Fiberglass Handles

1380 Beverage Drive, Suite W

Stone Mountain, GA 30083

1-800-426-6256 | 678-892-2323

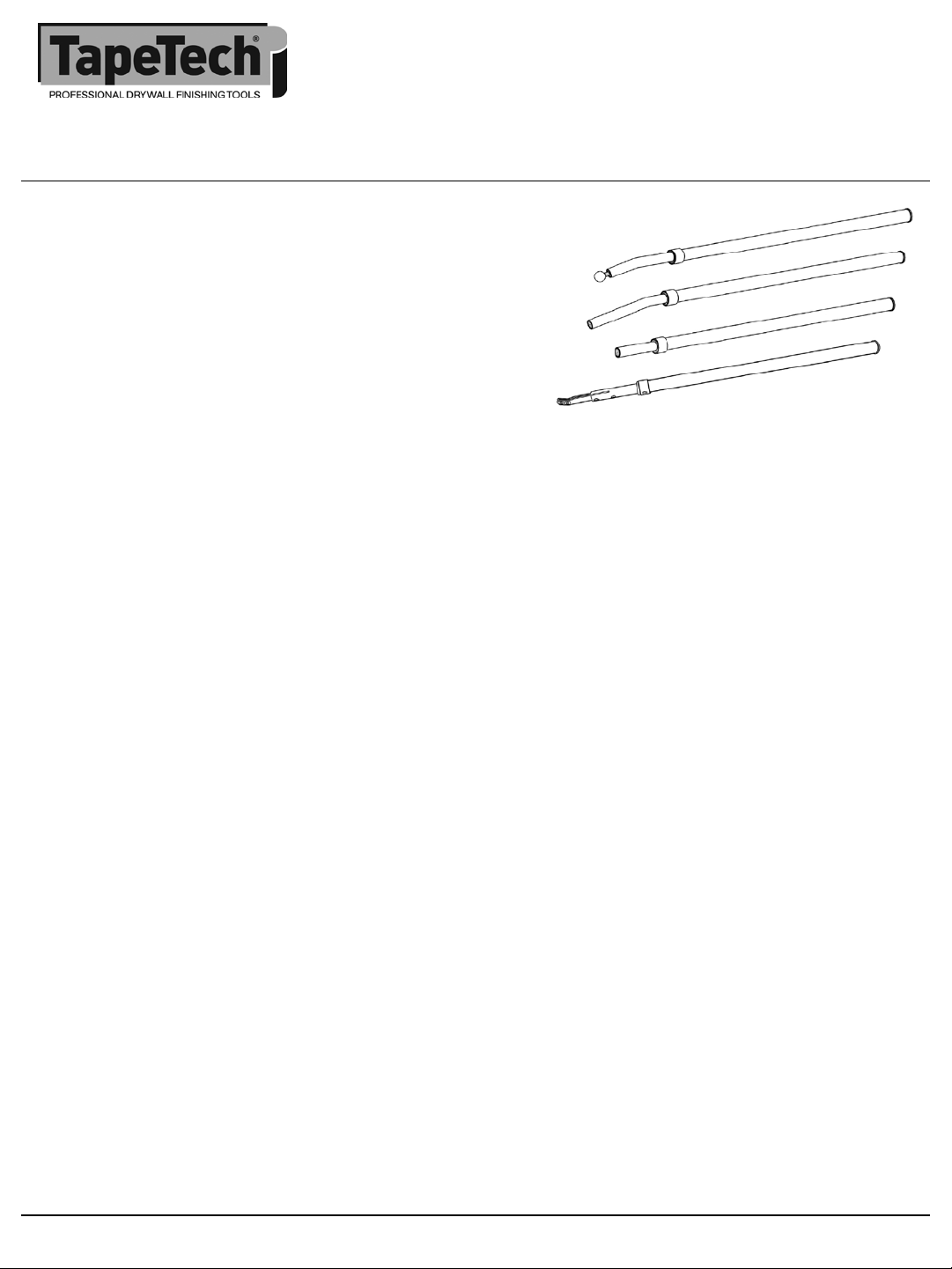

Models: HF, HA, HR, HN

The fiberglass handles are designed to fit corresponding tools. Made

of sturdy yet flexible fiberglass, they are durable and lightweight.

Operation and Maintenance Guide

Better – Faster – Every time

HF

HA

HR

HN

Operation

Corner Finisher Fiberglass Handle (HF)

Slide the ball retainer on the corner finisher upward and insert the ball of the corner finisher fiberglass

handle into the ball socket. Release pressure on the ball retainer to secure the corner finisher to the

handle. Reverse the process to remove.

Corner Applicator Fiberglass Handle (HA)

Attach the corner applicator fiberglass handle to the corner applicator by sliding the metal end of the

handle into the connector on the corner applicator. Tighten the thumbscrew to secure the handle to

the corner applicator. The bend in the handle should be oriented so that it is pointing toward the

internal corner when the tool is being used. Reverse the process to remove.

Corner Roller Fiberglass Handle (HR)

Attach the corner roller fiberglass handle to the corner roller by screwing the threaded fittings

together until snug. Reverse the process to remove.

Nail Spotter Fiberglass Handle (HN)

Attach the nail spotter fiberglass handle to the nail spotter body by inserting the metal tab of the nail

spotter handle between the two metal tabs on the back of the nails spotter. Insert the two screws and

tighten the locking nuts. Reverse the process to remove.

Maintenance

Clean thoroughly with brush and water (or water hose) to remove all joint compound from the tool.

After the tool is clean & dry, lightly oil the threads or contact points with Ames® Bazooka® Oil or any

light machine oil.

Updated 04 2012

www.tapetech.com

© 2012 TapeTech Tool Co. All Rights Reserved

Loading...

Loading...