Page 1

1

DOOR Series -

English

INSTALLATION GUIDE

DOOR

Automation for sliding automatic door

Via Enrico Fermi, 43 - 36066 Sandrigo (VI) Italia

Tel +39 0444 750190 - Fax +39 0444 750376 - info@tauitalia.com - www.tauitalia.com

D-MNL0DOOR-GB 26-01-2016 - Rev.22

GB - Translation of Original Instructions

Page 2

2

DOOR Series -

English

RECOMMENDATIONS

The 2nd version DOOR control unit features an important software upgrade that signicantly improves the way the door operates and

facilitates the way the parameters can be regulated by the installer.

The new software is installed from release 6.1 of the main microprocessor onwards (consult the label on microprocessor MP1).

GENERAL SAFETY RECOMMENDATIONS

Only begin to install the device after you have carefully read this instruction manual.

Both the mechanical part and the electrical part must be installed in a perfectly workmanlike manner, in compliance with the current laws

in force. Failure to comply with these latter may result in danger hazards for persons or property.

The installer must be a competent person who has been adequately trained. He must check to make sure that the structure on which

the actuator is installed is strong and stable. If necessary, structural modications must be made to strengthen it. The installer must

also check that all zones where there is a risk of crushing, dragging, shearing or other dangers, are protected by means of electronic

safety devices, safety freeboards or barriers. These devices must be installed in compliance with the current laws and in a perfectly

workmanlike way, also in relation to the place of use, the type of use and the operating logic of the product. The forces developed by

the complete system as it operates must comply with the current standards and, where this is not possible, the zones affected by these

forces must be protected with electronic safety devices. Moreover, dangerous zones must be indicated, as established by the current

laws in force.

Before the actuator is connected, make sure that the electricity main possesses characteristics that are compatible with those described

in the technical specications of this manual, and that there is a differential circuit-breaker and adequate protection against overcurrents

on the supply side of the system. Remember to turn off the power supply before installing or servicing the actuator and whenever the

cover must be opened.

Electrostatic charges can damage the electronic components on the boards. Wear a grounded antistatic bracelet if you must work on

the electronic boards. Never place the hands or other parts of the body in moving parts, such as belts, pulleys, carrelli, etc.

Servicing the actuator is of fundamental importance if the system is to operate correctly and safely. It is advisable to periodically inspect

all parts every 6 months, to make sure they operate in an efcient way.

The manufacturer declines all liability for improper installation or use of the product, or for damage deriving from unauthorized

modications to the system. Only use genuine spare parts if replacements or repairs are required. The manufacturer cannot be held

liable for the way the doors or gates to be automated are constructed, or for damages caused by failure to build the doors and gates in

compliance with good workmanlike techniques.

Protection degree IP10 requires that the actuator only be installed inside buildings. The manufacturer declines all liability for damage

caused by assembly on the outside, without adequate protections.

Always make sure that the product is in a good condition before it is installed.

This product cannot be installed in places with an explosive atmosphere or in the presence of inammable fumes or gases.

This product must be disposed of according to the current laws in force at the end of its useful life.

Do not leave parts of the product or its packaging within children’s reach, as they could become a danger hazard.

Do not stay within the door movement range and do not deliberately try to stop the door movement.

Do not allow children to stay or play within the door movement range.

MACHINE DIRECTIVE

As established by the EU commission, automated pedestrian closing systems are governed by the machine directive (2006/48/EC).

This latter species that the installer who ts a driving system on a door or gate has the same obligations as the manufacturer of the

machine. Thus, he must:

1. Prepare the technical report (complete with the documents described in annex VII of the Machine Directive).

2. Compile the relative CE conformity certicate (as per annex II-A of the Machine Directive).

3. Afx CE marking to the motorized door or gate (1.7.3, of annex I of the Machine Directive).

The installer must keep the technical report at the disposal of the competent authorities in the country for at least 10 years, running from

the date on which the motorized door or gate was manufactured.

The installer must consign the following documents to the customer:

1. Instructions on how to operate and safely use the system.

2. The routine maintenance instructions.

3. The declaration of conformity.

MAINTENANCE PROGRAM

Each 6 month:

Attention! Before work on the operator cut main power line.

- Check that all securing screws are well tightened.

- Check the tension of the belt.

- Clean the carriages sliding guide and the ground sliding guide .

- Check that carriages and wings are correctly aligned and stop are properly positioned.

- Check that elettrolock, if present, are correctly tted and that mechanical unlock system work ne.

- Check wiring connections.

- Check that door wings are stable and the movement is steady, without friction from full open to full close position.

- Check that speeds, timing, and safety functions are well set.

- lean sensors and check that safety and activation sensor are properly functioning.

Attention! Any part that appear damaged or worn must be changed.

For spare parts see the spare part list.

Page 3

3

DOOR Series -

English

CONTENTS

pag. 4 1_ TECHNICAL FEATURES

pag. 4 2_ TYPICAL SYSTEM

pag. 5 3_ AUTOMATION SECTION AND REFERENCES

pag. 6 4_ LEAF DIMENSIONS AND STANDARD REFERENCES

pag. 7 5_ CROSSPIECE ANCHORING

pag. 7 6_ ANCHORING THE LEAVES TO THE CARRIAGES AND MAKING ADJUSTMENTS

pag. 7 7_ MOUNTING AND ADJUSTING THE ELECTRIC BLOCK AND THE MANUAL EMERGENCY RELEASE DEVICE

pag. 10 8_ POSITIONING THE BRAKE BUMPER

pag. 10 9_ REGOLAZIONE DELLA TENSIONE DELLA CINGHIA

pag. 10 10_ ELECTRONIC CONTROL UNIT

pag. 10 10.1_ DESCRIPTION OF PARTS

pag. 11 11_ ELECTRICAL CONNECTIONS

pag. 12 12_ DOORFOTO1 PHOTOCELL CARD

pag. 12 12.1_ INSERTING THE CARD IN THE CONNECTOR LOCATED ON THE MOTHERBOARD

pag. 12 12.2_ HOW TO DISTINGUISH THE TRANSMITTER CAPSULES FROM THE RECEIVER ONES

pag. 12 12.3_ SELECTING THE NUMBER OF PHOTOCELL PAIRS UTILIZED

pag. 13 12.4_ CONNECTING THE RECEIVER AND TRANSMITTER CAPSULES

pag. 13 12.5_ ADJUSTING THE CAPSULE SENSITIVITY

pag. 13 12.6_ OPERATING FAULTS

pag. 13 12.7_ DOOR STOP WITH STOP BUTTON

pag. 14 13_ THE DOORPROG SELECTOR SWITCH

pag. 15 14_ DOORBATT BATTERY OPERATED OPENING DEVICE

pag. 16 15_ ADJUSTING THE AUTOMATISM

pag. 16 15.1_ INITIALIZATION PROCEDURE

pag. 16 15.2_ ADJUSTING THE AUTOMATISM FROM THE CONTROL UNIT

pag. 16 15.3_ ADJUSTING THE AUTOMATISM THROUGH REMOTE PROGRAMMING FROM THE SELECTOR

SWITCH

pag. 17 15.4_ RESET OPERATION

pag. 21 16_ INTERLOCK SYSTEM

pag. 22 17_ DOORSELF MECHANICAL SELECTOR SWITCH

pag. 22 17.1_ ELECTRICAL CONNECTIONS

pag. 22 17.2_ OPERATING MODE

pag. 22 18_ DOORIM MODULE

pag. 23 19_ FIRE DOOR FUNCTION

pag. 23 20_ MEANING OF BUZZER SIGNALS (BEEPS)

pag. 23 21_ ADVANCED FUNCTIONS - TECHNICAL MENÙ

pag. 25 22_ TROUBLES, CAUSES and CURE

pag. 26 GUARANTEE: GENERAL CONDITIONS

pag. 27 MANUFACTURER’S DECLARATION OF INCORPORATION

Page 4

4

DOOR Series -

English

MODEL DOOR DOORX

Power rating 80 Watt 130 Watt

Max. door weight 1 wing 100 daN (Kg) - 2 wings 75 daN (Kg) per wing 1 wing 150 daN (Kg) - 2 wings 130 daN (Kg) per wing

Opening speed 70 cm/s (for wing)

Closing speed 50 cm/s (for wing)

Voltage input 230 Vac ± 10% 50-60 Hz

Type of work Continuos (100%)

Operating temperature -20°C ÷ +50°C

Carriages 1 wheel Ø 65 mm + anti-lifting 2 wheels Ø 65 mm + anti-lifting

Beam dimensions 135 x180 x 6000 mm (max. length)

Degree of protection IP 12

Electric motor 40Vdc with encoder

Ext. accessories power supply 12 and 24Vac

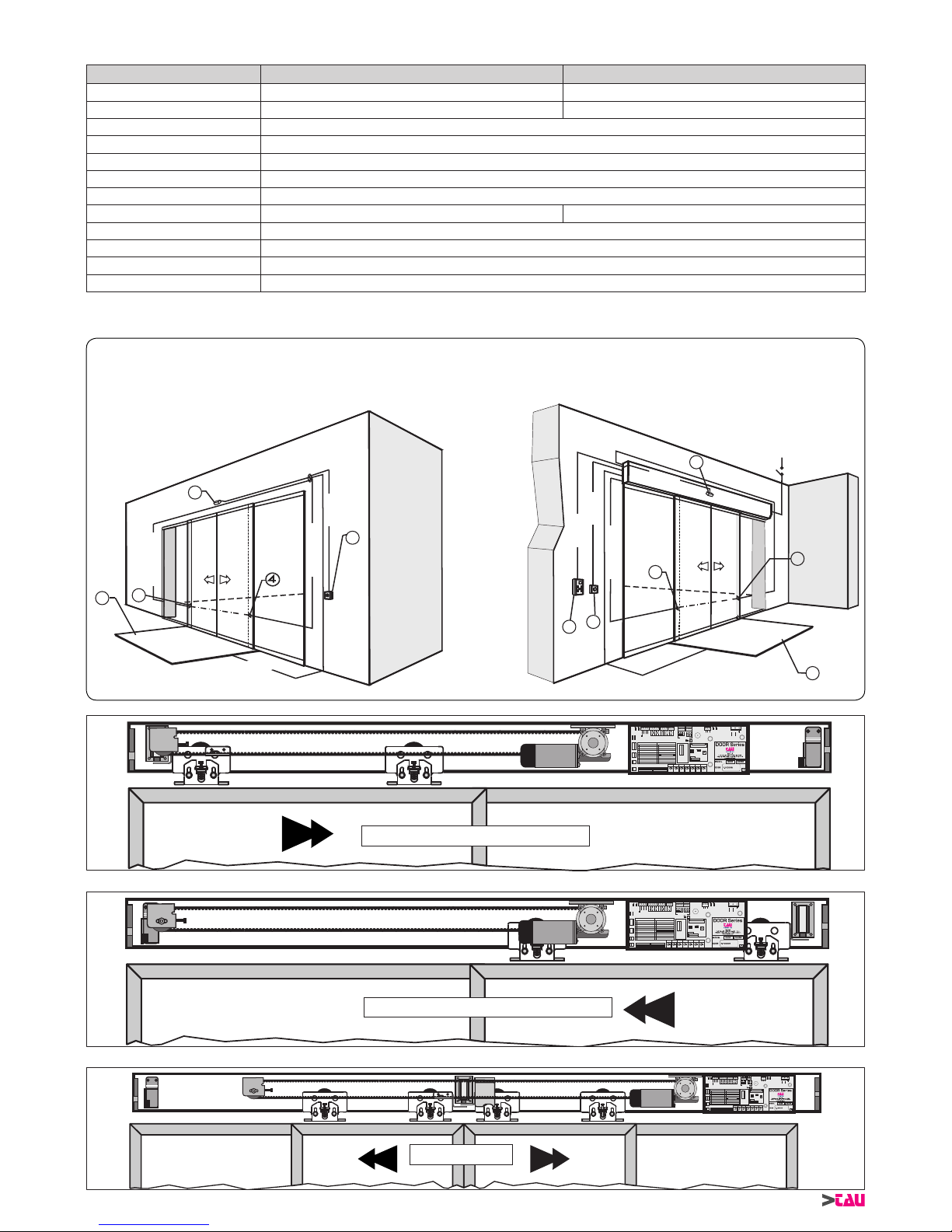

1_ TECHNICAL FEATURES

g. 1

U

T

Q

V

S

R

U

Q

T

T

S

R

U

Q

T

T

2_ TYPICAL SYSTEM

FT= 2x0,25

FR= 3x0,25

2x0,35

4x0,75

3x0,5

4x0,35

2x0,35

FT= 2x0,25

FR= 3x0,25

3x0,5

4x0,75

ANTA FISSA

FIXED WING

VANTAIL FIXE

FEST TÜRFLÜGEL

HOJA FIJA

minidip sRminidip sQlockR

motore

lockQ

encoder

battery

f•š•†ˆ’’N R „ššŒœ„š„

f•š•†ˆ’’N S „ššŒœ„š„

switch

start

modulo fotocellule

carica batteria

wd

buzzer

T U V W X Y QP QQ QR QS QT QUQ R S

fotocellule

capN rx capN tx

frSfrRfrQvccgnd ftSftRftQ

K

encQ

encR

QRv

dato

P

comune

start

interblocco

emergenza

radar estN

comune

sensore latN

fotocellula

aux Q

radar intN

apN pedonale

comune

J f›”¡Œ•”ˆ –•˜š„ š„Š’Œ„‰›•†•

J a›š•“„¡Œ•”ˆ “•‡ˆ’’• doorx

minidip sQ

minidip sR

i” ‰›”¡Œ•”ˆ ”•ššˆ –•˜š„ …’•††„š„

e“ˆ˜Šˆ”¡„ „–˜ˆ Œ” ‰›”¡Œ•”ˆ ”•ššˆ

f›”¡Œ•”ˆ …„”†„ H…’•††„ ™ˆ“–˜ˆI

a”šŒ–„”Œ†• ”ˆ’’ˆ ‰›”¡Œ•”Œ ŠŒ•˜”•

a–ˆ˜š›˜„ †•” …„ššˆ˜Œ„ ‡„””ˆŠŠŒ„š„

r„‡„˜ „ššŒœŒ Œ” “„”†„”¡„ ˜ˆšˆ

cŒ†’• †•”šŒ”›• H™•’• –ˆ˜ šˆ™šI

a–ˆ˜šN t•šN d•–• Q¹ Œ” Œ”œˆ˜”„’ˆ

Q

R

S

T

U

V

W

X

Y

QP

i”†˜ˆ“N a›š•“N tˆ“–• ‡Œ –„›™„

f›”¡Œ•”„“ˆ”š• †•” ™ˆ’ˆšš•˜ˆ

f›”¡Œ•”ˆ –„™™•M–„™™•

J p•˜š„ „‡ Q „”š„ „–ˆ˜šN œˆ˜™• dx

m•‡›’• ‰•š•†ˆ’’›’„ Œ”™ˆ˜Œš•

gˆ™šŒ•”ˆ S„ ‰•š•†ˆ’’›’„

rŒ†‹Œ›™›˜„ Œ““ˆ‡Œ„š„

p˜•Š˜„““„¡Œ•”ˆ ‡„ ™ˆ’ˆšš•˜ˆ

sˆšš„ŠŠŒ• Œ”Œ¡Œ„’ˆ

led verde

lampeggiante]

…„ššˆ˜Œ„ Œ” †„˜Œ†„

led verde fisso]

…„ššˆ˜Œ„ †„˜Œ†„š„

QVQW QX

QRv

RTv

RSPv

QRvRTvP

f n

fotocellula Q

fotocellula R

fotocellula S

M

K

QR

Q

R

switch

sensibilita¹

QPa fR

Ua

fQ

Ta

fS

K M

tmQ tmR tmS tmT tmU tmV tmW

Q

R

S

T

U

V

W

X

Y

QP

g

–•šˆ”¡„

„–ˆ˜š›˜„

œˆ’•†Œšà

„–˜ˆ

œˆ’•†Œšà

†‹Œ›‡ˆ

–•šˆ”¡„

†‹Œ›™›˜„

‰˜ˆ”„š„ Œ”

„–ˆ˜š›˜„

„–ˆ˜š›˜„

Œ”œˆ˜”„’ˆ

šˆ“–• ‡Œ

–„›™„

Jdip ‡„ Œ“–•™š„˜ˆ –˜Œ“„ ‡ˆ’ settaggio iniziale

SINGLE LEAF – Right hand

1 INFRARED SENSOR

2 EMERGENCY BUTTON

3 KEYPAD FOR PROGRAMMING

4 PHOTOCELL (FT=transmitting ph., FR=receiving ph.)

5 MAGNETIC FOOTBOARD

6 KEYLOCK SELECTOR

ANTA FISSA

FIXED WING

VANTAIL FIXE

FEST TÜRFLÜGEL

HOJA FIJA

minidip sRminidip sQlockR

motore

lockQ

encoder

battery

f•š•†ˆ’’N R „ššŒœ„š„

f•š•†ˆ’’N S „ššŒœ„š„

switch

start

modulo fotocellule

carica batteria

wd

buzzer

T U V W X Y QP QQ QR QS QT QUQ R S

fotocellule

capN rx capN tx

frSfrRfrQvccgnd ftSftRftQ

K

encQ

encR

QRv

dato

P

comune

start

interblocco

emergenza

radar estN

comune

sensore latN

fotocellula

aux Q

radar intN

apN pedonale

comune

J f›”¡Œ•”ˆ –•˜š„ š„Š’Œ„‰›•†•

J a›š•“„¡Œ•”ˆ “•‡ˆ’’• doorx

minidip sQ

minidip sR

i” ‰›”¡Œ•”ˆ ”•ššˆ –•˜š„ …’•††„š„

e“ˆ˜Šˆ”¡„ „–˜ˆ Œ” ‰›”¡Œ•”ˆ ”•ššˆ

f›”¡Œ•”ˆ …„”†„ H…’•††„ ™ˆ“–˜ˆI

a”šŒ–„”Œ†• ”ˆ’’ˆ ‰›”¡Œ•”Œ ŠŒ•˜”•

a–ˆ˜š›˜„ †•” …„ššˆ˜Œ„ ‡„””ˆŠŠŒ„š„

r„‡„˜ „ššŒœŒ Œ” “„”†„”¡„ ˜ˆšˆ

cŒ†’• †•”šŒ”›• H™•’• –ˆ˜ šˆ™šI

a–ˆ˜šN t•šN d•–• Q¹ Œ” Œ”œˆ˜”„’ˆ

Q

R

S

T

U

V

W

X

Y

QP

i”†˜ˆ“N a›š•“N tˆ“–• ‡Œ –„›™„

f›”¡Œ•”„“ˆ”š• †•” ™ˆ’ˆšš•˜ˆ

f›”¡Œ•”ˆ –„™™•M–„™™•

J p•˜š„ „‡ Q „”š„ „–ˆ˜šN œˆ˜™• dx

m•‡›’• ‰•š•†ˆ’’›’„ Œ”™ˆ˜Œš•

gˆ™šŒ•”ˆ S„ ‰•š•†ˆ’’›’„

rŒ†‹Œ›™›˜„ Œ““ˆ‡Œ„š„

p˜•Š˜„““„¡Œ•”ˆ ‡„ ™ˆ’ˆšš•˜ˆ

sˆšš„ŠŠŒ• Œ”Œ¡Œ„’ˆ

led verde

lampeggiante]

…„ššˆ˜Œ„ Œ” †„˜Œ†„

led verde fisso]

…„ššˆ˜Œ„ †„˜Œ†„š„

QVQW QX

QRv

RTv

RSPv

QRvRTvP

f n

fotocellula Q

fotocellula R

fotocellula S

M

K

QR

Q

R

switch

sensibilita¹

QPa fR

Ua

fQ

Ta

fS

K M

tmQ tmR tmS tmT tmU tmV tmW

Q

R

S

T

U

V

W

X

Y

QP

g

–•šˆ”¡„

„–ˆ˜š›˜„

œˆ’•†Œš적

„–˜ˆ

œˆ’•†Œš적

†‹Œ›‡ˆ

–•šˆ”¡„

†‹Œ›™›˜„

‰˜ˆ”„š„ Œ”

„–ˆ˜š›˜„

„–ˆ˜š›˜„

Œ”œˆ˜”„’ˆ

šˆ“–• ‡Œ

–„›™„

Jdip ‡„ Œ“–•™š„˜ˆ –˜Œ“„ ‡ˆ’ settaggio iniziale

SINGLE LEAF – Left hand

ANTA FISSA

FIXED WING

VANTAIL FIXE

FEST TÜRFLÜGEL

HOJA FIJA

ANTA FISSA

FIXED WING

VANTAIL FIXE

FEST TÜRFLÜGEL

HOJA FIJA

minidip sRminidip sQlockR

motore

lockQ

encoder

battery

f•š•†ˆ’’N R „ššŒœ„š„

f•š•†ˆ’’N S „ššŒœ„š„

switch

start

modulo fotocellule

carica batteria

wd

buzzer

T U V W X Y QP QQQR QS QT QUQ R S

fotocellule

capN rx capN tx

frSfrRfrQvccgnd ftS ftRftQ

K

encQ

encR

QRv

dato

P

comune

start

interblocco

emergenza

radar estN

comune

sensore latN

fotocellula

aux Q

radar intN

apN pedonale

comune

J f›”¡Œ•”ˆ –•˜š„ š„Š’Œ„‰›•†•

J a›š•“„¡Œ•”ˆ “•‡ˆ’’• doorx

minidip sQ

minidip sR

i” ‰›”¡Œ•”ˆ ”•ššˆ –•˜š„ …’•††„š„

e“ˆ˜Šˆ”¡„ „–˜ˆ Œ” ‰›”¡Œ•”ˆ ”•ššˆ

f›”¡Œ•”ˆ …„”†„ H…’•††„ ™ˆ“–˜ˆI

a”šŒ–„”Œ†• ”ˆ’’ˆ ‰›”¡Œ•”Œ ŠŒ•˜”•

a–ˆ˜š›˜„ †•” …„ššˆ˜Œ„ ‡„””ˆŠŠŒ„š„

r„‡„˜ „ššŒœŒ Œ” “„”†„”¡„ ˜ˆšˆ

cŒ†’• †•”šŒ”›• H™•’• –ˆ˜ šˆ™šI

a–ˆ˜šN t•šN d•–• Q¹ Œ” Œ”œˆ˜”„’ˆ

Q

R

S

T

U

V

W

X

Y

QP

i”†˜ˆ“N a›š•“N tˆ“–• ‡Œ –„›™„

f›”¡Œ•”„“ˆ”š• †•” ™ˆ’ˆšš•˜ˆ

f›”¡Œ•”ˆ –„™™•M–„™™•

J p•˜š„ „‡ Q „”š„ „–ˆ˜šN œˆ˜™• dx

m•‡›’• ‰•š•†ˆ’’›’„ Œ”™ˆ˜Œš•

gˆ™šŒ•”ˆ S„ ‰•š•†ˆ’’›’„

rŒ†‹Œ›™›˜„ Œ““ˆ‡Œ„š„

p˜•Š˜„““„¡Œ•”ˆ ‡„ ™ˆ’ˆšš•˜ˆ

sˆšš„ŠŠŒ• Œ”Œ¡Œ„’ˆ

led verde

lampeggiante]

…„ššˆ˜Œ„ Œ” †„˜Œ†„

led verde fisso]

…„ššˆ˜Œ„ †„˜Œ†„š„

QVQW QX

QRv

RTv

RSPv

QRvRTvP

f n

fotocellula Q

fotocellula R

fotocellula S

M

K

QR

Q

R

switch

sensibilita¹

QPa fR

Ua

fQ

Ta

fS

K M

tmQ tmR tmS tmT tmU tmV tmW

Q

R

S

T

U

V

W

X

Y

QP

g

–•šˆ”¡„

„–ˆ˜š›˜„

œˆ’•†Œš적

„–˜ˆ

œˆ’•†Œš적

†‹Œ›‡ˆ

–•šˆ”¡„

†‹Œ›™›˜„

‰˜ˆ”„š„ Œ”

„–ˆ˜š›˜„

„–ˆ˜š›˜„

Œ”œˆ˜”„’ˆ

šˆ“–• ‡Œ

–„›™„

Jdip ‡„ Œ“–•™š„˜ˆ –˜Œ“„ ‡ˆ’ settaggio iniziale

DOUBLE LEAF

3x1,5

230V~

Page 5

5

DOOR Series -

English

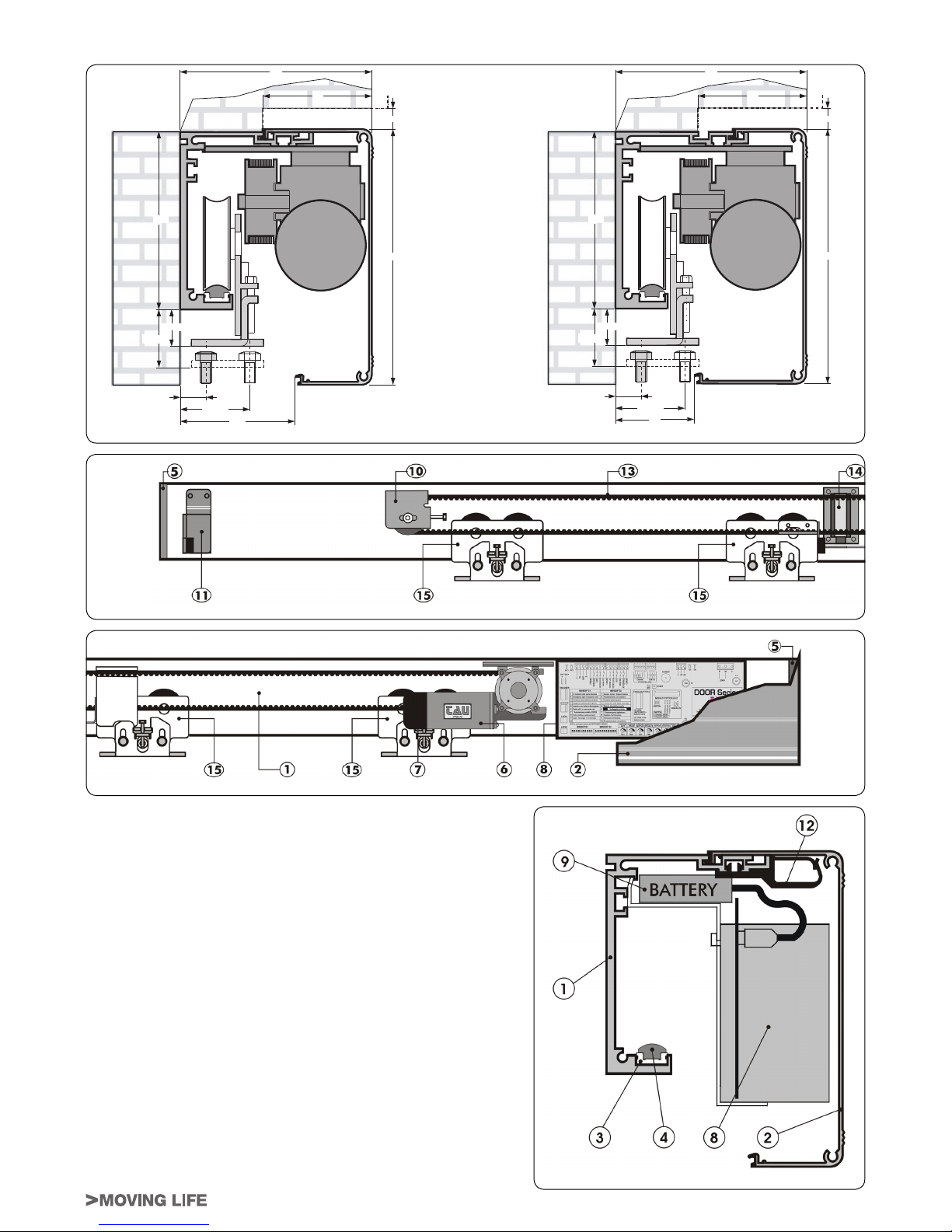

1 Aluminium crosspiece

2 Aluminium cover

3 Sound insulating polyzene guide

4 Aluminium sliding track

5 Sides

6 Gearmotor

7 Encoder

8 Electronic equipment with transformer

9 Battery

10 Snub pulley

11 Brake bumper

12 Cable guide

13 Timing belt

14 Electric block

15 Carriages

g. 2

3_ AUTOMATION SECTION AND REFERENCES

QSU

QXP

c‘‡ƒ—ƒ“…‡ ˆ”— ‰šƒ—† ”•‡“‹“‰

XR

QS

RV min

TQ max

QRU

TY max

XP

QX min

QSU

c‘‡ƒ—ƒ“…‡ ˆ”— ‰šƒ—† ”•‡“‹“‰

XR

RV min

TQ max

QRU

TY max

VP

QX min

QXP

QS

g. 4

g. 3

g. 5

Page 6

6

DOOR Series -

English

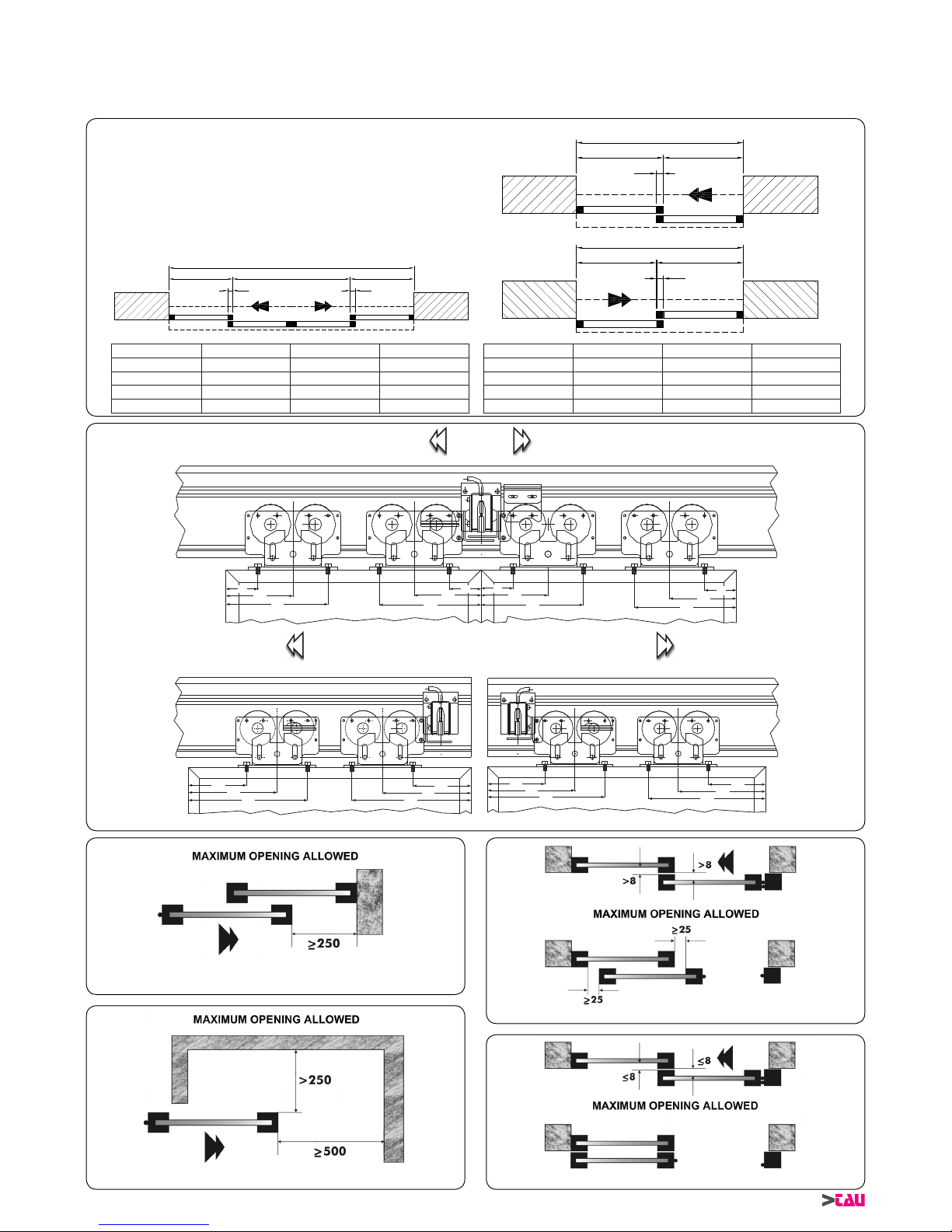

4_ LEAF DIMENSIONS AND STANDARD REFERENCES

For proper door operation, the carriage centre distances and the distance between the carriages and the end of the door frame must

be observed, as shown in gure 6.

Refer also to gures 7, 8, 9 and 10 regarding the safety clearance regulations to be observed.

LT Crosspiece length

S Leaf overlap

X Leaf length

Y Pass-through opening

LT S X1 Y1

1600 mm 50 mm 450 mm 700 mm

1600 mm 25 mm 437,5 mm 725 mm

2000 mm 50 mm 550 mm 900 mm

2000 mm 25 mm 537,5 mm 925 mm

LT S X2 Y2

1600 mm 50 mm 875 mm 725 mm

1600 mm 25 mm 862,5 mm 737,5 mm

2000 mm 50 mm 1075 mm 925 mm

2000 mm 25 mm 1062,5 mm 937,5 mm

LT

X2

Y2

S

LT

Y2

X2

S

LT

Y1

X1

S

X1

S

UP

QPU

QVP

UP

QPU

QVP

UP

QPU

QVP

UP

QPU

QVP

QPU

QVP

RQU

QPU

QVP

RQU

QPU

QVP

RQU

QPU

QVP

RQU

g. 6

g. 7

g. 10g. 9

g. 8

Open

P-10DOOR P-10DOORX

Open Open

Page 7

7

DOOR Series -

English

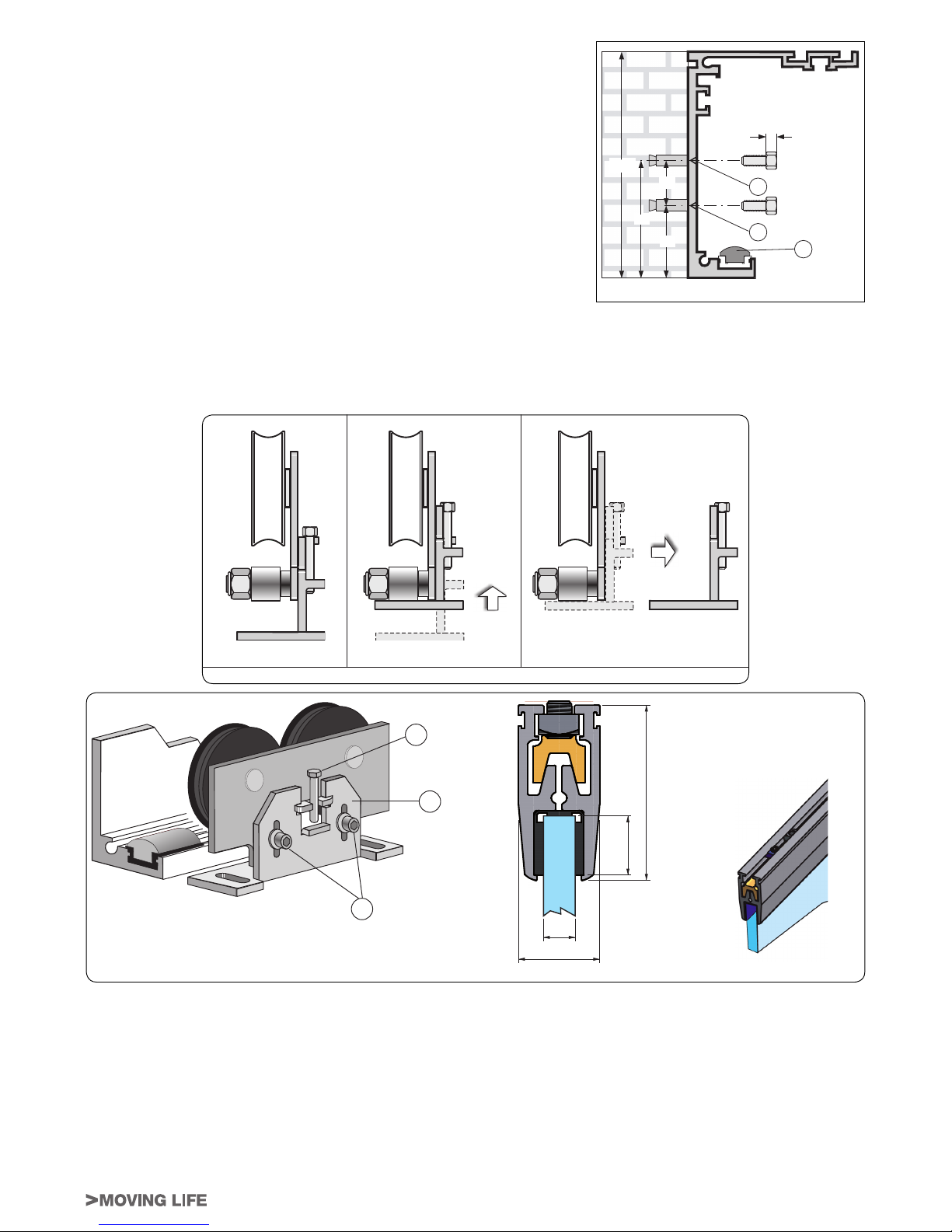

5_ CROSSPIECE ANCHORING (g. 11)

The transom must be xed to a straight surface solid enough to bear the weight of

the wing used. If the wall or bearing surface fail to comply with these parameters, an

adequate iron tube must be installed as the transom is not self-supporting.

It is advisable to use a level to prevent the transom being mounted out of square.

Fix the transom to the wall or bearing surface with M6 steel expansion plugs or

equivalent.

The xing points must be distributed alternately between the two reference lines on the

beam (L1 and L2), every 600 mm.

Make sure that the track (B1) is not damaged when the beam is drilled as this

would impair the way the automation works and prevent it from operating

silently.

Once the beam has been xed, clean the drilling waste from the sliding zone with a

brush or small vacuum cleaner.

6_ ANCHORING THE LEAVES TO THE CARRIAGES AND MAKING

ADJUSTMENTS

Loosen and remove the two screws (A) in each carriage and pull out the removable part

(C) by sliding it upward and then outward as shown in gure 12. Fasten the removable part (C) to the door frame at the distance shown

in g. 6. Now the leaf can be hung: perform the operations described in gure 12 in the reverse order. Now re-position the screws ( A ) in

their seats without tightening them. Once the desired height of the leaf has been adjusted using the adjusting screw (B) tighten the two

screws rmly (A). The horizontal adjustment of the leaf is made by means of the slots found in the movable part of the carriage.

For proper operation of the automation the moving leaf must be perpendicular to the crosspiece.

g. 11

QRU

VU

max X““

bQ

lR

TU

RP

lQ

g. 12

1 2 3

g. 13

Groove for glass

a

b

c

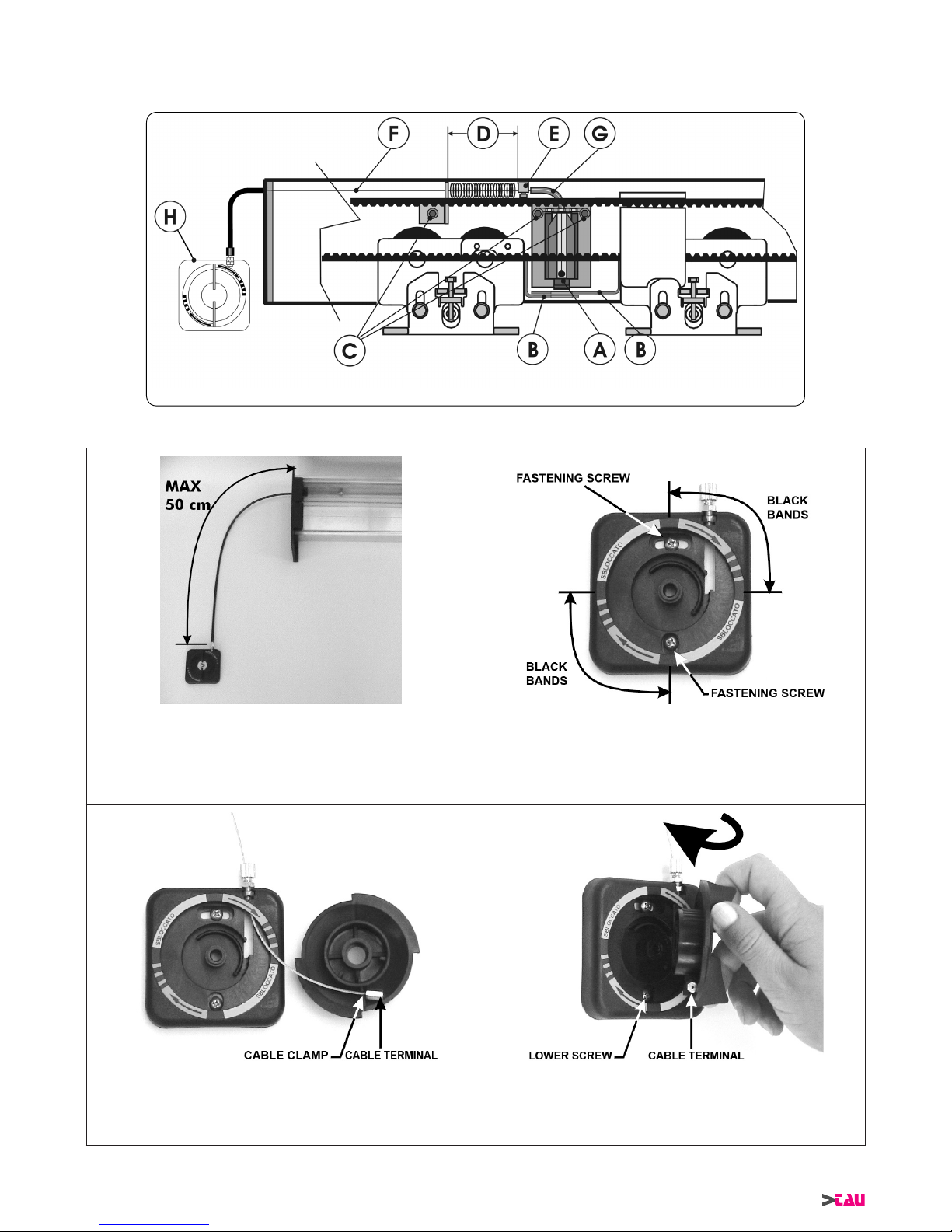

7_ MOUNTING AND ADJUSTING THE ELECTRIC BLOCK AND THE MANUAL EMERGENCY RELEASE DEVICE

If there is no door locking solenoid (optional) go straight on to the next chapter, otherwise strictly comply with the following instructions:

Important: the following operations must be carried out in the absence of mains voltage and with the battery disconnected!

Move the wings to the closed position by hand and make sure that the mobile part A of the electro-lock connects the two locking brackets

B on the carriages (there is only one bracket if the door has one wing). If it fails to connect, unscrew the screws C that x the electrolock and move everything to the position in which the locking brackets are able to couple with mobile part A. Check that the distance D

between clamp E and the spring stop is about 45 mm.

Unscrew the screw of clamp E so that the release cable can slide in it. Allow the mobile part A of the electro-lock to drop fully downwards

until it touches the track. Pull the release cable F very slowly until the mobile part A starts to lift. Keeping cable F at a standstill, move

clamp E until it touches the end of tube G and tighten the clamp screw. Repeatedly pull and release cable F to make sure that the mobile

part A is free to drop to the track when the cable is released and that locking brackets B are freed when the cable is taut. After having

18,5

56,5

24

10 min.

11 max.

Page 8

8

DOOR Series -

English

pulled the cable taut from the outlet of tube H so that it remains in this condition but without the mobile part A being lifted, tighten the

screw of clamp I as near as possible to adjuster L. Regulate this adjuster until the releasing wire is taut. Release ring N can now be

xed with clamp M at the required height. In doors with one wing that open towards the right, the position of the components is directly

opposite to the ones shown in the drawing, but the operations to carry out are exactly the same.

g. 14

At this stage, the H release device must be prepared as follows (wall mounted):

Locate the exact point on the wall where the device is to be mounted,

bearing in mind that the standard cable sheathing is 50 cm long

(a kit

containing a 300 cm length sheath + cable is also available).

Drill a hole in the wall, and fasten the base of the release

mechanism using special screws. Attach the adhesive label as

shown in the gure, making sure the four black bands correspond

to the cardinal points.

Insert the adjuster with 2 nuts, one in the relative slit in the plastic

and the other on the outside of it.

Thread the release cable through the bottom slot, then into the

adjustment register. Then place the cable terminal on the release

knob cable clamp.

At this stage, slide the release knob into the base of the mechanism

taking care to keep the cable terminals in the cable clamp seat,

and the knob in the correct position. The cable terminal must

be set just after the lower fastening screw (clockwise) when the

knob is inserted .

1 2

3 4

Page 9

9

DOOR Series -

English

Once the knob has been inserted, fasten the locking screw, insert

the sheath and move the knob to the NOT RELEASED setting.

Only the orange part of the label with the black arrows must be

visible in this position.

Make sure that the system operates correctly by turning the knob

clockwise and keeping the cable taut with the hand.

WARNING: THE KNOB WILL ONLY TURN ABOUT 45-50

DEGREES AND HAS MECHANISMS IN THE FINAL PART,

ALLOWING IT TO REMAIN IN POSITION AFTER BEING

LOCKED.

Apply the supplied label to cover the screw as shown in the gure,

then move the knob back to the NOT RELEASED position.

The cable must now be fastened to the beam, in one of the ways described below:

1_ by using the special slot on the lateral plastic plug (g. 6A);

g. A

2_ from underneath the beam, using the 90° bent guide supplied

(g. 6B). This system is used when there is no room on either

side of the automation.

g. B

In both cases, when the cable from the solenoid is connected to

the one from the release mechanism, make sure that the release

knob is in the NOT RELEASED position, and that the wire and

sheath from the release mechanism are taut. Route both the

cables (naturally in the opposite direction) into the supplied terminal and tighten them both but without activating the solenoid

(the spring on this latter must only compress a few millimeters).

Now strongly tighten the loose terminal and make sure that both

cables remain taut.

If the cables fail to remain taut, regulate the cable tension using

the relative adjuster in the release mechanism.

Lastly, check to make sure that when the release mechanism is operated, the solenoid’s core is raised and able to free

the door, and that when the release mechanism is set back

to the NOT RELEASED position, the solenoid’s core is free

to move up and down without impediments or obstructions

of any type.

The release device can be installed directly on the side of the

mechanism by threading the cable through the slot designed for

this purpose.

Install the device using the same procedure as the wall mounted

device.

5

6

7

8 9

Page 10

10

DOOR Series -

English

8_ POSITIONING THE BRAKE BUMPER

The brake bumpers must be adjusted in such a way that, both during the closing and opening manoeuvres, they will stop the carriages

before the moving leaf hits the wall, frame or any other obstacle. They are also used by the microprocessor to acquire the limit switch

positions if there is a power failure and the battery is not connected.

While adjusting the brake bumper for the opening manoeuvre keep in mind that, except for the rst manoeuvre after a power failure,

during normal operation the moving leaf stops 5 mm before it strikes the bumper.

9_ ADJUSTING THE BELT TENSION

To adjust the tension of the belt, loosen screw A in the idle pulley lightly, then

screw (to tighten) or unscrew (to loosen) hex screw B.

Once the desired tightness has been obtained, tighten screw A rmly.

g. 15

10_ MOTHER BOARD

10.1_ DESCRIPTION OF PARTS

DL1 (ENC1) - DL2 (ENC2): display the signals coming from the encoder sensor.

DL3 (WD): if the LED ashes quickly it means that the main MP1 microprocessor is operating correctly. If the LED is off or ashes

slowly it means that the electronic board is malfunctioning.

DL4 (12V): it displays the presence of 12 Vac voltage on the M5 terminal board.

DL5 (24V): it displays the presence of 24 Vac voltage on the M5 terminal board.

J1, J2 CONNECTORS: connection of supply transformer.

J3 CONNECTOR: DOORPHOTO1 photocells management card (paragraph 12).

J4 CONNECTOR: DOORBATT battery charge card (paragraph 14).

J5 CONNECTOR: ENCODER connection.

J6 CONNECTOR: MOTOR connection.

J7 CONNECTOR: connection of MAIN LOCK1 ELECTRIC BLOCK (paragraph 7).

J8 CONNECTOR (operation 2): DOORIM module activation (paragraph 18).

F1 FUSE: 5A, protection of 230 Vac power supply line.

F2 FUSE: 10A, protection of motor power supply line.

F3 FUSE: 4A, protection of logic card 12V power supply.

g. 16

MINIDIP S2MINIDIP S1

MOTOR

LOCK 1

ENCODER

BATTERY

Photocell 2 activated

Photocell 3 activated

opening

speed

SWITCH

START

PHOTOCELL CONTROL

BATTERY CHARGER

WD

BUZZER

T U V W X Y QP QQ QR QS QT QU

PHOTOCELL

capN rx capN tx

ENC1

ENC2

12V

DATO

0

COMMON

START

INTERLOCK

EMERGENCY

RADAR EXT.

COMMON

LAT. SENSOR

PHOTOCELL

AUX 1

RADAR INT.

PEDESTRIAN

COMMON

* 130 Kg for wing model

MINIDIP S1

MINIDIP S2

Door locked in night function

Emergency opens in night function

Antipanic in day functions

Continuous cycle (just for test)

Full open after 1’ in winter

Q

R

S

T

U

V

W

X

Y

QP

Self adjusting pause time

Step by step function

* One wing towards DX

Photocell FK38 module inserted

Immediate closing

Initial set-up activated

QV QW QX

12V

24V

230V

12V 24V0

F N

PHOTOCELL 1

PHOTOCELL 2

PHOTOCELL 3

-

+

1 2

1

2

SWITCH

SENSITIVITY

10A F2

5A

F1

4A

F3

+ -

TM1 TM2 TM3 TM4 TM5 TM6 TM7

Q

R

S

T

U

V

W

X

Y

QP

LOCK 2

Q R Sg

Opening with damaged battery

Radar activated in a power failure

* Fire door function

Operation with SMB selector

Control of 3rd FK38 photocell

Programming via selector PS1

Bank function (always blocks)

FLASHING

GREEN LED =

battery charging

FIXED GREEN LED =

battery charged

opening

power

closing

power

braking on

opening

winter

opening

hold

time

closing

speed

*DIP switches to set prior to INITIAL SETUP

frS frR frQ vcc gnd ftS ftR ftQ

K

Page 11

11

DOOR Series -

English

11_ ELECTRICAL CONNECTIONS

TERMINAL BOARD M1 (G – 1 – 2 – 3)

G = EARTH

QRv

dato

P

Q R S Tg

1 = 12V DC

2 = DATO

3 = 0

Connection to the selector switch. Connect the selector switch to the control unit using a 4-pole 0.5 mm diameter cable, maintaining

the same correspondence (12V - DATO - 0 - G). The max length of the cable is 50 metres.

To prevent any false displays on the selector switch, keep the connection cable away from sources of electrical disturbance.

TERMINAL BOARD M2 (4 – 5 – 6 – 7 – 8)

4 = COMMON

S YT U V W X

P

common

emergency

start

interlock

radar extN

5 = EMERGENCY input N.C. It opens the door in any condition.

6 = START input (PS1 button) N.O. It opens the door in all conditions except when the selector

switch is in night locking mode ; it is also the only input

that starts the initial setting.

7 = INTERLOCK input N.C. a) Inhibits door opening when the INTERLOCK function

is selected (see INTERLOCK SYSTEM in section 16).

b) Can be used as a STOP button with DIP 7 of S2

OFF.

c) Can be used for connecting a smoke sensor in re

doors, with DIP 7 of S2 ON (see FIRE DOOR

FUNCTIONin section 19)

8 = EXTERNAL RADAR input N.O. It opens the door in all conditions except when the selector

switch is in night locking mode , or in exit only mode

.

TERMINAL BOARD M3 (9 – 10 – 11 – 12)

9 = COMMON

YXQP QQ QR QS QT

com

latN sensor

photocell

aux Q

common

radar intN

rian

adar extN

ck

10 = SIDE SENSOR input N.C. It opens slowly if it detects an obstacle in the safety

clearance areas.

11 = PHOTOCELL input N.C. If it detects an obstacle in the passage during the closing

manoeuvre, it reverses direction and opens.

12 = AUXILIARY input AUX1 N.O.

a) Selects the night lock (contact made) or 2 ways

function (contact broken) with dip 2 of S2 OFF.

- If selector DOORPROGis used, closing of the AUX1

input activates the NIGHT LOCK function, inhibiting

the setting of selector DOORPROG.

b) Selection of the INTERLOCK mode (dip12 of S1

ON) inhibits detection of the INTERLOCK contact on

terminal 7 (contact made), see section16.

c) If mechanical selector DOORSELF is used (dip2 of

S2 ON), the AUX1 input cannot be used for the above

mentioned functions (see section 17).

TERMINAL BOARD M4 (13 – 14 – 15)

13 = INTERNAL RADAR input N.O. It opens the door in all conditions except when the selector

switch is in night locking mode or in input mode only

.

QS QT QUQQ QR

common

tocell

aux Q

radar intN

pedestrian

frS

14 = PEDESTRIAN input N.O.

a)

It opens the door approx. 90 cm for passage in all

conditions, except when the system is in night locking

mode

(the pedestrian opening distance can be

modied only from the DOORPROG selector switch).

b) If the DOORSELF mechanical selector switch is used, the

PEDESTRIAN function is deactivated (

see paragraph

17).

15 = COMMON input

Page 12

12

DOOR Series -

English

TERMINAL BOARD M5 (16 – 17 – 18)

16 = 0 output

QV QW QX

QRv

P QRv RTv

17 = 12V a.c. max 700mA output - Visualized by led DL4 (12V).

18 = 24V a.c. max 400mA output - Visualized by led DL5 (24V).

Power supply for external devices (radar, photocells, etc.)

In case of power failure, no voltage will be present on these terminals.

EARNING: If you need the radar sensors or external photocells to be operational even in the

BATTERY work mode, draw the power supply for the sensors from terminal board M1 between

terminals 1 (+12V) and 3 (0). Maximum current 250mA.

TERMINAL BOARD M6 (F – N – ) Mains power supply

F = 230V a.c. – 50-60Hz input PHASE

RSPv

f

n

N = 230V a.c. – 50-60Hz input NEUTRAL

=

GROUND; connect the ground conductor to the faston located on the control unit’s metal

casing.

- Provide the mains with an omnipolar isolator with contact opening distance of at least 3mm.

- The power supply line must be protected against short circuit and ground leakage.

- Separate the 230V~ power supply line of the control unit from the very low voltage line of the

control and safety accessories.

12_

DOORFOTO1 PHOTOCELL CARD

12.1_ INSERTING THE CARD IN THE CONNECTOR LOCATED ON THE MOTHERBOARD

Insert the photocell card in the appropriate connector on the motherboard (J3).

12.2_ HOW TO DISTINGUISH THE TRANSMITTER CAPSULES FROM THE RECEIVER ONES

Each pair of photocells consists of a receiver capsule and a transmitter capsule, plus a cable equipped with mini connector for quick

and easy replacement. The receiver capsules are square in shape on the side where the connection cable comes out, while the

transmitter capsules are round. An 11-mm diameter hole is required for both, in order to fasten them to the door frame. The cables

are marked TX (for the transmitters) and RX (for the receivers) at both ends.

RECEIVER TRANSMITTER

12.3_ SELECTING THE NUMBER OF PHOTOCELL PAIRS UTILIZED

The photocell card can handle up to 3 pairs of photocells with incorporated self-diagnostic function, including 2 pairs (FT1 /FR1 and

FT2/FR2) for closing safety, while the third pair (FT3/FR3) can be set to one of the following functions using switches 5 and 8 of DIP S2

(see TABLE 2): closing safety photocell, door crash sensor if a crash panic system is used (in this case the power supply to the motor

is disconnected) or as an opening mode input. The self-diagnostic function makes it necessary to set the number of photocell pairs that

are actually used in the system. The selected number of pairs is signalled through the SW1 dip located on the photocell card (see TABLE

1). Ths rst couple of photocells ft1/fr1 has to be installed 1 mt above the ground level; the second couple of photocells (recommended)

ft2/fr2 at 50 cm above the ground level (please see the diagram below).

TABLE 1 TABLE 2

SW1 dip on DOORFOTO 1 photocell card S2 dip on electronic control unit

1 2 5 8

OFF OFF Only FT1/FR1 is active OFF OFF DOORFOTO1 photocell card absent!!

ON OFF

Only FT1/FR1 - FT2/FR2 are

active

ON OFF

DOORFOTO1 card present,

FT3/FR3 = door crash sensor

OFF ON

Only FT1/FR1 - FT3/FR3 are

active

OFF ON

DOORFOTO1 card present,

FT3/FR3 = safe closing manoeuvre

ON ON All pairs are active ON ON

DOORFOTO1 card present,

FT3/FR3 = open command

PHOTOCELL REFERENCE HEIGHTS

RX1TX1

RX2 TX2

1000 mm

500 mm

Page 13

13

DOOR Series -

English

12.4_ CONNECTING THE RECEIVER AND TRANSMITTER CAPSULES

To prevent interference due to direct sunlight, it is advisable to position the receiver sensors on the side most sheltered from the sun’s

rays.

TERMINAL BOARD M7 (FR1 – FR2 – FR3 – VCC – GND)

FR3 = input RECEIVER CAPSULE 3 (BROWN CABLE)

frS frR

frQ

vcc

gnd

K

capN rx

frS

FR2 = input RECEIVER CAPSULE 2 (BROWN CABLE)

FR1 = input RECEIVER CAPSULE 1 (BROWN CABLE)

VCC = + POWER SUPPLY FOR ALL RECEIVER CAPSULES (BLUE CABLES)

GND = - POWER SUPPLY FOR ALL RECEIVER CAPSULES (BLACK CABLES)

TERMINAL BOARD M8 (FT1 – FT2 – FT3 – +)

FT3 = input TRANSMITTER CAPSULE 3 (BROWN CABLE)

K

capN tx

ftS ftR ftQgndc

FT2 = input TRANSMITTER CAPSULE 2 (BROWN CABLE)

FT1 = input TRANSMITTER CAPSULE 1 (BROWN CABLE)

+ = Power supply

POWER SUPPLY FOR ALL TRANSMITTER CAPSULES (BLUE CABLES)

12.5_ TRANSMITTER AND RECEIVER SENSITIVITY ADJUSTMENT

Once the sensors have been positioned, their sensitivity must be regulated by

means of the potentiometer on the board. Proceed in the following way:

1) Calibrate the potentiometer depending on the distance between the

sensors (see gure alongside).

2) The sensitivity is correct if the leds of the sensors selected in the mini dip

are off.

3) If the leds are on, turn the potentiometer slowly towards the maximum

setting until the leds go out.

4) Check to make sure that the relative leds come on when the infrared beam

from the photocells is broken.

12.6_ OPERATING FAULTS

The photocell module constantly checks the photocells to guarantee their

reliable operation. In the event of capsule malfunction, the motherboard emits

one, two or three beeps according to which pair of capsules has generated the

malfunction. Moreover, in order to prevent the automatic door from being locked in the open position and to guarantee its proper closing,

the door slows down during the closing manoeuvre until the normal operation of the photocells has been restored.

12.7_ DOOR STOP WITH STOP BUTTON

A STOP button with N.C. contact can be connected between terminals FT3 and FR3 in order to stop the movement of the door.

In order to exploit this possibility it is necessary to enable FT3/FR3 on the photocell card and to make it operational as a door crash

sensor (see TABLES 1 and 2).

MAX

SENSITIVITY

MINI DIP Sw1

L1 L2 L3

MIN

SENSITIVITY

POTENTIOMETER

AT HALF SETTING

from 2 to 4 meters

MAXIMUM

POTENTIOMETER

SETTING

from 4 to 6 meters

MINIMUM

POTENTIOMETER

SETTING

up to 2 meters

Page 14

14

DOOR Series -

English

13_ THE DOOR PROG SELECTOR SWITCH

Connect the digital selector DOORPROG to connector M1 of the control unit “Door” (paragraph 11).

Exhausted battery and power failure signals

Input status signals

Work program selection

Reduced opening selection

Free functions

Locked functions

The key is used to block the selected functions. The required program can be set with the SET button in the FREE FUNCTIONS

mode. The SET button is not activated in the FUNCTIONS BLOCKED mode and the work program will be the last one to have

been selected. The key is also used to access the remote programming menu via selector DOORPROG (see section 15.3).

Exhausted battery and power failure signals:

If the LED shows a steady light, it means that there is no mains power supply but the battery is charged.

If the LED ashes, it means that there is no mains power supply and the battery is almost exhausted, or it signals also the battery

malfunction status with mains power supply.

If the LED shows a steady or ashing light, it means that there is no communication between the selector switch and the control unit.

In this case, check the connections between the selector switch and the control unit.

Input status signals:

These LED’s indicate the real-time status of the inputs. Refer to TABLE 4 for the meaning of each LED.

Work program selection:

Press centre button

to switch work program. Refer to TABLE 3 for the meaning of each program.

Reduced opening selection

:

Press the button to reduce the clear opening (winter opening mode). If the LED on the button is on, it means that the function is

enabled regardless of the selected work program.

To regulate the winter opening distance by potentiometer TM6 from DOORPROG selector switch (see TABLE 7).

Press the button to obtain a clear opening of approx. 10 cm. (pharmacy opening). If the LED on the button is on, it means that the

function is enabled. To enable the PHARMACY function, set dip 7 of mini-dip S1 in the OFF position (TABEL 5).

TABLE 3

Work programs Active inputs Active safety devices

Two-way trafc

Outgoing trafc only

Incoming trafc only

Doors always open

Night lock

Page 15

1/4

The release is automatic in the event there is no mains voltage and the

door remains open until the power is restored again. If this does not

occur, turn the release knob in the direction of the arrows (clockwise)

until they are covered (the writing UNLOCKED appears) and then

manually operate the leaf or leaves.

To block the leaf or leaves again, turn the release knob in an anti-

clockwise direction until the writing UNLOCKED is hidden (the arrows

appear again). The automation performs an initial operation at low

speed when the power is restored, after which it starts to function

normally.

The manual manoeuvre must ONLY be done with the door stopped and AFTER disconnecting power from the electrical control unit.

N.B.: if your remote control unit (if supplied) starts working badly after a time, or does not work at all, the batteries may be fl at (they can last from

several months to 2/3 years depending on what type is used). This can be seen from the fact that the transmission confi rmation LED gets dimmer

or only turns on for brief moments. Before contacting your fi tter, try exchanging the battery with one from a good transmitter: if this is the reason

for the fault, simply replace the battery with another one of the same type.

If you wish to add a new automated system to your house, contact your fi tter and we at Tau to have the advice of a specialist, the most developed

products on the market, best operation and maximum automation compatibility.

Thank you for reading these suggestions and we trust you are fully satisfi ed with your new system: please contact your fi tter for any further

requirements.

English

INSTRUCTIONS AND WARNINGS FOR AUTOMATIC SYSTEM USERS

CONGRATULATIONS on choosing a Tau product for your automation system!

Tau S.r.l. produces components for automatic gates, doors, barriers and shutters. These include gear motors, control units, radio control devices,

fl ashing lights, photocells and accessories.

Tau products are exclusively made with top quality materials and processes and, as a company, we constantly research and develop innovative

solutions in order to make our equipment increasingly easier to use. We also pay great attention to all details (technology, appearance and

ergonomics). The extensive Tau range makes it possible for your fi tter to choose the product which best meets your requirements.

Tau, however, does not produce your automated system as this is the outcome of a process of analysis, evaluation, choice of materials and

installation performed by your fi tter.

Each automated system is unique, therefore, and only your fi tter has the experience and professionalism required to create a system that is

tailor-made to your requirements, featuring long-term safety and reliability, and, above all, professionally installed and compliant with current

regulations.

An automated system is handy to have as well as being a valid security system. Just a few, simple operations are required to ensure it lasts for

years.

Even if your automated system satisfi es regulatory safety standards, this does not eliminate “residue risks”, that is, the possibility of dangerous

situations being generated, usually due to irresponsible and/or incorrect use. For this reason we would like to give you some suggestions on how

to avoid these risks:

- Before using the system for the fi rst time: ask your fi tter to explain how residue risks can arise and read the instructions and warnings in

the user handbook that your fi tter will have given you. Keep this manual for future use and, if you should ever sell your automated system,

hand it over to the new owner.

- Your automated system carries out your commands to the letter: irresponsible and/or incorrect use may cause it to become dangerous.

Do not use the system if people, animals and/or objects enter its operating area.

- IT IS NOT A TOY! Make sure children do not play near the system and keep the remote control device out of their reach.

- Faults: If you notice any abnormal behaviour, disconnect the system from the power supply immediately and perform the manual release

operation (see fi gure). Do not attempt to repair the door but call in your fi tter: the system will operate manually as it did before installation.

- Maintenance: to ensure long life and totally safe operation, the system required routine maintenance, just like any other piece of machinery.

Establish maintenance times together with your fi tter. Tau recommends a frequency of 6 months for normal domestic installations but this

may vary depending on the intensity of use (always every 3000 work cycles).

N.B.: All controls, maintenance work and/or repairs may only be carried out by qualifi ed personnel.

- Do not modify the plant or the relative programming and adjustment parameters: your fi tter will see to that.

N.B. Final testing, routine maintenance and any repairs must be documented by the fi tter (in the relative spaces) and such documents

kept by the owner of the system (IF THE DOCUMENTS ARE NOT PRODUCED, THE WARRANTY WILL EXPIRE)

.

- Disposal: At the end of system life, make sure that it is demolished by qualifi ed personnel and that the materials are recycled or disposed

of according to local regulations.

- - -- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Page 16

2/4

Data

Date

Datum

Date

Fecha

Descrizione intervento

Description of job

Beschreibung des Eingriffs

Description intervention

Descripción del trabajo

Parti sostituite

Parts replaced

Ersetzte teile

Parties remplacées

Piezas sustituidas

Firma manutentore

Fitter’s signature

Unterschrift des

Wartungsmannes

Signature réparateur

Firma del técnico

Firma utilizzatore

User’s signature

Unterschrift des

Benutzers

Signature utilisateur

Firma del usuario

Page 17

3/4

Data

Date

Datum

Date

Fecha

Descrizione intervento

Description of job

Beschreibung des Eingriffs

Description intervention

Descripción del trabajo

Parti sostituite

Parts replaced

Ersetzte teile

Parties remplacées

Piezas sustituidas

Firma manutentore

Fitter’s signature

Unterschrift des

Wartungsmannes

Signature réparateur

Firma del técnico

Firma utilizzatore

User’s signature

Unterschrift des

Benutzers

Signature utilisateur

Firma del usuario

Page 18

4/4

Data

Date

Datum

Date

Fecha

Descrizione intervento

Description of job

Beschreibung des Eingriffs

Description intervention

Descripción del trabajo

Parti sostituite

Parts replaced

Ersetzte teile

Parties remplacées

Piezas sustituidas

Firma manutentore

Fitter’s signature

Unterschrift des

Wartungsmannes

Signature réparateur

Firma del técnico

Firma utilizzatore

User’s signature

Unterschrift des

Benutzers

Signature utilisateur

Firma del usuario

- - -- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Page 19

15

DOOR Series -

English

TABLE 4

Emergency input Photocell 3 input

Start input Pedestrian opening input

Internal radar input Interlock input

External radar input Side sensor input

Photocell 1 input Auxiliary input

Photocell 2 input

14_ DOORBATT BATTERY OPERATED OPENING DEVICE

Insert the battery charge card in the J4 connector located on the

motherboard (see side gure). Be careful not to insert the connector

with the pins misaligned. Connect the battery, pay attention to the

polarity (red cable = +, black cable = -) with respect to the 2 male

fastons on the motherboard.

The DOORBATT card performs the self-testing of the battery charge

level and features a green LED and a red LED. The green LED ashes

while the battery is charging and shows a steady light when the battery

has been charged and is in holding mode. The red LED ashes if the

battery is exhausted or damaged, with or without mains power supply,

whereas it is constantly on when the battery is charged without mains

power. If both LEDs are on it means that the battery is disconnected.

● Check periodically the battery efciency

● To allow battery reload, batteries must always be connected to the electronic control unit

● The device must be disconnected from power supply when removing the battery

● In case of replacement, use always original batteries (18V, 600mAh).

● The replacement must be carried out by qualied personnel.

● Batteries must be removed before its disposal.

● Batteries contain pollutants, disposal must be performed complying with local rules and regulations.

Battery connector

Battery card connector

Page 20

16

DOOR Series -

English

15_ ADJUSTING THE AUTOMATISM

After having xed the door wings to the rails, make sure that they slide smoothly., then make all the electrical connections described in

section 11 and comply with the INITIAL SETUP PROCEDURE. This operation is OBLIGATORY, since it allows the control unit to acquire

all the data without which it would not be able to operate (door wing weight, limit switches, inertia, etc.).

STRICTLY COMPLY WITH THE FOLLOWING CHAPTER WHEN THIS OPERATION IS CARRIED OUT.

15.1_ INITIALIZATION PROCEDURE (INITIAL SETTING)

WARNING: the initialization procedure is the phase during which the automation learns and samples all the factors which

will affect its subsequent operation. Execute the procedure only after performing the operations described in the previous

chapters.

IMPORTANT: be careful to remove all obstacles from the doorway and from the radar detection range during the initialisation

procedure, otherwise the procedure will fail and will have to be repeated. The door must not be helped manually and the

settings of the potentiometers must not be modied. The initialisation procedure will have to be repeated if any of the following

parameters are modied: leaf travel, leaf weight, opening direction, type of motor (DOORX or DOOR).

1_ Make sure that the mains power source is OFF, then temporarily disconnect the battery-powered opening device DOORBATT if

installed.

2_ Set all the minidips (S1 e S2) at OFF.

3_ If you are using a DOORX, set DIP7 of S1 at ON, otherwise leave it in the OFF position.

4_ If you use the DOORPROG SELECTOR switch, leave DIP SWITCH 2 of S2 in the OFF setting; if you use the DOORSELF

mechanical selector switch, set it to ON. Set the knob of the DOORSELF mechanical selector to trafc in both directions or to

NIGHT LOCK.

5_ If the automation is a RIGHT-HAND OPENING LEAF, set DIP4 of S2 at ON, otherwise leave it in the OFF position.

6_ If the door is a re dor and a smoke sensor is connected to the INTERLOCK input, set DIP 7 of S2 ON, otherwise leave it OFF.

7_ If you have installed the DOOR PHOTO1 PHOTOCELL CARD, set DIP5 of S2 at ON, otherwise leave it in the OFF position.

8_ Check to make sure that potentiometers TM3 (pushing power on opening) and TM4 (pushing power on closing) are set between

halfway and the maximum value.

9_ Power the system and wait for the initial beep to sound.

10_ Disconnect the power supply and wait for 3 seconds.

11_ Set DIP6 of S2 at ON.

12_ Power the system and wait for the double initial beep to sound.

13_ Press the START control (or the PS1 button on the control unit).

The door will begin a Closing / Opening / Closing cycle at slow speed which it must necessarily complete if the initial setup is to be

successful. At the end of a manoeuvre, a long BEEP will indicate that the procedure has terminated correctly.

14_ By leaving DIP 6 of S2 ON, the door thrust can be checked by means of the buzzer. Its effective intensity can be ascertained by

obstructing its movement. This should cause the door to stop immediately and then reverse its direction.

Poteniometers TM3 and TM4 can be used to regulate the door’s pushing power in the opening and closing phases, respectively,

and to calibrate the activation threshold with precision.

A very brief signal from the buzzer during start-up indicates that the pushing force has been well calibrated, while intermittent

signals as the door moves indicate that the pushing force is insufcient.

Set DIP 6 of S2 to the OFF position to inhibit the buzzer signal that indicates limited power.

Once the initialisation procedure has been performed, you can select the work program best suited to the application among the ones

available, you can modify the door speed, change the times and distances etc. There are two ways of performing these operations:

a) directly from the control unit;

b) through remote programming from the selector switch;

15.2_ ADJUSTING THE AUTOMATISM FROM THE CONTROL UNIT

Operate MINIDIPS S1 and S2 to select the programs listed in TABLES 5 and 6.

Operate potentiometers TM1 to TM7 to modify the parameters listed in TABLE 7.

Any regulations that cannot be made from the control unit due to the absence of additional dip switches or potentiometers can be made

only using the DOORPROG digital selector switch.

15.3_ ADJUSTING THE AUTOMATISM THROUGH REMOTE PROGRAMMING FROM THE SELECTOR SWITCH

To enable remote programming, rst of all DlP10 of S2 must be set at ON.

To access the programming mode follow these steps:

a) Set the selector switch’s locking key in the locked functions position .

b) Press and hold down the selector switch’s SET button .

c) Return the locking key to the free functions position .

d) Release the SET button .

e) The inputs LED’s will light up sequentially from left to right to signal the loading of the data (UPLOAD).

Page 21

17

DOOR Series -

English

f) Once the UPLOAD has been completed, the red BATTERY LED and the yellow PHOTOCELL3 LED will light up.

g) The battery LED signals that the S1 MINIDIP is being operated, while the photocell 3 LED signals:

g1) DIP1 of S1 in the ON position if the LED shows a steady light .

g2) DIP1 of S1 in the OFF position if the LED shows a ashing light.

h) To change the status of the DIP (ON -OFF), press the WINTER OPENING button .

i) To go to DIP2 of S1, press the PHARMACY OPENING button .

l) Repeat the last operation above to go to the other DIPS of S1.

m) Refer to TABLES 5 and 6 for the meaning of the DIPS.

n) To operate MINIDIP S2, press the SET button , a POWER LED will light up.

o) Repeat the operations described for MINIDIP S1 to select and change the status of the single DIPS.

p) To go to POTENTIOMETER TM1, press the SET button the 2-WAY trafc LED will light up.

q) When you operate the potentiometers, the inputs LED’s will form a scale to indicate the set value.

r ) To change the value of the selected potentiometer, press:

r1) the WINTER OPENING button to lower the value.

r2) the PHARMACY OPENING button to increase the value.

s) To go to POTENTIOMETER TM2, press the SET button .

t) Repeat the last operation above to go to the other potentiometers.

u) Refer to TABLE 7 for the meaning of the potentiometers.

v) To exit the programming mode and memorize the modied values, proceed as follows:

v1) Set the selector switch’s locking key in the locked functions position .

v2) Press and hold down the selector switch’s SET button .

v3) Return the locking key to the free functions position .

v4) Release the SET button .

v5) The inputs LED’s will light up sequentially from right to left to signal the DOWNLOAD.

v6) Once the DOWNLOAD has been completed, the control unit will emit 2 beeps.

v7) The selector switch will return to normal operation.

z) To exit the programming mode without memorizing the modied values, proceed as follows:

z1) Set the selector switch’s locking key in the locked functions position ;

z2) Return the locking key to the free functions position ,

z3) The selector switch will return to normal operation and the control unit will emit 1 beep.

15.4_ RESET OPERATION

To RESET the control unit without disconnecting the mains power source, proceed as follows: access the programming mode with

selector DOORPROG, follow steps A) to E) in section 15.3, then quit the programming mode by following steps Z1) to Z3) of section

15.3.

Page 22

18

DOOR Series -

English

TABLE 5

Programming from

control unit

Programming from

selector switch

Functions related to the S1 MINIDIP or to LED with programming from the

selector switch

W

O

R

K

P

R

O

G

R

A

M

S

OFF OFF OFF

In the day functions, the electric block is released (powered) and all the control inputs are

enabled. In NIGHT LOCKING mode the door cannot be opened.

ON ON OFF

In the day functions, the electric block is released (powered) and all the control inputs

are enabled. With the DOORPROG selector switch set to the NIGHT LOCKING mode,

the door opens 10” and stays open before re-closing. It can be opened again only via the

emergency input .

OFF ON OFF

In the day functions, the electric block is released (powered) and all the control inputs are

enabled. With the DOORPROG selector switch set to the NIGHT LOCKING mode, the door

can be opened using the emergency input .

OFF OFF ON

Bank function. The door locks the leaves at each closing through the electric block in the

day functions; in the night locking mode the door cannot be opened.

BATTERY OPENING MODE. In the event of a power failure, if the program selector switch

is set to one of the day functions, the door opens and stays open until the power supply has

been restored.

WARNING: if the dip switch is set to OFF, in the event of a power failure the door can be

opened using the emergency input .

BATTERY MONITORING. With the battery exhausted or damaged, the door will open and

stay open in the day functions.

WARNING: if the dip switch is set to OFF and the battery is exhausted or damaged, the

control unit will sound a beep for 1” before performing any opening manoeuvres.

This beep is sounded for the rst 10 manoeuvres starting from detection of the event in the

day functions.

In the event of a power failure, in the battery operating mode the door can be opened via all

the control inputs. To enable the radars to operate in battery mode, the power supply must

be drawn from terminals 1(+) and 3 (-) of the M1 terminal board.

WARNING: if the dip switch is set to OFF and there is a power failure, the door can be

opened only using the EMERGENCY input.

Before performing the initial setting of the control unit, set the parameters for motor management: ON=DOORX; OFF=DOOR.

After completing the initial setting procedure, when the door is in work mode, select the

operating mode for the LOCK2 output:

OFF = PHARMACY function; ON = AIR BLADE or OPEN DOOR INDICATOR LIGHT man-

agement (see paragraph 18).

It activates the cyclic opening function (open and close cycle repeated until the DIP is

switched back to OFF). N.B.: Use this function only for internal testing purposes.

If the door cannot be closed in winter mode due to high trafc, after approx. 1’ it switches to fully open. It will return to winter mode after a complete closing manoeuvre.

With the dip-switch OFF, the door always stops at the winter opening point.

WARNING: Function disabled. Keep the DIP in ther OFF position.

11

Keep in the PFF position!!

This dip is used for resetting the default values of the TECHNICAL MENU (see section

21).

12

Activates the interlock function (see paragraph 16).

It makes the interlock input operational; if this input is engaged, the door can be opened

only via the EMERGENCY button.

Page 23

19

DOOR Series -

English

TABLE 6

Programming from

control unit

Programming from

selector switch

Functions related to the S2 MINIDIP or to LED with programming from the

selector switch

It automatically increases the pause time if the door cannot be closed due to high trafc.

The pause time is kept at a constant value with the dip-switch in the OFF position.

It activates work program selection via the DOORSELF mechanical selector switch (see

paragraph 17).

N.B. keep the DIP switch in the OFF position if you use the DOORPROG digital selector

switch or if a simple switch is used on the AUX1 input to manage the day function (switch

on) or night lock function (switch off).

It activates the STEP-BY-STEP function (an impulse opens, an impulse closes, etc.). With

this function, the active inputs are: emergency and start .

With dip on OFF position, automatic door closing is always enabled.

Set at ON if the automation is SINGLE-LEAF opening to the RIGHT. N.B. With LEFT hand

DOUBLE-LEAF or SINGLE-LEAF, keep the DIP in the OFF position.

For “BLOW / BLOW-X” telescopic doors, set to ON if the device is for a single wing

opening towards.

Together with switch 8 it selects the DOORFOTO1 photocell card (if installed) and the op-

erating mode of photocell FR3/FT3. Refer to TABLES 1 and 2 in chapter 12.3 for instruc-

tions on how to use this switch.

WARNING: keep the dip-switch OFF if photocell DOORFOTO1 is not installed.

N.B. It activates the initial setting cycle. Read carefully the chapter regarding this

operation.

ON = FUNCTION FOR FIRE DOORS (see section 20)

WARNING: Activate the function before making the INITIAL SETUP described in SECTION

15.

OFF =standard function for INTERLOCK input activated as door stop.

Together with switch 5 it selects the DOORFOTO1 photocell card (if installed) and the op-

erating mode of photocell FR3/FT3. Refer to TABLES 1 and 2 in chapter 12.3 for instruc-

tions on how to use this switch.

WARNING: keep the dip-switch OFF if photocell DOORFOTO1 is not installed.

The door closes immediately if the radars and photocells are not activated (the other inputs

work normally).

With the dip-switch OFF, the door carries out a complete opening, pause and closing cycle

on each radar detection.

It activates the programming of the POTENTIOMETER DIPS from the DOORPROG. selector switch. After setting this DIP at ON, execute a complete open and close cycle in order

to activate this function (the dips and potentiometers on the control unit have no effect).

N.B. if this DIP is left at OFF, it will not be possible to switch the position of DIPS 1

to 10 of S1 and S2 and of potentiometers TM1 to TM7 from the DOORPROG selector

switch.

11

Operation of LOCK2 output in the INTERLOCK function (see paragraph 16):

OFF: it is activated 0.5” before the opening of the door;

ON: it is activated at the same time as the door opens.

12

N.B. function not enabled, keep the DIP in the OFF position.

Page 24

20

DOOR Series -

English

TABLE 7

Regulating from

control unit

Regulating from

selector switch

N.B. If the program

symbol is highlighted, it

means the LED is on.

Work parameters

Opening speed max 70 cm/sec

Closing speed max 50 cm/sec

PUSHING FORCE ON OPENING

Increase the value to obtain a stronger pushing force on opening.

PUSHING FORCE ON CLOSING

Increase the value to obtain a stronger pushing force on closing.

BRAKING CURVE ON OPENING

Increase the value to obtain faster braking during the slowing phase on opening.

Winter opening distance: max. 150 cm* , min. 40 cm*

NOTE: the Winter opening distance is never lower than the pedestrian opening

distance, therefore to reduce the Winter opening distance again, the pedestrian

opening distance shall be reduced rst by means of potentiometer TM8.

*for each wing

Pause time: max 20 sec

TM8

Pedestrian opening distance: max 150 cm*, min. 40 cm*

*for each wing

TM9

BRAKING CURVE ON CLOSING

Increase the value to obtain faster braking during the slowing phase on closing.

TM10

REDUCED SPEED

The door moves at this speed if its direction is reversed after having covered a short distance from start-up. This prevents it from moving at an excessively high speed when it

nears the end of travel during the reversing phase.

Page 25

21

DOOR Series -

English

16_ INTERLOCK SYSTEM

g. 17

DIP SWITCH 12 of S1 (see TABLE 5)

ON INTERLOCK function ENABLED

OFF INTERLOCK function DISABLED

DIP SWITCH 11 of S2 (see TABLE 6)

ON

LOCK2 is activated at the same time

as the door opens (to be set on control unit A)

OFF

LOCK2 is activated 0.5” before the

opening of the door (to be set on

control unit B)

PT5

PT6

DL1 DL2

G 1 2 3

4 5 6 7 8 9 10 11

R2

R3

RS1

- +

~ ~

C8

C7

C6

C9

-+

BAT

ENCODER

MOTORLOCK1LOCK2

-

+

BATTERY CHARGER

MFT1

MFT3

MFT4

MFT2

IC2

IC3

R8

R9

SPEED

ONON

S1

S2

TM1

-

+

-

OPEN

PT5

PT6

DL1 DL2

G 1 2 3

4 5 6 7 8 9 10 11

R2

R3

RS1

- +

~ ~

C8

C7

C6

C9

-+

BAT

ENCODERMOTORLOCK1LOCK2

-

+

BATTERY CHARGER

MFT1

MFT3

MFT4

MFT2

IC2

IC3

R8

R9

SPEED

ONON

S1

S2

TM1

-+-

OPEN

CONTROL UNIT “A” CONTROL UNIT “B”

The diagram shows a connection between two control units that control two automatic doors in the INTERLOCK conguration. Plug

module DOORIM (see paragraph 18) into the control units’ LOCK2 connector.

Terminal “-” of the DOORIM module coupled to control unit “A” must be connected to terminal 7 (interlock input) of control unit “B” and

vice-versa.

Terminals 4 of both control units must be connected to each other.

The DOORPROG digital selector switch is required.

Set dip switch 12 of S1 on both control units to ON, so as to enable the interlock function.

Next, set dip switch 11 of S2 to ON on control unit “A”, and set the same dip switch to OFF on control unit “B”.

When one of the two control units receives an opening command, it reads the status of the interlock input (to check whether it is enabled

to start) and it simultaneously sends a locking signal to the other control unit (via the LOCK2 output) before it proceeds with the opening

manoeuvre.

The START input on terminal 6 is used by both control units for connection of a radar or common footboard, for instance for presence

detection between the rst and second doors in a short hallway.

While the rst door is closing, and for 5 seconds after completion of the closing manoeuvre, the START input is ignored in order to enable the moving door to shut completely and enable the second door to open while preventing access through the rst.

If you wish to open the door immediately upon completion of the closing manoeuvre, connect the opening device on the PEDESTRIAN

input to terminal 14, which, in the interlock conguration, commands total opening rather than partial.

With the interlock input engaged, the door can be opened only by using the EMERGENCY button at terminal 5.

By connecting a switch on the AUX1 input at terminal 12, and closing the contact, the detection function can be disconnected on the

interlock input, thus enabling free passage.

By re-opening the contact on AUX1, the operating mode with interlock function is restored.

If you wish to install a closed-door detection device (microswitch, magnetic reed, etc.) for additional system security, you need to connect the N.C. contact in series between terminal “-” of LOCK2 and the control unit’s INTERLOCK input.

Page 26

22

DOOR Series -

English

17_ DOORSELF MECHANICAL SELECTOR SWITCH

The DOORSELF mechanical selector switch allows you to set the work program of the automatic DOOR. To enable its operation, position dip switch 2

of S2 at ON (see TABLE 6).

WARNING: If you use the DOORSELF mechanical selector switch, the

AUX1 and PEDESTRIAN inputs of the DOOR control unit will lose all their

functions described in paragraph 11.

The DOOR control unit, enabled for operation with the DOORSELF mechanical selector switch, must use the software version of the main

microprocessor MP1 R.4.5 or a higher version.

17.1 – ELECTRICAL CONNECTIONS

TERMINAL 1 = connect to input 13 (INTERNAL RADAR) of the DOOR

control unit;

TERMINAL 2 = connect to input 9 (COMMON) of the DOOR control unit;

TERMINAL 3 = connect to input 12 (AUX1 auxiliary) of the DOOR control

unit;

TERMINAL 4 = connect to input 14 (PEDESTRIAN) of the DOOR control

unit.

17.2 – OPERATING MODE

Rotate the DOORSELF selector knob to select the desired function among

the ve available ones:

DOOR ALWAYS OPEN = to keep the door completely open.

If you start opening the door by setting the selector switch to the WINTER OPENING mode, and then immediately turn the knob to

the DOOR ALWAYS OPEN position, the door will stop in the winter opening position.

WINTER OPENING = used to reduce the opening size.

TWO-WAY TRAFFIC = used to open the door via all the control inputs.

OUTBOUND TRAFFIC = used to override inbound trafc detection (EXTERNAL RADAR).

NIGHT LOCK = used to keep the door closed, allowing it to be opened only via the EMERGENCY input.

18_ DOORIM MODULE

The DOORIM module is an optional interface card designed for management of

the functions described below.

It has a relay output with dry contact (terminals 1-2), which can be N.O. or N.C.

type (depending on the position of jumper J1) and an OPEN COLLECTOR type

signal output “-”.

The DOORIM module must be plugged into the LOCK2 connector of the

Door control unit.

• AIR BLADE

Position dip switch 7 of mini-dip S1 at ON.

Use the dry contact on terminals 1 and 2 of the DOORIM module to command

an air blade, i.e. a device that generates a ow of cold or heated air to separate the temperature outside from that inside. The output is active when the

door is moving or open, it is deactivated when the door is closed.

• OPEN DOOR INDICATOR LIGHT

Position dip switch 7 of mini-dip S1 at ON.

Use the dry contact on terminals 1 and 2 of the DOORIM module to power an

indicator light signalling the door status. The output is active when the door is

moving or open, it is deactivated when the door is closed.

• INTERLOCK FUNCTION (see paragraph 16)

Connect terminal “-” (OPEN COLLECTOR output) of the DOORIM module to the interlock input (terminal 7) of the second control

unit.

g. 18

M1

1 2 3 4

SM

0419

44

80

80

g. 19

J1

J1

NC*

NA**

NC NAJ1

- 1 2

UR1

* N.C. contact between terminals 1-2.

** N.O. contact between terminals 1-2.

Page 27

23

DOOR Series -

English

19_ FIRE DOOR FUNCTION

The DOOR device has a specic function for use on re doors.

Connect a smoke sensor with N.C. Contact on the INTERLOCK input to terminal 7 to obtain forced door closing at slow speed after

detection by the sensor. None of the control and safety inputs will be activated during this closing manoeuvre. To enable the function, set

DIP 7 of S2 ON before making the initial setup. After this, it will not be possible to deactivate the function by simply switching the status

of the DIP. It will be necessary to make a new initial setup.

After re-closing caused by smoke sensor detection, the door can only be re-opened by means of the EMERGENCY input (terminal 5),

which will act in the impulsive mode if the sensor no longer detects the smoke alarm condition or in the CONSTANT PRESSURE mode

if the sensor continues to indicate the presence of smoke.

20_ MEANING OF BUZZER SIGNALS (BEEPS)

5 BEEPS = door not set.

5 BEEPS – 0.5” pause -1 BEEP = ENCODER not operating correctly.

4 BEEPS = activation of PHOTO 3 as door crash sensor.

2 BEEPS = exit from programming procedure from DOORPROG selector switch with data memorization.

1 BEEP = exit from programming procedure from DOORPROG selector switch without data memorization.

1 BEEP = obstacle detection in the event of collision, followed by a reversal manoeuvre.

1, 2, 3 BEEPS = self-diagnosis failed at photocells 1, 2, 3 respectively (the signal is given at the starting of each

manoeuvre).

1 prolonged BEEP (5”) = initial setting completed.

1 long BEEP (1”) = battery failure signal followed by opening of door.

Series of rapid BEEPS = insufcient pushing power (check the settings of TM3 and TM4)

21_ ADVANCED FUNCTIONS - TECHNICAL MENU

The adjustments in the technical menu allow you to change the various door operating parameters. This is of use when the default

settings are not the optimal ones.

Selector DOORPROG must be available for access to the TECHNICAL MENU.

Turn the to the horizontal function locking position, press the two key and , and keep them depressed, then turn the key back to

the vertical work position.

The yellow leds will come on in sequence from left to right, showing that data are being loaded. After this, the red battery led and the

yellow led of photocell 3 will come on.

The keypad will now be operating on dip-switch 1 of switch S1, thus in the basic adjustments phase described in the main instructions

provided for the door.

Press the SET key 11 times several times to go to the end of the basic regulations

Described in tables 5, 6 and 7 of the main instructions, i.e. Low speed.

This situation coincides with the beginning of the TECHNICAL MENU.

Transmit a pulse to the SET key to access the point 1 adjustment option:

similarly to the previous adjustments, the yellow leds form a scale that indicates the value entered.

Press the key to decrease, or the key to increase this value.

1) ACCELERATION CURVE ON OPENING

This is the door’s acceleration thrust during the opening phase so as to reach the normal speed calibrated by

TM1.

Acceleration is faster if the value is increased.