Page 1

l

Stamp9261

Technical Manual

Page 2

taskit GmbH

Seelenbinderstrasse 33

D-12555 Berlin

http://www.taskit.de

++49 30 611295-0

- 2 -

© taskit GmbH, Berlin

All rights reserved. This document and the products referred to herein are copyrighted works of

taskit GmbH. Information in this document is subject to change without notice. No part of this

document may be reproduced or transmitted in any form, without the express written permission of

taskit GmbH. If however, your only means of access is electronic, permission to print one copy is

hereby granted. Neither taskit GmbH nor taskit’s distributors assume any liability arising from the

use of this manual or any product described herein.

Copyright (C) taskit GmbH, Berlin V1.00en (17.03.2008)

Page 3

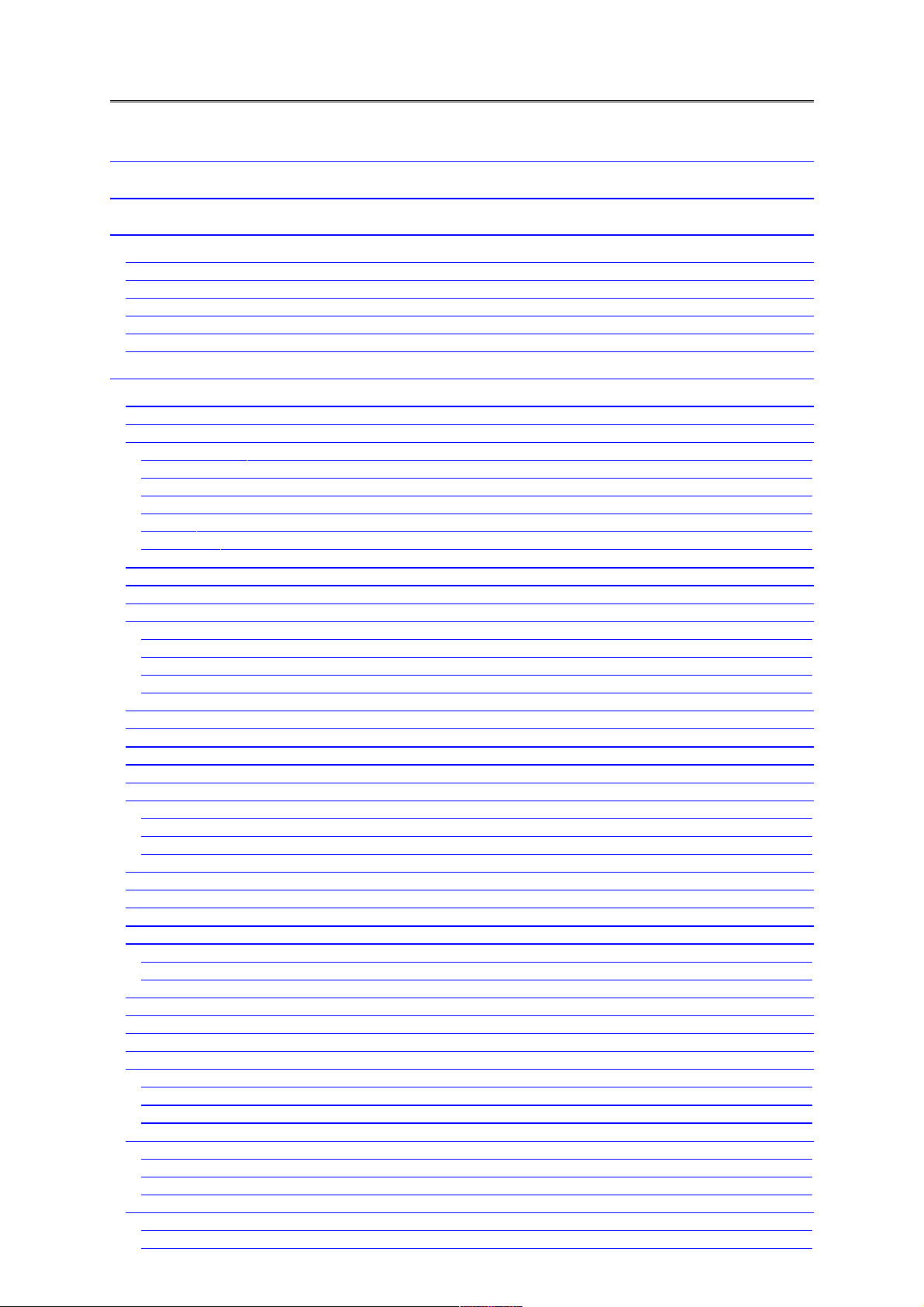

1.INTRODUCTION ............................................................................................................................................... 5

2.SCOPE ................................................................................................................................................................. 6

3.OVERVIEW OF TECHNICAL CHARACTERISTICS ................................................................................. 7

3.1.CPU ................................................................................................................................................................ 7

3.2.MEMORY ........................................................................................................................................................... 7

3.3.INTERFACES AND EXTERNALS SIGNALS .................................................................................................................... 7

3.4.MISCELLANEOUS ................................................................................................................................................. 7

3.5.POWER SUPPLY ................................................................................................................................................. 7

3.6.DIMENSIONS ...................................................................................................................................................... 7

4.HARDWARE DESCRIPTION .......................................................................................................................... 8

4.1.MECHANICS ....................................................................................................................................................... 8

4.2.ARM926EJ-S™ CORE .................................................................................................................................... 8

4.3.MEMORY ........................................................................................................................................................... 9

a)Flash memory ............................................................................................................................................... 9

b)Boot Mode Select Signal (BMS) .................................................................................................................. 9

c)EEPROM ...................................................................................................................................................... 9

d)SDRAM ......................................................................................................................................................... 9

e)SRAM ............................................................................................................................................................ 9

f)DataFlash ...................................................................................................................................................... 9

4.4.BATTERY BACKUP ............................................................................................................................................. 10

4.5.RESET CONTROLLER (RSTC) ............................................................................................................................ 10

4.6.SERIAL NUMBER ............................................................................................................................................... 10

4.7.CLOCK GENERATOR AND POWER MANAGEMENT CONTROLLER (PMC) .................................................................... 11

a)SAM9261 Clocks ......................................................................................................................................... 11

b)Programmable Clocks ................................................................................................................................ 11

c)PMC Control Functions .............................................................................................................................. 11

d)PMC Supervisory Functions ....................................................................................................................... 11

4.8.REAL-TIME TIMER (RTT) ................................................................................................................................. 12

4.9.TIMER COUNTER (TC) ...................................................................................................................................... 12

4.10.PERIODIC INTERVAL TIMER (PIT) ..................................................................................................................... 12

4.11.WATCHDOG TIMER ......................................................................................................................................... 12

4.12.BUS MATRIX ................................................................................................................................................. 13

4.13.LCD CONTROLLER (LCDC) .......................................................................................................................... 14

a)LCDC Initialization and LCD Power Sequencing ..................................................................................... 14

b)LCDC Video Memory Selection ................................................................................................................. 14

c)LCDC Frame Buffer ................................................................................................................................... 14

4.14.LCDC DMA AND FIFO .............................................................................................................................. 15

4.15.DISPLAY (TFT) ............................................................................................................................................. 15

4.16. TOUCHSCREEN .............................................................................................................................................. 15

4.17. ADVANCED INTERRUPT CONTROLLER (AIC) ..................................................................................................... 15

4.18. PERIPHERAL DMA CONTROLLER (PDC) ......................................................................................................... 16

a) PDC Registers ........................................................................................................................................... 16

b) PDC Interrupts .......................................................................................................................................... 16

4.19. DEBUG UNIT (DBGU) ................................................................................................................................. 17

4.20. JTAG UNIT ................................................................................................................................................ 17

4.21. TWO-WIRE INTERFACE (TWI) ......................................................................................................................... 18

4.22. MULTIMEDIA CARD INTERFACE (MCI) ........................................................................................................... 19

4.23. USB HOST PORTS (UHP) ............................................................................................................................. 20

a) External Parts ........................................................................................................................................... 20

b) VBUS considerations for USB Host .......................................................................................................... 20

c) Layout considerations ................................................................................................................................ 20

4.24.USB DEVICE PORT (UDP) ............................................................................................................................ 21

a)External Parts ............................................................................................................................................ 21

b)Operation with VBUS as a Supply .............................................................................................................. 21

c)Layout considerations ................................................................................................................................. 21

4.25.ETHERNET CONTROLLER .................................................................................................................................. 22

a)MAC Address .............................................................................................................................................. 22

b)Layout considerations ................................................................................................................................. 22

- 3 -

Page 4

c)Ethernet LEDs ............................................................................................................................................. 22

4.26. SYNCHRONOUS / ASYNCHRONOUS SERIAL INTERFACES (USART) ....................................................................... 23

a)USART Modes ............................................................................................................................................. 23

b)Signals of the serial interfaces .................................................................................................................... 23

c)Hardware Interrupts of the Serial Interfaces ............................................................................................. 24

4.27.SYNCHRONOUS PERIPHERAL INTERFACE (SPI) .................................................................................................... 25

4.28.SYNCHRONOUS SERIAL CONTROLLER (SSC) ...................................................................................................... 25

4.29.PARALLEL INPUT /OUTPUT CONTROLLER (PIO) ................................................................................................. 26

4.30.POWER MANAGEMENT ..................................................................................................................................... 27

a)Beware of tampering with the LCDC ! ....................................................................................................... 27

b)Idle Mode .................................................................................................................................................... 27

c)Slowing down MCK .................................................................................................................................... 27

d)Low Power SDRAM .................................................................................................................................... 27

5.STAMP9261 STARTER KIT ........................................................................................................................... 28

5.1.STARTER KIT CONTENTS ................................................................................................................................... 28

5.2.PANEL-CARD EVB .......................................................................................................................................... 28

a)First Steps ................................................................................................................................................... 28

b)Power Supply ............................................................................................................................................. 28

c)RS232 Interface ........................................................................................................................................... 28

d)Connectors .................................................................................................................................................. 28

e)Rotary Encoder ........................................................................................................................................... 29

6.SCHEMATICS OF "PANEL-CARD EVB" EVALUATION AND PROTOTYPING BOARD .............. 30

6.1.DISCLAIMER .................................................................................................................................................... 30

6.2.BUS CONNECTOR ............................................................................................................................................ 31

6.3.INTERFACES ..................................................................................................................................................... 32

6.4.POWER SUPPLY ................................................................................................................................................ 33

6.5.EXTENSION CONNECTORS ................................................................................................................................... 34

6.6.HID DEVICES .................................................................................................................................................. 35

7.ADDRESS MAP (PHYSICAL ADDRESS SPACE) ...................................................................................... 36

8.PERIPHERAL IDENTIFIERS ........................................................................................................................ 37

9.STAMP ADAPTOR .......................................................................................................................................... 38

9.1.CONNECTOR PIN ASSIGNMENT AND PIN MULTIPLEXING ......................................................................................... 38

9.2.CONNECTOR PIN DESCRIPTION ............................................................................................................................ 39

9.3.STAMP ADAPTOR SCHEMATICS AND DIMENSIONS .................................................................................................. 42

a)Dimensions ................................................................................................................................................. 42

b)Bus Interface ............................................................................................................................................... 44

c)Wrapfield .................................................................................................................................................... 45

d)Ethernet ...................................................................................................................................................... 46

10.DC CHARACTERISTICS ............................................................................................................................. 47

DC CHARACTERISTICS ............................................................................................................................................. 47

CLOCKS CHARACTERISTICS ........................................................................................................................................ 47

11.STAMP9261 PIN ASSIGNMENT ................................................................................................................. 48

12.ENVIRONMENTAL RATINGS ................................................................................................................... 50

13.STAMP9261 DIMENSIONS .......................................................................................................................... 51

- 4 -

Page 5

1. Introduction

The Stamp is intended to be used as a small size "intelligent" display module as well as a universal

Linux CPU card. It can be used anywhere where restricted energy and space requirements play a role.

The Stamp9261 has all the necessary interfaces to support a huge variety of peripheral devices.

Equipped with a 32-Bit parallel bus it gives fast access to a number of chips and additional devices.

The ARM architecture as a modern and widely supported processor architecture is currently the

platform of choice for medium performance embedded devices. Almost all major processor

manufacturers have ARM products in their portfolio.

The availability of the widespread operating system "Linux" for the ARM platform opens access to a

broad range of software, including tools, drivers, and software libraries. Programs written for ARM can

easily be cross-compiled for the PC platform for testing and debugging.

Examples of actual or potential applications are: terminals, measuring and test equipment, datalogging, as well as any simple or more complex control and automation tasks.

- 5 -

Page 6

2. Scope

This document describes the most important hardware features of the SAM9261 Stamp9261. It

includes all informations necessary to develop a customer specific hardware for the Stamp9261. The

Operating System Linux is described in a further document.

The manual comprises only a brief description of the AT91SAM9261 processor, as this is already

described in depth in the manual of the manufacturer Atmel (document 6062). Descriptions of the

ARM core ARM926EJ-S are available from Atmel and also at http://www.arm.org. It is much

recommended to have a look at these documents for a thorough understanding of the processor and

its integrated peripherals.

- 6 -

Page 7

3. Overview of Technical Characteristics

3.1. CPU

Atmel AT91SAM9261 Embedded Processor featuring an ARM926EJ-S™ ARM® Thumb® Core

- CPU clock 200+ MHz

- 16kB Instruction Cache

- 16kB Data Cache

- Memory Management Unit (MMU)

- 3.3V Supply Voltage, 1.2V Core Voltage

3.2. Memory

- 16 or 64 MB flash memory (optional 128 MB)

- 32MB or 64MB SDRAM

- 128 KB serial Dataflash

- 160 KB Fast SRAM

- 256 Bytes EEPROM

3.3. Interfaces and externals signals

- 2x 100-pin fine-pitch low-profile Connectors (Hirose FX8)

- Ethernet 10/100 Mbit MAC

- Dual USB 2.0 Full Speed (12 MBit/s) Hosts

- USB 2.0 Full Speed (12 MBit/s) Device

- 3 USARTs

- 1 UART

- 1 Synchronous Serial Controller (SSC, I²S)

- 2 Serial Peripheral Interfaces (SPI)

- 1 Two Wire Interface (TWI, I²C)

- 1 MultiMedia Card Interface

- JTAG debug port

- Digital Ports – up to 39 available

- Control Signals: IRQs, BMS, SHDN, WKUP

- 4 Programmable Clocks

- LCD/TFT-Controller up to 2048x2048 pixel, 24 Bit color depth

- 32-Bit parallel CPU-Bus

Some of the various functions are realized by multiplexing connector pins; therefore not all functions

may be used at the same time (see table in chapter 11).

3.4. Miscellaneous

- Three 16-Bit Timer/Counter

- Real Time Timer (RTT), with battery backup support

- Periodic Interval Timer (PIT)

- Watchdog Timer (WDT)

- Unique Hardware Serial Number

- extended temperature range, -25°C ... +70°C

3.5. Power Supply

- 3.3V power supply

- 3V backup power supply, e.g. from a lithium battery

3.6. Dimensions

- Dimensions: 53x38x4 mm (WxDxH)

- 7 -

Page 8

4. Hardware Description

4.1. Mechanics

The Stamp9261 was designed as a flexible CPU-Module, which can be connected to base boards via

2x 100-pin fine-pitch low profile Hirose FX8 connectors.

The size of the Stamp9261's PCB is only 53x38x4 mm fitting it in even the smallest design. While

having implemented the sensible CPU, SDRAM and Flash design it still exports almost all possible

CPU-Pins on it's connectors to allow a flexible design on base boards.

4.2. ARM926EJ-S™ Core

Here are some of the most important features of the SAM9261 core:

- up to 240 MHz CPU Clock

- 16 Kbyte Data Cache, 16 Kbyte Instruction Cache, Write Buffer

- 32 bit Data Bus

- Memory Management Unit

- ARM Thumb Instruction Format supported

- DSP Instruction Extensions

- ARM Jazelle® Technology for Java® Acceleration

- EmbeddedICE™ Debug Communication Channel Support

- Mid-level implementation Embedded Trace Macrocell (ETM)

Some of these features – like Jazelle – are currently not supported by the operating system of the

Stamp9261.

- 8 -

Page 9

4.3. Memory

a) Flash memory

• Flash memory layout

The Stamp9261 can be equipped with 16MB, 32MB, 64MB, 128MB Flash memory. This is organized

in blocks of 128KB. Each block can be erased individually.

The flash memory is made up of 1 IC. In case that 128MB chips should be installed, the PIO line PC0

is used as A26, as the CPU has only 26 external address lines.

• Limited number of erase cycles

The Flash memory consists of "Large Sector Flash-ICs" (e.g. Spansion’s S29GL256 or similar). Only

a limited number of erase cycles per block are tolerable for these devices (usually one hundred

thousand erase cycles are guaranteed by the manufacturer). This means that the flash memory, in

particular the flash disk, is not suitable for permanent write operations of a program, since the

permissible number of erase cycles per block might be exceeded in a relatively short time. A RAM disk

must be used for such purposes.

b) Boot Mode Select Signal (BMS)

This pin is normally low and enables the standard boot code from the Stamp9261's flash memory. If

pulled high, the Stamp9261 boots from the internal ROM of the SAM9261 processor. The ROM code

initializes the CPU and tries to boot from an external DataFlash® memory. Currently, the Stamp9261

provides no support for using the ROM code. This ROM-boot program also supports the SAM-BA

programming tool from Atmel©

c) EEPROM

256 Bytes within a serial EEPROM are available to store configuration data. The EEPROM is

accessed via the TWI.

d) SDRAM

The Stamp9261 can be equipped with up to 64MB SDRAM. The starter-kit Stamp9261 is equipped

with 64MB Mobile SDRAM.

e) SRAM

The SAM9261 processor integrates 160 KB of fast static RAM which can be used as "Tightly Coupled

Memory" (TCM) with dedicated instruction and data blocks. Time-critical sections of the code, e.g.

interrupt handlers, are recommended to be placed within the SRAM, as well as critical data sections

like the stack.

f) DataFlash

A 128 KB Dataflash connected to the processor's SPI-Bus is provided. It can be used for booting

purposes or storing configuration data in designs without further flash memory

- 9 -

Page 10

4.4. Battery backup

The following parts of the SAM9261 Processor can be backed-up by a battery:

- the Slow Clock Oscillator;

- the Real Time Timer;

- the Reset Controller;

- the four General Purpose Backup Registers.

It is recommended to always use a backup power supply (normally a battery) in order to speed up the

boot-up time and to avoid reset problems.

4.5. Reset Controller (RSTC)

The SAM9261 has an integrated Reset Controller which samples the backup and the core voltage

(both typically at 1.2V). As the Stamp9261 uses an additional reset comparator to supervise the 3.3V

supply, the user reset function of the RSTC should always be enabled. This requires the presence of a

backup voltage (VDDBU) when the card is powered down.

4.6. Serial Number

Every Stamp9261 has a unique 48-bit hardware serial number chip which can be used by application

software. A Linux driver for reading the serial number is available.

- 10 -

Page 11

4.7. Clock Generator and Power Management Controller (PMC)

a) SAM9261 Clocks

The Stamp9261's SAM9261 Processor generates its necessary clocks based on two crystal

oscillators:

- Slow Clock (SLCK) Oscillator, running at 32768 Hz,

- Main Clock Oscillator, running at 18.432 MHz.

From the Main Clock Oscillator, the Clock Generator produces two further clocks by using two PLLs:

- PLLA provides the 200 MHz Processor Clock (PCK) and the

- Master Clock (MCK) = PCK/2 = 100 MHz

- PLLB provides the 96 MHz USB Clock.

Apart from the USB Clock, most of the peripheral clocks are derived from MCK:

- SDRAM, LCDC, USART, SPI, TWI, SSC, PIT, TC.

The TC unit can also run on SLCK. The RTT always runs on SLCK.

b) Programmable Clocks

Four programmable clock outputs PCK0, PCK1, PCK2 and PCK3 are available on the connectors of

the Stamp9261. They can individually be programmed to the SLCK, PLLA, PLLB, and Main Clock, as

well as these values divided by 2, 4, 8, 16, 32, or 64.

c) PMC Control Functions

The PMC has a Peripheral Clock register which allows to enable or disable the clocks of all integrated

peripherals individually using their "Peripheral Identifier" (see table Peripheral Identifiers).

The System Clock register allows to enable or disable each of the following clocks individually:

- Processor clock,

- LCD clock (HCK1)

- USB Host clock (common for both channels)

- USB Device clock

- Programmable Clocks

The HCK0 bit mentioned in the Atmel manual is not used in the SAM9261 processor.

d) PMC Supervisory Functions

The PMC provides status flags for the

- Main Oscillator

- Master Clock

- PLLA

- PLLB

- Programmable Clocks

The PMC status register provides "Clock Ready" or, respectively, "PLL Lock" status bits for each of

these clocks. An interrupt is generated when any of these bits changes from 0 to 1.

The Main Oscillator frequency can be measured by using the PMC Main Clock Frequency register.

The SLCK is used as reference for the measurement.

- 11 -

Page 12

4.8. Real-time Timer (RTT)

The Real-time Timer is a 32-bit counter combined with a 16-bit prescaler running at Slow Clock

(SLCK = 32768 Hz). As the RTT keeps running if only the backup supply voltage is availbale, it is used

as a Real-time clock on the Stamp9261.

The RTT can generate an interrupt every time the prescaler rolls over. Usually the RTT is configured

to generate an interrupt every second, so the prescaler will be programmed with the value 7FFFh.

The RTT can also generate an alarm if a preprogrammed 32-bit value is reached by the counter.

4.9. Timer Counter (TC)

The TC consists of three independent 16-bit Timer/Counter units. They may be cascaded to form a 32bit or 48-bit timer/counter. On the Stamp9261, the external signals are not available as they are

multiplexed on the Processor with the upper 16 bits of the data bus. The timers can therefore only run

on the internal clock sources:

- MCK/2, MCK/8, MCK/32, MCK/128, SLCK,

- or the output of another timer channel.

4.10. Periodic Interval Timer (PIT)

The PIT consists of a 20-bit counter running on MCK / 16. This counter can be preloaded with any

value between 1 and 220. The counter increments until the preloaded value is reached. At this stage it

rolls over and generates an interrupt. An additional 12-bit counter counts the interrupts of the 20 bit

counter.

The PIT is intended for use as the operating system’s scheduler interrupt.

4.11. Watchdog Timer

The watchdog timer is a 12-bit timer running at 256 Hz (Slow Clock / 128) The maximum watchdog

timeout period is therefore equal to 16 seconds. If enabled, the watchdog timer asserts a hardware

reset at the end of the timeout period. The application program must always reset the watchdog timer

before the timeout is reached. If an application program has crashed for some reason, the watchdog

timer will reset the system, thereby reproducing a well defined state once again.

The Watchdog Mode Register can be written only once. After a Processor Reset, the watchdog is

already activated and running with the maximum timeout period. Once the watchdog has been

reconfigured or deactivated by writing to the Watchdog Mode Register, only a Processor Reset can

change its mode once again.

- 12 -

Page 13

4.12. Bus Matrix

The SAM9261 Processor's Bus Matrix consists of 5 masters and 5 slaves:

The Bus Masters are:

- ARM926EJS Core Instruction Fetch,

- ARM926EJS Core Data I/O,

- USB Host DMA,

- LCDC-DMA,

- Peripheral DMA Controller (PDC).

Bus Slaves are:

- internal ROM,

- internal SRAM,

- EBI,

- internal peripherals,

- LCDC and USB Host port.

EBI connects to external devices. In the case of the Stamp9261 these consist in the SDRAM, the flash

memory and the Ethernet Controller. The LCDC and the USB Host ports share a common slave bus

connection.

The Bus Matrix provides independent paths for each Master/Slave connection. For example, the

LCDC-DMA can fetch video data from its video RAM (which we assume is allocated within the

SDRAM) at the same time as the USART DMA (a PDC channel) stores data within the internal SRAM.

- 13 -

Page 14

4.13. LCD Controller (LCDC)

The LCD Controller of the SAM9261 processor (theoretically) supports displays with a resolution up to

2048x2048 pixels with a color depth of 24 bit per pixel, or 8 bit per color. To implement a fitting LCD,

glue hardware is necessary.

The LCD controller relies on a relatively simple frame buffer concept, which means that all graphics

and character functions have to be implemented in software: character sets and graphic primitives are

not integrated in the controller.

a) LCDC Initialization and LCD Power Sequencing

LCD cells (pixels) should not be subjected to DC power for prolonged periods of time, as chemical

decomposition might take place. The LCD controller therefore provides for a strict AC control of the

LCD pixels. To do so, the LCD controller has to be initialized appropriately. Switching on the LCD

supply voltage therefore has to take place after the LCDC initialization or shortly before.

Accordingly, the LCDC should not be powered down without deactivating the LCD supply voltage. The

same is true if the LCDC is stopped indirectly by stopping the respective clock source, namely the

PLLA.

The LCD backlight supply is not involved in these considerations. It may switched on or off at any time

independently of the state of the LCDC.

b) LCDC Video Memory Selection

The video memory of the LCDC is part of the working memory of the processor. It might either reside

in the internal SRAM, as well as in the external SDRAM. Using the internal SRAM has the advantage

that the LCDC can access its video memory via an autonomous bus and does not affect the processor

performance. However, as the internal SRAM has a capacity of only 160 KBytes, the color depth for a

QVGA display is only 16 bit / pixel (320 x 240 x 2 = 153600 bytes are necessary). For a high quality

display 16 bit per pixel might not be sufficient.

On the other hand, using the SDRAM as video memory has the advantage that there is plenty of

space for all resolutions. Also the internal SRAM is now available for time critical software sections. Of

course the LCDC will now be permanently scanning its video memory and might therefore reduce the

overall performance to some degree.

c) LCDC Frame Buffer

The LCDC video memory is organized as a frame buffer in a straight forward way. It supports color

depths of 1, 2, 4, 8, 16, or 24 bit per pixel. The video data is stored in a packed form with no unused

bits in the video memory.

The color resolutions of 1, 2, 4, and 8 bpp (bits per pixel) use a palette table which is made up of 16-bit

entries. The value of each pixel in the frame buffer serves as an index into the palette table. The value

of the respective palette table entry is output to the display by the LCDC.

Each palette table entry has the form

Bit 15 Bit[14..10] Bit[9..5] Bit[4..0]

Intensity Bit Blue[7..3] Green[7..3] Red[7..3]

The bits 2..0 of each color channel are not used in the palletized configuration – they are set to zero.

The intensity bit sets the least significant valid bits of every color, that is, the bits 2, 10, and 18 of a 24bit LCDC output word.

The same scheme as above is used in the 16-bit color resolution configuration, although in this case

the frame buffer entry is output directly to the display instead of indexing a palette table.

In the 24-bit color resolution configuration, each frame buffer entry consists of one byte for each color:

Bit[23..16] Bit[15..8] Bit[7..0]

Blue[7..0] Green[7..0] Red[7..0]

- 14 -

Page 15

The "BGR" (blue-green-red) sequence in the SAM9261 LCDC is not frequently used by graphics

libraries or bitmaps ("RGB" is more of a standard), neither is the use of bit 15 as an intensity bit. Of

course, the first problem can be circumvented by connecting the LCDC lines to the LCD in a way

deviating from the Atmel designation, that is, by exchanging the "blue" against the "red" lines.

The Linux frame buffer driver offers a function which returns the information about the frame buffer

structure including the assignment of each frame buffer bit to a color channel bit. It is recommended

that graphics software uses this function in order to achieve a correct color representation.

4.14. LCDC DMA and FIFO

To provide for a periodic display refresh, the LCDC comprises a DMA channel and a 2 KB FIFO.

4.15. Display (TFT)

The Stamp9261 is provided without a display. The implementation of a display design is subject to the

user.

4.16. Touchscreen

The SPI-based ADS7843 is is implemented on the Evaluation-Board Design. It is connected to the

Second SPI-Bus of the AT91SAM9261. It's Pins are multiplexed with the Knob on the EvaluationBoard so both input devices can't be used at the same time.

4.17. Advanced Interrupt Controller (AIC)

The Advanced Interrupt Controller can handle up to 32 internal or external interrupt sources. On the

SAM9261 processor, only 24 of them are actually used.

The AIC integrates an 8-level priority controller.

Interrupt sources can be programmed to be level sensitive or edge triggered. The polarity can be

programmed for all external interrupt sources.

There are three external interrupt signals available on the connectors of the Stamp9261:

- IRQ0, IRQ1, and IRQ2.

Moreover, all PIO lines can be used to generate a PIO interrupt. However, the PIO lines can only

generate level change interrupts, that is, positive as well as negative edges will generate an interrupt.

The PIO interrupt itself (PIO to AIC line) is usually programmed to be level-sensitive. Otherwise

interrupts will be lost if multiple PIO lines source an interrupt simultaneously.

- 15 -

Page 16

4.18. Peripheral DMA Controller (PDC)

The PDC provides both a receive and a transmit channel for each of the following full-duplex devices:

- USARTs

- Debug UART

- SPIs

- SSCs

The following half duplex device uses one bidirectional DMA channel:

- MCI

The DMA controllers of the USB Host interface and the LCD controller have specific characteristics

and are not part of the PDC.

The address space of the DMA registers of one DMA channel as well as the interrupt of that channel

are assigned to the appropriate peripheral. The PDC registers thus do not occupy a contiguous

address range.

a) PDC Registers

A DMA channel consists of a

- pointer register

- counter register

- new pointer register

- new counter register

- status register (enable/disable status)

- control (enable/disable) register

The counter register has 16 bits. The maximum buffer size for a single DMA transfer is thus limited to

64kB. The PDC supports 8-bit, 16-bit and 32-bit data words. They are selected according to the

requirements of the associated peripheral device.

b) PDC Interrupts

There are four kinds of interrupt generated by the PDC:

- End of Receive Buffer

- End of Transmit Buffer

- Receive Buffer Full

- Transmit Buffer Empty

The "End of Receive Buffer" / "End of Transmit Buffer" interrupts signify that the DMA counter has

reached zero. The DMA pointer and counter register will be reloaded from the reload registers ("DMA

new pointer register" and "DMA new counter register") provided that the "DMA new counter register"

has a non-zero value. Otherwise a "Receive Buffer Full" or, respectively, a "Transmit Buffer Empty"

interrupt is generated, and the DMA transfer terminates. Both reload registers are set to zero

automatically after having been copied to the DMA pointer and counter registers.

- 16 -

Page 17

4.19. Debug Unit (DBGU)

The Debug-Unit is a simple UART which provides only RX/TX lines. It is used as a simple serial

console for Firmware and Operating Systems.

4.20. JTAG Unit

The JTAG unit can be used for hardware diagnostics, hardware initialization, flash memory

programming, and debug purposes.

The JTAG unit supports two different modes, namely the "ICE Mode", and the "Boundary Scan" mode.

The Stamp9261 is normally jumpered for "ICE Mode".

JTAG interface devices are available for the SAM9261. However, the use of the JTAG unit is not

within the scope of this document.

- 17 -

Page 18

4.21. Two-wire Interface (TWI)

The TWI is also known under the expression "I²C-Bus", which is a trademark of Philips and may

therefore not be used by other manufacturers. However, interoperability is guaranteed.

The TWI uses only two lines, namely serial data (SDA) and serial clock (SCL). According to the

standard, the TWI clock rate is limited to 400 kHz in fast mode and 100 kHz in normal mode. On the

SAM9261, however, the baudrate can be fixed to any value between

MCK/6 and

MCK / (255*128*2 + 6) ~= MCK / 64k.

- 18 -

Page 19

4.22. MultiMedia Card Interface (MCI)

The Stamp9261, or its SAM9261 processor, offer full support for interfacing MultiMedia Cards. The

MCI ist multiplexed with the SPI-0 port.

Offering SD-Card support on devices like the Stamp9261 is not royalty-free. It is therefore not

documented in this manual.

- 19 -

Page 20

4.23. USB Host Ports (UHP)

Two independent USB 2.0 Full Speed host ports are integrated in the SAM9261 processor. According

to the USB specification, the term "Full Speed" denotes a transmission rate of 12 MBit/s. A "High

Speed" mode (480 MBit/s) is not available with the SAM9261.

a) External Parts

A few external parts are required for the proper operation of the UHP:

- Pull-down resistors on each line of approximately 15 kΩ. These should be installed even if the

UDP is not to be used at all in order to keep the signals from floating.

- Series resistors of 27 Ω (5%) on each line.

- Small capacitors (e.g. 15pF) to ground on each line (optional).

- ESD protection devices are recommended for applications which are subject to external

contact. The restrictions with regard to capacitive loading have to be applied when selecting a

protection device.

- A circuit to generate the 5V V

BUS

supply voltage.

b) V

BUS

considerations for USB Host

A USB host port has to provide a supply voltage V

BUS

of 5V +- 5% which has to be able to source a

maximum of 500mA, or 100mA in case of battery operation. Please refer to the appropriate rules in the

USB specification. A low ESR capacitor of at least 120µF has to be provided on V

BUS

in order to avoid

excessive voltage drops during current spikes.

V

BUS

has to have an over-current protection. The over-current drawn temporarily on V

BUS

must not

exceed 5A. Polymeric PTCs or solid state switches are recommended by the specification. Suitable

PPTCs are "MultiFuse" (Bourns), "PolyFuse" (Wickmann/Littelfuse), "PolySwitch" (Raychem/Tyco).

It is required that the over-current condition can be detected by software, so that V

BUS

can be switched

off or be reduced in power in such a case.

c) Layout considerations

The external resistors should be placed in the vicinity of the Stamp9261 connector. The two traces of

any of the differential pairs (USB-Host A+ and USB-Host A- , as well as USB-Host B+ and USB-Host

B-) should not encircle large areas on the base board, in order to reduce signal distortion and noise.

The are preferably routed closely in parallel from the Stamp9261 to the USB connector.

- 20 -

Page 21

4.24. USB Device Port (UDP)

a) External Parts

A few external parts are required for the proper operation of the UDP:

- Pull-down resistors on each line of approximately 330 kΩ. These should be installed even if

the UDP is not to be used at all in order to keep the signals from floating.

- Series resistors of 27 Ω (5%) on each line.

- Small capacitors (e.g. 15pF) to Ground on each line (optional).

- A voltage divider on the 5V USB supply voltage V

BUS

converting this voltage to 3.3V, e.g.

27 kΩ / 47 kΩ, for the V

BUS

monitoring input (USB_CNX).

- ESD protection devices are recommended for applications which are subject to external

contact. The restrictions with regard to capacitive loading have to be applied when selecting a

protection device.

The USB specification (revision 2.0 of April 27, 2000, chapter 7.1.1.1) demands a cable with a

characteristic impedance of 90 Ω ± 15% . Matching this impedance would require a driver output

impedance of 45 Ω on both the negative and the positive driver. Nevertheless, the SAM9261 manual

demands external resistors of 27 Ω. These would correspond to intrinsic resistances of the drivers of

18 Ω.

The USB specification demands a switchable pull-up resistor of 1.5 kΩ on USB-Device+ which

identifies the UDP as a full speed device to the attached host controller. On the AT91SAM9261

processor, this resistor is integrated on the chip. It can be switched on or off using the "USB Pad Pullup Control Register", which is part of the "Bus Matrix User Interface" (not the "USB Device Port User

Interface", as one might expect). This pull-up resistor is required to be switchable in order not to

source current to an attached but powered down host. This would otherwise constitute an irregular

condition on the host. The software has to take care of this fact.

The capacitors are intended to improve the signal quality (edge rate control) in dependency of the

specific design. They are not mandatory. The total capacitance to ground of each USB pin, the PCB

trace to the series resistor, and the capacitor must not exceed 75pF.

b) Operation with V

BUS

as a Supply

Special care has to be taken if the Stamp9261 is powered by the V

BUS

supply. Please refer to the

appropriate rules in the USB specification with regard to inrush current limiting and power switching.

As the Stamp9261 draws more than 1W in normal mode, it is a "high-power" device according to the

specification (<100mA = "low-power", 100..500mA = "high-power"). It therefore requires staged

switching which means that at power-up it should draw not more than 100mA on V

BUS

. The capacitive

load of a USB device on V

BUS

should be not higher than 10µF.

c) Layout considerations

The external resistors should be placed in the vicinity of the Stamp9261 connector. The traces of the

differential pair (USB-Device+ and USB-Device- ) should not encircle large areas on the base board,

in order to reduce signal distortion and noise. The are preferably routed closely in parallel from the

Stamp9261 to the USB connector.

- 21 -

Page 22

4.25. Ethernet Controller

A Davicom DM9000A 10/100 MBit Ethernet Controller is implemented on the Stamp Adaptor Board. It

serves as a reference Design and a 10/100 MBit Twisted-Pair Magnetic Module (transformer plus

filter).

Software drivers are available for the DM9000A for Linux 2.4/2.6 and Windows CE 4.2/5.0/6.0.

a) MAC Address

An individual 48-bit MAC address (Ethernet hardware address) is allocated to each Stamp9261. This

number is stored in flash memory as a U-Boot parameter. It is recommended not to change the MAC

address in order to comply with the IEEE Ethernet standards.

b) Layout considerations

Please take care of the specific layout requirements of the Ethernet port when designing a base board.

The two signals of the transmitter pair (ETX+ and ETX-) should be routed in parallel (constant

distance, e.g. 0.5mm) with no vias on their way to the RJ45-jack. The same is true for the receiver pair

(ERX+ and ERX-). No other signals should be crossing or get next to these lines. If a ground plane is

used on the base board, it should be omitted in the vicinity of the Ethernet signals.

A 1nF / 2kV capacitor should be connected between board ground and chassis ground (which is

usually connected to the shield of the RJ45-jack).

c) Ethernet LEDs

Two LED outputs from the DM9000A controller can be used on the base board. LED_S indicates the

current speed of the Ethernet connection (100MBit = on, 10 MBit = off). LED_L indicates the combined

link and carrier sense signal (LED mode 1 of the DM9000A), or only the carrier sense signal (LED

mode 0).

- 22 -

Page 23

4.26. Synchronous / Asynchronous Serial Interfaces (USART)

Three USARTs and one UART are integrated into the SAM9261 processor.

The UART ("Debug" UART) is used as the Stamp9261’s standard input/output port. It supports only

the normal mode (RS232 mode).

A receive and a transmit DMA channel is assigned to each USART / UART.

a) USART Modes

Six different modes are implemented within the USARTs:

- Normal (standard RS232 mode)

- RS485

- Hardware Handshaking

- ISO7816 Protocol: T=0

- ISO7816 Protocol: T=1

- IrDA

• RS485 Operating Mode

In this mode, the RTS pin is automatically driven high during transmit operations. If RTS is connected

to the "enable" line of the RS485 driver, the driver will thus be enabled only during transmit operations.

• Hardware Handshaking Operating Mode

The hardware handshaking feature enables an out-of-band flow control by automatic management of

the pins RTS and CTS. The receive DMA channel must be active for this mode. The RTS signal is

driven high if the receiver is disabled or if the DMA indicates a buffer full condition. As the RTS signal

is connected to the CTS line of the connected device, its transmitter is thus prevented from sending

any more characters.

• Smart Card Operating Modes

The USARTs have an ISO7816-compatible mode which permits interfacing with smart cards and

Security Access Modules (SAM). Both T=0 and T=1 protocols of the ISO7816 specification are

supported.

• IrDA Operating Mode

The USART features an infrared (IrDA) mode supplying half-duplex point-to-point wireless

communication. It includes the modulator and demodulator which allows a glueless connection to the

infrared transceivers.

The modulator and demodulator are compliant with the IrDA specification version 1.1 and support data

transfer speeds ranging from 2.4 kb/s to 115.2 kb/s.

b) Signals of the serial interfaces

All UARTs/USARTs have one receiver and one transmitter data line (full duplex). The UARTS #1 and

#2 also have two handshake lines – RTS and CTS – as well as a clock line (SCK) for the synchronous

protocols.

The Debug UART only has receiver and transmitter data lines. The same is true for USART #0 - its

handshake lines are not externally available on the Stamp9261.

The RI, DTR, DSR and DCD lines of USART #1 designated in the pin description of the Stamp9261

are not really part of the USART unit of the SAM9261. They are rather implemented as standard digital

ports (PIO ports).

- 23 -

Page 24

c) Hardware Interrupts of the Serial Interfaces

There are several interrupt sources for each USART.

- Receive: RX Ready, (DMA) Buffer Full, End of Receive Buffer

- Transmit: TX Ready, (DMA) Buffer Empty, End of Transmit Buffer, Shift Register Empty

- Errors: overrun, parity, framing, and timeout errors

- Handshake: the status of CTS has changed

- Break: the receiver has detected a break condition on RXD

- NACK: non acknowledge (ISO7816 mode only)

- Iteration: the maximum number of repetitions has been reached (ISO7816 mode only)

Please refer to the chapter about the DMA unit (PDC) for a description of the "Buffer Full" and "End of

Receive / Transmit Buffer" events.

- 24 -

Page 25

4.27. Synchronous Peripheral Interface (SPI)

Two SPI ports, each of them with three chip selects, are available on the Stamp9261. The SPI baud

rate is Master Clock (MCK) divided by a value between 1 and 255.

A receive and a transmit DMA channel is assigned to each of the two SPIs.

4.28. Synchronous Serial Controller (SSC)

The three Synchronous Serial Controllers of the SAM9261 processor are available which one to use

depends on the multiplexing of the pins with other devices used in the application.

The SSC supports many serial synchronous communication protocols generally used in audio and

telecom applications such as I2S, Short Frame Sync, Long Frame Sync, etc.

The SSC has separated receive and transmit channels. Each channel has a data, a clock and a frame

synchronization signal (RD, RK, RF, resp. TD, TK, TF).

Both a receive and a transmit DMA channel are assigned to each SSC.

- 25 -

Page 26

4.29. Parallel Input /Output Controller (PIO)

The Stamp9261 has a maximum of 39 freely programmable digital I/O ports on its connectors. They

can be configured independently of each other as input or output. These pins are also used by other

peripheral devices.

The SAM9261 Processor comes with 3 PIO controllers, each of them can manage up to 32

programmable I/O ports. Each I/O port is associated with a bit number in the 32 bit register of the user

interface. Each I/O port may be configured for general purpose I/O or assigned to a function of an

integrated peripheral device. In doing so multiplexing with 2 integrated devices is possible. That

means a pin may be used as GPIO,device A or device B.

The following characteristics are individually configurable for each PIO pin:

- PIO enable

- Peripheral A or B enable

- Output enable

- Output level

- Write Enable

- Level change interrupt

- Glitch filter: pulses that are lower than a half clock cycle are ignored

- Open-drain outputs

- Pull-up resistor

All configurations as well as the pin status can be read back by using the appropriate status register.

Multiple pins of each PIO can also be written simultaneously by using the synchronous output register.

A number of the PIO signals are used internally on the Stamp9261. Care has to be taken when

accessing the PIO registers in order not to change the settings of these internal signals – otherwise a

system crash is likely to happen.

- 26 -

Page 27

4.30. Power Management

Using power management can dramatically reduce the power consumption of an Embedded Device.

We assume that almost no application will use the maximum performance of the CPU and the

peripherals all of the time. The following possibilities for power management are available on the

Stamp9261:

- switching off the TFT supply voltage

- putting the SDRAM into self-refresh mode

- putting the Ethernet controller in power down mode

- stopping the PLLs (PLLA and / or PLLB)

- stopping the clocks of the various peripherals

- reducing the clock rates of peripherals, especially by changing MCK.

a) Beware of tampering with the LCDC !

It is not recommended to reduce the clock speed of the LCD controller. Instead, the LCDC clock

should be stopped and the power supply for the LCD switched off, as otherwise the LCD can be

damaged.

b) Idle Mode

In idle mode, the processor clock will be re-enabled by any interrupt. The peripherals, however, are

only able to generate an interrupt if they still have a clock, so care has to be taken as to when a

peripheral can be powered down.

It should also be taken into account that when a PLL is stopped it will take some time to restart it.

Changing the PLL frequencies or stopping them can therefore be done only at a moderate rate. If

short reaction times are required, this is not a choice.

c) Slowing down MCK

However, in many cases a system waits for a user action or some other rare event. In such a case, it

is possible to change MCK to SLCK. Any external event which changes the state on peripheral pins

(not the USB) can then be detected by the PIO controller or the AIC.

d) Low Power SDRAM

The Stamp9261 makes use of Low Power (Mobile) SDRAM. The enhanced low power features of the

SDRAM controller are thus available:

- deep power down (all SDRAM data is lost)

- partial self-refresh (only part of the SDRAM is refreshed, data of all other parts is lost).

- 27 -

Page 28

5. Stamp9261 Starter Kit

5.1. Starter Kit Contents

The Stamp9261 starter kit contains the following components:

- Stamp9261

Stamp9261 Adaptor: Adapter board for connecting Stamp9261 and Stamp9261 Base

- Panel-Card EVB: Evaluation and Prototyping Board

- Wall Adapter Power Supply, Input AC 230V, Output DC 9 to 16V, min. 400 mA

- Serial "Null-Modem" Cable with two 9-pin D-type Connectors

- Adapter cable for accessing the Debug UART

- CD with Operating System, Toolchain, and Documentation

5.2. Panel-Card EVB

The Panel-Card EVB is designed to be both simple and universal. Some elements of the circuit board

will not always be needed, but facilitate implementation for certain purposes. It was designed to serve

both, the Panel-Card and the Stamp9261 as an evaluation platform.

a) First Steps

The Starter Kit board "Panel-Card EVB" makes it easy to put the Stamp9261 to use. The first steps

involve the following:

- connecting the wall adapter to the main supply

- connecting the DBGU-Adapter and the serial cable to a COM port of a PC

- starting a terminal program for the selected COM port at 115200 baud, 8N1

- starting the Stamp9261 by connecting the DC plug of the wall adapter.

Boot messages of the Stamp9261 are now expected to appear on the terminal.

b) Power Supply

From an unregulated input voltage between 8 and 35V, two voltages are produced:

- 3.3V for the CPU module,

- 5V for USB and optional peripherals,

c) RS232 Interface

The RS232 port provides RS232 drivers/receivers for the RxD, TxD, RTS, CTS, RI and DCD signals of

the USART1 of the Stamp9261. Instead of the usual DTR and DSR signals, the connector integrates

the RxD and TxD lines of the Stamp9261's "Debug UART". To use the console port of the Stamp9261,

which usually is identical to the Debug UART, the "DBGU adapter" has to be used. It connects the

PC's TxD, RxD, and Ground lines to the appropriate pins of the DSUB-9 connector of the Stamp9261

Base.

d) Connectors

The following connectors are part of the Panel-Card EVB:

- Stamp9261 Adaptor slot, consisting of two 40-pin header connectors (0.1 inch pitch)

- Ethernet 10/100 MBit

- USB Host (dual)

- USB Device

- RS232

- MMC-Card Slot

- 28 -

Page 29

- Matrix keyboard

Touch controller

- JTAG

- User Connector D-type 25pin

- User Connector 26pin header (optional)

- 2-contact terminal block for power supply

- DC connector for power supply

e) Rotary Encoder

The Panel-Card EVB includes a rotary encoder with push-button which is a "Human Interface Device"

well suited for many embedded applications. Generally spoken, it is a simplified replacement for a

computer mouse, touch pad, or keyboard. The rotary encoder represents a pointing device with only

one dimension, while the push-button serves as a "return" key or mouse button.

The rotary encoder is accessed by two PIO ports of the Stamp9261 (see circuit diagram). The pushbutton occupies another PIO port.

- 29 -

Page 30

6. Schematics of "Panel-Card EVB" Evaluation and Prototyping Board

6.1. Disclaimer

The following circuit diagram is intended for reference only and does not dispense the user from

checking and applying the appropriate standards. No warranty can be granted if parts of the circuit are

used in customer applications.

The part of the schematics dealing with the power supply is not recommended for new designs. An

updated schematics will be published in a later version of this document.

- 30 -

Page 31

6.2. BUS Connector

- 31 -

Page 32

6.3. Interfaces

- 32 -

Page 33

6.4. Power Supply

- 33 -

Page 34

6.5. Extension Connectors

- 34 -

Page 35

6.6. HID Devices

- 35 -

Page 36

7. Address Map (Physical address space)

After the execution of the remap command the 4 GB physical address space is separated as shown in the

following table. Accessing these addresses directly is only possible if the MMU (memory management unit) is

deactivated. As soon as the MMU is activated the visible address space is changed completely.

If absolute memory addresses should be accessed within an application, the corresponding address space has first

to be mapped to the virtual address space using mmap or ioremap under Linux.

Address Mnemonic Function

00 0000 Boot Memory Flash (NCS0) or internal ROM or internal SRAM

10 0000 ITCM Instruction TCM (Tightly Coupled Memory)

Internal SRAM A: 0, 16, 32 or 64 kB

20 0000 DTCM Data TCM (Tightly Coupled Memory)

Internal SRAM B: 0, 16, 32 or 64 kB

30 0000 SRAM Internal SRAM C

SRAM A + SRAM B + SRAM C = 160 kB

40 0000 ROM Internal ROM 32 kByte

50 0000 UHP USB Host Port

60 0000 LCD LCD Controller

1000 0000 EBI NCS0 Chip Select 0: Flash Memory #1, up to 128 MB

2000 0000 EBI NCS1 Chip Select 1: SDRAM, up to 64 MB

3000 0000 EBI NCS2 Chip Select 2: Ethernet Controller

4000 0000 EBI NCS3 Chip Select 3: Flash Memory #2, up to 128 MB

FFFA 0000 TC0, TC1, TC2 3 Timer Counter, 16-Bit

FFFA 4000 UDP USB Device Port

FFFA 8000 MCI Multimedia Card / SD-Card Interface

FFFA C000 TWI Two Wire Interface (I²C)

FFFB 0000 USART0 Synchronous or Asynchronous Serial Port #0

FFFB 4000 USART1 Synchronous or Asynchronous Serial Port #1

FFFB 8000 USART2 Synchronous or Asynchronous Serial Port #2

FFFB C000 SSC0 Serial Synchronous Controller (I²S) #0

FFFC 0000 SSC1 Serial Synchronous Controller (I²S) #1

FFFC 4000 SSC2 Serial Synchronous Controller (I²S) #2

FFFC 8000 SPI0 Serial Peripheral Interface #0

FFFC C000 SPI1 Serial Peripheral Interface #1

FFFF EA00 SDRAMC SDRAM Controller

FFFF EC00 SMC Static Memory Controller

FFFF EE00 MATRIX Bus Matrix User Interface

FFFF F000 AIC Interrupt Controller

FFFF F200 DBGU Debug Unit, including UART

FFFF F400 PIOA 32 Bit Parallel I/O Controller A

FFFF F600 PIOB 32 Bit Parallel I/O Controller B

FFFF F800 PIOC 32 Bit Parallel I/O Controller C

FFFF FC00 PMC Power Management Controller

FFFF FD00 RSTC Reset Controller, Battery Powered

FFFF FD10 SHDWC Shutdown Controller, Battery Powered

FFFF FD20 RTT Real-time Timer 32 Bit, Battery Powered

FFFF FD30 PIT Periodic Interval Timer 32 Bit

FFFF FD40 WDT Watchdog Timer

FFFF FD50 GPBR 4 General Purpose Backup Registers, Battery Powered

various PDC Peripheral DMA Controller (each channel's address space is

assigned to the address space of its respective device)

- 36 -

Page 37

8. Peripheral Identifiers

The Peripheral Identifiers are used to address the corresponding peripheral unit in the interrupt

controller (AIC) and in the power management controller (PMC).

ID Mnemonic Usage External

Interrupt

0 FIQ External Fast IRQ FIQ

1 SYSIRQ System Interrupt: OR'red IRQs of

SDRAMC, DBGU, PIT, RTT, WDT, RST, PMC

2 PIOA Parallel I/O Controller A

3 PIOB Parallel I/O Controller B

4 PIOC Parallel I/O Controller C

5 Reserved

6 USART0 Synchronous or Asynchronous Serial Port #0

7 USART1 Synchronous or Asynchronous Serial Port #1

8 USART2 Synchronous or Asynchronous Serial Port #2

9 MCI Multi-Media Card / SD-Card

10 UDP USB Device

11 TWI Two Wire Interface (I²C-Bus)

2 SPI0 Serial Peripheral Interface #0

13 SPI1 Serial Peripheral Interface #1

14 SSC0 Serial Synchronous Controller (I²S) #0

15 SSC1 Serial Synchronous Controller (I²S) #1

16 SSC2 Serial Synchronous Controller (I²S) #2

17 TC0 Timer Counter #0

18 TC1 Timer Counter #1

19 TC2 Timer Counter #2

20 UHP USB Host

21 LCDC LCD Controller

22 Reserved

23 Reserved

24 Reserved

25 Reserved

26 Reserved

27 Reserved

28 Reserved

29 IRQ0 External IRQ0 IRQ0

30 IRQ1 External IRQ1 IRQ1

31 IRQ2 External IRQ2 IRQ2

Page 38

9. Stamp Adaptor

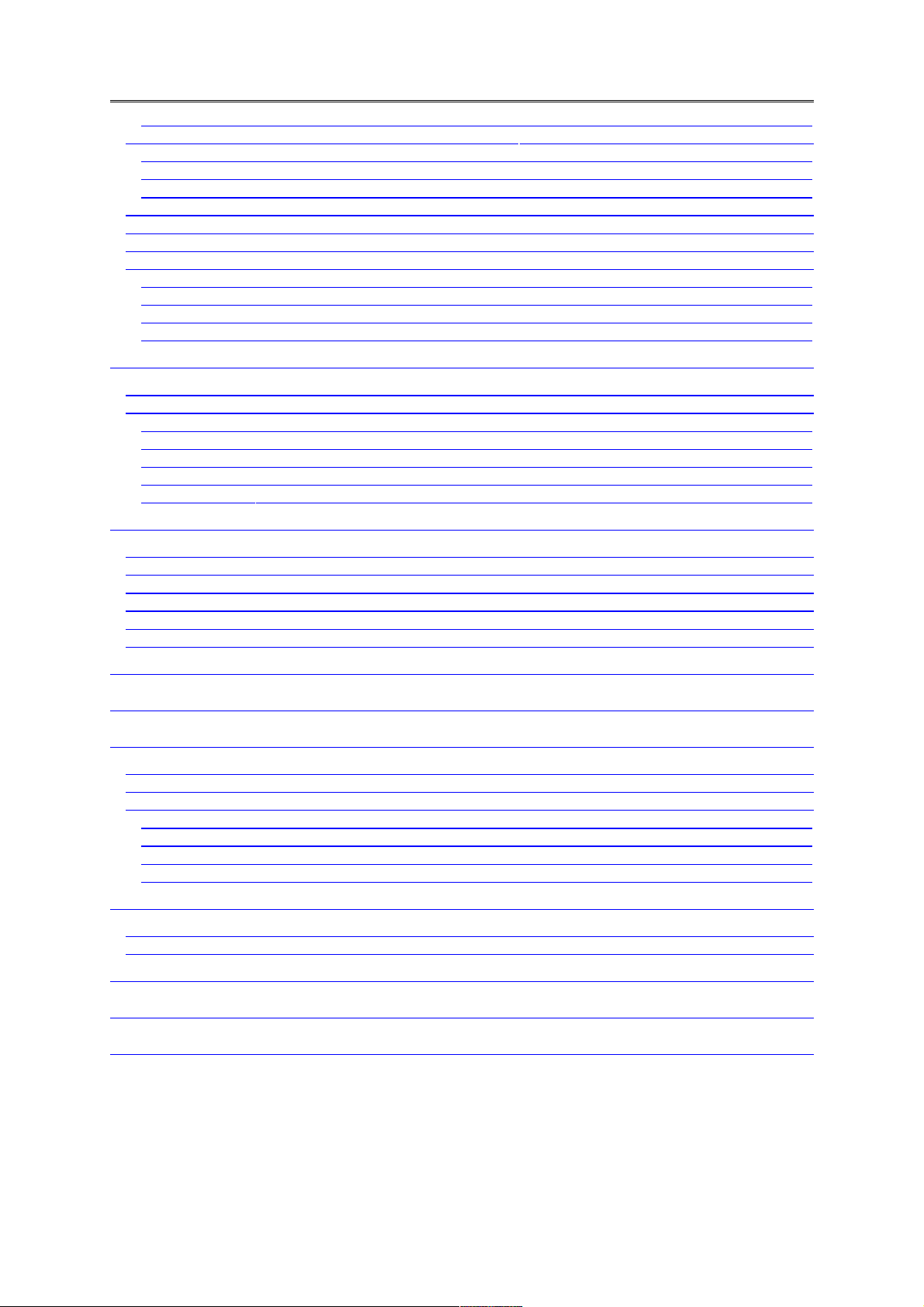

9.1. Connector Pin Assignment and Pin Multiplexing

40 Pin Header X21 40 Pin Header X22

1 VCC DSR1 PA27 2 1 VCC SCK2 PA14 2

3 PA23 RI1 RXD1 PC13 4 3 PA11 SCK1 RXD2 PC15 4

5 PC12 TXD1 DTR1 PA28 6 5 PC14 TXD2 TXD0 PCK2 PC8 6

7 PA12 RTS1 CTS1 PA13 8 7 PA15 RTS2 CTS2 PA16 8

9 PA29 DCD1 GND 10 9 PC9 PCK3 RXD0 GND 10

11 PA9 PCK2 DRXD DTXD PCK3 PA10 12 11 PA7 PCK0 TWD TWCK PCK1 PA8 12

13 PA1

SPI0

MOSIMCCDAMCCK

SPI0

CLK PA2 14 13 VCC GND 14

15 PA0

SPI0

MISOMCDA0MCDA1

SPI0

CS1 PA4 16 15 PB30

SPI1

MISO IRQ1 PCK2

SPI1

MOSI PB31 16

17 PA5

SPI0

CS2MCDA2MCDA3

SPI0

CS3 PA6 18 17 PB29

SPI1

CLK IRQ2

SPI1

CS1 PA24 18

19 VCC GND 20 19 PA25

SPI1

CS2

SPI1

CS3 PA26 20

21 USB Host A- USB Host B- 22 21 22

23 USB Host A+ USB Host B+ 24 23 24

25 USB Device- USB Device+ 26 25 26

27 PC2 IRQ0 USBCNX /RESET 28 27 VCC GND 28

29 VCC GND 30 29 TDI TMS 30

31 PA17 TF1 RF1 PA22 32 31 TDO TCK 32

33 PA18 TK1 RK1 PA21 34 33 ELED_L ELED_S 34

35 PA19 TD1 RD1 PA20 36 35 ETX+ ETX- 36

37 BMS WKUP 38 37 ERX+ ERX- 38

39 SHDN VBATT 40 39 POE1 POE2 40

Color Code:

USART

Power Supply /

Ground

Debug UART TWI (I2C-Bus)

SD-Card/MMC SPI

USB Reserved

Synch ronous Serial

Controller (SSC) JTAG

Control Ethernet

Digital I/O Port

Programmable

Clock Output

Page 39

9.2. Connector Pin Description

Mnemonic Description Type Pin on

X21

Pin on

X22

VCC System Supply 3.3V Supply 1,19,29 1,13,27

VBATT Backup Battery 2 ~ 3.3V. Must be connected to VCC if no

battery is used.

Supply 40

GND System Ground Ground 10,20, 3010,14, 28

/RESET System Reset OD, PU 1K 28

BMS Boot Mode Select: 1 = ROM Boot, 0 = Flash Boot I, PD 1K 37

IRQ0 Interrupt Request #1 I 27

IRQ1 Interrupt Request #2 I 15

IRQ2 Interrupt Request #3 I 17

SHDN Shutdown Controller Shutdown Output O, 1.2V 39

WKUP Shutdown Controller Wakeup Input I, 1.2V 38

ERX- Ethernet Receiver - Analog I 37

ERX+ Ethernet Receiver + Analog I 38

ETX- Ethernet Transmitter - Analog O 35

ETX+ Ethernet Transmitter + Analog O 36

ELED_S Ethernet LED 1: 100MBit Indicator (speed LED, active low) OD 34

ELED_L Ethernet LED 2: Link/Carrier Sense Indicator OD 33

POE1 Center Tap of Transmit Transformer for Power over Ethernet Analog I/O 39

POE2 Center Tap of Receive Transformer for Power over Ethernet Analog I/O 40

TCK JTAG Test Clock I 32

TDI JTAG Test Data In I 29

TDO JTAG Test Data Out O 31

TMS JTAG Test Mode Select I 30

MC-CK MultiMedia Card /SD-Card Clock O 14

MC-CDA MultiMedia Card /SD-Card Command/Response I/O 13

MC-DA0 MultiMedia Card Data 0/ SD-Card Data[0] I/O 15

MC-DA1 SD-Card Data[1] I/O 16

MC-DA2 SD-Card Data[2] I/O 17

MC-DA3 SD-Card Data[3] I/O 18

PA00 PIO Line PA[0] I/O 15

PA01 PIO Line PA[1] I/O 13

PA02 PIO Line PA[2] I/O 14

PA04 PIO Line PA[4] I/O 16

PA05 PIO Line PA[5] I/O 17

PA06 PIO Line PA[6] I/O 18

PA07 PIO Line PA[7] I/O 11

PA08 PIO Line PA[8] I/O 12

PA09 PIO Line PA[9] I/O 11

PA10 PIO Line PA[10] I/O 12

PA11 PIO Line PA[11] I/O 3

PA12 PIO Line PA[12] I/O 7

PA13 PIO Line PA[13] I/O 8

PA14 PIO Line PA[14] I/O 2

PA15 PIO Line PA[15] I/O 7

PA16 PIO Line PA[16] I/O 8

PA17 PIO Line PA[17] I/O 31

PA18 PIO Line PA[18] I/O 33

PA19 PIO Line PA[19] I/O 35

Page 40

(Connector Pin Description continued)

Mnemonic Description Type Pin on

X21

Pin on

X22

PA20 PIO Line PA[20] I/O 36

PA21 PIO Line PA[21] I/O 34

PA22 PIO Line PA[22] I/O 32

PA23 PIO Line PA[23] I/O 3

PA24 PIO Line PA[24] I/O 18

PA25 PIO Line PA[25] I/O 19

PA26 PIO Line PA[26] I/O 20

PA27 PIO Line PA[27] I/O 2

PA28 PIO Line PA[28] I/O 6

PA29 PIO Line PA[29] I/O 9

PB29 PIO Line PB[29] I/O 17

PB30 PIO Line PB[30] I/O 15

PB31 PIO Line PB[31] I/O 16

PC02 PIO Line PC[2] I/O 27

PC08 PIO Line PC[8] I/O 6

PC09 PIO Line PC[9] I/O 9

PC12 PIO Line PC[12] I/O 5

PC13 PIO Line PC[13] I/O 4

PC14 PIO Line PC[14] I/O 5

PC15 PIO Line PC[15] I/O 4

PCK0 Programmable Clock #0 O 11

PCK1 Programmable Clock #1 O 12

PCK2 Programmable Clock #2 O 11 6, 16

PCK3 Programmable Clock #3 O 12 9

SPI0-CS1 Serial Peripheral Interface #0 Chip Select 1 O 16

SPI0-CS2 Serial Peripheral Interface #0 Chip Select 2 O 17

SPI0-CS3 Serial Peripheral Interface #0 Chip Select 3 O 18

SPI0-CLK Serial Peripheral Interface #0 Clock I/O 14

SPI0-MISO Serial Peripheral Interface #0 Master In / Slave Out I/O 15

SPI0-MOSI Serial Peripheral Interface #0 Master Out / Slave In I/O 13

SPI1-CS1 Serial Peripheral Interface #1 Chip Select 1 O 18

SPI1-CS2 Serial Peripheral Interface #1 Chip Select 2 O 19

SPI1-CS3 Serial Peripheral Interface #1 Chip Select 3 O 20

SPI1-CLK Serial Peripheral Interface #1 Clock I/O 17

SPI1-MISO Serial Peripheral Interface #1 Master In / Slave Out I/O 15

SPI1-MOSI Serial Peripheral Interface #1 Master Out / Slave In I/O 16

RF1 Synchronous Serial Controller #1 Receive Frame Sync I/O 32

RK1 Synchronous Serial Controller #1 Receive Clock I/O 34

RD1 Synchronous Serial Controller #1 Receive Data I 36

TD1 Synchronous Serial Controller #1 Transmit Data 35

TF1 Synchronous Serial Controller #1 Transmit Frame Sync 31

TK1 Synchronous Serial Controller #1 Transmit Clock 33

TWCK Two Wire Bus (I²C-Bus) Clock OD, PU

2k7

12

TWD Two Wire Bus (I²C-Bus) Data OD, PU

2k7

11

Page 41

(Connector Pin Description continued)

Mnemonic Description Type Pin on

X21

Pin on

X22

DRXD Debug UART Receive (Console Port) I 11

DTXD Debug UART Transmit (Console Port) O 12

RXD0 USART #0 Receive I 9

TXD0 USART #0 Transmit O 6

SCK1 USART #1 Clock I/O 3

CTS1 USART #1 CTS I 8

DCD1 USART #1 DCD I 9

DSR1 USART #1 DSR I 2

DTR1 USART #1 DTR O 6

RI1 USART #1 RI I 3

RTS1 USART #1 RTS I 7

RXD1 USART #1 Receive I 4

TXD1 USART #1 Transmit O 5

SCK2 USART #2 Clock I/O 2

CTS2 USART #2 CTS I 8

RTS2 USART #2 RTS I 7

RXD2 USART #2 Receive I 4

TXD2 USART #2 Transmit O 5

USB D- USB Device Port Data - Analog I/O 25

USB D+ USB Device Port Data + Analog I/O 26

USB_CNX USB Device V

BUS

(5V) Monitoring Input 27

USB HA- USB Host Port A Data - Analog I/O 21

USB HA+ USB Host Port A Data + Analog I/O 22

USB HB- USB Host Port B Data - Analog I/O 23

USB HB+ USB Host Port B Data + Analog I/O 24

Page 42

9.3. Stamp Adaptor Schematics and Dimensions

a) Dimensions

Page 43

Page 44

b) Bus Interface

Page 45

c) Wrapfield

Page 46

d) Ethernet

Page 47

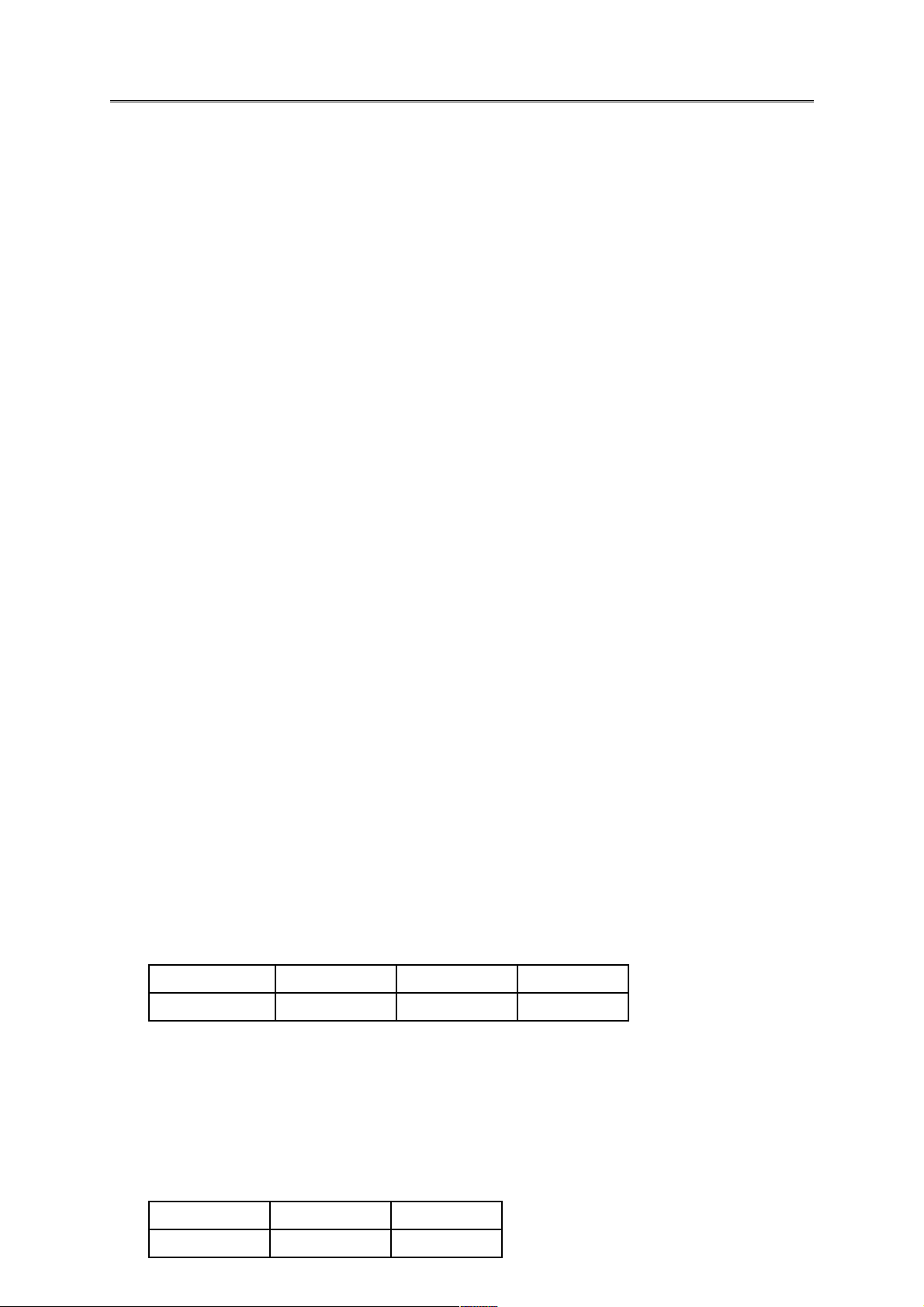

10. DC Characteristics

DC Characteristics

Ambient temperature 25°C, unless otherwise indicated.

Symbol Description Parameter Min. Typ. Max. Unit

Vcc Operating Voltage 3.0 3.3 3.6 V

Vres Reset Threshold 2.9 V

tres Duration of Reset Pulse 150 280 ms

V

IH

High-Level Input Voltage 2 Vcc+

0.3

V

V

IL

Low-Level Input Voltage -0.3 0.8 V

Icc Operating current 65 mA

in normal operation max 110 mA

Vbatt Battery Voltage for RTC 2.0 3 Vcc V

Ibatt Battery current with operating

voltage turned off

Battery Voltage = 3V

Ambient temp. = 25°C

5 µA

Ambient temp. = 70°C 17 µA

Ambient temp. = 85°C 22 µA

Clocks Characteristics

Symbol Description Dependency Admissible

Range or

Tolerance

Typical

Value.

Unit

MAINCK Main Oscillator frequency 18.4320 MHz

SLCK Slow Clock 32768 Hz

PLLACK PLLA Clock = MAINCK * 13 239.616

PCK Processor Clock = PLLACK 239.616 MHz

MCK Master Clock = PCK / 2 119.808 MHz

SDCK SDRAM Clock = MCK 119.808

BCK Baudrate Clock = MCK / 65 1.5% 1.84320 MHz

LCDCK LCD Dot Clock

Sharp LQ035Q7DH03 = MCK / 25 4.5..6.8 4.7923 MHz

EDT ET035005DM6 = MCK / 19 6.3057 MHz

PLLBCK PLLB Clock = MAINCK / 14*73 0,25% 96.110 MHz

USBCK USB Clock = PLLBCK / 2 48.055 MHz

Page 48

11. Stamp9261 Pin Assignment

I/O Interface B 1-50. 100pol. Hirose FX8

1 VCC VCC 2

3 Reserved Reserved 4

5 Reserved Reserved 6

7 Reserved Reserved 8

9 LCDVSYNC/PB0 PB00 PB01 LCDHSYNK/PB1 10

11 LCDDOTCK/PCK0/PB2 PB02 PB03 BMS/LCDDEN/PB3 12

13 LCDCC/LCDD2/PB4 PB04 PB05 LCDD0/LCDD3/PB5 14

15 LCDD1/LCDD4/PB6 PB06 PB07 LCDD2/LCDD5/PB7 16

17 LCDD3/LCDD6/PB8 PB08 PB09 LCDD4/LCDD7/PB9 18

19 LCDD5/LCDD10/PB10 PB10 PB11 LCDD6/LCDD11/PB11 20

21 LCDD7/LCDD12/PB12 PB12 PB13 LCDD8/LCDD13/PB13 22

23 LCDD9/LCDD14/PB14 PB14 PB15 LCDD10/LCDD15/PB15 24

25 GND GND 26

27 LCDD11/LCDD19/PB16 PB16 PB17 LCDD12/LCDD20/PB17 28

29 LCDD13/LCDD21/PB18 PB18 PB19 LCDD14/LCDD22/PB19 30

31 LCDD15/LCDD23/PB20 PB20 PB21 TF0/LCDD16/PB21 32

33 TK0/LCDD17/PB22 PB22 PB23 TD0/LCDD18/PB23 34

35 RD0/LCDD19/PB24 PB24 PB25 RK0/LCDD20/PB25 36

37 RF0/LCDD21/PB26 PB26 PB27 SPI1_NPCS1/LCDD22/PB27 38

39 SPI1_NPCS0/LCDD23/PB28 NPCS0 SPCK SPI1_SPCK/IRQ2/PB29 40

41 SPI1_MISO/IRQ1/PB30 MISO MOSI SPI1_MOSI/PCK2/PB31 42

43 PA24/TPK8/SPI1_NPCS1 NPCS1 NPCS2 PA25/TPK9/SPI1_NPCS2 44

45 PA26/TPK10/SPI1_NPCS3 NPCS3 PA3 PA3/SPI0_NPCS0 46

47 PA7/TWD/PCK0 TWD TWCK PA8/TWCK/PCK1 48

49 GND GND 50

51 VCC VCC 52

53 TXD1/NCS6/PC12 TXD1 RDX1 RXD1/NCS7/PC13 54

55 PA12/TCLK/RTS1 RTS1 CTS1 PA13/TPS0/CTS1 56

57 PA28/TPK12/SPI0_NPCS2 DTR1 DSR1 PA27/TPK11/SPI0_NPCS1 58

59 PA29/TPK13/SPI0_NPCS3 DCD1 RI1 PA23/TPK7/RTS0 60

61 TXD0/PCK2/PC8 TXD0 RXD0 RXD0/PCK3/PC9 62

63 RTS0/SCK0/PC10 RTS0 CTS0 CTS0/FIQ/PC11 64

65 TXD2/SPI1_NPCS2/PC14 TXD2 RXD2 RXD2/SPI1_NPCS3/PC15 66

67 PA15/TPS2/RTS2 RTS2 CTS2 PA16/TPK0/CTS2 68

69 PA10/DTXD/PCK3 DTXD DRXD PA9/DRXD/PCK2 70

71 PA11/TSYNK/SCK1 SCK1 SCK2 PA14/TPS1/SCK2 72

73 PA17/TPK1/TF1 TF1 RF1 PA22/TPK6/RF1 74

75 PA18/TPK2/TK1 TK1 RK1 PA21/TPK5/RK1 76

77 PA19/TPK3/TD1 TD1 RD1 PA20/TPK4/RD1 78

79 PA1/SPI0_MOSI/MCCDA MCCDA MCCK PA2/SPI0_SPCK/MCCK 80

81 PA0/SPI0_MISO/MCDA0 MCDA0 MCDA1 PA4/SPI0_NPCS1/MCDA1 82

83 PA5/SPI0_NPCS2/MCDA2 MCDA2 MCDA3 PA6/SPI0_NPCS3/MCDA3 84

85 HDMA HDMA HDPA HDPA 86

87 HDMB HDMB HDPB HDPB 88

89 DDM DDM DDP DDP 90

91 GND GND 92

93 Reserved ELED_L ELED_S Reserved 94

95 Reserved ETX+ ETX- Reserved 96

97 Reserved ERX+ ERX- Reserved 98

99 Reserved EVCC EGND Reserved 100

Page 49

Bus Interface 1-50. 100pol. Hirose FX8

1 VCC VCC 2

3 NBS0/A0 A00 A01 NWR2/NBS2/A1 4

5 A2 A02 A03 A3 6

7 A4 A04 A05 A5 8

9 A6 A06 A07 A7 10

11 A8 A08 A09 A9 12

13 A10 A10 A11 A11 14

15 A12 A12 A13 A13 16

17 A14 A14 A15 A15 18

19 BA0/A16 A16 A17 BA1/A17 20

21 A18 A18 A19 A19 22

23 A20 A20 A21 A21/NANDCLE 24

25 A22/NANDALE A22 A23 PA30/TPK14/A23 26

27 PA31/TPK15/A24 A24 A25 A25/CFRNW/PC3 28

29 GND GND 30

31 Reserved Reserved 32

33 Reserved Reserved 34

35 NCS0 NCS0 NCS1 SDCS/NCS1 36

37 NCS2 NCS2 NCS3 NANDCS/NCS3 38

39 NCS4/CFCS0/PC4 NCS4 NCS5 NCS5/CFCS1/PC5 40

41 NANDOE/NCS6/PC0 NCS6 NCS7 NANDWE/NCS7/PC1 42

43 CFOE/NRD NRD NWR0 CFWE/NWE/NWR0 44

45 CFIOR/NBS1/NWR1 NWR1 NWR3 CFIOW/NBS3/NWR3 46

47 CFCE1/PC6 CFCE1 CFCE2 CFCE2/PC7 48

49 GND GND 50

51 VCC VCC 52

53 D0 D00 D01 D1 54

55 D2 D02 D03 D3 56

57 D4 D04 D05 D5 58

59 D6 D06 D07 D7 60

61 D8 D08 D09 D9 62

63 D10 D10 D11 D11 64

65 D12 D12 D13 D13 66

67 D14 D14 D15 D15 68

69 GND GND 70

71 D16/TCLK0/PC16 D/PC16 D/PC17 D17/TCLK1/PC17 72

73 D18/TCLK2/PC18 D/PC18 D/PC19 D19/TIOA0/PC19 74

75 D20/TIOB0/PC20 D/PC20 D/PC21 D21/TIOA1/PC21 76

77 D22/TIOB1/PC22 D/PC22 D/PC23 D23/TIOA2/PC23 78

79 D24/TIOB2/PC24 D/PC24 D/PC25 D25/TF2/PC25 80

81 D26/TK2/PC26 D/PC26 D/PC27 D27/TD2/PC27 82

83 D28/RD2/PC28 D/PC28 D/PC29 D29/RK2/PC29 84

85 D30/RF2/PC30 D/PC30 D/PC31 D31/PCK1/PC31 86

87 SHDN SHDN WKUP WKUP 88

89 NRST NRST VBATT VDDBU 90

91 RTCK RTCK NWAIT NWAIT/IRQ0/PC2 92

93 NTRST NTRST JTAGSEL JTAGSEL 94

95 TDI TDI TMS TMS 96

97 TDO TDO TCK TCK 98

99 GND GND 100

Page 50

12. Environmental Ratings

Symbol Description Parameter Operating Storage

Min. Max. Min. Max. Unit

T

A

Ambient temperature -25 +70 -45 +80 °C

Relative Humidity no condensation 90 90 %RH

Absolute Humidity ≤ Humidity @TA = 60°C,

90%RH

Shock 3 50 G

Vibration 0.25 1.2 G

Corrosive Gas not admissible

Page 51

13. Stamp9261 Dimensions

Page 52

Loading...

Loading...