Page 1

KLEAN/pakTM

Portable Mass Disinfection System

INSTRUCTIONS FOR SAFE OPERATION AND MAINTENANCE

The KLEAN/pak is an industrial grade, portable mass disinfection system that is designed to provide disinfecting solution over a large

area with an easy to use standard garden hose water supply. Using the KLEAN/pak, with appropriate disinfecting solutions, gives a

quick and easy way to disinfect larger items and items with areas that are dicult to reach with a wipe.

Since the KLEAN/pak is not an aerosol dispenser, the spray droplets are larger and won’t get carried away by the wind, resulting in

more disinfecting solution making it to the items being disinfected. Ideal for indoor and outdoor disinfection of items such as outdoor

furniture, gates and doorways, vehicles, shopping carts, and golf carts.

TASK FORCE TIPS LLC

MADE IN USA • KLEAN-pak.com

©Copyright Task Force Tips LLC 2020 LIU-055 June 24, 2020 Rev01

3701 Innovation Way, Valparaiso, IN 46383-9327 USA

800-348-2686 • 219-462-6161 • Fax 219-464-7155

Page 2

Table Of Contents

1.0 PUT ON PPE (PERSONAL PROTECTIVE EQUIPMENT)

2.0 FILL THE RESERVOIR

3.0 ATTACH THE METERING HEAD

4.0 SET THE CONTROLS

5.0 CONNECT HOSES AND NOZZLE

6.0 SPRAY

7.0 SPECIFICATIONS

8.0 PART IDENTIFICATION

9.0 FLOW

10.0 CONCENTRATE RATIO

11.0 PERFORMANCE

12.0 SHUT DOWN AND CLEAN OUT

13.0 STORAGE

14.0 WARRANTY

15.0 TROUBLE-SHOOTING

©Copyright Task Force Tips LLC 2020 LIU-055 June 24, 2020 Rev01

2

Page 3

PERSONAL RESPONSIBILITY CODE

DANGER

WARNING

NOTICE

WARNING

Dispensing disinfectants comes with a risk of injury, requiring proper training in hazards

and use.

1. It is your responsibility to read and understand these instructions

2. It is your responsibility for the safe handling and application of the disinfectants you

will use

3. It is your responsibility to know that your equipment is in operable condition

4. It is your responsibility to use appropriate personal protective equipment

Failure to follow these guidelines may result in disinfectant exposure and injury to yourself

or others.

MEANING OF SAFETY SIGNAL WORDS

A safety related message is identied by a safety alert symbol and a signal word to

indicate the level of risk involved with a particular hazard. Per ANSI standard Z535.6, the

denitions of the four signal words are as follows:

DANGER indicates a hazardous situation which, if not

avoided, will result in death or serious injury.

WARNING indicates a hazardous situation which, if not

avoided, could result in death or serious injury.

CAUTION indicates a potentially hazardous situation

CAUTION

which, if not avoided, may result in minor or moderate

injury.

NOTICE is used to address practices not related to

personal injury.

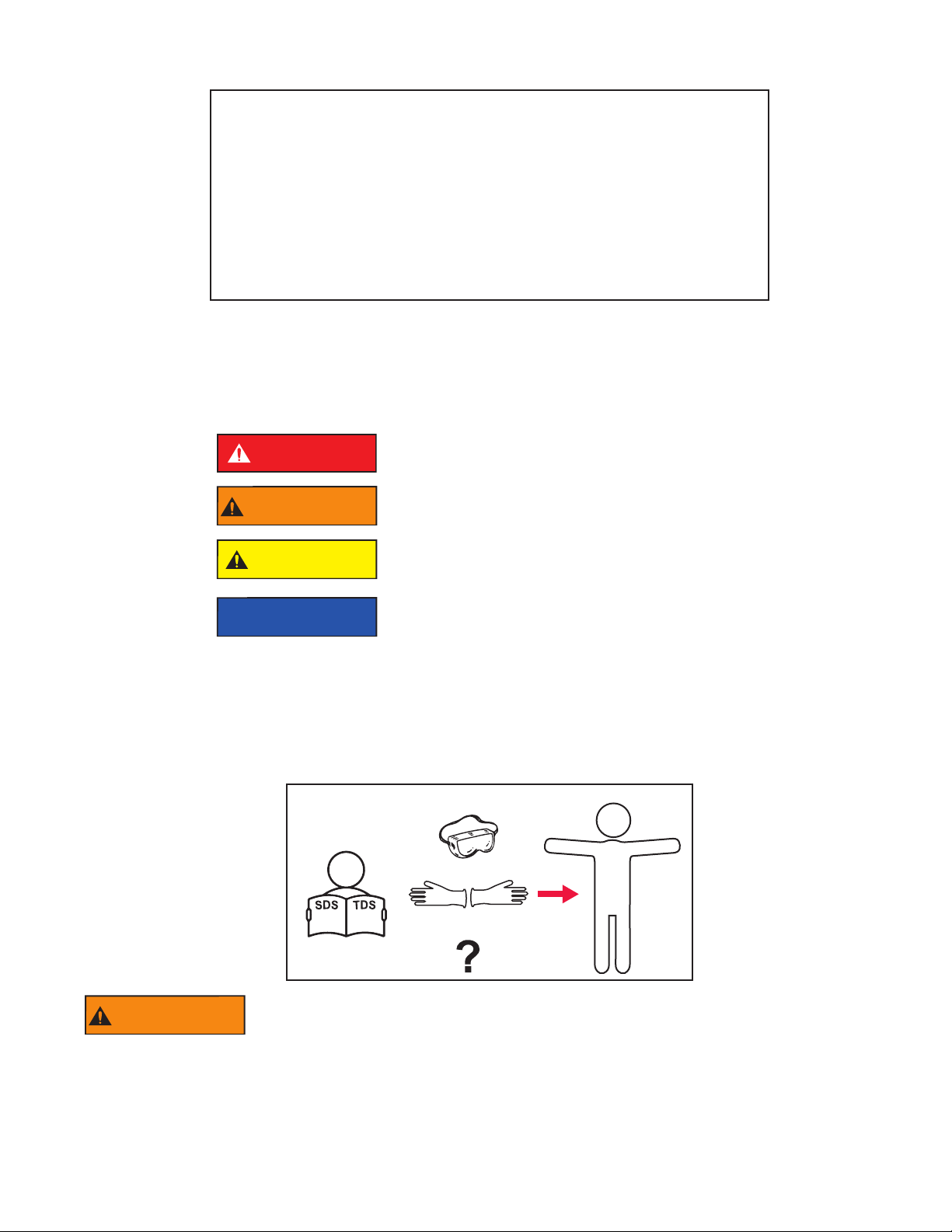

1.0 PUT ON PPE (PERSONAL PROTECTIVE EQUIPMENT)

1) Put on your PPE

+

+

Dispensing disinfectants can be a risk. Keep yourself safe by;

• Understanding the operating manual before use. Obtain safety information at KLEAN-pak.com

• Always wearing appropriate PPE (Personal Protective Equipment) like eye protection, gloves,

etc. Recommendations are found in the disinfectant manufacturer’s TDS and SDS (Technical

Data Sheet and Safety Data Sheet).

• Never apply liquids to live electrical equipment

• Do NOT spray ammable alcohol solutions from this device

• Determine suitability of the disinfectant for your application by referring to EPA’s List N:

Disinfectants for Use Against SARS-CoV-2.

https://www.epa.gov/pesticide-registration/list-n-disinfectants-use-against-sars-cov-2

©Copyright Task Force Tips LLC 2020 LIU-055 June 24, 2020 Rev01

3

Page 4

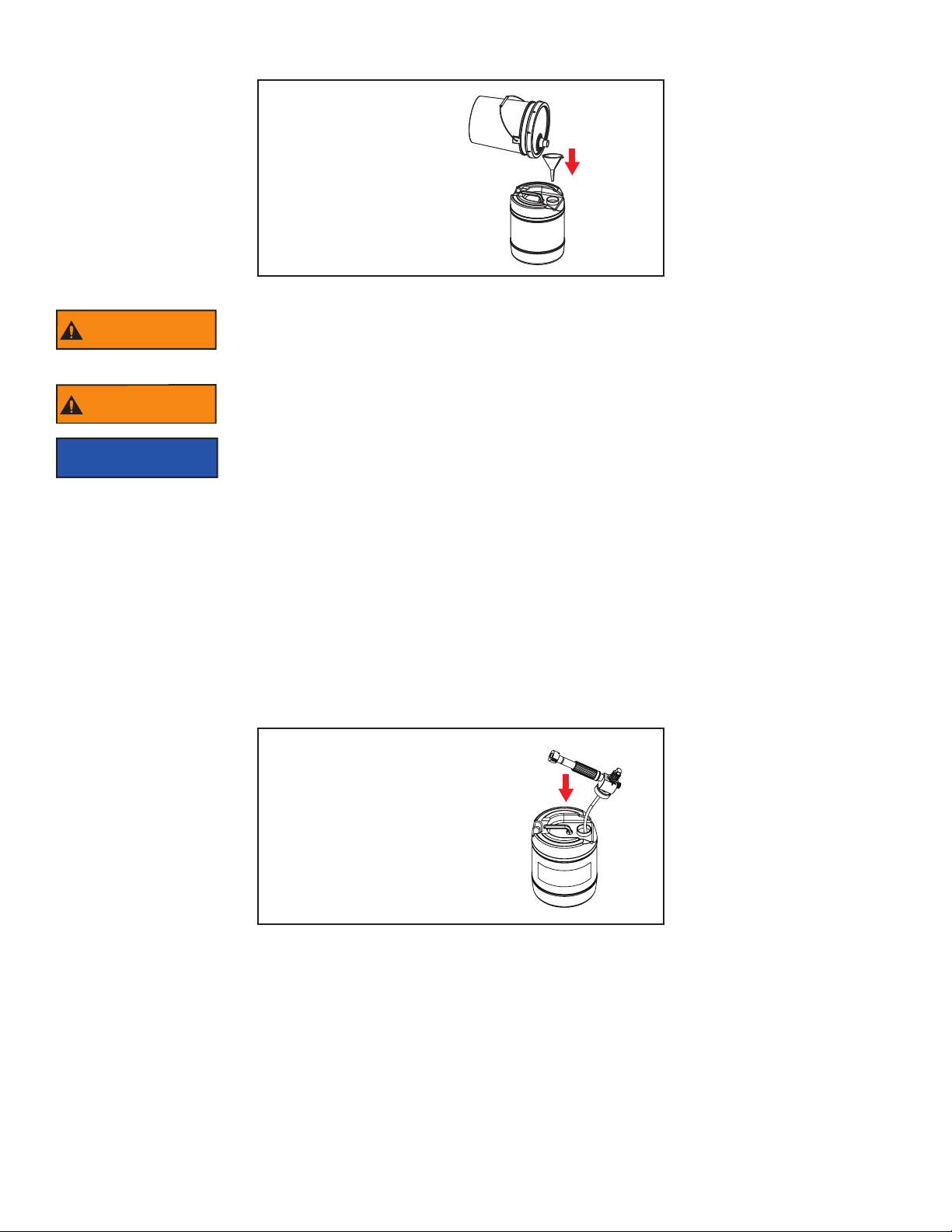

2.0 FILL THE RESERVOIR

WARNING

WARNING

2) Fill the reservoir

5 Gal

20 L

Unscrew the ll lid by turning counterclockwise. Fill reservoir to bottom of ll lid. Disinfectant may seep out if over lled.

Mixing dierent types of disinfectants can cause harmful reactions and/or produce unpredictable

results. For example mixing ammonia or peroxide with bleach causes a reaction that can overow

or burst the reservoir while generating toxic fumes. Never mix dierent types or dierent brands

of concentrate. Always rinse reservoir and passages clean before changing concentrate types.

Make sure that the disinfectant concentrate in the reservoir is the right type for the situation.

(Refer to concentrate manufacturer’s recommendations for proper disinfectant choice.)

Components of the KLEAN/pak may be subject to degradation by harsh disinfectants such

NOTICE

Clearly label the contents of the reservoir according to the Technical Data Sheet and local requirements. Secondary container

labeling requirements may be found in standards such as:

• GHS Labeling: The Globally Harmonized System of Labeling, United Nations GHS (Rev.8) (2019)

• ANSI Z129.1 Precautionary Labeling Preparation

• Right-to-Know (RTK) labels per OSHA’s Federal Hazard Communication Standard 29 CFR 1910.1200

• Hazardous Material Information System (HMIS) labeling per DOD INSTRUCTION 6050.05

Transfer of disinfectant concentrates to secondary containers may be avoided if the original packaging is compatible with the KLEAN/

pak’s 2.75” (70 mm) screw cap.

3.0 ATTACH THE METERING HEAD

as bleach, D-Limonine and other strong solvents. Avoid long-term storage of disinfectant that

may damage the reservoir, lid, or other components. It is the responsibility of the end user to

determine the disinfectant compatibility between the KLEAN/pak and any solutions to be stored

in it. Some solutions may require additional dilution with water. Consult the solution manufacturer

or distributer if necessary.

3) Attach metering head

Insert the pickup tube into the reservoir and screw on the ll lid, align the waterway with the reservoir handle.

Debris entering the reservoir can plug up the concentrate intake passages resulting in questionable disinfection. Avoid potential

problems by using clean funnels, reservoir openings, caps, and contents. Lay the metering head and pickup hose on a clean area

during lling. Rinse it clean before recapping the reservoir.

©Copyright Task Force Tips LLC 2020 LIU-055 June 24, 2020 Rev01

4

Page 5

4.0 SET THE CONTROLS

B

WARNING

4) Set the controls

A

OFF

Turn the concentrate ratio knob to the required concentration per the disinfectant manufacturer’s Technical Data Sheet. You may

need to use the dilution equivalent table to convert concentration from other units to oz/gal (mL/L).

EXAMPLE: Concentrate is specied for dilution of 2 oz/gal. Set the concentrate ratio knob to 2 oz/gal.

EXAMPLE: Concentrate is specied for dilution of 20 mL/L. Set the concentrate ratio knob to 20 mL/L.

To increase accuracy of ratios specied at less than 1 oz/gal (7.8 mL/L), solution may be diluted in the reservoir. Mix the solution at

1 part concentrate to 9 parts water. Multiply the specied ratio by 10 to determine the concentrate ratio knob setting.

EXAMPLE: Concentrate is specied for dilution at 0.3 oz/gal. Mix the solution at 1 part concentrate to 9 parts water. Set the

concentrate ratio knob to 3 oz/gal.

EXAMPLE: Concentrate is specied at 6 mL/L. Mix the solution at 1 part concentrate to 9 parts water. Set the concentrate ratio knob

to 60 mL/L.

The knob may be turned to the RINSE position which shuts o chemical feed when you need to spray water only.

Make sure the Flow Control Valve is o and the correct nozzle and Outlet Hose are securely

CAUTION

attached to the metering head before the hose line is charged.

Disinfectant concentrates can be ineective if not used at the correct concentration. Make sure

that the concentrate ratio knob is set to the correct concentration for the type of disinfectant

being used.

DILUTION EQUIVALENTS

Oz/Gallon US Liquid Measure/Gallon Ratio Percentage mL/L

0.3 2 US teaspoons 1:427 0.23% 2.3

SET

0.5 1 US tablespoons 1:256 0.39% 3.9

0.64 1-1/4 US tablespoons 1:200 0.50% 5.0

1 2 US tablespoons 1:128 0.78% 7.8

1.3 2-1/2 US tablespoons 1:100 1.0% 10

2 1/4 US cup 1:64 1.6% 16

3 3/8 US cup 1:43 2.3% 23

4 1/2 US cup 1:32 3.1% 31

5 5/8 US cup 1:26 3.9% 39

6 3/4 US cup 1:21 4.7% 47

7 7/8 US cup 1:16 5.5% 55

8 1 US cup 1:16 6.3% 63

9 1-1/8 US cup 1:14 7.0% 70

10 1 1/4 US cup 1:13 7.8% 78

11 1 3/8 US cup 1:12 8.6% 86

Table 4.0

See “CONCENTRATE RATIO” on page 9 for adjustment factor for inlet pressures not equal to 70 psi (4.8 bar).

©Copyright Task Force Tips LLC 2020 LIU-055 June 24, 2020 Rev01

5

Page 6

WARNING

5.0 CONNECT HOSES AND NOZZLE

5) Connect hoses and nozzle

B C

D

A

5/8” (15.8 mm)

50 ft (15 m)

You must have a fully functional backow preventer that meets all applicable codes in your area

WARNING

CAUTION

CAUTION

CAUTION

A. Attach 5/8” (16 mm) garden hose to the water source. More hose can be added to the metering head inlet as needed, if the

pressure at the metering head inlet is at least 30 PSI (2 bar) while owing.

B. Screw the inlet coupling on the KLEAN/pak onto the hose.

C. Attach 5/8” (16 mm) x 50ft (15 m) garden hose to the outlet threads of the KLEAN/pak.

D. Screw at fan nozzle onto the garden hose output. Screw the wand into the nozzle. The wand connection is a standard extension

pole thread. Use extension for longer reach and safer distance from disinfectant spray.

E. Stretch hoses straight. Kinked or overly twisted hoses will restrict ow and aect performance.

6.0 SPRAY

installed at your water source connection to protect against any concentrates entering your

drinking water supply.

Dispensing disinfectants at uncertain concentrations will give questionable results. Changing

hose, nozzle, or adding a shuto will cause additional back pressure which can prevent intake of

concentrates, or cause unintentional back ow of water into the reservoir, articially diluting its

contents resulting in ineective disinfection.

Never add more than 50’ of 5/8” (15 m of 16 mm) hose between the metering head and the nozzle

Never install a shuto between the KLEAN/pak and the nozzle.

Use only the at fan nozzle supplied with the KLEAN/pak.

Always turn the ow control knob to full open to ensure full inlet ow and accurate concentration

mix.

Do not install a shut o valve between the Klean/pak and the fan nozzle. Do not use nozzles other

than the fan nozzle provided. Other nozzles may not match the ow of the fan nozzle and may

adversely aect the concentrate ratio.

The air gap between the metering control and the reservoir is needed to equalize the reservoir

pressure and ensure a proper vacuum. Do not seal or restrict this air gap. Doing so may aect

concentrate ratio adversely.

6) Spray

A B

Pressurize the hose line. Turn the ow control valve fully on to start water owing through the KLEAN/pak. Grasp the wand with the

hose feeding upward from below the wand, directing spray away from people. Keep the wand above the hose to avoid contact with

disinfectant dribble. Always turn the control valve completely on or o.

Avoid directing disinfectant onto the faces of yourself and other personnel. Improper use of

disinfectant could result in death or serious injury, including damage to the eyes. To reduce the

chance of injury, you and other personnel must wear eye protection at all times.

©Copyright Task Force Tips LLC 2020 LIU-055 June 24, 2020 Rev01

6

= C+

Page 7

7.0 SPECIFICATIONS

TELESCOPING WAND

FLOW CONTROL VALVE

METERING HEAD

Reservoir Capacity 5 US gallons 20 liters

Weight Empty 5.45 lb 2.47 kg

Length x Width x Height 13.75 x 11.75 x 18.875 in 34.9 x 29.8 x 47.9 cm

US Units Metric Units

Metering range (maximum) 11 US Oz/Gallon

Pressure range 30-300 PSI

Hose connections Garden Hose Thread

Hose length (feed) 50 ft** 15 m**

Hose length (discharge) 50 ft 15 m

Discharge nozzle Low pressure at fan

Spray coverage (distance) 4 ft width at 4 ft

Maximum spray (reach) 9 ft

Packaged size 18 x 18 x 24 in

Packaged weight 12 lb

Packaged Pallet size (8) 48 x 40 x 42 in

Packaged Pallet weight 96 lb

**Longer hose may be used if inlet to device is at least 30 psi (2 bar).

8.0 PART IDENTIFICATION

85.9 mL/L

2 to 20 bar

1” BSP inlet, US GHT outlet, US GHT fan

nozzle. Use inlet adapter as required.

1.2 m width at 1.2 m

2.7 m

46 x 46 x 61 cm

5.4 kg

122 x 102 x 107 cm

43.5 kg

Table 7.0

INLET COUPLING

ON/OFF

RESERVOIR

CONCENTRATE RATIO KNOB

OUTLET (GARDEN HOSE THREADS)

SERIAL NUMBER

FILL LID

FAN NOZZLE INLET

(GARDEN HOSE

THREADS)

Figure 8.0

©Copyright Task Force Tips LLC 2020 LIU-055 June 24, 2020 Rev01

7

Page 8

9.0 FLOW

The KLEAN/pak is rated to ow 2 GPM (7.6 LPM) when supplied with 70 PSI (4.8 bar) inlet pressure. The KLEAN/pak can be used

at any pressure from 30 PSI (2 bar) up to 300 PSI (20.6 bar). Flow increases as pressure increases, and decreases as pressure

decreases at inlet pressures 70 PSI (4.8 bar). The amount of disinfectant produced depends on your inlet pressure.

INLET PRESSURE BAR

0.00 4.00 8.00 12.00 16.00 20.00

4.50

4.00

3.50

3.00

2.50

2.00

1.50

1.00

WATER FLOW GPM

0.50

0.00

0 50 100 150 200 250 300

INLET PRESSURE PSI

Figure 9.0

Droplet size becomes smaller as pressure increases. Smaller droplets have a greater tendency to stay airborne which can result

in unintentional airborne dispersion of disinfectants in harmful ways. Windy conditions also contribute to unintentional airborne

dispersion.

16.00

14.00

12.00

10.00

8.00

6.00

4.00

2.00

0.00

WATER FLOW LPM

©Copyright Task Force Tips LLC 2020 LIU-055 June 24, 2020 Rev01

8

Page 9

10.0 CONCENTRATE RATIO

The KLEAN/pak concentrate ratio knob is adjustable from zero to 11 oz/gal (85.9 mL/L). Water velocity in the throat of a venturi

creates vacuum which sucks uid from the reservoir into the water stream. The markings are calibrated using suction of water from

the reservoir at an inlet pressure of 70 PSI (4.8 bar) to the metering head (Water = 1.00 centipoise viscosity, 20 deg C, 1.00 gram/

CC). Concentrate rating is volumetric, not by weight.

Actual concentrations vary when concentrate has a viscosity, temperature, or density, dierent from calibration conditions. Higher

(thicker) viscosity results in weaker solutions. Higher temperatures result in increasing concentration. Higher densities result in

weaker solutions. Consult the SDS and TDS sheets from the disinfectant manufacturer.

Actual Concentrations vary when inlet pressure to the waterway diers from rated pressure.

• Increasing the water inlet pressure above 70 PSI (4.8 bar) causes more water to mix with a set disinfectant inow, resulting in

LOWER concentration than the label markings.

• Decreasing the water inlet pressure below 70 PSI (4.8 bar) causes less water to mix with a set disinfectant inow, resulting in

HIGHER concentration than the label markings.

Dilution Correction Factor

Below 70 PSI = stronger than expected • Above 70 PSI = weaker than expected

INLET PRESSURE BAR

0.00 4.00 8.00 12.00 16.00 20.00

60%

50%

40%

30%

20%

10%

0%

-10%

-20%

-30%

CORRECTION FACTOR %

-40%

-50%

0 50 100 150 200 250 300

70

INLET PRESSURE PSI

Figure 10.0

Compensated Knob Setting = Specied Knob setting + (Specied Knob Setting X Dilution Correction Factor)

EXAMPLE: Inlet pressure is 50 psi and concentration is specied at 4 oz/gal. Dilution correction factor = -20%. Compensated Knob

setting = 4 + (4 X -.2) = 3.2 oz/gal

EXAMPLE: Inlet pressure is 3.8 bar and concentration is specied at 31.3 mL/L. Dilution correction factor = -20%. Compensated

Knob setting = 31.3 + (31.3 X -.2) = 25 mL/L

The user must verify that the concentrate’s performance is suitable for use in their application. Always follow the disinfectant

manufacturer’s recommendations.

Test strips are available for the common types of disinfectants. Concentration of disinfectant sprayed from the nozzle can be checked

by collecting a sample and using a test strip. Adjust knob setting as required.

©Copyright Task Force Tips LLC 2020 LIU-055 June 24, 2020 Rev01

9

Page 10

11.0 PERFORMANCE

Operating the KLEAN/pak with 70 psi (4.8 bar) inlet pressure with ve gallons (20 L) of concentrate produces 2 GPM (8 L/min) of

disinfectant per minute.

NOTICE

Concentration Total Disinfectant

Produced

oz/gal mL/L gal L Minutes Hours

1 8 640 2423 320 5.3

2 16 320 1211 160 2.7

3 23 213 808 107 1.8

4 31 160 606 80 1.3

5 39 128 485 64 1.1

6 47 107 404 53 0.9

7 55 91 346 46 0.8

8 63 80 303 40 0.7

9 70 71 269 36 0.6

10 78 64 242 32 0.5

11 86 58 220 29 0.5

Table 11.0

When the reservoir is empty air will be sucked up into the venturi causing a sputtering sound from the

nozzle. Disinfection is ineective when concentrate supply is interrupted. Interruption can be avoided by

relling the reservoir before the reservoir becomes empty.

Run Time Between

Rells

12.0 SHUT DOWN AND CLEANOUT

SHUT DOWN

After each use, turn the concentrate ratio knob to the RINSE position. Use plain water to rinse o the KLEAN/pak and any undesirable

disinfectant deposits nearby.

Leave the concentrate ratio knob in RINSE when nished to minimize concentrate evaporation.

Disconnect hoses and secure the reservoir, wand, and fan nozzle between uses.

DEBRIS

Debris entering the waterway or the reservoir may interfere with operations.

The KLEAN/pak includes a debris screen on the waterway inlet. If the screen

becomes clogged with debris the device will ow less than intended. Remove

debris by shutting o the water supply and cleaning the screen.

Debris in the concentrate passageways can result in weak disinfectants. If

concentrate is weak:

1. Shutdown the water supply to the KLEAN/pak

2. Remove screw #1, spring #2, and concentrate ratio knob #3

3. Unscrew the lid and remove the metering head & pickup hose from the

reservoir

4. Inspect reservoir for particulate contamination and clean as required

5. Clean out concentrate passageways

6. Rinse o pickup hose, screw #1, spring #2, and concentrate ratio knob #3

7. Reassemble & resume operation

For years of service, periodically inspect your KLEAN/pak. Make sure the

hose and fan nozzle are in place. Look for debris in the bottom of the reservoir

and ush if necessary.

UNSCREW

CLEAN

Figure 12.0

1

2

3

©Copyright Task Force Tips LLC 2020 LIU-055 June 24, 2020 Rev01

10

Page 11

13.0 STORAGE

If the KLEAN/pak is to be stored with disinfectant concentrate in it, use the provided spare

reservoir lid to replace the metering head and ensure no evaporation or leakage of concentrate.

Refer to disinfectant manufacturer’s TDS for recommended storage temperature.

Equipment subject to freezing conditions must be fully drained to avoid freeze damage.

Figure 13.0

14.0 WARRANTY

Task Force Tips LLC, 3701 Innovation Way, Valparaiso, Indiana 46383-9327 USA (“TFT”) warrants to the original purchaser of its

KLEAN/pak, and to anyone to whom it is transferred, that the equipment shall be free from defects in material and workmanship

during the one (1) year period from the date of purchase.

TFT’s obligation under this warranty is specically limited to replacing or repairing the equipment (or its parts) which are shown by

TFT’s examination to be in a defective condition attributable to TFT. To qualify for this limited warranty, the claimant must return the

equipment to TFT, at 3701 Innovation Way, Valparaiso, Indiana 46383-9327 USA, within a reasonable time after discovery of the

defect. TFT will examine the equipment. If TFT determines that there is a defect attributable to it, it will correct the problem within a

reasonable time. If the equipment is covered by this limited warranty, TFT will assume the expenses of repair.

If any defect attributable to TFT under this limited warranty cannot be reasonably cured by repair or replacement, TFT may elect to

refund the purchase price of the equipment, less reasonable depreciation, in complete discharge of its obligations under this limited

warranty. If TFT makes this election, claimant shall return the equipment to TFT free and clear of any liens and encumbrances.

This is a limited warranty. The original purchaser of the equipment, any person to whom it is transferred, and any person who is

an intended or unintended beneciary of the equipment, shall not be entitled to recover from TFT any consequential or incidental

damages for injury to person and/or property resulting from any defective equipment manufactured or assembled by TFT. It is agreed

and understood that the price stated for the equipment is in part consideration for limiting TFT’s liability. Some states or countries do

not allow the exclusion or limitation of incidental or consequential damages, so the above may not apply to you.

TFT shall have no obligation under this limited warranty if the equipment is, or has been, misused or neglected (including failure to

provide reasonable maintenance) or if there have been accidents to the equipment or if it has been repaired or altered by someone

else.

THIS IS A LIMITED EXPRESS WARRANTY ONLY. TFT EXPRESSLY DISCLAIMS WITH RESPECT TO THE EQUIPMENT ALL

IMPLIED WARRANTIES OF MERCHANTABILITY AND ALL IMPLIED WARRANTIES OF FITNESS FOR A PARTICULAR PURPOSE.

THERE IS NO WARRANTY OF ANY NATURE MADE BY TFT BEYOND THAT STATED IN THE DOCUMENT.

This limited warranty gives you specic legal rights, and you may also have other rights which vary from state to state.

©Copyright Task Force Tips LLC 2020 LIU-055 June 24, 2020 Rev01

11

Page 12

15 TROUBLE-SHOOTING

SYMPTOM POSSIBLE CAUSE REMEDY

KLEAN/pak

will not make

disinfectant

Solution is

Intermittent

Poor Quality Debris in nozzle Inspect nozzle, look for plugged holes

Sputtering sound from nozzle indicates you’re out of

concentrate.

Hose is kinked or twisted preventing full ow to KLEAN/pak. Stretch hoses straight.

Concentrate Ratio Knob is in RINSE Select desired concentration

Concentrate Ratio Knob is plugged Remove screw on Concentrate Ratio Knob, inspect

Wrong outlet hose, nozzle, or added shuto causes back

pressure

Reservoir is nearly empty Rell reservoir

KLEAN/pak tilted Keep Twist Grip Horizontal

Air vents are plugged Remove metering head by unscrewing the lid.

Debris under concentrate ratio knob Unscrew concentrate ratio knob, inspect and clean

Solution velocity too high Reduce supply pressure at the source

Concentration too high or too low Review correction factor and inlet pressure (sections 9

Debris in hose inlet Remove inlet hose and clean out screen

Rell reservoir

and clean holes in top of control block and passages in

bottom of Concentrate Ratio Knob

Setup discharge connections per section 5

Rinse the cap with plain water until it spins freely.

& 10)

TASK FORCE TIPS LLC

MADE IN USA • KLEAN-pak.com

©Copyright Task Force Tips LLC 2020 LIU-055 June 24, 2020 Rev01

3701 Innovation Way, Valparaiso, IN 46383-9327 USA

800-348-2686 • 219-462-6161 • Fax 219-464-7155

Loading...

Loading...