EasyClean®, EasyClean® High Capacity &

EasyClean® Extra High Capacity Box

1380 Beverage Drive, Suite W

Stone Mountain, GA 30083

1-800-426-6256 | 678-892-2323

Models: 20TTX, 25TTX, 30TTX, 22TT, 27TT, 32TT,

EZ07H, EZ10H, EZ12H, EHC07, EHC10, EHC12

Operation and Maintenance Guide

Better – Faster – Every time

Updated 01 2014

BETTER

FASTER

EVERY TIME

www.tapetech.com

© 2014 TapeTech Tool Co. All Rights Reserved

EasyClean®, EasyClean® High Capacity &

EasyClean® Extra High Capacity Box

1380 Beverage Drive, Suite W

Stone Mountain, GA 30083

1-800-426-6256 | 678-892-2323

Models: 20TTX, 25TTX, 30TTX, 22TT, 27TT, 32TT, EZ07H, EZ10H, EZ12H, EHC07, EHC10, EHC12

Operation and Maintenance Guide

Better – Faster – Every time

Updated 01 2014

www.tapetech.com

© 2014 TapeTech Tool Co. All Rights Reserved

EasyClean®, EasyClean® High Capacity &

EasyClean® Extra High Capacity Box

1380 Beverage Drive, Suite W

Stone Mountain, GA 30083

1-800-426-6256 | 678-892-2323

Operation and Maintenance Guide

Better – Faster – Every time

Models: 20TTX, 25TTX, 30TTX, 22TT, 27TT, 32TT, EZ07H, EZ10H, EZ12H, EHC07, EHC10, EHC12

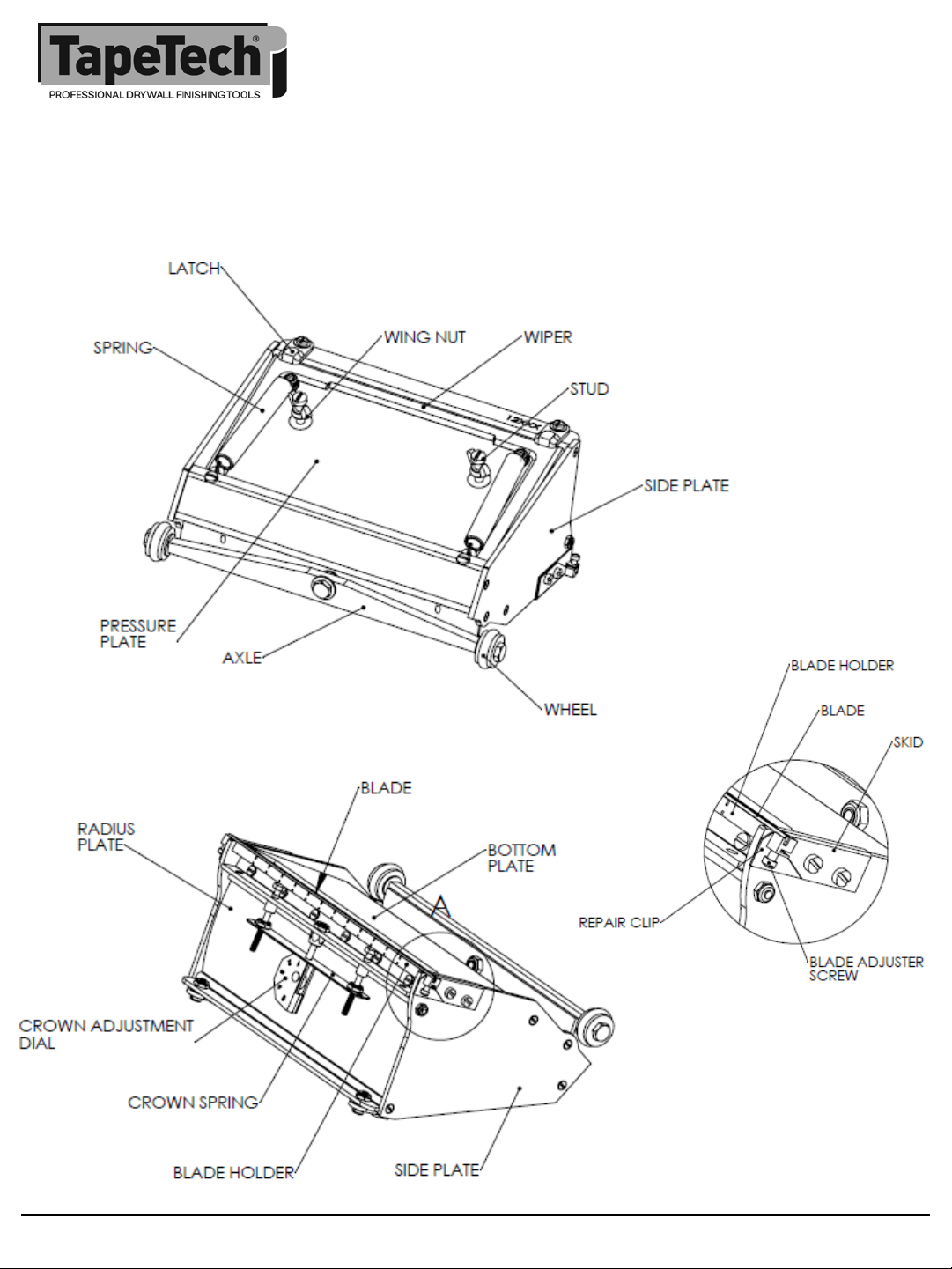

Operation

The EasyClean® finishing box , EasyClean® High Capacity and EasyClean®

Extra High Capacity Finishing boxes apply joint compound over taped joints.

They come in three widths, generally used for finishing as follows:

(175 mm): applies bed coat

7”

(250 mm): applies finish coat

10”

(300 mm): applies skim coat

12”

These tools require little effort to operate and are designed to produce uniform results every time. The

difference in the two boxes are their capacity and cleaning; the EasyClean® High Capacity Box and

Extra High Capacity Box holds more joint compound and is even easier to clean because the back

opens even more than the standard EasyClean™ boxes.

The boxes are controlled by a specially designed handle. These handles come in multiple lengths from

34” to 72” as well as an XTender™ Handle that adjusts between 41” and 63“. The handle is attached to

the box by sliding the box onto the handle and tightening the two wing nuts.

Load the box through the opening behind the blade using the box adapter with the slot adapter

inserted.

To apply compound, draw the box steadily along the joint while applying pressure with the handle.

This dispenses compound through the opening at a steady rate. The tool is always run with the wheels

leading and the blade trailing. The handle should lead the box, except at the end of joints.

The adjustable metal blade trowels the compound with the precise crown needed. This is set using the

crown adjustment wheel. This dial controls the amount of crown left by the box with #1 being the

most and #5 the least.

Before starting to run any joint, lock the box handle at a slight angle by squeezing the handle grip with

one hand. Your other hand should grip the handle near the box.

Place the box at the end of the joint and apply pressure with the handle to start the compound

flowing. Release the hand grip to unlock the handle and allow it to find its own natural position. Draw

the tool along the joint, leading with the handle and applying pressure to distribute the joint

compound onto the wallboard surface.

Near the middle of the joint, lock the handle and by gradually decreasing pressure, remove the box

from the wallboard surface with a sweeping motion.

Reverse hand positions and begin again at the other end of the joint. Again draw the box along until

you reach the previous stopping point. Lock the handle and remove the box from the surface with a

sweeping motion. This procedure is followed for all ceiling joints and horizontal wall joints.

Updated 01 2014

www.tapetech.com

© 2014 TapeTech Tool Co. All Rights Reserved

EasyClean®, EasyClean® High Capacity &

EasyClean® Extra High Capacity Box

1380 Beverage Drive, Suite W

Stone Mountain, GA 30083

1-800-426-6256 | 678-892-2323

Operation and Maintenance Guide

Better – Faster – Every time

Operation (continued)

To cover vertical wall joints, lock the handle and begin covering the joint from the bottom up to a

height of about 30” (.75 m), sweep off and begin again at the top of the joint.

Draw down the joint until you reach the previous stopping point. Then lock the handle and sweep off

the surface, neatly joining the two finished sections.

For door or window openings, always work from the corner, moving toward the opening. Just before

the wheels reach the opening, lock the handle and lift the wheels to keep them from dropping into the

opening, then sweep away from the wall.

Before starting the finish coat, lightly sand the dried topping coat to remove any small crumbs. Fill the

10” or 12” (250-300 mm) box and set the dial to #3 for a medium crown. Apply a finish coat to all

joints. For butt joints, apply a coat on either side of the center of the joint. After the two side by side

coats have dried, finish them with a 10” or 12” (250-300mm) skim coat over the center of the joint.

Reset the crown dial to #5 for a tight crown then cover the joints on the ceilings and walls.

Maintenance

To open the boxes for cleaning, simply turn the two latches on the back and pull open. Clean

thoroughly with a brush and water (or a water hose) to remove all joint compound from the tool.

Then, after the tool is clean, lightly oil with Ames® Bazooka® Oil or any light machine oil.

Box Blade Replacement

1. To remove the used blade, place the tip of a screwdriver against one end of the blade and tap the

screwdriver with the palm of your hand.

2. If the blade does not pop out, tighten the screw at one end of the brass blade holder, forcing the

end of the blade out. Back the screw up and again tap the end of the blade.

3. Use one end of the used blade to clean any dried compound from the blade holder slot.

4. Remove both right and left skids, but leave the repair clips in place.

5. Slightly bend the new blade approximately 2 inches from both ends. This will help secure the blade

while the tool is in use.

6. Start at one end, pressing the blade all the way into the blade holder, working to the other end.

Install new skids. The “dog ear” on the skids should press against the back side of the new

blade and be flush with the blade holder (about the thickness of a thumbnail lower than the blade

edge).

Common Wear Parts

7” (175mm) Stainless Steel Blade: 200001

10” (250mm) Stainless Steel Blade: 250001

12” (300mm) Stainless Steel Blade: 300001

Skid Cover (Right): 209006

Skid Cover (Left): 209039

Updated 01 2014

www.tapetech.com

© 2014 TapeTech Tool Co. All Rights Reserved

Loading...

Loading...