Taski swingobot 1650 CE, swingobot 1650 CE UV, duobot 1850 CE, duobot 1850 CE UV User Manual

www.intellibotrobotics.com

Rev. B:

01/09/17

TASKI SWINGOBOT 1650 CE

TASKI SWINGOBOT 1650 CE UV

USER MANUAL

1

Original Language Version (ENGLISH)

Attention:

Read and understand these instructions

before use.

This manual includes important information about the safe

use of this machine. Keep these instructions in an easily

accessible location for reference.

1. System Overview

The TASKI Intellibot SWINGOBOT 1650 and TASKI Intellibot

SWINGOBOT 1650 UV are robotic oor scrubbing machines

intended for commercial use. The following is an overview of

the machine features.

INTELLIGENT FEATURES

Main Computer Monitors all functions; commands robot

to perform stored cleaning routes

Drive

Subsystem

Monitors and controls the robot’s

movement and position

Controls Manual and autonomous

Navigation 16 sensors provide a complete,

360-degree view around robot

Front Touch

Shield

Full width, ABS, touch-sensitive shield

provides immediate braking

Rear Touch

Shield

Full width, ABS, touch-sensitive shield

provides immediate braking

Security User-specic password protection to

prevent unauthorized use

Safety Systems Sonar obstacle detection, infrared oor

sensors, touch shields, emergency

stop button

SOLUTION RECYCLING SYSTEM

Solution Feed Computer-controlled, adjustable ow

rate to center of each brush

Solution Tank Integral 14-gallon (53-liter) molded

high-density polyethylene with easyaccess lid

Recycling

System

Four-stage automatic recycling system

lters to 10 micron standard, 1 micron

optional for SWINGOBOT 1650 UV

BRUSHES AND SQUEEGEE

Pads Two counter-rotating 15” drivers and

pads

Brush Head Pads are changeable without removing

head from machine

Scrubbing

Width

29" (73.66 cm)

Scrubbing

Pressure

100 lbs. (45.36 kg)

Squeegee 32" (81.28 cm), parabolic, self-

centering swing style with plastic end

rollers and quick change, four-edge,

reversible rubber blade

SECTIONS

1. System Overview ............................................. 1

2. Customer Assistance ...................................... 2

3. Supplies, Parts and Accessories ....................2

4. Intended Use .................................................... 2

5. Personnel Responsibilities ............................. 2

6. General Safety Awareness .............................. 3

7. System Safety Awareness ............................... 4

8. Risk ................................................................... 6

9. Preventing Unsafe Situations ......................... 7

10. Healthcare/UV User and Service Personnel

Warnings ........................................................... 8

11. Machine Overview ............................................ 8

12. Theory of Operation: .....................................10

13. Safety Devices ................................................ 13

14. Safety Circuit Wiring ...................................... 15

15. Batteries .......................................................... 16

16. Charging ......................................................... 17

17. Language Setup ............................................. 18

18. Administrative Setup ..................................... 18

19. System Preferences ....................................... 20

20. Commissioning After Storage ...................... 20

21. Weekly Safety Device Check......................... 20

22. Daily Startup Procedure ................................ 23

23. Review of Work Area ..................................... 24

24. Manual Drive ................................................... 25

25. Manual Cleaning ............................................25

26. Hands Free Cleaning .....................................25

27. Daily Shutdown Procedure ...........................28

28. Maintenance ................................................... 30

29. Replacement Components ............................ 31

30. Storage ............................................................ 31

31. Troubleshooting ............................................. 31

32. Diagnostics ..................................................... 32

33. Sonar Diagnostic ...........................................32

34. Touch Shield Diagnostic ...............................32

35. Floor Sensor Diagnostic ...............................33

36. Gyro Diagnostic .............................................33

37. Gyro Calibration ............................................. 33

38. Network Diagnostic .......................................34

39. WiFi Diagnostic .............................................. 34

40. Memory Diagnostic ........................................ 34

41. Outputs Diagnostic ........................................ 35

42. Flow Diagnostic .............................................35

43. Drive Motor Diagnostic .................................. 35

44. Technical Data ................................................ 36

45. Revisions ........................................................ 37

2

DRIVE SYSTEM

Drive Motors Two 24 VDC precision motors, built-in

encoders, traction water displacement

tread

Vacuum Motor Single 67 CFM vacuum

PRODUCTION

Cleaning Rate Approximately 10,000 sq ft (approx.

929 sq m) per hour (avg.)

BATTERY SYSTEM

Battery Sealed gel cell or AGM deep cycle,

180 AH, 24 VDC output

Run Time Approximately four hours

Optional

Exchange Kit

Run time can be doubled with battery

exchange kit

Charger Unit 20 amp, 24 VDC output, 115 VAC input

with automatic shutoff

Charge Time: Approximate full charge time minimum

12 hours.

CONSTRUCTION

Frame Powder-coated 5052 aluminum and

stainless steel

Exterior High-density, molded, seamless

polyethylene

Machine Length 48" (121.92 cm)

Machine Width 32" (81.28 cm)

Machine Height 43" (109.22 cm)

Machine Weight 720 lbs. (326.6 kg)

ENVIRONMENT

Temperature 59° to 86° F (15° to 30° C) operation,

-22° to 140° F (-30° to 60° C) storage

Humidity 20% to 75% relative humidity

1.1. Statement of Airborne Noise Emission

This machine does not exceed 75 dB(A) during operation or

maintenance.

1.2. Statement of Compliance

This product complies with all applicable European Union

Directives and Harmonized standards as of the date of

manufacture. See product ratings label for specic model

and serial number information.

Applicable EU Directives

2006/42/EC 2004/108/EC 1995/5/EC

1.3. Applicable EU Harmonized Standards

EN 60204-1 EN 60335-1 EN 12100

EN 60335-1

EN 60335-2-72 (manual mode operation)

EN 12100 EN 13857 EN 349

EN 14121 EN 55014-1 EN 55014-2

2. Customer Assistance

For questions relating to the operation, maintenance, or

service of this robotic oor scrubber system, please contact:

2.1. Equipment Manufacturer:

Diversey Care Intellibot

12820 West Creek Parkway

Suite B

Richmond, Virginia 23238 U.S.A.

Phone (US): 01.888.837.0002

Email: ir-service@sealedair.com

Web: www.intellibotrobotics.com

2.2. European Union Representative:

Diversey Europe Operations B.V.

Maarssenbroeksedijk 2

3542 DN Utrecht, Netherlands

Email: customerservice.nl@sealedair.com

Phone (EU): 31.030.247.6885

3. Supplies, Parts and Accessories

For optimal machine performance, only Diversey Care

cleaning solutions approved for use with this machine

should be used. To maintain performance, and safety of the

machine, personnel, and property, only TASKI Intellibot parts

and accessories should be used to maintain this robotic oor

scrubber system.

Please contact Customer Assistance for any questions

regarding the use, maintenance, or service of this robotic

oor scrubbing system

4. Intended Use

This robotic oor scrubbing system is an industrial oor

scrubbing machine intended for interior use in commercial

buildings. The machine should only be used for the wet

cleaning of hard commercial oor surfaces.

This machine must be attended by an operator at all times

during use. The operator is responsible for the safe operation

of this machine and must follow the operating and safety

instructions provided in this manual.

5. Personnel Responsibilities

The following Identies personnel requirements for the safe

use of this equipment.

5.1. Manager

It is the manager’s responsibility to ensure that operator(s)

and maintenance personnel are properly trained in the

use and maintenance of this robotic oor scrubber system.

Managers must ensure that operator and maintenance

personnel are provided with the appropriate supplies and

equipment needed to safely operate the machine.

3

5.2. Operator

A operator refers to a user of this equipment who is properly

trained in the use, maintenance, and troubleshooting of this

robotic oor scrubber system. The operator is responsible

for ensuring that maintenance is performed only by trained

maintenance personnel.

5.3. Maintenance Personnel

Maintenance personnel must be properly trained to maintain

this robotic oor cleaning equipment. Maintenance includes

replacement of consumables such as water, detergent,

lters, scrubbing pads, and scheduled cleaning of the

machine.

5.4. Service Technician

A service technician refers to a eld engineer who is properly

trained in the use, maintenance, troubleshooting, and service

of this robotic oor scrubber system. A service technician

must have factory service training.

The service technician is responsible for all repairs,

upgrades, and accessory installations requested by

the customer or mandated by TASKI Intellibot. Service

technicians are equipped with proper tools and parts for the

installation, maintenance, and service of this robotic oor

scrubber system.

6. General Safety Awareness

The following section includes important information required

for safe operation of this robotic oor scrubber system.

6.1. User Manual Safety Symbols

The following symbols are used to identify important safety

information:

Warning:

Failure to follow this information could result

in serious harm to people and/or property.

Caution:

Failure to follow this information could result

in damage to the machine and/or property.

Note:

Failure to follow this information could result

in malfunction or damage to the machine.

6.2. General Safety Instructions

The following symbols are used to identify important safety

information:

This machine may only be used by a trained

operator that is physically and mentally

capable of maintaining control and safety of

the machine. Physical or mental impairment

of the user may result in serious injury to

people, property, and/or the machine.

In case of damage to safety relevant

components such as the Emergency Stop

switch, safety interlock, safety touch shields,

front door, batter, etc., the machine must be

stopped immediately. Repair or replacement

of the damaged component by a qualied

service.

Unauthorized use or modication of this

machine may result in unsafe operating

conditions, personal injury, property damage

or machine malfunction. Any unauthorized

modication or use contrary to the intended

purpose will result in voiding the machine

warranty, CE marking, and applicable safety

marks.

Do not use this machine around any

explosive or ammable materials or in

any areas where vapors from ammable

materials such as solvents, fuel, oil or dust

could ignite.

Do not use this machine to vacuum

ammable, toxic, caustic, or irritating

substances. The machine is not designed

for this use and serious injury to persons

and damage to property and the machine

may result.

Do not use this machine in areas with

high electromagnetic elds (EMF). This

machine uses electronics susceptible

to electromagnetic elds. Use of this

equipment in high EMF areas may result in

unintended and uncontrolled operation.

Stairways and doorways must be blocked

when the scrubber is used in robotic mode.

Failure to block a stairway could result in the

machine tumbling down the stairs, resulting

in serious property damage, machine

damage and injury.

Operators must take note of the

surrounding area and be ready to stop the

machine in case a hazardous situation. The

machine must be stopped if any potentially

hazardous situation arises, such as children

entering the cleaning area, objects falling

in the machine path, stairway blocks are

moved, etc. Children should never be

allowed to play in or around the cleaning

area while the robotic oor scrubber system

is in operation.

Never use the robotic oor scrubber system

to transport people or materials. Serious

injury and property damage may result.

4

Regularly inspect the battery charger,

mains cord, and machine charging cable

for damage and replace the cord or charger

immediately if any damage is found. Frayed

or damaged charging components could

lead to shock or re.

Caution:

This machine is not intended for the

application of wax, polishing, carpet

cleaning, or the dry vacuuming of dust.

Cleaning of wood or laminate oors is not

recommended. The owner assumes all

risk for use on surfaces not designed to

be cleaned with commercial scrubbing

equipment.

Caution:

This machine is only intended for indoor

use in dry areas. Do not use or store this

machines outdoors or in damp conditions.

Caution:

This machine uses detergent as part

of the scrubbing system. Please read,

understand, and follow all manufacturer’s

instructions for the safe and effective

use of the detergent. Failure to follow the

manufacturer’s recommendations, including

the use of safety equipment, such as

gloves and safety glasses, could result in

hazards to people, property, and/or machine

malfunction.

Caution:

The machine may only be operated with

the top cover closed. Foam or liquid leaking

from the sides or top of the machine

indicates a malfunction. The machine must

be stopped immediately and the malfunction

identied and corrected before the machine

is returned to operation.

Caution:

Always use the parking brake when the

machine is unattended.

Caution:

The machine is intended for use on at

surfaces. Operating the machine on a grade

exceeding 2% may result in unintended

operation. Do not store or transport the

system on a grade exceeding 8% or the

machine may tip over resulting in injury and/

or damage to the machine.

7. System Safety Awareness

Safety and informational labeling is included on the machine

to remind the operator of specic hazards encountered while

operating and maintaining the robotic oor scrubber system.

The following is a denition of the machine safety labels.

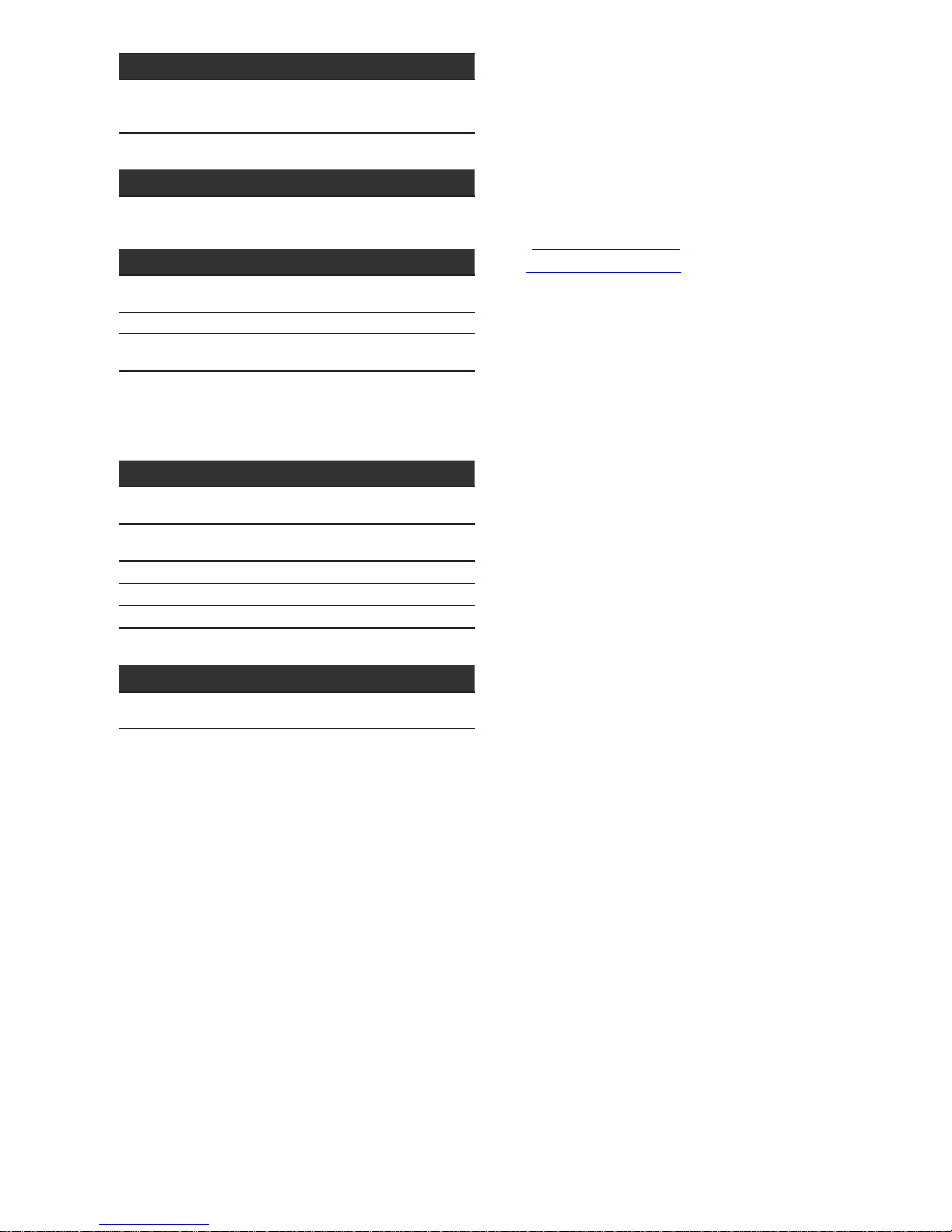

7.1. Ratings Label

Example machine ratings label:

SWINGOBot 1650-UV

Robotic Floor Scrubber System

Input: 24V , 53.2A, 1280W

Weight:

208kg without battery pack

342kg with battery pack

IPX4

September

11609-1105-0001

Diversey Europe Operations B.V.

Maarssenbroeksedijk 2

3542 DN Utrecht, Netherlands

www.sealedair.com

This equipment is manufactured by Diversey Inc. (US) and

is covered under U.S. Patent #'s 6,580,246, 6,667,592,

9,028,617. Other patents pending. Commercial Use Only.

1

2

3

4

5

7

Figure: 1

The ratings label contains the following information:

1 Model: The model name and description of the

machine.

2 Serial Number: The unique serial number of

this machine. The serial number of the machine

should always be noted when customer

assistance is needed.

3 Input Ratings: The machine is powered by 24 Volt

DC batteries. For more information on appropriate

batteries, see the Battery Safety section of this

manual.

Weight: The weight of the machine is important

for operation and shipping. Always ensure

stability of the operating environment. Always

ensure shipping containers and securement is

appropriate for a machine of this weight.

4 Manufacturer: Information regarding the

manufacturer and intellectual properties.

5 Informational Labeling:

Refer to this manual for important

information regarding operation and safety

of this machine.

This machine is powered from a safety

extra-low voltage power source and

is considered a Class III device when

operating in a dry environment.

This machine complies with all relevant

safety and health requirements of the

applicable EU Directive(s). See the

Declaration of Conformity for the specic

Directives and standards applicable to this

machine.

IPX4

This machine was designed and tested to

meet the standards for a level 4 protection

against liquid ingress.

6 European Union Representative: The

manufacturer’s representative for the European

Union.

7 Date of Manufacture: The date of manufacture of

this machine.

5

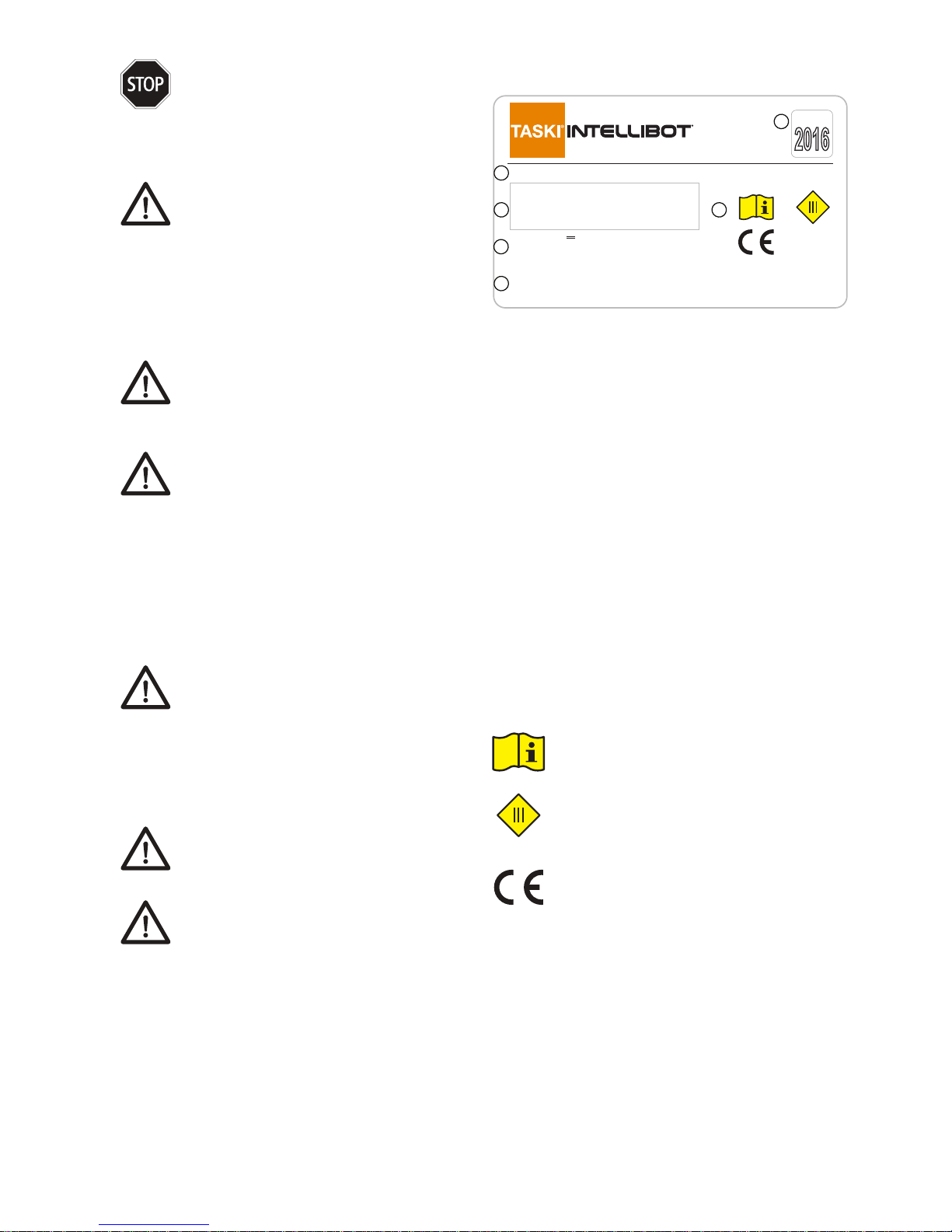

7.2. System Warning Labels

The following labels are used to warn and remind the

operator, maintenance, and service personnel of specic

hazards when using the machine:

High Voltage

Warning Label

Input: 24V , 20.0A

Charger Input/Warning

Identification Label

Maximum 8% Grade

Warning Label

G

R

A

D

E

M

A

X

8

%

SwingoBot Rating Label

SWINGOBot 1650-UV

Robotic Floor Scrubber System

Input: 24V , 53.2A, 1280W

Weight:

208kg without battery pack

342kg with battery pack

IPX4

September

11608-1105-0001

Diversey Europe Operations B.V.

Maarssenbroeksedijk 2

3542 DN Utrecht, Netherlands

www.sealedair.com

This equipment is manufactured by Diversey Inc. (US) and

is covered under U.S. Patent #'s 6,580,246, 6,667,592,

9,028,617. Other patents pending. Commercial Use Only.

Figure: 2

This symbol identies the location of the

machine battery charging port. Only gel cell

battery chargers should be used with this

machine. Do not exceed the maximum 20

Amp charging current.

Hazardous current is present at the

machine charging port. Never use any

metallic object, such as a screw driver, to

open the charging ap or pry the charging

connector. Never place any object in the

charging port other than the charging

connector.

The maximum stable angle for storage

and transport. Do not store or transport the

system on a grade exceeding 8% or the

machine may tip over resulting in injury and/

or damage.

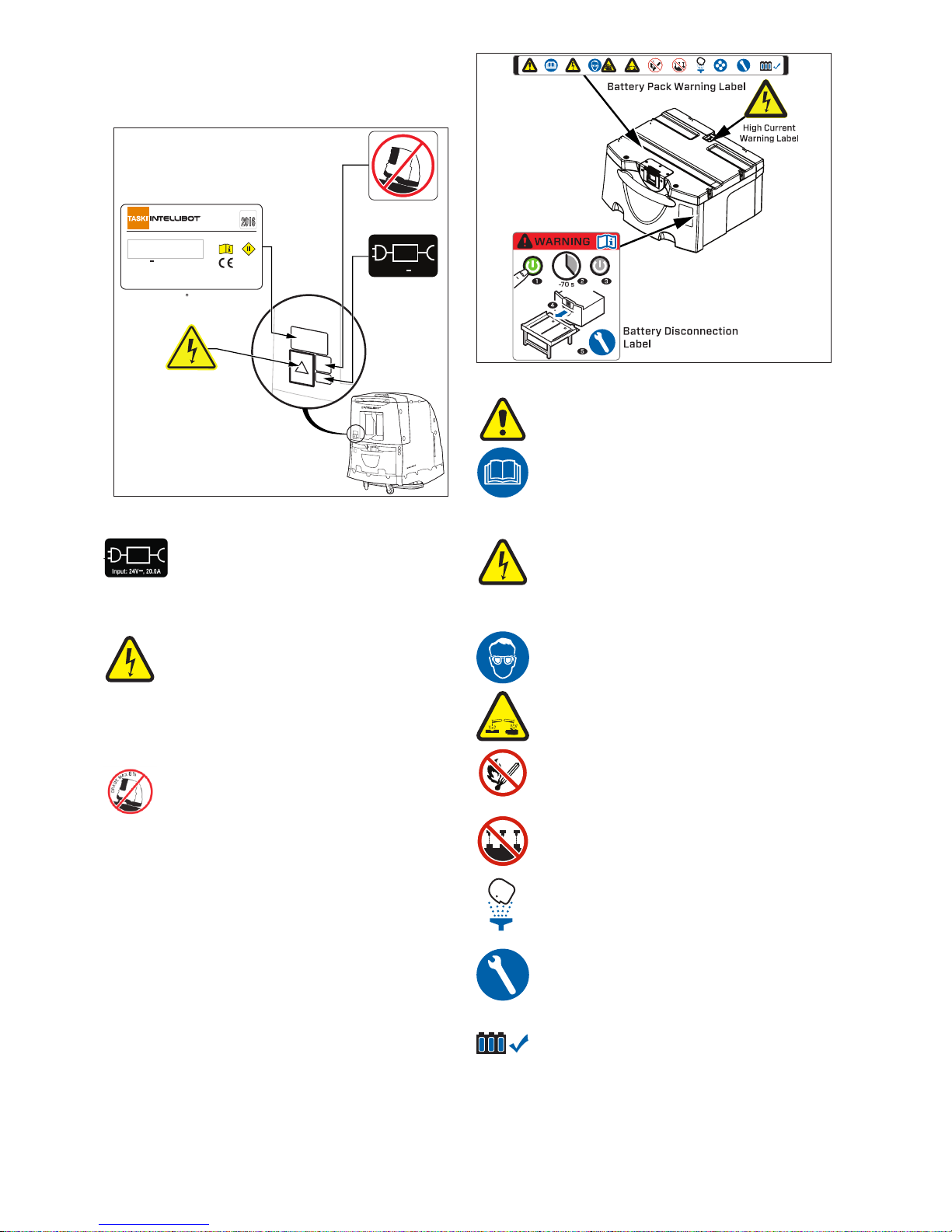

7.3. Battery Warning Labels

The following labels are used to warn and remind the

operator, maintenance, and service personnel of specic

hazards associated with the batteries used in this robotic

oor scrubber system:

Figure: 3

This is the attention symbol, warning of

hazards to persons and property.

This symbol refers the operator,

maintenance, or service personnel to

the appropriate manual for important

information.

Hazardous current is present at the battery

charging port and the battery terminals at

all times. Never store anything on top of the

batteries. Always use caution when using

any metallic object near the batteries.

Protective eye-wear must be worn when

working on the batteries.

The batteries contain caustic acid that can

cause severe burn or blindness.

The batteries emit ammable/explosive gas.

Do not allow sparks, re or ame near the

batteries. Never smoke near the batteries.

Do not remove the battery vent valve.

Caustic acid is present inside the batteries.

If exposed to acid, immediately ush with

water and consult medical attention.

Batteries should only be serviced by a

trained service technician.

Use only approved gel cell or AGM batteries

in this machine.

7.4. Battery Charger Labeling

When a battery charger is used on a battery cart, the charger

should be equipped with a cover to prevent accidental

spillage of liquid onto the unit.

6

The cover has the following safety labels:

High Voltage

Warning Label

Charger IP

Rating Label

Figure: 4

Hazardous voltage is present when the

charger is plugged into the mains.

Hazardous currents are also present at all

times when the charger is connected to the

battery.

Cover was designed to meet the standards

for a level 4 protection against liquid ingress

into the battery charger.

The battery shutdown warning label instructs the user to

shut down the machine and wait for the standby button

illumination to turn off.

Figure: 5

Before Removing Batteries, hold ~ Standby button,

listen for 3 Beeps, which is the computer acknowledging your

button push. Computer will turn off 24V circuits & start saving

data.

Caution, for the next 30-90 seconds the computer

saves data, wait for button light to go "Off" or you will lose the

data. If light is still on after 120 Seconds, to prevent damage

or injury hit e-stop to assure 24V power is disconnected from

battery before breaking connection by pulling on battery

handle.

Button goes dark; computer has shut down all power.

All power is off; no trickle power is leaking from the battery to

any circuit.

8. Risk

Although all reasonable precautions have been taken to

ensure the safety of this machine, there are certain foreseen

risks that the manager, operator, maintenance and service

personnel must address:

8.1. General Risk: Care should be

taken to prevent the following:

Inadequate Training: Operators,

maintenance, and service personnel must

be properly trained. It is the manager’s

responsibility to ensure the machine is not

accessible to inadequately trained persons.

Lack of Supervision: The robotic oor

scrubbing system must be supervised at all

times. The operator must be able to react

to situations that may endanger people or

property.

Lack of Stairway Obstruction: When

using the robotic oor scrubbing system

in autonomous mode, all stairways and

doorways must be blocked to prevent the

unit from proceeding on an unintended

path. Stairways must be blocked to prevent

the unit from tumbling down the stairs and

potentially causing serious damage or injury.

Unt Components: Only components

authorized by TASKI Intellibot may be tted

to this machine. Use of unt components

may result in serious damage and injury.

Bacterial Growth: Proper cleaning during

maintenance and service is required to

prevent the growth of bacteria in the robotic

oor scrubber system.

Transportation Incidents: The machine can

tip over if subjected to a grade in excess of

8%, resulting in serious damage and injury.

When transporting the unit by vehicle, it

must be strapped to a supporting structure

capable of securing the full specied weight.

Operating While Damaged: The machine

must never be operated while damaged.

Damage to the machine may result in

unsafe conditions for people and property.

A damaged machine must be serviced by a

trained service technician before returning

to use.

Operating Without Safety Measures: The

machine is designed with specic safety

measures to protect people and property.

Damage or defeat of these mechanisms

may result in serious injury.

8.2. Operational Risk: Care should

be taken to prevent the following while

operating the machine:

Entrapment: Avoid situations that could trap

an operator between the machine and an

object.

Inadvertent Motion: Be aware that gripping

the handle can initiate machine motion. Do

not grip the handle unless intending to move

the machine in manual mode.

7

Operating on an Incline: The machine

can tip over causing damage and injury if

operated on an incline.

Parking on Incline: Always apply the parking

break to prevent the machine from moving.

Setting Wrong Direction or Speed: Be

aware of the direction and speed set in

manual mode. Setting the incorrect speed

or direction could entrap the operator

between the machine and an object.

Unauthorized Use: Never leave the

machine unattended.

Brush or Squeegee Entanglement: Use

care when lowering the brush or squeegee

assemblies. Always ensure adequate

clearance from people and objects to

prevent entanglement.

Safety System Malfunction: Safety systems

need to be checked for proper operation

before operating the machine.

Insufcient Braking Distance: Care must

be taken to ensure an appropriate braking

distance is maintained at all speeds and

slopes.

8.3. Residual Risk: The operator should

be aware of the following residual risks

when using the machine:

Rotating Mechanism Pinch Hazard:

The robotic oor scrubber system includes

motors and scrubbing brushes with

pads. A pinch hazard exists when these

mechanisms are raised and lowered. Do

not allow access to these areas while the

machine is turned on.

Rotating Mechanism Entanglement

Hazard: The rotating mechanisms can

entangle clothing or body parts. Do not

allow access to these areas while the

machine is turned on.

Squeegee Pinch Hazard: The squeegee

bar support may cause a pinch hazard

when raised. Do not allow access to the

squeegee when raising or lowering the

mechanism.

Squeegee Grab/Hook Hazard: It is

possible for the squeegee to grab or hook

objects projecting from the oor or located

in the plane of the squeegee. The operator

must be aware of the operating environment

and ensure that the machine is not used

around objects or people that could be

grabbed by the squeegee mechanism.

Machine Impact Hazard: When in

autonomous mode, the robotic oor

scrubber system uses sonar for locating

objects in its path. The sonar system cannot

be relied on for safety. It is possible for the

sonar to malfunction or for personnel to be

located in gaps between sonar sensors,

posing an impact hazard. The operator

must never allow personnel to located in the

autonomous operating area.

Uncontrolled Motion (E-Stop): The

machine may pose an impact hazard if the

Emergency Stop switched is pressed while

on an incline. Always engage the parking

brake when the machine is unattended.

Entrapment Hazard: It is possible for

an operator to trap themselves between

the machine and an object . Care should

be taken to avoid tight spaces. In case of

emergency, let go of the handle and press

the Emergency Stop button.

Warning: Never operate the unit in the

presence of unsupervised young children.

Their curiosity and reduced mass puts them

in danger of severe injury.

9. Preventing Unsafe Situations

The following additional information should be considered

to prevent unsafe situations when using the robotic oor

scrubber system.

9.1. Protective Equipment

The following protective equipment is recommended when

dealing with detergents, wash water, waste water, or spills:

Protective eye-wear with side shields.

Protective rubber or neoprene gloves and

apron.

Non-slip footwear.

9.2. Operating the Machine

The machine uses water and detergent

during the cleaning process. The oor

immediately behind the machine may

be wet and slippery. Non-slip footwear

is recommended to prevent falls while

operating the machine.

Operators should always wear clothing

appropriate for working with a commercial

scrubber. Do not wear loose or torn

clothing that may get entangled on or in the

machine.

8

9.3. Spilled Clean Water

For water spills, wipe the machine with

paper towels and mop the oor as required.

9.4. Spilled Waste Water

Waste water will contain detergents and dirt

from the oor. Protective eye-wear, gloves,

and an apron are recommended.

Rinse the equipment with clean water as

required and wipe with paper towels.

Rinse and mop the oor with clean water as

required.

9.5. Spilled Detergent

Always follow the manufacturer’s

recommendations for handling the

detergent. Detergents can be caustic,

protective eye-wear, gloves, and an apron

are recommended.

Rinse the equipment with clean water as

required and wipe with paper towels.

Rinse and mop the oor with clean water as

required.

9.6. Battery Acid

Consult the battery manufacturer’s

recommendations for cleanup. For help

with batteries supplied by TASKI Intellibot,

please contact Customer Assistance.

10. Healthcare/UV User and Service Personnel

Warnings

Personnel should be made aware of the following hazards:

10.1. UV Hazard

WARNING:

The UV light given off by this unit can cause

serious burns to unprotected eyes and skin.

Never look directly at an illuminated UV

lamp. Never operate the unit with the lamp

outside of the UV chamber. Never operate

the unit without the rubber boot in place.

10.2. Mercury

UV lamps contain Mercury, a heavy metal.

Lamps should be recycled, not disposed of

in a landll. Recyclers accepting uorescent

lamps will typically also accept UV lamps.

The Mercury from a broken UV lamp must

be recovered and recycled appropriately.

10.3. Puncture and Cutting Hazard

The UV lamp and quartz sleeve are fragile.

If they break, pieces will be very sharp and

the fragments must be handled only with

protective gloves.

10.4. High Voltages

The UV ballast uses and produces

hazardous voltages. Caution should be

taken when servicing components near the

ballast or UV reactor.

The UV ballast is designed for a dry

environment only. If the ballast is exposed

to water, remove power immediately. Never

operate a ballast that has been exposed to

water.

Hazardous voltages exist in the UV reactor

vessel. Never operate a leaking UV unit.

Remove power before inspecting the unit

for damage.

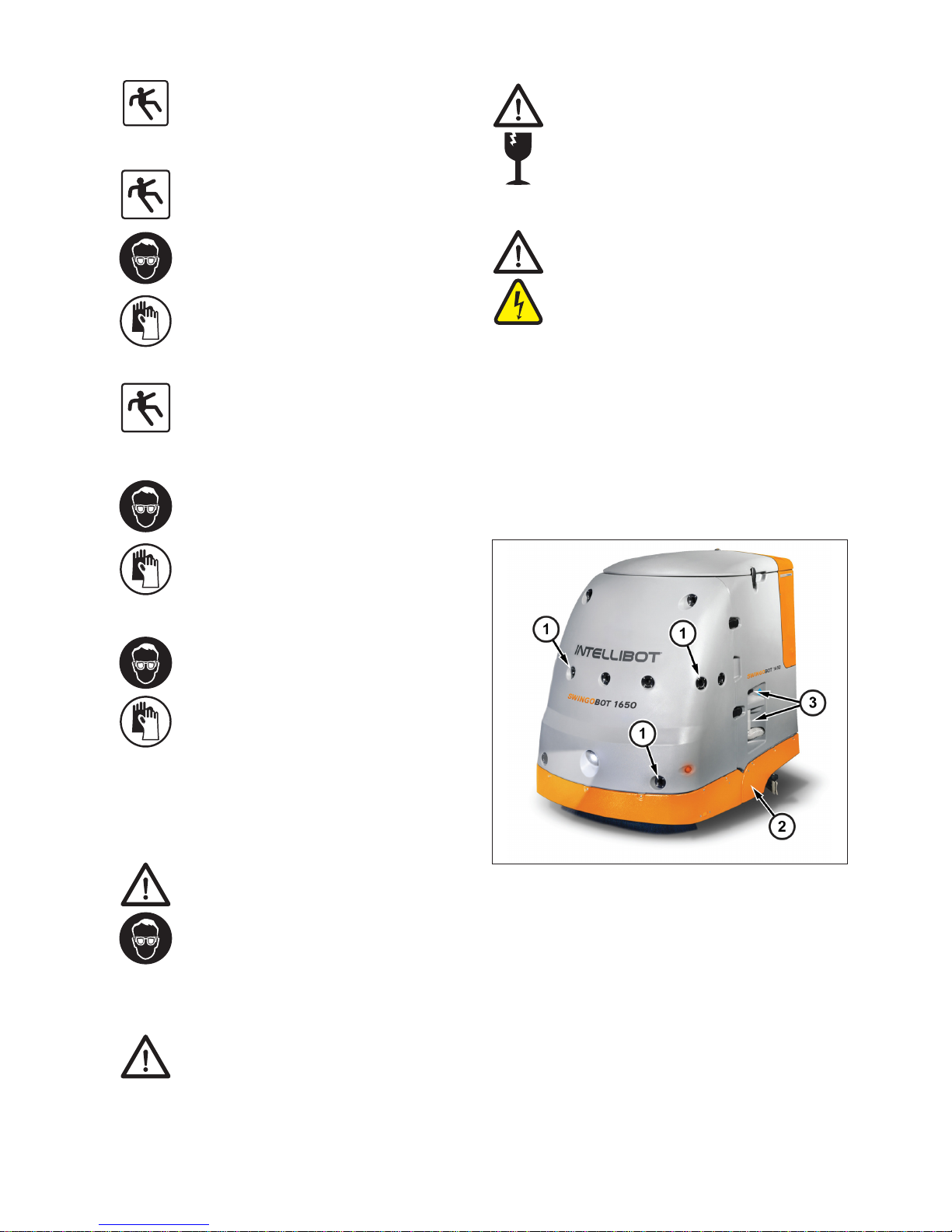

11. Machine Overview

The following are basic components of the robotic oor

scrubbing machine:

Figure: 6

1 Sonar Horns

2 Safety Touch Shield

3 Drain Valve and Drain Hose

9

Figure: 7

4 Front Access Door

5 Electronics Box

6

8

9

6

7

Figure: 8

6 Filters

7 Filter Wrench

8 Battery Pack

9 Parking Brake

14

11

12

13

10

Figure: 9

10 Emergency Stop Button

11 User Interface

12 Standby Button

13 Touch Control Handlebar

14 Warning Lamp

15

Figure: 10

15 Scrubber Head

16

Figure: 11

16 Squeegee Assembly

10

11.1. SWINGOBOT 1650 CE UV ONLY

17

18

Figure: 12

17 UV Sterilizer Power Supply

18 UV Sterilizer Reactor

12. Theory of Operation:

The TASKI Intellibot SWINGOBOT 1650 CE and CE UV

machines are commercial wet oor scrubbing systems

capable of manual and autonomous robotic operation.

Figure: 13

The system utilizes a 14 gallon (53 liter) tank for storing and

recycling cleaning solution that is applied to the scrubber

head for effective cleaning.

The scrubber head is comprised of two independent motors

with brushes and 15-inch pads for wet scrubbing.

Figure: 14

The machine uses a vacuum squeegee system located in

front of the rear casters. The squeegee uses a parabolic

32-inch, 4-edge, reversible blade system with a vacuum for

pickup and recycling of used cleaning solution.

Figure: 15

The used cleaning solution is returned to the tank, where it is

circulated through a ltration system. Dirt and contaminates

are removed from the cleaning solution and it is recycled for

use in scrubbing.–

TASKI Intellibot SWINGOBOT 1650 CE UV systems include

an additional UV sterilizer in the water recycling system.

Figure: 16

The sterilization system reduces biological contaminates in

the recycled cleaning solution, which reduces the spread of

microorganisms from contaminated oor surfaces.

The system is powered by a 24 Volt, 180 Amp-hour battery

pack, providing approximately 4-hours system run time.

An optional battery cart is available for using multiple battery

packs, extending system productivity.

Figure: 17

11

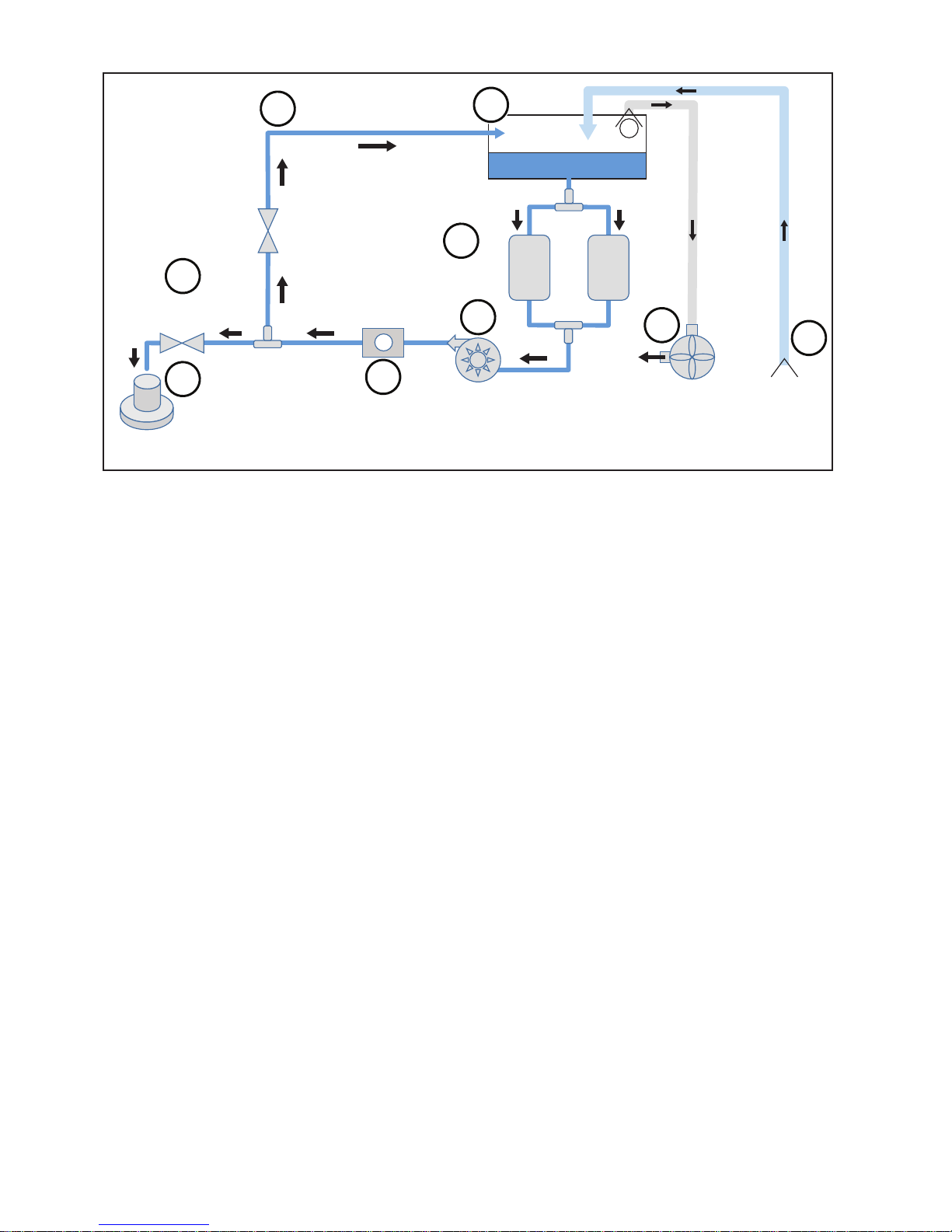

12.1. TASKI Intellibot SWINGOBOT 1650 CE Flow Diagram (Parallel)

10

um

10

um

BYPASS

VALVE

WATER

VALVE

TANK

FLOW

SENSOR

FILTRATION

VACUUM SQUEEGEE

F

CYLINDER

SCRUB

CIRCULATION

PUMP

1

7

4

3

2

8

9

6

5

Figure: 18

1 The robotic oor scrubber system utilizes 53-liter tank for storing and recycling cleaning solution.

2 The standard system uses a parallel canister ltration system with two 10 micron lters. Optional lters are

also available.

3 The circulation pump provides ow for the cleaning solution.

4 A ow sensor is used to detect and set an appropriate ow rate for effective scrubbing.

5 Water valves provide ow regulation for wash water or recycling of the cleaning solution.

6 Cleaning solution is distributed directly onto the scrubbing head.

7 When not scrubbing, the cleaning solution is recycled back to the tank and continually ltered.

8 A vacuum system evacuates air from the top of the tank, providing suction for the vacuum squeegee

9 The squeegee system wipes used cleaning solution from the oor and the pickup tube directs the used

solution back to the tank.

12

12.2. TASKI Intellibot SWINGOBOT 1650 CE UV Flow Diagram (In Series Healthcare Only)

BYPASS

VALVE

WATER

VALVE

TANK

SERIES

FILTRATION

VACUUM SQUEEGEE

SCRUBBER

FLOW

SENSOR

CIRCULATION

PUMP

REACTOR

1

um

10

um

F

BALLAST

DC-TO-AC

INVERTER

UV POWER SUPPLY

1

8

5

3

2

9

10

7

6

4

UV

STERALIZER

Figure: 19

1 The robotic oor scrubber system utilizes 53-liter tank for storing and recycling cleaning solution.

2 The UV ltration system utilizes a 10 micron pre-lter and a 1 micron primary lter to eliminate turbidity for

effective UV penetration into the cleaning solution.

3 The circulation pump provides ow for the cleaning solution.

4 The UV sterilization system includes a power supply, UV ballast, UV lamp, and sterilization reactor to

eliminate microorganisms from the recycled cleaning solution.

5 A ow sensor is used to detect and set an appropriate ow rate for effective scrubbing.

6 Water valves provide ow regulation for wash water or recycling of the cleaning solution.

7 Cleaning solution is distributed directly onto the scrubbing head.

8 When not scrubbing, the cleaning solution is recycled back to the tank and continually ltered.

9 A vacuum system evacuates air from the top of the tank, providing suction for the vacuum squeegee

10 The squeegee system wipes used cleaning solution from the oor and the pickup tube directs the used

solution back to the tank.

13

12.3. Robotic Operation:

The machine uses a number of advanced systems enabling

it to clean robotically.

Figure: 20

A system of 16 individual sonar transceivers

are used for detecting both short-range and

long-range objects to determine the robot’s

environment.

A gyroscopic compass is used to determine

the robotic heading to follow pre-installed or

custom designed cleaning maps.

WiFi and cellular communications are

available for reporting system status and

remote diagnostics.

13. Safety Devices

The robotic oor scrubber system is equipped with the

following safety devices:

13.1. Emergency Stop Button

The Emergency Stop Button is the red switch located on the

top right of the handlebar assembly. Pressing the Emergency

Stop Switch will interrupt power to the system. The operator

should be prepared to press the Emergency Stop Button

at any time to address unintended operation or to avoid a

hazardous situation in an emergency.

1

Figure: 21

1 Emergency Stop Button

13.2. Front Cover Interlock

The front cover interlock is the red magnetic switch located

inside the front cover. The front cover interlock switch will

interrupt power to the system if the front cover should ever

be opened during operation.

Front Cover

(Open Position)

Parking Brake

(Unlocked Position)

Cover Interlock

Switch

Figure: 22

13.3. Parking Brake

The parking brake is located under the machine between the

rear casters. The brake is activated by moving it to the left to

lock the drive wheels.

14

Figure: 23

Moving the handle to the right unlocks the brake. The parking

brake should be locked whenever the machine is not in use.

13.4. Touch shields

The system is equipped with front and rear touch sensitive

panels. If an object bumps into the panels the system will

stop.

1

2

Figure: 24

1 Front Touch Shield

2 Rear Touch Shield

13.5. Warning Lamp

The system is equipped with a yellow warning lamp. The

lamp ashes to alert people when the unit is operating.

1

Figure: 25

1 Warning Lamp Light

13.6. Floor Sensors

The robotic oor scrubber system includes four infrared

oor sensors located underneath the machine. The sensors

measure the distance to the oor at each of the four corners

and are used to detect drops in the oor, such as a stairwell.

1

1

1

1

Figure: 26

1 Infrared Sensor

During robotic operation, the machine monitors this distance

and will stop automatically if the distance exceeds a preset

number.

13.7. Safety Device Warnings

The operator should be aware of the following

warnings regarding the safety devices:

Always set the parking brake when the

machine is not running or unattended.

Do not remove or modify the safety devices

in any way.

Do not open the front cover unless

instructed to do so in this manual

15

14. Safety Circuit Wiring

1

2

4

5

3

70A

BATTERY FUSE

BATTERY BOX

SAFETY

CONTACTOR

FRONT COVER

MAGNETIC INTERLOCK

SAFETY

RELAY

EMERGENCY

STOP BUTTON

MAIN

CONTROLLER

24V

GND

CONTACTOR

STATE

Safety Relay

- 24V

MIRROR

CONTACTS

41

31

2111

12 22 32

42

K1

A1A21 3 5

3

2 4 6

4

F6

R50955

Fuse - Blade 30A - 32V

Bussmann ATC-30

F5

1300573

Fuse - Blade 4A - 32V

Bussmann

BK/ATC-4

F2

1300589

Fuse - Blade 1A - 32V

Bussmann

ATC-1

F1

1300633

Fuse - Blade -

7.5A - 32V

Bussmann

BK/ATC-7 1/2

F1

1300614

Fuse - Blade 15A - 32V

Bussmann

BK/ATC-15

F1

1300614

Fuse - Blade 15A - 32V

Bussmann

BK/ATC-15

CB1

2300129

Circuit Breaker Resettable - 40A

Klixon 7851-1340i

LINEAR MOTORS

AND SOLENOID

BRUSH

MOTORS

VACUUM

MOTORS

RECYCLE

PUMP

UV

LIGHT

I/O

BOARD

DRIVE

MOTOR

(L)

DRIVE

MOTOR

(R)

Figure: 27

1 A safety contactor is used to safely remove power from all motors and the UV sterilizer system

2 The safety contactor is controlled by a safety relay. The safety relay will open the safety contactor when

either the Emergency Stop Button is pressed or the front cover is opened.

3 The system main controller monitors the status of the safety contactor to alert the operator when the circuit

is tripped.

4 A main battery fuse is provided in the battery box to protect the primary power wiring.

5 Branch fuses are provided to protect the branch wiring to each of the motors and subsystems.

Important:

The components of the safety circuit are essential to the safe operation of the machine. Never tamper

with or substitute any safety component, serious damage or injury may result.

16

15. Batteries

The robotic oor scrubber system utilizes a battery pack

containing 4 six-volt gel cell, or AGM deep cycle batteries.

The battery pack is heavy and requires special handling.

Figure: 28

If replacement of the batteries within the battery pack is

needed, contact Customer Assistance. Battery replacement

can be hazardous and should only be performed by a trained

service technician.

Do not attempt to remove the battery pack

from the machine unless you are using

an approved accessory stand or cart The

battery pack weighs 293 lbs (133 kg) and

can cause serious injury.

15.1. Battery Safety

Batteries store a signicant amount of energy and emit

explosive gases when charging. Attention, care, and

planning should be taken when storing and charging this

machine and the battery packs. Review and understand the

warnings shown in the battery warning label section and plan

in advance for battery storage, charging and accidents.

15.2. Accessory Battery Cart

TASKI Intellibot offers an accessory battery cart that allows

for battery pack removal and charging in one station. If a

second battery is also purchased, it can be stored on the

cart and charged while the machine is in use, allowing for

improved efciency.

Figure: 29

When using a charger on the battery cart,

ensure the charger cover is installed to

maintain IPX4 protection.

15.3. Removing the Battery Pack

Before removing the battery, ensure the parking brake is set.

Figure: 30

Turn off the system by pressing the green standby switch

and waiting until the green light is extinguished before

proceeding.

Figure: 31

Before Removing Batteries, hold ~ Standby button,

listen for 3 Beeps, which is the computer acknowledging your

button push. Computer will turn off 24V circuits & start saving

data.

Caution, for the next 30-90 seconds the computer

saves data, wait for button light to go "Off" or you will lose the

data. If light is still on after 120 Seconds, to prevent damage

or injury hit e-stop to assure 24V power is disconnected from

battery before breaking connection by pulling on battery

handle.

Button goes dark; computer has shut down all power.

All power is off; no trickle power is leaking from the battery to

any circuit.

Caution:

If the standby button remains illuminated

for more than 120 seconds, press the

Emergency Stop button before removing

the battery pack.

Attach the accessory cart to the machine.

17

Always lock the wheels on the battery

cart to prevent the cart from moving while

removing the battery from the machine.

Figure: 32

Depress the battery latch and pull the battery from the

system onto the accessory battery cart.

Figure: 33

Attention

Never store the machine with discharged

batteries. Otherwise, the batteries will be

damaged beyond repair. Be sure to fully

charge batteries whenever storing the

machine.

16. Charging

The battery pack may be recharged while in the robotic oor

scrubber system.

Only recommended 24 volt gel cell

battery charging systems should be used.

Overheating, re, and explosion could result

from improper battery charging.

The charge current should be limited to 20

Amps or less. Do not charge the system

with a current higher than 20 Amps or

damage could result.

It is typical of a gel cell charger set at 20

Amps to initially overshoot to as much as

30 Amps and then settle back to around

20 Amps. This is acceptable as long as

it settles back to 20 Amp within a few

seconds.

16.1. Locating the Charger

The location and mounting of the battery charger should be

considered before charging the system or battery pack.

Figure: 34

The battery charger connects to the high

voltage mains. The charger must be located

on a wall, away from wet areas, to avoid a

shock hazard.

Caution

To avoid water shorting the charger it should

be mounted above tank no less than 12"

(31 cm) above, either on a shelf or to the

wall per charger manufacturers instructions.

Periodically inspect the mains and charging

cables to ensure the integrity of the

insulation. Do not use the charger if the

insulation is nicked or cracked.

16.2. Charging the System

Before charging the battery, ensure the parking brake is set.

Figure: 35

Turn off the system by following instructions from "Figure: 31"

on page 16.

18

Caution:

If the standby button remains illuminated

for more than 120 seconds, press the

Emergency Stop button before charging the

system.

Caution:

Never remove battery pack while charging.

Damage to the electronic controls will likely

result!

Locate the system charging port under the rubber ap.

Figure: 36

Plug in the charger and fully charge the batteries.

CHARGER SPECIFICATIONS

MODEL

BATTERY

VOLTAGE

CHARGING

CURRENT

BATTERY RANGE

(5H) (20H)

CBHF2

24-20

24 V 20 A

120÷195 Ah150÷240

Ah

17. Language Setup

The robotic oor scrubber system interface supports

three languages, English, German, and Spanish.

Perform the following to select the system interface

language:

Turn on the system by pressing the standby

button.

Wait approximately 2 minutes until the LOG

IN screen is displayed.

••••••

1 2 3

4 5 6

7 809

x

Press the LOG IN key and enter your

administrative password.

The prep guide will appear. Touch the OK

button to move to the home screen.

Figure: 37

From the home screen, press the right

arrow button to access the system settings

menu.

Press the Prefs button to access system

preferences.

Press the language button and select

English, Spanish, or German.

18. Administrative Setup

The following are instructions for adding operators and

setting operator privileges.

Turn on the system by pressing the standby

button.

Wait approximately 2 minutes until the LOG IN screen is

displayed.

19

Figure: 38

Conrm "CE" is in lower left of screen as a

software update may have occurred since

last use.

If "CE" is not displayed, write down the

serial number and software version,

shut down the machine and then contact

Customer Assistance. Give Customer

Assistance this data and ask for further

instructions.

••••••

1 2 3

4 5 6

7 809

x

Press the LOG IN key and enter your

administrative password.

The prep guide will appear. Press the OK

button to move to the home screen.

Press the Admin button to access the

administrator screen.

Figure: 39

1 Press the Add Operator key to add a new system

operator.

2 To edit operator information press the information

key to access the user setting screen.

3 To inactivate an operator, press the inactivate

operator key. This prevents an operator from

accessing the machine.

4 To edit or delete an existing operator, press the

operator name.

The following buttons are used to grant or revoke privileges

from the user setting screen:

Pressing the manual mode button allows

the operator to use the machine in manual

mode.

Pressing the robotic mode button allows

the operator to use the machine in robotic

mode.

Pressing the mapping button allows the

operator to create new maps and edit

existing maps.

Pressing the reporting button allow s the

operator to view machine statistics.

Pressing the administrative privilege button

allows the operator to add, modify, or delete

other operators.

Pressing the diagnostics button allows the

operator to view machine diagnostics.

20

19. System Preferences

Perform the following to set the WiFi, beeper, language,

measurement system, and water ow rate system

preferences.

Turn on the system by pressing the standby

button.

Wait approximately 2 minutes until the LOG

IN screen is displayed.

••••••

1 2 3

4 5 6

7 809

x

Press the LOG IN key and enter your

administrative password.

The prep guide will appear. Touch the OK

button to move to the home screen.

Figure: 40

From the home screen, press the right

arrow button to access the system settings

menu.

Press the Prefs button to access system

preferences.

Press the WiFi button to congure the

system WiFi. WiFi must be turned on when

the Intelli-Track reporting system is in use.

Press the beeper button to set the safety

beeper on or off. When set to ‘ON’ the

beeper will sound while the machine is

running.

Press the language button to select

English, Spanish, or German for the system

interface.

Press the measurement button to congure

the measurement system to metric or

imperial.

Press the water ow button to congure the

system ow rate from 1.1 to 2.6 liters per

minute.

Press the OK button to exit the system

preference menu.

20. Commissioning After Storage

If the machine has been in storage, the following items must

be reviewed:

The robotic oor scrubber system must be

acclimated to the operating environment.

Failure to do so can result in condensation

inside the machine, shortening the life of

critical components. Allow the machine to

acclimate one hour for every 9° F (5° C).

Gel cell batteries will lose charge if not

maintained while in storage. Ensure the

batteries go through a full charge cycle

before turning on the system.

21. Weekly Safety Device Check

To ensure the safe operation of this machine, the operator

must periodically verify the operation of the system safety

devices. The following operational safety device check

should be performed on a weekly basis.

If any safety device fails the operational

safety device check, the machine must be

serviced by a trained service technician. Do

not use the system if any safety device is

not operating properly.

21.1. Emergency Stop Button Check

Perform the following steps to verify operation of the

Emergency Stop button:

Turn on the system by pressing the standby

button.

Wait approximately 2 minutes until the LOG IN screen is

displayed.

Figure: 41

Press the Emergency Stop button.

Verify that the system alerts the user with

three audible beeps and the user interface

displays the attention symbol and the

words.

Emergency Stop pressed

Twist and release to resume

If the system fails the Emergency

Stop button operational check, turn off

immediately by pressing and holding the

standby button. Do not use the system,

it must be repaired by a trained service

technician.

21

If the system passes the operational

check, twist the Emergency Stop button

counterclockwise to reset and press the OK

button on the user interface.

21.2. Front Cover Interlock Check

Perform the following steps to verify operation of the front

cover interlock:

Verifying the front cover interlock requires

partially opening the front door with the

machine turned on. Do not open the door

more than ¼ of the full swing. If the interlock

fails to operate, personnel may be exposed

to hazards within the machine.

Verify that the LOG IN screen is shown on

the user interface.

Release the two latches on the front cover

and open the door ¼ of the full swing.

Verify that the system alerts the user with

three audible beeps and the user interface

displays the attention symbol and the

words:

Front door open

Close front door to resume

If the interlock operational check fails, press

the Emergency Stop button immediately,

then turn off the system by pressing and

holding the standby button. Do not use the

system, it must be repaired by a trained

service technician.

If the system passes the operational check,

close the front cover and attach both

latches, then press the OK button on the

user interface.

21.3. Parking Brake Check

Perform the following steps to verify operation of the

parking brake:

This procedure requires engaging the drive

in manual mode. Only use the slowest

forward speed to verify operation of the

parking brake. If the parking brake fails,

using a higher speed reverse direction could

result in damage to the machine, property,

or injury to the operator.

Verify that the LOG IN screen is shown on

the user interface and log into the system

using your operator code.

Touch the Manual clean button on the home

screen.

Touch the forward arrow button once to set

the slowest speed.

Squeeze the handlebar for one second,

then release. Verify that the parking brake

is holding and the machine does not drive

forward.

Verify the yellow safety light on top of the

machine ashes while the handlebar is

pressed.

If the parking brake operational check

fails, press the Emergency Stop button

immediately, then turn off the system by

pressing and holding the standby button. Do

not use the system, it must be repaired by a

factory trained service technician.

Turn off the system by pressing and holding

the standby button.

21.4. Touch Shield Check

There are two touch shields. The front touch shield is

attached to the front cover door. The rear touch shield is

attached to the main body of the machine.

1

2

Figure: 42

1 Front Touch Shield

2 Rear Touch Shield

Each touch shield is divided into six zones, front, left front,

right front, rear, left rear, right rear. Each of the six zones

must be tested for operation.

22

6

5

2

3

2

2

Figure: 43

1 Front Zone

2 Right Front Zone

3 Right Rear Zone

4 Rear Zone

5 Left Rear Zone

6 Left Front Zone

Perform the following steps with the system turned on and

the parking brake set.

From the home screen, press the right

arrow button to access the system settings

menu.

Press the diagnostics key to enter the

diagnostics menu.

Press the touch shield button to enter the

touch shield diagnostic.

1

5

2 3 4

6

Figure: 44

1 Zone contact indicator

2 Zone indicator (yellow text)

3 Total number of contact detections since machine

installation (white text)

4 Total number of contact detections since

machines last startup or diagnostics where

performed (orange text)

5 Resets total number of contact detections to 0

since machine last startup

6 Return to diagnostics main screen

Record the orange numbers (4) if needed.

Press the reset button to reset the orange

number counters to zero.

Press each of the six touch shield zones, applying at least

1.5 lbf (6.7 Newtons) of force.

Review the orange number and verify that the machine

recorded each touch.

If the machine does not recognize any

of the touch shield zones it is not safe

to operate in robotic mode. Turn off the

machine by pressing and holding the

standby button. Do not use the system,

it must be repaired by a factory trained

service technician.

Press the reset button to reset the orange

number counters to zero.

Press the forward key to return to return to

the diagnostics menu.

Press the return key to return to the main

menu.

21.5. Floor Sensor Check

There are four infrared sensors that measure the distance

from the machine frame to the oor. The sensor operation is

checked by using the system diagnostics menu.

Perform the following steps with the system turned on and

the parking brake set.

From the home screen, press the right

arrow button to access the system settings

menu.

Press the diagnostics key to enter the

diagnostics menu.

Press the oor sensor button to enter the

oor sensor diagnostic.

23

1

4

2

3

Figure: 45

1 Reports sensor distance in mm

2 Reports sensor voltage in mV

3 Sensor

4 Return to diagnostics main screen

Verify that all four of the sensors report a reasonable

distance to the oor and the “No ground” warning is not

displayed.

It is possible to receive a false “no ground”

warning on black shiny surfaces. If the

oor is causing false readings, move the

machine to a different location to perform

the test.

If the machine does not recognize any

of the sensors it is not safe to operate In

robotic mode. Turn off the machine by

pressing and holding the standby button. Do

not use the system, it must be repaired by a

factory trained service technician.

22. Daily Startup Procedure

The following procedure should be performed daily before

operating the robotic oor scrubbing system.

22.1. Set the Parking Brake

Ensure the parking brake is in the locked position by moving

the red lever to the left.

Figure: 46

22.2. Power Off

Ensure the machine is turned off.

22.3. Remove Charging Cable

If the system is being charged, disconnect

the battery charging cable from the system

charging port.

The machine will not turn on with the

charger mechanically connected.

22.4. Remove Empty Canisters

Remove both canisters using the supplied wrench.

1

1

2

Figure: 47

1 Cannister Filters

2 Filter Wrench

22.5. Install Clean Filters

Install clean lters and ensure they are seated properly in

each canister.

Filter elements should be replaced every

30 days.

The TASKI Intellibot SWINGOBOT 1650 CE

UV utilizes a series ltration system. The

10-micron pre-lter must be installed in the

left canister and the 1-micron primary lter

must be installed in the right canister.

22.6. Install Canisters With Filters

Ensure the black rubber O ring is on the

interior lip of each blue canister. Seat the

canister, hand tighten, and use the lter

wrench to provide an additional 1/4 turn.

24

22.7. Inspect Squeegee

Check the squeegee blades for wear.

Flip worn blades and replace if necessary.

22.8. Inspect and Replace Scrubber Pads

Unlatch and open the front cover. Inspect the scrubber pads.

Replace if pads are worn to within 10 mm of brushes.

To replace the pads, rotate the brushes toward the center of

the machine to release the brush.

Figure: 48

Replace the pad on the brush. Replace the brush on the

head by rotating in the opposite direction.

Inspect pads for wear and replace if

necessary.

Flip the pads every other day to extend

brush life.

Close the front door and secure both latches.

22.9. Fill the Tank

Fill the tank with 14 gallons (53 liters) of cool water.

Diversey recommends using cold water

since hot water will adjust to the oor

temperature as soon as it is in contact with

the oor. Thus there are no advantages to

the using of hot water.

Add recommended cleaning solution

to the water in the tank according to

the manufacturer’s instructions. Use of

protective glasses, gloves, and apron is

recommended.

Only use cleaning products recommended

by TASKI Intellibot. Use of products

containing chlorine, acids, or unsuitable

solvents may damage the machine and

may be hazardous to the operator.

22.10. System Power Up

Perform the following steps to power up the system.

Turn on the system by pressing the standby

button.

Wait approximately 2 minutes until the LOG IN screen is

displayed.

Figure: 49

Conrm "CE" is in lower left of screen as a

software update may have occurred since

last use.

••••••

1 2 3

4 5 6

7 809

x

Press the LOG IN key and enter your

operator password.

You will be prompted with a series of

screens to guide you through machine

preparation steps. Touch any of these

screens for more information.

Release the parking brake by moving the red lever to the

right.

Figure: 50

Press the OK button to begin using the

machine.

23. Review of Work Area

Before beginning cleaning, the operator is responsible for

reviewing and preparing the work area.

Remove any objects from the oor that

could get caught or be thrown by the

scrubber head. Objects entangled or

thrown by the scrubber could cause serious

property or machine damage and injury.

25

Block all stairways and doorways when

using robotic mode. Failure to block a

stairway could result in the machine

tumbling down the stairs, resulting in serious

property damage, machine damage and

injury.

24. Manual Drive

The machine must be manually driven to the cleaning

area and placed at the cleaning start location. To manually

transport the machine, perform the following:

From the home screen, press the manual

clean button

Press the forward or reverse arrow buttons

to set the desired speed then squeeze the

handlebar to engage the drive system.

Take care when reversing to prevent

tripping over object or trapping the operator

between the machine and an object.

To prevent accidental movement, the

handlebar must be squeezed within 4

seconds of selecting a speed. If the timer

has elapsed, select the speed again and

squeeze the handle within 4 seconds.

The system uses a gyroscopic inertia sensor to sense

operator input for steering. Pull the handlebar left or right

and the machine will respond by turning in the appropriate

direction.

Release the handlebar to stop.

25. Manual Cleaning

Use the following functions to operate the machine in manual

clean mode:

From the home screen, press the manual

clean button.

Press the vacuum button to lower the

squeegee and turn on the vacuum system.

Press the scrubber button to lower the head

and activate the scrubber motors.

Press the forward arrow button to set the

desired speed then squeeze the handlebar

to engage the drive system.

26. Hands Free Cleaning

Three options are available for hands free cleaning, Spot

Clean, Area Clean, and Map Clean.

MODE

WIDTH (MIN) WIDTH(MAX)

END WALL

FT M FT M

Spot

Clean

5.58 ft 1.7 m 60 ft 18.3 m NO

Area

Clean

5.58 ft 1.7 m 60 ft 18.3 m YES

Spot Clean is used to robotically clean a dened area when

no end wall is present. There must be a left and right wall

present for the machine to accurately measure the width of

the cleaning area. The machine will clean the area between

the side walls to an operator set distance between 20 ft and

196.18 ft (6.1 meters and 60.1 meters.).

Area Clean is used to robotically clean an area when an end

wall or obstacle is present. The machine robotically cleans

according to any one of twelve selectable built-in cleaning

patterns.

Map Clean allows an authorized operator to create a custom

cleaning pattern for robotic cleaning.

26.1. Spot Clean

Using the Manual Drive mode, position the machine at the

cleaning start location. To enable Spot Clean, perform the

following from the home screen:

Press the Spot Clean button and use the

(+) and (-) buttons to select a spot cleaning

distance from 20 ft and 196.18 ft (6.1 meters

and 60.1 meters.).

GO

Press the GO button and the machine will

begin robotic cleaning.

26

26.2. Area Clean

Area clean uses any of twelve different cleaning patterns

with the option of having the machine return to the starting

location when the cleaning is complete. For example the

following is a Side T Right cleaning pattern:

Figure: 51

The machine starting location is shown as (3). The machine

ending location is shown as (4).

Figure: 52

Alternately, the same Side T Right pattern can be chosen

with the machine returning to the start location (2)

27

The following cleaning patterns are available:

Single Area

Single Area Return

Side T Right

Side T Right Return

L Left

L Left Return

Side T Left

Side T Left Return

L Right

L Right Return

Cross Left

Cross Left Return

T Left

T Left Return

Cross Right

Cross Right Return

T Right

T Right Return

U Style Right U Style Right Return

Large Room Large Room Return U Style Left U Style Left Return

Figure: 53

28

Using the Manual Drive mode, position the machine at the

cleaning start location. The machine must be located within

2 ft (61 cm) of start location shown on cleaning pattern.

To enable Area Clean, perform the following from the home

screen:

Press the Area Clean button and choose an

area cleaning pattern.

GO

Press the GO button and the machine will

begin robotic cleaning.

After the GO button is pressed the machine will spend a few

moments calculating the cleaning plan before proceeding

robotically. The machine will continue to clean until it reached

the end of the cleaning pattern.

To interrupt the cleaning pattern, press the

PAUSE button.

GO

To resume the cleaning pattern after a

pause, press the GO button.

To terminate the cleaning pattern, press the STOP button.

On the rst pass of the cleaning area, the machine is looking

for openings that match the selected pattern. If the openings

are not found, the machine will stop.

If the machine nds a partial match, it will clean the area

corresponding to the map and then stop.

26.3. Map Clean

Map Clean utilizes custom cleaning patterns created and

downloaded to the machine by authorized operators. To

enable Map Clean:

Using the Manual Drive mode, position the machine at the

cleaning start location. The machine must be located within 2

ft (61 cm) of the start location shown on the cleaning pattern.

Press the Map Clean button and chose a

custom cleaning pattern.

GO

Press the GO button and the machine will

begin robotic cleaning.

After the GO button is pressed the machine will spend a few

moments calculating the cleaning plan before proceeding

robotically. The machine will continue to clean until it reached

the end of the cleaning pattern.

To interrupt the cleaning pattern, press the PAUSE button.

GO

To resume the cleaning pattern after a

pause, press the GO button.

To terminate the cleaning pattern, press the STOP button.

On the rst pass of the cleaning area, the machine is looking

for openings that match the selected pattern. If the openings

are not found, the machine will stop.

If the machine nds a partial match, it will clean the area

corresponding to the map and then stop.

27. Daily Shutdown Procedure

After completing cleaning, the following steps should be

performed daily:

Use of protective glasses, gloves, and

apron is recommended when in contact with

waste water or cleaning any element of the

system.

27.1. Parking

Use manual drive to position the machine next to the

disposal area.

Ensure the scrubber is turned off and the scrubber heads are

in the up position.

Ensure the vacuum is off and the squeegee is in the up

position.

Place the parking brake in the locked position by moving the

red lever to the left.

Figure: 54

Turn off the system by pressing and holding

the standby button.

27.2. Drain and Clean the Tank

Before draining the tank, take note of any

local or national regulations for disposal.

Waste water must be disposed of in a

responsible manner, consistent with

applicable environmental and safety

regulations.

Locate the drain hose, remove the end

from the holder and position the drain hose

over the disposal area.

Pull the drain valve and drain the waste

water into the disposal area.

Clean out debris and sediment from the

basket lter and bottom of tank.

29

Flush the tank with clean water and lose the drain valve.

27.3. Clean the Squeegee:

Clean the squeegee by removing any debris between the

squeegee blades.

Check the pickup tube for obstructions.

27.4. Clean Caster Wheels

Inspect and clean the rear caster wheels

Figure: 55

27.5. Remove and Clean Filters

Remove both canisters using the supplied lter wrench.

Remove the lters from the canisters and

replace the canisters on the system and

the lter wrench in it’s holder.

Rinse and dry the lters to prepare for next

use.

30

28. Maintenance

The following maintenance schedule should be followed for proper machine operation:

MAINTENANCE ITEM DAILY WEEKLY

□ Drain and clean tank X

□ Clean tank basket lter X

□ Remove and clean canister lters X

□ Clean squeegee and pick up area X

□ Inspect pick up tube for obstructions X

□ Inspect squeegee for wear and adjust, ip, or replace as necessary X

□ Clean caster wheels X

□ Inspect pads and brushes for wear. Flip or replace as necessary. X

□ Perform Emergency Stop Button check X

□ Perform front cover interlock check X

□ Perform parking brake and safety light check X

□ Perform touch shield check X

□ Perform the oor sensor check X

□ Replace canister lters X

□ Inspect pickup hose and replace as necessary X

□ Inspect hinges and lubricate as necessary X

□ Apply grease to squeegee pivot bracket X

□ Inspect battery box ball bearings and lubricate if necessary X

□ Clean undercarriage X

28.1. Daily Maintenance Points

• Strainer Basket

Empty large items into the trash and rinse thoroughly.

• Primary Solution Filter

Remove the primary solution lter from the machine. Rinse and gently clean dirt and debris from the lter

using a soft bristle brush.

• Blue Secondary Filters

Remove both blue secondary lters from the back of the machine. Rinse and clean both lters. Allow

lters to air dry if possible. Visually inspect the condition of both lters and replace as necessary

• Squeegee Assembly

Disconnect the squeegee assembly from the SWINGOBOT 1650. Rinse the squeegee and wipe clean.

Hair and other debris may hinder results by leaving streaks on the oor. Visually inspect the condition of

the squeegee blades and rotate or replace as necessary. Check the condition of the frame gasket and

replace as necessary.

• Pads & Brushes

Remove pads or brushes from the machine. Rinse thoroughly and replace as needed.

• Solution Tank Seals

Clean and visually inspect the solution tank seal.

• Solution Tank

Tank should be drained, rinsed and cleaned at the end of every shift.

31

29. Replacement Components

TASKI NO. INTELLIBOT SKU ITEM

7523968 049870 Filter - Cotton 10 Micron

7523969 1300165 Filter - Pleated 1 Micron

7523970 1300755 Filter - Cotton 20 Micron 10"

4132145 3300051 Front Blade - Squeegee - Linatex - SS

4132144 3300052 Rear Blade - Squeegee - Linatex - SS

4132108 1300027 Pad 15" Scrubbing Red

N/A 1300066 Pad 15" Scrubbing White

30. Storage

The following items should be taken into consideration when storing the robotic oor scrubbing system.

ENVIRONMENT

Temperature 59° to 86° F (15° to 30° C) operation, -22° to 140° F (-30° to 60° C) storage

Humidity 20% to 75% relative humidity

Attention

Never store the machine with discharged batteries. Otherwise, the batteries will be damaged beyond

repair. Be sure to fully charge batteries whenever storing the machine.

31. Troubleshooting

MALFUNCTION POSSIBLE CAUSES TROUBLESHOOTING

Machine without function

Charger plugged into robot • Unplug the charger

Battery pack not engaged • Push battery pack into place

Battery not charged • Load batteries

Leaving water

Water ow set too high

• Go to settings menu; lower water valve setting

default

Dirty squeegee

• Wipe squeegee with rag

• Flip or replace squeegee blade (can be

ipped up to 3 times before replacement)

Navigation issues

Sonar faulty • Perform sonar diagnostic, clean sonar

Mechanical drag • Inspect casters

Not cleaning oor surface Brush motor not running

• Reset circuit breaker

• Verify no obstacles are trapped in brush head

Machine pulling to one side when

manually driving

Parking brake is not fully

disengaged

• Move parking brake lever all the way to the

left, then all the way back to the right

If solution fails to correct the

problem

• Contact your service partner

32

32. Diagnostics

The following diagnostics may be performed by operators

with diagnostic privileges.