Taski ergodisc 165, ergodisc 238, ergodisc 175, ergodisc 200, ergodisc 400 Translation Of The Original Instructions Of Use

...

ergodisc 165/175/200/238/300/400/

438/duo

*12088-01*

V013 / 12088-01 1028

I25 I24 I23 I22 I21 I20 I19 I18 I17 I16 tr sv sl pt pl no nl it fr fi es en de da cz

Translation of the original instructions of use

STOPSTOP

•

STOPSTOP

STOPSTOP

STOPSTOP

STOPSTOP

STOPSTOP

STOPSTOP

STOPSTOP

STOPSTOP

Before first start-up, it is essential that you

read the instructions of use and the safety

notes carefully.

Keep the instructions of use in an easily

accessible place so that they can be consulted

at any time.

Symbols

Safety instructions

Due to their design and construction, TASKI machines comply with health and

safety requirements of the EC guidelines and therefore carry the CE sign.ATTENTION!

Persons (including children) who are not able to use this machine

safely due to their physical, sensory or mental capabilities or their

lack of experience or knowledge may not operate this machine

without supervision or instruction by a person resp onsible for their

safety!

Children should be supervised to ensure that th ey do not play with

the appliance.

Non-observance of this information can endanger people and / or

cause servere damage!

Non-observance of this information can lead to malfunctions an d

property damage!

Important information about correct use. Non-observance of this

information can lead to malfunctions!

Marks work steps that you must carry out in turn.

Intended use of machinery

The TASKI ergodisc 165/175.... is a single disc machine that is intended for

commercial use (e.g. in hotels, schools, hospital s, fa ctor ies, shop ping centres,

offices, etc.).

Under strict compliance with these Instructions for Use, the application

techniques stated on page 25 of these Instructions for Use apply for the

individual models.

This machine has been exclusively designed for indoor use only.

Caution:

This machine may not be used for the deep cleanin g of hard floor

coverings.

The wet cleaning of parquet and laminate floors with this machine

is carried out at your own risk.

Modifications to this machine that have not been authorised by

Diversey will lead to the cancellation of the Safety Marks and the

CE Conformity.

Any use of this machine other than its defined intended use could

lead to injuries to persons and damage to the machine and the

working environment.

In such cases, all guarantee and warranty claims will normally

become null and void.

Content

Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Translation of the original EU Declaration of Conformity . . . . . . . . . 21

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Machine installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Recommended chemicals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Application technique . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Beginning work . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Transport over stairs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

End of operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Service, maintenance and care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Malfunctions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Transport over stairs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Do not use the machine in rooms where explosive and flammable

substances (e.g. petrol, thinners, heating oil, solvents, etc.) are

stored or processed. The electrical or mechanical components of

the machine could lead to ignition of these materials.

While operating the machine, take note of the surrounding area

and pay particular attention to third parties and children!

In particular, the speed of the machine must be reduced in unclear

situations, for example, near doors or curves .

Themachine may only be used by persons who have been

suitably instructed in its use.

Regularly check the power supply cord for tearing or aging, and

do not put the machine into operation if it is not in a safe and

suitable condition, but have it repaired by an authorised specialist!

Before the machine is used, the operating leve r should b e tested

prior to mains power being applied to the machine. The lever

should be operated so an audible click is heard and felt when the

switch operates.

In case of a malfunction or a defect of the machine (for example,

at a safety lever or operating lever), after being dropped or a

damaged, the machine must be check by TASKI specialists

before being putr back into operation. The same applies if the

machine has been left in the open, been im mersed in water or has

been exposed to damp.

Caution:

Repairs to mechanical or electrical parts of the machine must only

be undertaken by Diversey authorised customer service

workshops or experts who are experienced in all relevant safety

regulations.

Minimum requirements on the H05VV-F2x1.5 or H07RN-F2x1.5

power cord.

Caution:

This machine is only intended for use in dry areas, and must not

be used or stored in the open air or under damp conditions.

Caution:

Pay attention to the accident prevention regulations!

Caution:

Only use the tools that are defined in these Instructions for Use

under Accessories or that have been recommended by the TASKI

specialist (Page 25), as other tools could impair the safety of the

machine.

Caution:

Only tools (brushes and pads) that are mentioned in these

instructions for use may be hung from the tool hook, as other tools

could cause damage.

20

Caution:

The power outlet may only be used for additional equipment,

which is specified in the instructions of use (page 25).

Caution:

The protection of persons is based on the special national

regulations and the information from the detergent producer!

Caution:

It is forbidden to plug in or unplug the main power supply cord with

wet hands!

Caution:

120 Volt plug

Earthed pin

Earthed outlet

120 Volt plug

Earthed outlet box

Metal

screw

Earthed

outlet

Tab for earthing screw

Dipl. Ing. (FH) D.Windmeisser

Dipl. Ing. (FH) P. König

Technical Director

Value Chain Director

Floor Care Equipment

Floor Care Equipment

Ensure that the rotating brush does not come into contact with the

power supply cord!

Caution:

Take care not to damage the power supply cord by driving over it.

Avoid crimping, tearing or damaging the power supply cord

through heat, oil, or sharp objects!

Caution:

Please make sure that the voltage stated on the machine label is

the same as the voltage rating of the plug socket!

Caution:

Danger of injury by sharp objects.

The personal protection is based on the national regulations!

Important! Switch the machine off when you:

• E.g. replace cleaning, service or repair parts or if you change to another

function

• store it in a suitable room to avoid any unauthorised use of the unit

• leave it standing without supervision

You should also pull the plug out of the mains socket.

Store the machine in a dry, dust-free room with a corrosion-free atmosphere.

The temperature must not fall below +10 °C or exceed +35°C. Low

temperatures, damp and dust can significantly reduce the service life of the

electrical components.

Noise emission and vibrations:

TASKI machines and units have been designed so that they

present no danger to health through their noise emission or

vibrations according to the current state of scientific knowledge.

See the technical information on page 25.

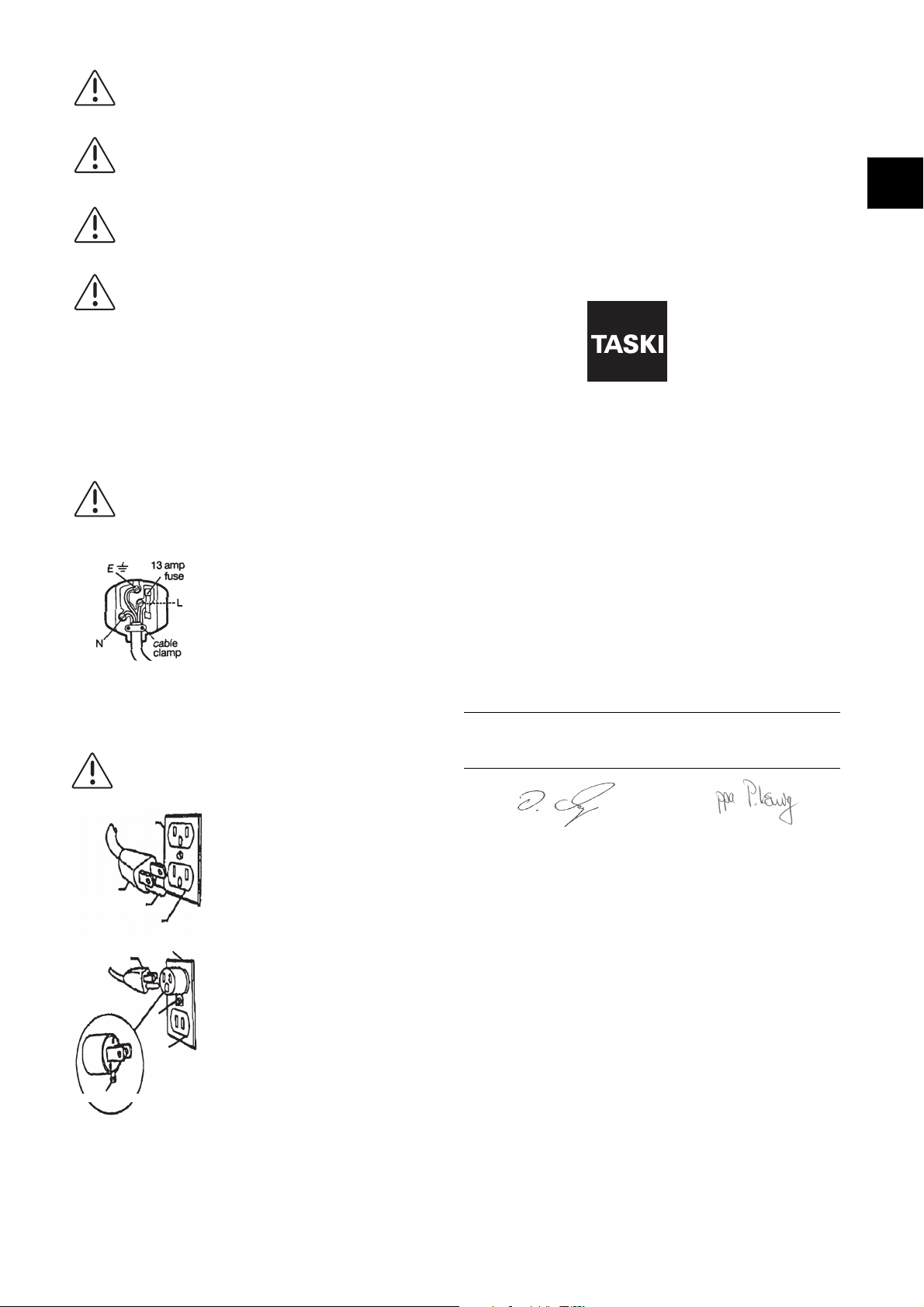

Version for UK electrical connection

The flexible cord fitted to this machine is of 3 core

construction for use with a 3 pin plug. For your

convenience a 13-amp plug conforming to BS

1363 has been fitted. This machine must be

fused at 10 amps. If you need to change the plug,

the correct wiring is set out below.

Green and yellow wire to terminal marked „ E “ or

with the „Earth Symbol“ or coloured green, or

green and yellow.

Blue wire to terminal marked „ N “ or coloured

black.

Brown wire to terminal marked „ L “ or coloured

red.

Translation of the original EU Declaration of Conformity

We hereby declare that the product described below both in this basic design

and con-struction and in the version marketed by us conforms to the relevant

health and safety related requirements of the appropriate EU Directive.

This declaration shall cease to be valid if modifications are made to the product

without our approval.

Designation: Floor treatment, floor cleaning machine for commercial

Product: Single Disc Rotary

Name: ergodisc165/200/238/400/438/duo

Model: 43DLS/43DLSL (230-240VAC / 50Hz, 1100W)

43LS/43LSL (230-240VAC / 50Hz, 800W)

Serial number: see rating label at the machine

Trademark:

Producer: Diversey, 9542 Münchwilen - Switzerland

Applicable EU Directives:

Directive 2006/42/EC of the European parliament and of the council of

17 May 2006 on machinery, and amending Directive 95/16/EC (recast)

Directive 2004/108/EC of the European parliament and of the council of

15 December 2004 on the approximation of the laws of the Member States relating to electromagnetic compatibility and repealing Directive 89/336/EEC

Harmonised standarts applied:

EN 60335-1/EN 60 335-1-A1/EN 60 335-1-A11/ EN 60 335-1-A13/

EN 60 335-2-67: 2009/EN 50 366/

EN 55 014-1/EN 55 014-1-A1/EN 55 014-1-A2/EN 55 014-2/EN 55 014-2-A1/

EN 61 000-3-2/EN 61 000-3-3/EN 61 000-3-3-A1

It is ensured through internal measures that series-production un its conform at

all times to the requirements of current EU Directives and relevant standards.

Person authorised to compile the technical file:

use

38LSL (230-240VAC / 50Hz, 800W)

43HS/43HSL (230-240VAC / 50Hz, 1100W)

38HSL (230-240VAC / 50Hz, 1100W)

43LHS/43LHSL (230-240VAC / 50Hz, 1100W)

Stephan Engler

Diversey Europe B.V. Utrecht

Zweigniederlassung Münchwilen

CH-9542 Münchwilen

Caution:

This machine must be properly earthed to project the operator

from electrical shock. Rea d th e sa fe ty i nstructions below

operating this machine!

Version for USA and Canada of the electrical

connection

120 Volt machines have a three-prong plug

attached to a three-wire power supply cord. The

earthing pin on this plug earths the machine

when plugged into a three-prong outlet.

An adaptor must be installed as shown here if

only two prong outlets are available.The outlet

box must be earthed and the earthing tab (or

wire) must be installed under the head of the

centre screw ot the outlet cover. 120 Volt plugs

are available at most hardwear stores. Earthing

adaptors are not approved for use in Canada.

• Replace the plug if the grounding pin is damaged

or broken.

• The green (or green/yellow) wire in the cord is

the grounding wire. When replacing a plug, this

wire must be attached to the grounding pin only.

Münchwilen, 25.02.2010

The signatories act on behalf of company management and with full power of

attorney.

21

I25 I24 I23 I22 I21 I20 I19 I18 I17 I16 tr sv sl pt pl no nl it fr fi es en de da cz

Overview

14151618 1317

1

2

3

4

5

678 9

10

11

12

1920212223

1 Cord support

2 Power outlet 700W (except for ergodisc 200/238)

3 Power supply cord

4 Central steel pillar

5 Additional equipment holder

6 Cable hook (not standard ex-factory for all models)

7 Wheels

8 Tools (brush, pad drive, etc.)

9 Brush cover

10 Motor ventilation

11 Spray valve connector

12 Central water and spray inlet

13 Selection switch 165/330 rpm (only duo)

14 Recessed grip (for transportation)

15 Height adjustment lever

16 Safety switch

17 Right operating lever (Motor ON/OFF)

18 Machine handle

19 On Iight (Plugged into mains socket)

20 Tool holder (Brushes, pads)

21 Push button for electrical spray unit (except for ergodisc 200/238)

22 Operating lever left (Motor ON/OFF)

23 Action lever for mechanical spray unit and water outlet tank

Machine installation

Attaching tools

Check:

• that the brush has not fallen below the red mark or a brush length of 1 cm.

• the pad for wear and foreign bodies (e.g. grains of sans) before use.

• that the tool is mounted.

Could cause damage to floor surface by negligence!

• Lay the tool on the floor in front of the machine.

• Stand behind the machine.

• Pull the height adjustment lever on the machine

handle and slowly lower the guide pillar into a

comfortable working position, making sure your

arms are almost straight.

• Let go of the height adjustment lever, the guide

pillar will locate into place and stay at that angle.

• Tilt the machine back slightly and position it

over the tool until it touches the back of the tool

unit.

• Return the machine to its upright position.

• Move the machine from left to right until the tool

locates into place.

Now the machine is ready for use.

Recommended chemicals

Only use the chemical products recommended by the manufacturer.

The correct dosage is recommended on the product's packaging and on the "

TASKI Product Information Sheet".

Caution:

Using other chemicals (e.g. chemicals containing solvents,

chlorine, hydrochloric acid and hydrofluoric acid) can damage or

destroy the machine.

22

Application technique

Machine 165 200 238

type 43DLS/

43DLSL

Wet cleaning & prime cleaning yes yes yes

Spray cleaning yes yes 1

Shampoo wet yes yes 2

Shampoo dry yes yes 2

Polish yes yes yes

Burnish 4 4 no

Crystallize 4 4 no

Machine 400 438 duo

43LS/

43LSL

38LSL

Transport over stairs

We recommend the transporting of the machine up or down steps

to be performed by two people.

• Release the operation levers.

• Disconnect the power supply cord from the mains socket.

Caution:

Due to the weight of the machine, there are risks involved in such

transportation!

Slipping can result in damage to the machine and injuries to

persons.

• Turn the tool away from the coupler.

• When lifting, one person should hold the

machine at the brush cover, and the second

person at the machine handle.

type 43HS/

Wet cleaning & prime cleaning no no yes

Spray cleaning yes yes yes

Shampoo wet no no 3

Shampoo dry no no 3

Polish yes yes 5

Burnish no no yes

Crystallize no no yes

• 1 = Electr. spray device is not possible

• 2 = Machine performance is limited; for this reason not recommended

• 3 = Only when the additional weight from the front is taken away

• 4 = Machine weight only conditionally sufficient

• 5 = This application is only recommended when the power selection switch

is set to level 2 (high number of revolutions)

43HSL

38HSL 43LHS/

43LHSL

Beginning work

Caution:

It is recommended that inexperienced users should first practice

operating the machine on a smooth surface with free areas until

they have mastered the handling of the machine.

• Connect the power supply cord to the mains

socket.

The display lights up.

End of operation

• Release the operation levers.

• Pull the power supply cord out of the mains socket.

• Tilt the machine back slightly.

• Turn the tool away from the coupler.

• Carefully lower the machine onto the tool unit.

• Pull the height adjustment lever and slowly lift

the guide pillar until it is in the upright position.

• Lead the power supply cord with your hand.

Make sure that the power supply cord does not touch the tool.

• Hold on to the machine.

By slightly lifting the guide pillar the machine moves to the right

and by lowering it the machine moves to the left.

• Push the safety switch and press the operating

levers at the same time.

By doing this the tool is activated.

• Let go of the height adjustment lever, the guide

pillar will locate into place and stay at that angle.

• Clean the power supply cord with a damp cloth

and wrap it around the machine handle and the

cord hook.

23

I25 I24 I23 I22 I21 I20 I19 I18 I17 I16 tr sv sl pt pl no nl it fr fi es en de da cz

Emptying solution

The disposal of solution must be carried out in accordance with the national

regulations.

• Remove the water tank from the machine and empty it.

• Empty the solution from the spray unit.

Emptying procedures for the Foam Generator are explained in their own

instructions of use.

Cleaning the tool

• Clean the tool under running water with a brush.

• Rinse out the spray unit thoroughly with warm water.

If the cleaning solution dries up, it could cause blockages.

Cleaning the pad

• Lay the pad into cleaning solution for a few hours and then rinse it off.

The pads may be put into the washing machine and washed at a max. of

40°C.

• Air dry the pads.

Caution:

Do not tumble dry the pads!

Cleaning the machine

Caution:

Never clean the machine with high water pressure or a water

hose.

The ingress of water into the machine might cause considerable

damage to mechanical or electrical parts.

• Wipe down the machine with a damp cloth.

Storing the machine

Caution:

Never store the machine with a mounted tool!

The tool may get damaged and become unusable.

Service, maintenance and care

The correct maintenance of the machine is a precondition for error-free

operation and a long service life.

Caution:

Always unplug the mains plug from the main socket when carrying

out any maintenance work!

Service centre

Should you contact us due to a malfunction or for placing an order, please

always state the type, description and the serial number of your machine.

You can find this information on the name plate of your machine, and the

address of your nearest TASKI partner can be found on the last page of this

manual.

Malfunctions

Malfunction Possible causes Troubleshooting page

• Insert the plug into the

mains socket

• Place the machine in

the working position

• Call your Service

Partner

• Wait a while, try again

(the protection switch

will automatically

reset)

• Drive belt is torn or

lose

• Call your Service

Partner

• Check that you are

using the correct

working technique

• Remove extention

• Check power supply

voltage

•Replace

• Clean spray unit

•Replace

22

22

23

Machine does not

run

Machine cannot

be operated, but

the on light

shows

Tool does not

rotate

Machine does not

reach rated

speed, motor

protection cuts in

Machine runs

uneasy

Spray pump is

working, cleaning

solution is not

coming out

No power supply

Guide pillar in upright

position

Safety switch defect

Machine has

overheated causing

motor protection

switch (trip) to cut in.

Motor runs but not

tool

Machine is

overloaded

Insufficient voltage,

power cord is too long

Tool deformed or

damaged

Cleaning solution has

dried up in spray unit

or tube is blocked

Transport

• Remove the tool (refer to Page 23).

• Pull the height adjustment lever and fold the

guide pillar towards the front.

Caution:

Only TASKI branded spare parts must be used, otherwise

warranties and liabilities will be omitted!

Symbols:

◊ = after use, ◊◊ = every week, ◊◊◊ = every month

Activity ◊◊◊◊◊◊ page

Check the motor ventilation for the collection of

dust and clean when necessary

Empty spray unit and clean with warm water

Clean the brushes

Clean the pads and let them dry

Clean the machine with a damp cloth

Service intervals

TASKI machines are high quality machines that have been checked for safety

at the factory by authorised inspectors. Electrical and mechanical components

are subject to wear and/or ageing after longer periods of use.

• In order to maintain operational reliability and availability for use, the service

must be carried out after 250 working hours or at least once a year.

Shorter intervals are necessary in case of rough environments or special

conditions of use and/or inadequate maintenance.

22

23

24

24

24

• Let go of the height adjustment lever, the guide

pillar will locate into place and stay at that angle.

• To lift the machine, one person must hold the tool unit and the other person

must hold the machine handle.

Caution:

The machine must always be carried by two persons and should

only be lifted by a single person in cases of emergency!

Ensure that the machine is firmly lashed down and secured in the transport

vehicle.

Disposal

After becoming no longer fit for use, the machine and its accessories must be

disposed of in the correct manner in accordance with the national regulations.

On request, your TASKI partner can assist you with this.

24

Technical data Accessories

Machine 165 200 238

type 43DLS/

Working width 43 43 38 cm

Dimensions (L x W x H) 67x48x119 67x48x119 67x48x119 cm

Machine weight 34 32 30.5 kg

Rated voltage 230-240V 230-240V 230-240V AC

Rated power 1100 800 800 W

Rated power (intergrated

socket)

Frequency 50 50 50 Hz

Power supply cord length 15 15 15 m

Brush rpm 165 165 165 min-1

Brush pressure 0.3 0.28 0.27 N/cm2

Assessed sound level

LPA according to EN

60704-1

The assessed effective

acceleration value

according to ISO 5349

Splash water protection IPX4 IPX4 IPX4

Electrical protection class II II II

Machine 400 438 duo

type 43HS/

Working width 38 38 43 cm

Dimensions (L x W x H) 67x48x119 67x48x119 67x48x119 cm

Machine weight 34 32.5 47 kg

Rated voltage 230-240V 230-240V 230-240V AC

Rated power 1100 1100 1100 W

Rated power (intergrated

socket)

Frequency 50 50 50 Hz

Power supply cord length 15 15 15 m

Brush rpm 400 400 165/330 min-1

Brush pressure 0.3 0.28 0.4 N/cm2

Assessed sound level

LPA according to EN

60704-1

The assessed effective

acceleration value

according to ISO 5349

Splash water protection IPX4 IPX4 IPX4

Electrical protection class II II II

43DLSL

700 -- -- W

<70 <70 <70 dB(A)

<0.5 <0.5 <0.5 m /s2

43HSL

700 700 700 W

<70 <70 <70 dB(A)

<0.5 <0.5 <0.5 m /s2

43LS/

43LSL

38HSL 43LHS/

38LSL

43LHSL

Article

8504360 Spray unit electrical 230V X X X

8504370 Spray unit mechanical XXXX

8504390 Water tank X X X

8504380 Suction aggregate 230V X X X

8505100 Double filter paper sack for suction aggregate

8505110 Microfilter for suction aggregate ergodisc (5

8505180 HEPA filter for suction aggregate ergodisc X X X

8504660 Foam Generator 230V X X

8504410 Driving disc Instalok 43cm X X X

7510030 Drive disc Instalok 43 cm X X

8504400 Spray brush 43 cm XXXX

8504750 Scrubbing brush 43 cm X X X

8504800 Scrubbing brush for washed concrete 43cm X X X

8504780 Abrasive scrubbing brush 43 cm X X X

8504830 Dry shampoo brush 43 cm X X

8504860 Wet shampoo brush 43 cm X X X

8504890 Polishing brush union for parquet 43 cm X X X

8503830 Carrier disc for diamond pads 43 cm X X

8505090 Driving disc for carrier disc 8503.830 X X

ergodisc (10 pieces per pack)

pieces per pack)

165

200

400

XXX

XXX

duo

25

I25 I24 I23 I22 I21 I20 I19 I18 I17 I16 tr sv sl pt pl no nl it fr fi es en de da cz

Loading...

Loading...