ITEM #241482

YARD CHIPPER

MODEL # 26093

RE

AD YOUR OPERATOR’S MANUAL COMPLETELY AND CAREFULLY BEFORE

ATTEMPTING

EQUIPMENT SHOULD READ AND UNDERSTAND ALL SAFETY RULES PRINTED ON THE MACHINE

AND IN THIS OPERATOR’S MANUAL BEFORE USE.

NOTICE: On the nameplate of your machine you will find the serial number and MFG date code of your unit.

Please record these numbers on this manual cover for future service reference.

MFG. DATE ________ PURCHASE DATE: _________

TO SET UP OR OPERATE YOUR NEW POWER TOOL. ALL OPERATORS OF THIS

Questions, problems, missing parts? Before returning to your retailer, call our customer

service department at 1-800-444-6742, 8:00 a.m.-6:00 p.m., EST, Monday-Thursday,

8:00 a.m.-5:00 p.m.,

CAUTION - FOR YOUR SAFETY

EST, Friday.

PRINTED IN CHINA

2

Product specification............................................................................................2

General safety rules.............................................................................................3

Specific safety rules for yard chippers.................................................................5

Electrical information............................................................................................6

Know your chipper...............................................................................................8

Assembly and Adjustments..................................................................................9

Operation............................................................................................................12

Maintenance.......................................................................................................14

Warranty.............................................................................................................16

Parts lists............................................................................................................17

YARD CHIPPER

ITEM NUMBER:...........................................................................................241482

MODEL NUMBER:.........................................................................................26093

MOTOR..................................................................................120V AC, 60 Hz, 15A

SPEED....................................................................................................4,000RPM

CHIPPER CAPACITY...................................................................1-3/8 in. (35 mm)

DIAMETER.....................................................................................1-3/8 in.(35 mm)

HEIGHT....................................................................................37-1/2 in. ( 950 mm)

WEIGHT................................................................................... 31 lb 6 oz (14.35 kg)

TABLE OF CONTENTS

PRODUCT SPECIFICATIONS

Assembling this YARD Chipper need as follows tools:

(1) L-wrench

(2) 13mm wrench

(3) screwdriver

Safety is a combination of common sense, staying alert, and knowing how to

use your yard chipper properly.

1. READ and become familiar with this entire instruction manual. LEARN the

tool’s applications, limitations, and possible hazards.

2. AVOID DANGEROUS CONDITIONS. DO NOT use power tools in wet or

damp areas or expose them to rain.

3. DO NOT use power tools in the presence of flammable liquids or gases.

4. KEEP BYSTANDERSAT A SAFE DISTANCE FROM the work area when

the tool is operating. NEVER allow children near the tool.

5. DO NOT FORCE THE TOOL to do a job for which it was not designed.

6. DRESS FOR SAFETY. DO NOT wear loose clothing, gloves, neckties, or

jewelry (rings, watches, etc.) when operating tool. Loose clothing can get

caught and pull you into moving parts.

7. ALWAYS WEAR EYE PROTECTION.

8. ALWAYS remove the power cord plug from the electric outlet when making

adjustments, changing parts, cleaning or working on the tool.

9. AVOIDACCIDENTAL START-UPS. Make sure the power switch is in the

OFF position before plugging in the power cord.

10. DO NOT abuse the power cord. Do not use it to carry the tool. Keep cord

away from heat, oil, sharp edges, or moving parts. Replace damaged cords

immediately; they may create a shock or fire hazard.

11. NEVER LEAVE A RUNNING TOOL UNATTENDED. Turn the power switch

to OFF. Do not leave the tool until it has come to a complete stop.

12. Keep proper footing and balance at all times. Wear oil-resistant,

rubber-soled footwear.

TO AVOID MISTAKES THAT COULD CAUSE SERIOUS

INJURY, DO NOT PLUG IN THE CHIPPER UNTILTHE FOLLOWING

STEPS HAVE BEEN READ THOROUGHLY.

3

GENERAL SAFETY RULES

WARNING

13. ALWAYS keep tool clean and in good working order.

14. Check for proper alignment of moving parts, binding, breakage, or any other

conditions that may affect the tool’s operation. Any part that is damaged

15. DO NOT operate tool if you are under the influence of any drugs, alcohol

or medication that could affect your ability to use the tool properly.

16. Do not use solvents, brake fluids, gasoline, or other petroleum products to

clean the tool, they may damage plastic parts.

4

should be properly repaired or replaced before use.

GENERAL SAFETY RULES-CONTINUE

ALWAYS WEAR EYE PROTECTION.

A yard chipper can throw foreign objects into your eyes which could

cause permanent eye damage.

ALWAYS wear safety goggles (not glasses). Ordinary eyeglasses

have only impact-resistant lenses—they are

NOT safety goggles.

1. Be thoroughly familiar with the operation of the chipper before initial use.

2. NEVER put your hands into the hopper. Always use the push stick supplied

with your chipper to push items into the hopper.

3. DO NOT try to force objects that exceed the recommended diameter and

capacity of the chipper: 1-3/8 in. (35cm).

4. AVOID ACCIDENTAL START-UPS. Be sure switch is OFF when

plugging in.

5. DO NOT FORCE THE CHIPPER. It will do the job better and with less

likelihood of injury at the rate for which it was designed.

6. Before putting objects into the hopper, remove any stones, debris, or

objects that could damage the blades.

7. During operation, ensure that there are no other persons or animals within

a radius of 10 feet. Stop using the machine while people, especially

children, or pets, are nearby.

8. NEVER reach under the chipper until it has completely stopped. The

blade may continue to rotate for a time after being switched OFF.

9. MAKE all adjustments with the power OFF and the chipper disconnected

from the power source.

10. ALWAYS use accessories provided or recommended by the manufacturer.

Do not use substitutes.

11. KEEP guards in place and in working order. Keep blades sharp. Keep

hands and feet away from cutting areas.

5

NEVER REACH INTO THE HOPPER UNTIL THE

CHIPPER HAS COME TO A COMPLETE STOP AND IS

UNPLUGGED.

THE CHIPPER WILL CONTINUE TO ROTATE FOR A FEW

SECONDS

AFTER IT IS SWITCHED OFF.

NEVER PLACE HANDS INTO THE EJECTION CHUTE—A

SERIOUS INJURY WILL OCCUR.

SPECIFIC SAFETY RULES FOR YARD CHIPPERS

WARNING

WARNING

This yard chipper has a plug that looks like the one shown in Fig. A.

The yard chipperis double insulated to providea dual thickness of insulation

between you and the tool’s electrical system. All exposed metal parts are

insulated.

IN ALL CASES, MAKE CERTAIN THE RECEPTACLE IN

QUESTION IS PROPERLY GROUNDED. IF YOU ARE NOT SURE,

HAVE A CERTIFIED ELECTRICIAN CHECK THE RECEPTACLE.

6

Fig. A

1) 2-prong plug

2) Properly grounded extension cord

ELECTRICAL INFORMATION

CAUTION

WARNING: TO AVOID ELECTRIC SHOCK HAZARDS, FIRE HAZARDS,

OR DAMAGE TO THE TOOL, USE PROPER CIRCUIT PROTECTION.

YOUR CHIPPER IS WIRED AT THE FACTORY FOR 12OV OPERATION.

CONNECT TO 120 V, 15 A CIRCUIT AND USE A 15 A CIRCUIT BREAKER.

TO AVOID SHOCK OR FIRE WHEN THE POWER CORD IS WORN, CUT,

OR DAMAGED IN ANYWAY, REPLACE IT IMMEDIATELY.

DOUBLE INSULATED

WARNING:TO AVOID INJURY,WHEN SERVICING THE CHIPPER

USE ONLY IDENTICAL REPLACEMENT PARTS.1-800-444-6742

WARNING:DOUBLE INSULATION DOES NOT TAKE THE PLACE OF

NORMAL SAFETY PRECAUTION WHEN OPERATING THIS TOOL.

WARNING:TO AVOID ELECTRIC SHOCK:

1. Use only identical replacement parts when serving a tool with double

insulation. Servicing should be performed by a qualified technician.

2. Do not use in wet or damp or expose to rain.

GUIDELINES FOR USING EXTENSION CORDS

Make sure your extension cord is in good condition. When using an extension

cord, be sure to use one of heavy enough gauge to carry the current your product

will draw. An undersized cord will cause a drop in line voltage resulting in loss of

power and overheating. The table below shows the correct size to be used

according to cord length and nameplate ampere rating. If in doubt, use the next

heavier gauge. The smaller the gauge number, the heavier the cord.

Minimum

Gauge for Extension Cords(AWG)

(when using 120 V only)

Be sure your extension cord is properly wired and in good condition. Always replace

a damaged extension cord or have it repaired by a qualified person before using it.

Keep your extension cords away from sharp objects, excessive heat and damp or

wet areas.

Use a separate electrical circuit for your tools. This circuit must not be less than

12 gauge cord and should be protected with a 15 amp time delayed fuse.

Before connecting the motor to the power line, make sure the switch is in the OFF

position and the electric current is rated the same as the current stamped on the

motor nameplate. Running at a lower voltage will damage the motor.

THIS TOOL MUST BE GROUNDED WHILE IN USE TO

PROTECT THE OPERATOR FROM ELECTRICAL SHOCK.

Amp Rating Total Lengthof Cord in Feet (meters)

More Than Not More Than 25 (7.6) 50 (15.2) 100 (30.4) 150(45.7)

0 6 18 16 16 14

6 10 18 16 14 12

10 12 16 16 14 12

12 16 14 12 Not Recommended

THIS LAWN TOOL IS FOR OUTDOOR USE ONLY. DO

NOT EXPOSE TO RAIN OR USE IN DAMP LOCATIONS.

7

ELECTRICAL INFORMATION

WARNING

WARNING

8

1. Hopper

2. Handle

3. Housing

4. Motor Housing

5. Release Knob

6. Power Switch

7. Discharge Chute

8. Stand with Wheels

9. Circuit Breaker

10. Clip Holder

11. Bag Clip

2

5

6

4

8

7

3

9

10

11

KNOW YOUR YARD CHIPPER

12

14

12. Push Bar Holder

14. Push Bar

13. Underlay

13

1

1

2

3

4

5

8

9

13

6

10

11

12

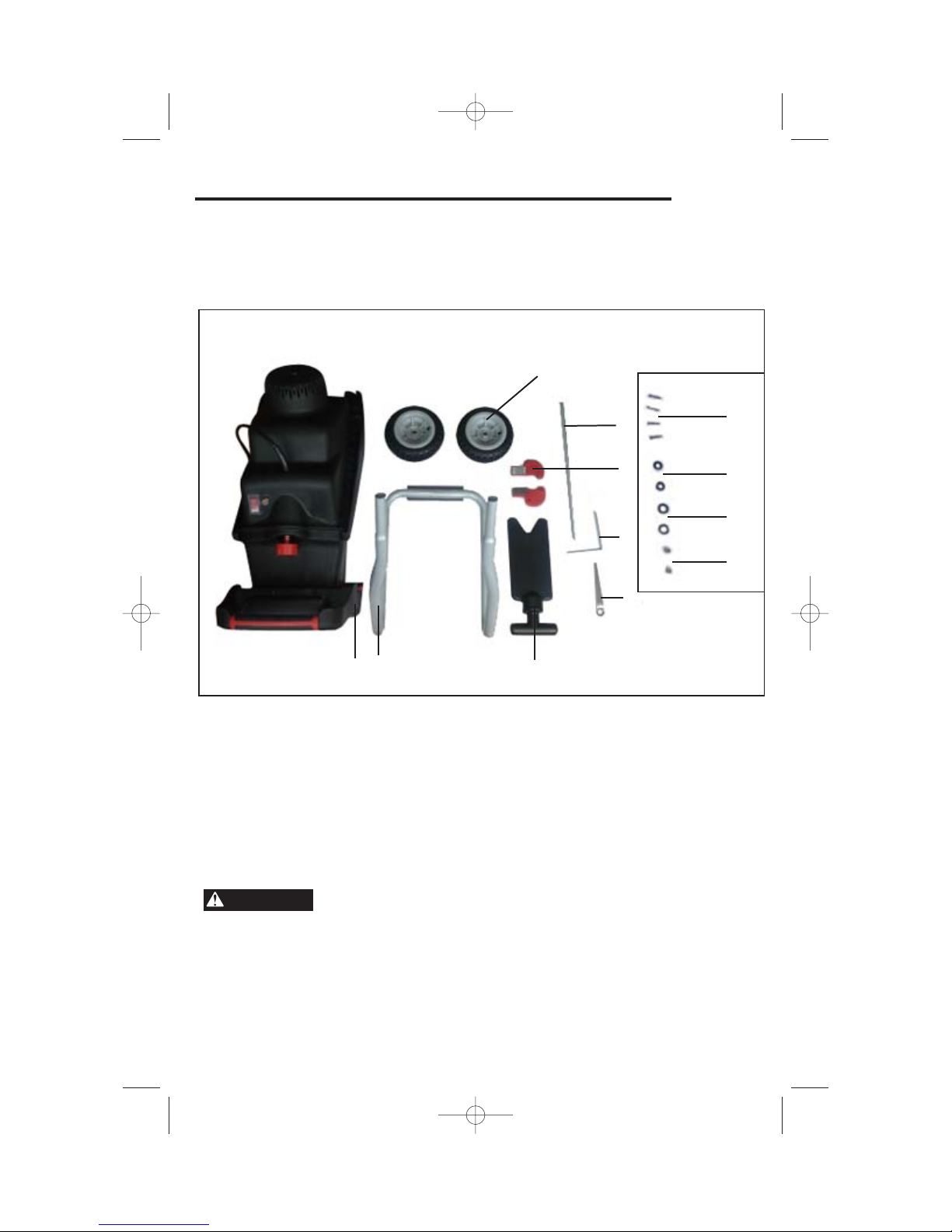

UNPACKING (Fig. B)

Remove the chipper components from the packaging and examine them carefully.

.

NOTE: Do not discard box or any packing material until all parts are examined.

9

1

Housing with hopper 1 pcs

2 Push Bar 1 pcs

3 Wheel 2 pcs

4 Axle 1 pcs

5 Clip Holder 2 pcs

6 Screw 4 pcs

7 Collecting Bag (not show) 1 pcs

8 L-wrench 1 pcs

9 13mm wrench 1 pcs

10 Wheel Nut 2 pcs

11 Inner Washer 2 pcs

12 Outer Washer 2 pcs

13 Stand Assembly 1 pcs

IF ANY PART OF THE CHIPPER IS MISSING OR

DAMAGED, DO NOT PLUG

THE TOOL IN

UNTIL THE DAMAGED PART IS

REPAIRED OR REPLACED..

Fig. B

WARNING

ASSEMBLY AND ADJUSTMENTS

ASSEMBLY INSTRUCTIONS

The chipper must be fully assembled before use.

Fig.3

BEFORE MAKING ANY ADJUSTMENTS.

10

TO AVOID INJURY, ALWAYS TURN THE SWITCH OFF

AND DISCONNECT THE CHIPPER FROM THE POWER OUTLET

BEFORE MAKING ANY ADJUSTMENTS.

Fig.1

Fig.2

Fig.3

1

2

3

5

4

6

7

8

1. Place one end of the axle (2) into the

hole on the leg (1) as shown in Fig.1

Spread legs slightly to allow the other

end of the axle into the opposite hole.

2. Place large washer (3) onto axle.

3. Place wheel (4) onto axle followed by

the small washer (5) and wheel nut (6)

as Fig.2.

4. Repeat steps 2 and 3 for the opposite

side.

5. Place the “L” wrench (7) through the

hole in the axle and then using the

14mm wrench (8), tighten each wheel

nut in turn, while holding the axle

steady with the “L” wrench.

WARNING

ASSEMBLY AND ADJUSTSMENTS

11

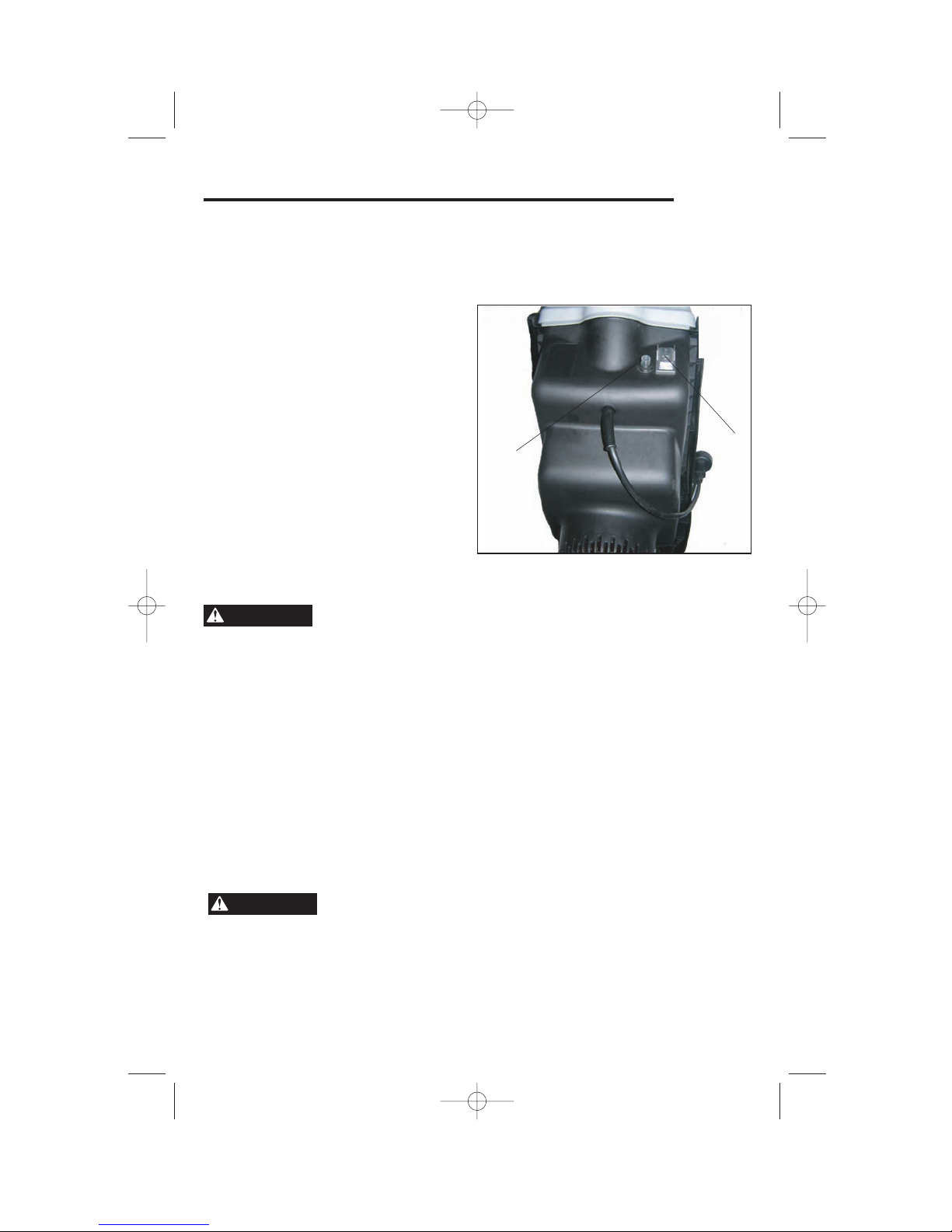

Attach legs to chipper (Figs.5 and 6)

The legs are attached to the bottom of the chipper. The top pa rt of the chipper

is held closed by a lock knob.

1. Turn the chipper housing upside down.

(Step 1,Fig.4)

2. Place the leg assembly into the holes

on the housing. (Step 2,Fig.5)

3. Push firmly into place.

4. Position a clip holder (Step 3,Fig.6) on

the side of the housing and screw

(Step 4,Fig.6) into place. Repeat for the

opposite side.

5. Make sure the chipper is properly

assembled, and then turn the right way

up.

Fig.4

Step 1

Fig.5

Step 2

Fig.6

Step 4

Step 3

ASSEMBLY AND ADJUSTMENTS

OPERATING INSTRUCTIONS

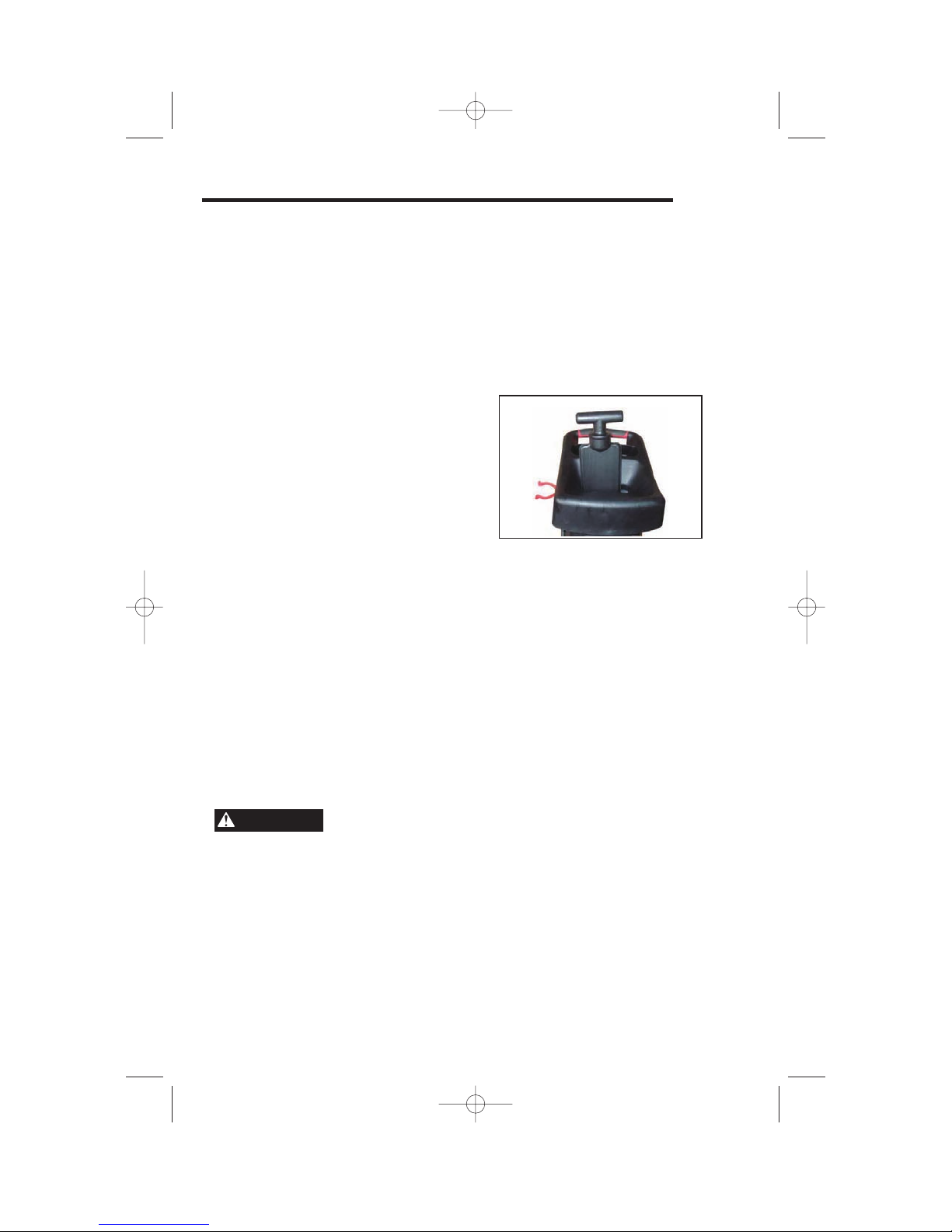

ON/OFF Switch (Fig. 7)

The ON/OFF switch (1). A circuit breaker (2) is located below the switch.

To operate the shredder:

1. Plug the shredder into a properly

grounded 3-prong outlet.

2. Flip the switch (1)

to the ON

position. If the shredder does not

start, flip the switch to the OFF

position and press the reset

button

(2)

, then flip the switch to the

ON position.

3. Flip the switch (1) to the OFF

position to turn offthe shredder.

Allow at least 5 seconds for the

blade to stop rotating.

Overload protection (Fig. 7)

This yard chipper has a reset overload

feature. The reset button

will restart the

motor after it shuts off due to overloading or low voltage. If the motor stops

during operation:

1.Turn the ON/OFF (1) switch to the OFF position.

2.Wait about five minutes for the motor to cool.

3.Push in on the reset button (2) .

4.Turn the switch (1) to the ON position.

12

ALWAYS ALLOW 5 SECONDS OR MORE FOR THE

BLADE

TO STOPROTATING AFTER TURNING OFF THE CHIPPER.

TO PREVENT AN ACCIDENTAL START-UP IF THE RESET

BUTTON IS PUSHED,

THE ON/OFF SWITCH SHOULD BE IN THE OFF

POSITION AND THE PLUG SHOULD BE REMOVED FROM THE POWER

SOURCE WHILE COOLDOWN TAKES PLACE.

Fig. 7

1

2

OPERATION

WARNING

WARNING

Chipping yard waste (Fig. 8)

The chipper is designed to work on leaves, other yard waste and debris, and

sticks and twigs up to 1-3/8 in. (35mm) in diameter. The chipper material will

accumulate directly on the ground under the chipper .

CAUTION: Do not attempt to chip material that exceeds the capacity of t he

chipper.

1. Turn ON the chipper.

2. Place sticks in the narrow opening of

the hopper. Do not place your hands

inside the hopper.

3. Do not feed sticks that are greater than

1-3/8 in.(35mm) in diameter.

4. Turn the chipper OFF and allow it

to come to a complete stop.

13

DO NOT TRY TO CHIP ANY MATERIAL THAT EXCEEDS

THE CAPACITY OF THIS TOOL. DOING SOMAYCAUSE THE MOTOR TO JAM

AND OVERHEA

T. NEVER PUTYOUR HANDS IN THE HOPPER OR NEAR THE

BLADE

WHEN THE TOOL IS RUNNING.

Fig. 8

OPERATION

WARNING

BLADE MAINTENANCE

The chipper has two blades that are attached to a rotating support. When one

side of a blade becomes dull, it can be turned to use the other side. Replace or

properly sharpen dull blades.

Replace a blade

1. Turn OFF the chipper and remove

the plug from the outlet.

2. Turn the lock knob counterclockwise

until the housing cover can be

opened.

3. Lift up the housing cover to expose

the two blades

(1).

4. Place a 6 mm wrench (2) on one

of the four 6 mm bolts below the

blade support

(3) to secure it and

stop it from rotating.

5. Use the other 6 mm wrench to

loosen and remove the two

screws (5) that hold each blade to the support.

6. Lift out the old blade. Either reinsert the blade with the sharp edge in

position as the cutting surface or insert a replacement blade.

7. Replace and tighten the two screws to secure the new blade to the support.

GENERAL MAINTENANCE

1. Keep the chipper clean and in good repair for maximum performance and

machine longevity.

2. Before each use, inspect the switch and cord for damage.

3. Check for damaged, missing, or worn parts. Check for loose screws, moving

parts that are jammed or any other conditions that may affect the operation.

4. If abnormal vibration or noise occurs, turn OFF the tool immediately and

correct the problem before further use.

5. Do not use the chipper until it is properly repaired or replaced.

14

Fig. 9

2

1

3

4

5

ALWAYS TURN OFF THE TOOL AND UNPLUG THE

POWER CORD FROM THE OUTLET BEFORE MAINTAINING THE

CHIPPER.

MAINTENANCE

WARNING

• Wipe the outside of the chipper with a dry soft cloth.

• Remove the hopper from the housing body before washing the inside of the

hopper.

• Do not hose down or wash the tool with water.

TO AVOID INJURY, ELECTRIC SHOCK, OR DAMAGE

TO THE CHIPPER, NEVER ALLOW A LIQUID TO FLOW INSIDE THE

TOOL.

15

TO AVOID DAMAGE OR ELECTRIC SHOCK, DO NOT

USE STRONG SOLVENTS OR DETERGENTS ON THE PLASTIC

HOUSING OR PLASTIC COMPONENTS. CERTAIN HOUSEHOLD

CLEANERS MAY CAUSE DAMAGE AND MAY ALSO CAUSE A SHOCK

HAZARD.

MAINTENACE

WARNING

WARNING

CLEANING

16

LIMITED TWO-YEAR WARRANTY

The manufacturer warranties to the original purchaser that each new product and service part is free from defects in

material and workmanship and agrees to repair or replace under this warranty any defective product or part as follows

from the original date of purchase.

2 —Year Limited Warranty

THIS WARRANTY IS NOT TRANSFERABLE AND DOES NOT COVER:

Products sold damaged or incomplete, sold “as is”, sold reconditioned or used as rental equipment.

Delivery, installation or normal adjustments explained in the owner’s manual.

Damage or liability caused by shipping, improper handling, improper installation, incorrect voltage or improper wiring,

improper maintenance, improper modification, or the use of accessories and /or attachments not specifically recommended.

Repairs necessary because of operator abuse or negligence, or the failure to install, operate, maintain and store the product

according to the instructions in the owner’s manual.

Damage caused by cold, heat, rain, excessive humidity, corrosive environments and materials, or other contaminants.

Expendable items that become worn during normal use.

Cosmetic defects that do not interfere with tool functionality.

Freight costs from customer to vendor.

ANY INCIDENTAL, INDIRECT OR CONSEQUENTIAL LOSS, DAMAGE, OR EXPENSE THAT MAY RESULT FROM ANY

DEFECT, FAILURE OR MALFUNCTION OF THE PRODUCT.

Some states do not allow the exclusion or limitations on how long an implied warranty lasts, so the above limitations may

not apply to you.

WARRANTY REPLACEMENT PARTS are available by calling the toll free number, 1-800-444-6742, 8:00am – 6:00pm EST,

Monday-Thursday, 8:00 a.m.-5:00 p.m., EST, Friday.

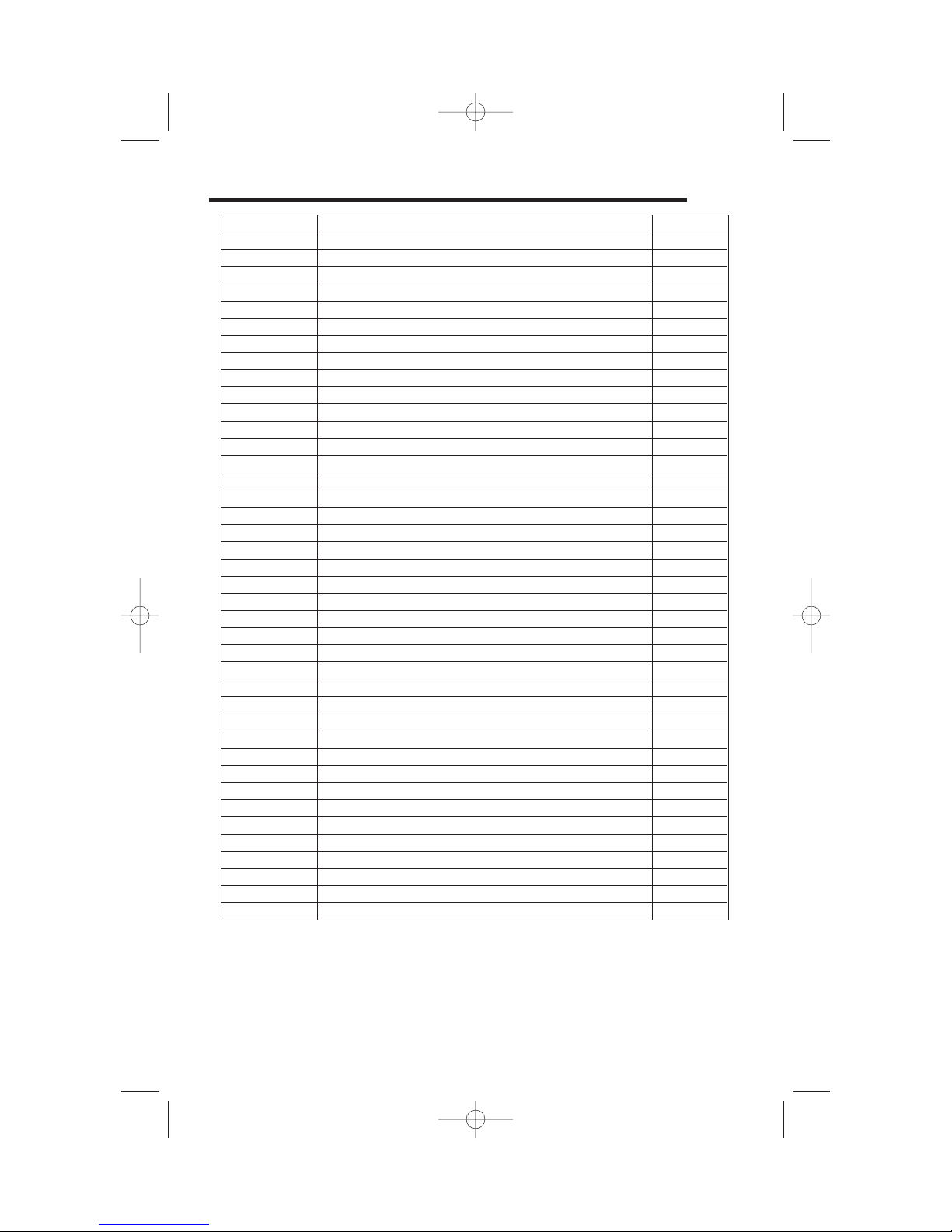

PARTS LIST

17

1

2

3

4

5

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

6

18

PARTS LIST

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

1

1

1

1

1

1

1

1

2

1

27

1

1

1

1

2

4

1

5

1

1

1

4

2

1

1

1

1

1

2

4

1

1

1

1

1

1

4

1

1

1

1

1

10

2

Description Item Qty

Upper handle

Lower handle

Warning label

Feeder hopper

Flat push stick

Flap

Spring

Steel ball

Push stick holder

Clamp block

Screw

Washer 5

Upper housing

Up housing

Bolt frame plate

Screw

Spring washer 2

Switch pin

Hex type screw

Screw

Spring washer 1

Clamp block

Hex nut

Blade

Blade plate

Drive block

Blade cover plate

Latch rod

Washer 3

Hex nut

Screw

Lower housing

Knob

Spring

Retaining ring

Fixup nut

Nut frame plate

Hex nut

Overload swtich

Supply cord

Cord sheath

Cord clamp plate

Switch frame plate

Screw

Screw

19

PARTS LIST

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

1

1

1

1

1

1

1

1

1

1

1

2

1

1

2

1

2

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

2

3

1

1

1

2

2

Description Item Qty

Sponge

Connecting wire 1

Connecting wire 2

On/Off switch

Trip switch

Label

Motor housing

Capacitor

Fan

Bearing sheath

Bearing

Screw

Motor support

Field

Screw

Right hook clip

Hook

Armature

Bearing

Small belt wheel

Left hook clip

Wind defend board

Plastic pin

Lower gearbox cover

Bearing

Eccentric wheel

Rolling wheel

Washer 4

Big belt wheel

Belt

Upper gearbox cover

Bearing

Hex wrench

Hex nut

Washer 1

Leg stand

Axle

“L” wrench

Washer 2

Wheel

Loading...

Loading...