MudRunner®

1380 Beverage Drive, Suite W

Stone Mountain, GA 30083

1-800-426-6256 | 678-892-2323

Model: 14TT

Operation and Maintenance Guide

Better – Faster – Every time

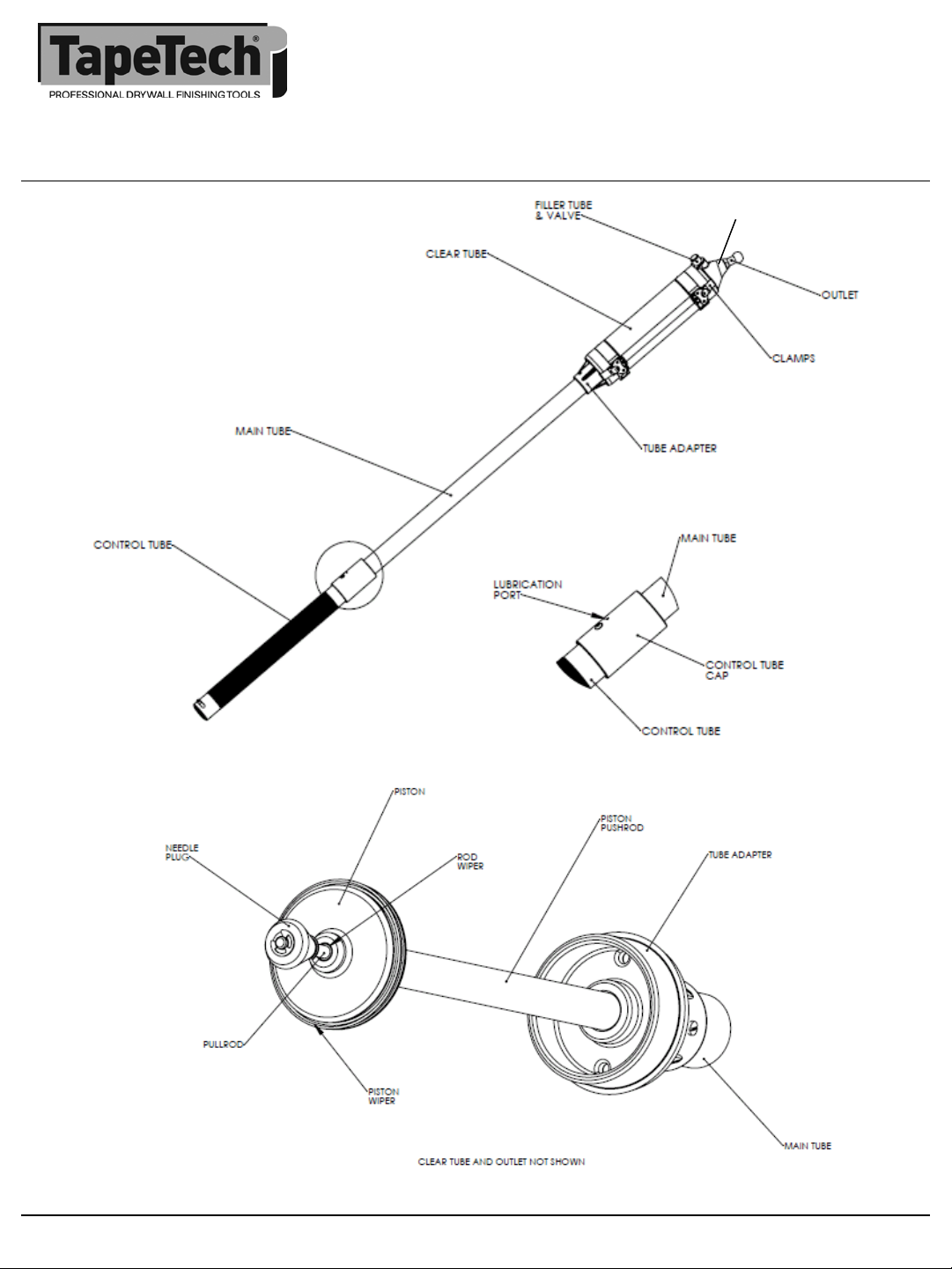

MAIN TUBE CAP

Updated 04 2012

www.tapetech.com

© 2012 TapeTech Tool Co. All Rights Reserved

MudRunner®

1380 Beverage Drive, Suite W

Stone Mountain, GA 30083

1-800-426-6256 | 678-892-2323

Models: 14TT

The MudRunner® is essentially a power-assisted corner applicator and is intended

to work with corner finishers and mud heads.

Operation and Maintenance Guide

Better – Faster – Every time

Operation

In general, you will want to use joint compound thicker than you would normally use for

finishing corners. To start, it is recommended to thin the compound to about midway between

the consistency you normally use for corner finishers and finishing boxes. This varies based on

personal preference and the brand of joint compound you typically use.

To fill the MudRunner® with compound, insert the filler valve fully into the discharge tube of the

Loading Pump. You will need to maintain pressure against the Loading Pump as the MudRunner® is

filled or the pumping pressure will force the MudRunner® off of the filler valve.

Whenever there is any compound in the tool, it is under constant pressure from the internal gas

spring. Pump until the MudRunner® piston is forced all the way back to its stop. Once full, do not

continue pumping. Attach the finishing tool to the ball outlet of the MudRunner®. Compound flow is

controlled by twisting the control tube. The more you twist, the faster compound flows.

Place the tool at one end of the joint to be finished with the filler valve pointing away from the corner.

Twist the control tube. If you are using the corner finisher or mud head for the first time or after it has

been cleaned, you may want to wait an instant until you see compound filling it. Move the tool toward

the other end of the joint, relaxing your grip on the control tube when you wish compound flow to

stop. The outlet valve will automatically close off compound flow as you relax your grip. Place the tool

at the other end of the joint and repeat, relaxing your grip on the control tube when you have

overlapped the point where the previous pass ended.

Maintenance

It is good practice to empty the tool if it is not going to be used for a time. The outlet end of the tool

can be placed in a bucket of water. However, DON’T SUBMERGE THE HANDLE END OF THE TOOL! The

handle end can be sprayed with water, but should not be submerged. Do not directly spray the white

cover at the top end of the control tube. Should water find its way into the handle, stand the handle

up vertically to allow it to drain.

Clean the tool by removing the main tube cap. Clean all compound from the inside of the cap, the filler

valve and around the piston. If compound has gotten on the backside of the piston, remove the main

tube and clean as needed. Lubricate the rubber piston seal with Ames® Bazooka® oil or any light

machine oil.

Keep the area around the white cover clean. Avoid flushing joint compound or debris under the white

cover as it may make operation of the control tube more difficult. Lubricate the control mechanism as

shown after every cleaning and as needed to maintain proper operation of the tool. Replace the main

tube and the main tube cap as soon as the tool is clean to reduce the chances of damaging the tool.

Updated 04 2012

www.tapetech.com

© 2012 TapeTech Tool Co. All Rights Reserved

Loading...

Loading...