ATTENTION!

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

Before first start-up, it is essential that you read the instructions of use

and the safety notes carefully.

Keep the instructions of use in a good and easily accessible place so that they

can be consulted at any time.

combimat

swingo 2500/3500

Instructions of use

Content

STOP

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

before putting into service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Beginning work. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

End of operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Finishing work . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Service, maintenance and care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Malfunctions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Squeegee settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Accessories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Recommended chemicals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

EU Declaration of Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Symbols

Nonobservance of this information can endanger people and / or cause

STOP

t

servere damage!

Nonobservance of this information can lead to malfunctions and property

damage!

Important information about economical use. Nonobservance of this

information can lead to malfunctions!

Action points.

Intended use of machinery

The scrubber dryer is used to clean hard floor surfaces according to these

instructions of use.

The machine is suitable for floor cleaning applications in industrial and commercial

areas such as hotels, schools, hospitals, factories, shopping centres, offices etc.

2

Safety instructions

STOP

STOP

STOP

STOP

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

Due to their design and construction, TASKI machines comply with health and

safety requirements of the EC guidelines and therefore carry the CE sign.

This machine may only be used by persons who have been properly

STOP

STOP

STOP

trained to do so!

Do not use the machine in rooms where explosive and flammable

substances (e.g. petrol, paint thinners, heating oil, solvents, etc.) are

stored or processed. The electrical or mechanical components of the

machine could lead to an ignition of these materials.

Do not use this machine to vacuum toxic, poisonous, caustic or irritating

substances (e.g. acids, alkalis, hazardous dusts, etc.). The filter system

will not adequately retain these kinds of material. A possible impairment

of the health of the user and of third parties cannot be excluded.

STOP

While operating the machine, take note of the surrounding area and pay

particular attention to third parties and children!

Caution:

Pay attention to the accident prevention regulations!

Caution:

No second person may be transported!

Caution:

Only use tools which are specified in the instructions of use under

accessories and which the TASKI-technical specialist recommends

(Page 30), as the use of other tools could impair safety.

Caution:

Personnel safety is covered by appropriate national regulations!

Only use the machine on level floors or inclines of maximum 13%.

This symbol on the machine indicates that it is not suitable for use on surfaces

with greater inclines.

13%

3

Important! Switch the machine off when you:

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

• e.g., carry out cleaning, maintenance or repair work, replace components or

change to another function

• replace the tools or other accessories

• store it in a suitable room to avoid any unauthorised use of the unit

• leave the machine unsupervised

To do so, pull out the main switch key and stop the machine from rolling away (e.g. by

fixing a wedge).

This machine is only intended for use in dry areas, and must not be used

or stored in the open air under damp conditions.

The tank cap must be closed when moving or driving the machine.

Store the machine in a dry, dust-free room with a corrosion-free atmosphere.

The temperature must not fall below +10 °C nor exceed +35 °C. Low temperatures,

damp and dust can significantly reduce the service life of the electrical components.

4

Transport

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

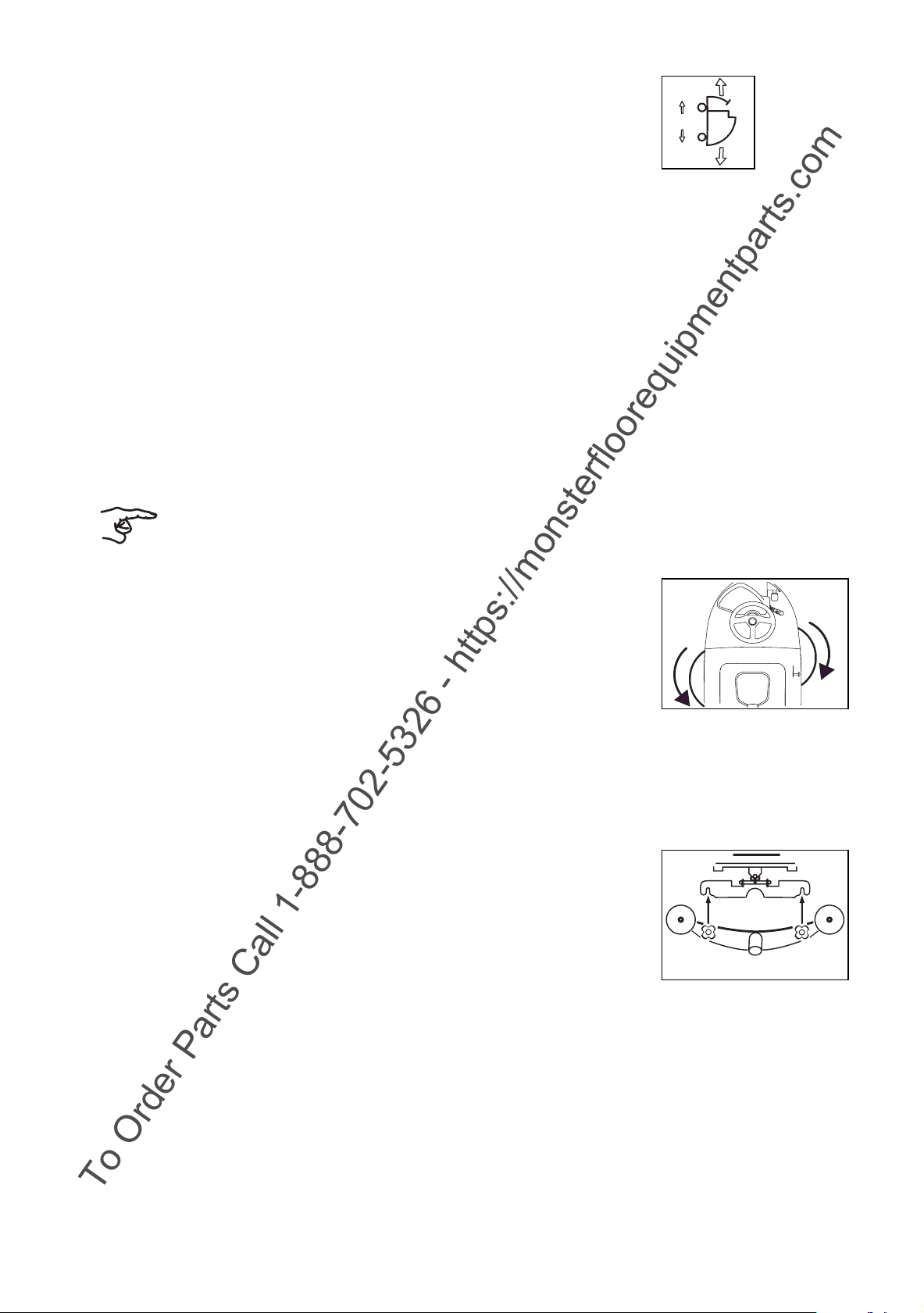

Transport the machine in upright position or disassemble the batteries for

transportation.

Make sure that the machine is tightly secured in the transportation vehicle so that

the batteries cannot fall over in any way.

Disposal

When placed out of service, the machine and its accessories must be disposed of

according to the national regulations. Your TASKI partner can support you with

proper disposal upon notification.

Batteries

The batteries must be removed from the machine before being disposed of

properly.

Used batteries must be disposed of in an environmentally appropriate way

according to EU guidelines 91/157/EEC

5

Overview

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

23242526

1

2

3

4

5

6

2122

20

19

18

17

16

15

7

1 Probe (dirty water tank full)

2 Nozzle-/ tube holder

3 Option: Recycling filter

4 Soiled solution tube

5 Flexible suction hose

6 Tank cover

7 Squeegee

8 Suction filter

9 Recovery tank

10 Rear steering drivewheel

11 Fresh water tank (diaphragm sack)

with dosing cup

12 Disconnector charger jack

13 Brush unit

8 9 10 11 12 13 14

14 Impact protection

15 Parking brake

16 Drive pedal

17 Brake pedal

18 Forwards / Backwards lever and

horn

19 Keyswitch

20 Control panel

21 Steering wheel

22 Drivers seat adjustment

23 Driver seat with safety switch

24 Battery cover (main fuse and battery

plug)

25 Tank hood

26 Suction filter

6

27

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

28

29

Display

37383940414243444546

36

31

32 3330

34 35

27 Brush button ( +/- )

28 Cleaning solution button ( +/- )

29 Display button

30 Slow drive button

31 Vacuum on/off

32 Service indicator

33 Recovery tank full indicator

34 Cleaning solution empty indicator

35 Display indication while turning on

the machine

36 Suction aggregate ON

37 Suction aggregate OFF

(soiled solution tank full)

38 Tool aggregate ON

39 Fault accelerator pedal

40 Hours in total

41 Tool aggregate hour indicator

42 Hours of operation

43 Error code

44 Brush pressure on / off

45 Battery indicator

46 Cleaning solution on/off

7

before putting into service

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

Batteries

Safety measures when working with batteries:

• Never bring an open flame or a glowing objects into the vicinity of the battery,

as there is a danger of explosion from the electrolytic gas present in the cells!

No smoking!

• The battery must always be clean and dry. Do not place any metallic objects on

the battery.

• Beware of sulphuric acid! Caustic. Do not inhale. Avoid any contact with the

skin or eyes. Wear protective goggles when working on the battery.

• Observe the operating regulations of the battery manufacturer.

Charging procedure (traction block batteries with external charging

unit)

t Pull out the key and operate the parking brake (see Parking brake‘ Page 9).

t Fold the driver seat forward and open the battery cover.

t Disconnect the connection between the battery and the machine with the

battery disconnection socket.

Caution:

Battery compartment must be open during charging.

t Connect battery plug with the external battery charger.

After completing the charging and with immediate use:

t Switch off charger.

t Disconnect the charger plug.

t Connect the battery to the machine with the battery disconnection socket.

8

Parking brake

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

Locking:

t By first pressing down the brake pedal (1) and then the

parking brake (2).

Release the brake pedal,and the machine is locked.

Unlocking:

t By pressing the brake pedal fully down.

The machine is unlocked.

2

Adjust the seat:

t Pull out the key and operate the parking brake (see Parking brake‘ Page 9).

1

t Loosen the lock on the left side of the driver's seat and

push it to the desired position.

t Lock the seat into position.

Check seat locking device!

t Unlocj the parking brake (see ‚Parking brake‘ Page 9).

Transport

The driving direction and speed can be controlled with the steering wheel and

accelerator pedal. The speed is continuously adjustable.

t Unlocj the parking brake (see ‚Parking brake‘ Page 9).

t Switch on the machine (keyswitch).

The indicators light up.

The battery indicator displays that the machine is ready for

operation

(on malfunction see page 25).

9

t specify driving direction by using the driving direction

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

lever (Forwards/Backwards).

t Run the machine to the destination and then release the drive pedal.

Fixing tools

t Pull out the key and operate the parking brake (see Parking brake‘ Page 9).

Check:

• that the brushes are not below the red marking and that the bristle length is not

less than 1 cm.

• the pad for wear before using.

Working with worn out, damaged and or wrong tools, could result in possible

damage to floor or their protective layers.

t Turn the left tool counter-clockwise and the right tool

clockwise into the lock.

This locks the tool into place.

Attach squeegee

t Pull out the key and operate the parking brake (see Parking brake‘ Page 9).

t Loosen the fixation knobs on the squeegee.

t Assemble the squeegee and tighten the fixation knobs.

The washers must be positioned above the suction nozzle support.

t Attach the suction hose (squeegee) to the connector.

Fill the fresh water tank

t Pull out the key and operate the parking brake (see Parking brake‘ Page 9).

10

t Fold the driver seat forward and open the tank cover.

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

t Take the dosing cup out of the fresh water tank (diaphragm sack).

Caution:

Maximum permissible water temperature 60 °C/140 °F.

t Fill the fresh water tank with water (diaphragm sack).

The markings show you the maximum permitted filling

level.

t Add the product measured with the measuring cup to the water in the fresh

water tank (diaphragm sack).

Dose the cleaning solution, Page 31.

t Lay dosing cup in tank.

t Close the tank lid and fold the driver's seat back.

Beginning work

Begin cleaning operation

t Turn the machine on (main switch).

The indicators light up.

The last used cleaning program will be saved.

t Unlocj the parking brake (see ‚Parking brake‘ Page 9).

t Press the button vacuum.

The indicators light up.

t Press the solution button.

The indicators light up.

11

t Choose the amount of solution with +/- button for

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

setting the amount (min. level 1/ max. level 7).

t Press the brush pressure button.

The indicators light up.

t Increase the brush pressure by using +/- button (min.

level 1/ max. level 4).

t specify driving direction by using the driving direction

lever (Forwards/Backwards).

Caution:

Take turning radius into account!

t By gently pressing the speed control in driving

direction, the machine is set in to motion.

The tools start to turn and the solution is fed through the

middle of the tool.

t Press slow drive button, when in delicate environment.

The indicators light up and the drive speed is reduced.

If none of the bars in the battery indicator have lit up, drive

the sweeping-suction machine to the battery charging unit.

If you do not drive the machine to the battery charger, then:

• after 10 min. the tool aggregate and the suction nozzle will be lifted off the

ground.

• after 10 sec. the suction aggregate turns itself off.

• you have 10 more min. of time to get to the battery charger before the machine

turns itself off.

12

Recycling mode (Option)

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

Caution:

The recycling system is not to use in areas with high hygienic demand e.g.

Hospitals, Food-processing companies, Kitchens, etc.

The recycling system is recommended for low till middle congested areas only.

t Pull out the key and operate the parking brake (see Parking brake‘ Page 9).

t Fold the driver seat forward and open the tank cover.

t Pull the recycling filter out of the fresh water tank (diaphragm sack).

t Set the recycling filter into Recovery tank.

Caution:

Maximum permissible water temperature 60°C/140°F.

t Fill water into the solution tank.

The maximum allowable filling level must be 20 cm bellow the rim the of tank!

t Add the product measured with the measuring cup to the water in the fresh

water tank

Dose the cleaning solution, Page 31.

t Close the tank lid and fold the driver's seat back.

Cleaning method

Direct method:

Scrubbing and Vacuuming in one pass.

Indirect working method:

Scrubbing and vacuuming in several passes.

Cleaning methods are described in detail in the "Method Card". You can obtain

"Method Cards" from your TASKI partner or representative.

13

Refilling the solution tank

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

Caution:

Do not clean without solution, as it could cause floor damage.

Cleaning solution tank indication empty:

t When the cleaning solution indicator lights up it is

accompanied by a tone simultaneously.

Cleaning solution tank is empty.

t Pull out the key and operate the parking brake (see Parking brake‘ Page 9).

t Empty or refill the machine again (page 16/10).

t When tank is filled, the cleaning solution indicator

empty continues to light up.

t Drive machine to desired destination.

t Press the vacuum button.

The indicators light up.

t Press the solution button.

The indicators light up.

t Press the brush pressure button.

The indicators light up.

t Slowly press down the acceleration pedal (approx. 5

sec.).

Then the "cleaning solution empty indicator" will be reset.

14

Emptying soiled recovery tank

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

Recovery tank full indicator:

t When the soiled solution tank indicator lights up, the

suction nozzle will rise and the suction aggragate turns

off.

t Empty the recovery tank (Page 16).

15

End of operation

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

After cleaning

t Stop the flow of solution.

t Drive a further few metres to avoid subsequent ,,dripping’’.

Very important when using contact pads!

t Press the brush pressure button.

The tools will be stopped.

t Drive on a few metres further in order to pick up the remaining waste water.

t Only now switch off the vacuum unit.

The suction nozzle rises and the suction aggregate keeps on

running for approx. 10 sec.

t Pull out the key and operate the parking brake (see Parking brake‘ Page 9).

Always drain and clean the recovery tank every time you use the machine.

If the dirty water is allowed to stand, unpleasant smells and deposition of the

dirt will take place after a few hours.

Finishing work

Drain the recovery tank / fresh water tank

The disposal of the dirty water or the cleaning solution must be carried out in

accordance with the appropriate national regulations.

t Pull out the key and operate the parking brake (see Parking brake‘ Page 9).

Proceed as follows for both tanks:

t Remove the hose from its holder.

Open the red cover at handle height and slowly lower the end of the hose

to pour out the contents.

16

t Lift the fresh water tank (diaphragm sack).

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

t Lay the fresh water tank (diaphragm sack) in the recovery tank.

Cleaning solution leakage.

t Remove the empty fresh water tank (diaphragm sack) from the recovery

tank.

Soiled solution pump (Option)

t Pull out the key and operate the parking brake (see Parking brake‘ Page 9).

Empty into higher elevation:

t Conduct the emptying hose to a drain sink or a bucket.

t Press the soiled solution pump button.

It will only be emptied up to the standpipe in the soiled

solution tank.

Drain the recovery tank / fresh water tank

t Pull out the key and operate the parking brake (see Parking brake‘ Page 9).

t Fold the driver seat forward and open the tank cover.

t Unscrew the tank lid (page 6).

If necessary with the special tank tool.

t Clean the recovery tank thoroughly.

t Screw down the tank lid with both hands.

t Thoroughly flush out the fresh water tank (diaphragm sack) with fresh water.

t Refit the fresh water tank (diaphragm sack) onto the equipment.

t Remove dirt from tube.

t Brush the suction filter with a soft brush or remove the fluff with a cloth.p

Recycling filter (optional):

t Take out recycling filter after every use and clean it if necessary.

17

Caution:

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

Clogged filters reduce the flow of the cleaning solution. As a consequence

you may damage the floor coating.

t Place the recycling filter in the fresh water tank (diaphragm sack).

Remove and clean the squeegee

t Pull out the key and operate the parking brake (see Parking brake‘ Page 9).

t Lift the tool lightly.

t Turn the left tool clockwise and the right tool counter

clockwise out the lock.

t Clean the tools under running water.

Removing and cleaning the squeegee

t Pull out the key and operate the parking brake (see Parking brake‘ Page 9).

t Remove the suction hose.

t Loosen the fixation knobs on the squeegee.

t Disassemble the suction nozzle and tighten the fixation

screw.

t Clean the squeegee under running water with a brush.

t Hang the suction nozzle onto the nozzle-/tube holder.

Clean blades produce streak-free results!

18

Cleaning the machine

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

t Pull out the key and operate the parking brake (see Parking brake‘ Page 9).

Caution:

Never clean the machine with a high water pressure or a water hose.

The ingress of water into the machine might cause considerable damage to

mechanical or electrical parts.

storage / parking of machine (machine is idle)

Never store the machines with closed tanks.

t Pull out the key and operate the parking brake (see Parking brake‘ Page 9).

t Fold the driver seat forward and open the tank cover.

t Fit the ventilation strap,and plave the tank cover on it .

The ventilation clamp keeps the tank open for air

circulation.

In this way the tank can dry out. Unpleasant smells and the occurrence of mould will be

reduced.

19

Service, maintenance and care

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

Maintenance

Caution:

Only original spare parts must be used, otherwise Warranties and

liabilities will be omitted!

The machine's maintenance is a pre-condition for trouble-free running and a long

life.

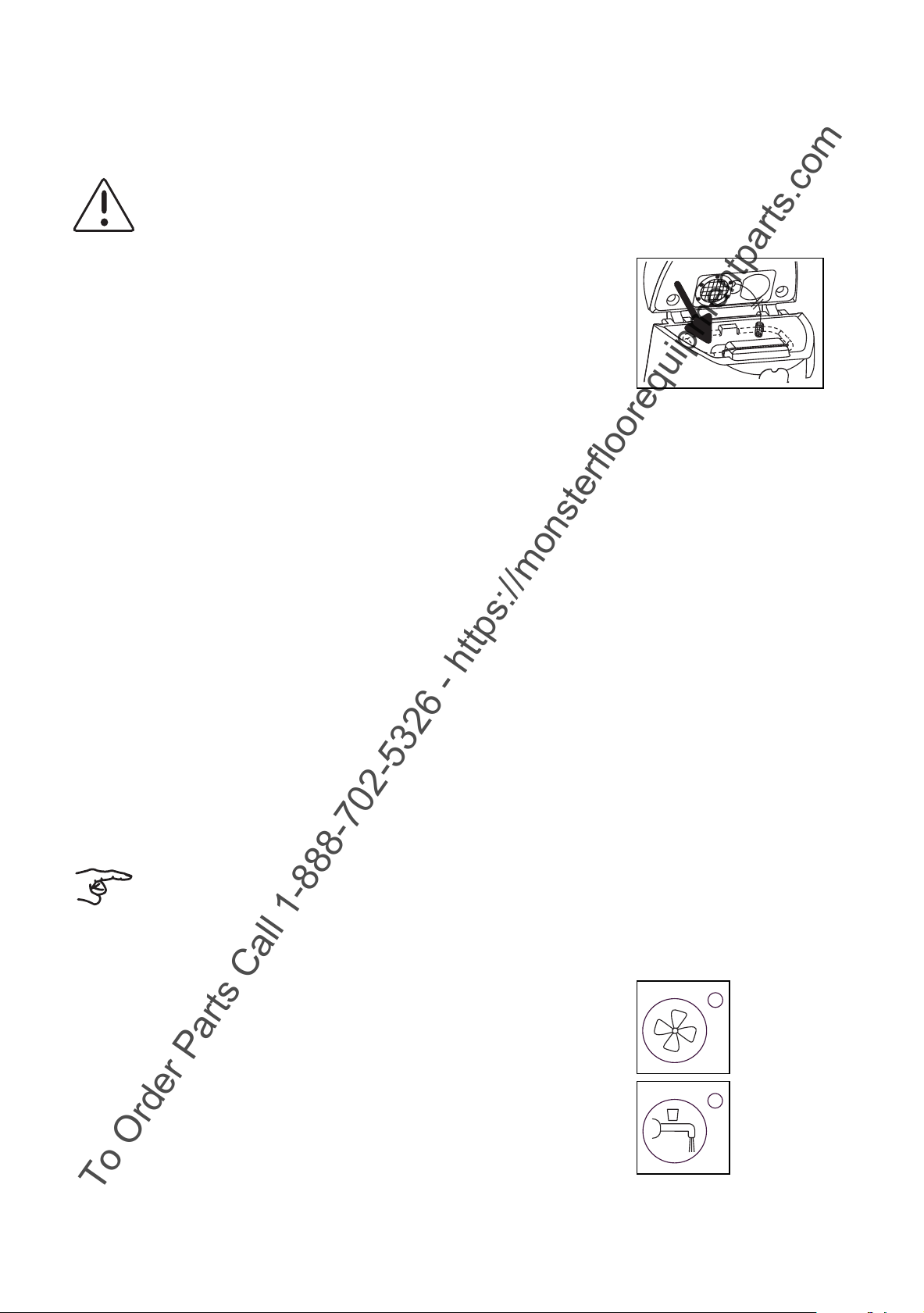

Symbols:

◊ = After use, ◊◊ = Every week, ◊◊◊ = Every month, ⊗ = Service light

Activity ◊ ◊◊ ◊◊◊ ⊗ page

Recharge batteries 8

Refill distilled water (wet batteries) Please adhere the monitoring booklet! 21

Drain and clean the recovery tank 16

Clean the suction filter 25

Cleaning recycling filter (Option) 17

Check suction filter and clean if necessary 6

Empty the fresh water tank (diaphragm sack) and rinse out with fresh water 16

Cleaning the tools

Clean squeegee, check whether the blades are worn and replace if

necessary

Wipe down the machine with a moist cloth 19

Clean level probe (full recovery tank) and test functionality 17

18

18

Clean seal of tank hood, check for cracks and replace if necessary 17

Maintenance programs by TASKI service made by TASKI technician

20

Maintenance of batteries (wet batteries)

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

Caution:

Observe the operating instructions of the battery manufacturer!

Daily, after charging:

t Measure the acidity in 3 or 4 cells.

It should be approx. 30° Bé.

The batteries are discharged when the acidity is reduced to approx. 18° Bé.

t Please enlist the measurements into the booklet.

t Please check the electrolyte, and if needed, fill it with distilled or desalinated

water up to 10mm above the separators.

Monthly, after charging:

t Measure the acidity in every cell.

t Please enlist the measurements into the booklet.

t Check:

-Connectors, cable, cable connections and the poles are screwed-in tightly.

Preparation for use after charging:

t Return tank in position for charging.

Closing battery compartment:

t Close the tank lid and fold the driver's seat back.

21

Maintenance of batteries (dry batteries)

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

Caution:

Observe the operating rukews and the operating instructions of the

battery manufacturer!

t Disconnect the charger plug.

t Return tank in position for charging.

t Close the tank lid and fold the driver's seat back.

Service intervals

TASKI machines are build to the highest quality standards . This is supported by

internationally regonized quality control procedures. Electrical and mechanical

parts are subject to wear or aging if used for long periods of time.

t To maintain functional safety and operational

readiness, a service must be carried out when the

Service indicator (factory setting 650 working hours) or

carry out the service at least once a year.

Under rough or special conditions and / or insufficient maintenance, shorter

periods are needed.

Service centre

Should you contact us due to a malfunction or for placing an order, please always

state the type, description and the serial number of your machine.

You can find this information on the name plate of your machine, and the address

of your nearest TASKI partner can be found on the last page of these operating

instructions.

22

Blades replacement

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

Blade on the inside radius

t Place the clean squeegee unit with the outer radius face down on a solid

surface table, floor etc.

t Press one hand onto the squeegee body at the hose connector.

t Grasp the blade with your thumb and forefinger in the middle of the arch and

pull strongly until the metal band clicks open and the blade is released from

the squeegee body.

t Release the metal strap and pull the blade off the squeegee body.

t Clean squeegee (body, metal straps and blads) with a brush.

t Mount the "rotated" or replaced blade onto the squeegee body.

t Lock the metal strap (Check position of mounting slots) into place and press

onto the centre of it until it clicks into place and presses the blade onto the

squeegee body (Risk of injury).

Blade at outer radius

t Place the squeegee onto the hose connector and the bumper wheels.

t Release the metal band by loosening the fixation screw (torx).

t Release the metal band and pull the blade off the squeegee body.

t Clean squeegee (body, metal straps and blads) with a brush.

t Mount the "rotated" or replaced blade onto the squeegee body.

t Hook the metal strap into place (Check position of mounting slots) and fix

it with the screw until the blade is pressed onto the squeegee body.

t The shape of the blades allow them to be used on all sides before needing

replacement.

23

Replace fuses

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

t Pull out the key and operate the parking brake (see Parking brake‘ Page 9).

t Fold the driver seat forward and open the battery cover.

t Disconnect battery plug with external battery charger.

Caution:

Use fuses with the correct value only!

False fuses can cause damages on the machine.

Replace main fuse:

t Loose insulating nut (19mm spanner) of battery pole.

t Remove red insulating nut and replace the battery

charger leads.

t Replace main fuse.

Fuse ratings: co 2500/3500

Main fuse= 125A (Pudenz)

t Mount battery charger leads onto the battery pole and

mount the insulating nut of battery pole.

t Return tank in position for charging.

t Close the tank lid and fold the driver's seat back.

24

Malfunctions

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

Malfunction Possible causes Troubleshooting page

Machine does not run

Machine dos not move

Batteries not or not

sufficiently charged

Machine switched off

Activated emergency

stop button

Main fuse defective

Error code on display

Immobiliser is activated

Acceleration pedal

activated when

switching on

Parking brake locked

Batteries discharged

Charger or connecting

cable defective

Batteries defective

t Turn the key

t Connect the battery plug with the

machine

t Check/replace the fuse

t Call for technical service

On t he las t page of these instructions of

use

t Set on the driver seat

t Let go of acceleration pedal and turn

on machine again

t Loose the fixing brake

t Charging batteries

t Call for technical service

On t he las t page of these instructions of

use

t Call for technical service

On t he las t page of these instructions of

use

6

6

24

9

8

Not able to switch off

brush- or suction unit

Brush does not turn

Wrong charger type for

batteries

Relay defective

Brush drive switched off

Main fuse defective

Motor runs but not tool

t Clarify and, if necessary, replace

t INterrupt the machine using the

battery disconnection socket

t Call for technical service

On t he las t page of these instructions of

use

t Press the Brush button

t Replace fuses

t Drive belt torn

t Call for technical service

On t he las t page of these instructions of

use

6

6

24

25

Malfunction Possible causes Troubleshooting page

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

Poor vacuum

performance

Floor remains wet

Soiled solution not

picked up

Vacuum motor not

activated

Suction hose not

connected

Squeegee not on the

floor

Worn blades

Hose or nozzle blocked

(e.g. by pieces of wood,

fabric)

Suction filter blocked

t Press the Vacuum on/off button

t Suction hose connect

t Clean the squeegee

t Check that the squeegee up/down

mechanism is functioning correctly

t Replace blades

t Remove the blockage

t Remove the blockage

t Check fuse and replace if necessary

6

10

18

23

6

Vacuum switched off

Insufficient outflow of

cleaning solution.

Indicator is lightning

but vacuum motor does

not work

Squeegee pressure

incorrect

Recovery tank full

Probe soiled

Cleaning solution tank

empty

Cleaning solution to low

Solution dosing control

switched off

t If the fuse is not defective, call for

technical service

On the last page of these instructions of

use

t Readjust

t Empty recovery tank

t Check the battery indicator

t Check the fuses

t Check the probe, and clean i

necessary

t Check the tank cleaning solution

t Choose the volume of cleaning

solution with +/-

t Press the Cleaning Solution button

24

27

16

17

14

6

6

26

Squeegee settings

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

A

2

1

x

3

4

5

B

2

1

5

3

4

x

27

If you have an uneven suction result, the settings of the suction nozzle should be

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

corrected:Proceed as follows::

Before carrying out the settings, check that:

• the slats are not damaged (replace).

• the suction nozzle is not damaged.

Height setting(Fig. A)

• Unlock the squeegee lowering lever and push it forward.

• Pull out the key and operate the parking brake (See ‚Parking brake‘ Page 9).

• Unscrew the hexagonal nut.

• Turn the Allen screw left or right.

The distance between the floor and the running wheel (with slats perpendicular to the

floor) must be between 1 - 3 mm.

• Retighten the hexagonal nut.

• Check the result during the cleaning and refer to "Angle of inclination (Fig. B)"

if the result is unsatisfactory.

Angle of inclination(FIg. B)

• Switch off the brush drive and the suction unit.

• Pull out the key and operate the parking brake (see Parking brake‘ Page 9).

• Unscrew the Allen screw Nos. 1 to 4 on the suction nozzle adjustment (half a

turn).

• Insert a screw driver into the slot in the cam and hold it in its current position

while unscrewing the Allen screw No. 5.

• Only change the angle of inclination in small steps using the cam.

• Keep the screwdriver in this position while tightening the cylindrical screws

numbers 1 to 5.

• Check the result and correct it again if necessary.

A correct setting has been achieved if the atripper edge of

the rear slat (x) is distributed over the complete width“ of

the suction nozzle..

28

Technical data

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

type Co 2500 Co 3500

Theoretical performance area operation width x drive

speed (7) x 1000

Working width 70 85 cm

Squeegee width 93 108 cm

Cleaning solution tank / recovery tank 95 95 l

Machine weight / for operation (max.) 273/652 276/653 kg

Rated voltage 24V 24V dc

Tools 2 x 35 1 x 43 cm

Brush rpm 150 150 min-1

Brush pressure 52-74 60-102 kg

Dimensions (L x W x H) 169x78x137 169x91x137 cm

Rated power 1000 1000 W

Splash water protection IPX3 IPX3

Assessed sound level LPA according to EN 60704-1 67 67 dB(A)

The assessed effective acceleration value according to

ISO 5349

5250 5950 m2/h

<0.5 <0.5 m /s2

Electrical protection class III III

29

Accessories

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

Article 2500 3500

Scrubbing brush for washed concret 35cm 2X

Scrubbing brush 35cm nylon 2X

Scrubbing brush abrasive 35cm 2X

Driving disc Instalok 35cm 2X

Scrubbing brush for washed concret 43cm 2X

Scrubbing brush 43cm nylon 2X

Scrubbing brush abrasive 43cm 2X

Driving disc Instalok 43cm 2X

Filling hose with universal water coupling XX

Recycling filter XX

Drainage pump XX

Different pads

(Polyester brown, blue, red, fibre pad and contact pad)

XX

30

Recommended chemicals

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

Please use the recommended TASKI chemical products only.

Caution:

Using other chemicals (e.g. chemicals containing solvents, chlorine,

hydrochloric acid and hydrofluoric acid) can damage or destroy the

machine.

Dosage:

The max. filling level in the tank corresponds to the quantity of the measuring cup.

Dosing examples (The concentration is product dependent)

Instructions on the product’s packaging Tank

capacity

1% 100ml to 10l water 95l 950ml = 0,95l

2% 200ml to 10l water 95l 1900ml = 1,90l

3% 500ml on 10l water 95l 4750ml = 4,75l

The volume per tank

filling

31

Index

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

A

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Adjust the seat

9

After cleaning

Angle of inclination

Attach squeegee

B

Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5, 8

Battery indicator

before putting into service

Begin cleaning operation

Beginning work

Blades replacement

Brush pressure on / off

C

Charging procedure (traction block batteries with

external charging unit)

Clean the fresh water tank

Clean the recovery tank

Cleaning method

Cleaning solution on/off

Cleaning the machine

Content

D

Declaration of Conformity . . . . . . . . . . . . . . . . . . . . . . 34

Disposal

Dosage

Drain the fresh water tank

Drain the recovery tank

E

Emptying soiled recovery tank . . . . . . . . . . . . . . . . . . . 15

End of operation

Error code

F

Fault accelerator pedal . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Fill the fresh water tank

Finishing work

Fixing tools

H

Height setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Hours in total

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

. . . . . . . . . . . . . . . . . . . . . . . 8

. . . . . . . . . . . . . . . . . . . . . . . 11

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

. . . . . . . . . . . . . . . . . . . . . . . . . . . 23

. . . . . . . . . . . . . . . . . . . . . . . . . 7

. . . . . . . . . . . . . . . . . . . . . . . . . . 8

. . . . . . . . . . . . . . . . . . . . . . 17

. . . . . . . . . . . . . . . . . . . . . . . . 17

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

. . . . . . . . . . . . . . . . . . . . . . . . . 7

. . . . . . . . . . . . . . . . . . . . . . . . . . 19

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

. . . . . . . . . . . . . . . . . . . . . . 16

. . . . . . . . . . . . . . . . . . . . . . . . . 16

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

. . . . . . . . . . . . . . . . . . . . . . . . 10

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Hours of operation

I

Immobiliser is activated . . . . . . . . . . . . . . . . . . . . . . . . 25

Index

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Intended use of machinery

M

Machine is idle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Maintenance

Maintenance of batteries (dry batteries)

Maintenance of batteries (wet batteries)

Malfunction

O

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

P

Parking brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

R

Recommended chemicals . . . . . . . . . . . . . . . . . . . . . . 31

Recycling mode (Option)

Refilling the solution tank

Remove and clean the squeegee

Removing and cleaning the squeegee

Replace fuses

S

Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Service

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Service centre

Service indicator

Service intervals

Service, maintenance and care

Soiled solution pump (Option)

Squeegee settings

storage / parking of machine

Symbols

T

Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Tool aggregate hour indicator

Transport

W

Water temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5, 9

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

. . . . . . . . . . . . . . . . . . . . . . 2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

. . . . . . . . . . . 22

. . . . . . . . . . 21

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

. . . . . . . . . . . . . . . . . . . . . . . 13

. . . . . . . . . . . . . . . . . . . . . . 14

. . . . . . . . . . . . . . . . . 18

. . . . . . . . . . . . . 18

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

. . . . . . . . . . . . . . . . . . 20

. . . . . . . . . . . . . . . . . . 17

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

. . . . . . . . . . . . . . . . . . . . 19

. . . . . . . . . . . . . . . . . . . . 7

32

33

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

EU Declaration of Conformity

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

We

JohnsonDiversey Switzerland

CH-9542 Münchwilen

hereby declare that the product described below both in this basic design and construction

and in the version marketed by us conforms to the relevant safety- and health-related

requirements of the appropriate EU Directive.

This declaration shall cease to be valid if modifications are made to the product without our

approval.

Product: scrubber dryer

Name: combimat swingo

Model: CO 2500 / CO 3500

Technical Data: 24Vdc

2000W

Applicable EU Directives:

Machinery Directive (98/37/EEC) in version 98/79/EEC

EMC (Electro Magnetic Compatibility) (89/336/EEC) in version 98/13/EEC

Harmonised standards applied:

EN 60 335-1;94/EN 60 335-1-A1;96/EN 60 335-1-A11;95/EN 60 335-1-A12;96/

EN 60 335-1-A13;98/EN 60 335-1-A14;98/EN 60 335-2-72;98/

EN 55011;98/EN 61 000-4-2;95/EN 61 000-4-3;96/

Internal measures ensure that the products always correspond to the requirements of the

latest EG directives and the standards that are currently in use

Dipl. Ing. (FH) D.Windmeisser Dipl. Ing. (FH) P. König

The signatories act on behalf of company management and with full power of attorney.

34

AT JohnsonDiversey

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

Austria Trading GmbH

Guglgasse 7-9

1030 Wien

Tel (43) 1 605 57 0

Fax (43) 1 605 57 1908

BE JohnsonDiversey

Haachtsesteenweg 672

1910 Kampenhout

Tel (32) 16 617 802

Fax (32) 16 605 395

CH JohnsonDiversey

Eschlikonerstrasse

9542 Münchwilen

Tel (41) 71 969 27 27

Fax (41) 71 969 22 53

CZ JohnsonDiversey

Ceska republika, s.r.o

K Hájum 2

155 00 Praha 5 - Stodulky

Tel (420) 296 357 460

Fax (420) 296 357 112

ES JohnsonDiversey S.A.

C/San Gabriel 43-45

08950 Esplugues de

LIobregat

Tel (34) 93 474 98 73

Fax (34) 93 474 98 07

GB JohnsonDiversey

Weston Favell Centre

NN3 8PD Northampton

Tel (44) 1604 405 311

M (44) 796 76 94 383

DE JohnsonDiversey

Deutschland

GmbH & Co. OHG

Mallaustrasse 50-56

68219 Mannheim

Tel (49) 621 875 73 73

Fax (49) 621 875 73 11

FI JohnsonDiversey

Valuraudankuja 3

00700 Helsinki

Tel (358) 20 747 42 00

Fax (358) 20 747 42 01

GR JohnsonDiversey

5 Chimaras St

15125 Marousi

Tel (30) 210 638 59 00

Fax (30) 210 638 59 01

DK JohnsonDiversey

10, Teglbuen

2990 Nivaa

Tel (45) 70 10 66 11

Fax (45) 70 10 66 10

FR JohnsonDiversey

(France) SAS.

9/11, avenue du Val de

Fontenay

94133 Fontenay sous

Bois Cédex

Tel (33) 1 45 14 76 76

Fax (33) 1 45 14 77 99

HU JohnsonDiversey

Magyarország Kft.

Puskás Tivadar u. 6.

2040 Budaörs

Tel (36) 23 509 100

Fax (36) 23 501 700

IE JohnsonDiversey Ltd.

Ballyfermot office

Westlink industrial estate

Kylemore road

Dublin 10

Tel (353) 1 626 11 82

Fax (353) 1 626 20 13

NL JohnsonDiversey B.V.

Maarssenbroeksedijk 2

P.O. Box: 40441

3504 AE Utrecht

Tel (31) 30 247 69 11

Fax (31) 30 247 63 17

IT JohnsonDiversey S.p.A.

Via Meucci 40

20128 Milano

Tel (39) 02 25 80 32 33

Fax (39) 02 25 92 255

NO Lileborg Storforbrukere

Postbooks 4236 - Nydalen

0401 Oslo

Tel (47) 22 89 50 00

Fax (47) 22 89 50 80

MT Forestals (Appliances)

Ltd.

The Strand

SLM 07 Sliema

Tel (356) 21 344 700-7

Fax (356) 21 344 709

PL JohnsonDiversey Polska

Sp. z.o.o.

Al. St. Zjednoczonych 61A

04-028 Warsaw

Tel (48) 22 516 30 00

Fax (48) 22 516 30 01

35

PT JohnsonDiversey

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

Z. Ind. Abrunheira

2714-505 Sintra

Tel (351) 2 191 57 000

Fax (351) 2 192 50 615

RO JohnsonDiversey

Romania s.r.l.

Baneasa Business Center,

Etaj 5

Sos. Bucuresti - Ploiesti

17-21

Sector 1, Bucaresti

Tel (40) 21 233 3894

Fax (40) 21 233 3896

RU JohnsonDiversey

Zvenigorodskaya 2-aya

ul.,13, bld. 15

123022 Moscow

Tel (7) 095 970 17 97

Fax (7) 095 970 17 98

SE JohnsonDiversey AB

Liljeholmsvägen 18

Box 47313

10074 Stockholm

Tel (46) 877 99 300

Fax (46) 877 99 399

TR JohnsonDiversey

Degirmenyolu caddesi

Huzur

Hoca sokak No: 84

Unilever Binasi Kat: 18

34572 Icerenköy /

ISTANBUL

Tel (90) 216 57 86 400

Fax (90) 216 57 86 401

SI JohnsonDiversey d.o.o.

Trzaska cesta 37a

2000 Maribor

Tel (386) 2 320 7000

Fax (386) 2 320 7071

SK JohnsonDiversey

Slovensko s.r.o

Trnavska cesta 33

831 04 Bratislave

Tel (421) 2 4445 4895

Fax (421) 2 4445 4896

*12089-04*

V004 / 12089-04 0602

Loading...

Loading...