Tappan TGF605EW2, TGF605EU1, TGF605EW1 Installation Guide

iNSTALLATiON AND SERVICE MUST BE PERFORMED BY

A QUALiFiED iNSTALLER.

iMPORTANT: SAVE FOR LOCAL ELECTRICAL iNSPECTOR'S USE.

@

causing property damage, personal injury or death.

FOR YOUR SAFETY:

-- Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any other

appliance.

-- WHAT TO DO IF YOU SMELL GAS:

Do not try to light any appliance.

Do not touch any electrical switch; do not use any phone in your building.

Immediately call your gas supplier from a neighbor's phone. Follow the gas supplier's instructions.

If you cannot reach your gas supplier, call the fire department.

-- Installation and service must be performed by a qualified installer, service agency or the gas supplier.

READ AND SAVE THESE iNSTRUCTiONS FOR FUTURE REFERENCE.

If the information in this manual is not followed exactly, a fire or explosion may result

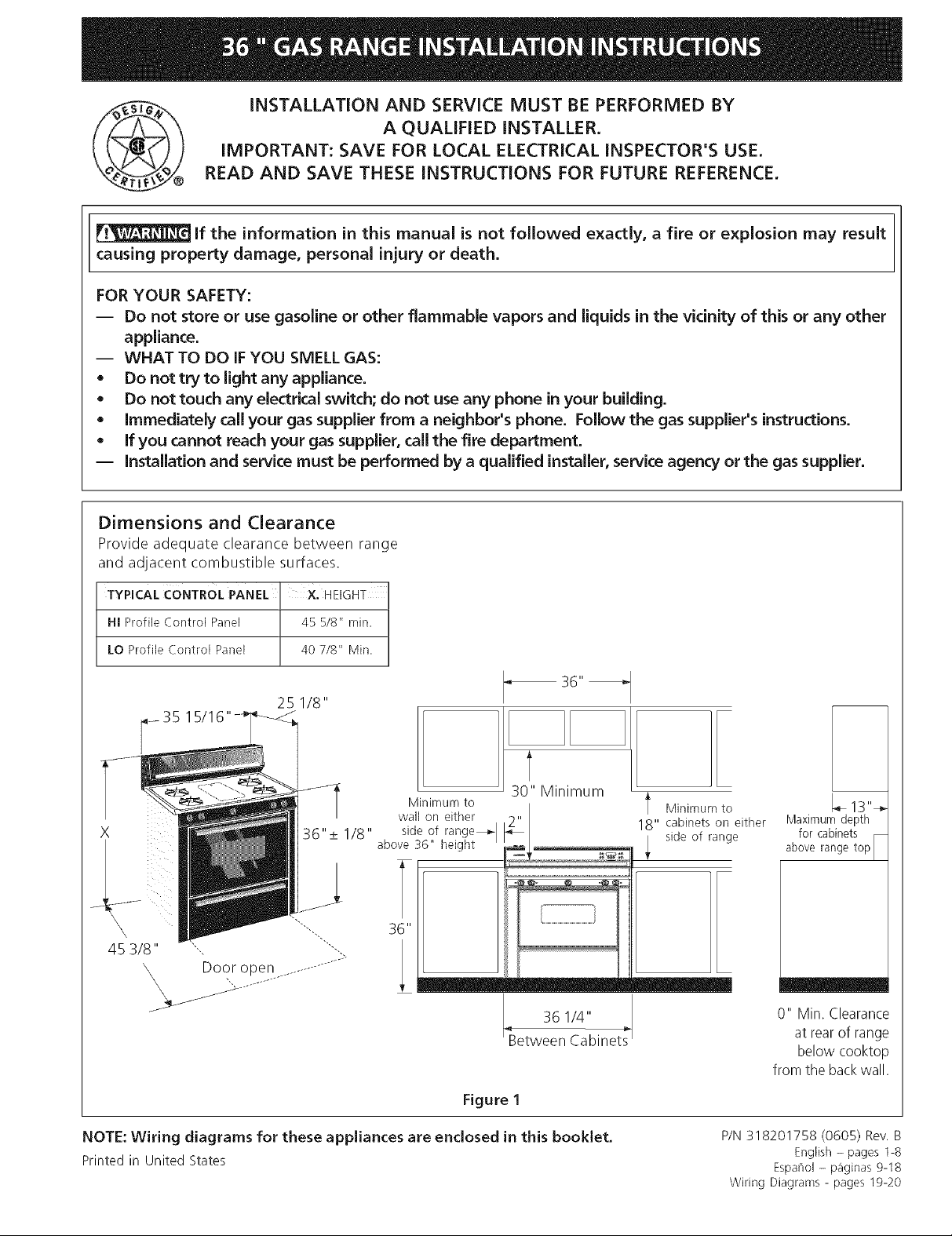

Dimensions and Clearance

Provide adequate clearance between range

and adjacent combustible surfaces.

TYPICAL CONTROL PANEL X. HEIGHT

HI Profile Control Panel 45 5/8" min.

LO Profile Control Panel 40 7/8" Min.

35

X

45 318.... " ....

' Door open .................:"

\_ , _°-

25 1/8"

36"+ _ I/8" side of range_

"-,..

Minimum to

wall on either

above 36" heigilt

36"

_36"

30" Minimum

I 36 1/4"

Between Cabinets

Minimum to

18" cabinets on either

side of range

I_ 13"-_

Maximum depth

for cabinets

above range top |

0" Min. Clearance

at rearof range

below cooktop

from the backwall.

Figure 1

NOTE: Wiring diagrams for these appliances are enclosed in this booklet.

Printed in United States

PIN 318201758 (0605) Rev. B

English - pages 1-8

Espahol - paginas g-18

Wiring Diagrams- pages 19-20

Important Notes to the Installer

I. Read all instructions contained in these installation

instructions before installing the range.

2. Remove all packing material before connecting the

electrical supply to the appliance.

3. Observe all governing codes and ordinances.

4. Be sure to leavethese instructions with the consumer.

Important Note to the Consumer

Keep these instructions with your Useand Care Guide for

future reference.

IMPORTANT SAFETY

INSTRUCTIONS

Installation of this range must conform with local codes,

or in the absence of local codes, with the National Fuel

Gas Code ANSI Z223. l--latest edition.

This range has been design certified by American Gas

Association (A.G.A.). As with any appliance using gas

and generating heat, there are certain safety precautions

you should follow. You will find them in the Use and

Care Guide, read it carefully.

* Be sure your range is installed and grounded

properly by a qualified installer or service

technician.

* This range must be electrically grounded in

accordance with local codes, or in their absence,

with the National Electrical Code ANSI/NFPA No.

70--latest edition.

* The installation of appliances designed for

manufactures (mobile) home installation must conform

with Manufactured Home Construction and Safety

Standard, title 24CFR, part 3280 [Formerly the Federal

Standard for Mobile Home Construction and Safety,

title 24, HUD (part 280)] or when such standard is not

applicable, the Standard for Manufactured Home

Installation 1982 (Manufactured Home Sites,

Communities and Set ups), ANSI Z225.1 latest edition,

or local codes.

, All ranges

can tip.

* Injury to

persons

could result.

* Install anti-

tip device

packed with

range.

To reduce the dsk of tipping

of the range, the range

must be secured by properly

installed anti-tip bracket (s)

provided with the range. To

check if the bracket(s) is

installed properly, grasp the

top rear edge of the range

and carefully tilt it forward

to make sure the range is

anchored.

• Before installing the range in area covered with

linoleum or any other synthetic floor covering,

make sure the floor covering can withstand heat

at least 90°F above room temperature without

shrinking, warping or discoloring. Do not install

the range over carpeting unless you place an

insulating pad or sheet of 1/4"thick plywood

between the range and carpeting.

• Make sure the wall coverings around the range

can withstand the heat generated by the range.

• Do not obstruct the flow of combustion air at the oven

vent nor around the base or beneath the lower front

panel of the range. Avoid touching the vent openings

or nearby surfaces as they may become hot. This

range requires fresh air for proper burner combustion.

• Do not store items of interest to children in the

cabinets above the range. Children could be

seriously burned climbing on the range to reach items.

• To eliminate the need to reach over the surface

burners, cabinet storage space above the burners

should be avoided.

• Adjust surface burner flame size so it does not

extend beyond the edge of the cooking utensil.

Excessive flame is hazardous.

• Do not use the oven as a storage space. This

creates a potentially hazardous situation.

• Never use your range for warming or heating the

room. Prolonged use of the range without adequate

ventilation can be hazardous.

• Do not store or use gasoline or other flammable

vapors and liquids near this or any other

appliance. Explosions or fires could result.

• Remove broiler pan and other utensils and wipe up

excess spillage before self-cleaning the oven (if

equipped).

Do not make any attempt to operate

the electric ignition oven during an electrical power

failure. Resumption of electric power when OVENTEMP

and OVEN SETcontrols are in any position other than OFF

will result in automatic ignition of the oven or broiler

burner.

In case of a power outage, you can light the surface

burners on your range with a match. Hold a lighted

match to the burner, then slowly turn the knob to the

LITEposition. Use extreme caution when lighting

burners this way.

Surface burner in use when electrical power failure occurs

will continue to operate normally.

The oven burner and broil burner on your range are

lighted by electrical ignition. The oven and broiler

cannot be operated in the event of a power failure.

1. Before Installing Screws

the Range

Remove shipping material

Remove all tape, shipping and

packaging materials and the

oven rack packaging. Lift up

cooktop and remove the two

shipping screws from the

cooktop burners (see figure 2). Figure 2

2. Provide an Adequate Gas Supply

This range is designed to operate on natural gas at 4" of

manifold pressure or on LPgas at 10" of manifold

pressure. It is shipped from the factory set for natural

gas. If it isto be used with LPgas, adjustments must be

made.

A convertible pressure regulator is connected in series

with the manifold of the range and must remain in series

with the supply line regardless of whether natural or LP

gas is being used.

For proper operation, the maximum inlet pressure to

the regulator must be no more than 14" of water column

(W.C.) pressure.

For checking the regulator, the inlet pressure must be at

least 1" water column pressure greater than the

regulator manifold outlet setting. If the regulator is set

for 4" of manifold pressure, the inlet pressure must be at

least 5". If the regulator isset for10", the inlet pressure

must be at least 11 ".

C. Because solid pipe restricts moving the range we

recommended use of A.G.A. design certified flexible

metal appliance connector. Connect flexible

appliance to flare union.

D. Move range into approximate position and connect

flexible appliance connector to gas supply line with

proper flare union adaptor. The adaptor supplied with

the flexible connector must be used.

E. Check for leaks. Turn the gas supply on the range

and use a liquid leak detector at all joints and

connections to check for leaks in the system.

3-Wire Polarized

120_ Outlet

32 7/8" _+Y4'

Pipe

20"

or Lower i

The gas supply line into the range should be 1/2"or 3A"

I.D. flexible metal appliance connector five feet in

length.

3. Seal the Openings

Seal any openings in the wall behind the range and in

the floor under the range when hookups are completed.

4. Connect the Range to Gas

Refer to figure 4 to 7 for recommended connections.

A. Install a manual shut-off valve in the gas line in an

easily accessible location outside of the range. Be

sure you know how and where to shut-off the gas

supply to the range.

B. Install Y2" flare union adaptor supplied with the

connector, to the Y2" NPT internal thread on pressure

regulator.

Gas Connection for Electric Ignition Models

FlareUnion Adaptor

Flexible Applia_nce Pressure

Connector Regulator

Figure 3

Recommended locations for installing the electrical

outlet and pipe opening may be adjusted to meet

specific requirements.

Figure 4

Do not use a flame to check for leaks

from gas connections. Checking for leaks withaflame

may result in a fire or explosion.

Disconnect this range and its individual shutoff

valve from the gas supply piping system during any

pressure testing of that system at test pressures greater

than 14" of water column pressure (approx. F2" psig).

isolate the range from the gas supply piping system

by closing its individual manual shutoff valve during any

pressure testing of the gas supply piping system at test

pressures equal to or lessthan 14" of water column

(approx. 1/2"psig).

Backof

Range

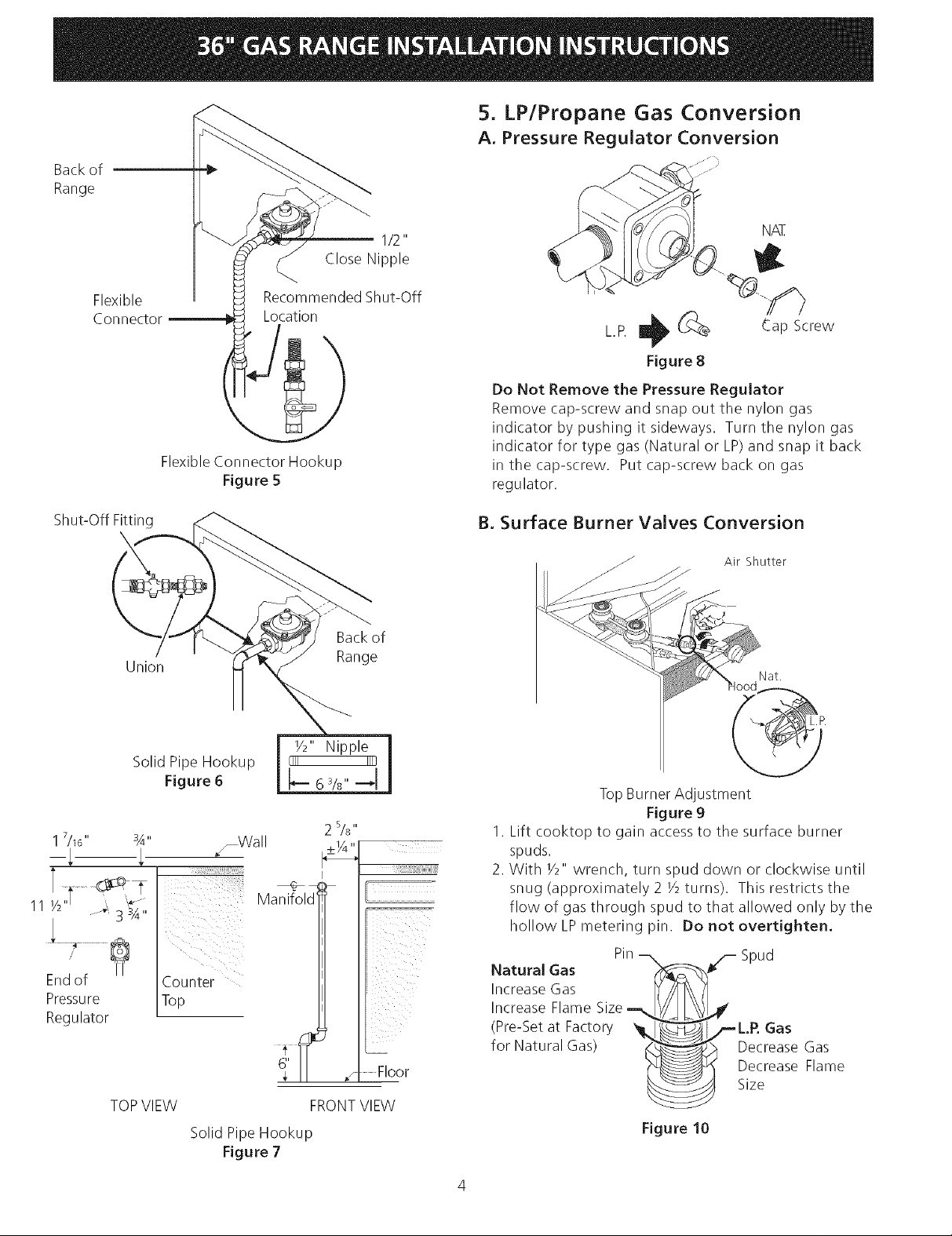

5. LP/Propane Gas Conversion

A. Pressure Regulator Conversion

Flexible

Connector

Union

Close Nipple

Recommended Shut-Off

_cation

Flexible Connector Hookup

Figure 5

Back of

Range

1/2"

NAT.

L.P. 1]]_ Cap Screw

Figure 8

Do Not Remove the Pressure Regulator

Remove cap-screw and snap out the nylon gas

indicator by pushing it sideways. Turn the nylon gas

indicator for type gas (Natural or LP)and snap it back

in the cap-screw. Put cap-screw back on gas

regulator.

B. Surface Burner Valves Conversion

Air Shutter

Nat.

1 7A6" sA,,

..........

End of

Pressure

Regulator

TOPVIEW FRONTVIEW

iii_ ii _!_?_iii_ii_i_!ii_i_!i_!i!i_i;i_i

Counter

Top

_WaU

Solid Pipe Hookup

Figure 7

2 5/8 "

it i_

Floor

Top Burner Adjustment

Figure 9

I. Lift cooktop to gain access to the surface burner

spuds.

2. With 1/2"wrench, turn spud down or clockwise until

snug (approximately 2 1/2turns). This restricts the

flow of gas through spud to that allowed only by the

hollow LP metering pin. Do not overtighten.

Pin

Natural Gas

Increase Gas

Increase Flame Size _,,

(Pre-Set at Factory

for Natural Gas)

Figure 10

!

A

_--LoP.Gas

Decrease Gas

Decrease Flame

Size

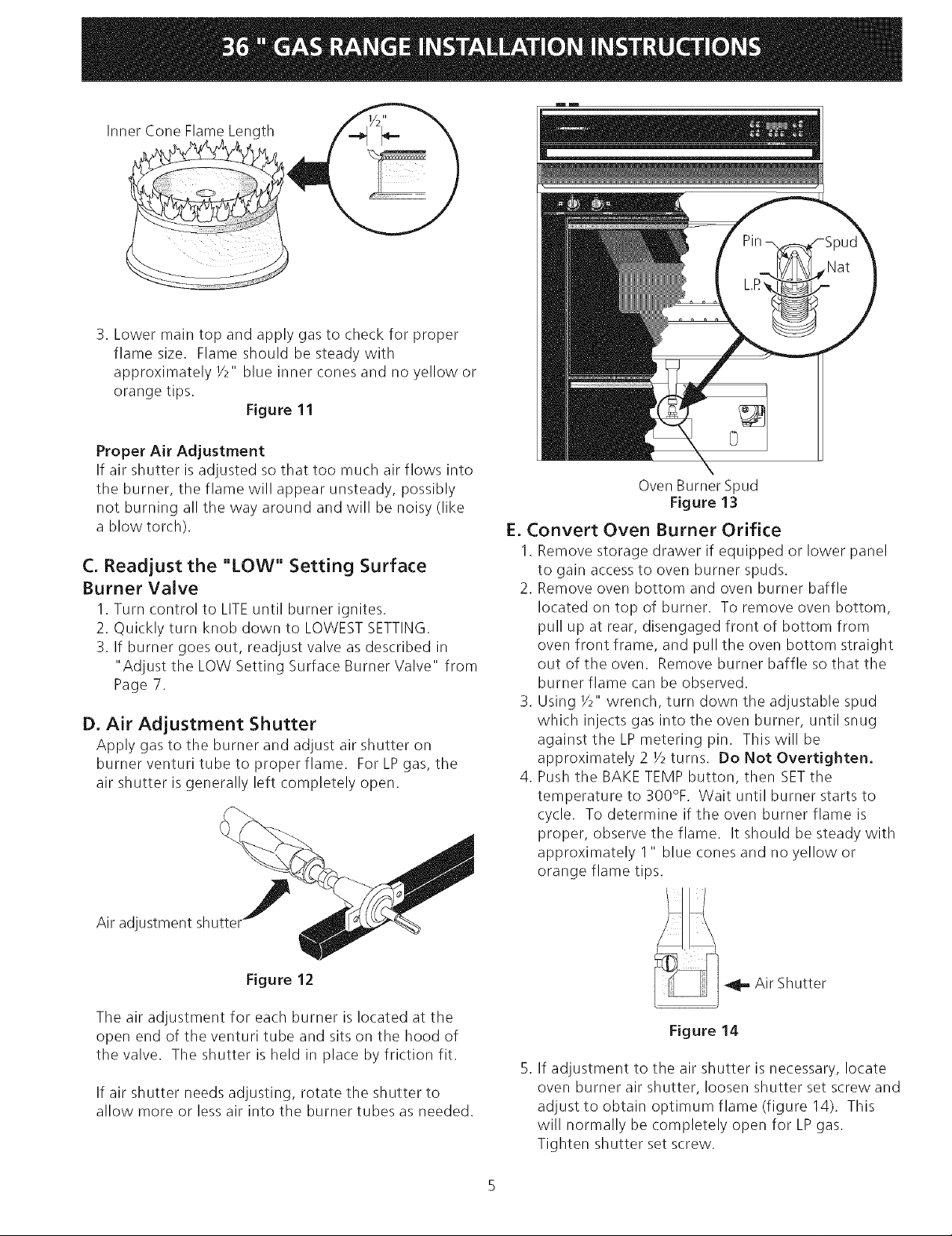

InnerCone Flame Length

3. Lower main top and apply gas to check for proper

flame size, Flame should be steady with

approximately 1/2" blue inner cones and no yellow or

orange tips.

Figure 11

Proper Air Adjustment

If air shutter is adjusted so that too much air flows into

the burner, the flame will appear unsteady, possibly

not burning all the way around and will be noisy (like

a blow torch).

C. Readjust the "LOW" Setting Surface

Burner Valve

1. Turn control to LITEuntil burner ignites.

2. Quickly turn knob down to LOWEST SETTING.

3. If burner goes out, readjust valve as described in

"Adjust the LOW Setting Surface Burner Valve" from

Page 7.

D. Air Adjustment Shutter

Apply gas to the burner and adjust air shutter on

burner venturi tube to proper flame. ForLPgas, the

air shutter is generally left completely open.

Oven Burner Spud

Figure 13

E. Convert Oven Burner Orifice

I. Remove storage drawer if equipped or lower panel

to gain access to oven burner spuds.

2. Remove oven bottom and oven burner baffle

located on top of burner. To remove oven bottom,

pull up at rear, disengaged front of bottom from

oven front frame, and pull the oven bottom straight

out of the oven. Remove burner baffle so that the

burner flame can be observed.

3. Using 1/2"wrench, turn down the adjustable spud

which injects gas into the oven burner, until snug

against the LP metering pin. This will be

approximately 2 1/2turns. Do Not Overtighten.

4 Push the BAKE TEMP button, then SETthe

temperature to 300% Wait until burner starts to

cycle To determine if the oven burner flame is

proper, observe the flame It should be steady with

approximately 1" blue cones and no yellow or

orange flame tips.

Air adjustment shutter _

Figure 12

The air adjustment for each burner is located at the

open end of the venturi tube and sits on the hood of

the valve. The shutter is held in place by friction fit.

If air shutter needs adjusting, rotate the shutter to

allow more or less air into the burner tubes as needed.

f _ Air Shutter

Figure 14

5. If adjustment to the air shutter is necessary, locate

oven burner air shutter, loosen shutter set screw and

adjust to obtain optimum flame (figure 14). This

will normally be completely open for LP gas.

Tighten shutter set screw.

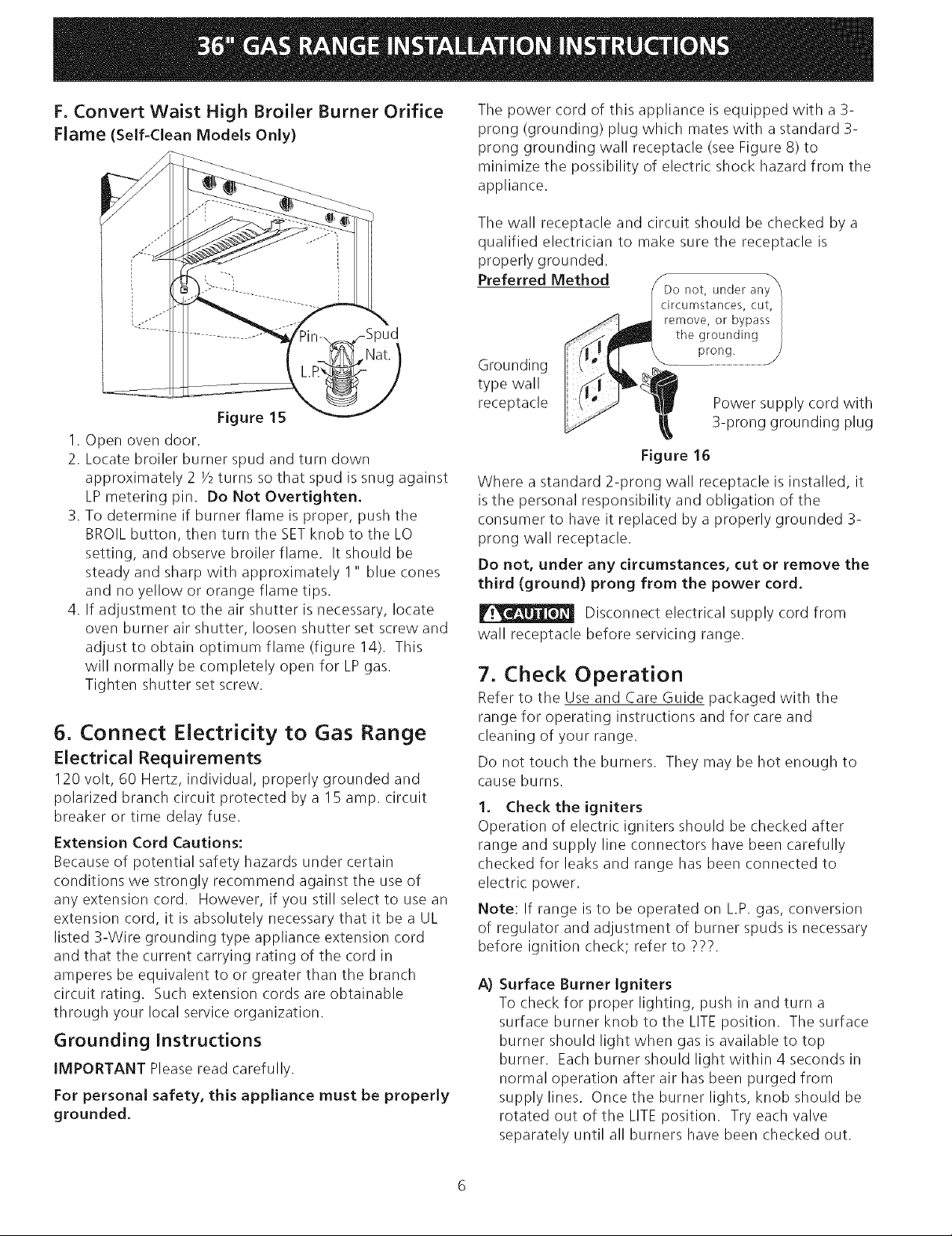

F. Convert Waist High BroiJer Burner Orifice

Flame (SeJf-Clean Models Only)

Figure 15

1. Open oven door.

2. Locate broiler burner spud and turn down

approximately 2 Y2turns so that spud is snug against

LPmetering pin. Do NotOvertighten.

3. To determine if burner flame is proper, push the

BROILbutton, then turn the SETknob to the LO

setting, and observe broiler flame. It should be

steady and sharp with approximately I " blue cones

and no yellow or orange flame tips.

4. If adjustment to the air shutter is necessary, locate

oven burner air shutter, loosen shutter set screw and

adjust to obtain optimum flame (figure 14). This

will normally be completely open for LP gas.

Tighten shutter set screw.

6. Connect Electricity to Gas Range

EJectrical Requirements

120 volt, 60 Hertz, individual, properly grounded and

polarized branch circuit protected by a 15 amp. circuit

breaker or time delay fuse.

Extension Cord Cautions:

Because of potential safety hazards under certain

conditions we strongly recommend against the use of

any extension cord. However, if you still select to use an

extension cord, it is absolutely necessary that it be a UL

listed 3-Wire grounding type appliance extension cord

and that the current carrying rating of the cord in

amperes be equivalent to or greater than the branch

circuit rating. Such extension cords are obtainable

through your local service organization.

Grounding Instructions

IMPORTANT Please read carefully.

For personal safety, this appliance must be properly

grounded.

The power cord of this appliance is equipped with a 3-

prong (grounding) plug which mates with a standard 3-

prong grounding wall receptacle (see Figure 8) to

minimize the possibility of electric shock hazard from the

appliance.

The wall receptacle and circuit should be checked by a

qualified electrician to make sure the receptacle is

properly grounded.

Preferred Method

Grounding

type wall

receptacle

f

Do not, under any

circumstances, cut,

remove, or bypass

the grounding

prong.

Power supply cord with

3-prong grounding plug

Figure 16

Where a standard 2-prong wall receptacle is installed, it

is the personal responsibility and obligation of the

consumer to have it replaced by a properly grounded 3-

prong wall receptacle.

Do not, under any circumstances, cut or remove the

third (ground) prong from the power cord.

Disconnect electrical supply cord from

wall receptacle before servicing range.

7. Check Operation

Refer to the Use and Care Guide packaged with the

range for operating instructions and for care and

cleaning of your range.

Do not touch the burners. They may be hot enough to

cause burns.

1. Check the igniters

Operation of electric igniters should be checked after

range and supply line connectors have been carefully

checked for leaks and range has been connected to

electric power.

Note: If range is to be operated on LP. gas, conversion

of regulator and adjustment of burner spuds is necessary

before ignition check; refer to ???.

A) Surface Burner Igniters

To check for proper lighting, push in and turn a

surface burner knob to the LITEposition. The surface

burner should light when gas is available to top

burner. Each burner should light within 4 seconds in

normal operation after air has been purged from

supply lines. Once the burner lights, knob should be

rotated out of the LITEposition. Try each valve

separately until all burners have been checked out.

Loading...

Loading...