Taski ergodisc 165, ergodisc 175, ergodisc 200, ergodisc 238, ergodisc 300 Instructions Of Use

...

ergodisc 165/175/200/238/300/400/

438/duo

V010 / 12088-01 0736

I25 I24 I23 I22 I21 I20 I19 I18 I17 tr sl se pt no nl it hu hr fr fi es en el de da

*12088-01*

18

Instructions of use

Symbols

Intended use of machinery

Various single disc machines are available enabling the cleaning and treatment

of both hard and textile surfaces, please ask your TASKI representative for

possible cleaning activities for each machine, and refer to the application

techniques in these instructions of use.

The machine is suitable for floor cleaning applications in industrial and

commercial areas such as hotels, schools, hospitals, factories, shopping

centres and offices.

Content

Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

EU Declaration of Conformity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Machine installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Recommended chemicals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Application technique . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Beginning work . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Transport over stairs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

End of operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Service, maintenance and care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Malfunctions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Transport over stairs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Safety instructions

Due to their design and construction, TASKI machines comply with health and

safety requirements of the EC guidelines and therefore carry the CE sign.

Important! Switch the machine off when you:

• E.g. replace cleaning, service or repair parts or if you change to another

function

• store it in a suitable room to avoid any unauthorised use of the unit

• leave it standing without supervision

You should also pull the plug out of the mains socket.

Store the machine in a dry, dust-free room with a corrosion-free atmosphere.

The temperature must not fall below +10 °C or exceed +35 °C. Low

temperatures, damp and dust can significantly reduce the service life of the

electrical components.

ATTENTION!

Before first start-up, it is essential that you

read the instructions of use and the safety

notes carefully.

Keep the instructions of use in an easily

accessible place so that they can be consulted

at any time.

Non-observance of this information can endanger people and / or

cause servere damage!

Non-observance of this information can lead to malfunctions and

property damage!

Important information about correct use. Non-observance of this

information can lead to malfunctions!

Marks work steps that you must carry out in turn.

Persons (including children) who are not able to use this machine

safely due to their physical, sensory or mental capabilities or their

lack of experience or knowledge may not operate this machine

without supervision or instruction by a person responsible for their

safety!

Children should be supervised to ensure that they do not play with

the appliance.

Do not use the machine in rooms where explosive and flammable

substances (e.g. petrol, thinners, heating oil, solvents, etc.) are

stored or processed. The electrical or mechanical components of

the machine could lead to ignition of these materials.

While operating the machine, take note of the surrounding area

and pay particular attention to third parties and children!

Regularly check the power supply cord for tearing or aging, and

do not put the machine into operation if it is not in a safe and

suitable condition, but have it repaired by an authorised specialist!

In case of a malfunction or a defect of the machine (for example,

at a safety lever or operating lever), after being dropped or a

damaged, the machine must be check by TASKI specialists

before being putr back into operation. The same applies if the

machine has been left in the open, been immersed in water or has

been exposed to damp.

STOP

•

STOP

STOP

STOP

STOP

STOP

Caution:

Repairs to mechanical or electrical parts of the machine must only

be undertaken by JohnsonDiversey authorised customer service

workshops or experts who are experienced in all relevant safety

regulations.

Minimum requirements on the H05VV-F2x1.5 or H07RN-F2x1.5

power cord.

Caution:

This machine is only intended for use in dry areas, and must not

be used or stored in the open air or under damp conditions.

Caution:

Pay attention to the accident prevention regulations!

Caution:

Only use the tools that are defined in these Instructions for Use

under Accessories or that have been recommended by the TASKI

specialist (Page 23), as other tools could impair the safety of the

machine.

Caution:

Only tools (brushes and pads) that are mentioned in these

instructions for use may be hung from the tool hook, as other tools

could cause damage.

Caution:

The power outlet may only be used for additional equipment,

which is specified in the instructions of use (page 23).

Caution:

The protection of persons is based on the special national

regulations and the information from the detergent producer!

Caution:

It is forbidden to plug in or unplug the main power supply cord with

wet hands!

Caution:

Ensure that the rotating brush does not come into contact with the

power supply cord!

Caution:

Take care not to damage the power supply cord by driving over it.

Avoid crimping, tearing or damaging the power supply cord

through heat, oil, or sharp objects!

Caution:

Please make sure that the voltage stated on the machine label is

the same as the voltage rating of the plug socket!

Caution:

Danger of injury by sharp objects.

The personal protection is based on the national regulations!

19

I25 I24 I23 I22 I21 I20 I19 I18 I17 tr sl se pt no nl it hu hr fr fi es en el de da

EU Declaration of Conformity

We

JohnsonDiversey Switzerland

CH-9542 Münchwilen

hereby declare that the product described below both in this basic design and

construction and in the version marketed by us conforms to the relevant safetyand health-related requirements of the appropriate EU Directive.

This declaration shall cease to be valid if modifications are made to the product

without our approval.

Applicable EU Directives:

Machinery Directive (98/37/EEC) in version 98/79/EEC

Low-Voltage Directive (73/23/EEC)

EMC (Electro Magnetic Compatibility) (89/336/EEC) in version

98/13/EEC

Harmonised standards applied:

EN 60 335-1/EN 60 335-1-A1/EN 60 335-1-A11/EN 60 335-2-67/ EN 50366/

EN 55014-1/ EN 55014-1-A1/ EN 55014-1-A2/ EN 55014-2/ EN 55014-2-A1/

EN 61 000-3-2/ EN 61 00-3-2-A2/ EN 61 000-3-3/ EN 6100-3-3-A1

Internal measures have been taken to ensure that the products always

correspond to the requirements of the latest EU Regulations and the standards

that are currently in use

The signatories act on behalf of company management and with full power of

attorney.

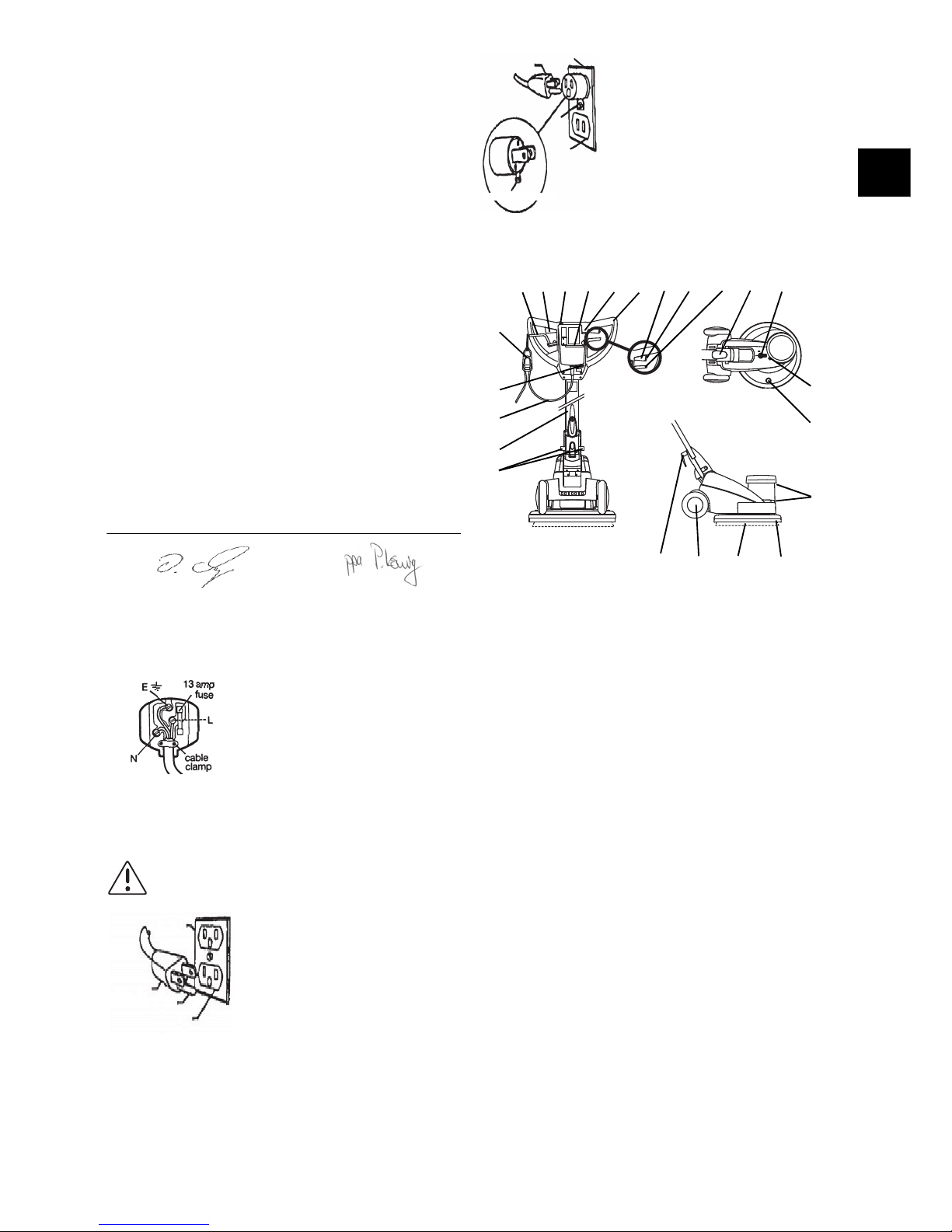

Overview

1

Cord support

2

Power outlet 700W (except for ergodisc 200/238)

3

Power supply cord

4

Central steel pillar

5

Additional equipment holder

6

Cable hook (not standard ex-factory for all models)

7

Wheels

8

Tools (brush, pad drive, etc.)

9

Brush cover

10

Motor ventilation

11

Spray valve connector

12

Central water and spray inlet

13

Selection switch 165/330 rpm (only duo)

14

Recessed grip (for transportation)

15

Height adjustment lever

16

Safety switch

17

Right operating lever (Motor ON/OFF)

18

Machine handle

19

On Iight (Plugged into mains socket)

20

Tool holder (Brushes, pads)

21

Push button for electrical spray unit (except for ergodisc 200/238)

22

Operating lever left (Motor ON/OFF)

23

Action lever for mechanical spray unit and water outlet tank

Product: Single disc machine

Name: ergodisc 165 (43DLS,43DLSL)

ergodisc 200 (43LS,43LSL)

ergodisc 238 (38LSL)

ergodisc 400 (43HS,43HSL)

ergodisc 438 (38HSL)

ergodisc duo (43LHS,43LHSL)

Model: 43DLS,43DLSL (230-240V~/50Hz/1800W)

43LS.43LSL (230-240V~/50Hz/800W)

38LSL (230-240V~/50Hz/800W)

43HS,43HSL (230-240V~/50Hz/1800W)

38HSL (230-240V~/50Hz/1800W)

43LHS,43LHSL (230-240V~/50Hz/1800W)

Version for UK electrical connection

The flexible cord fitted to this machine is of 3 core

construction for use with a 3 pin plug. For your

convenience a 13-amp plug conforming to BS

1363 has been fitted. This machine must be

fused at 10 amps. If you need to change the plug,

the correct wiring is set out below.

Green and yellow wire to terminal marked „ E “ or

with the „Earth Symbol“ or coloured green, or

green and yellow.

Blue wire to terminal marked „ N “ or coloured

black.

Brown wire to terminal marked „ L “ or coloured

red.

Caution:

This machine must be properly earthed to project the operator

from electrical shock. Read the safety instructions below

operating this machine!

Version for USA and Canada of the electrical

connection

120 Volt machines have a three-prong plug

attached to a three-wire power supply cord. The

earthing pin on this plug earths the machine

when plugged into a three-prong outlet.

Dipl. Ing. (FH) D.Windmeisser

Dipl. Ing. (FH) P. König

120 Volt plug

Earthed pin

Earthed outlet

An adaptor must be installed as shown here if

only two prong outlets are available.The outlet

box must be earthed and the earthing tab (or

wire) must be installed under the head of the

centre screw ot the outlet cover. 120 Volt plugs

are available at most hardwear stores. Earthing

adaptors are not approved for use in Canada.

• Replace the plug if the grounding pin is damaged or broken.

• The green (or green/yellow) wire in the cord is the grounding wire. When

replacing a plug, this wire must be attached to the grounding pin only.

120 Volt plug

Earthed outlet box

Metal

screw

Earthed

outlet

Tab for earthing screw

14151618 1317

1

2

3

4

5

6 7 8 9

10

11

12

1920212223

20

Machine installation

Attaching tools

Check:

• that the brush has not fallen below the red mark or a brush length of 1 cm.

• the pad for wear and foreign bodies (e.g. grains of sans) before use.

• that the tool is mounted.

Could cause damage to floor surface by negligence!

Recommended chemicals

Only use the chemical products recommended by the manufacturer.

The correct dosage is recommended on the product's packaging and on the "

TASKI Product Information Sheet".

Application technique

• 1 = Electr. spray device is not possible

• 2 = Machine performance is limited; for this reason not recommended

• 3 = Only when the additional weight from the front is taken away

• 4 = Machine weight only conditionally sufficient

• 5 = This application is only recommended when the power selection switch

is set to level 2 (high number of revolutions)

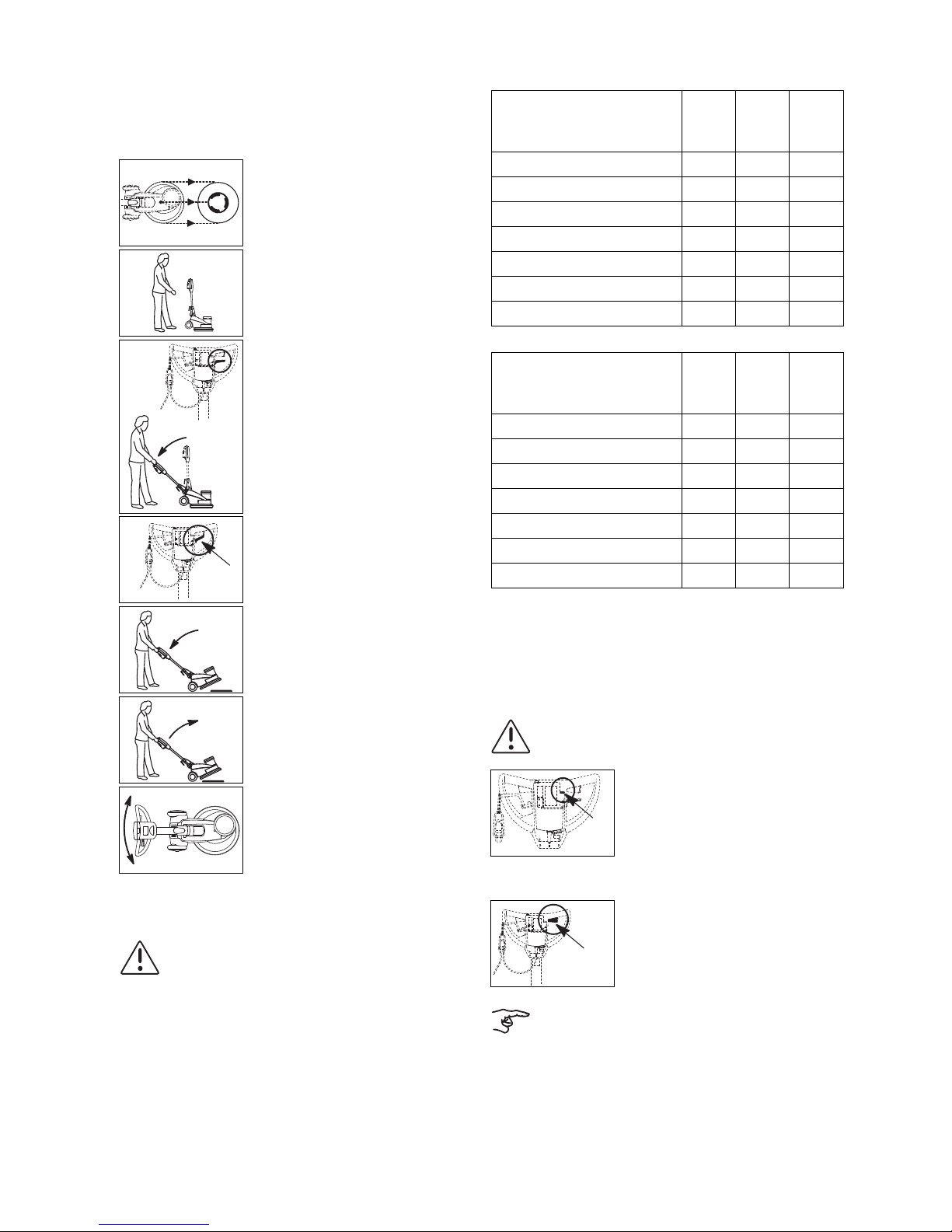

Beginning work

• Lay the tool on the floor in front of the machine.

• Stand behind the machine.

• Pull the height adjustment lever on the machine

handle and slowly lower the guide pillar into a

comfortable working position, making sure your

arms are almost straight.

• Let go of the height adjustment lever, the guide

pillar will locate into place and stay at that angle.

• Tilt the machine back slightly and position it

over the tool until it touches the back of the tool

unit.

• Return the machine to its upright position.

• Move the machine from left to right until the tool

locates into place.

Now the machine is ready for use.

Caution:

Using other chemicals (e.g. chemicals containing solvents,

chlorine, hydrochloric acid and hydrofluoric acid) can damage or

destroy the machine.

Machine 165 200 238

type 43DLS/

43DLSL

43LS/

43LSL

38LSL

Wet cleaning & prime cleaning yes yes yes

Spray cleaning yes yes 1

Shampoo wet yes yes 2

Shampoo dry yes yes 2

Polish yes yes yes

Burnish 4 4 no

Crystallize 4 4 no

Machine 400 438 duo

type 43HS/

43HSL

38HSL 43LHS/

43LHSL

Wet cleaning & prime cleaning no no yes

Spray cleaning yes yes yes

Shampoo wet no no 3

Shampoo dry no no 3

Polish yes yes 5

Burnish no no yes

Crystallize no no yes

Caution:

It is recommended that inexperienced users should first practice

operating the machine on a smooth surface with free areas until

they have mastered the handling of the machine.

• Connect the power supply cord to the mains

socket.

The display lights up.

• Lead the power supply cord with your hand.

Make sure that the power supply cord does not touch the tool.

• Hold on to the machine.

• Push the safety switch and press the operating

levers at the same time.

By doing this the tool is activated.

By slightly lifting the guide pillar the machine moves to the right

and by lowering it the machine moves to the left.

21

I25 I24 I23 I22 I21 I20 I19 I18 I17 tr sl se pt no nl it hu hr fr fi es en el de da

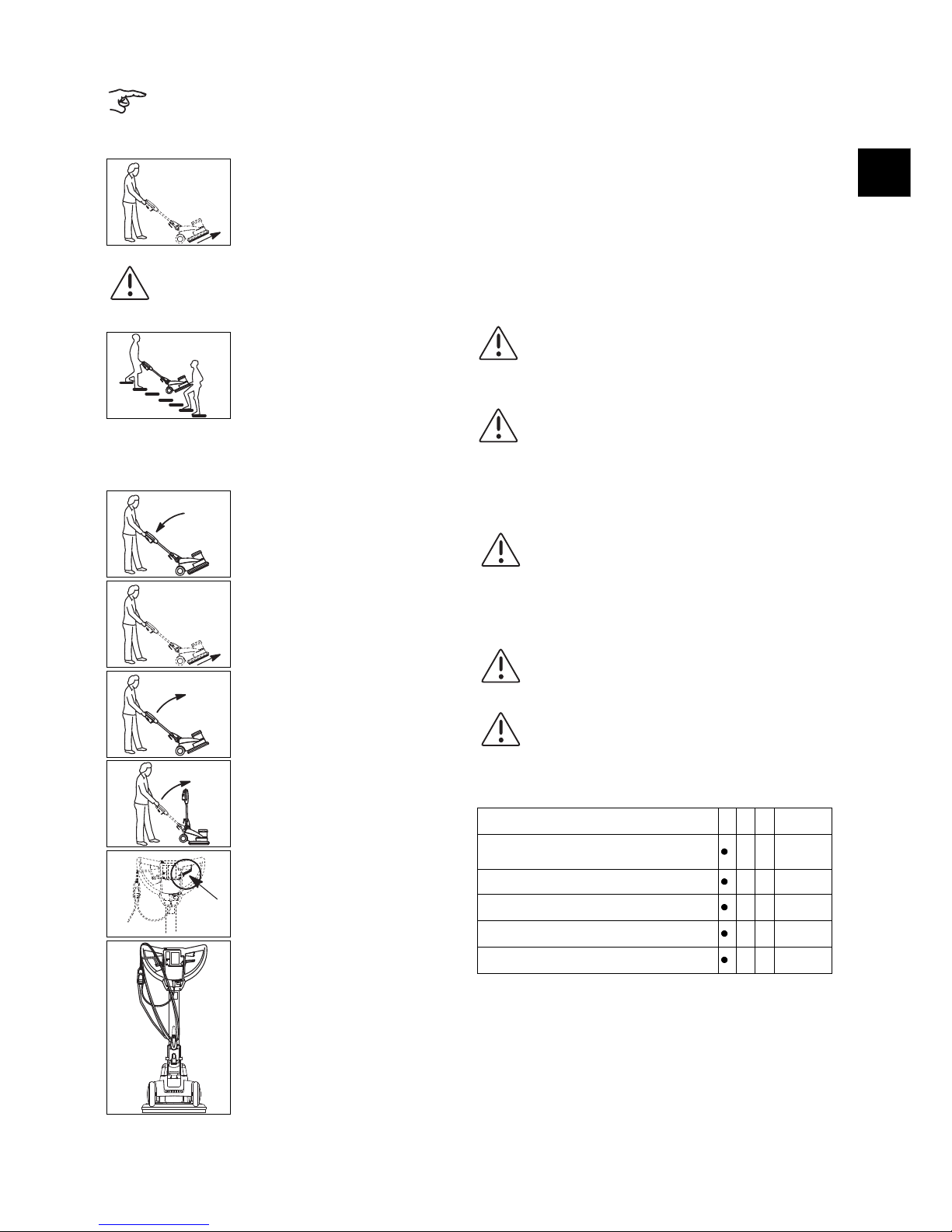

Transport over stairs

End of operation

Emptying solution

The disposal of solution must be carried out in accordance with the national

regulations.

Emptying procedures for the Foam Generator are explained in their own

instructions of use.

Cleaning the tool

Cleaning the pad

Cleaning the machine

Storing the machine

Service, maintenance and care

The correct maintenance of the machine is a precondition for error-free

operation and a long service life.

Service intervals

TASKI machines are high quality machines that have been checked for safety

at the factory by authorised inspectors. Electrical and mechanical components

are subject to wear and/or ageing after longer periods of use.

We recommend the transporting of the machine up or down steps

to be performed by two people.

• Release the operation levers.

• Disconnect the power supply cord from the mains socket.

• Turn the tool away from the coupler.

Caution:

Due to the weight of the machine, there are risks involved in such

transportation!

Slipping can result in damage to the machine and injuries to

persons.

• When lifting, one person should hold the

machine at the brush cover, and the second

person at the machine handle.

• Release the operation levers.

• Pull the power supply cord out of the mains socket.

• Tilt the machine back slightly.

• Turn the tool away from the coupler.

• Carefully lower the machine onto the tool unit.

• Pull the height adjustment lever and slowly lift

the guide pillar until it is in the upright position.

• Let go of the height adjustment lever, the guide

pillar will locate into place and stay at that angle.

• Clean the power supply cord with a damp cloth

and wrap it around the machine handle and the

cord hook.

• Remove the water tank from the machine and empty it.

• Empty the solution from the spray unit.

• Clean the tool under running water with a brush.

• Rinse out the spray unit thoroughly with warm water.

If the cleaning solution dries up, it could cause blockages.

• Lay the pad into cleaning solution for a few hours and then rinse it off.

The pads may be put into the washing machine and washed at a max. of

40°C.

• Air dry the pads.

Caution:

Do not tumble dry the pads!

Caution:

Never clean the machine with high water pressure or a water

hose.

The ingress of water into the machine might cause considerable

damage to mechanical or electrical parts.

• Wipe down the machine with a damp cloth.

Caution:

Never store the machine with a mounted tool!

The tool may get damaged and become unusable.

Caution:

Always unplug the mains plug from the main socket when carrying

out any maintenance work!

Caution:

Only TASKI branded spare parts must be used, otherwise

warranties and liabilities will be omitted!

Symbols:

◊ = after use, ◊◊ = every week, ◊◊◊ = every month

Activity ◊ ◊◊ ◊◊◊ page

Check the motor ventilation for the collection of

dust and clean when necessary

19

Empty spray unit and clean with warm water 21

Clean the brushes 21

Clean the pads and let them dry 21

Clean the machine with a damp cloth 21

• In order to maintain operational reliability and availability for use, the service

must be carried out after 250 working hours or at least once a year.

Shorter intervals are necessary in case of rough environments or special

conditions of use and/or inadequate maintenance.

22

Service centre

Should you contact us due to a malfunction or for placing an order, please

always state the type, description and the serial number of your machine.

You can find this information on the name plate of your machine, and the

address of your nearest TASKI partner can be found on the last page of this

manual.

Malfunctions

Transport

Ensure that the machine is firmly lashed down and secured in the transport

vehicle.

Disposal

After becoming no longer fit for use, the machine and its accessories must be

disposed of in the correct manner in accordance with the national regulations.

On request, your TASKI partner can assist you with this.

Technical data

Malfunction Possible causes Troubleshooting page

Machine does not

run

No power supply

• Insert the plug into the

mains socket

Guide pillar in upright

position

• Place the machine in

the working position

20

Safety switch defect

• Call your Service Partner

19

Machine cannot

be operated, but

the on light

shows

Machine has

overheated causing

motor protection

switch (trip) to cut in.

• Wait a while, try again

(the protection switch

will automatically reset)

Tool does not

rotate

Motor runs but not

tool

• Drive belt is torn or

lose

• Call your Service Partner

Machine does not

reach rated

speed, motor

protection cuts in

Machine is

overloaded

• Check that you are

using the correct working technique

20

Insufficient voltage,

power cord is too long

• Remove extention

• Check power supply

voltage

Machine runs

uneasy

Tool deformed or

damaged

• Replace

Spray pump is

working, cleaning

solution is not

coming out

Cleaning solution has

dried up in spray unit

or tube is blocked

• Clean spray unit

• Replace

• Remove the tool (refer to Page 21).

• Pull the height adjustment lever and fold the

guide pillar towards the front.

• Let go of the height adjustment lever, the guide

pillar will locate into place and stay at that angle.

• To lift the machine, one person must hold the tool unit and the other person

must hold the machine handle.

Caution:

The machine must always be carried by two persons and should

only be lifted by a single person in cases of emergency!

Machine 165 200 238

type 43DLS/

43DLSL

43LS/

43LSL

38LSL

Working width 43 43 38 cm

Dimensions (L x W x H) 67x48x119 67x48x119 67x48x119 cm

Machine weight 34 32 30.5 kg

Rated voltage 230-240V 230-240V 230-240V dc

Rated power 1100 800 800 W

Rated power (intergrated

socket)

700 -- -- W

Frequency 50 50 50 Hz

Power supply cord length 15 15 15 m

Brush rpm 165 165 165 min-1

Brush pressure 0.3 0.28 0.27 N/cm2

Assessed sound level

LPA according to EN

60704-1

57 57 57 dB(A)

The assessed effective

acceleration value

according to ISO 5349

0.4 0.4 0.4 m /s2

Splash water protection IPX4 IPX4 IPX4

Electrical protection class II II II

Machine 400 438 duo

type 43HS/

43HSL

38HSL 43LHS/

43LHSL

Working width 38 38 43 cm

Dimensions (L x W x H) 67x48x119 67x48x119 67x48x119 cm

Machine weight 34 32.5 47 kg

Rated voltage 230-240V 230-240V 230-240V dc

Rated power 1100 1100 1100 W

Rated power (intergrated

socket)

700 700 700 W

Frequency 50 50 50 Hz

Power supply cord length 15 15 15 m

Brush rpm 400 400 165/330 min-1

Brush pressure 0.3 0.28 0.4 N/cm2

Assessed sound level

LPA according to EN

60704-1

57 57 57 dB(A)

The assessed effective

acceleration value

according to ISO 5349

0.4 0.4 0.4 m /s2

Splash water protection IPX4 IPX4 IPX4

Electrical protection class II II II

23

I25 I24 I23 I22 I21 I20 I19 I18 I17 tr sl se pt no nl it hu hr fr fi es en el de da

Accessories

Article

165

200

400

duo

8504360 Spray unit electrical 230V X X X

8504370 Spray unit mechanical X X X X

8504390 Water tank X X X

8504380 Suction aggregate 230V X X X

8505100 Double filter paper sack for suction aggregate

ergodisc (10 pieces per pack)

X X X

8505110 Microfilter for suction aggregate ergodisc (5

pieces per pack)

X X X

8505180 HEPA filter for suction aggregate ergodisc X X X

8504660 Foam Generator 230V X X

8504410 Driving disc Instalok 43cm X X X

7510030 Drive disc Instalok 43 cm X X

8504400 Spray brush 43 cm X X X X

8504750 Scrubbing brush 43 cm X X X

8504800 Scrubbing brush for washed concrete 43cm X X X

8504780 Abrasive scrubbing brush 43 cm X X X

8504830 Dry shampoo brush 43 cm X X

8504860 Wet shampoo brush 43 cm X X X

8504890 Polishing brush union for parquet 43 cm X X X

8503830 Carrier disc for diamond pads 43 cm X X

8505090 Driving disc for carrier disc 8503.830 X X

TASKI ergodisc Serie

8003840 165 SEV 43 DLS 230V/50Hz 04

8003800 200 SEV 43 LS 230V/50Hz 04

8003880 400 SEV 43 HS 230V/50Hz 04

8003850 165 EURO 43 DLS 230V/50Hz 04

8003810 200 EURO 43 LS 230V/50Hz 04

8003890 400 EURO 43 HS 230V/50Hz 04

7521877 165 EURO 43 DLSM 220V/60Hz 04

8003820 165 UK 43 DLSL 240V/50Hz 04

8003780 200 UK 43 LSL 240V/50Hz 04

8004030 238 UK 38 LSL 240V/50Hz 03

8003860 400 UK 43 HSL 240V/50Hz 04

8004040 438 UK 38 HSL 240V/50Hz 03

8003790 175 CSA 50 LSC 120V/60Hz 03

7510804 200 CSA 43 LSC 120V/60Hz 04

8003830 300 CSA 43 MSC 120V/60Hz 04

7517949 165 CN 43 DLS 230V/50Hz 04

7517950 200 CN 43 LS 230V/50Hz 04

8004410 165 KSA 43 DLSM 220V/60Hz 04

8004760 165 43 DLSO 100,110/60 04

8005000 165 43 DLSN 110/50z 04

8004010 DUO SEV 43 LHS 230V/50Hz 05

8004020 DUO EURO 43 LHS 230V/50Hz 05

8003990 DUO UK 43 LHSL 240V/50Hz 05

7517951 DUO CN 43 LHS 230V/50Hz 05

Postfach CH 9542 Münchwilen

Telefon +41 71 969 27 27 Fax +41 71 969 22 53

Ersatzteilliste

Liste des pièces de rechange

Spare parts list

TASKI ergodisc

Ausführung/Execution; List(e) /3.1

25.08.2010 SPS

1

TASKI ergodisc 165-438 & duo

S006015 TASKI ergodisc 165-438 &

duo

TASKI ergodisc 165-438 &

duo

TASKI ergodisc 165-438 &

duo

Pos.

No.

Artikelnr.

Article No.

Item No.

Bestellnr.

No. de com

Order No.

Model

Stck.

Piè.

Qty.

Bezeichnung Designation Description

1 S000010 1.00 Netzkabel & Anschlussbox Cable d'alimentation & boite de jonction Main cord & cable inlet box

2 S000011 1.00 Führungsstange Timon Guide bar

3 S000012 1.00 Antrieb part/1 Entrainement part/1 Drive part/1

4 S000013 1.00 Antrieb part/2 Entrainement part/2 Drive part/2

5 S000017 1.00 Spraygerät mechanisch Vaporisateur mécanique Dispensing unit mechnical

6 S000018 1.00 Spraygerät elektrisch Vaporisateur électrique Dispensing unit electrical

7 S000015 1.00 Elektroschema 230V/50Hz Schéma électrique 230V/50Hz Electrical diagram 230V/50Hz

8 S000016 1.00 Elektroschema 120V/60Hz Schéma électrique 120V/60Hz Electrical diagram 120V/60Hz

2

TASKI ergodisc 165-438 & duo

S000010 Netzkabel & Anschlussbox Cable d'alimentation & boite

de jonction

Main cord & cable inlet box

Pos.

No.

Artikelnr.

Article No.

Item No.

Bestellnr.

No. de com

Order No.

Model

Stck.

Piè.

Qty.

Bezeichnung Designation Description

101 14602-34 4108320 8003800 1.00 Netzkabel 2L SEV Câble d'alimentation 2L ASE Main cord 2L SEA

101 14602-34 4108320 8003840 1.00 Netzkabel 2L SEV Câble d'alimentation 2L ASE Main cord 2L SEA

101 14602-34 4108320 8003880 1.00 Netzkabel 2L SEV Câble d'alimentation 2L ASE Main cord 2L SEA

101 14602-34 4108320 8004010 1.00 Netzkabel 2L SEV Câble d'alimentation 2L ASE Main cord 2L SEA

101 14602-35 4108310 8003810 1.00 Netzkabel 2L EURO Câble d'alimentation 2L EURO Main cord 2L EURO

101 14602-35 4108310 8003850 1.00 Netzkabel 2L EURO Câble d'alimentation 2L EURO Main cord 2L EURO

101 14602-35 4108310 8003890 1.00 Netzkabel 2L EURO Câble d'alimentation 2L EURO Main cord 2L EURO

101 14602-35 4108310 8004020 1.00 Netzkabel 2L EURO Câble d'alimentation 2L EURO Main cord 2L EURO

101 14602-35 4108310 7521877 1.00 Netzkabel 2L EURO Câble d'alimentation 2L EURO Main cord 2L EURO

101 14602-36 4123192 8004410 1.00 Netzkabel 2L UK Câble d'alimentation 2L UK Main cord 2L UK

101 14604-65 7517949 1.00 Netzkabel 2L CN Câble d'alimentation 2P CN Main Cord 2P CN

101 14604-65 7517950 1.00 Netzkabel 2L CN Câble d'alimentation 2P CN Main Cord 2P CN

101 14604-65 7517951 1.00 Netzkabel 2L CN Câble d'alimentation 2P CN Main Cord 2P CN

102 14603-68 4108300 8003780 1.00 Anschlusskabel 2L UK Câble d'alimentation 2L UK Main cord 2L UK

102 14603-68 4108300 8003820 1.00 Anschlusskabel 2L UK Câble d'alimentation 2L UK Main cord 2L UK

102 14603-68 4108300 8003860 1.00 Anschlusskabel 2L UK Câble d'alimentation 2L UK Main cord 2L UK

102 14603-68 4108300 8003990 1.00 Anschlusskabel 2L UK Câble d'alimentation 2L UK Main cord 2L UK

102 14603-68 4108300 8004030 1.00 Anschlusskabel 2L UK Câble d'alimentation 2L UK Main cord 2L UK

102 14603-68 4108300 8004040 1.00 Anschlusskabel 2L UK Câble d'alimentation 2L UK Main cord 2L UK

102 14603-68 4108300 8005000 1.00 Anschlusskabel 2L UK Câble d'alimentation 2L UK Main cord 2L UK

102 14603-69 4108290 7510804 1.00 Anschlusskabel 2L+P CSA Câble d'alimentation 2L+P CSA Main cord 2L+P CSA

102 14603-69 4108290 8003790 1.00 Anschlusskabel 2L+P CSA Câble d'alimentation 2L+P CSA Main cord 2L+P CSA

102 14603-69 4108290 8003830 1.00 Anschlusskabel 2L+P CSA Câble d'alimentation 2L+P CSA Main cord 2L+P CSA

102 14603-69 4108290 8004760 1.00 Anschlusskabel 2L+P CSA Câble d'alimentation 2L+P CSA Main cord 2L+P CSA

103 1840/017 4101980 8.00 PT-Schr LK KS KA50x20 Vis pour plastique KA50x20 Screw for plastic KA50x20

104 14604-50 4126845 Option 1.00 Platte Plaque Plate

105 14604-41 4126557 Option 1.00 Riegel rochet Hook

106 4106/180 4108280 220-240V 1.00 Signalleuchte 230V Lampe temoin 230 V Signal Lamp 230 V

106 4106/181 4108270 100-120V 1.00 Signalleuchte 120V Lampe temoin 120 V Signal Lamp 120 V

107 14603-40 4109680 7510804 1.00 Kabeldeckel,UK Couvercle de câble Cable Cover

107 14603-40 4109680 8003780 1.00 Kabeldeckel,UK Couvercle de câble Cable Cover

107 14603-40 4109680 8003790 1.00 Kabeldeckel,UK Couvercle de câble Cable Cover

107 14603-40 4109680 8003820 1.00 Kabeldeckel,UK Couvercle de câble Cable Cover

107 14603-40 4109680 8003830 1.00 Kabeldeckel,UK Couvercle de câble Cable Cover

107 14603-40 4109680 8003860 1.00 Kabeldeckel,UK Couvercle de câble Cable Cover

107 14603-40 4109680 8003990 1.00 Kabeldeckel,UK Couvercle de câble Cable Cover

107 14603-40 4109680 8004030 1.00 Kabeldeckel,UK Couvercle de câble Cable Cover

107 14603-40 4109680 8004040 1.00 Kabeldeckel,UK Couvercle de câble Cable Cover

107 14603-40 4109680 8004760 1.00 Kabeldeckel,UK Couvercle de câble Cable Cover

107 14603-40 4109680 8005000 1.00 Kabeldeckel,UK Couvercle de câble Cable Cover

107 14600-64 4109690 7517949 1.00 Kabeldeckel Couvercle de câble Cable Cover

107 14600-64 4109690 7517950 1.00 Kabeldeckel Couvercle de câble Cable Cover

107 14600-64 4109690 7517951 1.00 Kabeldeckel Couvercle de câble Cable Cover

107 14600-64 4109690 8003800 1.00 Kabeldeckel Couvercle de câble Cable Cover

107 14600-64 4109690 8003810 1.00 Kabeldeckel Couvercle de câble Cable Cover

107 14600-64 4109690 8003840 1.00 Kabeldeckel Couvercle de câble Cable Cover

107 14600-64 4109690 8003850 1.00 Kabeldeckel Couvercle de câble Cable Cover

107 14600-64 4109690 8003880 1.00 Kabeldeckel Couvercle de câble Cable Cover

107 14600-64 4109690 8003890 1.00 Kabeldeckel Couvercle de câble Cable Cover

107 14600-64 4109690 8004010 1.00 Kabeldeckel Couvercle de câble Cable Cover

3

TASKI ergodisc 165-438 & duo

S000010 Main cord & cable inlet boxCable d'alimentation & boite

de jonction

Netzkabel & Anschlussbox

Pos.

No.

DescriptionDesignationBezeichnung

Stck.

Piè.

Qty.

Model

Bestellnr.

No. de com

Order No.

Artikelnr.

Article No.

Item No.

107 14600-64 4109690 8004020 1.00 Kabeldeckel Couvercle de câble Cable Cover

107 14600-64 4109690 8004410 1.00 Kabeldeckel Couvercle de câble Cable Cover

108 14602-60 4110120 7517950 1.00 Abdeckung Couvercle Cover

108 14602-60 4110120 8003780 1.00 Abdeckung Couvercle Cover

108 14602-60 4110120 8003800 1.00 Abdeckung Couvercle Cover

108 14602-60 4110120 8003810 1.00 Abdeckung Couvercle Cover

108 14602-60 4110120 8004030 1.00 Abdeckung Couvercle Cover

109 4413/115 4110300 100-120V 1.00 Gerätesteckdose 2P+E Prise d.cordon d'alumentation Socket

109 4408/108 4110110 7517949 1.00 Gerätesteckdose Prise d.cordon d'alumentation Socket

109 4408/108 4110110 7517951 1.00 Gerätesteckdose Prise d.cordon d'alumentation Socket

109 4408/108 4110110 7521877 1.00 Gerätesteckdose Prise d.cordon d'alumentation Socket

109 4408/108 4110110 8003820 1.00 Gerätesteckdose Prise d.cordon d'alumentation Socket

109 4408/108 4110110 8003840 1.00 Gerätesteckdose Prise d.cordon d'alumentation Socket

109 4408/108 4110110 8003850 1.00 Gerätesteckdose Prise d.cordon d'alumentation Socket

109 4408/108 4110110 8003860 1.00 Gerätesteckdose Prise d.cordon d'alumentation Socket

109 4408/108 4110110 8003880 1.00 Gerätesteckdose Prise d.cordon d'alumentation Socket

109 4408/108 4110110 8003890 1.00 Gerätesteckdose Prise d.cordon d'alumentation Socket

109 4408/108 4110110 8003990 1.00 Gerätesteckdose Prise d.cordon d'alumentation Socket

109 4408/108 4110110 8004010 1.00 Gerätesteckdose Prise d.cordon d'alumentation Socket

109 4408/108 4110110 8004020 1.00 Gerätesteckdose Prise d.cordon d'alumentation Socket

109 4408/108 4110110 8004040 1.00 Gerätesteckdose Prise d.cordon d'alumentation Socket

109 4408/108 4110110 8004410 1.00 Gerätesteckdose Prise d.cordon d'alumentation Socket

109 4408/108 4110110 8005000 1.00 Gerätesteckdose Prise d.cordon d'alumentation Socket

110 14603-29 4107150 1.00 Dichtung Joint Gasket

111 14603-70 4107300 1.00 Klappe Oburateur de prise Flap

112 14603-39 4114450 1.00 Torsionsfeder Ressort de torsion Torsion spring

113 3340/236 4089580 1.00 Spannstift 2x36 Goupille élastique 2x36 Extensible pin 2x36

114 4016/203 4047410 1.00

Klemmenleiste 3-Pol 2.5 mm@ Serre-fils 3-pôles 2.5 mm@ Connection bloc 3-ways 2.5 mm@

115 1840/003 4062420 3.00 Delta PT-Schr LK As Torx 30x16 Vis pour plastique KA30x16 Screw for plastic KA30x16

116 10140-4 4001020 1.00 Bride Bride de câble Cable Clamp

117 4503/104 4110100 Option 1.00 Blindstopfen Bouchon Stopple

118 17562-20 4078770 8003780 1.00 Anschlussgehäuse 2L Fiche de connecteur 2L Plug socket 2L

118 17562-20 4078770 8003820 1.00 Anschlussgehäuse 2L Fiche de connecteur 2L Plug socket 2L

118 17562-20 4078770 8003860 1.00 Anschlussgehäuse 2L Fiche de connecteur 2L Plug socket 2L

118 17562-20 4078770 8003990 1.00 Anschlussgehäuse 2L Fiche de connecteur 2L Plug socket 2L

118 17562-20 4078770 8004030 1.00 Anschlussgehäuse 2L Fiche de connecteur 2L Plug socket 2L

118 17562-20 4078770 8004040 1.00 Anschlussgehäuse 2L Fiche de connecteur 2L Plug socket 2L

118 17562-20 4078770 8005000 1.00 Anschlussgehäuse 2L Fiche de connecteur 2L Plug socket 2L

118 55042-71 4081620 7510804 1.00 Anschlussgehäuse 2L+P Fiche de connecteur 2L+P Plug socket 2L+P

118 55042-71 4081620 8003790 1.00 Anschlussgehäuse 2L+P Fiche de connecteur 2L+P Plug socket 2L+P

118 55042-71 4081620 8003830 1.00 Anschlussgehäuse 2L+P Fiche de connecteur 2L+P Plug socket 2L+P

118 55042-71 4081620 8004760 1.00 Anschlussgehäuse 2L+P Fiche de connecteur 2L+P Plug socket 2L+P

119 1840/002 4015720 2.00 PT-Schr LK KS KA40x14 Vis pour plastique KA40x14 Screw for plastic KA40x14

120 1840/001 4015590 4.00 PT-Schr LK KS KA35x10 Vis pour plastique KA35x10 Screw for plastic KA35x10

121 17562-79 4088150 1.00 Steckerdeckel Couvercle pour fiche Plug Cover

122 55042-89 4088140 7510804 1.00 Winkelstecker 2P+E Fiche coudé Right Angle Plug

122 55042-89 4088140 8003790 1.00 Winkelstecker 2P+E Fiche coudé Right Angle Plug

122 55042-89 4088140 8003830 1.00 Winkelstecker 2P+E Fiche coudé Right Angle Plug

122 55042-89 4088140 8004760 1.00 Winkelstecker 2P+E Fiche coudé Right Angle Plug

122 17562-77 4095210 8003780 1.00 Winkelstecker 2P Fiche coudé Right Angle Plug

4

TASKI ergodisc 165-438 & duo

S000010 Main cord & cable inlet boxCable d'alimentation & boite

de jonction

Netzkabel & Anschlussbox

Pos.

No.

DescriptionDesignationBezeichnung

Stck.

Piè.

Qty.

Model

Bestellnr.

No. de com

Order No.

Artikelnr.

Article No.

Item No.

122 17562-77 4095210 8003820 1.00 Winkelstecker 2P Fiche coudé Right Angle Plug

122 17562-77 4095210 8003860 1.00 Winkelstecker 2P Fiche coudé Right Angle Plug

122 17562-77 4095210 8003990 1.00 Winkelstecker 2P Fiche coudé Right Angle Plug

122 17562-77 4095210 8004030 1.00 Winkelstecker 2P Fiche coudé Right Angle Plug

122 17562-77 4095210 8004040 1.00 Winkelstecker 2P Fiche coudé Right Angle Plug

122 17562-77 4095210 8005000 1.00 Winkelstecker 2P Fiche coudé Right Angle Plug

123 1840/011 4079480 1.00 PT-Schr LK KS KA35x20 Vis pour plastique KA35x20 Screw for plastic KA35x20

124 17562-42 4081460 8003780 1.00 Knickschutztülle Douille anti-flambage Cable grommet

124 17562-42 4081460 8003820 1.00 Knickschutztülle Douille anti-flambage Cable grommet

124 17562-42 4081460 8003860 1.00 Knickschutztülle Douille anti-flambage Cable grommet

124 17562-42 4081460 8003990 1.00 Knickschutztülle Douille anti-flambage Cable grommet

124 17562-42 4081460 8004030 1.00 Knickschutztülle Douille anti-flambage Cable grommet

124 17562-42 4081460 8004040 1.00 Knickschutztülle Douille anti-flambage Cable grommet

124 17562-42 4081460 8005000 1.00 Knickschutztülle Douille anti-flambage Cable grommet

124 55042-82 4089210 7510804 1.00 Knickschutztülle Douille anti-flambage Cable grommet

124 55042-82 4089210 7517949 1.00 Knickschutztülle Douille anti-flambage Cable grommet

124 55042-82 4089210 7517950 1.00 Knickschutztülle Douille anti-flambage Cable grommet

124 55042-82 4089210 7517951 1.00 Knickschutztülle Douille anti-flambage Cable grommet

124 55042-82 4089210 7521877 1.00 Knickschutztülle Douille anti-flambage Cable grommet

124 55042-82 4089210 8003790 1.00 Knickschutztülle Douille anti-flambage Cable grommet

124 55042-82 4089210 8003800 1.00 Knickschutztülle Douille anti-flambage Cable grommet

124 55042-82 4089210 8003810 1.00 Knickschutztülle Douille anti-flambage Cable grommet

124 55042-82 4089210 8003830 1.00 Knickschutztülle Douille anti-flambage Cable grommet

124 55042-82 4089210 8003840 1.00 Knickschutztülle Douille anti-flambage Cable grommet

124 55042-82 4089210 8003850 1.00 Knickschutztülle Douille anti-flambage Cable grommet

124 55042-82 4089210 8003880 1.00 Knickschutztülle Douille anti-flambage Cable grommet

124 55042-82 4089210 8003890 1.00 Knickschutztülle Douille anti-flambage Cable grommet

124 55042-82 4089210 8004010 1.00 Knickschutztülle Douille anti-flambage Cable grommet

124 55042-82 4089210 8004020 1.00 Knickschutztülle Douille anti-flambage Cable grommet

124 55042-82 4089210 8004410 1.00 Knickschutztülle Douille anti-flambage Cable grommet

124 55042-82 4089210 8004760 1.00 Knickschutztülle Douille anti-flambage Cable grommet

125 4503/101 4108260 7510804 1.00 Drucktaster Interrupteur Switch

125 4503/101 4108260 7517949 1.00 Drucktaster Interrupteur Switch

125 4503/101 4108260 7517951 1.00 Drucktaster Interrupteur Switch

125 4503/101 4108260 7521877 1.00 Drucktaster Interrupteur Switch

125 4503/101 4108260 8003790 1.00 Drucktaster Interrupteur Switch

125 4503/101 4108260 8003830 1.00 Drucktaster Interrupteur Switch

125 4503/101 4108260 8003840 1.00 Drucktaster Interrupteur Switch

125 4503/101 4108260 8003850 1.00 Drucktaster Interrupteur Switch

125 4503/101 4108260 8003880 1.00 Drucktaster Interrupteur Switch

125 4503/101 4108260 8003890 1.00 Drucktaster Interrupteur Switch

125 4503/101 4108260 8004010 1.00 Drucktaster Interrupteur Switch

125 4503/101 4108260 8004020 1.00 Drucktaster Interrupteur Switch

125 4503/101 4108260 8004410 1.00 Drucktaster Interrupteur Switch

125 4503/101 4108260 8004760 1.00 Drucktaster Interrupteur Switch

126 14604-42 4126558 Option 1.00 Torsionsfeder Ressort de torsion Torsion spring

14603-94 4116440 1.00 Schild Ergonomie Plaquette ergonomie Label ergonomics

S0000105 TASKI ergodisc 165-438 & duo

01

106

118

119

110

107

111

112

114

115

116

115

120

121

122

123

125

113

103

103

104

126

124

101

109

117

108

102

ergodisc /3

105

6

TASKI ergodisc 165-438 & duo

S000011 Führungsstange Timon Guide bar

Pos.

No.

Artikelnr.

Article No.

Item No.

Bestellnr.

No. de com

Order No.

Model

Stck.

Piè.

Qty.

Bezeichnung Designation Description

101 1840/017 4101980 22.00 PT-Schr LK KS KA50x20 Vis pour plastique KA50x20 Screw for plastic KA50x20

102 14600-59 4108670 1.00 Griffschale Poignée Handle housing

103 14600-62 4109830 1.00 Hebel Levier Lever

104 14603-74 4109820 1.00 Hebel Levier Lever

105 14603-51 4109810 1.00 Taste Touche de sécurité Safety Key

106 14602-45 4118190 7517949 1.00 Verbindungskabel 4L Câble de connection 4L Connecting cable 4L

106 14602-45 4118190 7517951 1.00 Verbindungskabel 4L Câble de connection 4L Connecting cable 4L

106 14602-45 4118190 7521877 1.00 Verbindungskabel 4L Câble de connection 4L Connecting cable 4L

106 14602-45 4118190 8003840 1.00 Verbindungskabel 4L Câble de connection 4L Connecting cable 4L

106 14602-45 4118190 8003850 1.00 Verbindungskabel 4L Câble de connection 4L Connecting cable 4L

106 14602-45 4118190 8003880 1.00 Verbindungskabel 4L Câble de connection 4L Connecting cable 4L

106 14602-45 4118190 8003890 1.00 Verbindungskabel 4L Câble de connection 4L Connecting cable 4L

106 14602-45 4118190 8004010 1.00 Verbindungskabel 4L Câble de connection 4L Connecting cable 4L

106 14602-45 4118190 8004020 1.00 Verbindungskabel 4L Câble de connection 4L Connecting cable 4L

106 14602-45 4118190 8004410 1.00 Verbindungskabel 4L Câble de connection 4L Connecting cable 4L

106 14602-46 4114440 7510804 1.00 Verbindungskabel 4L+P Câble de connection 4L+P Connecting cable 4L+P

106 14602-46 4114440 8003790 1.00 Verbindungskabel 4L+P Câble de connection 4L+P Connecting cable 4L+P

106 14602-46 4114440 8003830 1.00 Verbindungskabel 4L+P Câble de connection 4L+P Connecting cable 4L+P

106 14602-46 4114440 8004760 1.00 Verbindungskabel 4L+P Câble de connection 4L+P Connecting cable 4L+P

106 14603-56 4116830 7517950 1.00 Verbindungskabel 2L Câble de connection 2L Connection cable 2L

106 14603-56 4116830 8003780 1.00 Verbindungskabel 2L Câble de connection 2L Connection cable 2L

106 14603-56 4116830 8003800 1.00 Verbindungskabel 2L Câble de connection 2L Connection cable 2L

106 14603-56 4116830 8003810 1.00 Verbindungskabel 2L Câble de connection 2L Connection cable 2L

106 14603-56 4116830 8003820 1.00 Verbindungskabel 2L Câble de connection 2L Connection cable 2L

106 14603-56 4116830 8003860 1.00 Verbindungskabel 2L Câble de connection 2L Connection cable 2L

106 14603-56 4116830 8003990 1.00 Verbindungskabel 2L Câble de connection 2L Connection cable 2L

106 14603-56 4116830 8004030 1.00 Verbindungskabel 2L Câble de connection 2L Connection cable 2L

106 14603-56 4116830 8004040 1.00 Verbindungskabel 2L Câble de connection 2L Connection cable 2L

106 14603-56 4116830 8005000 1.00 Verbindungskabel 2L Câble de connection 2L Connection cable 2L

107 14600-76 4109800 1.00 Profilrohr Timon Guide Bar

108 14603-53 4109790 1.00 Kabeltülle Passe-fil en caoutchouc Cable Bushing

109 1840/002 4015720 7.00 PT-Schr LK KS KA40x14 Vis pour plastique KA40x14 Screw for plastic KA40x14

110 1759/113 4093840 1.00 Scheibe 5,3/15x1,2 Rondelle 5,3/15x1,2 Washer 5,3/15x1,2

111 14600-68 4109580 1.00 Kabelhaken Crochet de câble Cleat, Cable

113 10140-4 4001020 1.00 Bride Bride de câble Cable Clamp

114 14603-47 4109840 1.00 Kabelhalter Fixation pour câble Cable Fixation

115 2804/116 4121580 1.00 Druckfeder Ressort de pression Pressure spring

116 14600-65 4109850 1.00 Führung Console de guidage Guide Block

117 14600-79 4108350 1.00 Abdeckung Couvercle Cover

118 14603-48 4109970 4.00 Bundbolzen Goujon fileté Stud Bolt

119 1755/16 4031090 4.00 Scheibe 8,4/20x1,2 Rondelle 8,4/20x1,2 Washer 8,4/20x1,2

120 14603-58 4108340 8.00 Lagerblock Amortisseur Buffer

121 1721/106 4092870 12.00 Sicherungsmutter M6 Écrou de sureté M6 Self-locking nut M6

125 1132/116 4123656 4.00 Zyl-Schr I-6Kt M6x45/24 Vis cyl. à trou 6 p. M6x45/24 Socket head cap screw M6x45/24

126 1752/14 4007470 4.00 Scheibe 6,4/12x1,6 Rondelle 6,4/12x1,6 Washer 6,4/12x1,6

127 1132/33 4042630 3.00 Zyl-Schr I-6Kt M8x40 Vis cyl. à trou 6 p. M8x40 Socket head cap screw M8x40

128 14600-74 4109960 1.00 H-Profil Profil en H H-Profile

129 3037/120 4059860 1.00 Kugel 8,5 Bille 8,5 Ball 8,5

130 14603-31 4109950 1.00 Hebel Levier Lever

132 14504-16 4027910 1.00 Zugschlinge Boucle de retention Retention Loop

7

TASKI ergodisc 165-438 & duo

S000011 Guide barTimonFührungsstange

Pos.

No.

DescriptionDesignationBezeichnung

Stck.

Piè.

Qty.

Model

Bestellnr.

No. de com

Order No.

Artikelnr.

Article No.

Item No.

133 4425/021 4025940 1.00 Kabelzugentlastung Etrangloir Strain Relief

134 14603-65 4109940 1.00 Hebel Levier Lever

135 14600-58 4108680 1.00 Griffschale Poignée Handle housing

136 14602-08 4109930 1.00 Rolle Rouleau Roller

137 4502/009 4108230 220-240V 1.00 Motorschutzschalter 12A Disjoncteur moteur 12A Protective motor switch 12A

137 4502/010 4108240 100-120V 1.00 Motorschutzschalter 16A isjoncteur moteur 16A Protective motor switch 16A

138 14600-56 4109920 1.00 Bowdenzug Câble bowden Bowden cable

139 2803/108 4109860 1.00 Druckfeder Ressort de pression Pressure spring

142 14602-27 4109570 1.00 Bolzen Goujon Bolt

143 14602-28 4109560 1.00 Einlage Plaque de guidage Sliding Block

144 14600-80 4109730 1.00 Rasterbolzen Doigt verrouilleur denté Locking Bolt With Teeth

145 1752/15 4019790 4.00 Scheibe 6,4/20x1,5 Rondelle 6,4/20x1,5 Washer 6,4/20x1,5

146 14600-81 4109720 1.00 Zahnblock Bloc dentée Gear

149 1721/6 4007340 3.00 Sicherungsmutter M8 Écrou de sureté M8 Self-locking nut M8

150 14602-13 4109760 1.00 Support Support Support

151 14602-32 4109780 2.00 Lagerring Coussinet Bearing Bush

152 3002/110 4109910 2.00 O-Ring 55x3 Joint-O 55x3 O-ring 55x3

153 14600-78 4109740 1.00 Gelenk Articulation Articulation

154 14600-66 4108380 1.00 Abdeckung Couvercle Cover

155 14602-12 4109770 1.00 Support Support Support

156 14603-93 4122268 2.00 Ring Anneau Ring

157 10140-4 4001020 1.00 Bride Bride de câble Cable Clamp

158 1840/003 4062420 2.00 Delta PT-Schr LK As Torx 30x16 Vis pour plastique KA30x16 Screw for plastic KA30x16

8907/1 4118240 Mehrzweckfett OKS 265 1000gr Graisse OKS 265 1000gr Lubricant OKS 265 1000gr

S0000118 TASKI ergodisc 165-438 & duo

02

ergodisc /2.2

132

133

134

129

103

135

107

111

117

143

144

121

155

154

146

150

142

130

105

116

109

153

151

152

149

126

125

127

139

136

137

101

102

101

128

109

110

115

121

138

121

120

145

109

113

114

108

(153)

118

119

120

156

104

106

siehe, voir, see

Gruppe, group(e) 03

Pos. 103

157

158

9

TASKI ergodisc 165-438 & duo

S000012 Antrieb part/1 Entrainement part/1 Drive part/1

Pos.

No.

Artikelnr.

Article No.

Item No.

Bestellnr.

No. de com

Order No.

Model

Stck.

Piè.

Qty.

Bezeichnung Designation Description

101 14600-46 4109590 1.00 Abdeckung Couvercle Cover

101 14602-91 4109600 Duo Speed 1.00 Abdeckung Couvercle Cover

102 1840/012 4082610 4.00 PT-Schr LK KS KA50x16 Vis pour plastique KA50x16 Screw for plastic KA50x16

103 14600-43 4109490 1.00 Getriebegehäuse Bâti d'engrenage ergodisc Gear Housing Ergodisc

104 3061/220 4110030 2.00 Schutzstopfen 15 Bouchon 15 Plug 15

105 14604-17 4117100 1.00 Schlauchnippel Raccord avec joint-O Hose Nipple With O-Ring

106 3002/13 4008950 2.00 O-Ring 10x2 Joint-O 10x2 O-ring 10x2

107 8662/008 4116970 0,25m 1.00 Dichtprofil Joint profile Sealing profile

108 1840/002 4015720 4.00 PT-Schr LK KS KA40x14 Vis pour plastique KA40x14 Screw for plastic KA40x14

109 14604-25 4122439 1.00 Nippel Raccord Nipple

110 1840/019 4109370 6.00 PT-Schr LK KS KA50x25 Vis pour plastique KA50x25 Screw for plastic KA50x25

111 14600-22 4109900 1.00 Support Support Support

112 1840/004 4109990 10.00 Delta PT-Schr LK As Torx 60x25 Vis Delta PT Torx 60x25 Screw delta PT Torx 60x25

112 1840/004 4109990 D43 6.00 Delta PT-Schr LK As Torx 60x25 Vis Delta PT Torx 60x25 Screw delta PT Torx 60x25

114 1747/15 4007400 3.00 Scheibe 8,4/16x1,6 Rondelle 8,4/16x1,6 Washer 8,4/16x1,6

115 1132/30 4042650 3.00 Zyl-Schr I-6Kt M8x25 Vis cyl. à trou 6 p. M8x25 Socket head cap screw M8x25

116 2157/005 4108250 1.00 Keilrippenriemen 23 PH 820 Courroie poly-V 23 PH 820 Poly-V-belt 23 PH 820

117 14602-22 4108450 1.00 Riemenscheibe 192 Poulie D 192 Pulley D 192

117 14600-23 4108440 8003830 1.00 Riemenscheibe Poulie D 158,4 Pulley D 158,4

117 14600-23 4108440 8003860 1.00 Riemenscheibe Poulie D 158,4 Pulley D 158,4

117 14600-23 4108440 8003880 1.00 Riemenscheibe Poulie D 158,4 Pulley D 158,4

117 14600-23 4108440 8003890 1.00 Riemenscheibe Poulie D 158,4 Pulley D 158,4

117 14600-23 4108440 8004040 1.00 Riemenscheibe Poulie D 158,4 Pulley D 158,4

118 2911/23 4008690 1.00 Sicherungsring 25 A Anneau de retenue 25 A Retaining ring 25 A

119 14604-26 4122440 1.00 Dichtung Joint d'étanchéité Gasket

120 1840/113 4130053 3.00 PT-Schr LK KS KA50x30 Vis pour plastique KA50x30 Screw for plastic KA50x30

121 14603-46 4110060 4.00 Dämpfungstülle Anneau de protection Absorbing Ring

122 14603-60 4110080 8004030 1.00 Klemmscheibe Boîte de serrage Clamp Bush

122 14603-60 4110080 8004040 1.00 Klemmscheibe Boîte de serrage Clamp Bush

123 14604-27 4122441 1.00 Zapfen Pivot a crapaudine Centre Plug

124 14603-43 4109630 7510804 1.00 Zusatzgewicht Poids Weight

124 14603-43 4109630 7517949 1.00 Zusatzgewicht Poids Weight

124 14603-43 4109630 7517951 1.00 Zusatzgewicht Poids Weight

124 14603-43 4109630 7521877 1.00 Zusatzgewicht Poids Weight

124 14603-43 4109630 8003790 1.00 Zusatzgewicht Poids Weight

124 14603-43 4109630 8003820 1.00 Zusatzgewicht Poids Weight

124 14603-43 4109630 8003840 1.00 Zusatzgewicht Poids Weight

124 14603-43 4109630 8003850 1.00 Zusatzgewicht Poids Weight

124 14603-43 4109630 8003990 1.00 Zusatzgewicht Poids Weight

124 14603-43 4109630 8004010 1.00 Zusatzgewicht Poids Weight

124 14603-43 4109630 8004020 1.00 Zusatzgewicht Poids Weight

124 14603-43 4109630 8004410 1.00 Zusatzgewicht Poids Weight

124 14603-43 4109630 8004760 1.00 Zusatzgewicht Poids Weight

124 14603-43 4109630 8005000 1.00 Zusatzgewicht Poids Weight

125 1755/16 4031090 1.00 Scheibe 8,4/20x1,2 Rondelle 8,4/20x1,2 Washer 8,4/20x1,2

126 2433/101 4088430 1.00 Sterngriff M6 Bouton étoile M6 Star knob M6

127 14603-44 4109650 1.00 Bundbolzen Goujon Flange bolt

128 14603-64 4109670 1.00 Platte Plaque Plate

129 1840/012 4082610 3.00 PT-Schr LK KS KA50x16 Vis pour plastique KA50x16 Screw for plastic KA50x16

130 14603-63 4109660 1.00 Flansch Flasque Flange

10

TASKI ergodisc 165-438 & duo

S000012 Drive part/1Entrainement part/1Antrieb part/1

Pos.

No.

DescriptionDesignationBezeichnung

Stck.

Piè.

Qty.

Model

Bestellnr.

No. de com

Order No.

Artikelnr.

Article No.

Item No.

131 8936/1 4017370 1.00 Sicherungs-Klebstoff mittel Colle pour blocage moyen Adhesive locking middle

132 14604-24 4122438 1.00 Zwischenring Anneau intermédiaire Intermediate Ring

133 14600-33 4109190 1.00 Kupplungsring Disque d'embrayage Coupling Flange

134 14501-49 4037840 1.00 Durchführungstülle 13,9 Douille de passage 13,9 Grommet 13,9

134a 14603-49 4110020 2.00 Abdeckung Couvercle Cover

135 1207/235 4121973 3.00 L-Schr KS M6x35 Vis à tête cyl. bomb. M6x35 Raised cheese hd.screw M6x35

136 1755/11 4007550 3.00 Scheibe 6,4/16x0,8 Rondelle 6,4/16x0,8 Washer 6,4/16x0,8

139 14604-53 4127045 Ø 38 1.00 Bürstenhaube Capot de brosse Brush housing

139 14604-46 4126760 Ø 43 1.00 Bürstenhaube Capot de brosse Brush housing

139 14604-52 4127043 Ø 50 1.00 Bürstenhaube Capot de brosse Brush housing

142 14604-32 4122574 S04 1.00 Gewicht Poids Weight

142 14604-32 4122574 S05, DUO 1.00 Gewicht Poids Weight

142 14602-26 4109540 8004040 1.00 Gewicht Poids Weight

142 14602-26 4109540 8004030 1.00 Gewicht Poids Weight

142 14602-29 4109550 8003790 1.00 Gewicht Poids Weight

143 4571/105 4112110 1.00 Nockenschalter Commutateur à came Cam Commutator

144 14602-92 4110320 1.00 Flachdichtung Joint Gasket

145 14603-79 4126350 2.00 Buchse 4,5/6x3 Douille 4,5/6x3 Bush 4,5/6x3

146 1307/166 4035560 2.00 S-Schr KS M4x12 Vis à tête conique M4x12 Counters. head screw M4x12

147 14603-28 4110330 1.00 Schild I/O Plaquette I/O Label I/O

148 14604-35 4122624 1.00 Mutter M6 spez Écrou M6 spec Nut M6 spec

149 1132/21 4006440 3.00 Zyl-Schr I-6Kt M6x16 Vis cyl. à trou 6 p. M6x16 Socket head cap screw M6x16

150 14604-34 4122577 2.00 Stehbolzen Goujon fileté Stud Bolt

151 14604-37 4122798 2.00 Bolzen Goujon Bolt

152 17608-38 4123215 1.00 Dichtung Joint d'étanchéité Gasket

153 14600-20 4127001 1.00 Verschlusswinkel Insertion Insert

155 8936/62 4031660 Sicherungs-Klebstoff schwach Colle pour blocage faible Adhesive locking faint

156 3395/094 4122309 1.00 Schaltergriff Bouton de commutateur Commutator Knob

157 70016-45 4123156 1.00 Distanzscheibe Disque de distance Distance Disc

158 1840/012 4082610 3.00 PT-Schr LK KS KA50x16 Vis pour plastique KA50x16 Screw for plastic KA50x16

159 8909/61 4039680 Synthesefett 53B 1000gr Graisse synsetral 53B 1000gr Lubricant synsetral 53B 1000gr

S00001211 TASKI ergodisc 165-438 & duo

03

ergodisc /4.1

101

109

103

108

102

105

107

135

136

104

106

143

144 145

146

147

TASKI ergodisc duo

101

110

117

155

Verwendung siehe

149

155

126

125

124

127

128

130

129

application voir

usage see

134a

131

149

156

Mod. / exe. 43 Mod. / exe. 38, 50

112

142

134

139

120

133

118

115

114

111

132

119

116

151

150

121

112

142

122

148

Position

siehe, see Gr. 06

(Gr.04,P.124)

Model - pos. 124

134a

123

157

158

159

135

152

153

(Gr.04)

12

TASKI ergodisc 165-438 & duo

S000013 Antrieb part/2 Entrainement part/2 Drive part/2

Pos.

No.

Artikelnr.

Article No.

Item No.

Bestellnr.

No. de com

Order No.

Model

Stck.

Piè.

Qty.

Bezeichnung Designation Description

101 4802/350 4108210 7517949 1.00

Anlaufkondensator 80µF Condensateur de démarrage 80µF Start capacitor 80µF

101 4802/350 4108210 7517950 1.00

Anlaufkondensator 80µF Condensateur de démarrage 80µF Start capacitor 80µF

101 4802/350 4108210 7517951 1.00

Anlaufkondensator 80µF Condensateur de démarrage 80µF Start capacitor 80µF

101 4802/350 4108210 7521877 1.00

Anlaufkondensator 80µF Condensateur de démarrage 80µF Start capacitor 80µF

101 4802/350 4108210 8003780 1.00

Anlaufkondensator 80µF Condensateur de démarrage 80µF Start capacitor 80µF

101 4802/350 4108210 8003800 1.00

Anlaufkondensator 80µF Condensateur de démarrage 80µF Start capacitor 80µF

101 4802/350 4108210 8003810 1.00

Anlaufkondensator 80µF Condensateur de démarrage 80µF Start capacitor 80µF

101 4802/350 4108210 8003820 1.00

Anlaufkondensator 80µF Condensateur de démarrage 80µF Start capacitor 80µF

101 4802/350 4108210 8003840 1.00

Anlaufkondensator 80µF Condensateur de démarrage 80µF Start capacitor 80µF

101 4802/350 4108210 8003850 1.00

Anlaufkondensator 80µF Condensateur de démarrage 80µF Start capacitor 80µF

101 4802/350 4108210 8003990 1.00

Anlaufkondensator 80µF Condensateur de démarrage 80µF Start capacitor 80µF

101 4802/350 4108210 8004010 1.00

Anlaufkondensator 80µF Condensateur de démarrage 80µF Start capacitor 80µF

101 4802/350 4108210 8004020 1.00

Anlaufkondensator 80µF Condensateur de démarrage 80µF Start capacitor 80µF

101 4802/350 4108210 8004030 1.00

Anlaufkondensator 80µF Condensateur de démarrage 80µF Start capacitor 80µF

101 4802/350 4108210 8004410 1.00

Anlaufkondensator 80µF Condensateur de démarrage 80µF Start capacitor 80µF

101 4802/351 4108160 8003860 1.00

Anlaufkondensator 100µF Condensateur de démarrage 100µF Start capacitor 100µF

101 4802/351 4108160 8003880 1.00

Anlaufkondensator 100µF Condensateur de démarrage 100µF Start capacitor 100µF

101 4802/351 4108160 8003890 1.00

Anlaufkondensator 100µF Condensateur de démarrage 100µF Start capacitor 100µF

101 4802/351 4108160 8004040 1.00

Anlaufkondensator 100µF Condensateur de démarrage 100µF Start capacitor 100µF

101 4802/353 4108170 8004760 1.00

Anlaufkondensator 400µF Condensateur de démarrage 400µF Start capacitor 400µF

101 4802/354 4118050 7510804 1.00

Anlaufkondensator 300µF Condensateur de démarrage 300µF Start capacitor 300µF

101 4802/354 4118050 8003790 1.00

Anlaufkondensator 300µF Condensateur de démarrage 300µF Start capacitor 300µF

101 4802/354 4118050 8003830 1.00

Anlaufkondensator 300µF Condensateur de démarrage 300µF Start capacitor 300µF

101 4802/354 4118050 8005000 1.00

Anlaufkondensator 300µF Condensateur de démarrage 300µF Start capacitor 300µF

102 4808/181 4108150 7510804 1.00

Betriebskondensator 25µF Condensateur de service 25µF Run capacitor 25µF

102 4808/181 4108150 8003790 1.00

Betriebskondensator 25µF Condensateur de service 25µF Run capacitor 25µF

102 4808/181 4108150 8003830 1.00

Betriebskondensator 25µF Condensateur de service 25µF Run capacitor 25µF

102 4808/181 4108150 8004760 1.00

Betriebskondensator 25µF Condensateur de service 25µF Run capacitor 25µF

102 4808/182 4108200 7517949 1.00

Betriebskondensator 32µF Condensateur de service 32µF Run capacitor 32µF

102 4808/182 4108200 7517951 1.00

Betriebskondensator 32µF Condensateur de service 32µF Run capacitor 32µF

102 4808/182 4108200 7521877 1.00

Betriebskondensator 32µF Condensateur de service 32µF Run capacitor 32µF

102 4808/182 4108200 8003820 1.00

Betriebskondensator 32µF Condensateur de service 32µF Run capacitor 32µF

102 4808/182 4108200 8003840 1.00

Betriebskondensator 32µF Condensateur de service 32µF Run capacitor 32µF

102 4808/182 4108200 8003850 1.00

Betriebskondensator 32µF Condensateur de service 32µF Run capacitor 32µF

102 4808/182 4108200 8003860 1.00

Betriebskondensator 32µF Condensateur de service 32µF Run capacitor 32µF

102 4808/182 4108200 8003880 1.00

Betriebskondensator 32µF Condensateur de service 32µF Run capacitor 32µF

102 4808/182 4108200 8003890 1.00

Betriebskondensator 32µF Condensateur de service 32µF Run capacitor 32µF

102 4808/182 4108200 8003990 1.00

Betriebskondensator 32µF Condensateur de service 32µF Run capacitor 32µF

102 4808/182 4108200 8004010 1.00

Betriebskondensator 32µF Condensateur de service 32µF Run capacitor 32µF

102 4808/182 4108200 8004020 1.00

Betriebskondensator 32µF Condensateur de service 32µF Run capacitor 32µF

102 4808/182 4108200 8004040 1.00

Betriebskondensator 32µF Condensateur de service 32µF Run capacitor 32µF

102 4808/182 4108200 8004410 1.00

Betriebskondensator 32µF Condensateur de service 32µF Run capacitor 32µF

102 4808/184 4108190 7517950 1.00

Betriebskondensator 20µF Condensateur de service 20µF Run capacitor 20µF

102 4808/184 4108190 8003780 1.00

Betriebskondensator 20µF Condensateur de service 20µF Run capacitor 20µF

102 4808/184 4108190 8003800 1.00

Betriebskondensator 20µF Condensateur de service 20µF Run capacitor 20µF

102 4808/184 4108190 8003810 1.00

Betriebskondensator 20µF Condensateur de service 20µF Run capacitor 20µF

102 4808/184 4108190 8004030 1.00

Betriebskondensator 20µF Condensateur de service 20µF Run capacitor 20µF

102 4808/185 4123187 8005000 1.00

Betriebskondensator 50µF Condensateur de service 50µF Run capacitor 50µF

103 4586/114 4117820 220-240V 1.00 Relais 230V 50/60Hz Relais 230V 50/60Hz Relay 230V 50/60Hz

103 4586/115 4117480 100-120V 1.00 Relais 120V 50/60Hz Relais 120V 50/60Hz Relay 120V 50/60Hz

13

TASKI ergodisc 165-438 & duo

S000013 Drive part/2Entrainement part/2Antrieb part/2

Pos.

No.

DescriptionDesignationBezeichnung

Stck.

Piè.

Qty.

Model

Bestellnr.

No. de com

Order No.

Artikelnr.

Article No.

Item No.

104 14600-03 4126796 1.00 Support Support Support

106 1790/123 4027410 2.00 Wellenscheibe 13,2/18,8x0,2 Entretoise 13,2/18,8x0,2 Waved washer 13,2/18,8x0,2

107 14602-44 4110010 1.00 Radachse Axe Axle

108 14603-59 4110000 2.00 Lagertülle Douille à caoutchouc Rubber Bush

109 1871/100 4111200 4.00 Blechmutter 4.2 Écrou rapide 4,2 Quick nut 4,2

110 3340/216 4090280 2.00 Radkappe Chapeau de roue Wheel, Cover

111 2904/061 4111460 2.00 Sicherungsscheibe 12,7 Anneau de retenue 12,7 Retaining washer 12,7

113 14604-28 4122530 2.00 Rad 180/44 Roue Wheel

114 1742/80 4007380 4.00 Scheibe 14/26x0,5 Rondelle 14/26x0,5 Washer 14/26x0,5

115 14603-89 4110450 7.00 Scheibe 7/20x1 Rondelle 7/20x1 Washer 7/20x1

116 1840/004 4109990 4.00 Delta PT-Schr LK As Torx 60x25 Vis Delta PT Torx 60x25 Screw delta PT Torx 60x25

117 2804/113 4110050 1.00 Druckfeder Ressort de pression Pressure spring

118 2804/112 4110310 1.00 Druckfeder Ressort de pression Pressure spring

119 8819/105 4057260 0,036m 1.00 Schlauch m Gewebe 10/16 Tuyau 10/16 av. tresse le m Fabric-Reinforced Hose 10/16p.M

120 8819/105 4057260 0,048m 1.00 Schlauch m Gewebe 10/16 Tuyau 10/16 av. tresse le m Fabric-Reinforced Hose 10/16p.M

121 14600-41 4109880 1.00 Bundbuchse spez Douille à épaul. spec Flanged bush spec

122 1132/94 4052720 1.00 Zyl-Schr I-6Kt M8x35 Vis cyl. à trou 6 p. M8x35 Socket head cap screw M8x35

123 14601-18 4111350 1.00 Ventilatorflügel Pale d'hélice Fan blade

124 14600-01 4108800 7517949 1.00 Motor 230V 50Hz 1110W 7A Moteur 230V/50Hz Motor 230V/50Hz

124 14600-01 4108800 8003820 1.00 Motor 230V 50Hz 1110W 7A Moteur 230V/50Hz Motor 230V/50Hz

124 14600-01 4108800 8003840 1.00 Motor 230V 50Hz 1110W 7A Moteur 230V/50Hz Motor 230V/50Hz

124 14600-01 4108800 8003850 1.00 Motor 230V 50Hz 1110W 7A Moteur 230V/50Hz Motor 230V/50Hz

124 14602-14 4108780 8003860 1.00 Motor 230V 50Hz 1100W 7A Moteur 230V/50Hz Motor 230V/50Hz

124 14602-14 4108780 8003880 1.00 Motor 230V 50Hz 1100W 7A Moteur 230V/50Hz Motor 230V/50Hz

124 14602-14 4108780 8003890 1.00 Motor 230V 50Hz 1100W 7A Moteur 230V/50Hz Motor 230V/50Hz

124 14602-14 4108780 8004040 1.00 Motor 230V 50Hz 1100W 7A Moteur 230V/50Hz Motor 230V/50Hz

124 14602-62 4108820 7510804 1.00 Motor 120V 60Hz 1110W 14,5A Moteur 120V/60Hz Motor 120V/60Hz

124 14602-62 4108820 8003790 1.00 Motor 120V 60Hz 1110W 14,5A Moteur 120V/60Hz Motor 120V/60Hz

124 14602-63 4108790 8003830 1.00 Motor 120V 60Hz 1110W 14,5A Moteur 120V/60Hz Motor 120V/60Hz

124 14602-64 4110340 7517951 1.00 Motor 230-240V 50Hz 1100W 7,8A Moteur 230V/50Hz, 2 Vitesses Motor 230V/50Hz, 2 Speed

124 14602-64 4110340 8003990 1.00 Motor 230-240V 50Hz 1100W 7,8A Moteur 230V/50Hz, 2 Vitesses Motor 230V/50Hz, 2 Speed

124 14602-64 4110340 8004010 1.00 Motor 230-240V 50Hz 1100W 7,8A Moteur 230V/50Hz, 2 Vitesses Motor 230V/50Hz, 2 Speed

124 14602-64 4110340 8004020 1.00 Motor 230-240V 50Hz 1100W 7,8A Moteur 230V/50Hz, 2 Vitesses Motor 230V/50Hz, 2 Speed

124 14603-54 4108810 7517950 1.00 Motor 230V 50Hz 800W 5,2A Moteur 230V/50Hz Motor 230V/50Hz

124 14603-54 4108810 8003780 1.00 Motor 230V 50Hz 800W 5,2A Moteur 230V/50Hz Motor 230V/50Hz

124 14603-54 4108810 8003800 1.00 Motor 230V 50Hz 800W 5,2A Moteur 230V/50Hz Motor 230V/50Hz

124 14603-54 4108810 8003810 1.00 Motor 230V 50Hz 800W 5,2A Moteur 230V/50Hz Motor 230V/50Hz

124 14603-54 4108810 8004030 1.00 Motor 230V 50Hz 800W 5,2A Moteur 230V/50Hz Motor 230V/50Hz

124 14603-91 4118000 7521877 1.00 Motor 220V 60Hz 1100W 7A Moteur 220V/60Hz Motor 220V/60Hz

124 14603-91 4118000 8004410 1.00 Motor 220V 60Hz 1100W 7A Moteur 220V/60Hz Motor 220V/60Hz

124 14604-06 4126431 8004760 1.00 Motor 100-110V 60Hz 1100W 18A Moteur 100-110V/60Hz Motor 100-110V/60Hz

124 14604-09 4122524 8005000 1.00 Motor 100-110V 50Hz 1100W 18A Moteur 100-110V 50Hz Motor 100-110V 50Hz

125 14600-25 4109620 1.00 Hebel Tendeur de courroie Belt Stretcher

126 14600-31 4109870 1.00 Bundbuchse 8,1/17/24x32,2 Douille à épaul. 8,1/17/24x32,2 Flanged bush 8,1/17/24x32,2

127 14600-24 4109640 1.00 Spannrolle Galet tendeur Tensioning roller

128 1752/124 4110070 1.00 Scheibe 8,4/25x2 Rondelle 8,4/25x2 Washer 8,4/25x2

129 1137/37 4028060 1.00 Zyl-Schr I-6Kt M8x50/28 Vis cyl. à trou 6 p. M8x50/28 Socket head cap screw M8x50/28

130 14603-42 4108690 1.00 Schutzring Anneau de protection Bumper Ring

131 14600-45 4108700 1.00 Motorhaubendeckel Capot du moteur Motor Cover

132 14600-44 4108720 7510804 1.00 Motorhaube Manteau de moteur Motor Covering

14

TASKI ergodisc 165-438 & duo

S000013 Drive part/2Entrainement part/2Antrieb part/2

Pos.

No.

DescriptionDesignationBezeichnung

Stck.

Piè.

Qty.

Model

Bestellnr.

No. de com

Order No.

Artikelnr.

Article No.

Item No.

132 14600-44 4108720 7517949 1.00 Motorhaube Manteau de moteur Motor Covering

132 14600-44 4108720 7521877 1.00 Motorhaube Manteau de moteur Motor Covering

132 14600-44 4108720 8003790 1.00 Motorhaube Manteau de moteur Motor Covering

132 14600-44 4108720 8003820 1.00 Motorhaube Manteau de moteur Motor Covering

132 14600-44 4108720 8003830 1.00 Motorhaube Manteau de moteur Motor Covering

132 14600-44 4108720 8003840 1.00 Motorhaube Manteau de moteur Motor Covering

132 14600-44 4108720 8003850 1.00 Motorhaube Manteau de moteur Motor Covering

132 14600-44 4108720 8003860 1.00 Motorhaube Manteau de moteur Motor Covering

132 14600-44 4108720 8003880 1.00 Motorhaube Manteau de moteur Motor Covering

132 14600-44 4108720 8003890 1.00 Motorhaube Manteau de moteur Motor Covering

132 14600-44 4108720 8004040 1.00 Motorhaube Manteau de moteur Motor Covering

132 14600-44 4108720 8004410 1.00 Motorhaube Manteau de moteur Motor Covering

132 14600-44 4108720 8004760 1.00 Motorhaube Manteau de moteur Motor Covering

132 14600-44 4108720 8005000 1.00 Motorhaube Manteau de moteur Motor Covering

132 14603-52 4108730 7517950 1.00 Motorhaube Manteau de moteur Motor Covering

132 14603-52 4108730 8003780 1.00 Motorhaube Manteau de moteur Motor Covering

132 14603-52 4108730 8003800 1.00 Motorhaube Manteau de moteur Motor Covering

132 14603-52 4108730 8003810 1.00 Motorhaube Manteau de moteur Motor Covering

132 14603-52 4108730 8004030 1.00 Motorhaube Manteau de moteur Motor Covering

132 14602-17 4108710 Mod Duo 1.00 Motorhaube Manteau de moteur Motor Covering

133 14602-33 4110040 1.00 Support Support Support

134 1840/003 4062420 3.00 Delta PT-Schr LK As Torx 30x16 Vis pour plastique KA30x16 Screw for plastic KA30x16

135 4044/015 4121969 Flachstecker 6,3 Cosse mâle 6,3 Flat Crimp Connector 6,3

136 4033/166 4121970 100-120V Steckhülsengehäuse 3 Pol Logement de prise 3-pôles Plug Housing 3-Ways

136 4033/164 4121971 Steckhülsengehäuse 2 Pol Logement de prise 2-pôles Plug Housing 2-Ways

137 4033/165 4122495 Flachsteckergehäuse 3 Pol Logement de prise 3 pôles Plug Housing 3-Ways

137 4033/163 4121972 Flachsteckergehäuse 2 Pol Logement de prise 2 pôles Flat Connector Housing 2-Ways

138 4034/145 4083230 Steckhülse 6,3-1 Clip femelle plat 6,3-1 Female plate clip 6,3-1

139 1840/004 4109990 4.00 Delta PT-Schr LK As Torx 60x25 Vis Delta PT Torx 60x25 Screw delta PT Torx 60x25

140 14602-65 4109610 Option 1.00 Abdeckung Couvercle Cover

141 1742/103 4122099 1.00 Scheibe 18/30x0,3 Rondelle 18/30x0,3 Washer 18/30x0,3

143 1202/55 4031670 1.00 Zyl-Schr KS M5x10 Vis à tête cyl. M5x10 Cheese head screw M5x10

144 1771/55 4007660 1.00 Fächerscheibe 5,1 Rondelle étoile 5,3 Serrated lock washer 5,1

145 1840/002 4015720 2.00 PT-Schr LK KS KA40x14 Vis pour plastique KA40x14 Screw for plastic KA40x14

146 1752/35 4007480 1.00 Scheibe 4,3/12x1 Rondelle 4,3/12x1 Washer 4,3/12x1

147 14604-69 4130402 7517950 1.00 Elektroplatte 220-240V 50/60Hz Plaque électrique 220-240V Electric panel 220-240V 50/60Hz

147 14604-69 4130402 8003780 1.00 Elektroplatte 220-240V 50/60Hz Plaque électrique 220-240V Electric panel 220-240V 50/60Hz

147 14604-69 4130402 8003800 1.00 Elektroplatte 220-240V 50/60Hz Plaque électrique 220-240V Electric panel 220-240V 50/60Hz

147 14604-69 4130402 8003810 1.00 Elektroplatte 220-240V 50/60Hz Plaque électrique 220-240V Electric panel 220-240V 50/60Hz

147 14604-69 4130402 8004030 1.00 Elektroplatte 220-240V 50/60Hz Plaque électrique 220-240V Electric panel 220-240V 50/60Hz

147 14604-70 4130403 7517949 1.00 Elektroplatte 220-240V 50/60Hz Plaque électrique 220-240V Electric panel 220-240V 50/60Hz

147 14604-70 4130403 7521877 1.00 Elektroplatte 220-240V 50/60Hz Plaque électrique 220-240V Electric panel 220-240V 50/60Hz

147 14604-70 4130403 8003820 1.00 Elektroplatte 220-240V 50/60Hz Plaque électrique 220-240V Electric panel 220-240V 50/60Hz

147 14604-70 4130403 8003840 1.00 Elektroplatte 220-240V 50/60Hz Plaque électrique 220-240V Electric panel 220-240V 50/60Hz

147 14604-70 4130403 8003850 1.00 Elektroplatte 220-240V 50/60Hz Plaque électrique 220-240V Electric panel 220-240V 50/60Hz

147 14604-70 4130403 8004410 1.00 Elektroplatte 220-240V 50/60Hz Plaque électrique 220-240V Electric panel 220-240V 50/60Hz

147 14604-71 4130404 8003860 1.00 Elektroplatte 220-240V 50/60Hz Plaque électrique 220-240V Electric panel 220-240V 50/60Hz

147 14604-71 4130404 8003880 1.00 Elektroplatte 220-240V 50/60Hz Plaque électrique 220-240V Electric panel 220-240V 50/60Hz

147 14604-71 4130404 8003890 1.00 Elektroplatte 220-240V 50/60Hz Plaque électrique 220-240V Electric panel 220-240V 50/60Hz

147 14604-71 4130404 8004040 1.00 Elektroplatte 220-240V 50/60Hz Plaque électrique 220-240V Electric panel 220-240V 50/60Hz

15

TASKI ergodisc 165-438 & duo

S000013 Drive part/2Entrainement part/2Antrieb part/2

Pos.

No.

DescriptionDesignationBezeichnung

Stck.

Piè.

Qty.

Model

Bestellnr.

No. de com

Order No.

Artikelnr.

Article No.

Item No.

147 14604-72 4130405 7517951 1.00 Elektroplatte 220-240V 50/60Hz Plaque électrique 220-240V Electric panel 220-240V 50/60Hz

147 14604-72 4130405 8003990 1.00 Elektroplatte 220-240V 50/60Hz Plaque électrique 220-240V Electric panel 220-240V 50/60Hz

147 14604-72 4130405 8004010 1.00 Elektroplatte 220-240V 50/60Hz Plaque électrique 220-240V Electric panel 220-240V 50/60Hz

147 14604-72 4130405 8004020 1.00 Elektroplatte 220-240V 50/60Hz Plaque électrique 220-240V Electric panel 220-240V 50/60Hz

151 8909/61 4039680 Synthesefett 53B 1000gr Graisse synsetral 53B 1000gr Lubricant synsetral 53B 1000gr

152 4215/3 4023260 1.00 Kabelbinder 200 Bande à lier les câbles 200 Cable tie 200

- - - -

- - - -

155 14603-83 4110410 1.00 Spannschlüssel Levier de serrage ergodisc Tension Lever Ergodisc

S00001316 TASKI ergodisc 165-438 & duo

04

ergodisc /4.1

102

131

132

123

124

111

106

114

107

110

125

126

127

128

129

101

103

104

130

113

108

115

155

109

116

133

117

120 141

121 122

126

127

128

129

Mod. 800 . . .

3830 3860 3880

3890 4040

Mod. 300, 400, 438

118

119

L = 0,048M L = 0,036M

134

(Service)

139

140

135

136 137

138

Details - siehe, voir, see

Gruppe, group(e) 05

(0/-2MM) (0/-2MM)

(124)

151

151

152

144

143

145

146

102

101

152

147

dat. 2013/02

Ausf./Exe. I

145

146

135

136 137

138

dat. 2013/02

Ausf./Exe. II

17

TASKI ergodisc 165-438 & duo

S000017 Spraygerät mechanisch Vaporisateur mécanique Dispensing unit mechnical

Pos.

No.

Artikelnr.

Article No.

Item No.

Bestellnr.

No. de com

Order No.

Model

Stck.

Piè.

Qty.

Bezeichnung Designation Description

101 70016-18 4110190 1.00 Gehäuse Bâti Housing

102 1852/89 4122315 2.00 Gew-Form-L-Schr Torx M5x25 Vis autofiletage M 5x25 Self-Thread-Form.Screw M 5x25

103 70016-36 4110230 1.00 Anschlagscheibe Disque de guidage End Disc

104 1810/363 4114430 1.00 Senk-Spanpl-Schr KS 4x16 Vis à tête fraisee KS M 4x12 Pan Head Tapp.Screw M 4x12

105 3821/120 4110220 1.00 Trigger Trigger Trigger

106 70016-25 4110250 1.00 Flasche 500 Bouteille 0,5 L Bottle 0,5 L

107 3821/102 4110260 1.00 Deckel Couvercle Cover

108 1840/009 4071680 1.00 PT-Schr LK KS KA50x12 Vis pour plastique KA 50x12 Screw For Plastic KA 50x12

109 1752/11 4007450 1.00 Unterlagscheibe 5,3/20x1,5 Rondelle 5/20 Washer 5/20

110 70016-23 4110200 1.00 Torsionsfeder 1,3/20,6 Ressort de tension Tension Spring

111 70016-19 4110210 1.00 Hebel Levier Lever

112 70016-39 4119750 1.00 Pumpendüse Jet compl. Nozzle Compl.

113 2951/123 4119760 1.00 Flachstrahldüse 80 Grad Buse à rainure Flat Jet Nozzle

114 70016-21 4110170 1.00 Düsenhalter Porte-injection Nozzle Holder

115 70016-43 4122587 1.00 Schlauch 2/4 mit Lanze Kit tuyau Hose, Set

115a 8722/12 4049370 0,50m 1.00 Schlauch 2/4 PA Tuyau 2/4 le m Hose 2/4 Per M

116 4212/113 4114400 1.00 Kabelbride 6 Bride pour câble 6 Cable Clamp 6

117 70016-37 4110270 1.00 Buchse 4,3/7,5x17 Douille de distance Distance Bush

118 1840/020 4114420 1.00 PT-Schr LK KS KA40x35 Vis pour plastique KA 40x35 Screw For Pastic KA 40x35

119 3002/12 4008940 1.00 O-Ring 10,82x1,78 Joint-O 10,82x1,78 O-Ring 10,82x1,78

120 70016-04 4110240 1.00 Bowdenzug Gaine et câble Bowden Cable

135 2530/4 4008500 1.00 Rillenkugellager 6203 2RS Roulement à billes 6203 2 RS Ball Bearing 6203 2 RS

136 2527/6 4044550 230V;D 19,7 1.00 Rillenkugellager 6204 2RS Roulement à billes 6204 2 RS Ball Bearing 6204 2 RS

136 2530/105 4022420 120V;D 24,5 1.00 Rillenkugellager 6005 2RS Roulement à billes 6005 2 RS Ball Bearing 6005 2 RS

138 2744/081 4123157 1.00 Gerade Verbindung 4 Connection rapide Quick Connector

S00001718 TASKI ergodisc 165-438 & duo

05

ergodisc /3.1

135

136

101

102

105

106

120

108 109 110

111

115

113

103 104

112

117

114

107

(Gr.03,P.109)

(Gr.03,P.134)

(Gr.02,P.117)

116

118

Var. II

180

8504.370

119

(Gr.02,P.130)

(Gr.03,P.103)

(Gr.04,P.124)

Ergänzung, supplement

Gruppe, group(e) 04

Var. I

138115a

19

TASKI ergodisc 165-438 & duo

S000018 Spraygerät elektrisch Vaporisateur électrique Dispensing unit electrical

Pos.

No.

Artikelnr.

Article No.

Item No.

Bestellnr.

No. de com

Order No.

Model

Stck.

Piè.

Qty.

Bezeichnung Designation Description

101 70016-32 4110130 1.00 Bügel bestückt Fixation compl. Pump Holder Compl.