Edition: V1.00/2014

Technical Manual

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

GTS Technical Manual

tecnical manual procarpet 30_V1.00IVZ.fm

14. March 2014 Edition: V1.00/2014

Copyright © 2014, Diversey Care

Index

1Forward

1.1 Target 1

1.2 Technical Training 1

1.3 Technical Manual 1

1.4 Summary 2

2Elementary

2.1 Health & Safety 1

2.2 ESD 1

3 General

3.1 General information 1

3.1.1 Part reference 1

3.1.2 Consumable supplies 1

3.1.3 Direction description 1

3.1.4 Power source 1

3.2 Required material 2

3.2.1 Tools 2

3.2.2 Material 2

4Technical data

4.1 Machine range 1

4.2 Technical information 2

4.2.1 Machine profile 2

4.2.2 Technical data 2

4.2.3 Dimensions and weights 3

4.2.4 Brush system 4

4.2.5 Suction power 4

4.3 Accessories & Additional parts 4

4.3.1 Accessories 4

5 Mechanical

5.1 Handle 1

5.1.1 Removing of housing 1

5.1.2 Mounting of housing 2

5.1.3 Removing of microswitch 3

5.1.4 Mounting of microswitch 5

5.1.5 Removing of switching bow 6

5.1.6 Mounting of switching bow 7

5.2 Tank cover and tank 8

5.2.1 Removing of fresh water tank assembly 8

5.2.2 Mounting of fresh water tank assembly 10

5.3 Brush & Motor 12

5.3.1 Removing of brush motor belt 12

5.3.2 Mounting of brush motor belt 13

5.3.3 Removing of brush motor 14

5.3.4 Mounting of brush motor 15

5.3.5 Removing of brush pulley 16

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

GTS Technical Manual

tecnical manual procarpet 30_V1.00IVZ.fm

14. March 2014 Edition: V1.00/2014

Copyright © 2014, Diversey Care

5.3.6 Mounting of brush pulley 17

5.3.7 Adjusting of brush height 18

5.4 Vacuum unit & squeegee 19

5.4.1 Removing of vacuum motor 19

5.4.2 Mounting of vacuum motor 20

5.4.3 Removing of shackle 21

5.4.4 Mounting of shackle 22

5.4.5 Removing of squeegee 23

5.4.6 Mounting of squeegee 24

5.4.7 Removing of brush level adjustment 25

5.4.8 Mounting of brush level adjustment 27

5.5 Magnetic valve & water outlet 28

5.5.1 Removing of pump 28

5.5.2 Mounting of pump 29

5.5.3 Removing of fresh water filter 30

5.5.4 Mounting of fresh water filter 31

5.5.5 Removing of bypass valve 32

5.5.6 Mounting of bypass valve 33

5.5.7 Removing of valve unit 34

5.5.8 Mounting of valve unit 35

6 Electrical

6.1 System architecture 1

6.1.1 Motor circuit 1

6.2 Main cord & cable inlet inbox 2

6.2.1 Removing of rockingswitch 2

6.2.2 Mounting of rockingswitch 3

6.2.3 Rockingswitch connections 4

6.3 Contactor 6

6.3.1 Removing of contactor 6

6.3.2 Mounting of contactor 7

6.3.3 Contactor connections K1/K2 8

6.3.3.1 Contactor connections K1 9

6.3.3.2 Contactor connections K2 10

6.4 Electrical schematics 11

6.4.1 Electrical schematics 11

7 Additional information

7.1 Available GTS Newsletter/Instructions 1

8Revision

9Appendix

10 Notes

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

14. March 2014 Edition: V1.00/2014

Copyright © 2014, Diversey Care

Technical Manual

1 Forward

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

GTS Technical Manual

14. March 2014 Edition: V1.00/2014 1-1

Copyright © 2014, Diversey Care

01.0 TASKI - foreword_V1.00.fm

1 Foreword

1.1 Target

To serve our customers faster and more efficient it is important to achieve a general

standard of technical know how with our partners in the market.

Therefore we developed a Technical Training concept which is based on e-spares. The

concept consists of a Technical Manual and a Technical Training.

These two tools will be produced for each newly launched machine with a certain complexity. The Technical Manual will be available as PDF file and can be downloaded from

e-spares. The Technical Training documentation will be distributed after having attended the technical training.

1.2 Technical Training

The Technical Training is addressed as reference book for the technical training sessions

and will be distributed to the floor care responsible and/or to the technical training responsible after attending a training session provided by GTS (max. 2 persons per country).

The intension is, that after this session, a technical trainer is able to perform technical

training for their local technical staff and in this way to transfer the knowledge to all

service technicians.

The Technical Training is not intended as manual for the service technicians and will be

distributed only to the training responsible of each country.

1.3 Technical Manual

The Technical Manual is addressed to the service technicians and should be translated

and distributed after a technical training.

It contains a summary of procedures, hints and suggestions etc. which are helpful and

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

GTS Technical Manual

14. March 2014 Edition: V1.00/2014 1-2

Copyright © 2014, Diversey Care

01.0 TASKI - foreword_V1.00.fm

essential for the daily business. The Technical Manual can be downloaded from espares/documents.

1.4 Summary

We are convinced that the Technical Manual concept together with the Technical Training

are powerful tools, which will help our service organisations to achieve a higher level of

quality in repairs and customer satisfaction.

If you have any comments or questions do not hesitate to contact your country responsible.

Sincerely yours

GTS Team

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

14. March 2014 Edition: V1.00/2014

Copyright © 2014, Diversey Care

Technical Manual

2 Elementary

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

GTS Technical Manual

14. March 2014 Edition: V1.00/2014 2-1

Copyright © 2014, Diversey Care

02.1 TASKI - elementary_V1.00.fm

2Elementary

2.1 Health & Safety

Scrubber dryers may be powered by mains electricity or batteries. There are risks associated with both, which call for proper precautions, such as the provision of good ventilation and the elimination of risk of ignition.

All work, carried out on such machines, should only be performed by trained personnel

in accordance with local regulations.

Before working on such a machine, isolate it from any electrical power source.

Always wear the required personal protective equipment (including gloves and goggles)

that must be worn when potentially exposed to any hazardous material and when carrying out hazardous tasks.

Note that parts may be contaminated with chemical product. If possible flush hoses out

with fresh water prior to carrying out any maintenance. For information on chemical

products that are used in this machine, please carefully read the product label and Material Safety Data Sheet (MSDS).

Empty water tanks prior to carrying out any maintenance. Ensure contaminated water is

emptied into an approved drain. Avoid pollution.

2.2 ESD

Static electricity is electricity at rest or the accumulation of electric charge, as opposed

to an electric current which is the movement of electricity. The flow or movement of people and/or materials in and through the environment causes separation of electrons and

therefore static electricity. A familiar example of static electricity is when a person walks

across a carpeted floor. Static electricity/electrostatic charge is generated simply by the

contact and separation of the soles of that individual's shoes from the carpeted floor.

Electrostatic Discharge (ESD) occurs when the electrostatic charge is transferred from a

material that carries the charge to an electrostatic sensitive device. In the example above,

this electrostatic discharge is the „shock“ felt after walking across the carpeted floor and

then touching a door knob. It is this electrostatic discharge, which comes in varying de-

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

GTS Technical Manual

14. March 2014 Edition: V1.00/2014 2-2

Copyright © 2014, Diversey Care

02.1 TASKI - elementary_V1.00.fm

grees, that can be most damaging to electronical devices.

Static electricity, is a natural phenomenon and consequently electrostatic discharge is

the primary cause of countless problems affecting industry, business and personal life.

These problems can be as simple as the shock resulting from walking across a carpet; as

costly as the destruction of sensitive electronic components.

Almost any material can generate static electricity. The ability to store or unload the

charge depends on the type of material.

Static discharge can damage devices, this can result in immediate product failure or in a

latent failure. Latent failures can go undetected for a period of time, the results are product failure in the field.

Electrostatic fields are associated with charged objects.

The degree of severity of ESD events depends on the type of discharge which occurs. The

three most common ESD charge transfers are:

• from an external object to the device.

• from a device to another object.

• resulting from electrostatic fields.

Please do not store electronics without ESD bags at any time.

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

14. March 2014 Edition: V1.00/2014

Copyright © 2014, Diversey Care

Technical Manual

3 General

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

GTS Technical Manual

14. March 2014 Edition: V1.00/2014 3-1

Copyright © 2014, Diversey Care

03.1 TASKI - general_V1.00.fm

3 General

3.1 General information

3.1.1 Part reference

Explicitly mentioned parts are defined by references corresponding to

the e-spares spare parts list.

E.g. Tank axle (02/118) corresponds to the parts list on e-spares, sub

assembly 2, position 118.

3.1.2 Consumable supplies

If you have to remove cable ties then position the new ones at the

original place.

If you have to remove self locking nuts, you should replace them by

new ones.

3.1.3 Direction description

On the „RH“ always means on the right hand side of the machine in

working direction (when you are standing behind the machine).

On the „LH“ always means on the left hand side of the machine in

working direction (when you are standing behind the machine).

3.1.4 Power source

Depending on the work it might be required to remove the power

source (mains/batteries) from the machine.

The in here mentioned sequences (mechanical and electrical) are

based on the assumption that the power source (mains/batteries)

were removed from the machine before.

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

GTS Technical Manual

14. March 2014 Edition: V1.00/2014 3-2

Copyright © 2014, Diversey Care

03.1 TASKI - general_V1.00.fm

3.2 Required material

3.2.1 Tools

• A standard range of tools is required e.g.

• Fork spanners.

• Allen keys.

•Torx keys.

3.2.2 Material

• No special tools are required.

The above listings are only a recommendation for the technical

training.

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

14. March 2014 Edition: V1.00/2014

Copyright © 2014, Diversey Care

Technical Manual

4 Technical data

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

GTS Technical Manual

14. March 2014 Edition: V1.00/2014 4-1

Copyright © 2014, Diversey Care

04.1 procarpet 30 - technical data_V1.00.fm

4Technical data

4.1 Machine range

SKU Description Version Series

7522307 procarpet 30 SEV 01

7522309 procarpet 30 EURO 01

7522310 procarpet 30 UK 01

7522308 procarpet 30 NA 01

7522311 procarpet 30 CN 01

7522377 procarpet 30 IN 01

7522312 procarpet 30 KSA 01

Table 1: Machine range

Remarks

SKU‘s for all TASKI porcarpet types are the „naked machine“. Tools and accessories have

to be ordered separately.

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

GTS Technical Manual

14. March 2014 Edition: V1.00/2014 4-2

Copyright © 2014, Diversey Care

04.1 procarpet 30 - technical data_V1.00.fm

4.2 Technical information

4.2.1 Machine profile

4.2.2 Technical data

Pos. Unit Value

Theoretical performance (Extraction/Encapsulation) (m²/h) 200/405

Working width (mm) 380

Solution tank (l) 29

Recovery tank (l) 32

Table 2: Machine profile

Pos. Unit Value

Noise level (dB(A)) <70

Vibration (m/s2) <0.5

Approvals CE

Nominal consumption (W) 2000

Power suction motor (W) 1266

Voltage (V) 100-120V/

60Hz

230-240 50Hz

220V/60Hz

Splash water protection class IPX4

Electrical protection class I

Table 3: Technical data

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

GTS Technical Manual

14. March 2014 Edition: V1.00/2014 4-3

Copyright © 2014, Diversey Care

04.1 procarpet 30 - technical data_V1.00.fm

4.2.3 Dimensions and weights

Picture 1: Dimensions

Pos. Unit Value

Dimensions L/W/H (mm) 1100/470/940

Door pass through width (mm) 470

Net weight (empty tank) (kg) 52

Weight, ready to use (kg) 81

Weight, ready for shipping (kg) 79

Max. floor pressure wheels (N/mm2) 0.13

Wheel diameter rear (mm) 300

Cable length (m) 15

Table 4: Dimensions and weights

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

GTS Technical Manual

14. March 2014 Edition: V1.00/2014 4-4

Copyright © 2014, Diversey Care

04.1 procarpet 30 - technical data_V1.00.fm

4.2.4 Brush system

4.2.5 Suction power

4.3 Accessories & Additional parts

4.3.1 Accessories

Pos. Unit Value

Brush diameter (mm) 88

Brush motor (W) 650

Brush speed (rpm) 1000

Brush pressure (kg) 10-17

Table 5: Brush system

Pos. Value

Vacuum motor (W) 1266

Max. air flow (l/s) 54

Max. vacuum (mbar) 250

Max. vacuum (kPa) 25

Table 6: Suction power

SKU Article

7522313 Extraction carpet brush 30

7522973 Encapsulation carpet brush 30

8505160 Extraction nozzle with hose

8505170 Extraction hose (6m)

8505150 Hand tool

7500780 Atomizer (Pump-up spray)

7512446 Hard floor cleaning tool

Table 7: Accessories

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

GTS Technical Manual

14. March 2014 Edition: V1.00/2014 4-5

Copyright © 2014, Diversey Care

04.1 procarpet 30 - technical data_V1.00.fm

8502830 Filling hose with universal water coupling

7522783 TASKI Nano Trolley

SKU Article

Table 7: Accessories

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

14. March 2014 Edition: V1.00/2014

Copyright © 2014, Diversey Care

Technical Manual

5 Mechanical

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

GTS Technical Manual

14. March 2014 Edition: V1.00/2014 5-1

Copyright © 2014, Diversey Care

05.10.70 handle - housing - 30_V1.00.fm

5.1 Handle

5.1.1 Removing of housing

Picture 1: Housing

• Remove the 4 screws (01/105) from the housing (01/104).

• Remove the housing from the handle of the fresh water tank (02/

119).

Picture 2: Remove housing

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

GTS Technical Manual

14. March 2014 Edition: V1.00/2014 5-2

Copyright © 2014, Diversey Care

05.10.70 handle - housing - 30_V1.00.fm

5.1 Handle

5.1.2 Mounting of housing

Picture 3: Remove housing

• Mount the housing onto the handle of the fresh water tank.

Make sure that the cables are not squeezed in between the handle and

housing.

• Mount the 4 screws into the housing.

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

GTS Technical Manual

14. March 2014 Edition: V1.00/2014 5-3

Copyright © 2014, Diversey Care

05.10.26 handle - microswitch - 30_V1.00.fm

5.1 Handle

5.1.3 Removing of microswitch

Picture 5: Microswitch

• Remove housing according to chapter REMOVING OF HOUSING.

• Remove the two screws (01/111) from the angle bracket (01/

118).

• Remove the angle bracket from the housing (01/104).

• Disconnect the wires from the microswitch.

Picture 6: Remove microswitch

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

GTS Technical Manual

14. March 2014 Edition: V1.00/2014 5-4

Copyright © 2014, Diversey Care

05.10.26 handle - microswitch - 30_V1.00.fm

Picture 7: Microswitch details

• Remove the two fixation screws (01/116), washers (01/117) and

nuts (01/119).

• Remove the microswitch from the switch insulation (01/121).

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

GTS Technical Manual

14. March 2014 Edition: V1.00/2014 5-5

Copyright © 2014, Diversey Care

05.10.26 handle - microswitch - 30_V1.00.fm

5.1 Handle

5.1.4 Mounting of microswitch

Picture 8: Mount microswitch

• Position the microswitch into the switch insulation and angle

bracket.

• Mount and tighten the two fixation screws, washers and nuts

slightly.

• Connect the wires to the new microswitch.

• Mount the angle bracket with the two screws.

• Adjust the switching point of the microswitch.

Adjustment

The microswitch shall switch when the switching bow is moved half

way.

• Mount the housing according to chapter MOUNTING OF

HOUSING.

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

GTS Technical Manual

14. March 2014 Edition: V1.00/2014 5-6

Copyright © 2014, Diversey Care

05.10.72 handle - switch lever - 30_V1.00.fm

5.1 Handle

5.1.5 Removing of switching bow

Picture 9: Switching bow

• Remove housing according to chapter REMOVING OF HOUSING.

• Remove microswitch according to chapter REMOVING OF

MIRCOSWITCH.

• Loosen the 4 screws (01/111) from the two clamps (01/110) and

the flat spring (01/109).

• Remove the two clamps and flat spring.

• Remove the switch bow (01/106).

Picture 10: Remove switching bow

• Remove the two covers (01/108) and splash guards (01/107)

from the switching bow and mount it onto the new one.

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

GTS Technical Manual

14. March 2014 Edition: V1.00/2014 5-7

Copyright © 2014, Diversey Care

05.10.72 handle - switch lever - 30_V1.00.fm

5.1 Handle

5.1.6 Mounting of switching bow

Picture 11: Mount switching bow

• Mount the two splash guards onto the switching bow.

• Position the switching bow.

• Mount the two covers onto the housing.

• Mount the two clamps and flat spring for the switching bow and

tighten the 4 screws.

• Mount the microswitch according to chapter MOUNTING OF

MICROSWITCH.

• Mount the housing according to chapter MOUNTING OF

HOUSING.

Picture 12: Switching bow

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

GTS Technical Manual

14. March 2014 Edition: V1.00/2014 5-8

Copyright © 2014, Diversey Care

05.54.20 tank cover and tank - fresh water tank - 30_V1.00.fm

5.2 Tank cover and tank

5.2.1 Removing of fresh water tank assembly

Picture 13: Fresh water tank assembly

Ensure that no water is in the fresh water system before you remove

the fresh water tank.

• Disconnect the two flexible hoses (02/124,125) from the tank

cover (02/101).

• Remove the tank cover (02/101).

• Remove the recovery tank (02/107).

• Unlock the fresh water tank (02/119) by removing the two

screws (03/138) on the LH and RH side.

• Tilt the fresh water tank.

Picture 14: Angle nipple

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

GTS Technical Manual

14. March 2014 Edition: V1.00/2014 5-9

Copyright © 2014, Diversey Care

05.54.20 tank cover and tank - fresh water tank - 30_V1.00.fm

Open the fresh water tank slowly and disconnect the angle nipple (06/

107) from the filter (06/102).

• Remove the hose clamp (06/126) from the fresh water hose (06/

115).

• Remove the fresh water hose from the angle nipple of the fresh

water tank.

• Pull out the two suction hoses (02/124, 125) from the fresh

water tank (02/119).

• Remove the hose (06/121) from the quick connector (02/112) to

the option tool.

• Disconnect the wires at the appropriate place.

• Remove the screw (02/121) of the cable hose clamp (02/117).

• Remove the cable hose clamp.

• Remove the two screws (02/127) of the angle flange (02/116).

• Remove the angle flange.

• Thread out the wires from the fresh water tank.

• Remove the two screws (03/140) from the two tank bolts (03/

144, 145).

Picture 15: Fresh water tank fixation

• Lift the fresh water tank off the chassis (03/105).

• According to what you need to exchange, remove the existing

parts from the fresh water tank an place it onto the new one.

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

GTS Technical Manual

14. March 2014 Edition: V1.00/2014 5-10

Copyright © 2014, Diversey Care

05.54.20 tank cover and tank - fresh water tank - 30_V1.00.fm

5.2 Tank cover and tank

5.2.2 Mounting of fresh water tank assembly

Picture 16: Fresh water tank assembly

• Mount the necessary parts onto the new fresh water tank.

• Position fresh water tank on the chassis.

• Mount the two screws from the two tank bolts.

• Mount the hose onto the quick connector of the option tool.

• Thread in the two suction hoses into the fresh water tank hole.

• Mount the water hose onto the tank connector.

• Thread in the wires into the fresh water tank.

• Mount the angle flange and the two screws.

• Mount the cable hose clamp and the screw onto the tank.

• Connect the wires at the appropriate place.

Close the fresh water tank slowly and connect the angle nipple (06/

107) onto the filter (06/102).

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

GTS Technical Manual

14. March 2014 Edition: V1.00/2014 5-11

Copyright © 2014, Diversey Care

05.54.20 tank cover and tank - fresh water tank - 30_V1.00.fm

• Close the fresh water tank.

• Mount the screws from the fresh water tank on the LH and RH

side.

• Mount the recovery tank.

• Mount the tank cover.

• Connect the two flexible hoses onto the tank cover.

Ensure that the fresh water tank fits nicely onto the chassis.

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

GTS Technical Manual

14. March 2014 Edition: V1.00/2014 5-12

Copyright © 2014, Diversey Care

05.58.30 brush & motor - brush motor belt - 30_45_V1.00.fm

5.3 Brush & Motor

5.3.1 Removing of brush motor belt

Picture 17: Brush motor belt

• Open fresh water tank according to chapter REMOVING OF FRESH

WATER TANK ASSEMBLY.

• Remove the screw (30:04/101, 45:05/101) and the two screws

(30:04/103, 45:05/103) of the brush cover (30:04/102, 45:05/

102).

• Remove brush cover.

• Untighten the fixation and center nut (30:04/110, 45:05/110) of

the brush motor belt holder (30:04/132, 45:05/132), with a

10mm fork spanner/socket.

• Untension the brush motor belt (30:04/115, 45:05/115).

Picture 18: Remove brush motor belt

• Remove the brush motor belt as the tension is released now.

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

GTS Technical Manual

14. March 2014 Edition: V1.00/2014 5-13

Copyright © 2014, Diversey Care

05.58.30 brush & motor - brush motor belt - 30_45_V1.00.fm

5.3 Brush & Motor

5.3.2 Mounting of brush motor belt

Picture 19: Mount brush motor belt

• Mount the brush motor belt.

• Turn the holder with a screw driver to tension the belt.

• Tighten the fixation and the center nut of the belt holder.

Picture 20: Tension belt

• Mount the brush cover.

• Mount the brush cover screws.

• Close fresh water tank according to chapter MOUNTING OF

FRESH WATER TANK ASSEMBLY.

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

GTS Technical Manual

14. March 2014 Edition: V1.00/2014 5-14

Copyright © 2014, Diversey Care

05.58.31 brush & motor - brush motor - 30_45_V1.00.fm

5.3 Brush & Motor

5.3.3 Removing of brush motor

Picture 21: Brush motor

• Open fresh water tank according to chapter REMOVING OF FRESH

WATER TANK ASSEMBLY.

• Remove brush motor belt according to chapter REMOVING OF

BRUSH MOTOR BELT.

• Remove the 4 fixation screws (30:04/105, 45:05/105) of the

brush motor (30:04/117, 45:05/117).

Picture 22: Remove brush motor

• Disconnect brush motor plug.

• Remove the motor by pulling it out of the axle (30:04/111,

45:05/111).

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

GTS Technical Manual

14. March 2014 Edition: V1.00/2014 5-15

Copyright © 2014, Diversey Care

05.58.31 brush & motor - brush motor - 30_45_V1.00.fm

5.3 Brush & Motor

5.3.4 Mounting of brush motor

Picture 23: Mount brush motor

• Mount the brush motor.

• Mount the brush motor fixation screws.

Remarks

Make sure that the key (30:04/104, 45:05/104) of the motor is

correctly positioned, as it has to fit into the axle.

Ensure that the motor cover (30:04/118, 45:05/118) is correctly

mounted onto the brush motor.

Picture 24: Brush motor cover

• Connect brush motor plug.

• Mount brush motor belt according to chapter MOUNTING OF

BRUSH MOTOR BELT.

• Close fresh water tank according to chapter MOUNTING OF

FRESH WATER TANK ASSEMBLY.

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

GTS Technical Manual

14. March 2014 Edition: V1.00/2014 5-16

Copyright © 2014, Diversey Care

05.58.32 brush & motor - brush pulley - 30_45_V1.00.fm

5.3 Brush & Motor

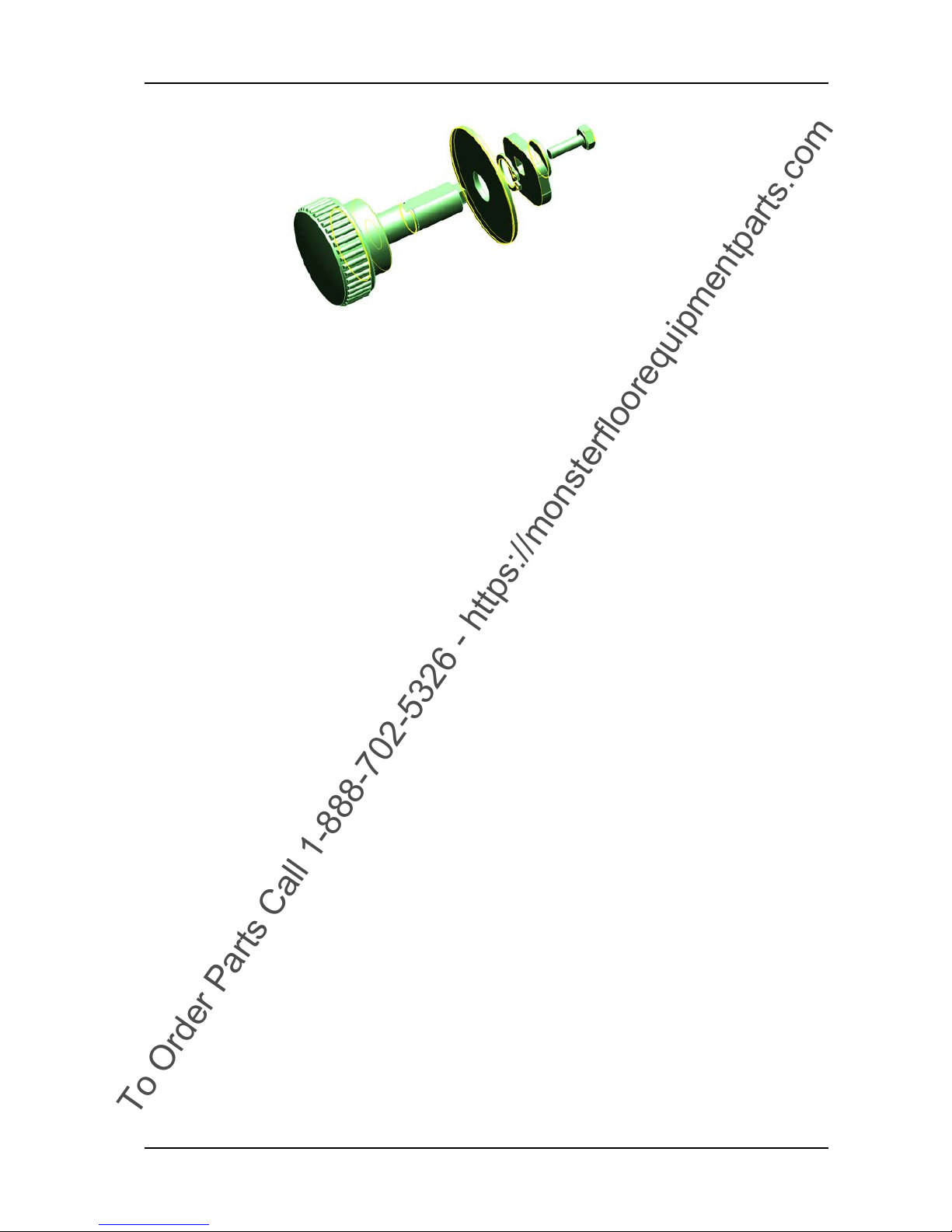

5.3.5 Removing of brush pulley

Picture 25: Brush pulley

• Open fresh water tank according to chapter REMOVING OF FRESH

WATER TANK ASSEMBLY.

• Remove brush motor belt according to chapter REMOVING OF

BRUSH MOTOR BELT.

• Remove the 3 self locking nuts (30:04/110, 45:05/110) with a

10mm fork spanner/socket.

Picture 26: Remove brush pulley

• Remove the whole brush pulley assembly.

• According to what you need to exchange, remove the existing

parts from the brush pulley assembly and place it on the new

one.

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

GTS Technical Manual

14. March 2014 Edition: V1.00/2014 5-17

Copyright © 2014, Diversey Care

05.58.32 brush & motor - brush pulley - 30_45_V1.00.fm

5.3 Brush & Motor

5.3.6 Mounting of brush pulley

Picture 27: Brush pulley

• Position the brush pulley assembly.

• Mount the 3 self locking nuts with a 10mm fork spanner/socket.

Picture 28: Mount brush pulley

• Complete assembling according to chapter MOUNTING OF

BRUSH MOTOR BELT.

• Close fresh water tank according to chapter MOUNTING OF

FRESH WATER TANK ASSEMBLY.

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

GTS Technical Manual

14. March 2014 Edition: V1.00/2014 5-18

Copyright © 2014, Diversey Care

05.58.33 brush & motor - brush height adjustment - 30_45_V1.00.fm

5.3 Brush & Motor

5.3.7 Adjusting of brush height

Picture 29: Adjusting brush height

• Loosen handle (30:04/122, 45:05/122) for brush holder (30:04/

133, 45:05/133).

• Remove brush holder.

• Remove the brush take up from the brush holder with a 8mm

fork spanner/socket.

The brush take up has a left hand thread.

Adjustment

You can vary the height by placing the special screw in the positions

1-6. This could be necessary if the brush is not touching the floor or

wearing uneven.

Leaving the factory it is set to number 3.

• Mount the brush take up onto the special screw.

Service

Apply adhesive locking on the special screw.

• Mount the brush holder.

• Mount the handle for the brush holder.

Remarks

You can only order the whole brush holder (30:04/133, 45:05/133).

The adjustment is set to number 3.

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

GTS Technical Manual

14. March 2014 Edition: V1.00/2014 5-19

Copyright © 2014, Diversey Care

05.17.10 vacuum unit & squeegee - vacuum motor - 30_45_V1.00.fm

5.4 Vacuum unit & squeegee

5.4.1 Removing of vacuum motor

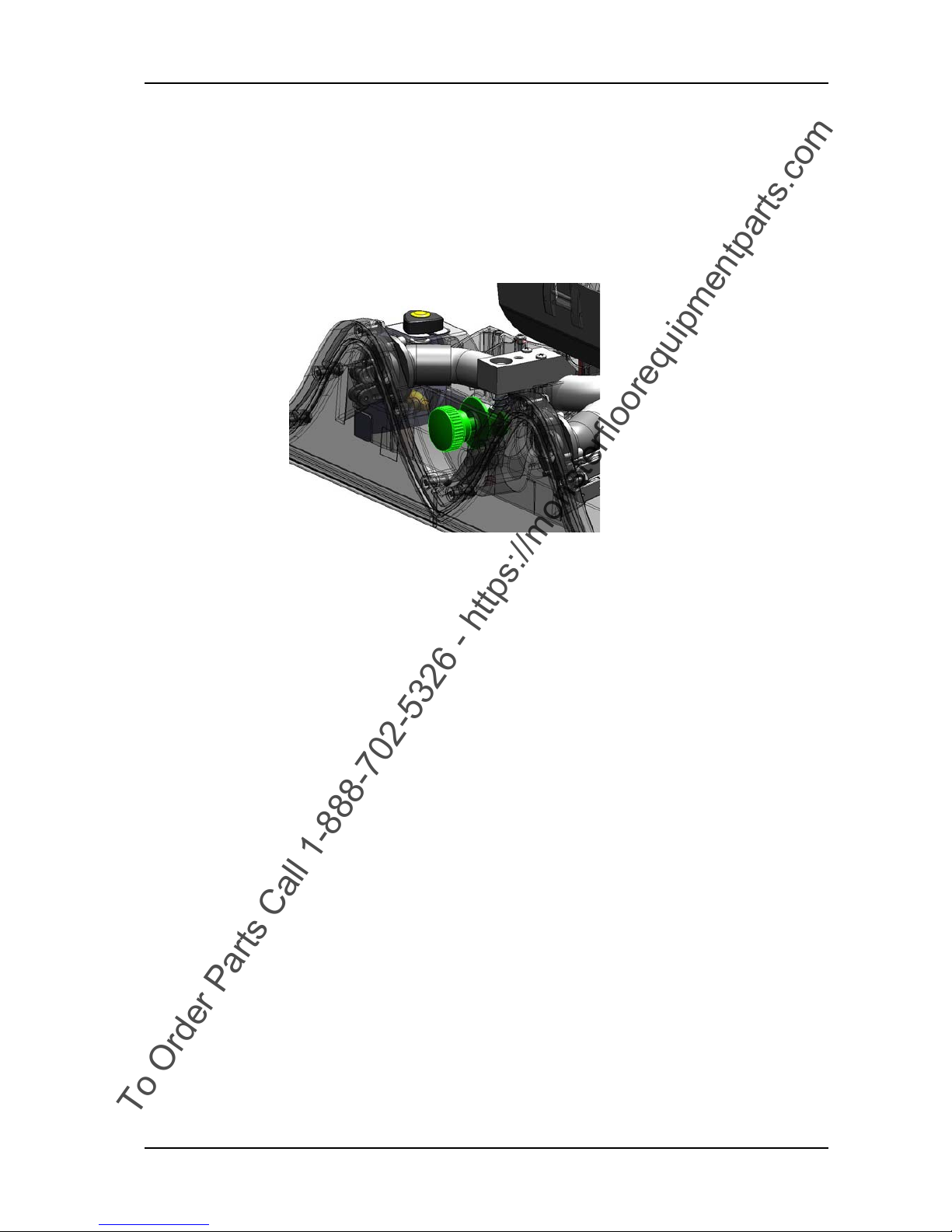

Picture 30: Vacuum motor

• Open fresh water tank according to chapter REMOVING OF FRESH

WATER TANK ASSEMBLY.

• Lift the vacuum motor (30:05/104, 45:06/104) with all the seals

and absorber out of the chassis (30:03/105, 45:04/105).

• Disconnect vacuum motor wires at the connection block (30:05/

127, 45:06/127).

• Remove noise absorbers (30:05/101, 45:06/101) and (30:05/

107, 45:06/107), covers (30:05/102, 45:06/102) and (30:05/

106, 45:06/106), seals (30:05/103, 45:06/103) and (30:05/

105, 45:06/105).

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

GTS Technical Manual

14. March 2014 Edition: V1.00/2014 5-20

Copyright © 2014, Diversey Care

05.17.10 vacuum unit & squeegee - vacuum motor - 30_45_V1.00.fm

5.4 Vacuum unit & squeegee

5.4.2 Mounting of vacuum motor

• Position seals, noise absorbers and covers correctly.

Remarks

The sequence of the seals, noise absorbers and covers is described in

the spare parts list.

Picture 31: Vacuum motor details

• Connect vacuum motor wires to the connection block.

• Position the assembled vacuum motor into the chassis.

• Complete assembling according to chapter MOUNTING OF

FRESH WATER TANK ASSEMBLY.

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

GTS Technical Manual

14. March 2014 Edition: V1.00/2014 5-21

Copyright © 2014, Diversey Care

05.17.11 vacuum unit & squeegee - shackle - 30_45_V1.00.fm

5.4 Vacuum unit & squeegee

5.4.3 Removing of shackle

Picture 32: Shackle

• Open fresh water tank according to chapter REMOVING OF FRESH

WATER TANK ASSEMBLY.

• Remove brush cover according to chapter REMOVING OF BRUSH

MOTOR BELT.

Picture 33: Remove shackle

• Remove the 4 screws (30:05/111, 45:06/111) from the shackles

(30:05/110, 45:06/110).

• Remove the 8 shackles from the brush chassis (30:04/125,

45:05/125) and squeegee body (30:05/119, 45:06/119).

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

GTS Technical Manual

14. March 2014 Edition: V1.00/2014 5-22

Copyright © 2014, Diversey Care

05.17.11 vacuum unit & squeegee - shackle - 30_45_V1.00.fm

5.4 Vacuum unit & squeegee

5.4.4 Mounting of shackle

• Position the squeegee body in front of the brush chassis.

• Mount the 8 shackles.

• Mount the 4 screws onto the shackles.

Remarks

All the shackles are the same spare part.

Picture 34: Shackle details

• Mount brush cover according to chapter MOUNTING OF BRUSH

MOTOR BELT.

• Close fresh water tank according to chapter MOUNTING OF

FRESH WATER TANK ASSEMBLY.

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

GTS Technical Manual

14. March 2014 Edition: V1.00/2014 5-23

Copyright © 2014, Diversey Care

05.17.12 vacuum unit & squeegee - squeegee - 30_45_V1.00.fm

5.4 Vacuum unit & squeegee

5.4.5 Removing of squeegee

Picture 35: Nozzle

• Open fresh water tank according to chapter REMOVING OF FRESH

WATER TANK ASSEMBLY.

• Remove brush cover according to chapter REMOVING OF BRUSH

MOTOR BELT.

• Remove squeegee body according to chapter REMOVING OF

SHACKLE.

Picture 36: Remove nozzle

• Remove the 6 screws (30:05/124, 45:06/124) from the suction

hose (30:02/124, 45:03/124).

• Remove the suction hose.

• According to what you need to exchange, remove the existing

parts from the squeegee body and place it onto the new one.

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

GTS Technical Manual

14. March 2014 Edition: V1.00/2014 5-24

Copyright © 2014, Diversey Care

05.17.12 vacuum unit & squeegee - squeegee - 30_45_V1.00.fm

5.4 Vacuum unit & squeegee

5.4.6 Mounting of squeegee

• Mount the necessary parts onto the new suction unit.

• Position the suction hose and mount the 6 screws.

• Mount squeegee body according to chapter MOUNTING OF

SHACKLE.

• Mount brush cover according to chapter MOUNTING OF BRUSH

MOTOR BELT.

• Close fresh water tank according to chapter MOUNTING OF

FRESH WATER TANK ASSEMBLY.

Picture 37: Nozzle

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

GTS Technical Manual

14. March 2014 Edition: V1.00/2014 5-25

Copyright © 2014, Diversey Care

05.17.13 vacuum unit & squeegee - brush level adjustment - 30_45_V1.00.fm

5.4 Vacuum unit & squeegee

5.4.7 Removing of brush level adjustment

Picture 38: Brush adjustment

• Open fresh water tank according to chapter REMOVING OF FRESH

WATER TANK ASSEMBLY.

• Remove brush cover according to chapter REMOVING OF BRUSH

MOTOR BELT.

• Remove the screw (30:05/112, 45:06/112) and the washer

(30:05/113, 45:06/113).

• Pull of the adjustment plate (30:05/114, 45:06/114) from the

axle (30:05/117, 45:06/117).

• Remove the retaining ring (30:05/115, 45:06/115).

• Remove the disc (30:05/116, 45:06/116) together with the label

(30:05/123, 45:06/123).

• Remove the axle together with the star knob (30:05/121, 45:06/

121).

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

GTS Technical Manual

14. March 2014 Edition: V1.00/2014 5-26

Copyright © 2014, Diversey Care

05.17.13 vacuum unit & squeegee - brush level adjustment - 30_45_V1.00.fm

Picture 39: Brush adjustment details

Remarks

If necessary replace the star knob (30:05/121, 45:06/121) by pulling

it off from the axle (30:05/117, 45:06/117).

The star knob needs to be pressed onto the axle.

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

GTS Technical Manual

14. March 2014 Edition: V1.00/2014 5-27

Copyright © 2014, Diversey Care

05.17.13 vacuum unit & squeegee - brush level adjustment - 30_45_V1.00.fm

5.4 Vacuum unit & squeegee

5.4.8 Mounting of brush level adjustment

• Mount the axle together with the star knob onto the squeegee

body.

• Mount the label and the disc.

• Mount the retaining ring.

• Mount the adjustment plate onto the axle.

• Mount the washer and screw.

Remarks

The label (30:05/123, 45:06/123), disc (30:05/116, 45:06/116) and

adjustment plate (30:05/114, 45:06/114) are coded. Therefore it will

fit only in one position onto the axle (30:05/117, 45:06/117).

• Mount brush cover according to chapter MOUNTING OF BRUSH

MOTOR BELT.

• Close fresh water tank according to chapter MOUNTING OF

FRESH WATER TANK ASSEMBLY.

Picture 40: Brush adjustment

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

GTS Technical Manual

14. March 2014 Edition: V1.00/2014 5-28

Copyright © 2014, Diversey Care

05.72.28 mangetic valve & water outlet - pump - 30_45_V1.00.fm

5.5 Magnetic valve & water outlet

5.5.1 Removing of pump

Picture 41: Pump

• Open fresh water tank according to chapter REMOVING OF FRESH

WATER TANK ASSEMBLY.

Ensure that no water is in the fresh water system before you

disconnect the hoses.

Remarks

For a better access to the pump, remove the vacuum motor.

• Remove the 3 screws (30:06/110, 45:07/110) and washers

(30:06/127, 45:07/127) from the pump (30:06/101, 45:07/

101).

Picture 42: Remove pump

• Lift out the pump.

• Disconnect the cables of the pump.

• Remove the two hoses (30:06/116, 45:07/116) and (30:06/117,

45:07/117) from the fast connectors of the pump.

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

GTS Technical Manual

14. March 2014 Edition: V1.00/2014 5-29

Copyright © 2014, Diversey Care

05.72.28 mangetic valve & water outlet - pump - 30_45_V1.00.fm

5.5 Magnetic valve & water outlet

5.5.2 Mounting of pump

Picture 43: Pump

• Mount the two hoses onto the fast connectors of the pump.

• Connect the cables of the pump.

• Position the pump onto the chassis.

• Mount the 3 washers and screws onto the pump.

• Close fresh water tank according to chapter MOUNTING OF

FRESH WATER TANK ASSEMBLY.

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

GTS Technical Manual

14. March 2014 Edition: V1.00/2014 5-30

Copyright © 2014, Diversey Care

05.72.25 mangetic valve & water outlet - filter - 30_45_V1.00.fm

5.5 Magnetic valve & water outlet

5.5.3 Removing of fresh water filter

Picture 44: Filter housing

• Open fresh water tank according to chapter REMOVING OF FRESH

WATER TANK ASSEMBLY.

Ensure that no water is in the fresh water system before you

disconnect the hoses.

Remarks

For a better access to the filter, remove the vacuum motor and pump.

• Remove the hose (30:06/116, 45:07/116) from the fast

connector on the filter (30:06/102, 45:07/102).

• Remove the two cable ties of the filter.

• Lift out the filter.

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

GTS Technical Manual

14. March 2014 Edition: V1.00/2014 5-31

Copyright © 2014, Diversey Care

05.72.25 mangetic valve & water outlet - filter - 30_45_V1.00.fm

5.5 Magnetic valve & water outlet

5.5.4 Mounting of fresh water filter

Picture 45: Filter housing

• Place the filter into the machine.

• Mount two new cable ties for the fixation of the filter.

Remarks

Cable tie 200 ordering number 4023260.

• Mount the hose onto the fast connector of the filter.

• Close fresh water tank according to chapter MOUNTING OF

FRESH WATER TANK ASSEMBLY.

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

GTS Technical Manual

14. March 2014 Edition: V1.00/2014 5-32

Copyright © 2014, Diversey Care

05.72.26 mangetic valve & water outlet - bypass valve - 30_45_V1.00.fm

5.5 Magnetic valve & water outlet

5.5.5 Removing of bypass valve

Picture 46: Bypass valve

• Open fresh water tank according to chapter REMOVING OF FRESH

WATER TANK ASSEMBLY.

Ensure that no water is in the fresh water system before you

disconnect the hoses.

Remarks

For a better access to the bypass valve, remove the vacuum motor.

• Remove the pump according to chapter REMOVING OF PUMP.

• Loosen the two fixation screws (30:05/128, 45:06/128) from

the bypass valve (30:06/104, 45:07/104).

• Lift out the bypass valve.

Remarks

The connection block for the vacuum motor is mounted on the screws

of the bypass valve.

• Remove the two hoses (30:06/119, 45:07/119) and (30:06/120,

45:07/120) from the fast connectors of the bypass valve.

• Remove the cable from the magnetic valve.

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

GTS Technical Manual

14. March 2014 Edition: V1.00/2014 5-33

Copyright © 2014, Diversey Care

05.72.26 mangetic valve & water outlet - bypass valve - 30_45_V1.00.fm

5.5 Magnetic valve & water outlet

5.5.6 Mounting of bypass valve

Picture 47: Bypass valve

• Mount the cable from the magnetic valve.

• Mount the two hose onto the fast connectors of the bypass valve.

• Place the bypass valve into the chassis.

• Tighten the two fixation screws of the bypass valve.

• Mount the pump according to chapter MOUNTING OF PUMP.

• Close fresh water tank according to chapter MOUNTING OF

FRESH WATER TANK ASSEMBLY.

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

GTS Technical Manual

14. March 2014 Edition: V1.00/2014 5-34

Copyright © 2014, Diversey Care

05.72.27 mangetic valve & water outlet - valve unit - 30_45_V1.00.fm

5.5 Magnetic valve & water outlet

5.5.7 Removing of valve unit

Picture 48: Valve unit

• Remove the two nozzles (30:06/105, 45:07/105) and (30:06/

106, 45:07/106) from the valve unit (30:06/103, 45:07/103).

Remarks

Use the additional tool (30:06/142, 45:07/142) to remove the two

nozzles.

• Open fresh water tank according to chapter REMOVING OF FRESH

WATER TANK ASSEMBLY.

Ensure that no water is in the fresh water system before you

disconnect the hoses.

• Remove brush cover according to chapter REMOVING OF BRUSH

MOTOR BELT.

• Remove the two fixation screws (30:06/108, 45:07/108) from

the two valve holders (30:06/109, 45:07/109) and (30:06/112,

45:07/112).

• Lift out the complete valve unit together with the two valve

holders.

• Disconnect the cables of the valve unit at the connection block.

• Remove the two hoses (30:06/117, 45:07/117) and (30:06/118,

45:07/118) from the fast connectors (30:06/113, 45:07/113)

and (30:06/114, 45:07/114).

• Remove the valve holders from the valve unit.

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

GTS Technical Manual

14. March 2014 Edition: V1.00/2014 5-35

Copyright © 2014, Diversey Care

05.72.27 mangetic valve & water outlet - valve unit - 30_45_V1.00.fm

5.5 Magnetic valve & water outlet

5.5.8 Mounting of valve unit

Picture 49: Valve unit details

• Position the valve unit into the valve holders.

• Mount the two hoses onto the fast connectors.

• Connect the cables into the connection block.

• Position the complete valve unit onto the chassis.

• Mount the two fixation screws onto the valve holders.

• Mount the brush cover according to chapter MOUNTING OF

BRUSH MOTOR BELT.

• Close fresh water tank according to chapter MOUNTING OF

FRESH WATER TANK ASSEMBLY.

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

14. March 2014 Edition: V1.00/2014

Copyright © 2014, Diversey Care

Technical Manual

6 Electrical

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

GTS Technical Manual

14. March 2014 Edition: V1.00/2014 6-1

Copyright © 2014, Diversey Care

06.10.17 system architecture - 30_45_350E_455E_755E_1255E_V1.10.fm

6.1 System architecture

Remove the power supply/mains before you work on the machine.

6.1.1 Motor circuit

• The motor that is used in electrical TASKI machines is a single

phase AC-motor.

• To generate a rotating magnetic field, that enables a rotation of

the rotor, following conditions have to be given:

• The currents have to be phase shifted.

• A second coil is available and fed with phase shifted cur-

rent.

• This means that the current in the main coil (thicker wires, low

quantity of windings => inductivity marginal) is aligned with the

voltage but the current in the auxiliary coil (thin wires, high

quantity of windings => inductivity higher) is phase shifted,

which ensures the rotation of the rotor.

Picture 1: Phase shifting main and auxiliary coil

• To start and run an AC-motor with single phase we use a

running capacitor and a start capacitor.

• The serial connection of the auxiliary coil and a running

capacitor ensures the required phase shifting.

• To gain a higher motor hinge moment during the start phase, a

start capacitor is connected parallel to the running capacitor.

• The start capacitor will be disconnected by the relay as soon the

motor reaches a certain inductive voltage that switches the relay

off and disconnects the start capacitor from the circuit.

• The switch off point is given by the load that is pulled by the

motor in relation to the main voltage.

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

GTS Technical Manual

14. March 2014 Edition: V1.00/2014 6-2

Copyright © 2014, Diversey Care

06.14.19 dashboard - 30_V1.00.fm

6.2 Main cord & cable inlet inbox

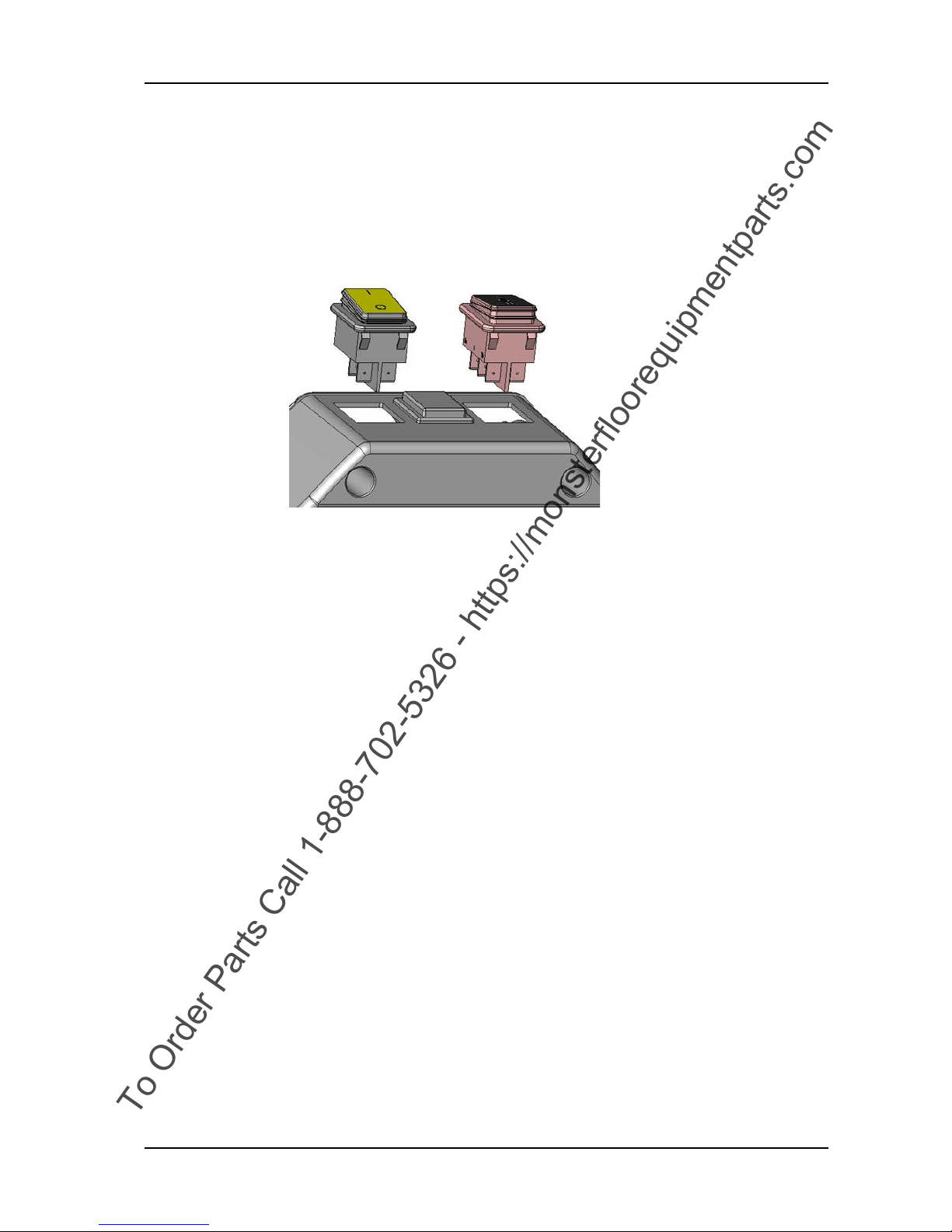

6.2.1 Removing of rockingswitch

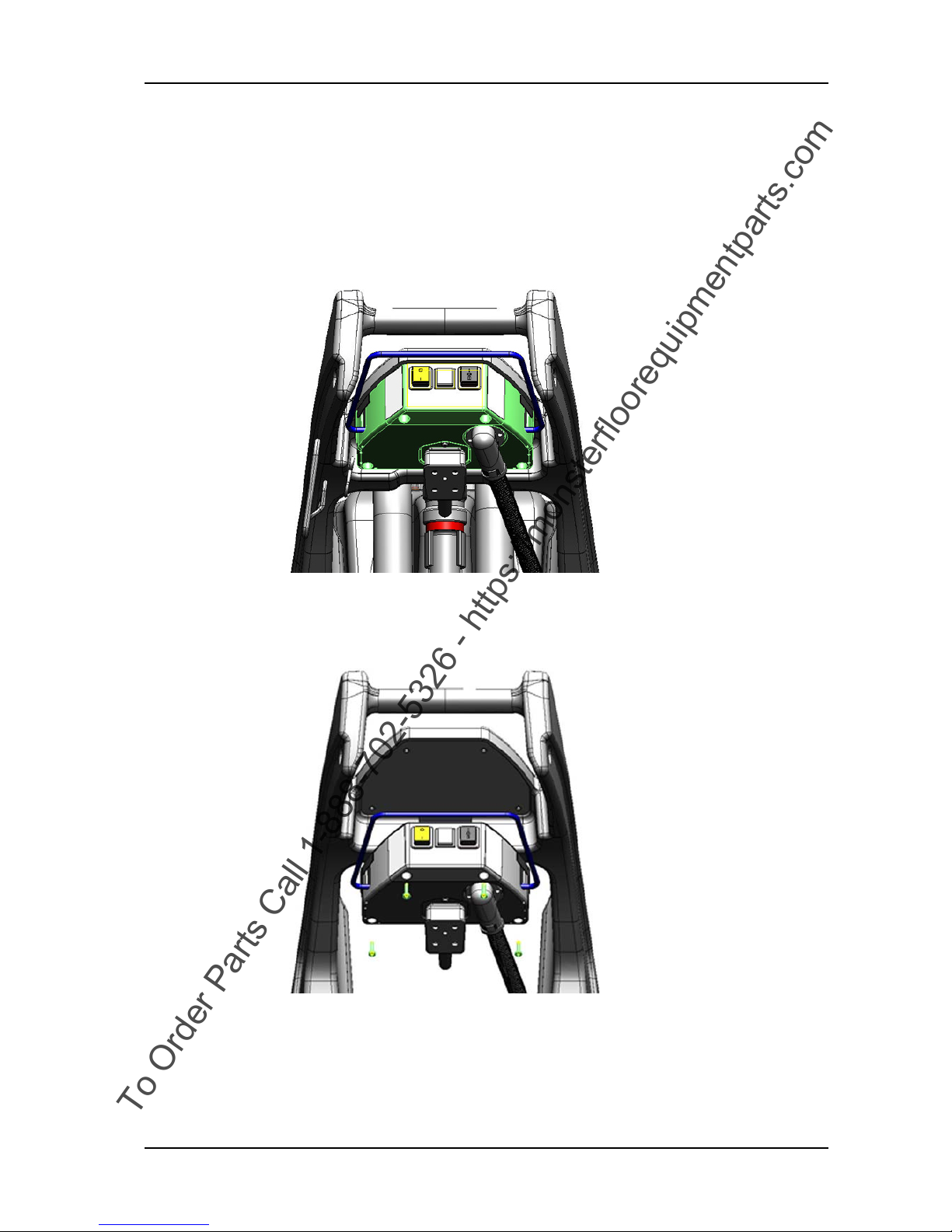

Picture 2: Rockingswitch

• Remove the housing according to chapter REMOVING OF

HOUSING in the section mechanical.

• Disconnect the electrical connections of the rockingswitch (01/

101, 102).

• Push out the rockingswitch from the inner side of the housing

(01/104).

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

GTS Technical Manual

14. March 2014 Edition: V1.00/2014 6-3

Copyright © 2014, Diversey Care

06.14.19 dashboard - 30_V1.00.fm

6.2 Main cord & cable inlet inbox

6.2.2 Mounting of rockingswitch

Picture 3: Rockingswitch

• Push the rockingswitch into the housing from the outer side.

Remarks

Make sure that the rockingswitch is correctly positioned and clicks

into the housing.

• Connect the electrical connections to the rockingswitch.

• Mount the housing according to chapter MOUNTING OF

HOUSING in the section mechanical.

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

GTS Technical Manual

14. March 2014 Edition: V1.00/2014 6-4

Copyright © 2014, Diversey Care

06.14.40 dashboard - connections - 30_V1.00.fm

6.2 Main cord & cable inlet inbox

6.2.3 Rockingswitch connections

Picture 4: Dashboard connections

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

GTS Technical Manual

14. March 2014 Edition: V1.00/2014 6-5

Copyright © 2014, Diversey Care

06.14.40 dashboard - connections - 30_V1.00.fm

Pos. Plug Description [plug] Pin Description [pin]

1 HS Main rockingswitch 1 (OUT) OUT main phase

=> Pump

=> Contactor K1

=> Magnetic valve DS1/DS2/DS3

2 HS Main rockingswitch 2 (OUT) OUT main neutral

=> Vacuum motor rockingswitch, further to

contactor K1

=> Pump

3 HS Main rockingswitch 1a (IN) IN main phase

=> contactor K1/K2

4 HS Main rockingswitch 2a (IN) IN main neutral

=> contactor K1/K2

5 BS Vacuum motor/pump/dosing rockingswitch 1b (OUT) Magnetic valve

=> DS1

=> DS3

6 BS Vacuum motor/pump/dosing rockingswitch 2b (OUT) (Not connected)

7 BS Vacuum motor/pump/dosing rockingswitch 1 (IN) Microswitch brush motor

=> contactor K2

8 BS Vacuum motor/pump/dosing rockingswitch 2 (OUT) Microswitch brush motor

9 BS Vacuum motor/pump/dosing rockingswitch 1a (OUT) Magnetic valve

=> DS2

10 BS Vacuum motor/pump/dosing rockingswitch 2a (OUT) Contactor K1

=> Vacuum motor

Table 1: Rockingswitch connector description

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

GTS Technical Manual

14. March 2014 Edition: V1.00/2014 6-6

Copyright © 2014, Diversey Care

06.16.13 contactor - 30_45_V1.00.fm

6.3 Contactor

6.3.1 Removing of contactor

Picture 5: Contactor

• Open fresh water tank according to chapter REMOVING OF FRESH

WATER TANK ASSEMBLY.

Ensure that no water is in the fresh water system before you

disconnect the hoses.

• Disconnect the plugs from the contactor (30:03/104, 45:04/

104) or (30:04/120, 45:05/120).

• Remove the two screws (30:03/103, 45:04/103) or (30:04/101,

45:05/101) from the contactor.

• Remove the contactor.

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

GTS Technical Manual

14. March 2014 Edition: V1.00/2014 6-7

Copyright © 2014, Diversey Care

06.16.13 contactor - 30_45_V1.00.fm

6.3 Contactor

6.3.2 Mounting of contactor

Picture 6: Contactor

• Position the contactor on the chassis.

• Mount the two screws.

• Connect the plugs onto the contactors.

Connect the plugs according to the number coding.

• Close fresh water tank according to chapter MOUNTING OF

FRESH WATER TANK ASSEMBLY.

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

GTS Technical Manual

14. March 2014 Edition: V1.00/2014 6-8

Copyright © 2014, Diversey Care

06.16.22 contactor connections - 30_45_V1.00.fm

6.3 Contactor

6.3.3 Contactor connections K1/K2

Picture 7: Contactor connections

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

GTS Technical Manual

14. March 2014 Edition: V1.00/2014 6-9

Copyright © 2014, Diversey Care

06.16.22 contactor connections - 30_45_V 1.00.fm

6.3.3.1 Contactor connections K1

Pos. Plug Description [plug] Pin Description [pin]

1 0 Contactor - Coil 0 => Contactor - Coil (K2)

=> Main switch (HS)

2 1 Contactor - Coil 1 Dosing switch

32Contactor 2Vacuum motor

4 4 Contactor 4 => Main switch (HS)

=> Contactor (K2)

56Contactor 6Vacuum motor

68Contactor 8=> Neutral

=> Contactor (K2)

Table 2: Contactor connections description K1

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

GTS Technical Manual

14. March 2014 Edition: V1.00/2014 6-10

Copyright © 2014, Diversey Care

06.16.22 contactor connections - 30_45_V 1.00.fm

6.3.3.2 Contactor connections K2

Table 3: Contactor connections description K2

Pos. Plug Description [plug] Pin Description [pin]

1 0 Contactor - Coil 0 => Contactor - Coil (K1)

=> Main switch (HS)

2 1 Contactor - Coil 1 Dosing switch

32Contactor 2Brush motor

4 4 Contactor 4 => Main switch (HS)

=> Contactor (K1)

56Contactor 6Brush motor

68Contactor 8=> Neutral

=> Contactor (K1)

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

GTS Technical Manual

14. March 2014 Edition: V1.00/2014 6-11

Copyright © 2014, Diversey Care

06.28.20 schematics - electrical schematics - 30_45_V1.00.fm

6.4 Electrical schematics

6.4.1 Electrical schematics

Picture 8: Electrical schematics

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

14. March 2014 Edition: V1.00/2014

Copyright © 2014, Diversey Care

Technical Manual

7 Additional information

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

GTS Technical Manual

14. March 2014 Edition: V1.00/2014 7-1

Copyright © 2014, Diversey Care

08.1 procarpet 30 - additional information_V1.00.fm

7 Additional information

7.1 Available GTS Newsletter/Instructions

To find the up to date available GTS Newsletters and instructions refer to e-spares.

Newsletter Date of issue Machine Subassembly Topic/Modification Serial

number

Table 1: Newsletters/Instructions

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

14. March 2014 Edition: V1.00/2014

Copyright © 2014, Diversey Care

Technical Manual

8 Revision

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

GTS Technical Manual

14. March 2014 Edition: V1.00/2014 8-1

Copyright © 2014, Diversey Care

09.1 procarpet 30 - revision_V1.00.fm

8 Revision

Date Chapter Content Description Revision

Table 1: Revision

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

14. March 2014 Edition: V1.00/2014

Copyright © 2014, Diversey Care

Technical Manual

9 Appendix

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

GTS Technical Manual

tecnical manual procarpet 30_V1.00MIX.fm

14. March 2014 Edition: V1.00/2014

Copyright © 2014, Diversey Care

Glossar

A

Accessories 4-4

Additional information 7-1

Adjusting of brush height 5-18

B

Brush & Motor 5-12, 5-13, 5-14, 5-15,

5-16, 5-17, 5-18

Brush motor 5-14, 5-15

Brush motor belt 5-12, 5-13

Brush pulley 5-16, 5-17

Brush system 4-4

Bypass valve 5-32, 5-33

C

Consumable supplies 3-1

Contactor 6-6, 6-7, 6-8

Contactor connections 6-8

D

Dashboard connections 6-4

Dimensions and weights 4-3

Direction description 3-1

E

Electrical schematics 6-11

Elementary 2-1

ESD 2-1

F

Filter 5-30, 5-31

Foreword 1-1

Fresh water tank assembly 5-8, 5-10

G

General 3-1

H

Handle 5-1, 5-3, 5-5, 5-6, 5-7

Health & Safety 2-1

Housing 5-1, 5-2

M

Machine profile 4-2

Machine range 4-1

Magnetic valve & water outlet 5-28, 529, 5-30, 5-31, 5-32, 5-34, 5-35

Magnetic valve, electrical parts 5-33

Main cord & cable inlet inbox 6-2, 6-3,

6-4

Material 3-2

Microswitch 5-3, 5-5

Motor circuit 6-1

N

Newsletter/Instructions 7-1

P

Part reference 3-1

Power source 3-1

Pump 5-28, 5-29

R

Required material 3-2

Revision 8-1

Rockingswitch 6-2, 6-3, 6-4

Rockingswitch connections 6-4

S

Shackle 5-21, 5-22

Static discharge 2-2

Suction power 4-4

Summary 1-2

Switching bow 5-6, 5-7

System architecture 6-1

T

Tank cover and tank 5-8, 5-10

Technical data 4-1, 4-2

Technical information 4-2

Technical Manual 1-1

Technical Training 1-1

Tools 3-2

V

Vacuum motor 5-19, 5-20, 5-23, 5-24,

5-25, 5-27

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

GTS Technical Manual

tecnical manual procarpet 30_V1.00MIX.fm

14. March 2014 Edition: V1.00/2014

Copyright © 2014, Diversey Care

Vacuum unit 5-19, 5-21, 5-23, 5-25 Valve unit 5-34, 5-35

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

14. March 2014 Edition: V1.00/2014

Copyright © 2014, Diversey Care

Technical Manual

10 Notes

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

Loading...

Loading...