Instruction Manual

TM

D103666X012

January 2015 - Rev. 00

Relief Valves

SUMMARY

Introduction ........................................................................ 1

SEP Statement .................................................................. 1

P.E.D. Categories and Fluid Group ................................... 2

Characteristics ................................................................... 2

Labelling ............................................................................ 2

Overpressure Protection .................................................... 3

V Series

Transport and Handling ..................................................... 3

Atex Requirements ............................................................ 3

Operation ........................................................................... 3

Dimensions and Weights ................................................... 4

Installation ......................................................................... 5

Startup ............................................................................... 5

Setting ............................................................................... 5

Shutdown ........................................................................... 6

Periodical Checks .............................................................. 6

Maintenance ...................................................................... 6

Spare Parts ........................................................................ 7

Troubleshooting .................................................................

Parts Lists .......................................................................... 8

Schematic Assemblies ....................................................... 9

7

INTRODUCTION

Scope of Manual

This manual provides instructions for installation, startup,

maintenance and spare parts ordering for the V Series

spring-loaded relief valves.

This product has been designed to be used with fuel gases of

1st and 2nd family according to EN 437, and with other non

aggressive and non fuel gases. For any other gases, other

than natural gas, please contact your local sales agent.

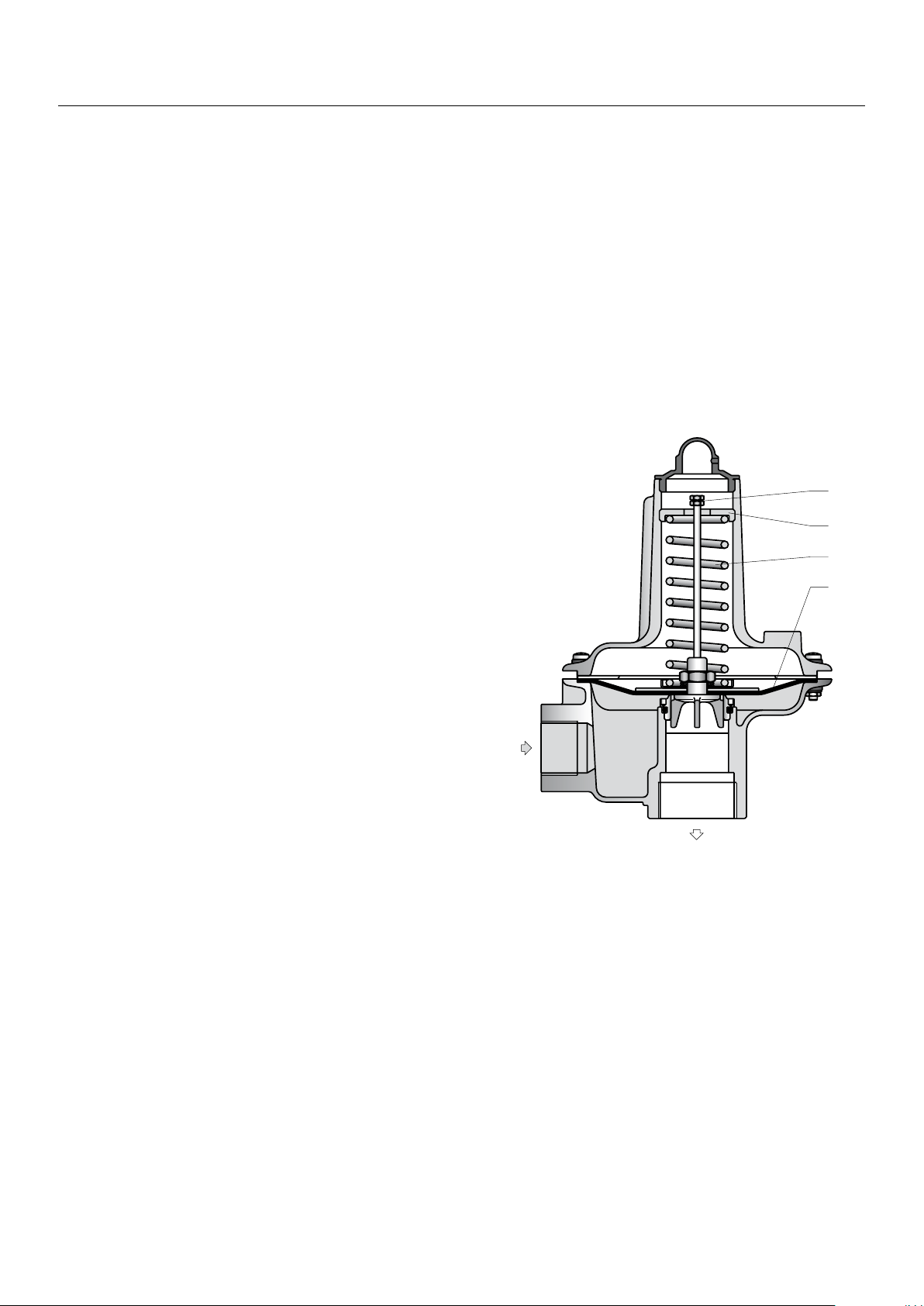

Figure 1. Relief Valves V/50, V/60 Series and Type V/20-2

SEP STATEMENT

Emerson Process Management declares this product (V/50

and V/20-2) conforms to Pressure Equipment Directive

(PED) 97/23/EC Article 3 section 3 and was designed

and manufactured in accordance with sound engineering

practice (SEP).

Per Article 3 section 3, this “SEP” product must not bear the

CE marking.

Product Description

The V Series are spring-loaded automatic type relief valves.

They are used in reduction, distribution and conveying

stations using suitably ltered natural gas.

They can also be used for air, propane, butane, LPG, city

gas, nitrogen, carbon dioxide.

The following versions are available:

V/50 and V/60 : for very low pressure applications

V/51 and V/61 : for low pressure applications

V/52 and V/62 : for middle pressure applications

V/20-2 : for high pressure applications

All standard gas pressure devices (relief valves) used

in assemblies will comply to EN 12186 and EN 12279

standards.

V Series

=x

P.E.D. CATEGORIES AND FLUID GROUP

The V Series relief valves are designed as functional

equipments and they are typically used in gas pressure

reducing stations for overpressure protection by releasing

small amounts of gas in the event of not perfect pressure

relief valve closing.

Table 1. P.E.D. Category for V Series Relief Valves

TYPE CATEGORY FLUID GROUP

V/50 - V/51 - V/52 SEP

1V/60 - V/61 - V/62 I

V/20-2 SEP

If V series relief valve is used as full-capacity relief

device (according clause 8.3.2 EN 12186) , downstream

equipments protected by this products shall have technical

features such as not to be category higher than following

category (according Directive 97/23/EC “PED”).

CHARACTERISTICS

End Connection Styles

V/50 Series

Outlet Set Pressure Ranges

V/50 Series: 0.025 ÷ 2 bar

V/60 Series: 0.025 ÷ 2 bar

Type V/20-2: 1.5 ÷ 40 bar

Minimum/Maximum Allowable Temperature (TS)

See label

Temperature

Standard Version : Working -10° to 60°C

Low Temperature Version : Working -20° to 60°C

Materials

V/50 and V/60 Series

Body / cover : Aluminium

Seat : Brass

Diaphragms : Fabric Nitrile (NBR) + PVC

Pads : Nitrile (NBR) rubber

Type V/20-2

Body : Brass

Pad retainer : Brass

Pad holder : Brass

Adjusting nut : Brass

Pad : Nitrile (NBR) rubber

1” x 1 1/2” GAS

V/60 Series

1 1/2” x 2” GAS

Type V/20-2

1” x 1” NPT

WARNING

!

The pressure/temperature limits indicated

in this instruction manual or any applicable

standard or code limitation should not be

exceeded.

Maximum Allowable Pressure

V/50 Series: 4 bar

V/60 Series: 2.5 bar

Type V/20-2: 100 bar

LABELLING

Notified

BOLOGNAITA LY

O.M.T.

MATRICOLA

SERIALNr.

ANNO

YEAR

NORMEARMONIZ.

HARMONIZEDSTD.

CLASSEDI PERDITA

LEAKAGECLASS

CLASSEFUNZIONALE

FUNCTIONALCLASS

FLUIDO GRUPPO

FLUIDGROUP

TS

Note2

EN

1

Figure 2. Label for V Series Relief Valves

Note 1: See “Characteristics”

Note 2: Year of manufacture

Note 3: Class 1: -10°/60°C

Class 2: -20°/60°C

Note 4: V/50 Series : 4 bar

V/60 Series : 2.5 bar

Type V/20-2 : 100 bar

body

xxxx

Cg

pmax

PS

°C

body

APPARECCHIO TIPO /DEVICE TYPE

Note 1

DN1

DN2

Wa

Wao

Wau

bar

PS

bar

covers

pao

bar PT

-

1.5Note 4Note 3

bar

bar

bar

bar

PS bar

2

V Series

M

G

D

S

OVERPRESSURE PROTECTION

The recommended safety pressure limitations are stamped

on the valve label.

Downstream overpressure protection shall be also provided

if the inlet pressure can be greater than the PS (see label).

Equipment’s operation below the maximum pressure

limitations does not preclude the possibility of damage from

external sources or debris in the line.

The relief valve should be inspected for damage after any

overpressure condition.

TRANSPORT AND HANDLING

Established transport and handling procedures shall be

followed to avoid any damage on the pressure containing

parts by shocks or anomalous stresses.

Ringbolts are designed just for handling of equipment

weight.

Built-up sensing lines and pressure accessories (e.g. pilots)

shall to be protected by shocks or anomalous stresses.

• provision in 9.3 of EN 12186 & 12279 shall be enforced

by pressure regulating/measuring station/installation’s end

user

• external tightness test shall be carried out after each

reassembly at installation site using testing pressure in

accordance with national rules

• periodical check/maintenance for surveillance shall be

carried out complying with national regulations, if any, and

specic manufacturer recommendations.

OPERATION

V/50 and V/60 Series

ATEX REQUIREMENTS

If the provisions of EN 12186 & EN 12279, national

regulations, if any, and specic manufacturer

recommendations are not put into practice before

installation and if purge by inert gas is not carried out before

equipment’s start-up and shut-down operations, a potential

external and internal explosive atmosphere can be present

in equipment & gas pressure regulating/measuring stations/

installations.

If a presence of foreign material in the pipelines is foreseen

and purge by inert gas is not carried out, the following

procedure is recommended to avoid any possible external

ignition source inside the equipment due to mechanical

generated sparks:

• drainage to safe area via drain lines of foreign materials, if

any, by inow of fuel gas with low velocity in the pipe-work

(5m/sec)

In any case,

• provisions of Directive 1999/92/EC and 89/655/EC shall

be enforced by gas pressure regulating/measuring station/

installation’s end user

• with a view to preventing and providing protection against

explosions, technical and/or organizational measures

appropriate to the nature of the operation shall be taken

(e.g. : lling/exhausting of fuel gas of internal volume

of the isolated part/entire installation with vent lines

to safe area - 7.5.2 of EN 12186 & 7.4 of EN 12279 ;

monitoring of settings with further exhaust of fuel gas to

safe area ; connection of isolated part/entire installation to

downstream pipeline; ….)

Figure 3. Closed V/50 Relief Valve

Whenever gas pressure under diaphragm (D) is higher than

the force exerted by spring (M), diaphragm is raised causing

sleeve (O), which is integral with the diaphragm itself, to

move and thereby open the release orice.

In order to check the efciency of the relief valve, pull up

valve opening stem (S).

Valve setting is carried out by adjusting the compression of

spring (M) through the appropriate ring (G).

Valve set point should generally be at an intermediate value

between active regulator or monitor and slam-shut valve

(if tted) set points.

In all other cases, it is recommended that relief valve be set

at a value at least 15% higher than the working pressure of

the equipment.

3

V Series

M

O

P

G

Ø B

63,5

Type V/20-2

A

C

Figure 4. Closed V/20-2 Relief Valve

Whenever gas pressure under pad (O) is higher than

the force exerted by spring (M) in the opposite direction,

pad older device (P) is raised, thereby causing the release

orice to open.

Setting is carried out by adjusting the compression of spring

(M) through the appropriate ring (G).

It is recommended that relief valve be set at a value at least

15% higher than the operating pressure of the station.

DIMENSIONS AND WEIGHTS

V/50 and V/60 Series

TYPE V/50 SERIES V/60 SERIES

Table 2. V Series Dimensions (mm)

D

Figure 5. V/50 and V/60 Series Dimensions

Type V/20-2

133

A 236 258

B 164 198

C 43 70

D 95 110

Weight (Kg) 1,3 1,9

4

Figure 6. Type V/20-2 Dimensions (mm)

Valve Weight 1.6 Kg

Loading...

Loading...