Page 1

swingo 150E

V011 / 12089-59 1624

*12089-59*

AR . 2

BG 14

CS .27

DA .40

DE .53

EN . 66

ES .79

ET . 92

FI ...105

FR .118

GR 132

HR .146

HU .159

IT ...172

LT ..185

LV .198

NL .211

NO 224

PL ..237

PT .250

RO .263

SK .277

SL ..290

SV .303

TR .316

ZH .329

AR

BG

CS

DA

DE

EN

ES

ET

FI

FR

GR

HR

HU

IT

LT

LV

NL

NO

PL

PT

RO

SK

SL

SV

TR

ZH

Page 2

Page 3

Page 4

60

Translation of the original instructions of use

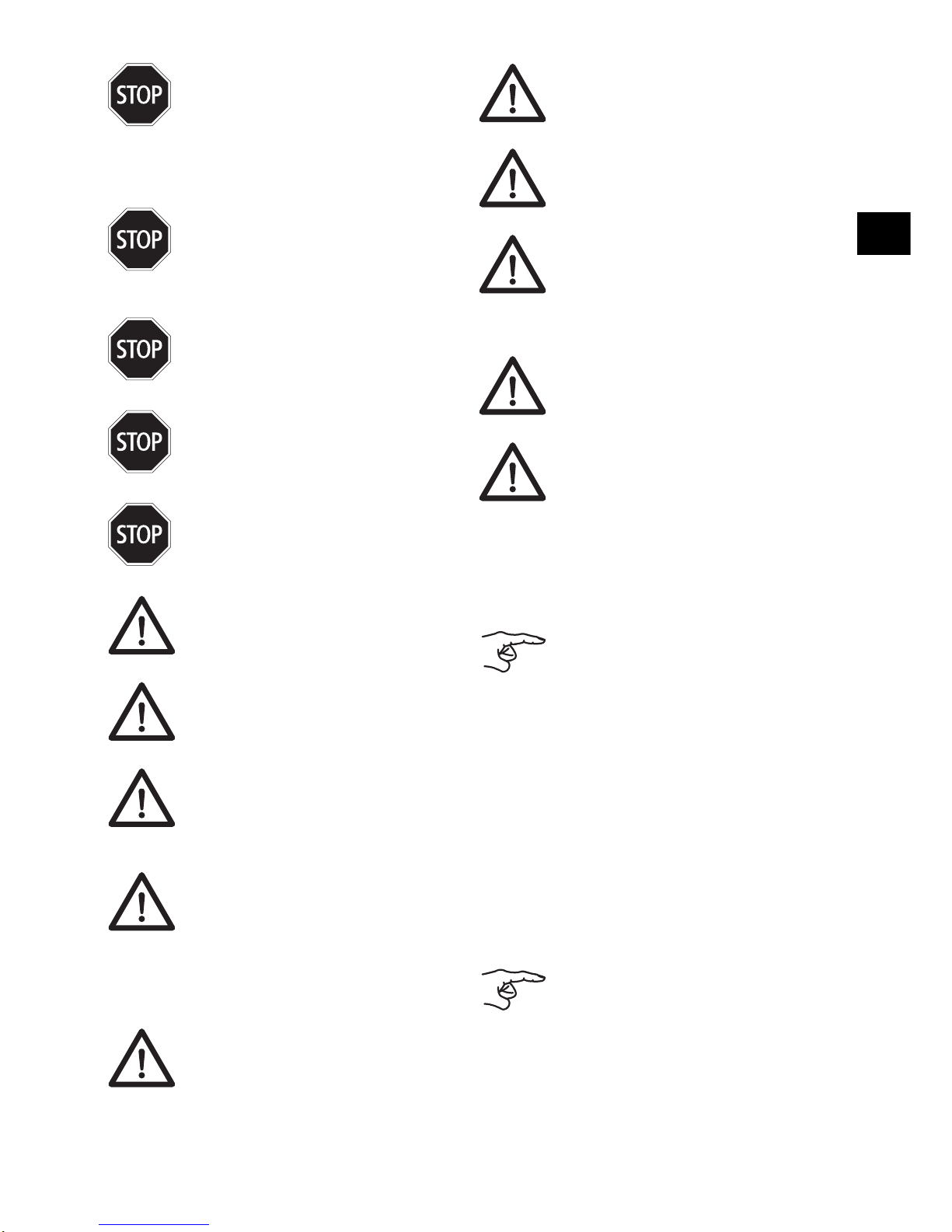

Legend:

Content

Intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Safety instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Cleaning products . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Further documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Structural layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Prior to commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Beginning work with the machine . . . . . . . . . . . . . . . . . . . . . . . 65

End of operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Service, maintenance and care. . . . . . . . . . . . . . . . . . . . . . . . . 68

Malfunctions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Technical data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Accessories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Transport. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Disposal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Machine dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Intended use

The machine is intended for commercial use (e.g. in hotels,

schools, hospitals, factories, shopping centers, offices, etc.).

Subject to the strict compliance with the instructions of use,

these machines are used for the wet cleaning of hard flooring.

These machines are exclusively designed for use in interior

zones.

Safety instructions

Due to their design and construction, TASKI machines comply

with the relevant essential health and safety requirements of

the EC directives; they therefore have the CE sign.

CAUTION!

Always read the instructions of use and

the safety instructions before using the

machine for the first time.

The instructions of use must be kept in a

safe and well accessible place so that

you can refer to them at any time.

Caution:

This sign designates important informa-

tion. Failure to follow these instructions

may result in danger to persons and/or extensive damage to property!

Attention:

This sign designates important informa-

tion. Failure to follow these instructions

may result in faults and damage to property!

Notice:

This sign designates important information

regarding the efficient use of the product.

Failure to follow these instructions may result in faults!

It includes instructions for the work steps that

you must carry out in order.

Attention:

The machine must not be used for polish-

ing, oiling, the application of wax, carpet

cleaning or dust removal. The wet cleaning of parquet and laminate flooring with

this machine is at your own risk.

t

Caution:

Changes to the machine that have not

been authorized by Diversey will lead to

the expiry of safety marks and CE conformity. Using the machine for purposes other than the intended purpose can cause

injuries to persons, and damage to the machine and the working environment. Such

cases will usually result in the termination

of any warranty and possible guarantee

claims.

Caution:

The machine may only be used by per-

sons who are adequately trained for the

use of the machine or who have provided

proof of their skills regarding the use of the

machine and who are explicitly commissioned to use the machine.

Caution:

The machine must not be used by people

with reduced physical, sensory or mental

capacities, including children or people

who lack experience or knowledge.

Children must be supervised to ensure

that they do not play with the machine.

Caution:

Do not use the machine in rooms where

explosive or highly combustible substances (e.g. gas, solvents, heating fuel, dust,

etc.) are stored or processed.

These substances could be ignited by the

electrical or mechanical components of

the machine.

Caution:

Do not use the machine for the vacuum

cleaning of poisonous, harmful, caustic or

irritating substances (e.g. dangerous dust,

etc.). The filter system does not adequately filter out these kinds of substances.

Possible impacts on the health of the user

or third persons cannot be ruled out.

Caution:

Pay attention to the local situation as well

as to third persons and children! In the vicinity of blind spots such as doors or

curves in particular, it is important to reduce speed.

Caution:

Do not transport other persons and objects

with this machine.

Page 5

61

Cleaning products

Further documents

Caution:

In case of malfunction or defect or after

collisions or toppling over, the machine

must be inspected by an authorized expert

before restarting. The same applies if the

machine was left outdoors, immersed in

water or subjected to moisture.

Caution:

The machine must be stopped immediate-

ly in case of damage to safety relevant

parts such as brush covers, main cords or

covers that enable access to live parts.

Caution:

The machine must not be stopped, parked

or stored on slopes.

Caution:

The machine must be switched off for any

work carried out on the machine.

Caution:

Do not use the machine in rooms with high

electromagnetic interference (electric

smog).

Attention:

The machine must be protected against

unauthorized use. Therefore, keep the

machine in a locked room before leaving it.

Attention:

Operate and keep the machine in a dry

and low-dust environment at temperatures

between +10 and +35 degrees only.

Attention:

Only authorized experts who are familiar

with all safety instructions relevant for this

machine are allowed to repair mechanical

or electrical machine parts.

Attention:

Only tools (brushes, pads or similar) that

are specified in these instructions of use

under accessories, or which have been

recommended by a TASKI consultant,

may be used. Any other brushes might impair the safety and functions of the machine.

Attention:

National regulations for personal protec-

tion and accident prevention as well as the

manufacturer's instructions for the use of

cleaning solutions must be consistently

observed.

Attention:

It is forbidden to plug in or unplug the main

power supply cord with wet hands!

Attention:

Make sure that the rated voltage stated on

the machine label is the same as the voltage rating of the plug socket!

Attention:

Take care not to damage the power supply

cord by rotating tools (brushes, pads or

similar), crimping, tearing or damaging the

power supply cord through heat, oil, or

sharp objects!

Attention:

In case of foam or liquid leakage from the

machine, the suction unit must be

switched off immediately.

Attention:

TASKI machines and devices are de-

signed such that health risks caused by

noise emissions or vibrations can be ruled

out according to the current state of science.

See the Technical Information on page 69.

Notice:

TASKI machines are designed in such a

way that optimal cleaning results can be

achieved if TASKI cleaning products are

used.

Other cleaning products may cause malfunctions and damage to the machine or

the environment.

Therefore, we recommend the exclusive

use of TASKI cleaning products.

Faults caused by inappropriate cleaning

products are not covered by the guarantee.

For further details, please contact your

TASKI service partner.

Notice:

The electric diagram of this machine is

provided in the spare parts list.

Please contact your customer service for

further information.

EN

Page 6

62

Structural layout

1 Handle

2 Cleaning solution pump switch (ON/OFF) (illuminat-

ed)

3 Suction unit motor switch (ON/OFF)

4 Main switch (ON/OFF)

5 Transport handle, front

6 Tank lid unlocking

7 Filter housing

8 Dosing lid

9 Tank lock

10 Fresh water tank

11 Recovery tank

12 Brush pressure regulation

13 Unlocking device for brush housing cover

14 Side bumper

15 Suction nozzle

16 Front bumper

17 Nozzle bodies

18 Transport wheels

19 Foot pedal

20 Suction hose

21 Transport handle, rear

22 Hose connection

23 Power supply cord

24 Cable hook

25 Upper winding hook

26 Pump protection filter

27 Suction channel maintenance cover

28 Sponge filter

1

2

3

4

5

6

7

8

9

10

11

12

13

14 15 17

19

20

27

26

28

21

22

23

24

25

18

16

Page 7

63

Prior to commissioning

Electrical circuit diagram

1 Distributor

2 Main switch

3 Suction switch

4 Pump switch

5 Cable loom for operating panel

6 Cable loom, upper housing

7 Pressure sensor (for pump)

8 Pump or electrical valve

9 Overheating protection for pump

10 Distributor

11 By-pass suction motor

12 Microswitch

13 Main cable loom

14 Circuit board

15 Brush motor

16 Cable loom suction unit

Notice:

Before the machine can be put into opera-

tion, you must connect the two machine

parts together electrically and screw the

handle onto the body of the machine. In

doing this, follow the assembly instructions

on page 66 of these Instructions of Use.

11

10

12

14

13

15

8

6

1

2

5

3

4

9

7

Y/G

WHITE

BLACKBLACK

BROWN

GREEN

WHITE

WHITE

WHITE

BLACK

BLACK

RED

BLUE

GREEN

RED

WHITE

BLACK

GREEN

RED

WHITE

Y/G

BLACK

BROWN

RED

11

10

12

16

16

14

13

15

8

6

1

2

5

3

4

9

7

BLACK

BROWN

Y/G

WHITE

WHITE

Y/G

Y/G

WHITE

BLACK

BLACK

RED

BLUE

GREENBROWN

RED

Y/G

220-240VAC/50-60Hz

100VAC/50-60Hz

120VAC/60Hz

WHITE WHITE

WHITE

BLACK

GREEN

EN

Page 8

64

Filling the fresh water tank

Dosing:

Dosing examples:

Pre-cleaning

Attention:

Max. permissible water temperature

60 °C/140 °F.

Diversey recommends using cold water

since hot water will adjust to the floor temperature as soon as it is in contact with the

floor. Thus there are no advantages to the

using of hot water.

Notice:

The marking will be shown by a label on

the side of the solution tank.

Attention:

Wear gloves, goggles and appropriate

(protective) working clothes when handling chemical products!

Notice:

Use chemical products recommended by

Diversey only and always observe the

product information.

Caution:

Using unsuitable products (e.g. products

containing chlorine, acids or solvents) may

cause harm to health and severe damage

to the machine.

5

4

3

MAX

WATER LEVEL

LIVELLO ACQUA

WASSER NIVEAU

NIVEAU DE L`EAU

NIVEL DE L`AGUA

Temperature

+5°C + +35°C

+41°F + +95°F

MAX

WATER LEVEL

LIVELLO ACQUA

WASSER NIVEAU

NIVEAU DE L`EAU

NIVEL DE L`AGUA

Temperature

+5°C + +35°C

+41°F + +95°F

21

Attention:

Do not use any foaming products. Note

the sticker on the front side of the tank.

Information on the packing

of the product

Tank capaci-tyProduct volume

per tank filling

1% MAX 1 x MAX

Attention:

Remove any objects (wooden, metal parts

etc.) from the cleaning surface.

The objects could be catapulted by the ro

-

tating tool, and thereby cause injuries to

people and damage to the environment.

4

3

max.

= 1% / 26ml =

1 2

Page 9

65

Beginning work with the machine

Cleaning start

Setting the brush pressure

Cleaning method

Direct working method:

Scrubbing and suction in one work step.

Indirect working method:

Applying the cleaning solution, scrubbing and suction in several work steps.

Replenishing cleaning solvent

Attention:

Always wear slip-resistant shoes and ap-

propriate working clothes when working

with this machine!

Attention:

Start familiarization with the machine by

making your first driving attempts in a free

area.

• Plug the power supply cord into the mains socket.

• Switch on the machine (key switch).

Switch lights up

• Hold the machine firmly by the handle and bring it into the working position (2) by pressing the red footpedal

(1).

The electrical brushes switch on.

• Press the suction switch (1) to switch

on the suction unit (no lamp).

• Press the water pump switch (2) to

switch the water pump on

Switch lights up

Attention:

If the red brush pressure control lamp

lights up, correct the brush height as described below.

• Adjust the brush height (brush pressure) by turning the regulator until the

green display lights up.

LED display Status indicator

Display green Brush height (brush pressure) correctly

set.

Display red Correct the brush height (brush pres-

sure). Turn the setting knob to the right for

more, and to the left for less brush pressure.

1

2

1

2

MAX

BRUSH PRESSURE

MIN

Notice:

More precise details regarding the direct

and indirect working method can be found

on the respective method sheet.

Please contact your TASKI customer consultant for further details.

Attention:

The flooring may be damaged when work-

ing without cleaning solution.

Notice:

A rattling sound of the pump indicates that

the fresh water tank is empty.

Attention:

The pump must never run dry for an ex-

tended period.

• The machine must be switched off.

• Open the tank lid.

• Fill the fresh water tank with water, see page 64.

• Add the cleaning product using the dosing cup.

• Close the tank lid.

EN

Page 10

66

End of operation

Removing and cleaning the squeegee

Empty and clean the recovery tank and fresh water tank

Empty the recovery tank and fresh water tank

• Switch off the water pump.

The cleaning solution supply is

stopped.

• Allow the suction unit to run further so that the remaining

water will be sucked out.

• Switch off the suction unit.

The suction motor is switched off.

• Switch the machine off (ON/OFF)

and pull the power supply cord out of

the mains socket.

• Lock the machine in the vertical position.

• Wind the mains cord around the cable hook.

Attention:

The machine must now be emptied and

cleaned. Switch off the machine (main

switch) and remove the plug from the

mains socket.

• Open the cover of the brush housing

by loosening the side latches.

• Turn the four yellow clips to the left to

loosen the squeegees.

• Turn the machine onto the side to remove the squeegees.

1

2

• Wash out the squeegees under run-

ning water.

Notice:

Check the condition of the suction lips be-

fore the installation.

Bristles that are too short or damaged suc-

tion lips will impair the cleaning result!

• Reinstall the squeegees into the noz-

zle body.

In doing this, note that the front and

rear squeeges are different. The po

-

sition is shown on the upper side of

the squeegees. (FRONT + REAR)

Notice:

Drain water or cleaning solution must be

disposed of in compliance with the national regulations.

Notice:

When draining the recovery tank, the reg-

ulations of the detergent supplier regarding personal protective equipment must be

observed.

• Remove the tank from the machine

by pulling on the tank unlocking device (1).

• Hold the tank (2) with the other hand

so that it does not fall out of the holder when unlocked.

• Pull the solution tank out of the hold-

er.

• Empty the soiled solution from the

tank through the opening provided on

the rear of the tank.

2

1

Page 11

67

Cleaning the recovery tank and fresh water tank

Wash out the motor protection filter

Washing out the filter housing and the float

Cleaning the sponge and pump protection filter

Cleaning / Replacing the sponge filter

Replacing pump protection filter

Cleaning / Replacing the brush roller

Replacing the brush roller

• Rinse the recovery tank and the fresh water tank thorough-

ly with clean water.

• Remove the motor protection filter

from the transparent filter protection

above the filter housing.

• Wash out the motor protection filter

under running water.

• After washing it out, wring out the

motor protection filter so that the water can flow out.

Attention:

Do not reinsert the motor protection filter

before it is completely dry.

• Remove the motor protection filter from the flter protection

before you wash out the filter housing.

• Wash out the filter housing and the

float (X), which is located on the underside of the filter housing, under

running water.

• Reinsert the dry motor protection fil-

ter.

MAX

WATER LEVEL

LIVELLO ACQUA

WASSER NIVEAU

NIVEAU DE L`EAU

NIVEL DE L`AGUA

Temperature

+5°C + +35°C

+41°F + +95°F

2

3

1

1

2

x

2

1

• Place the filter housing on the tank

and lock it into place.

• Remove the light-blue sponge filter

using pliers.

Notice:

Wash out the sponge filter monthly.

Replace the sponge filter as necessary.

• The pump protection filter should be

replaced once a year.

Attention:

Danger of injury due to sharp objects.

Wear gloves for your own protection!

Notice:

Check the brush roller for wear after every

use.

Bristles that are too short or a damaged

brush roller could lead to damage to the

floor and impair the cleaning result!

• Place the machine on its side so that

the brush holders on the side are

pointing upwards.

• Press the rotation lock (1) and turn

the brush holder (2) counterclockwise and pull it out of the housing (3)

in order to remove it.

• Take out the brush roller.

• Clean the brush roller under running

water.

2

1

3

EN

Page 12

68

Cleaning the brush housing

Installing/Replacing the brush roller

Cleaning the transport wheels

Cleaning the machine

Storing / parking the machine (not in operation)

Service, maintenance and care

The maintenance of the machine is a prerequisite for impeccable operation and a long service life.

Service intervals

TASKI machines are high-quality machines that have been

checked for safety in the factory and by authorized inspectors.

Electrical and mechanical parts are subject to wear and aging

after a longer period of use.

Service center

Please always indicate the type and number of the machine

whenever you contact us for order placing or in case of malfunctions.

The required data are provided on the nameplate of your machine. The address of your closest TASKI service partner is

provided on the last page of these instructions of use.

• Clean the brush housing with a damp

cloth.

• Reinstall the brush roller.

In order to reinstall the brush roller,

you must set the white traveller of the

roller into the white traveller in the

nozzle head. The ribs of the traveller

on the brush roller must be set into

the correct cutouts on the traveller of

the nozzle body.

• Reinsert the brush holder and turn it

clockwise until the rotation lock engages.

• Before and after every use of the machine, clean the running surfaces of

the transport wheels with a damp

cloth.

The transport wheels can become

soiled by transport over the asphalt.

Attention:

Never clean the machine with a high-pres-

sure cleaner or water jet.

Water ingress in the machine may cause

considerable damage to the mechanical or

electrical parts.

• Wipe the machine with a moist cloth.

Notice:

The machine must be switched off and the

plug must be removed from the mains

socket.

Notice:

Store the machine with the tool lifted.

Thus, the tank can dry,

and the generation of mold and unpleasant odors is prevented.

2

1

Attention:

Use original TASKI parts only; otherwise,

any warranty and liability claims will expire.

Legend:

◊ = whenever cleaning is completed, ◊◊ = every week,

◊◊◊ = every month

Activity

◊

◊◊

◊◊◊

Page

Wash out the squeegees ● 66

Clean the brush roller ● 67

Periodically check the length of the bristles ●

Replace the brush roller ● 67

Suction channel maintenance cover ● 62

Clean/replace the motor protection filter ● 67

Wash out the sponge filter ● 67

Replacing pump protection filter ● 67

Clean the machine with a moist cloth ●

Cleaning the transport wheels ● 68

• In order to maintain operational safety and readiness for

use, the machine must be serviced after 500 working hours

or at least once a year.

Notice:

In case of extraordinary use and/or insuffi-

cient maintenance, shorter intervals are

required.

Page 13

69

Malfunctions

Technical data

Accessories

Malfunction Possible causes Troubleshooting Page

Machine without function

No power supply

• Insert the plug into the mains sock-

et.

Machine is switched off • Switch on the main switch 62

Power supply cord defect • Contact your service partner

Motor does not turn • Contact your service partner

Main switch defect • Contact your service partner

Brush roller does not turn

Machine not in the working position

• Bring the machine into the working

position

65

Motor turns, brush does not

• Drive defective

• Contact your service partner

Poor suction performance

Motor protection filter soiled

• Clean or replace motor protection

filter

67

Suction hose not connected • Check the suction hose

Machine 150E

Working width 34 cm

Suction nozzle width 36 cm

Dimensions (LxWxH) 43 x 38 x 112 cm

Maximum weight of operational machine 12 kg

Rated voltage 220-240V~ 120V 100-110V~ 100V AC

Rated power, nominal 1100 W

Frequency 50-60 60 60 50 Hz

Power supply cord length 10 m

Fresh water tank, nominal +/- 5% 2.6 l

Values according to IEC 60335-2-72

Sound pressure level LpA 74 dB(A)

Uncertainty KpA 3 dB(A)

Vibration < 2.5 m/s2

Uncertainty K 0.25 m/s2

Splash water guard IPX4

Protection class II

No. Item 150E

7516236 Brush roller medium black X

7516237 Brush roller hard red X

7516546 Squeegee set X

EN

Page 14

70

Transport

Disposal

Machine dimensions

The dimensions are in centimeters!

Notice:

Transport the machine in upright position.

Notice:

Make sure that the machine is lashed and

secured in the transport vehicle.

Notice:

After withdrawal from service, the machine

and accessory parts must be adequately

disposed of in compliance with the national regulations. Please contact your Diversey service partner for help.

112

43

38

Loading...

Loading...