swingo 750B/1250B Power

V008 / 12088-69 0702

I25 I24 I23 I22 I21 I20 I19 I18 I17 I16 I15 I14 I13 tr sl pt no it hr fr fi es en de da

da...2

de...12

en...22

es...32

fi.....42

fr.....52

hr....62

it.....71

no...81

pt....91

sl ....101

tr.....111

*12088-69*

22

Instructions of use

Symbols

Intended use of machinery

The scrubber dryer is used to clean hard floor surfaces according to these

instructions of use.

The machine is suitable for floor cleaning applications in industrial and

commercial areas such as hotels, schools, hospitals, factories, shopping

centres and offices.

Content

Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

EU Declaration of Conformity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Preparation for operation/Operation . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Beginning work . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

End of operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Service, maintenance and care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Squeegee settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Malfunctions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Dimensions of the machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Safety instructions

Due to their design and construction, TASKI machines comply with health and

safety requirements of the EC guidelines and therefore carry the CE sign.

Important! Switch the machine off when you:

• e.g. carry out cleaning or maintenance work, or convert the machine to

another function

• store it in a suitable room to avoid any unauthorised use of the unit

• leave it standing without supervision

To do this, remove the keyswitch, pull out the battery disconnection socket and

prevent the machine from rolling away (e.g. by placing a wedge under it).

Store the machine in a dry, dust-free room with a corrosion-free atmosphere.

The temperature must not fall below +10 °C or exceed +35 °C. Low

temperatures, damp and dust can significantly reduce the service life of the

electrical components.

ATTENTION!

Before first start-up, it is essential that you

read the instructions of use and the safety

notes carefully.

Keep the instructions of use in an easily

accessible place so that they can be consulted

at any time.

Non-observance of this information can endanger people and / or

cause servere damage!

Non-observance of this information can lead to malfunctions and

property damage!

Important information about correct use. Nonobservance of this

information can lead to malfunctions!

Action points.

This machine may only be used by persons who have been

properly trained to do so!

Do not use the machine in rooms where explosive and flammable

substances (e.g. petrol, thinners, heating oil, solvents, etc.) are

stored or processed. The electrical or mechanical component s of

the machine could lead to ignition of these materials.

Do not use this machine to vacuum toxic, poisonous, caustic or

irritating substances (e.g. acids, alkalis, hazardous dusts, etc.).

The filter system will not adequately retain these kinds of

materials. A possible impairment of the health of the user and of

third parties cannot be excluded.

While operating the machine, take note of the surrounding area

and pay particular attention to third parties and children!

Neither persons or objects may be transported with the machine!

In case of damage to components that are relevant to safety, such

as tool covers, battery disconnection socket, power supply cord,

battery charger or covers provide access to current-carrying

parts, the operation of the machine must be stopped immediately!

STOP

STOP

•

STOP

STOP

STOP

STOP

STOP

STOP

STOP

STOP

STOP

STOP

STOP

STOP

Regularly check the power supply cord for tearing or aging, and

do not put the machine into operation if it is not in a safe and

suitable condition!

Caution:

Repairs to mechanical or electrical parts of the machine must only

be undertaken by JohnsonDiversey authorised customer service

workshops or experts who are experienced in all relevant safety

regulations.

Minimum requirements on the H05VV-F2x1 or H05VV-F2x1.5

power cord.

Caution:

This machine is only intended for use in dry areas, and must not

be used or stored in the open air or under damp conditions.

Caution:

Pay attention to the accident prevention regulations!

Caution:

Switch off the suction unit immediately if foam or liquid escape

from the machine!

See page 29 for further procedure .

Caution:

Only use tools which are specified in the instructions of use under

accessories and which the TASKI-technical specialist

recommends (Page 30), as the use of other tools could impair

safety.

Caution:

Personal safety is covered by appropriate national regulations!

Caution:

This machine may not be operated without batteries!

Caution:

The batteries may only be operated with a battery charger that

has been tested to the latest state-of-the-art according to

EN 60335-2-29!

(only Typ:CO750.1/CO1250.1/CO1250.2)

Only use the machine on level floors or on gradients of 2% or less.

This symbol on the machine indicates that it is not suitable for use

on surfaces with greater gradients.

The tank cap must be closed when moving or driving the machine.

STOP

STOP

2%

23

I25 I24 I23 I22 I21 I20 I19 I18 I17 I16 I15 I14 I13 tr sl pt no it hr fr fi es en de da

EU Declaration of Conformity

We

JohnsonDiversey Switzerland

CH-9542 Münchwilen

hereby declare that the product described below both in this basic design and

construction and in the version marketed by us conforms to the relevant safetyand health-related requirements of the appropriate EU Directive.

This declaration shall cease to be valid if modifications are made to the product

without our approval.

Applicable EU Directives:

Machinery Directive (98/37/EEC) in version 98/79/EEC

EMC (Electro Magnetic Compatibility) (89/336/EEC) in version 98/13/EEC

Harmonised standards applied:

EN 60 335-1/EN 60 335-1-A1/EN 60 335-1-A2/EN 60 335-1-A11/

EN 60 335-1-A12/EN 60 335-1-A13/EN 60 335-1-A14/EN 60 335-1-A15/

EN 60 335-1-A16/EN 60 335-2-72/EN 60 335-2-72-A1/EN 55014-1/

EN 61 000-4-2/EN 61 000-4-2-A1/EN 61 000-4-2-A2/EN 61 000-4-3/

EN 61 000-4-3-A1/EN 61 000-4-3-A2

It is ensured through internal measures that series-production units conf orm at

all times to the requirements of current EU Directives and relevant standards

The signatories act on behalf of company management and with full power of

attorney.

Overview

1 Speed control

2 Squeegee lowering device

3 Emptying hose for solution tank (blue cap)

4 Emptying hose for recovery tank (red cap)

5 Disconnector charger jack (coded)

6 Pedal brush unit (optional)

7 Squeegee settings

8 Squeegee

9 Hour counter (optional)

10 Lock battery compartment (optional)

11 Tools (brush, pad drive, etc.)

12 Brush unit

13 Brush unit button (optional)

14 Solution dosing control

15 Vacuum button

16 Keyswitch

17 Service indicator

18 Solution dosing control

19 Battery charging (Power plug connected)

20 Failure of battery or charger indicator

21 Battery fully charged

22 Battery indicator

23 Solution tank

24 Dosing aid

25 Tank lid catch

26 Filling level (max.)

27 Tool ejection handle (1250B only)

28 Recovery tank

29 Solution tank filter

30 Dirt sieve

31 Float (overfilling protection for recovery tank)

32 Suction filter

Product: scrubber dryer

Name: swingo 750B Power/ swingo 1250B Power

Model: CO750.1 (24Vdc/900W)

CO750.1X (230-240V~/50-60Hz/900W)

CO1250.1,CO1250.2 (24Vdc/1000W)

CO1250.1X,CO1250.2X (24Vdc/1000W)

Dipl. Ing. (FH) D.Windmeisser

Dipl. Ing. (FH) P. König

2

6

7891011

12

14

4

3

13

15

16

1718192021221

5

232425

26

27 28 29

303132

max.60˚C

max.140˚F

MAX

3/4

1/2

1/4

24

Preparation for operation/Operation

Batteries

Safety measures when working with batteries:

Battery connection diagram

Charging procedure (traction block batteries with integrated charging

unit)

After completing the charging and with immediate use

Charging procedure (traction block batteries with external charging unit)

Charging procedure (wet batteries with external charging unit)

• Protective goggles must be worn when working on the

batteries.

• Do not subject batteries to an open flame or heat as there is a

danger of explosion from the electolytic gas present in the

cells!

• No smoking!

• Danger of chemical burns!

Caution:

The battery must always be clean and dry. Do not place any

metallic objects on the battery.

The integrated charging unit is only suitable for maintenance-free

gel traction block batteries.

Caution:

Batteries may only be installed or dismounted by customer

service personnel or specialists approved by JohnsonDiversey

who are aware of all the safety regulations that apply here!

• Check that the machine has been switched off with the keyswitch.

• Disconnect the battery from the machine using the battery disconnection

socket.

• Plug the power supply cord into the mains socket.

The yellow indicator lights up permanently until

approx. 90% of the battery capacity has been

reached. After that, the indicator blinks until the

battery is fully charged.

-+-

+

-+-+-

+

-+-+-+-

+

Power

board

Power

board

+

-

+

-

+

-

+

-

SWINGO 1250B

Onboard

charger

Onboard

charger

Power

board

Power

board

Onboard

charger

Onboard

charger

-+-

+

-

+

-+-

+

+

-

+

-

+

-

+

-

SWINGO 750B

When the charging process is complete, the

green indicator lights up.

• Leave the power supply cord connected to the mains until you use the

machine again. The on-board charger unit automatically monitors and

charges the batteries. The energy consumption in the mode is limited to a

few milliwatts.

If a fault occurs during the charging process as

the result of a defect in the charging unit, an

interruption of a cable or a defective battery cell ,

the red indicator will light up.

• Unplug the connection to the mains socket.

• Connect the battery to the machine with the battery disconnection socket.

• Check that the machine has been switched off with the keyswitch.

• Disconnect the battery from the machine using the battery disconnection

socket.

• Connect the battery disconnection socket to the external battery charging

unit (pay attention to the voltage from the mains supply socket).

Caution:

Follow the instructions of use for your battery charger!

Caution:

If the machine is assembled with a wet battery kit (optional) the

machine must be used with wet batt e ri e s on l y!

Wet batteries must not be charged with the internal charger!

Battery compartment must be open during charging.

Wet batteries must be charged in ventilated rooms only!

The gas given off could be ignited!

• Switch the machine off using the keyswitch and remove the key.

• Disconnect the battery from the machine using the battery disconnection

socket.

• Check that the tanks are empty.

• Unlock the battery compartment (with a screw

driver) and in a sufficiently large area, lift the

tank until it locates into its self support position.

Tank position for charging.

• Connect the battery disconnection socket to the external battery charging

unit (pay attention to the voltage from the mains supply socket).

Caution:

Follow the instructions of use for your battery charger!

• Turn on the battery charger.

25

I25 I24 I23 I22 I21 I20 I19 I18 I17 I16 I15 I14 I13 tr sl pt no it hr fr fi es en de da

Maintenance of batteries (only wet batteries)

Please follow the instructions of use for your battery charger!

Opening battery compartment for maintenance

Closing battery compartment

After end of maintenance

Preparing to drive

Attaching tools

Check:

• that the brushes are not below the red marking and that the bristle length is

no less than 1 cm.

• the pad for wear before using.

Brush unit button

Pedal brush unit

Caution:

When maintenance of batteries takes place, they must be

disconnected from the machine!

• Check that the machine has been switched off with the keyswitch.

• Disconnect the battery from the machine using the battery disconnection

socket.

• Lower the squeegee.

• Check that the tanks are empty.

• Unlock the battery compartment, by pushing a

screw driver or a similar tool into the allowed

opening.

• Lift the tank until it locates into its self support

position.

Tank position before it is altered for battery

maintenance.

• Stand behind the machine.

• Carefully open battery compartment until the

machine handle rests on the floor.

Tank position for battery maintenance.

• Stand behind the machine and lift the tank until

it rests on the tank self support.

• Hold the tank and press the tank support

inwards.

Now lower the tank until it locates into place.

• Connect the battery to the machine with the bat tery disconnection socket.

• Raise the squeegee.

• Switch on the keyswitch.

The indicators light up briefly.

The battery indicator displays that the machine is

ready for operation

(on malfunction see page 29).

• Hold the handle and adjust to a height which is

comfortable to work with.

The speed controls can be moved up and down

by applying light pressure.

By lightly pressing the speed control in the

direction of drive, the machine is set in motion.

Letting the speed control go stops the machine.

• Switch the machine off using the keyswitch and remove the key.

Working with worn out, damaged and or wrong tools, could result

in possible damage to floors or their protective layers.

• Position the tool below the brush unit.

• Switch on the keyswitch.

The indicators light up briefly.

• Press the brush unit button.

While being lowered, the unit begins to turn

slowly. This centres and locks the tool into

place.

The indicators light up.

• Unlatch the foot lever and slowly lower the tool.

While being lowered, the unit begins to turn

slowly. This centres and locks the tool into

place.

The indicators light up.

Moving the machine forwards and backwards slightly as the brush

unit lowers, makes coupling easier.

26

Attach squeegee

Filling water

Dosage:

Only use chemical products recommended by the manufacturer.

The dosing aid is marked for a 0.5% cleaning solution.

The level indicators on the tank correspond to those on the dosing aid. The

machine type is noted on the dosing aid!

Dosing examples (The concentration is product dependent)

Beginning work

Cleaning method

Direct method:

Scrubbing and vacuuming in one pass.

Indirect working method:

Apply the cleaning solution (only scrubbing), afterwards scrubbing and

vacuuming.

The cleaning methods are described in detail in the ”Method Card”. You can

obtain this from your TASKI partner.

Refilling the solution tank

The rattling noise from the pump indicates that the solution tank is empty.

• Switch the machine off.

• Raise the squeegee and loosen the fixing

screws on the squeegee.

• Assemble the squeegee and tighten the fixation

knobs.

• Attach the suction hose to the squeegee.

Caution:

Maximum permissible water temperature 60 °C/140 °F.

• Switch the machine off using the keyswitch and remove the key.

• Reach into the opening between the tank lid and

the tank.

Palm facing upwards.

• Open the lid until the self support locates on the tank wall.

• Remove the dosing aid.

• Fill water into the solution tank.

Maximum permissible filling level (Page 23).

Caution:

Wear protective gloves, goggles and the corresponding

(protective) work clothing when handling chemical products!

Caution:

Using other chemicals (e.g. chemicals containing solvents,

chlorine, hydrochloric acid and hydrofluoric acid) can damage or

destroy the machine.

Dosage Tank capacity Dosing aid

0,5% 1/2 1 x 1/2

MAX 1 x MAX

1% 1/2 1 x MAX (2 x 1/2)

MAX 2 x MAX

1250

750

max.60˚C

max.140˚F

• Dosing aid application

• Add the product measured with the dosing aid to the water in the solution

tank.

• Lift the tank lid slightly.

• Gently press the self support inwards.

• Close the lid.

• By exerting slight pressure onto the front part of the lid, you can cl ick it in to

the latch.

Caution:

Always wear non-slip shoes and appropriate work clothing while

working with this machine!

• Lower the squeegee.

• Switch on the keyswitch.

The indicators light up briefly.

• Lower the brush unit using either the brush unit button or brush unit pedal,

see Page 25.

• First press the solution dosing control button,

and then the vacuum on.

The indicators light up briefly.

• Choose the volume of solution (+/- button for

volume control)..

The chosen setting is displayed with green

lights.

• By gently pressing the speed control in the

direction of drive, the machine is set in to

motion.

The tools start to turn and the solution is fed

through the centre.

Caution:

Do not clean without solution, as it could cause floor damage.

• Stop cleaning.

• Refill the tank, see Page 26.

27

I25 I24 I23 I22 I21 I20 I19 I18 I17 I16 I15 I14 I13 tr sl pt no it hr fr fi es en de da

End of operation

Brush unit button (optional):

Pedal brush unit (optional):

Drain the recovery tank / solution tank

The disposal of the dirty water or the cleaning solution must be carried out in

accordance with the appropriate national regulations.

Clean the recovery tank / solution tank

Clean solution tank filter

Cleaning the tools

Brush unit button (optional):

Pedal brush unit (optional):

Swingo 1250B model:

Swingo 750B model:

Removing and cleaning the squeegee

• Stop the flow of solution.

• Drive a few metres so that the tools rotate further for a short time. You will

avoid dripping by doing this.

Very important when using contact pads!

• Press the brush unit button to raise the tool.

• Press down the pedal and lock it in place to

raise the tool.

• Drive on a few metres further in order to pick up the remaining dirty water.

• Raise the squeegee.

Allow the suction unit to continue running until

the rest of the dirty water has been sucke d in to

the hose.

• Switch off the suction unit first, and then the

keyswitch.

Always drain and clean the recovery tank every time you use the

machine.

If the dirty water is allowed to stand, unpleasant smells and

deposition of the dirt will take place after a few hours.

• Switch the machine off.

• Remove the hose from its holder.

Open the red or blue cap situated near the handle and lower t he

end of the hose slowly to drain the solution out.

• Switch the machine off.

• Open the lid until the self support locates on the tank wall.

• Remove the coarse dirt sieve (yellow), empty and clean it.

• Thoroughly rinse out the recovery tank with clean water.

• Then thoroughly rinse out the solution tank with clean water.

• Check the float is functioning correctly and that the suction filter (yellow) is

clean.

In case of damage or soiling of the float and suction filter, please refer to

Page 28.

• After draining and cleaning, screw the red and b lue caps on again, and hang

the hoses from their holders again.

Caution:

Clogged filters reduce the flow of the cleaning solution. As a

consequence you may damage the floor coating.

• Switch the machine off.

• Once the solution tank has been drained, screw

the yellow cap from the solution tank filter and

pull it away from its holder.

• Rinse the filter under running water.

If necessary, the filter should be descaled with a 10% TASKI calcacid

solution.

The filter is lower than the tank outflow. A residual amount of

solution will flow out once the filter cap has been unscrewed.

• Refit the solution filter.

• Switch on the keyswitch.

The indicators light up briefly.

• Press the brush unit button to raise the tool.

• Switch the machine off using the keyswitch and remove the key.

• Switch the machine off using the keyswitch and remove the key.

• Press down the pedal and lock it in place to

raise the tool.

• Press the tool ejection handle briefly but firmly

with your foot.

• Clean the tools with water.

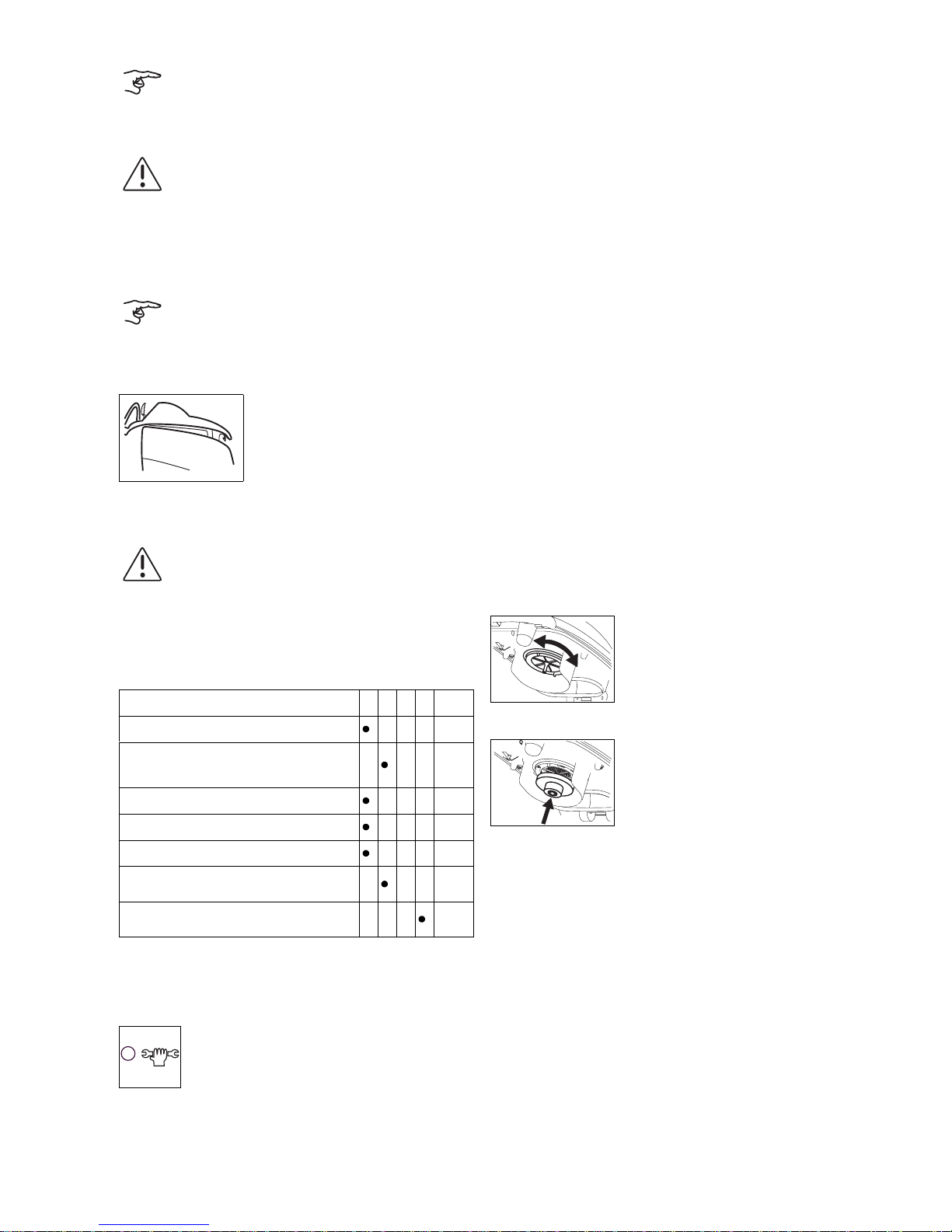

• Turn the tool anticlockwise away from the tool

coupling using your foot.

• Clean the tools with water.

• Switch the machine off.

• Pull the suction hose away from the squeegee support.

• Raise the squeegee and loosen the fixing

screws on the squeegee.

• Assemble the squeegee and tighten the fixation

screws.

• Clean the squeegee with water using a brush.

28

Cleaning the machine

Storage / parking of machine (machine is idle)

Store the machine with the tank cap slightly open, by:

• lifting the tank lid and turning the dosing aid upsid e down.

• then rest the tank lid on the dosing aid.

Service, maintenance and care

The machine's maintenance is a pre-condition for trouble-free running and a

long life.

Service intervals

TASKI machines are build to the highest quality standards . This is supported

by internationally recognised quality control procedures. Electrical and

mechanical parts are subject to wear or aging if used for long periods of time.

Service centre

Should you contact us due to a malfunction or for placing an order, please

always state the type, description and the serial number of your machine.

You can find this information on the name plate of your machine, and the

address of your nearest TASKI partner can be found on the last page of this

manual.

Blades replacement

Blade on the inner radius.

Blade on the outer radius

Cleaning or replacing the float (Indication for full recovery tank)

Disassembly:

Assembly:

Optimal result can only be obtained with clean and intact blades!

Caution:

Never clean the machine with high water pressure or a water

hose.

The ingress of water into the machine might cause considerable

damage to mechanical or electrical parts.

• Wipe down the machine with a damp cloth.

We recommend that you disconnect the battery from the machine

using the battery disconnection socket when storing / parking the

machine and when charging the battery.

The dosing aid holds the tank lid slightly open,

allowing the tank to dry out. As a result, the

formation of mould and unpleasant smells can

be reduced.

Caution:

Only TASKI branded spare parts must be used, otherwise

warranties and liabilities will be omitted!

Symbols:

◊ = After use, ◊◊ = Every week, ◊◊◊ = Every month,

⊗ = Service light

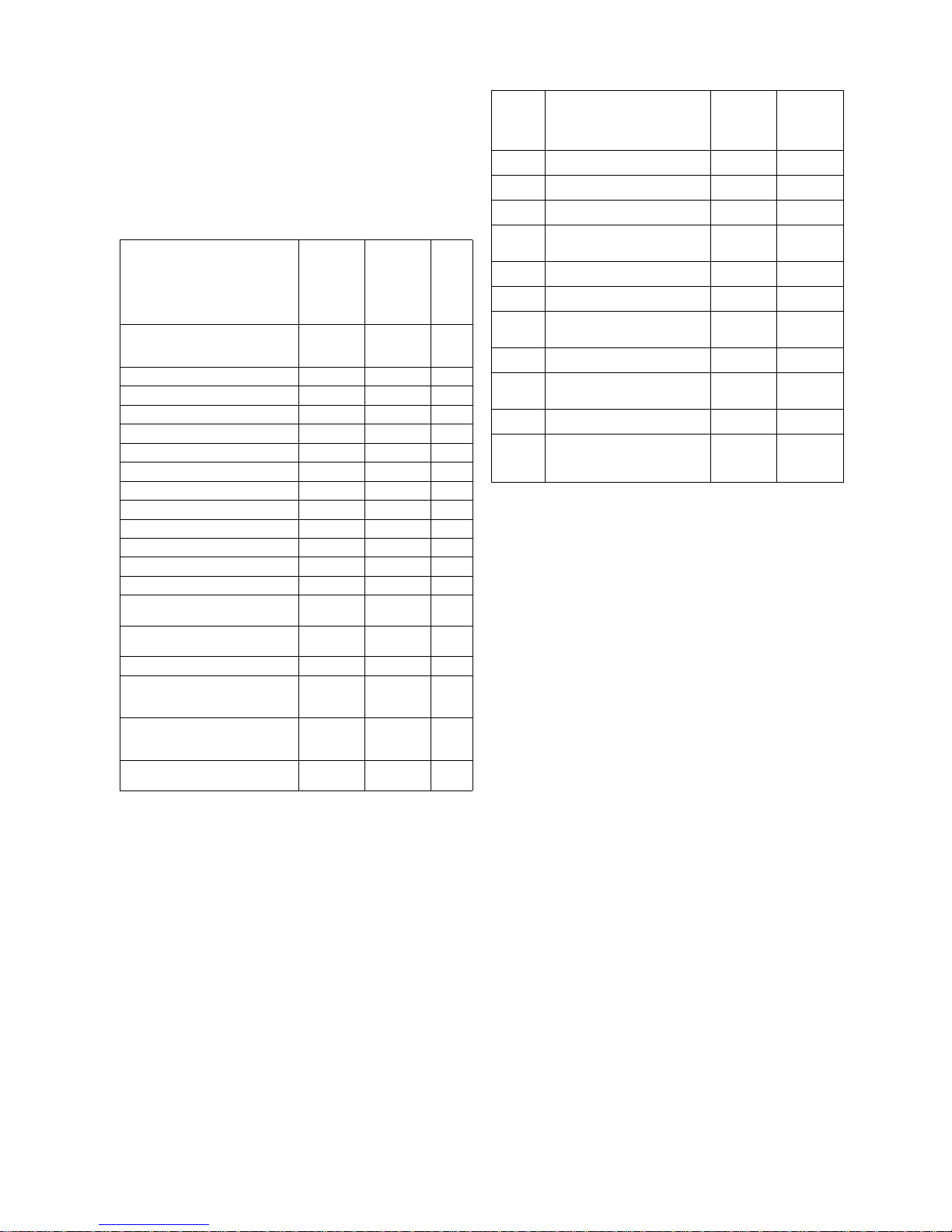

Activity ◊◊◊◊◊◊⊗ page

Recharge batteries

24

Refill distilled water (wet batteries). Please follow

the manufacturers instructions of use booklet for

these batteries!

Clean all parts marked yellow

Drain and clean the tanks 27

Wipe down the machine with a damp cloth

28

Clean the tank lid seal, check for cracks and replace if necessary

Maintenance programs by TASKI service made by

TASKI technician

• In order to ensure operational reliability and

availability for use, the service must be carried

out when the service indicatior lights up (factory

setting 450 working hours) or at least once a

year.

Under rough or extreme working conditions and/or insufficient maintenan ce,

shorter periods are necessary.

• Place the clean squeegee unit with the outer radius face down on a solid

surface e.g. table, floor.

• Press one hand onto the squeegee body by the hose connector.

• Grasp the blade with your thumb and forefinger in the middle of the arch and

pull strongly until the metal band clicks open and the blade is released from

the squeegee body.

• Release the metal strap and pull the blade off the squeegee body.

• Clean squeegee (body, metal straps and blades) with a brush.

• Mount the "rotated" or replaced blade onto the squeegee body.

• Lock the metal strap (Check position of mounting slots) into place and press

the centre of it until it ”clicks” into place and presses the blade onto the

squeegee body (Risk of injury).

• Turn the squeegee upside down by placing it on its suct ion hose co nnector

and the bumper wheels.

• Realease the metal band by loosening the fixation screw (torx 25).

• Release the metal band and pull the blade off the squeegee body.

• Clean squeegee (body, metal straps and blades) with a brush.

• Mount the "rotated" or replaced blade onto the squeegee body.

• Hook the metal strap into place (Check position of mounting slots) and fix it

with the screwdriver until the blade is pressed onto the squeegee body.

• The shape of the blades allow them to be used on all sides before need ing

replacement.

• Switch the machine off using the keyswitch and remove the key.

• Hold the float and pull it over the lower stopper.

• Clean it with water using a brush (let it dry out well).

• Brush the yellow suction filter with a soft brush

or remove the fluff with a cloth.

The yellow suction filter can be easily removed

(quick-fit seal).

• Hold the float at its small diameter. Push it over

the lower stopper until it clicks into place.

•Check:

-that the float easily moves up and down.

-that the float completely covers (seals) the suction filter.

29

I25 I24 I23 I22 I21 I20 I19 I18 I17 I16 I15 I14 I13 tr sl pt no it hr fr fi es en de da

Squeegee settings

If you experience an uneven suction result, the settings of the suction unit

should be corrected. Proceed as follows:

Before carrying out the adjustment, check that:

• the blades are not damaged (replace).

• the suction unit is not damaged.

Height setting (Fig. A)

• First check the distance between the floor and the running or support

wheels.

The distance between running wheels number 1 and 2 and the floor must be

between 1 mm and 3 mm in each case (with the blades standing vertically).

• Switch the machine off using the keyswitch and then lower the sq ueegee.

• To correct, loosen the hexagonal nuts number 1 and 2, and then adjust the

height by turning the Allen screw. Then firmly re-tight en the hexagonal nuts

Number 1 and 2.

• Check the result while cleaning (see illustration below) and go to "Angle of

Inclination" (Fig. B) if the result is unsatisfactory.

Angle of inclination(Fig. B)

• Switch the machine off.

• Lower the squeegee and move the machine forward by a few centimetres

so that the blades can adopt their working position.

• To correct, loosen Allen screw number 3 and adjust the angle of inclination

by turning Allen screw number 4.

Note: Carry out the correction with gradual adjustments!

Firmly retighten Allen screw number 3 afte r the correction has been made. Then

move the machine forward by a few centimetres and check the setting of the

scraper edge that has been achieved. Repeat this procedure until the correct

inclination is obtained.

Malfunctions

Transport

• Disconnect the battery from the machine using the battery disconnection

mechanism.

Transport the machine in an upright position and disconnect/remove the

batteries for transportation.

Make sure that the machine is securely fastened within the transportation

vehicle.

Refer to Page 30 for the dimensions and weights.

A correct angle has been achieved when the tip

of the rear blade (x) is distributed over the

complete width of the suction unit.

B

A

x

x

4

3

1

2

4

3

Malfunction Possible causes Troubleshooting page

Machine does not

run

Maschine switched off

• Switch on the

keyswitch.

23

• Connect the battery to

the machine with the

battery disconnection

socket.

23

Battery/mains

unit malfunction

(display on

control panel)

Discharged batteries

• Recharge batteries

24

Batteries/battery

charger defective

• Call for technical

assistence

Batteries not

sufficiently

charged

Power cord not

plugged in or

defective

• Plug in the power cord

• Call for technical

assistence

Batteries or battery

charging unit

defective

• Call for technical

assistence

Brush does not

turn

Motor runs but not

tool

• Call for technical

assistence

Poor vacuum

performance

Floor remains

wet

Soiled solution

not picked up

Float closes the air

inlet at the vacuum

motor (overfill

protection recovery

tank)

• Check the recovery

tank is not full

27

• Check that the float is

functioning correctly.

28

Squeegee not on the

floor

• Lower the squeegee.

26

Suction hose not

connected

• Connect suction hose

26

Check the seal on the

tank lid for cracks/dirt

• Clean the seal, or

replace if defective

Vacuum air filter

blocked

• Remove the blockage

Hose or nozzle

blocked (e.g. by

pieces of wood or

residual material)

• Remove the blockage

The blades do not

adjust well to the floor

consistancy

• Clean the squeegee

• Change/turn the

blades

28

• Check that the

squeegee suspension

is functioning correctly

• Squeegee adjustment 29

Dirt sieve full (yellow)

• Remove the dirt sieve

• Knock out the coarse

dirt from the sieve and

rinse it under running

water.

27

Vacuum switched

off

Recovery tank full

• Empty the recovery

tank

27

Insufficient

outflow of

cleaning solution

Solution tank empty

• Fill the solution tank

26

Solution tank filter

blocked

• Clean solution tank

filter

27

Foam or liquid

leaking from the

machine

Float malfunction

• Turn off the suction

aggregate

23

• Check that the float is

functioning correctly.

28

30

Disposal

When it has reached the end of its operational life, the machine and its

accessories must be disposed of according to the national regulations. Your

TASKI partner can support you with proper disposal upon notification.

Batteries

The batteries must be removed from the machine before being disposed of

properly.

Used batteries must be disposed of in an environmentally appropriate way

according to EU guidelines 91/157/EEC

Technical data

Accessories

Machine swingo

1250

swingo

750

type CO1250.1/

CO1250.2/

CO1250.1X/

CO1250.2X

CO750.1/

CO750.1X

Theoretical performance area

operation width x drive speed (4,5) x

1000

2475 1935 m2/h

Working speed 4.5 4.5 km/h

Working width 55 43 cm

Squeegee width 79 68 cm

Solution tank nominal 52 33 l

Recovery tank 50 30 l

Machine weight for operation 240 155 kg

Rated voltage 24V 24V dc

Tools 2 x 28 1 x 43 cm

Brush rpm 195 165 min-1

Brush pressure 46 35 kg

Dimensions (L x W x H) 135x77x119 112x68x116 cm

Rated power 1000 900 W

Assessed sound level LPA according

to EN 60704-1

58 58 dB(A)

The assessed effective acceleration

value according to ISO 5349

<0.5 <0.5 m /s2

Splash water protection IPX3 IPX3

Electrical protection class (without

battery charger) only model type:

CO1250.1/CO1250.2

III -

Electrical protection class (without

battery charger) only model type:

CO750.1

-III

Electrical protection class (with

battery charger)

II II

Nr. Article CO750.1/

CO750.1X

CO1250.1/

CO1250.2/

CO1250.1X/

CO1250.2X

7510829 Driving disc Instalok 43cm 1X

8504750 Scrubbing brush 43cm nylon 1X

8504780 Scrubbing brush abrasive 43cm 1X

8504800 Scrubbing brush for washed

concrete 43cm

1X

7510634 Driving disc Instalok 28cm 2X

7510631 Scrubbing brush 28cm nylon 2X

7510632 Scrubbing brush for washed

concrete 28cm

2X

7510633 Scrubbing brush abrasive 28cm 2X

8502830 Filling hose with universal water

coupling

XX

Wet battery set X X

Different pads

(Polyester brown, blue, red, and

contact pad)

XX

31

I25 I24 I23 I22 I21 I20 I19 I18 I17 I16 I15 I14 I13 tr sl pt no it hr fr fi es en de da

Dimensions of the machine

All dimensions in centimetres!

swingo 1250

swingo 750

119

77

58

135

116

68

46

112

AT JohnsonDiversey

Austria Trading GmbH

Guglgasse 7-9

1030 Wien

Tel (43) 1 605 57 0

Fax (43) 1 605 57 1908

BE JohnsonDiversey

Haachtsesteenweg 672

1910 Kampenhout

Tel (32) 16 617 802

Fax (32) 16 605 395

CH JohnsonDiversey

Eschlikonerstrasse

9542 Münchwilen

Tel (41) 71 969 27 27

Fax (41) 71 969 22 53

CZ JohnsonDiversey

Ceska republika, s.r.o

K Hájum 2

155 00 Praha 5 - Stodulky

Tel (420) 296 357 460

Fax (420) 296 357 112

DE JohnsonDiversey

Deutschland

GmbH & Co. OHG

Mallaustrasse 50-56

68219 Mannheim

Tel (49) 621 875 73 73

Fax (49) 621 875 73 11

DK JohnsonDiversey

10, Teglbuen

2990 Nivaa

Tel (45) 70 10 66 11

Fax (45) 70 10 66 10

ES JohnsonDiversey S.A.

C/Orense 4, 5 planta

28020 Madrid

Tel (34) 91 394 01 75

Fax (34) 91 394 01 51

FI JohnsonDiversey

Valuraudankuja 3

00700 Helsinki

Tel (358) 20 747 42 00

Fax (358) 20 747 42 01

FR JohnsonDiversey

(France) SAS.

9/11, avenue du Val de

Fontenay

94133 Fontenay sous Bois

Cédex

Tel (33) 1 45 14 76 76

Fax (33) 1 45 14 77 99

GB JohnsonDiversey UK

Limited

Weston Favell Centre

NN3 8PD Northampton

Tel (44) 1604 405 311

Fax (44) 1604 783 547

GR JohnsonDiversey

5 Himaras St

15125 Marousi

Tel (30) 210 638 59 00

Fax (30) 210 638 59 01

HU JohnsonDiversey Mo. kft.

Puskás Tivadar u. 6.

2040 Budaörs

Tel (36) 23 509 100

Fax (36) 23 509 101

IE JohnsonDiversey Ltd.

Ballyfermot office

Westlink industrial estate

Kylemore road

Dublin 10

Tel (353) 1 626 11 82

Fax (353) 1 626 20 13

IT JohnsonDiversey S.p.A.

Via Meucci 40

20128 Milano

Tel (39) 02 25 80 32 33

Fax (39) 02 25 92 255

MT Forestals (Appliances) Ltd.

The Strand

SLM 07 Sliema

Tel (356) 21 344 700-7

Fax (356) 21 344 709

NL JohnsonDiversey B.V.

Maarssenbroeksedijk 2

P.O. Box: 40441

3504 AE Utrecht

Tel (31) 30 247 69 11

Fax (31) 30 247 63 17

NO Lileborg Storforbrukere

Postbooks 4236 - Nydalen

0401 Oslo

Tel (47) 22 89 50 00

Fax (47) 22 89 50 80

PL JohnsonDiversey Polska

Sp. z.o.o.

Al. St. Zjednoczonych 61A

04-028 Warsaw

Tel (48) 22 516 30 00

Fax (48) 22 516 30 01

PT JohnsonDiversey

Z. Ind. Abrunheira

2714-505 Sintra

Tel (351) 2 191 57 000

Fax (351) 2 192 50 615

RO JohnsonDiversey Romania

s.r.l.

Baneasa Business Center,

Etaj 5

Sos. Bucuresti - Ploiesti 17-21

Sector 1, Bucuresti

Tel (40) 21 233 3894

Fax (40) 21 233 3896

RU JohnsonDiversey

Zvenigorodskaya 2-aya ul.,

13, bld. 15

123022 Moscow

Tel (7) 095 970 17 97

Fax (7) 095 970 17 98

SE JohnsonDiversey AB

Liljeholmsvägen 18

Box 47313

10074 Stockholm

Tel (46) 877 99 300

Fax (46) 877 99 399

SK JohnsonDiversey

Slovensko s.r.o

Trnavska cesta 33

831 04 Bratislava

Tel (421) 2 4445 4895

Fax (421) 2 4445 4896

SI JohnsonDiversey d.o.o.

Trzaska cesta 37a

2000 Maribor

Tel (386) 2 320 7000

Fax (386) 2 320 7071

TR JohnsonDiversey

Degirmenyolu caddesi Huzur

Hoca sokak No: 84

Unilever Binasi Kat::18

34752 Icerenköy /

ISTANBUL

Tel (90) 216 57 86 400

Fax (90) 216 57 86 401

Loading...

Loading...