Repair

Pump for Drywall Feed Pump System

- For water-based materials only -

- Not for use in explosive atmospheres -

- Not for use with quick-set materials -

READ ALL WARNINGS AND INSTRUCTIONS

Read all warnings and instructions in this manual.

Save these instructions.

Maximum Working Pressure 2500 psi (17.2 MPa, 172 bar)

Model 24E957

3A0912A

ENG

ti15866a

Warning

Warning

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point

symbol alerts you to a general warning and the hazard symbols refer to procedure-specific risks. When these symbols

appear in the body of this manual, refer back to these Warnings. Product-specific hazard symbols and warnings not covered in this section may appear throughout the body of this manual where applicable.

WARNING

WARNINGWARNINGWARNING

ELECTRIC SHOCK HAZARD

This equipment must be grounded. Improper grounding, setup, or usage of the system can cause electric

shock.

• Turn off and disconnect power cord before servicing equipment.

• Use only grounded electrical outlets.

• Use only 3-wire extension cords.

• Ensure ground prongs are intact on power and extension cords.

• Do not expose to rain. Store indoors.

SKIN INJECTION HAZARD

High-pressure fluid from dispensing device, hose leaks, or ruptured components will pierce skin. This may look

like just a cut, but it is a serious injury that can result in amputation. Get immediate surgical treatment.

• Engage trigger lock when not dispensing.

• Do not point dispensing device at anyone or at any part of the body.

• Do not put your hand over the fluid outlet.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

• Follow the Pressure Relief Procedure when you stop dispensing and before cleaning, checking, or

servicing equipment.

• Tighten all fluid connections before operating the equipment.

• Check hoses and couplings daily. Replace worn or damaged parts immediately.

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help prevent fire and

explosion:

• Do not dispense flammable or combustible materials near an open flame or sources of ignition such as

cigarettes, motors, and electrical equipment.

• Material or solvent flowing through the equipment is able to result in static electricity. Static electricity

creates a risk of fire or explosion in the presence of material or solvent fumes. All parts of the system,

including the pump, hose assembly, dispenser, and objects in and around the work area shall be properly

grounded to protect against static discharge and sparks. Use Graco conductive or grounded high-pressure

airless material hoses.

• Verify that all containers and collection systems are grounded to prevent static discharge.

• Connect to a grounded outlet and use grounded extensions cords. Do not use a 3-to-2 adapter.

• Do not use a material or a solvent containing halogenated hydrocarbons.

• Keep work area well-ventilated. Keep a good supply of fresh air moving through the area. Keep pump

assembly in a well ventilated area.

• Do not smoke in the work area.

• Do not operate light switches, engines, or similar spark producing products in the work area.

• Keep area clean and free of material or solvent containers, rags, and other flammable materials.

• Know the contents of the materials and solvents being dispensed. Read all Material Safety Data Sheets

(MSDS) and container labels provided with the materials and solvents. Follow the material and solvents

manufacturer’s safety instructions.

• Fire extinguisher equipment shall be present and working.

• Drywall feed pump generates sparks. When flammable liquid is used in or near the drywall feed pump or for

flushing or cleaning, keep unit at least 20 feet (6 m) away from explosive vapors.

2 3A0912A

Warning

WARNING

WARNINGWARNINGWARNING

MOVING PARTS HAZARD

Moving parts can pinch, cut or amputate fingers and other body parts.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Pressurized equipment can start without warning. Before checking, moving, or servicing equipment, follow the

Pressure Relief Procedure and disconnect all power sources.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Always wear appropriate gloves, eye protection, and a respirator or mask when dispensing.

• Do not operate or dispense near children. Keep children away from equipment at all times.

• Do not overreach or stand on an unstable support. Keep effective footing and balance at all times.

• Stay alert and watch what you are doing.

• Do not leave the unit energized or under pressure while unattended. When the unit is not in use, turn off the unit

and follow the Pressure Relief Procedure for turning off the unit.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not kink or over-bend the hose.

• Do not expose the hose to temperatures or to pressures in excess of those specified by Graco.

• Do not use the hose as a strength member to pull or lift the equipment.

PRESSURIZED ALUMINUM PARTS HAZARD

Use of fluids that are incompatible with aluminum in pressurized equipment can cause serious chemical reaction and

equipment rupture. Failure to follow this warning can result in death, serious injury, or property damage.

• Do not use 1,1,1-trichloroethane, methylene chloride, other halogenated hydrocarbon solvents or fluids containing

such solvents.

• Many other fluids may contain chemicals that can react with aluminum. Contact your material supplier for

compatibility.

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when operating, servicing, or when in the operating area of the

equipment to help protect you from serious injury, including eye injury, hearing loss, inhalation of toxic fumes, and

burns. This equipment includes but is not limited to:

• Protective eyewear, and hearing protection.

• Respirators, protective clothing, and gloves as recommended by the fluid and solvent manufacturer.

3A0912A 3

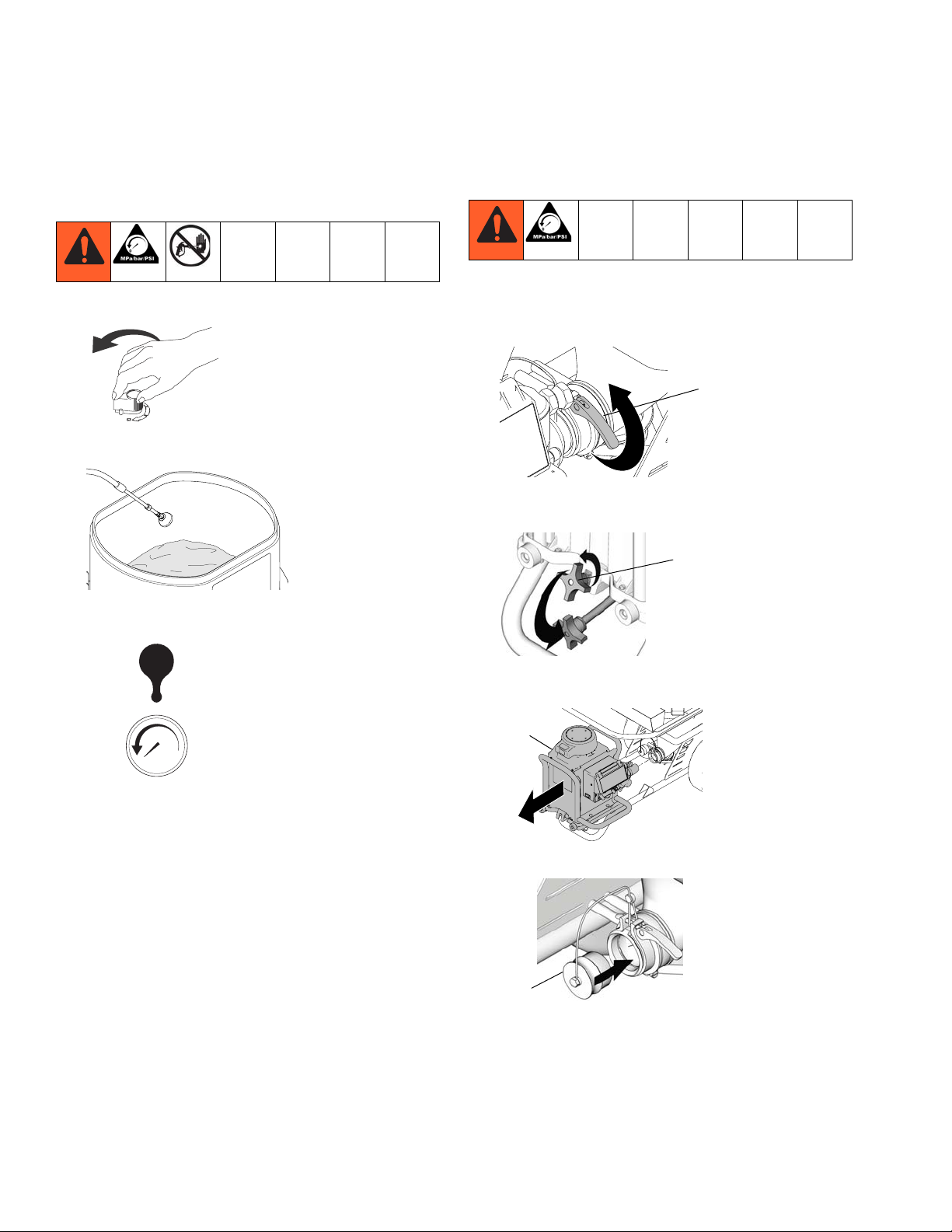

Pressure Relief Procedure

Pressure Relief

Procedure

1. Turn flow control knob to fully counterclockwise.

ti8793a

2. Place deflector in hopper or suitable container.

ti14876a

Power Module Removal

1. Perform Pressure Relief Procedure. Unplug power

cord.

2. Release hopper adapter clamp (158).

158

ti15684a

3. Loosen rod clamp knob (112) on front of pump module and push rod down.

112

3. Turn prime valve handle to PRESSURE RELIEF

position.

bar/psi

4. Display will read “----” when all pressure is relieved.

ti15614a

ti11675a

4. Lift and pull power module (153) off of unit.

NOTE: Power module weighs approximately 85 lb.

153

ti15623a

5. Install hopper plug (117) if needed.

117

ti15623a

4 3A0912A

Pump Removal

Power Module Installation

1. Remove hopper plug (117) if installed.

2. Replace power (153) module and insert pump outlet

into hopper inlet.

153

ti15625a

3. Pull rod clamp up and tighten knob (112) on front of

pump module.

112

ti11678a

4. Fasten hopper adapter clamp (158).

4. Loosen two screws (40) and remove pump rod

shield (48).

40

48

ti15619a

5. Turn flow control knob to a very low setting and turn

prime valve handle to TOOL FILL position (JOG

mode will appear in display). Use ON/OFF switch or

turn control knob OFF to stop pump when pin is

visible.

ti15620a

6. Use screwdriver to press pin (7b) out of pump.

7b

ti15617a

158

ti15683a

Pump Removal

1. Perform Pressure Relief Procedure, see page 4.

2. Remove Power Module, see page 4.

3. Disconnect material hose (79) from pump (18a).

79

NOTE: Pin should be removed by pressing the pin

out through the bottom side of the pump. Make sure

to control the pump pin when removing so that it

does not fall into the pump module.

7. Use hammer to loosen pump retaining nut (22).

22

ti15615a

8. Unscrew and remove pump (18a) from module.

18a

ti15618a

18a

ti15616a

3A0912A 5

Pump Removal

Pump Installation

1. Extend pump piston rod 1.5 in.

1.5 in.

ti7171a

2. Install pump pin (7b). Verify retaining spring is in

groove of connecting rod.

7b

ti13093a

NOTE: Pin should be installed from the top side of the

pump. Make sure to control the pump pin when installing

so that it does not fall into the pump module.

3. Push pump up until pump threads engage.

5. Align pump outlet to right side so that hose can be

reassembled.

ti15923a

6. Screw jam nut up toward drive housing until nut

stops. Tighten jam nut by hand, then tap 1/8

to 1/4 turn with a 20 oz. (maximum) hammer to

approximately 75± 5 ft-lb (102 N•m).

ti15925a

7. Replace pump rod shield (48) and torque two

screws (40) to 30 - 34 in-lb.

ti15924a

4. Screw in pump until threads are flush with drive

housing opening.

ti15621a

40

48

ti15619a

8. Reconnect material hose (79) to pump (18a).

79

18a

ti15616a

9. Replace Power Module, see page 5.

6 3A0912A

Pump Service

Pump Service

Disassemble the Pump

1. Perform Pressure Relief Procedure, page 4.

2. Perform Power Module Removal, page 4.

3. Perform Pump Removal, page 5.

4. Remove packing nut (312) and throat adjustment

spacer (302).

312

7. Tap piston rod out of cylinder with a hammer or flip

over and tap piston rod out against a bench.

8. Remove piston (311) from sleeve (306), or remove

sleeve from cylinder.

311

306

5. Unscrew intake valve (319) from cylinder (304).

304

319

6. Disassemble intake valve (319). Clean and inspect.

O-ring (315a) may require a pick for removal.

NOTE: if seat and ball need to be replaced, Carbide

Repair Kit 24F268 is available.

315a

319

COMPONENT RUPTURE HAZARD

Do not clean or wipe the piston valve threads. Cleaning

the piston valve threads could destroy the special sealing

patch and cause the piston valve to come loose during

operation, causing pump bursting and possible bodily

injury.

9. Unscrew piston valve (313) from piston rod (311).

Clean and inspect parts. The piston has a special

thread locking/sealing patch. Do not remove the

patch. The patch allows four disassembly/assembly

procedures before it is necessary to apply sealant to

threads.

313

311

3A0912A 7

Pump Service

10. Remove packings and glands from piston rod.

Discard packings and glands. Remove piston wiper

and back-up washer from piston rod. Discard piston

wiper and back-up washer.

11. Remove throat packings and glands from cylinder.

Discard throat packings and glands.

2. Install ball (315c) in piston rod. If thread sealant is

applied to piston valve threads, ensure that none

gets on ball.

315c

3. Tighten piston valve to 55 +/- 3 ft-lb.

Assemble the Pump

1. Soak all leather packings in SAE 30W oil for 1 hour

minimum prior to assembly. Stack male gland (315k)

on piston rod. Alternately stack UHMWPE and

packings (note orientation) on piston rod. Install

female gland (315f). The special sealing patch on

piston valve threads is good for four repackings.

Install piston wiper (315e) and back-up washer.

315f

315e

315j

315k

315g

4. Soak all leather packings in SAE 30W oil for 1 hour

minimum prior to assembly. Place male gland

(315p) in cylinder. Alternately stack UHMWPE and

packings (note orientation). Place female gland

(315g) in top of cylinder. Seat packings.

315q

315j

315g

315p

5. Install packing nut (312). Install throat adjustment

spacer (302) onto packing nut. Loosely install packing nut into cylinder.

312

302

8 3A0912A

Pump Service

6. Grease piston packings and sleeve top edge.

7. Carefully slide piston assembly into top of sleeve.

8. Grease top inch or two of piston rod that will go

through the cylinder throat packings.

10. Reassemble intake valve with new o-ring (315a),

seat (309a) and ball (315b). Seat may be flipped

over and used on other side. Clean seat thoroughly.

Place intake spring (315r) on top of ball guide (317).

317r

317

315b

309a

315a

11. Install intake valve on cylinder. If a wrench is used,

torque to 200 +/- 15 ft-lb. If a wrench is not used, be

sure intake valve is tight against cylinder.

9. Grease o-ring (315m) and place on sleeve. Slide

sleeve/piston rod assembly into bottom of cylinder.

Replace o-ring (315n) if desired. NOTE: O-ring

(315n) is not required for safe pump operation.

315m

12. Torque seal and packing nut (312) down onto throat

adjustment spacer (302) to 140 +/- 10 in-lb. Remove

throat adjustment spacer (302) when pump packings begin to leak after too much use. Then tighten

packing nut down until leakage stops or lessens.

This allows approximately 100 gallons of additional

operation before a repacking is required.

312

302

3A0912A 9

Pump 24E957 Service Reference

Pump 24E957

Service Reference

301

312

302

325

315q

315g315g315g315g

315p

311

326

304

315m

306

315j315j315j

315j315j315j

315k

315g315g315g315g

315f

315e

315d

315h

315c

313

315r

317

315b

309a

315a

315n

319

Pump 24E957 Parts List

Ref. Part Description Qty.

301 183171 PLUG 1

302 C20987 PACKING, o-ring 1

304 15W463 HOUSING, outlet 1

306 248979 SLEEVE, cylinder, chrome 1

309 24F268 KIT, seat, carbide

(includes 309a, 315a, 315b)

309a 15J038 SEAT, carbide 1

311 15W925 ROD, piston 1

312 15W963 NUT, packing 1

313 249177 VALVE, piston 1

315 24F267 KIT, pump repair

(includes 315a - 315r)

315a 107098 PACKING, o-ring 1

315b 102972 BALL, metallic 1

315c 107203 BALL, valve, check 1

315d 15J800 WASHER, back-up

315e 119636 WIPER, piston 1

315f 189588 GLAND, packing, female 1

315g 193722 PACKING, vee 8

315h 158918 SPRING, compression 1

315j 112591 PACKING, vee 6

315k 189585 GLAND, packing, male 1

315m 108822 PACKING, o-ring 2

315n 160325 PACKING, o-ring 1

315p 198768 GLAND, male 1

315q 194175 GLAND, female 1

315r 24E027 SPRING, intake ball 1

317 198505 GUIDE, ball 1

319 15X124 HOUSING, inlet 1

325 15D117 TUBE, fiber, pump 1

326 15Y925 FITTING, 5/8 jic x 1/2 npt 1

1

1

1

315m

Technical Data (Pump)

Maximum working pressure 2500 psi (172 bar, 17.2 MPa)

Fluid outlet size 1/2 npt(f)

Wetted parts stainless steel, PTFE, leather, zinc-plated carbon steel,

tungsten carbide, chrome plating, UHMWPE, nickel-plated iron, nickel-plated

carbon steel

10 3A0912A

Notes

Notes

3A0912A 11

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs will

be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED

TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite

de ou en rapport, directement ou indirectement, avec les procédures concernées.

Graco Information

For the latest information about Graco products, visit www.graco.com.

TO PLACE AN ORDER, contact your Graco distributor or call 1-800-690-2894 to identify the nearest distributor.

All written and visual data contained in this document reflects the latest product information available at the time of publication.

Graco reserves the right to make changes at any time without notice.

Original instructions. This manual contains English. MM 3A0912

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440-1441

Copyright 2010, Graco Inc. is registered to ISO 9001

www.graco.com

Loading...

Loading...