INSTRUCTIONS FOR SAFE OPERATION AND MAINTENANCE

Read Instruction Manual before use. Operation of this device without understanding the manual

WARNING

WARNING

and receiving proper training can be dangerous and is a misuse of this equipment. Download

this manual from http://tft.com/. Call 800-348-2686 with any questions.

This instruction manual is intended to familiarize fi refi ghters and maintenance personnel with

the operation, servicing, and safety procedures associated with the LDH Gated Wye.

This manual should be kept available to all operating and maintenance personnel.

NOTICE

OPERATING RANGE

Pressure Max 300 PSI

Pressure Min Full Vac

Hydrostatic Proof Test: 900 PSI

MANUAL: LDH GATED WYE

TASK FORCE TIPS, INC.

MADE IN USA • www.tft.com

©Copyright Task Force Tips, Inc. 2012 LIA-540 April 16, 2012 Rev00

3701 Innovation Way, Valparaiso, IN 46383-9327 USA

800-348-2686 • 219- 462-6161 • Fax 219-464-7155

Table Of Contents

1.0 MEANING OF SAFETY SIGNAL WORDS

2.0 SAFETY

3.0 GENERAL INFORMATION

3.1 PARTS IDENTIFICATION AND MODELS

3.2 SPECIFICATIONS

3.3 CORROSION

3.4 USE WITH SALT WATER

4.0 INSTALLATION

4.1 CHANGING OFFSET OF CRANK HANDLE

4.2 STORZ SUCTION GASKET REQUEST

5.0 USE

5.1 VALVE POSITION INDICATOR

5.2 AIR VENT AND WATER DRAIN

5.3 PRESSURE RELIEF VALVE

5.4 SUCTION SCREEN

5.5 VALVE PRESSURE LOSS

6.0 MAINTENANCE

7.0 EXPLODED VIEWS & PARTS LISTS

7.1 LDH GATED WYE

7.2 PARALLEL SHAFT GEARBOX

7.3 PRESSURE RELIEF VALVE

7.4 BLEEDER

7.5 SIDE A (SINGLE SIDE) COUPLING COMPONENTS

7.6 SIDE B (DUAL SIDE) COMPONENTS

8.0 ANSWERS TO YOUR QUESTIONS

9.0 WARRANTY

DANGER

The member companies of FEMSA that provide emergency response

equipment and services want responders to know and understand the

following:

1. Firefi ghting and Emergency Response are inherently dangerous activities

requiring proper training in their hazards and the use of extreme caution

at all times.

2. It is your responsibility to read and understand any user’s instructions,

including purpose and limitations, provided with any piece of equipment

you may be called upon to use.

3. It is your responsibility to know that you have been properly trained in

Firefi ghting and /or Emergency Response and in the use, precautions, and

care of any equipment you may be called upon to use.

4. It is your responsibility to be in proper physical condition and to maintain

the personal skill level required to operate any equipment you may be

called upon to use.

5. It is your responsibility to know that your equipment is in operable

condition and has been maintained in accordance with the manufacturer’s

instructions.

6. Failure to follow these guidelines may result in death, burns or other

severe injury.

FEMSA

©Copyright Task Force Tips, Inc. 2012 LIA-540 April 16, 2012 Rev00

PERSONAL RESPONSIBILITY CODE

Fire and Emergency Manufacturers and Service Association

P.O. Box 147, Lynnfi eld, MA 01940 • www.FEMSA.org

2

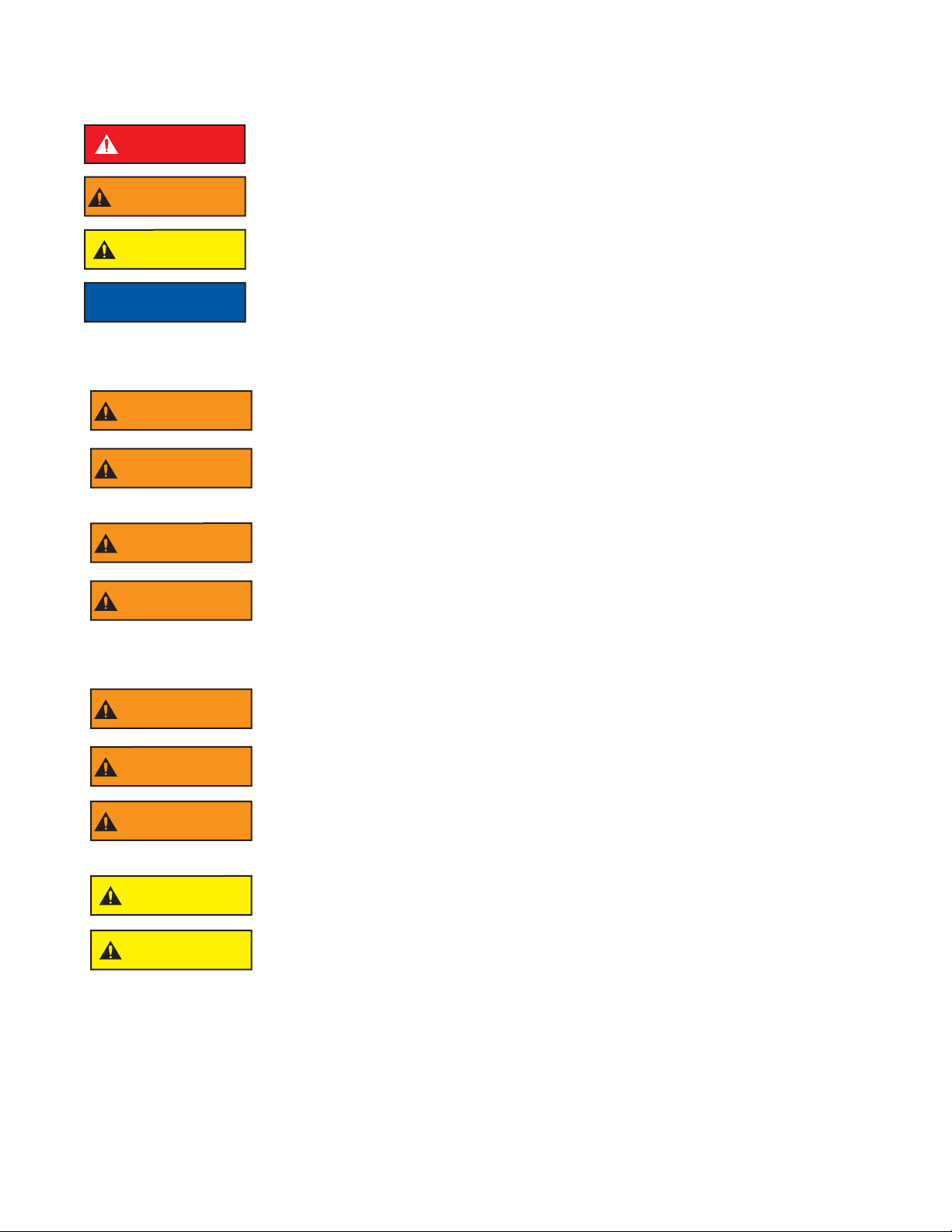

1.0 MEANING OF SAFETY SIGNAL WORDS

A safety related message is identifi ed by a safety alert symbol and a signal word to indicate the level of risk involved with a particular

hazard. Per ANSI standard Z535.6-2006, the defi nitions of the four signal words are as follows:

DANGER indicates a hazardous situation which, if not avoided, will result in death or serious

DANGER

WARNING

CAUTION

injury.

WARNING indicates a hazardous situation which, if not avoided, could result in death or serious

injury.

CAUTION indicates a potentially hazardous situation which, if not avoided, may result in minor

or moderate injury.

NOTICE is used to address practices not related to personal injury.

NOTICE

2.0 SAFETY

Quick changes in valve position can cause high pressure spikes due to water hammer and

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

may result in damaged equipment which could lead to injury or death. Open and close the

valve slowly to avoid water hammer.

The Pressure Relief Valve will open to relieve excess pressure but it may not have enough

fl ow capacity to protect against large pressure spikes such as those caused by water hammer.

Excess pressure can cause equipment failure and directly or indirectly lead to injury or death.

Always operate valves slowly to avoid the risk of water hammer.

Injury or death can result from burst hoses and fi ttings. Be sure the pressure relief valve is

set at the proper pressure for the type of hose and equipment you are using. See NFPA 1961

and NFPA 1962.

Injury or death may occur by attempting to use a damaged valve. Per NPFA 1962, the device

shall be inspected and tested at least quarterly. Before use, inspect for damage resulting

from:

• Failure to drain valve followed by exposure to freezing conditions

• Exposure to temperatures in excess of 160 degrees F

• Missing parts, physical abuse

This equipment is intended for use by trained personnel for fi refi ghting. Its use for other

purposes may involve hazards not addressed by this manual. Seek appropriate guidance and

training to reduce risk of injury.

Kinks in supply hose may reduce water fl ow and cause injury or death to persons dependant

on water fl ow. Avoid tight bends to minimize risk of hoseline kinks.

The valve may be damaged if frozen while containing signifi cant amounts of water. Such

WARNING

CAUTION

CAUTION

©Copyright Task Force Tips, Inc. 2012 LIA-540 April 16, 2012 Rev00

damage may to diffi cult to detect visually and can lead to possible injury or death. Any time

the valve is subject to possible damage due to freezing, it must be hydrostatically tested by

qualifi ed personnel before being considered safe for use.

Maximum operating pressure 300 psi (21 bar). Do not exceed 300 psi (21 bar) on either side

of the valve.

Valve must be properly connected. Mismatched or damaged connectors may cause leaking or

uncoupling under pressure and could cause injury.

3

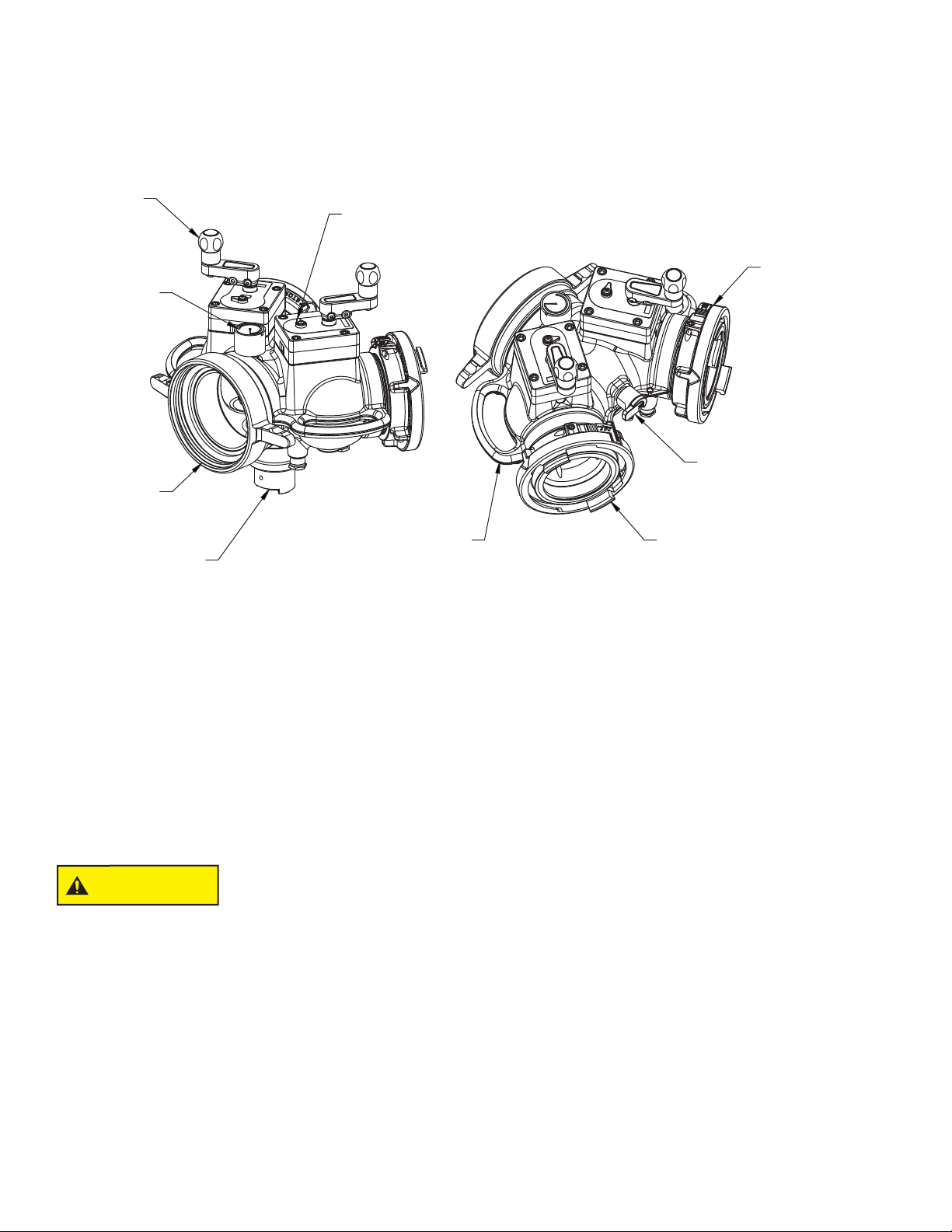

3.0 GENERAL INFORMATION

The LDH Gated Wye is a lightweight, low friction-loss valve that can be used in many water distribution applications. Dual robust

valve mechanisms from the TFT Ball Intake Valve are streamlined to a large waterway for the ultimate in versatility. Valve seats are

fi eld replaceable, Devices include a 300PSI pressure gage and quarter turn air vent and drain valve. Two robust carrying handles

make for easy deployment. A polymer bearing ring prevents galvanic corrosion on LDH couplings.

3.1 PARTS IDENTIFICATION AND MODELS

CRANK

VALVE POSITION INDICATOR

PRESSURE

GAUGE

SIDE A

COUPLING

CARRYING HANDLE

SIDE B

COUPLING

PRESSURE

RELIEF VALVE

3.2 SPECIFICATIONS

Dual LDH outlet waterway size (at valve seat): 3.65” (93mm)

Inlet waterway size: 5.5” for 6” Storz and 6” Threaded couplings, 4.5” for all other couplings.

LDH Valve meets NFPA 1965 slow close requirement.

Maximum Operating Pressure: 300 psi (20 bar)

Hydrostatic Proof Test Pressure: 900 psi (62 bar)

Temperature Rating*: -25°F to 135°F (-32°C to 57°C)

*For temperatures below 32°F (0°C), valves must be drained after use to avoid damage. See section

SIDE B

COUPLING

AIR VENT & DRAIN

2.0 SAFTEY.

3.3 CORROSION

Hose couplings are attached using polymer bearing rings which provide electrical insulation to help galvanic corrosion. The parts are

then hard anodized, and fi nally powder coated, inside and out, to help prevent corrosion. The effects of corrosion can be minimized

by good maintenance practice. See section 6.0 MAINTENANCE.

Dissimilar metals coupled together can cause galvanic corrosion that can result in the inability

CAUTION

to unscrew the threads or complete loss of thread engagement over time. Per NFPA 1962

(1998 edition), if dissimilar metals are left coupled together, an anti-corrosive lubricant should

be applied to the threads. Also the couplings should be disconnected and inspected at least

quarterly.

3.4 USE WITH SALT WATER

Use with salt water is permissible provided valve is thoroughly cleaned with fresh water after each use. The service life of the valve

may be shortened due to the effects of corrosion and is not covered under warranty.

©Copyright Task Force Tips, Inc. 2012 LIA-540 April 16, 2012 Rev00

4

4.0 INSTALLATION

4.1 CHANGING OFFSET OF CRANK HANDLE

When equipped with a crank handle, two offset positions are

available to adjust the swing radius of the crank and knob as

shown in the fi gure below. The longer offset position offers

reduced effort to operate the valve. The shorter offset is available

to avoid interference with other equipment. To change the offset,

remove the two ¼”-20 x 1/2” button head cap screws from crank.

Place crank in desired position and replace screws.

REINSTALL CRANK

IN THIS HOLE

IF SHORTER SWING

IS DESIRED

4.2 STORZ SUCTION GASKET REQUEST

If your application of this product requires drafting, you may need a suction gasket. Please call 1-800-348-2686 to receive a free

suction gasket by mail.

Part Numbers: 4” Storz- item#A4216, 5” Storz – item #A4221, 6” Storz - item #A4226

5.0 USE

5.1 VALVE POSITION INDICATOR

To open the valve turn the crank until the valve position indicator says “OPEN”. T o close the valve turn the valve crank the opposite

way until the valve position indicator says “CLOSED”.

5.2 AIR VENT AND WATER DRAIN

This device is equipped with an air vent/drain which will allow the air to escape from the valve when the inlet is charged. The air vent/

drain is opened by turning the knob counter-clockwise and closed by turning it clockwise.

To drain the water out of the valve after use, open the air vent/drain. A ½” diameter tube may be used to direct the drained water

away from the device.

Loss of prime can interrupt water fl ow and cause injury or death. Always bleed out air with air

DANGER

vent/drain to prevent possible loss of prime.

5.3 PRESSURE RELIEF VALVE

This device may be equipped with a pressure relief valve that can be set to any pressure between 50 and 200 psi. Its function is to

protect the pump and supply hose from excess pressure.

LIA-520 Pressure Relief Valve Instructions for Safe Operation and Maintenance.

See

5.4 SUCTION SCREEN

This device may be equipped with a suction screen to catch debris larger than 3/8” diameter in the waterway. See chart in section

5.6 Pressure Loss to determine additional loss caused by screen. To add or replace a suction screen, order TFT Part #A1410-KIT

for 4.5” waterway couplings or A1411-KIT for 6” waterway couplings.

5.5 PRESSURE LOSS

PRESSURE LOSS

0 1000 2000 3000 4000 5000 6000 7000

10

9

8

7

6

5

4

LOSS (PSI)

3

2

1

0

0 200 400 600 800 1000 1200 1400 1600 1800 2000

FLOW (GPM)

(LPM)

2

1.5

1

0.5

0

(BAR)

©Copyright Task Force Tips, Inc. 2012 LIA-540 April 16, 2012 Rev00

5

6.0 MAINTENANCE

This valve should be disconnected, cleaned and visually inspected inside and out at least quarterly for proper function per NFPA 1962

Section 8.2, or as water quality and use may require. Moving parts such as handles, valve ball and couplings should be checked for

smooth and free operation. Seals shall be greased as needed with silicone-based grease such as Dow Corning 112. Any scrapes

that expose bare aluminum should be cleaned and touched up with enamel paint such as Rust-Oleum.

In particular assure that:

• There is no damage such as cracks or dents

• There is no corrosion

• The waterway is clear of obstructions

• Pressure Relief Valve setting indications are readable

• The Pressure Relief Valve opens at the set pressure

Replace any missing or damaged parts before returning to service. Any repaired device must be tested before being placed in

service.

Any alterations to the device and its markings could diminish safety and constitute a misuse this

CAUTION

product.

©Copyright Task Force Tips, Inc. 2012 LIA-540 April 16, 2012 Rev00

6

7.0 EXPLODED VIEWS & PARTS LISTS

7.1 VALVE

2

3

6

20

4

7

5

8

9

10

11

12

21

1

13

14

15

16

17

13

19

ITEM DESCRIPTION QTY PART#

1 BODY 1 A2009

BODY A2008

2 GAGE 300PSI 1 AY176

3 SPRING 1 X165

4 GAGE PROTECTOR 1 AY170

5 BUSHING 1 VFHB4MX2F

6 3/8-16 X 1.75" SOCKET SCREW 1 VT37-16SH1.7

7 GEARBOX SUBASSEMBLY 1 A1633

GEARBOX SUBASSEMBLY 1 A1633R

8 O-RING 128 2 VO-128

9 DRAIN VALVE 1 A1621

10 HALF BALL 2 A1043S

18

ITEM DESCRIPTION QTY PART #

11 SEAL 2 A1520

12 MATE 2 A201*

13 1/4-20 X 1/2" SET SCREW 3 VT25-20SS500

14 O-RING 115 2 VO-115

15 TRUNNION 2 AY357

16 FOOT 4 A2037

17 O-RING 150 1 VO-150

18 PRV PLUG 1 A2155

19 PRV 1 A1755

20 SINGLE SIDE COUPLING 1 SEE CHART

21 DUAL SIDE COUPLING 2 SEE CHART

©Copyright Task Force Tips, Inc. 2012 LIA-540 April 16, 2012 Rev00

7

7.2 PARALLEL SHAFT GEARBOX

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

21

22

23

24

25

26

27

28

ITEM DESCRIPTION QTY PART #

KNOB 1 A1512

1

1/4-20 X 1/2 BUTTON HEAD SCREW 2 VT25-20BH500

2

CRANK 1 A1559

3

CRANK BUSHING 1 A1547

4

WASHER 1 VW812X406-65

5

3/8-16 X 1-1/2 BUTTON HEAD SCREW 1 VT37-16BH1.5

6

GEAR BOX 1 A1550

7

O-RING-116 1 VO-116

8

SPACER 1 A1556

9

DRIVE SHAFT 1 A1555

10

NYLON BUSHING 1 AY307

11

GEAR BUSHING 1 A1548

12

DOUBLE GEAR 1 A1554

13

BUSHING 1 A1549

14

INNER TRUNNION 1 A1553

15

INNER TRUNNION 1 A1553R

DOWEL PIN 2 VP312X.50

16

O-RING-154 1 VO-154

17

SUBPLATE 1 A1551

18

O-RING-028 1 VO-028

19

INNER BUSHING 1 A1552

20

FOLDING HANDLE LABEL 1 AY342

21

10-24 X 3/8 BUTTON HEAD SCREW 1 VT10-24BH500

22

WASHER 1 VW500X203-60

23

POSITION INDICATOR 1 A1558

24

NAME LABEL 1 A1550L

25

NAME LABEL RIGHT 1 A1550R

O-RING-206 1 VO-206

26

INDICATOR GEAR 1 A1557

27

O-RING-214 1 VO-214

28

1/4-20 X 3/4 SOCKET HEAD SCREW 1 VT25-20SH750

29

18

19

29

20

©Copyright Task Force Tips, Inc. 2012 LIA-540 April 16, 2012 Rev00

8

7.3 PRESSURE RELIEF VALVE

1

2

5

7

8

15

9

10

16

21

11

12

20

4

ITEM DESCRIPTION QTY PART#

1 1/2-13 X 1.0 SCREW 1 VT50-13BH1.0

2 DEBRIS WASHER 1 A1169

3 TURNED HOUSING 1 A2156

4 O-RING-232 1 VO-232

5 VALVE SEAT PRV 1 A1168

6 PISTON 1 A1160

7 QUAD-RING 222 2 VOQ-4222

8 SPRING SEAT 1 A1166

9 RELIEF SPRING 1 A1170

10 SMALLEY RING 1 V4210

11 ADJUSTING SCREW 1 A1167

12 SPRING HOUSING 200 MAX 1 A1164

13 SET SCREW PLUG 1 A1162

14 5/16-18 X 1/4 SET SCREW 1 VT31-18SS250

©Copyright Task Force Tips, Inc. 2012 LIA-540 April 16, 2012 Rev00

9

7.4 BLEEDER OPTION

1

2

6

5

4

ITEM DESCRIPTION QTY PART#

1 1/2" BARB X 1/4"NPTM NIPPLE 1 XX329

2 FOLLOWER 1 U251

3 3/8-24 X 3/8 DOG POINT 1 H515

4 DRAIN HOUSING 1 A1543

5 O-RING 115 2 VO-115

6 DRAIN SLEEVE 1 A1541

7 O-RING-110 1 VO-110

8 DRAIN LEVER 1 A1542

3

5

8

7

©Copyright Task Force Tips, Inc. 2012 LIA-540 April 16, 2012 Rev00

10

7.5 SIDE A (SINGLE SIDE) COUPLING COMPONENTS

QTY DESCRIPTION 4.0" STORZ 5.0" STORZ 6.0" STORZ 4.0" FEMALE LH4.5" FEMALE LH5.0" FEMALE LH6.0" FEMALE

1 INLET MATE A2115 A2115 -- A2115 A2116 A2116 -1 O-RING VO-252 VO-252 -- VO-252 VO-252 VO-252 -1 SOCKET HEAD SCREW VT25-20SH500 VT25-20SH500 -- VT25-20SH500 VT25-20SH500 VT25-20SH500 -1 GASKET -- -- -- V3198 V3210 V3220 V3240

1 INLET COUPLING A4124 A4125 A4326 A4562N A4568NR A4573NT A4575NX

1 PLASTIC STRIP A1292 A1291 A1293 A1291 A1293 A1293 A1293

1 CUP SEAL A1597 A1596 A1594 -- -- -- -1 LOCKOUT SCREW A1294 A1294 A1294 -- -- -- -1 NFS RING -- -- -- A4561 -- -- A4576

1 O-RING -- -- -- VO-248 -- -- VO-254

1 MATE PSM4.25 X PSF5.25 A4730 -- -- -- -- -- -1 CUP SEAL A1596 -- -- -- -- -- -1 PORT COVER A1298 -- -- -- -- -- -1 PLASTIC STRIP A1291 -- -- -- -- -- --

7.6 SIDE B (DUAL SIDE) COMPONENTS

QTY DESCRIPTION 4.0" STORZ 5.0" STORZ 6.0" STORZ 4.0" MALE 4.5" MALE 5.0" MALE 6.0" MALE

1 OUTLET MATE A2015 A2016 A2016 A2016 A2016 A2016 A2016

1 CUP SEAL A1597 A1596 A1596 A1596 A1596 A1596 A1596

1 PLASTIC STRIP A1292 A1291 A1291 A1291 A1291 A1291 A1291

1 LOCKOUT SCREW A1294 A1294 A1294 A1294 A1294 A1294 A1294

1 OUTLET COUPLING A4124 A4125 A4126 A4620N A4625N A4630N A4635N

LH

©Copyright Task Force Tips, Inc. 2012 LIA-540 April 16, 2012 Rev00

11

8.0 ANSWERS TO YOUR QUESTIONS

We appreciate the opportunity of serving you and making your job easier. If you have any problems or questions, our toll-free

“Hydraulics Hotline”, 800-348-2686, is normally available to you 24 hours a day, 7 days a week.

9.0 WARRANTY

Task Force Tips, Inc., 3701 Industrial Way, Valparaiso, Indiana 46383-9327 USA (“TFT”) warrants to the original purchaser of its

LDH GA TED WYE (“equipment”), and to anyone to whom it is transferred, that the equipment shall be free from defects in material

and workmanship during the fi ve (5) year period from the date of purchase.

TFT’s obligation under this warranty is specifi cally limited to replacing or repairing the equipment (or its parts) which are shown by

TFT’s examination to be in a defective condition attributable to TFT. To qualify for this limited warranty, the claimant must return

the equipment to TFT, at 3701 Industrial Way, Valparaiso, Indiana 46383-9327 USA, within a reasonable time after discovery of

the defect. TFT will examine the equipment. If TFT determines that there is a defect attributable to it, TFT will correct the problem

within a reasonable time. If the equipment is covered by this limited warranty, TFT will assume the expenses of repair.

If any defect attributable to TFT under this limited warranty cannot be reasonably cured by repair or replacement, TFT may elect to

refund the purchase price of the equipment, less reasonable depreciation, in complete discharge of its obligations under this limited

warranty. If TFT makes this election, claimant shall return the equipment to TFT free and clear of any liens and encumbrances.

This is a limited warranty. The original purchaser of the equipment, any person to whom it is transferred, and any person who is

an intended or unintended benefi ciary of the equipment, shall not be entitled to recover from TFT any consequential or incidental

damages for injury to person and/or property resulting from any defective equipment manufactured or assembled by TFT. It is

agreed and understood that the price stated for the equipment is in part consideration for limiting TFT’s liability. Some states do not

allow the exclusion or limitation of incidental or consequential damages, so the above may not apply to you.

TFT shall have no obligation under this limited warranty if the equipment is, or has been, misused or neglected (including failure to

provide reasonable maintenance) or if there have been accidents to the equipment or if it has been repaired or altered by someone

else.

THIS IS A LIMITED EXPRESS WARRANTY ONLY. TFT EXPRESSLY DISCLAIMS WITH RESPECT TO THE EQUIPMENT

ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND ALL IMPLIED WARRANTIES OF FITNESS FOR A PARTICULAR

PURPOSE. THERE IS NO WARRANTY OF ANY NATURE MADE BY TFT BEYOND THAT STATED IN THIS DOCUMENT.

This limited warranty gives you specifi c legal rights, and you may also have other rights which vary from state to state.

TASK FORCE TIPS, INC.

MADE IN USA • www.tft.com

©Copyright Task Force Tips, Inc. 2012 LIA-540 April 16, 2012 Rev00

3701 Innovation Way, Valparaiso, IN 46383-9327 USA

800-348-2686 • 219- 462-6161 • Fax 219-464-7155

Loading...

Loading...