Finishing Box Handles

1380 Beverage Drive, Suite W

Stone Mountain, GA 30083

1-800-426-6256 | 678-892-2323

Models: 8034TT, 8042TT, 8054TT, 8072TT, 8134TT, 8142TT, 8154TT, 8172TT

Operation and Maintenance Guide

Better – Faster – Every time

Updated 04 2012

www.tapetech.com

© 2012 TapeTech Tool Co. All Rights Reserved

Finishing Box Handles

1380 Beverage Drive, Suite W

Stone Mountain, GA 30083

1-800-426-6256 | 678-892-2323

Models: 8034TT, 8042TT, 8054TT, 8072TT, 8134TT, 8142TT, 8154TT, 8172TT

Operation and Maintenance Guide

Better – Faster – Every time

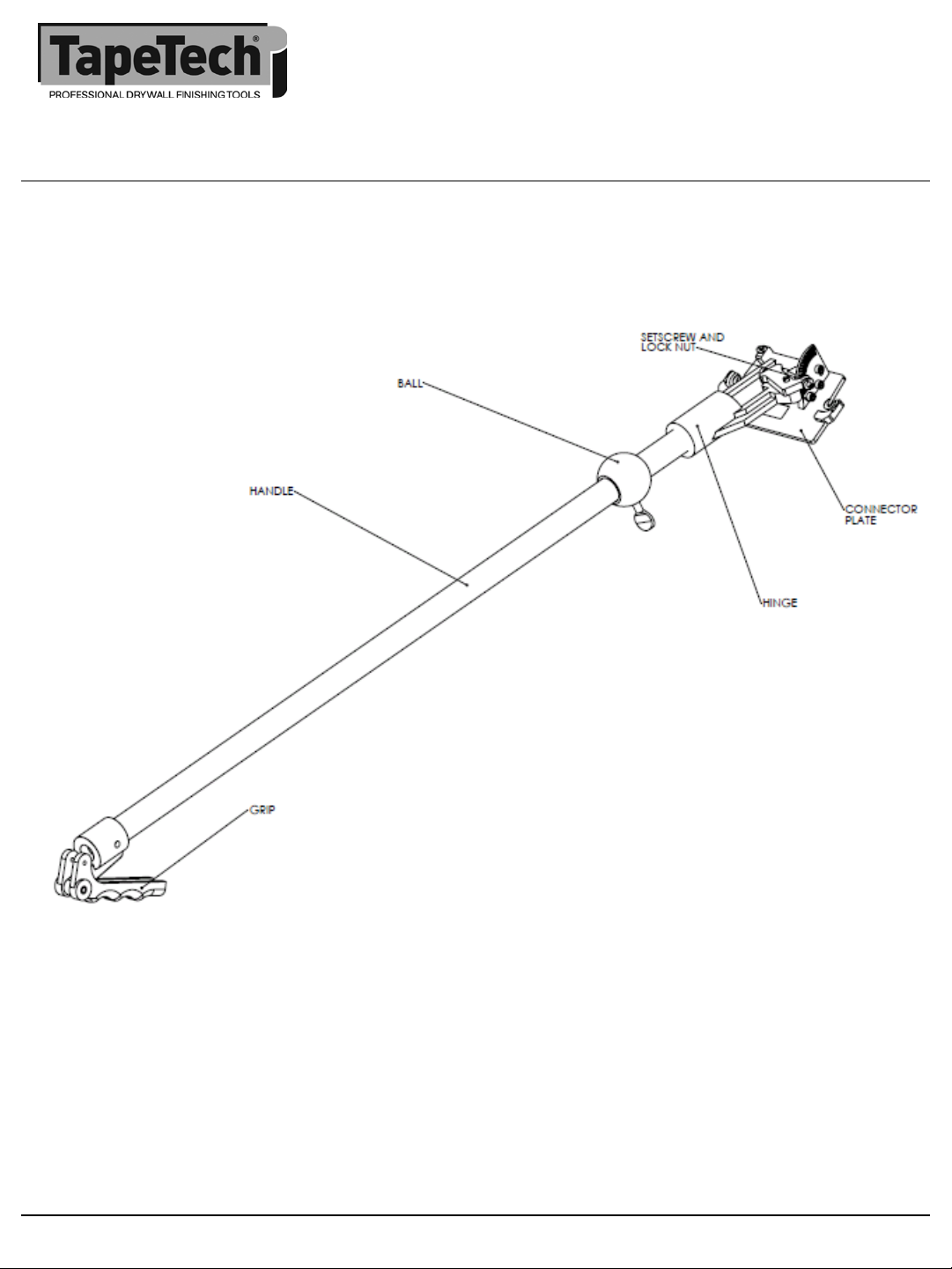

Operation

The finishing box is controlled by specially designed handles,

ranging from 34” to 72” (1-2 m), allowing heights of up to 12’

(4 m) to be finished from the floor. The handle is attached to the finishing

box by sliding the box onto the handle and tightening the wing nuts securely.

There are only two adjustments on the finishing box handle. First is the set screw in the pivot

arm, which may be screwed in or out to adjust the width of the brake locking handle. Next is the

aluminum ball on the handle which may be moved up or down the handle to ease operation of

the finishing box.

Maintenance

Clean thoroughly with brush and water (or water hose) to remove all joint compound from the tool.

Then, after the tool is clean, lightly oil with Ames® Bazooka® Oil or any light machine oil.

Updated 04 2012

www.tapetech.com

© 2012 TapeTech Tool Co. All Rights Reserved

Loading...

Loading...