Mount the backrest (73) to the backrest retaining frame (72) using hexagon bolts

M8*40 (74), spring washers Φ8 (52) and washers Φ8 (14).

3. Push the square tube from the retaining frame (72) into the retaining tube on

the front, diagonal frame tube designed for this purpose. If necessary, remove the

retaining pin beforehand, then tighten it up afterwards.

Page 42

WS7

42

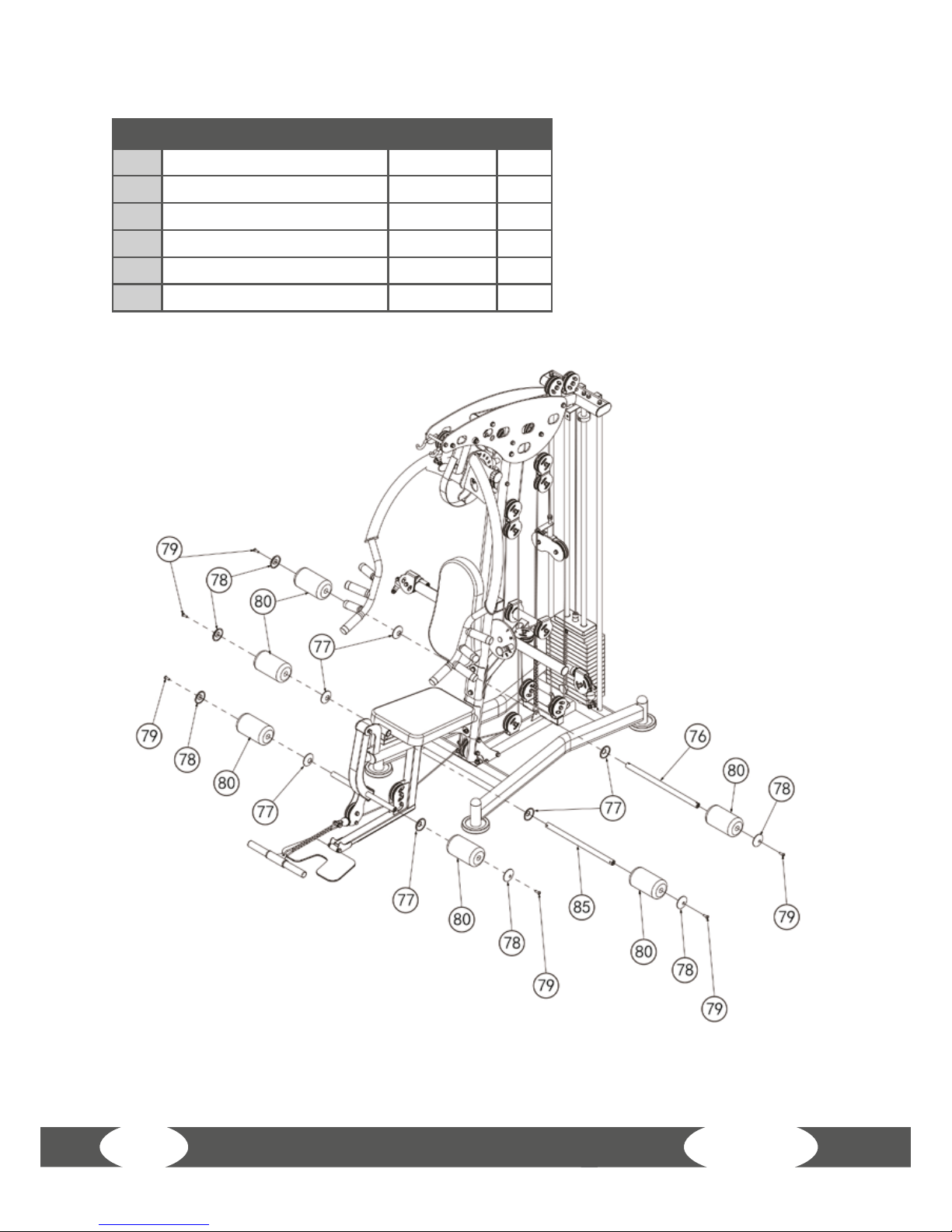

Step 14: Exploded drawing

No. Description Note

Qty.

76 sponge rod tube Φ25*480 1

77 sponge inner cap 6

78 sponge out cap 6

79 hexagon sock button head bolt M8*25 6

80 sponge Φ100*175 6

85 sponge pipe tube Φ25*450 1

Page 43

43

Step 14: Assembly

1. Push the holder of the upholstery rolls (76) into the guide on the backrest mount.

On the xture, turn the upholstery caps inwards (77), the upholstery rolls (80) and the

upholstery caps outwards (78), in order. Attach the upholstery rolls by tightening up

a hexagon bolt M8*28 (79) on both sides.

2. Push the holder of the upholstery rolls (85) into the upper guide on the front of the

seat upholstery. On the xture, turn the upholstery caps inwards (77), the upholstery

rolls (80) and the upholstery caps outwards (78), in order. Attach the upholstery rolls

by tightening up a hexagon bolt M8*28 (79) on both sides.

3. On the xture, at the base of the leg-curl module, turn the upholstery caps inwards

(77), the upholstery rolls (80) and the upholstery caps outwards (78), in order. Attach

the upholstery rolls by tightening up

a hexagon bolt M8*28 (79) on both

sides.

Page 44

WS7

44

Step 15: Exploded drawing

No. Description Note

Qty.

14 shim Φ8 8

38 outer hexagon bolt M8*16 8

52 spring shim Φ8 8

81 sheild 2

Page 45

45

Step 15: Assembly

1. Mount the weight stack cover (81) to the base frame on both sides. For this purpose,

use eight hexagon bolts M8*16, spring washers Φ8 (52) and washers Φ8 (14) in each

case.

Page 46

WS7

46

Step 16: Exploded drawing

No. Description Note

Qty.

60 9 hooks chain 1

61 long bar 1

70 7 hooks chain 2

71 hand pull belt 2

Page 47

47

Step 16: Assembly

1. On both sides, connect the 7-link chains (70) rstly to the end of the buttery arms

with the heads at the end of the pull cable. In each case, connect the other end of the

chain to the handles (71).

2. Connect the 9-link chain (60) to the pull cable head on the top of the lat pull.

Connect the other end of the chain (60) to the lat bar (61). If the lat bar hangs too low

down, you can remove the chain links and just connect the snap hook to the chain.

Page 48

WS7

48

Step 17: Exploded drawing

No. Description Note

Qty.

54 back pull rod weldment 1

55 back pull belt 1

57 hoist hook 3

Page 49

49

Step 17: Assembly

1. If necessary, remove the grips (71) from the buttery arms, including chain (70).

2. Hang the pull bar (54) on the buttery-arm head ends together with the two snap

hooks (57).

3. Now mount the abdominal belt (55) to the pull bar (54) using a snap hook (57).

WARNING: When assembly is complete, carry out a further check to ensure that

all of the screws, locking nuts and retaining pins are done up and secure. Then

you can get started with your workout – we hope you enjoy it!

Page 50

WS7

50

4 WORKOUT INSTRUCTIONS

4.1 Workout exercises

1. Seated crunches, start and nish

position:

The lower back maintains contact with

the backrest. Bend your body forward (in

the abdominal muscles) and then return

to the starting position.

2. Seated crunches, reversal point:

When the body is fully bent (in the

abdominal muscles), return to the

starting position. Carry out the exercise

in a slow, controlled manner.

3. Seated buttery, start and nish

position:

Your whole back maintains contact with

the backrest during the exercise. Your

arms should be held almost straight, the

elbow joint is slightly bent. Now bring

your hands together in front of your

chest.

Page 51

51

4. Seated buttery, reversal point:

Just before your hands touch, return

to the starting position. Carry out the

exercise in a slow, controlled manner.

5. Standing one-armed y, start and

nish position:

Take up a steady, relaxed stance. Maintain

tension in your abdominal muscles. Keep

your upper body straight. Keep your arm

almost straight during the exercise. Now

move your hand diagonally in front of

your upper body.

6. Standing one-armed y, reversal

point:

When your hand is at the center in front of

your body, return to the starting position

in a controlled movement.

7. Lat pull to the neck, start and nish

position:

You can vary the grip width in this

exercise. Always keep your arms slightly

bent. Your upper body should be, and

should stay, bent slightly forward. Now

pull the pull-up bar down to your neck.

Do not bend your upper body!

Page 52

WS7

52

8. Lat pull to the neck, reversal point:

Just before the pull-up bar reaches

your neck, stretch your arms back out

again. Carry out the exercise in a slow,

controlled manner.

9. Leg extension, start and nish

position

The upholstery roll should be slightly

above your feet. Now, stretch your legs

in a slow, controlled manner.

10. Leg extension, reversal point:

Never fully straighten your legs to the

point where you lock your knees. As you

return to the start position, do not drop

the weight.

11. Upright cable row, start and nish

position:

Your upper body should be, and should

stay, bent slightly backwards. Your arms

should be held almost straight. Pull the

pull-up bar towards your navel in a slow,

controlled movement. Pull your elbows

in closely passing your body.

Page 53

53

12. Upright cable row, reversal point:

Just before the pull-up bar makes contact

with your trunk, stretch your arms back

out again. Your upper body should still

stay straight.

13. Biceps curl, start and nish

position:

Place your hands in the upper or lower

grip. Your upper body should stay straight

during the exercise. Never fully straighten

your arms to the point where you lock

your elbows. Bend your arms at the

elbow. Keep your elbows xed. Perform

the exercise slowly and controlled.

14. Biceps curl, reversal point:

In a controlled movement, stretch your

arms back out to the starting position. Do

not drop the weight.

Page 54

WS7

54

4.2 Dehnübungen für Bein- & Brustmuskulatur

1. Exercise: Stretching of front thigh / leg extension (quadriceps)

• Stable position, grab arches of feet

• Pull heel towards buttocks, knee points downwards

(no abduction)

• Straight upper body, avoid tilting the pelvic forward

(hollow back) by tensing the abdominal muscles

• Change legs

2. Exercise: Stretching the back thigh / leg curl (hamstring)

• Pull thigh towards upper body with both

hands

• Stretch through increased stretching in

the knee joint

• The lower leg maintains contact with the

oor, keep hips bent

• Change legs

Page 55

55

3. Exercise: Stretching the calf muscles (gastrocnemius)

• Place feet parallel to each other pointing forward,

the heels touch the oor

• Support yourself on a chair coming from a lunge

• Move your body weight to the front leg, press

your heel from the rear leg towards the oor and

hold the contact

• Slowly stretch your knee of the rear leg until you

feel the stretch in your calves

• Change legs

4. Exercise: Stretching the chest muscles (pectoralis major)

• Stand parallel to a wall

• Place your forearm at 90° to the wall with the elbow

just above shoulder height

• Turn your head and upper body gradually to the

opposite sides until you feel a stretch in the front

chest, of the shoulder being leaned on

• Pay attention to tension in your abdominal and

gluteal muscles

• Your weight is on your front leg

• Change legs

All recommendations of these instructions apply solely to healthy persons and

are not suitable for those with heart or cardiovascular problems. All of the tips

are intended only as a guide to help you create a workout. Your physician can

oer appropriate advice for particular, personal requirements.

We hope you enjoy your workout and have a lot of success!

Page 56

WS7

56

4.3 Workout journal

Date

Training weight

Time (min.)

Calories burnt Body weight

Distance

Ø Pulse

Resistance level

I feel ...

(Copy template)

Page 57

57

5 WARRANTY INFORMATION

Taurus tness equipment is subject to strict quality controls. However, if a tness

equipment purchased from us does not work perfectly, we take it very seriously and

ask you to contact our customer service as indicated. We are happy to help you by

phone via our service hotline.

Error descriptions

Your tness equipment is developed for long-term, high-quality training. However,

should a problem arise, please rst read the operating instructions. For further

assistance, please contact your contract partner or call our service hotline. To ensure

your problem is solved as quickly as possible, please describe the defect as exactly as

possible.

In addition to the statutory warranty, we provide a warranty for every tness

equipment purchased from us according to the following provisions.

Your statutory rights are not aected.

Warrantee

The warrantee is the rst/original buyer and/or any person who received a newly

purchased product as a gift from the original buyer.

Warranty periods

The following warranty periods begin on delivery of the tness equipment.

Model Use Full warranty

WS7 Home use 24 months

Repair costs

According to our choice, there will either be a repair, a replacement of individual

damaged parts or a complete replacement. Spare parts, that have to be mounted

while assembling the equipment, have to be replaced by the warrantee personally

and are not a part of repair. After the expiration of the warranty period for repair costs,

a pure parts warranty applies, which does not include the repair, installation and

delivery costs.

Page 58

WS7

58

The terms of use are dened as follows:

• Home use: solely for private use in private households up to 3 hours per day

• Semi-professional use: up to 6 hours per day (e. g. rehabilitation centers, hotels,

clubs, company gyms)

• Professional use: more than 6 hours per day (e. g. commercial gyms)

Warranty service

Within the warranty period, equipment which develops faults as a result of material

or manufacturing defects, will be repaired or replaced at our discretion. Ownership

of equipment or parts of equipment which have been replaced is transferred to us.

The warranty period is not extended nor does a new warranty period begin following

repair or replacement under the warranty.

Warranty conditions

For the warranty to be valid, the following steps must be taken:

Please contact our customer service by email or phone. If the product under warranty

has to be sent in for repair, the seller bears costs. After expiry of the warranty, the buyer

bears the costs of transport and insurance. If the fault is covered by our warranty, you

will receive a new or repaired equipment in return.

Warranty claims are invalid in case of damage resulting from:

• misuse or improper handling

• environmental inuences (moisture, heat, electrical surge, dust, etc.)

• failure to follow the current safety measures for the equipment

• failure to follow the operating instructions

• use of force (e. g. hitting, kicking, falling)

• interventions which were not carried out by one of our authorized service centers

• unauthorized repair attempts

Proof of purchase and serial number

Please make sure that you are able to provide the appropriate receipt when claiming

on your warranty. So that we can clearly identify the model of your equipment, and

for the purposes of our quality control, you will need to give the serial number of

your equipment, when contacting the service team. Where possible please have your

serial number and your customer number ready when you call our service hotline. It

will help us to deal with your request swiftly.

Page 59

59

If you have trouble nding the serial number on your tness equipment, our service

team is at your disposal to oer further information.

Service outside the warranty period

We are also happy to issue an individual cost estimate if there is a problem with your

tness equipment after the warranty has expired, or in cases which do not fall under

the terms of the warranty, e. g. normal wear and tear. Please contact our customer

service team to nd a quick and cost-eective solution to your problem. In such a case

you will be responsible for the delivery costs.

Communication

Many problems can be solved just by speaking to us as your contract partner. We

know how important it is to you as a user of the tness equipment to have problems

solved quickly and simply, so you can enjoy working out with minimal interruption.

For that reason, we also want to resolve your queries quickly and in a straightforward

manner. Thus, please always keep your customer number and the serial number of the

faulty equipment handy.

Page 60

WS7

60

7 ORDERING ACCESSORIES

Sport-Tiedje hand grip for strength

training

Art. No. ST-HG-020

Sport-Tiedje oor mat set

Art. No. TF-FMS-B

GYMWATCH sensor

Art. No. GW-SENSOR

Sport-Tiedje silicone spray

Art. No. ST-1003

6 DISPOSAL

At the end of its operational life, this equipment cannot be disposed

of in normal household waste. Instead, it must be disposed of via an

electricals recycling centre. Further information can be obtained from

your local authority‘s recycling service.

The materials can be recycled as per their symbols. Through the reuse, recycling

of materials or other forms of recovery of old equipment, you make an important

contribution to the protection of the environment.

Page 61

61

8 ORDERING SPARE PARTS

8.1 Service hotline

So that we can give you the best possible service, please have your model name, part

number, serial number, exploded drawing and parts list ready.

SERVICE-HOTLINE

8.2 Serial number and model name

Before assembling your equipment, nd the serial number on the white sticker and

enter it in the appropriate space.

Serial number:

Brand/category: Model name:

Taurus Multi-gym WS7

+31 172 619961

info@tshop.nl

Mon - Thu 9 am - 5 pm

Fri 9 am - 9 pm

Sat 10 am - 5 pm

NL

+44 141 876 3972

orders@powerhousetness.co.uk

Mon - Fri 9 am - 5 pm

UK

+49 4621 4210-0

+49 4621 4210-699

service@sport-tiedje.de

Mon - Fri 8:00 am - 6:00 pm

Sat 9:00 am - 6:00 pm

DE

Page 62

WS7

62

8.3 Parts list

No Description Dimensions Qty.

1 ground frame 1

2 guide bar Φ25*1853 2

3 back support tube Φ259*1757.5 2

4 outer hexagon bolt M10*65 6

5 shim

Φ10

74

6 outer hexagon bolt M10*20 8

7 weight stack rubber crash Φ60*Φ26*20 2

8 hexagon sock button head bolt M8*70 2

9 lock nut M8 6

10 weight stack lift bar 92 KG 1

11 below steel weight stack 6 KG 14

12 top steel weight stack 8 KG 1

14 shim Φ8 25

15 upper frame weldment 1

16 luck out M10 31

17 side support xing plate 2

18 sheild support frame 1

19 outer hexagon bolt M12*70 4

20 shim Φ12 22

21 lock nut M12 11

22 outer hexagon bolt M10*130 8

23 umbrella shape lock pin 2

24 plum ower pull pin M18*1.5 Φ10 2

25 inclined support frame 1

26 saet cushion adjust frame 1

27 leg curl bending tube 1

28 right decorative plate 1

29 left decorative plate 1

30 axis of rotation Φ17*57 1

31 outer hexagon bolt M12*75 4

32 outer hexagon bolt M12*130 3

Page 63

63

No Description Dimensions Qty.

33 seat cushion tube 1

34 buttery arm-right 1

35 buttery arm-left 1

36 front push frame holder 1

37 front push holder axle Φ17*134 1

38 outer hexagon bolt M8*16 9

39 front push arm 1

40 front push frame axle Φ17*100 1

41 labeling arc plate 1

42 pulley support frame 1

43 big shim Φ25*10*2.0 6

44 hexagon sock button head bolt M10*16 2

45 long semicircle plate 1

46 feet pad 1

47 outer hexagon bolt M10*70 1

48 “-” shape pulley frame 2

49 pulley Φ95*26 25

50 link sleeve Φ14*100 1

51 double pulley guide plate 1

52 spring shim Φ8 12

53 outer hexagon bolt M10*115 1

56 outer hexagon bolt M10*45 19

58 pulley spacer sleeve Φ22*Φ10.5*45.5 4

59 lat pull cable L:4540mm 1

60 9 hooks chain 3

61 long bar 1

62 outer hexagon bolt M8*45 4

63 hexagon sock button head bolt M10*45 1

64 low pull cable L:3365mm 1

65 short bar 1

66 double pulley plate 1

68 middle cable L:1500mm 1

69 buttery arm cable L:5375mm 1

Page 64

WS7

64

No Description Dimensions Qty.

70 7 hooks chain 2

71 hand pull belt 2

72 back cushion adjust frame 1

73 back cushion 1

74 outer hexagon bolt M8*40 4

75 seat cushion 1

76 sponge rod tube Φ25*480 1

77 sponge inner cap 6

78 sponge out cap 6

79 hexagon sock button head bolt M8*25 6

80 sponge Φ100*175 6

81 sheild 2

82 plum ower pull pin-M18*1.5 Φ12 1

83 outer hexagon bolt M10*25 3

84 spring shim Φ10 14

85 sponge pipe tube Φ25*450 1

86 magnetic pin Φ10*100 1

87 cushion Φ60*Φ26*42 2

Page 65

65

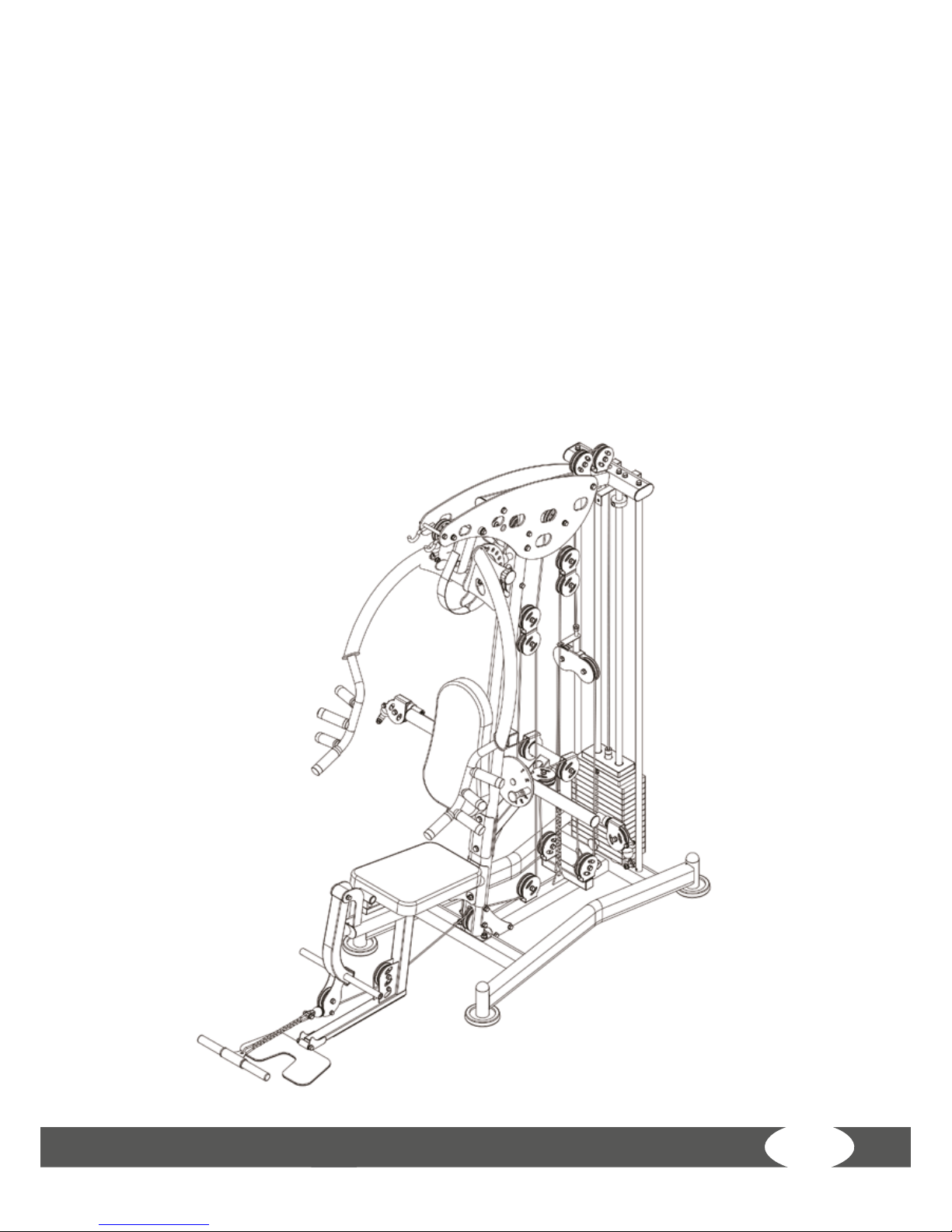

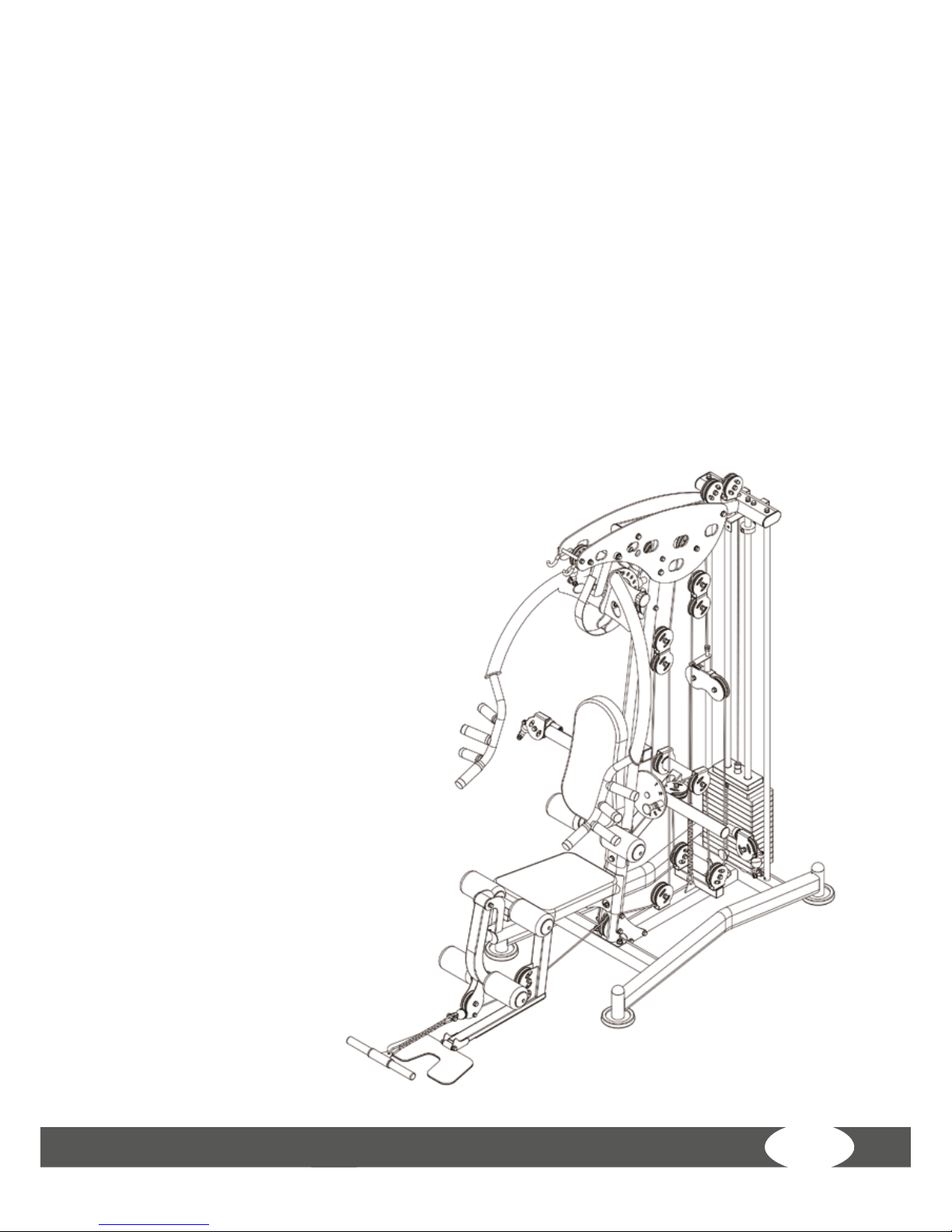

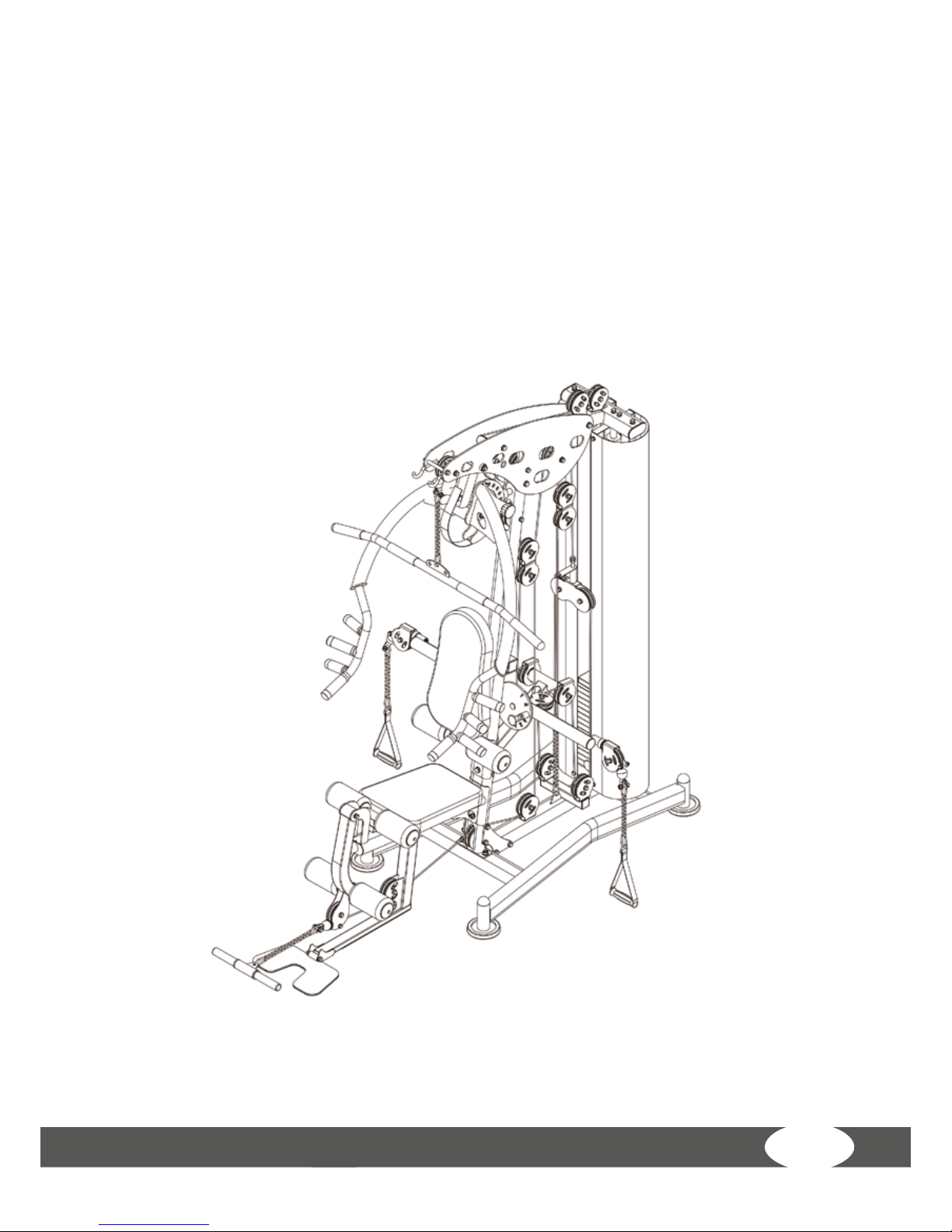

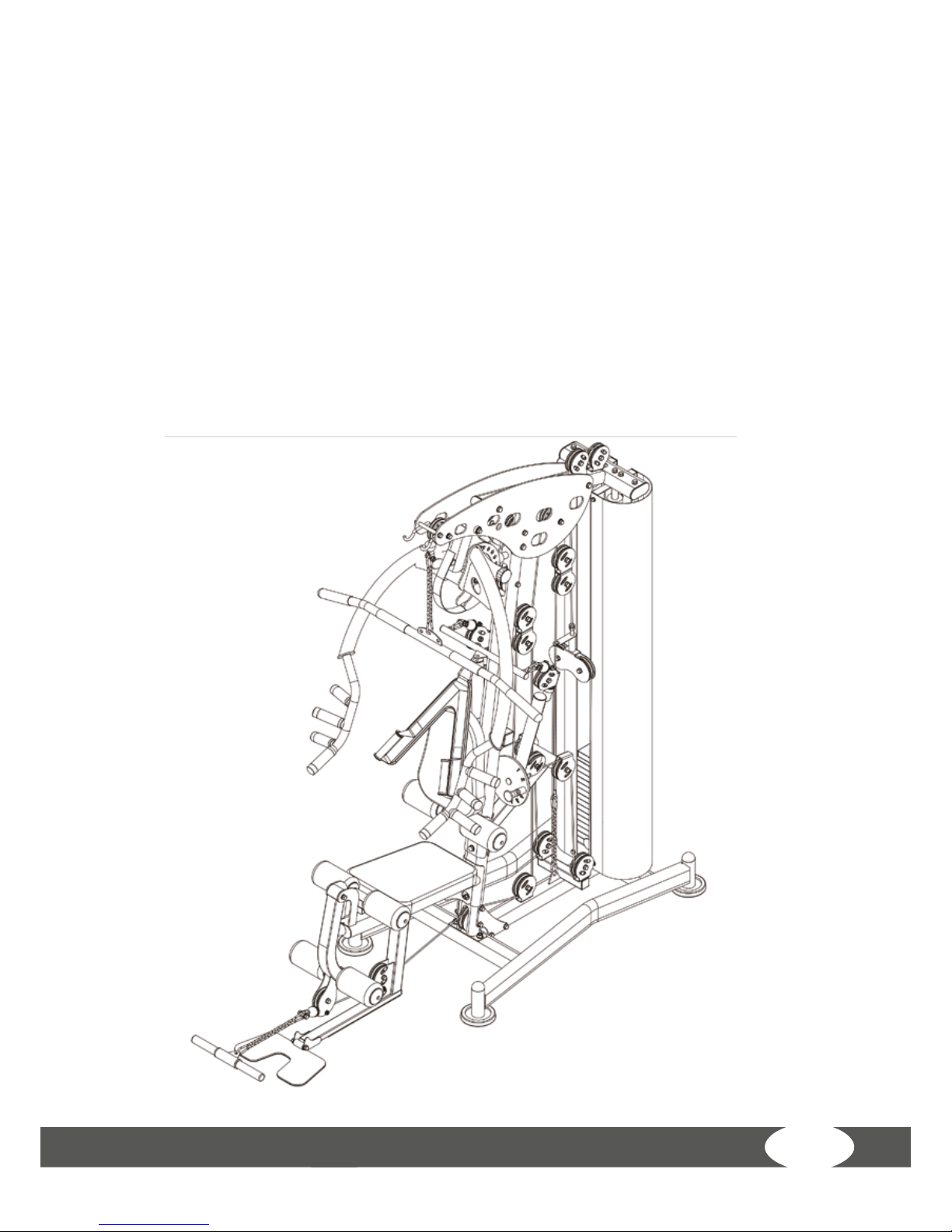

8.4 Exploded drawing

Page 66

WS7

66

CONTACT

Company head oce

Sport-Tiedje GmbH

Flensburger Str. 55

24837 Schleswig

Germany

GENERAL INFORMATION:

DE +49 4621 4210-0

info@sport-tiedje.com

NL +31 172 619961

info@tshop.nl

UK +44 141 876 3972

orders@powerhousetness.co.uk

DISCLAIMER

©2011 TAURUS is a registered brand of the company Sport-Tiedje

GmbH. All rights reserved. Any use of this trademark without the

explicit written permission of Sport-Tiedje is prohibited.

Product and manual are subject to change. Technical data can be changed without

advance notice.

Hotline for Technical Information

DE +49 4621 4210-0

+49 4621 4210-699

service@sport-tiedje.de

NL +31 172 619961

info@tshop.nl

UK +44 141 876 3986

support@powerhousetness.co.uk

www.sport-tiedje.com

www.taurus-tness.de

Please nd a detailed overview including address and opening hours for all specialist

tness stores of the Sport-Tiedje Group in Germany and abroad on the following

website.

www.sport-tiedje.com/en/stores

Page 67

67

Page 68

Multi-gym WS7

Loading...

Loading...