EasyRoll™ Corner Finisher

1380 Beverage Drive, Suite W

Stone Mountain, GA 30083

1-800-426-6256 | 678-892-2323

Operation and Maintenance Guide

Models: 48TT & 48XTT

Better – Faster – Every time

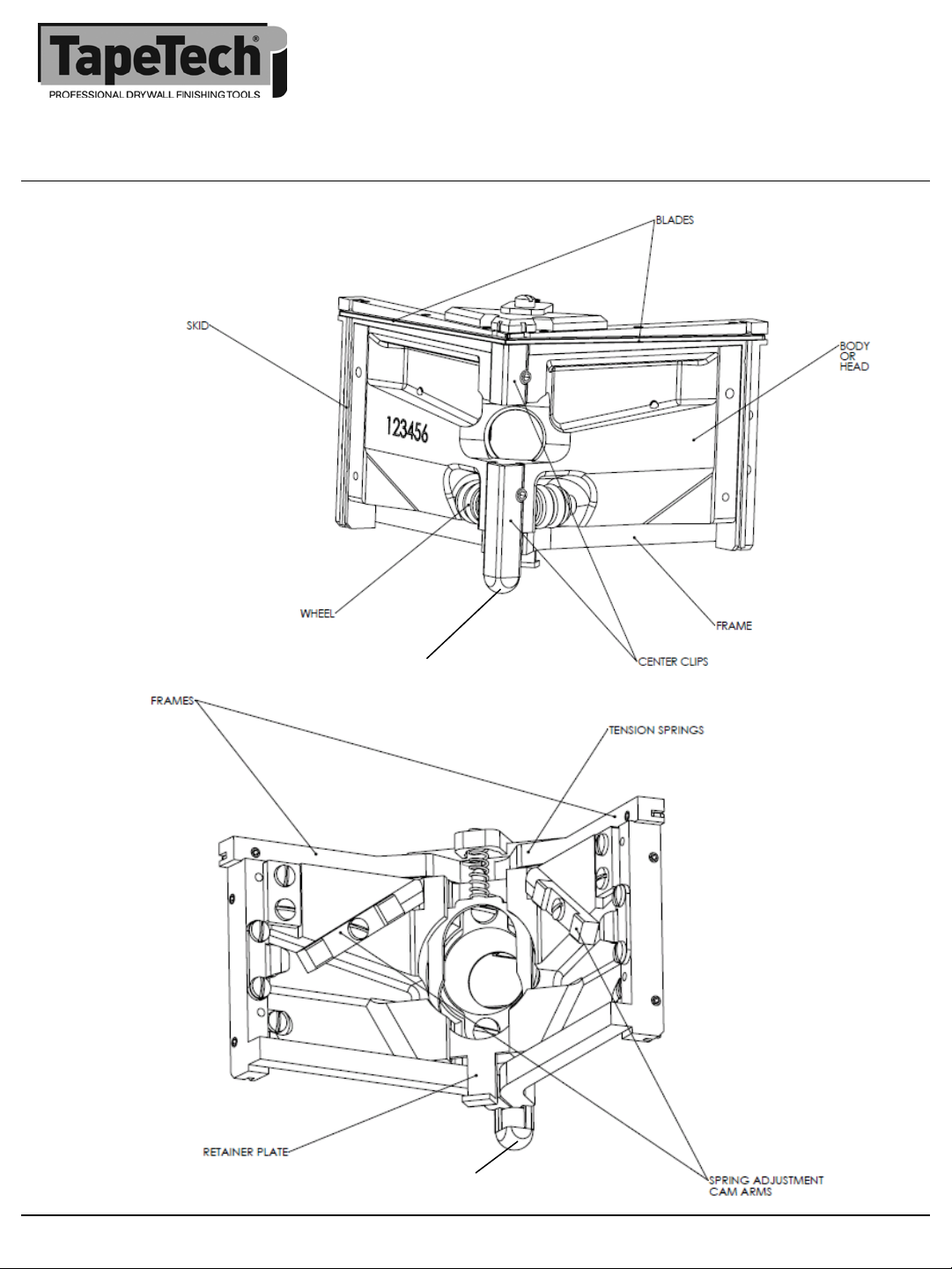

NOSE or BULLET

Updated 04 2012

NOSE or BULLET

www.tapetech.com

© 2012 TapeTech Tool Co. All Rights Reserved

EasyRoll™ Corner Finisher

1380 Beverage Drive, Suite W

Stone Mountain, GA 30083

1-800-426-6256 | 678-892-2323

Models: 48TT & 48XTT

Operation and Maintenance Guide

Better – Faster – Every time

Operation

The 3” (75 mm) and 3 ½” (89 mm)EasyRoll™ adjustable corner finishers

(models 48TT and 48XTT) are designed to wipe down and feather both

sides of an internal corner in one pass. The “adjustable” feature of this tool

refers to the ability to control the amount of spring pressure by engaging or

disengaging one set of tension springs on the back of the corner finisher.

The adjustable corner finisher is used in conjunction with the corner applicator (model 35TT or 50TT)

or the MudRunner ™(model 14TT) to apply the finish coat over the internal corners. The model 48TT

can also be used to follow the corner roller and wipe down excess compound left when the tape is

embedded in the corner. The spring action compensates for corners that are slightly over or under 90

degrees and the blade design produces smoothly feathered corners.

When using the 48TT to wipe down internal corners after the corner roller, snap the corner finisher

onto the ball-end handle (model HF or HFRE) and set the spring tension by moving both spring tension

cams to a vertical position which allows only one spring to exert pressure on the blade holders.

Use the corner finisher as a plow, with the nose end leading. Work from the bottom to the top of

vertical corners and from one end to the other on ceiling corners. Detail wall and ceiling corner

intersections with a drywall knife.

After the tape coat has dried, the adjustable corner finisher is used in conjunction with the corner

applicator (model 35TT or 50TT) or the MudRunner® to apply the finish coat over the internal corners.

Snap the adjustable corner finisher onto the ball-end of the corner applicator or MudRunner™ and fill

the applicator with joint compound. Reset the spring tension by moving both spring tension cams to a

horizontal position, which allows both springs to exert pressure on the blade holders.

With the wheels and nose end of the corner finisher leading, start on the bottom of the vertical angle

and apply pressure to the corner applicator or twist the MudRunner® grip to start the flow of

compound, while moving the tool along the corner. About 3 feet (1 m) from the floor, release the

pressure on the corner applicator and sweep it away from the corner. Then, starting at the top of the

angle, pull the tool down the corner and release the pressure when you reach the compound left

on the previous pass. Now sweep the corner applicator and corner finisher away from the corner.

Ceiling corners are finished using the same methods. Detail wall and ceiling corner intersections with a

drywall knife.

Maintenance

Clean thoroughly after every use, with a brush and water (or a water hose) to remove all joint

compound from the tool. Then, after the tool is clean, lightly oil with Ames® Bazooka® Oil or any

light machine oil.

Updated 04 2012

www.tapetech.com

© 2012 TapeTech Tool Co. All Rights Reserved

Loading...

Loading...