EasyClean™ Pump & Filler Adapter

1380 Beverage Drive, Suite W

Stone Mountain, GA 30083

1-800-426-6256 | 770-243-2323

Models: 76TT (Pump) & 90T (Filler)

Operation and Maintenance Guide

Better – Faster – Every time

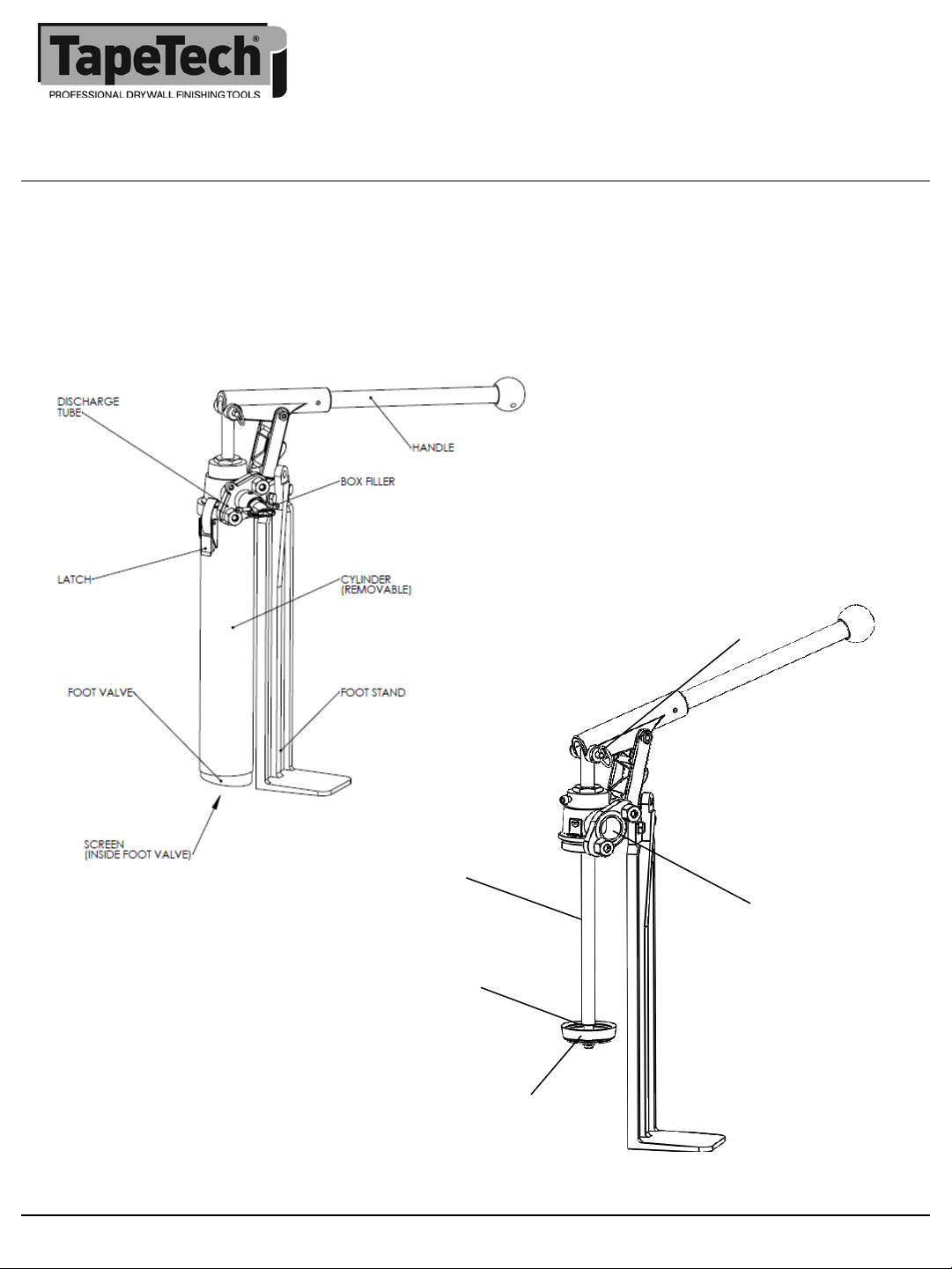

PULL PIN

Updated 01 2014

PUMP SHAFT

VALVE D ISK

PISTON CUP

www.tapetech.com

DISCHARGE FLANGE

(DISCHARGE TUBE OR

GOOSENECK MOUNTS

HERE)

© 2014 TapeTech Tool Co. All Rights Reserved

EasyClean™ Pump & Filler Adapter

1380 Beverage Drive, Suite W

Stone Mountain, GA 30083

1-800-426-6256 | 770-243-2323

Models: 76TT (Pump) & 90T (Filler)

Operation and Maintenance Guide

Better – Faster – Every time

Operation

With its two nozzles, the EasyClean™ Pump fills nail spotters, automatic tapers, flat boxes,

corner applicators and the MudRunner®

The filler attachment is secured to the EasyClean™ Pump by aligning the slots of the filler

over the studs on the EasyClean™ Pump housing and tightening the two hex nuts. There

is no additional gasket required between the EasyClean™ Pump and the filler .

Place the EasyClean™ Pump in a standard five gallon bucket, making sure the joint

compound is well mixed and free of lumps. A new or freshly cleaned EasyClean™ Pump

should be primed before use by pouring 1/2 cup (100 ml) of water into the outlet.

Once the EasyClean™ Pump is full of joint compound, no further priming is needed.

Maintenance

The EasyClean™ Pump can be disassembled by disengaging the two clasps at the top of the EasyClean®

Pump and pulling the barrel away from the main EasyClean™ Pump body. The plunger can then be

removed by disengaging the quick release pin and sliding the plunger through the EasyClean™ Pump

housing.

The foot valve can be removed by twisting and pulling the valve down and away from the cylinder.

The EasyClean™ Pump can now be cleaned by using a water hose or water and a brush to remove the

joint compound from the EasyClean® Pump housing and plunger. Then, after the tool is clean, lightly

oil with Ames® Bazooka® Oil or any light machine oil. To keep your EasyClean™ Pump in top working

order, you may need to replace the screen and o-rings on your EasyClean™ Pump. These items should

be checked when you clean your EasyClean™ Pump.

Common Wear Parts

Screen (Fine): 700032F

Screen (Coarse): 700033F

O-Ring: 729071

O-Ring: 729072

O-Ring: 709034

These wear parts are available as a maintenance kit - Model 501J.

Updated 01 2014

www.tapetech.com

© 2014 TapeTech Tool Co. All Rights Reserved

Loading...

Loading...