Release 7/2009 Ver. 1.0 Technical Manual: GS-120 Light Curtain Systems

GS-120 Photo-Electric Light Curtain Systems

Technical Manual

WARNING

Tapeswitch photo-electric safety systems are intended to protect operators working at or near

dangerous machinery. They can only perform this function if they are correctly fitted to a

suitable machine. It is essential that the full contents of this manual and all the international

documents referred to herein are fully understood before any attempt at installation is made.

If in doubt, contact Tapeswitch Corporation.

IMPORTANT

This manual must accompany the product throughout its working life. Those persons

responsible for the product must ensure that all persons involved in the installation,

commissioning, operation, maintenance and servicing of the product have access to all the

information supplied by the manufacturers of the machine and its safety system.

Release 7/2009 Ver. 1.0 Technical Manual: GS-120 Light Curtain Systems

TABLE OF CONTENTS

1.0 GENERAL

1.1 INTRODUCTION 4

1.2 PRODUCT Range

1.2.1 General 4

1.2.2 Detection Capability 5

1.2.3 Protected Heights

1.2.4 Accessories 5

1.2.4.1 Mirror Units 5

1.2.4.2 Mounting Stands 7

5

1.3 ORDERING INFORMATION

1.32 GS-120 Multi-Beam Order Code 8

1.3.3 Cable Options 9

1.3.4 Interface and Programming Units 9

1.3.1 GS-120 Light Curtain Order Code 8

4

7

2.0 TECHNICAL DESCRIPTION

9

2.1 CURTAIN 9

2.2 COMMUNICATIONS

2.3 TEST INPUT

2.4 INDICATORS

2.4.1 LED Option 11

2.4.2 Diagnostic Option 12

3.0 INSTALLATION

10

10

11

13

3.1 GENERAL 13

3.2 MECHANICAL INSTALLATION

13

3.2.1 General Considerations 13

3.2.1.1 Multi-Sided Guarding 15

3.2.2 Curtain Dimensions 16

3.2.2.1 GS-120 Basic Syste m 16

3.2.2.2 GS-120 Multi-Beam System 17

3.2.2.3 GS-120 Cascaded System 18

3.2.3 Separation Distance 19

3.2.3.1 Normal Approach 19

3.2.3.2 Parallel Approach 21

3.2.3.3 Angled Approach 22

3.2.3.4 Approach to ‘L’ Installation 22

3.2.4 Optical Alignment 23

3.2.5 Reflective Surfaces 23

3.2.6 Systems in Close Proximity 24

3.2.7 Mounting Brackets 24

3.3 ELECTRICAL INTERFACE, OPERATION, AND INSTALLATION 27

3.3.1 General 27

3.3.2 Emitter Unit 27

3.3.2.1 General 27

3.3.2.2. Test Input 28

3.3.3 Receiver Unit 28

3.3.3.1 General 28

3.3.3.2 PNP Version 29

3.3.3.3 SSR Version 30

3.3.4 Interfacing to a Machine 31

3.34.1 PNP Version Manual Reset 31

3.34.2 PNP Version Auto Reset 32

3.34.3 SSR Version 33

3.4 INITIAL CHECKING AND ALIGNMENT 34

4.0 INTERFACE AND AUXILIARY UNITS 35

4.1 GENERAL 35

4.1.2 Special Interfacing Considerations 36

4.1.1 Methods of Interfacing 35

TAPESWITCH CORPORATION Phone: 631-630-0442

100 Schmitt Boulevard

Farmingdale, New York 11735 www.tapeswitch.com

2 Fax: 631-630-0454

Release 7/2009 Ver. 1.0 Technical Manual: GS-120 Light Curtain Systems

4.1.2.1 PNP Version Manual Reset 36

4.1.2.2 PNP Version Auto Reset 36

4.1.2.3 SSR Version 36

4.1.3 Connections to an AS-i System 37

5.0 PERIODIC CHECKING, SERVICING, AND MAINTENANCE 38

5.1 PERIODIC CHECKING 38

5.1.1 Commissioning Checks 38

5.1.2 6 or 12 Month Periodic Checks 38

5.1.3 Daily/Setting Examination 39

5.1.4 Checking Detection Capability 39

5.1.4.1 GS-120 System 39

5.1.4.2 GS-120 Multi-Beam System 40

5.2 SERVICING 41

5.3 MAINTENANCE

6.0 TECHNICAL SPECIFICATIONS (GS-120Series Emitter & Receiver) 42

APPENDIX A: BSRSA INTERFACE UNIT

APPENDIX B: BSRUA-2 INTERFACE UNIT

APPENDIX C: SRUB INTERFACE UNIT

APPENDIX D: SRUS INTERFACE UNIT

APPENDIX E: C6 MULTIFUNCTION INTERFACE CONTROLLER

APPENDIX F: GDC-1 24 VDC POWER SUPPLY

APPENDIX G: LAT LAS ER A LI G N ME NT TOOL

41

43

49

57

63

67

68

69

TAPESWITCH CORPORATION Phone: 631-630-0442

100 Schmitt Boulevard

Farmingdale, New York 11735 www.tapeswitch.com

3 Fax: 631-630-0454

Release 7/2009 Ver. 1.0 Technical Manual: GS-120 Light Curtain Systems

1.0 GENERAL

1.1 INTRODUCTION

Tapeswitch GS-120 light curtains are through-beam

photo-electric machine gu arding devices, designed to

protect operators working at or near dangerous

machinery. They m eet the requirements for EN61496

Type 2 light curtains and Category 3 safety control units

as defined in EN954-1.

When correctly installed on a suitable machine, the

system will detect a person (or part of a person) ente ring

a dangerous area in the vicinity of the machine, and will

signal the dangerous motion to cease before that

person can reach a position where injury could occur.

Tapeswitch GS-120 light curtains use infra-red

technology. A curtain of infra-red light is projected

across the dangerous area. Intrusion into this curtain by

a person or part of a person will be detected by the

system. This will cause safety output signals to be

generated which will stop t he dangero us m otion of the

machine.

WARNING

The information in this manual relates to the

use of the basic GS-120 light c urtain, to provi de

a basic safety switching device.

In some applications, a GS-120 light curtain

may be used together with other Tapeswitch

equipment to provide additional functions and

features. The additional information nec essary

for the correct use of a GS-120 light curtain

when used with other Tapeswitch equipme nt is

provided within this manual.

In such cases, some installation parameters,

notably the mounting position of the light

curtain in relation to the dangerous part of the

machine, can be affected and close attention

must be paid to all the information supplied

with all equipment.

INTERNATIONAL CONSIDERATION: The heritage of

the Tapeswitch GS-120 system is strongly grounded in

international commerce and standards. They were

developed by Tapeswitch Ltd., of Chorley, England.

Both Tapeswitch Ltd . and Tapes witch U.S. are p art of

Indel Corporation, a private U.S industrial group . The

GS-120 product line was d eve lo ped t o meet published

and proposed safet y standards for the United States,

Germany, England, Finland, and Sweden, as well as the

common market unified standard. GS-120 systems are

manufactured both in Eng land and the United States.

Tapeswitch GS-120 products have been independently

third party tested to IEC 61496 by BG, and are certified

to this standard (CE approval/certification). Contact

Tapeswitch for more details.

Tapeswitch can provide additional assistance to

customers wishing to use GS-120 guards in

international applications. Some foreign language

technical manuals are available.

1.2 PRODUCT RANGE

1.2.1 GENERAL

The GS-120 light curtains are available in a rang e of

different protected heights and detection capabilities.

These two parameters are known by many other names

and therefore it ma y be useful to def ine them here, as

they are intended to be us ed in th is m anual. T o make

this clearer it is also necessary to define two further

parameters, detection zone and operating range:

Detection Zone: This is the actual curtain of infra-red

light generated between t he em itter and receiver u nits

within which an appropriately dimensioned obj ect will be

reliably detected and, for the GS-120, can be

considered to be a two dimensio nal, r ectangular plane

(see Figure 1).

Operating Range: One dimension of the detection

zone rectangle is given b y the distance between the

emitter and receiver units . T his is the operat ing ra nge

(see Figure 1).

Protected Height: The other dimension of the

detection zone rectangle is commonly known as the

protected height. The word “height” has been adopted

in the latest standards for this equipment because most

curtains are mounted vertically. The protected height is

often related to, but is not the same as, the length of the

emitter and receiver units (see Figure 1).

TAPESWITCH CORPORATION Phone: 631-630-0442

100 Schmitt Boulevard

Farmingdale, New York 11735 www.tapeswitch.com

4 Fax: 631-630-0454

Release 7/2009 Ver. 1.0 Technical Manual: GS-120 Light Curtain Systems

Figure 1

Detection Capability: This is the minimum dimension

of an opaque object which will be reliably detected

anywhere within the detection zone.

NOTE: The spacing or pitch of the beams or lenses in a

light curtain is not the same as the detection capability.

The detection capability is always greater than the

spacing or pitch. Spacing or pitch should not be used in

the calculation of separation distances (see Figure 2).

1.2.2 DETECTION CAPABILITY

GS-120 light curtains are available with detection

capabilities of 30mm or 70mm.

Figure 2

TAPESWITCH CORPORATION Phone: 631-630-0442

100 Schmitt Boulevard

Farmingdale, New York 11735 www.tapeswitch.com

1.2.3 PROTECTED HEIGHTS

GS-120 light curtains are available with nominal

protected heights as follows:

Detection Capability Nominal protected heights

(in mm and inches)

30mm (1-3/16 in.) 200-300-400-600-800-900 1000-1200-1400-1600 mm

(8-12-16-24-32-36-40-48-56 64-72 inches)

70mm (2-3/4 in.) 600-800-1000-1200-1400 1600-1800 mm

(24-32-40-48-56-64-72

inches)

The minimum separation distance is 0.5 m.

Note:

The actual protected hei ght is 8 mm greater than the

nominal protected height.

1.2.4 ACCESSORIES

1.2.4.1 Mirror Units

A range of mirr or units ar e avail ab le t o en ab le a s ingle

curtain to be used to guard two or three sides of a

machine or to avoid structural obstructions.

The mirror assem bly consists of a high quality silverbacked glass mir ror adhesive ly attach ed to a le ngth of

extruded aluminum . Two pivot brackets ar e bolted to

the aluminum extrusion and can be adjusted anywhere

along the length for mechanical attachment. The actual

length of the mirror is 4 inches (1000mm) larger tha n the

active curtain length to accommodate a wide tolerance

for height alignment. Al l of the necess ary hardwar e is

supplied to facilitate mounting to the mounting/floor

stands. The dimensions of the pivot brackets, extruded

aluminum and overall mirrors are shown below in

millimeters.

5 Fax: 631-630-0454

Release 7/2009 Ver. 1.0 Technical Manual: GS-120 Light Curtain Systems

40mm

6.8mm

40mm

6.8mm

X

Glass Refl ecti v e

Su rface

Overall Length =

Prot ec tive Height + 4"

180° Rotation

in t his Plan e

Pivot Brackets

(180° Rot at io n;

Dis t anc e X is Adjust abl e)

Suppl ied wi t h:

1. 1-40m m x 40m m e xt rusion, 100m m la rger t han

protec t ive heig ht .

2. 1-s il v e r bac k ed mi rror, 100m m larger t han

protec t ive heig ht .

3. 2-pivot joi nts .

4. 2-40m m x 40m m e nd covers .

5. 4-5m m T s l ot nuts .

6. 4-#12 f la t was hers .

7. 4-5mm s pring washers.

8. 4-5m m x 5/ 8 hex bol ts.

Curtain Lengths

Mirror Asse mb ly

Length

P/N

200mm - 8" 300mm - 12" 0960

300mm - 12" 400mm - 16" 0961

400mm - 16" 500mm - 20" 0962

600mm - 24" 700mm - 28" 0963

800mm - 32" 900mm - 36" 0964

900mm - 36" 1000mm - 40" 0965

1000mm - 40" 1100mm - 44" 0966

1200mm - 48" 1300mm - 52" 0967

1400mm - 56" 1500mm - 60" 0968

Pivot Bracket

Extrusion Dimensions

TAPESWITCH CORPORATION Phone: 631-630-0442

100 Schmitt Boulevard

Farmingdale, New York 11735 www.tapeswitch.com

For units greater than 56 inches, custom mirrors are available.

6 Fax: 631-630-0454

Release 7/2009 Ver. 1.0 Technical Manual: GS-120 Light Curtain Systems

3/8" holes

3 lev eling bolts

P/ N 0957

Supplied with:

1. 5 ft. item 40mm X 40mm extrusion

2. 1-base stand.

3. 1-40mm X 40mm end cap.

4. 2-T slot nuts M5.

5. 2-M5 X12mm hex head.

6. 2-M5 spring lock washers.

7. 2-fl at washers 5/5.3mm.

8. 2-5/16 bolts.

9. 3-3/8 24 x 1/2" hex head.

5"

5"

5

4"

4"

1.2.4.2 Mounting Stands

Floor mounting stands are ava ilable f or use where the

guard cannot be mounted directly to the machine.

The mounting stand set includes a floor-mounted base

into which the 5-foot mounting post can be secured.

The floor base is steel and can be permanently mounted

to the floor surface with the pre-drilled mounting holes.

The post is extrud ed aluminum with slots to allow the

light curtain to be positioned anywhere along its length.

The mounting stands are supplied with all of the

necessary hardware to fac ilitate mounting a standard

GS-120 light curtain. Leveling bolts allow for minor

adjustments to the floor stand orientation.

1.3 ORD E RING INFORMATION

Part numbers for the various m odels are s hown in t he

table on the right. To fully specify a model and its

options use an order code as shown in sections 1. 3.1

and 1.3.2 on the following page.

Model Number Part Number

GS-120/8”(208mm)/30 0801

GS-120/12”(308mm)/30 0802

GS-120/16”(408mm)/30 0803

GS-120/24”(608mm)/30 0804

GS-120/32”(808mm)/30 0805

GS-120/36”(908mm)/30 0806

GS-120/40”(1008mm)/30 0807

GS-120/48”(1208mm)/30 0808

GS-120/56”(1408mm)/30 0809

GS-120/64”(1608mm)/30 0810

GS-120/72”(1808mm)/30 0811

GS-120/24”(608mm)/70 0821

GS-120/32”(808mm)/70 0822

GS-120/40”(1008mm)/70 0823

GS-120/48”(1208mm)/70 0824

GS-120/56”(1408mm)/70 0825

GS-120/64”(1608mm)/70 0826

GS-120/72”(1808mm)/70 0827

GS-120-4 0828

GS-120-3 0829

GS-120-2 0830

TAPESWITCH CORPORATION Phone: 631-630-0442

100 Schmitt Boulevard

Farmingdale, New York 11735 www.tapeswitch.com

7 Fax: 631-630-0454

Release 7/2009 Ver. 1.0 Technical Manual: GS-120 Light Curtain Systems

1.3.1 GS-120 LIGHT CURTAIN ORDER CODE

GS120 /

Outputs:

PNP = 2 x PNP outputs

SSR = 2 x Solid-State Relays

Curtain Type:

S = Single Unit

M = Master Unit

A = Slave Unit

D = Double-Ended Slave Unit

Curtain Length:

200 mm to 1800 mm

Detection Capability:

30 mm or 70 mm

Curtain Display:

LED - Discrete LEDs

DIAG - Dot Matrix Diagnostic Display

Bracket options:

CB = Clamp Bracket

AB = Adjustable Bracket

EB = End Cap Bracket

XXX / X / XXXX / XX / XXXX / XX

1.3.2 GS-120 MULTI-BEAM ORDER CODE

GS120 /

XXX / X / X / XXXX / XX

Outputs:

PNP = 2 x PNP outputs

SSR = 2 x Solid-State Relays

Curtain Type:

S = Single Unit

M = Master Unit

A = Slave Unit

D = Double-Ended Slave Unit

Number of Beams:

2

3

4

Curtain Display:

LED - Discrete LEDs

DIAG - Dot Matrix Diagnostic Display

Bracket options:

CB = Clamp bracket

AB = Adjustable bracket

EB = End cap bracket

TAPESWITCH CORPORATION Phone: 631-630-0442

100 Schmitt Boulevard

Farmingdale, New York 11735 www.tapeswitch.com

8 Fax: 631-630-0454

Release 7/2009 Ver. 1.0 Technical Manual: GS-120 Light Curtain Systems

1.3.3 CABLE OPTIONS

Cable assemblies are used to connect the GS-120

emitter and receiver units to a c ontroller or machine.

The emitter has a 5-wire cable and the receiver has an

8-wire cable. One end of each cable has a keyed quickdisconnect connector and the other end is unterminated.

The cables are IP68 rated, and UL and CSA

recognized.

Order cable options using the following part numbers:

Description Part Number

Emitter Cable, 15 ft, 5 Conductor 0972

Emitter Cable, 30 ft, 5 Conductor 0973

Emitter Cable, 98 ft, 5 Conductor 0976

Receiver Cable, 15 ft, 8 Conductor 0974

Receiver Cable, 30 ft, 8 Conductor 0975

Receiver Cable, 98 ft, 8 Conductor 0977

1.3.4 INTERFACE AND PROGRAMMING

UNITS

(See electrical interface and operation for technical

details)

Order interface and programming units using the

following part numbers:

Model Description Part Number

BSRSA

Wall-mounted box

0950

110/240 Vac or 24 Vdc

BSRUA-2

DIN rail mount

0951

110/240 Vac or 24 Vdc

SRUB

DIN rail mount

0952

24 Vdc

SRUS

DIN rail mount

0949

24 Vdc

C6

Wall-mounted box

0480

Multi-zone

GDC1

LAT

24 Vdc power supply

Laser alignment tool

0953

0956

2.0 TECHNICAL DESCRIPTION

2.1 CURTAIN

A basic GS-120 light c urtain consis ts of two uni ts: an

emitter unit and a receiver unit. Both units are identical

in shape and size. T he units are enclosed in a rob ust

extruded aluminum section with reinforced composite

end covers.

The emitter and receiver units together generate a

curtain of infra-red light b etween t hem. This curtain is

mounted in such a position in relation to the dangerous

parts of a machine that a person or part of a person

approaching those dangerous parts must first penetrate

the curtain. This penetr ation is detected by the light

curtain system and, b y means of its output switching

devices, the light curtain system causes the dangerous

parts to go to a safe state (e.g. by stopping moving

parts) before the person can reach them.

IMPORTANT

From the information above, it can be seen

that safe use of a light curtain relies not only

on the safety integri ty of the cur tain its elf but

also on its proper mechan ical and electrical

interfacing to the machine.

The safety integrity of the light curta in itse lf is

the responsibility of Tapeswitch and the

remainder of this section describes the

features of the design by which safety

integrity is ensured.

Proper mechanical and el ectrical inte rfacing

of the overall system is the responsibility of

the user. Comprehensive information for t his

purpose is provided in sections 3 and 4 of

this manual.

The emitter unit contains a number of infra-red light

emitting diodes (LEDs) . The quantity and spacing of

these LEDs depends on the protected height and the

detection capabilit y of the particular light curt ain. The

devices are arranged equally-spaced in an array.

The receiver unit cont ains a corresponding number of

infra-red photodiodes similarly arranged.

TAPESWITCH CORPORATION Phone: 631-630-0442

100 Schmitt Boulevard

Farmingdale, New York 11735 www.tapeswitch.com

9 Fax: 631-630-0454

Release 7/2009 Ver. 1.0 Technical Manual: GS-120 Light Curtain Systems

Each LED and photodiode is fitted with a precision lens,

which produces an evenly intense, slightly diverging

beam of infra-red l ight from each LED and a n evenly

sensitive, slightly converging ‘reception cone’ into each

photodiode. This arr ange m ent provides a high s igna l to-noise ratio and maximum operating range for the

system together with ease of alignment and rejection of

extraneous reflected light sources.

The function of each LED and photodiode is controlled

by its own dedicated, specially-designed ASIC

(Application Specific Integrated Circuit). All the circuitry

necessary for the operation of an LED or photodiode is

contained within this sin gle component, resulting in a

very low component count and consequent

improvement in system reliability.

For each LED in the emitter unit there is a

corresponding photodiode at the same relative position

in the receiver unit. Each LED/photodiode pair makes a

‘beam’ and the curtain is made up of a number of such

beams, all parallel to each other. (See Figure 3.)

Figure 3

Only one LED and one photodiod e are active at any

time. The emitter unit runs independently from the

receiver unit. There are no c onnections between the

units.

The emitter unit activa tes each of its LEDs in turn and

the receiver unit synchronizes with the emitter unit.

Each receiver ASIC, in its turn, generates an output

signal which is pro portional to the level of infra-r ed it

receives from its corresponding LED. Signals from

other sources, such as background lighting, are filtered

out inside the ASIC.

There is one microprocessor in the emitter unit and two

in the receiver unit. All thr e e microprocessors perf orm

exhaustive checks on their own hardware and software,

prior to and during operation.

The two in the receiver unit continually communicate

their results to each other suc h that if a f ault occur s in

one device the other can shut the system down.

In the receiver unit there are two independent switching

channels each containing an output signal switching

device (OSSD). Each of the two microcontrollers in the

receiver unit controls one of these OSSDs and monitors

the other.

The OSSDs are very robust solid state devices. These

devices are intended to be connected directly to the

machine control system, a Tapeswitch interface unit or

a suitable safety rela y such that if one or both of them

are in the OFF state, the machine will go to or remain in

a safe condition, f or example, by stopp ing dangerous

motion or by preventing dangerous motion from sta rting.

2.2 COMMUNICATIONS

The receiver unit incorporates a serial communications

port. Various auxiliary Tapeswitch units can be

connected to this port for the purposes of programming

functions within the light curtain and for interrogating th e

system.

No equipment other than Tapes witch brand should b e

connected to this port. Full instruc tions for the use of

this port with auxiliary equipment are provided within this

manual.

2.3 TEST INPUT

A pair of terminals is pro vided across which a pair of

normally closed, volt free contacts should be co nnected .

When these contacts are opened the emitter unit will

stop scanning, forcing the OSSDs to the OFF state.

This input simulates a curtain obstructed condition.

NOTE: This input is provided to allow the GS-120 to be

used with machine control systems which need to cycle

the safety circuit prior to operation. The GS-120 system

itself does not require this input to be used. If this input

is not used it should be jumpered and remain jumpered

at all times.

TAPESWITCH CORPORATION Phone: 631-630-0442

100 Schmitt Boulevard

Farmingdale, New York 11735 www.tapeswitch.com

10 Fax: 631-630-0454

Release 7/2009 Ver. 1.0 Technical Manual: GS-120 Light Curtain Systems

Figure 5

Standard & Master Emitter

Figure 4

Figure 6

Table 1 – LED Indicator Descriptions

2.4 INDICATORS

2.4.1 LED OPTION

The standard/master receiver unit has four status

indicators as shown in Figure 4. The standard/master

emitter unit has two status indicators as shown in

Figure 5. The slave emitter and receiver have one

status indicator as shown in Figure 6.

A description of each indicator is given in Table 1.

TAPESWITCH CORPORATION Phone: 631-630-0442

100 Schmitt Boulevard

Farmingdale, New York 11735 www.tapeswitch.com

Standard & Master Receiver

Slave Emitter & Receiver

11 Fax: 631-630-0454

Release 7/2009 Ver. 1.0 Technical Manual: GS-120 Light Curtain Systems

Figure 7

Table 2 – Diagnostic Displays

2.4.2 DIAGNOSTIC OPTION

For this option, the LED indicators on the standard and

master emitter units and all slave units are the same as

shown for the LED option above in Figures 4, 5, and 6.

However, the standard and master receiver units

contain a scrolling 4-digit alphanumeric display, shown

in Figure 7, which is used for diagnostic purposes.

The various displays and t heir meanings ar e shown in

Table 2.

Diagnostic Receiver

TAPESWITCH CORPORATION Phone: 631-630-0442

100 Schmitt Boulevard

Farmingdale, New York 11735 www.tapeswitch.com

12 Fax: 631-630-0454

Release 7/2009 Ver. 1.0 Technical Manual: GS-120 Light Curtain Systems

3.0 INSTALLATION

3.1 GENERAL

WARNING

Tapeswitch GS-120 systems are d esign ed t o

protect operators working at or near

dangerous machinery . They ca n only pe rform

this function if they are correctly fitted and

interfaced to a suitable machine. Those

persons responsible for the machine must

ensure that all persons involved in the

installation of the photo-electric safety

system have the necessary knowledge,

training and experience and that they are fully

aware of all laws, rules, regulations and codes

of practice pertaining to their task.

The attention of the installer is drawn to following

general requirem ents for the installation of a GS-120

system:

(a) The dangerous motion of the machine must be

electrically controllable.

(b) The machine response/stopping performance must

be adequate and consistent.

(c) It must be possible to stop the dangerous motion of

the machine at any point in its operation, in any

operating mode.

(d) The control syst em as a whole must be designed

and constructed to prov ide the appropriate category of

safety integrity as defined in EN954-1 'Safety of

machinery: Principles for the design of safety related

control systems'. The appropriate category should be as

prescribed in the r elevant C type EN standar d for the

type of machine concerne d. In the absence of such a

standard the appropriate category of safety integrity

should be determined by performing a risk assessment

as described in EN1050 'Safety of machinery: Risk

assessment

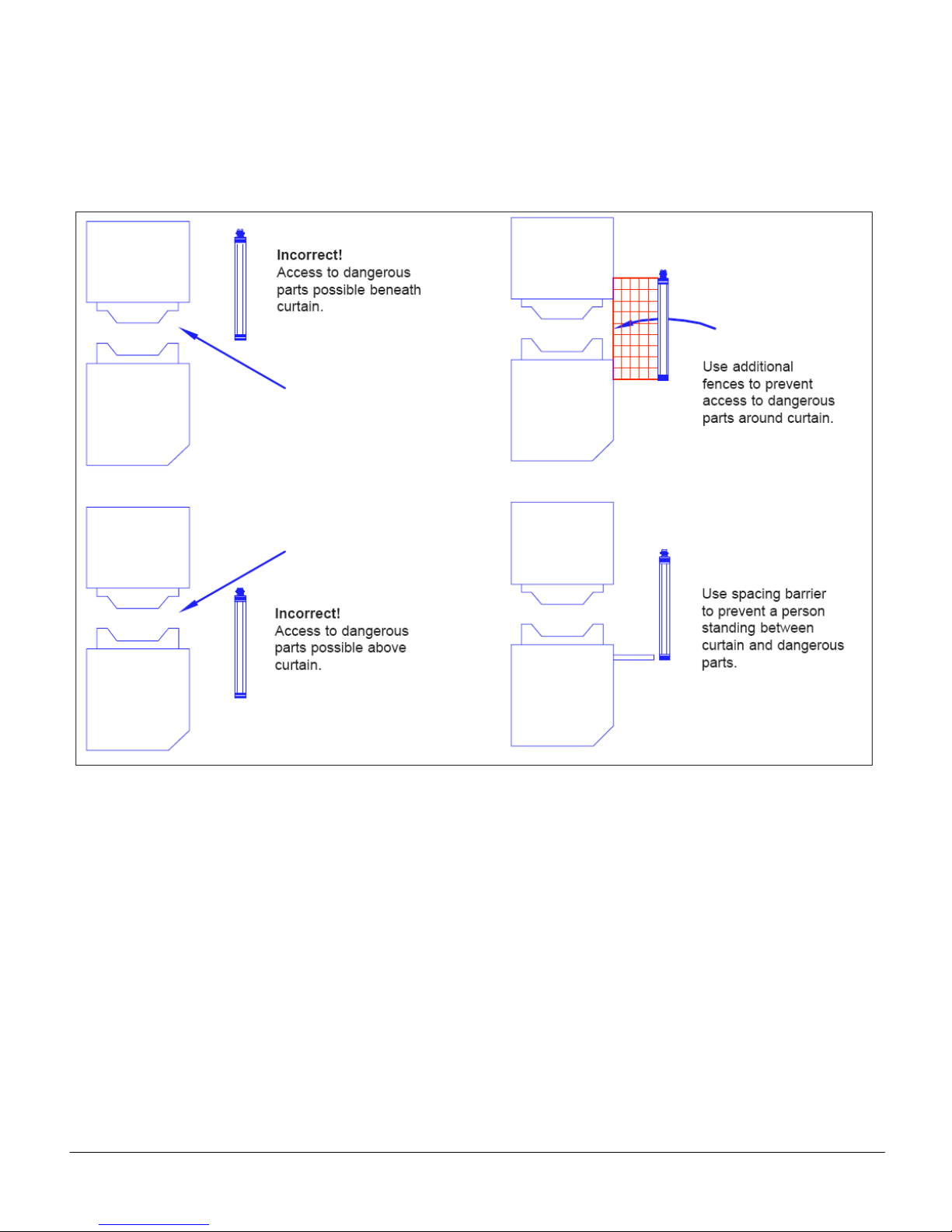

(e) Steps must be taken to prevent access to the

dangerous parts of t h e machine from an y direc tio n n ot

covered by the photo-electric curtain. Such steps could

include fixed or interlocking fences or screens,

additional photo-electr ic devices or pressure sens itive

mats. Similar steps should be taken to prevent a p erson

from st anding between the cur tain and the dangerous

parts of the machine.

(f) No devices other than those specified in this manual

should be connected to the internally-generated power

supply of the system.

(g) After installation, the machine/guard syste m must be

commissioned in ac cordanc e with the r equirem ents of

section 5.1.1 of this manual.

(h) Any covers removed during installation must be

replaced as soon as possible.

(i) At power on, af ter a power interruption or after the

curtain has been actuated, it must not be possib le for

the machine to star t (or restart) until a manual contr ol

has been operated. This is known as “start/restart

interlock”. The GS-120 can provide this function, but if it

is not installed, it must be provided elsewhere within the

safety system

(j) To avoid nuisance tripping, if a fluorescent lamp with

an electronic ballast is located within 5 feet (1.5 meters)

of the receiver unit, it mus t be outside of a 20º field of

view from the receiver unit (±10º about the center line).

If this is not practic al, a 60 H z fluorescent li ght fixture

should be used.

3.2 MECH ANICAL INSTALLATION

3.2.1 GENERAL CONSIDERATIONS

ANSI B11.19-1990 g ives guidance on the dim ensions

and positioning of photo-electric safety devices fitted to

industrial machines. The main considerations are

described below and are illustr ated in Figure 8.

(a) The appropriate protected height must be selected.

The curtain must be of sufficient height such that access

to the dangerous parts, from the direction of appr oach of

the operator, is only possible by obstructing the curtain

taking into account all possible operator positions.

(b) The c orrect minim um separation distanc e must be

observed. The curtain m ust be mounted in the correc t

position in relation to the dangerous parts of the

machine to take account of the stopping performance of

the machine, the curtain format used and the detection

capability of the curtain.

(c) Steps must be taken to prevent access to the

dangerous parts from any direction not covered by the

curtain and to prevent an operator from standing

between the curtain and the dangerous parts w ithout

obstructing the curtain. Additional mechanical guarding

will usually be necessary to achieve this.

TAPESWITCH CORPORATION Phone: 631-630-0442

100 Schmitt Boulevard

Farmingdale, New York 11735 www.tapeswitch.com

13 Fax: 631-630-0454

Release 7/2009 Ver. 1.0 Technical Manual: GS-120 Light Curtain Systems

The physical parameter s affecting the positioning are

the dimensions of the detection zone of the light curtain

(i.e. the protected height and the range) and the

minimum separation dis tan c e. T hes e ar e desc r ibed in

the following sections.

Figure 8

TAPESWITCH CORPORATION Phone: 631-630-0442

100 Schmitt Boulevard

Farmingdale, New York 11735 www.tapeswitch.com

14 Fax: 631-630-0454

Release 7/2009 Ver. 1.0 Technical Manual: GS-120 Light Curtain Systems

3.2.1.1 Multi-Sided Guarding

By using mirror columns the light curtain beams can be

deflected around corners t o form two and three sided

guard configurations. It should be borne in mind that for

each mirror used the range is reduced by approximately

20%. Also the alignment of systems with mirrors can be

difficult especially where the mounting surfaces are

uneven. It is therefore recommended that no more than

two mirrors are used between an y pair of emitter and

receiver units. Se e Figures 9, 10, an d 11 for diff erent

multi-sided guarding configurations.

Note: The arrangement shown in Figure 11 is not

recommended, as it is very difficult to determine that the

safety distance S is correct.

Figure 9 - Guarding a two-sided area

TAPESWITCH CORPORATION Phone: 631-630-0442

100 Schmitt Boulevard

Farmingdale, New York 11735 www.tapeswitch.com

Figure 10 – Guarding a 3-sided area

Figure 11 – Incorrect use of two-sided guarding

15 Fax: 631-630-0454

Release 7/2009 Ver. 1.0 Technical Manual: GS-120 Light Curtain Systems

Figure 12

3.2.2 CURTAIN DIMENSIONS

3.2.2.1 GS-120 Basic System

The curtain dimensions are defined by the protected

height and the range (i.e. the distance between the

emitter and receiver units ) . T he pr otec ted he igh t must

be selected to suit the application. The minimum range

for all systems is 500 millimeters. The maximum range

for systems with 30mm or 70mm detection capability is

15 meters (50 feet).

All the dimensions relating to the curtain, for each of the

GS-120 systems are s hown in Figure 12. T he upper

and lower boundaries of the curtain are indicated b y

arrows on the front window labels of each unit.

TAPESWITCH CORPORATION Phone: 631-630-0442

100 Schmitt Boulevard

Farmingdale, New York 11735 www.tapeswitch.com

16 Fax: 631-630-0454

Release 7/2009 Ver. 1.0 Technical Manual: GS-120 Light Curtain Systems

Figure 13

3.2.2.2 GS-120 Multi-Beam System

All the dimensions relating to the curtain, for

each of the Multi-beam systems (or multi-beam

slave systems) are shown in Figure 13.

TAPESWITCH CORPORATION Phone: 631-630-0442

100 Schmitt Boulevard

Farmingdale, New York 11735 www.tapeswitch.com

17 Fax: 631-630-0454

Release 7/2009 Ver. 1.0 Technical Manual: GS-120 Light Curtain Systems

3.2.2.3 GS-120 Cascaded Sy st e m

Additional flexibilit y to facilitate guarding in more than

one plane is provided, by the capability to connect slave

units to a basic or multi-beam master system.

The slave units can be ba sic or multi-beam systems,

with any of the defined detection characteristics of

30mm or 70mm.

The dimensions re lat ing t o the c urt ains , f or each slave

unit are as defined in the previous sections for each

model. The upper and lower boundaries of each curtain

are indicated b y ar rows on the front window labels of

each unit.

A maximum of two sets of slave units can be connected

to a master system as shown in Figure 14. Each

emitter-receiver pair has a type designation where:

Type GS-120/M is a master

Type GS-120/A is a slave

Type GS-120/D is a slave with a connector at each end

Master and slave units can be assembled up to a

maximum of 240 beams. Where:

30mm detection - 12 beams per 200mm curtain

70mm detection - 4 beams per 200mm curtain

Examples:

GS-120/M/1000/30 = 60 beams

GS-120/A/0400/70 = 8 beams

So, total = 68 beams

Notes:

1. When master/slave emitter-receiver sets have

different range capabilities, these must be

respected when systems are configured.

2. When master/slave emitter-receiver sets have

different detection capabilities, the separation

distance must be calculated and adhered to for

each set separately.

Figure 14

TAPESWITCH CORPORATION Phone: 631-630-0442

100 Schmitt Boulevard

Farmingdale, New York 11735 www.tapeswitch.com

18 Fax: 631-630-0454

Release 7/2009 Ver. 1.0 Technical Manual: GS-120 Light Curtain Systems

3.2.3 SEPARATION DISTANCE

Any machine, regardless of the efficiency of its braking

system, will take a certa in time to com e to rest after a

stop signal is generated.

The time from the instant that the c urtain is broken to

the instant that dangerous motion actually ceases is

called the “overall system response time”. The

dangerous parts will obviously continue to move during

this time. The curtain must therefore be positioned at a

certain minimum dis tance f rom the dang erous p arts to

prevent a person who h as obstruc ted the curtai n from

reaching the dangerous parts before they hav e stopped.

This distance is the “minimum separation distance” and

is defined as the distance, in the direction of approach,

between the physical point at which the curtain detects

an obstruction and the nearest dangerous parts.

ANSI B11.19-1990 provides guidelines on how to

determine the minimum separation distance for a given

application. Tapeswitch GS-120 systems are primarily

intended for use in norm al appr oach form at where t he

curtain is perpendicular to the direction of approach,

although they can be used in parallel and angled

approach formats.

3.2.3.1 Normal Approach

Normal approach form at is shown in Figure 15. For

normal approach format the inner edge of the front

window of each unit (i.e. the edge whic h is nearest to

the machine) should be considered to be t he point at

which an obstruction is detected. See plane X as

shown in Figure 15.

The effective sensing field of the device shall be located

at a distance from the nearest recognized hazard such

that the operator or others cannot reach the hazard with

a hand or other body part before stopping of the motion

during the hazardous portion of the machine cycle.

Figure 15

TAPESWITCH CORPORATION Phone: 631-630-0442

100 Schmitt Boulevard

Farmingdale, New York 11735 www.tapeswitch.com

19 Fax: 631-630-0454

Release 7/2009 Ver. 1.0 Technical Manual: GS-120 Light Curtain Systems

2.5

2.0

1.5

1.0

0.5

0.0

0.0 8.07.06.05.04.03.02.01.0

Blanked Dimensions or Minimum

Object Sensitivity in Inches

Penetration Fac tor D(pf) in Inc hes

DPF

1 inches

3.1 inches

8 inches

Detection

14mm

30mm

70mm

The minimum separation distance depends on the

application. The following formula should be used when

calculating this distance:

= K x (TS + TR+ TC+ TBM) + DPF

D

S

where:

DS = Minimum separation distance between the

device and the nearest point of operation

hazard in inches.

K = Hand speed constant.

See note.

T

= Stop time of the machine tool measured at

S

the final control element.

T

= Response time of the control system.

C

NOTE: TS and TC are usually measured by

a stop-time measurement device.

TAPESWITCH CORPORATION Phone: 631-630-0442

100 Schmitt Boulevard

Farmingdale, New York 11735 www.tapeswitch.com

= Response time of the presence-sensing device

T

R

and its interface, if any, as stated by the

manufacturer or as actually measured.

T

= Additional time allowed for the brake monitor (if

BM

used) to compensate for variations in normal

stopping time.

D

= Added distance due to t he penetration factor ,

PF

as recommended in the illustration below. The

minimum object sensitivity is stated by the

manufacturer. If beam blanking or floating

window features are used, these figures should

be added to the object sen s itivity figure before

using the chart.

NOTE: The value of the han d speed constan t, K, has

been determined by various studies.

Althou gh these studies indicate speeds of 63

in/sec to over 100 in/sec, they are not

conclusive determinations. The employer

should consider all factors, including the

physical ability of the operator, when

determining the value of K to be used.

20 Fax: 631-630-0454

Release 7/2009 Ver. 1.0 Technical Manual: GS-120 Light Curtain Systems

3.2.3.2 Parallel Approach

Parallel approach format is shown in Figure 16. For

parallel approach format the outer curtain detection limit

(as shown on the front window of each unit) m inus the

detection capability, should be considered to be the

point at which an obstruction is detected. See Plane X in

Figure 16.

Figure 16

For this type of protective equipment, the height H of the

detection zone shall not exceed 1000mm. If H is greater

than 300mm (200mm for non-industrial applicati ons),

the risk of undetected access beneath the detection

zone should be considered.

TAPESWITCH CORPORATION Phone: 631-630-0442

100 Schmitt Boulevard

Farmingdale, New York 11735 www.tapeswitch.com

21 Fax: 631-630-0454

Release 7/2009 Ver. 1.0 Technical Manual: GS-120 Light Curtain Systems

3.2.3.3 Angled Approach

If it is necessary to install the curtain, at an angle to the

direction of approach as shown in Figure 17, then the

following requirements apply:

An angle within ± 5° of normal or horizontal, need not be

considered to be angled, and the relevant formula used.

For detection zones which are positioned at angles

greater than ±5°, to the d irection of approach, account

shall be taken of the risks associated with the direction

of approach, and the most appropriate formula used.

3.2.3.4 Approach to ‘L’ Installation

If vertical and horizontal master/slave GS-120 light

curtains are used togeth er as in Figure 18, where the

vertical curtain is the main trip curtain and the horizontal

curtain performs presence sensing inside it, the

separation dista nce c alculations for the vert ical c urtain

are used. However, the detection capability calculations

of the horizontal curtain with respect to its height should

also be observed. Note: Where master/slave

combinations are used:

Total Master Unit Slave Unit

Response = Response + Response

Time Time Time

Figure 17

TAPESWITCH CORPORATION Phone: 631-630-0442

100 Schmitt Boulevard

Farmingdale, New York 11735 www.tapeswitch.com

Figure 18

22 Fax: 631-630-0454

Release 7/2009 Ver. 1.0 Technical Manual: GS-120 Light Curtain Systems

3.2.4 OPTICAL ALIGNMENT

The emitter and receiver units should be mounted facin g

each other at the same height with their axes al igned.

Misalignments, as il lustrated in Figure 19, should be

avoided. Tapeswitch offers a laser alignment t ool to add

visible assistance over longer range or when mirrors are

used. See section 4 for detailed information.

Figure 19

TAPESWITCH CORPORATION Phone: 631-630-0442

100 Schmitt Boulevard

Farmingdale, New York 11735 www.tapeswitch.com

3.2.5 REFLECTIVE SURFACES

There should be no reflective surfaces within the ‘fi eld of

view’ of the curtain units. Reflective surfaces within the

field of view can lead to non-detection of an obstruction.

The field of view of each of the emitter and receiver

units is approximately 5 degrees either side of the

optical axis.

A minimum distance from the optical axis to any

reflective surface must be observed. This distance

depends on the actual operating distance and must take

into account possible misalignment. This is illust rated in

Figure 20. The distance should be determined as

follows:

Operating distance L < 3m: X < 260 mm

Operating distance L > 3m: X > 0.0874L mm

Figure 20

23 Fax: 631-630-0454

Release 7/2009 Ver. 1.0 Technical Manual: GS-120 Light Curtain Systems

3.2.6 SYSTEMS IN CLOSE PROXIMITY

In order to avoid nuisance interference between

adjacent systems, whenever two or more emitterreceiver pairs are used within each other’s sensing

range, ensure that the fr ont window of an y unit is not

within the field of view of units of the opposite type

from other systems.

This can be achieved by ensuring that units of the same

type are mounted fac ing in opposite directions. See

Figure 21.

Figure 21

3.2.7 MOUNTING BRACKETS

Mounting brackets and their associated hard ware are

provided with the emitter and receiver units. The

brackets have been specially designed to allow

adjustment.

Each unit is supplied with two clamp brackets fitted, one

at each end. The clamp bracket is a short piece of

extruded aluminum which i s designed to interlock with

the unit housing extrusio n and to clamp in posit ion on

the rear of the hous ing by means of two set scr ews.

The set screws can be tightened or loosened with a

2mm Allen wrench, which is supplied with the unit. The

clamp bracket can be slid up and down the emitter and

receiver units to facilitate alternate positioning of the

bracket. The clamp brackets are a tight fit on the emit ter

and receiver units and may require some force to slide

them up and down on. The clamp bracket dimensions

are shown in Figure 22.

The clamp brackets can be moved to any position

over the length of the unit, but it is recommended

that they be kept in the supplied position.

Figure 22

TAPESWITCH CORPORATION Phone: 631-630-0442

100 Schmitt Boulevard

Farmingdale, New York 11735 www.tapeswitch.com

24 Fax: 631-630-0454

Release 7/2009 Ver. 1.0 Technical Manual: GS-120 Light Curtain Systems

Figure 24

This makes replacem ent of a unit much eas ier as

the new unit will have the brackets alre ady in the

correct position. The posi tion of the cl amps on the

units is shown in Figure 23.

The set screws may not be completely ti ghtene d in

the supplied position . These set screws must be

fully tightened before proceeding with the

installation. (A 2 mm Allen wrench is supplied for

use in tightening the brackets.) If these brackets are

not properly secured, the emitter and rece iver units

may shift causing nuisance tri pping, a false l ock-out

condition and/or a potential safety hazard.

Four wall brackets are supplied with each system

together with the 8 self-tapping screws needed to fix the

wall brackets to the clam p brackets. The wall brac ket

dimensions are shown in Figure 24.

The alternative mounting arrangements which these

brackets facilitate are shown in Figures 25, 26, & 27.

The internal construc tion of the units is such that the y

can withstand normal levels of vibratio n a nd shock. In

situations where the vibration of the machine cannot be

reduced to normal leve ls, v i br ation pr o of ing mountings

should be used.

Figure 23

TAPESWITCH CORPORATION Phone: 631-630-0442

100 Schmitt Boulevard

Farmingdale, New York 11735 www.tapeswitch.com

25 Fax: 631-630-0454

Release 7/2009 Ver. 1.0 Technical Manual: GS-120 Light Curtain Systems

2.56" (65mm)

1.85" (47mm)

2.56" (65mm)

Angular adjustment

screw

6mm dia.

mounting hole

Clamp plate

securing screw

.95" (24mm)

1.58" (40mm)

2.56" (65mm)

3.15" (80mm)

Figure 25

Figure 26

Figure 27

TYPE AB - MOUNTING BRACKETS

Type AB adjustable m ounti ng brac kets are an option al

choice for GS-120 Light Cu r tains . Combining a robust

design and quick release capability, these brackets

allow for s peed y installation and eas y interchange of a

light curtain unit without the need f or re-alignment. To

request this option when ordering your light curtain

please specify "AB" in your or der c ode. (part number

0978)

TAPESWITCH CORPORATION Phone: 631-630-0442

100 Schmitt Boulevard

Farmingdale, New York 11735 www.tapeswitch.com

26 Fax: 631-630-0454

Release 7/2009 Ver. 1.0 Technical Manual: GS-120 Light Curtain Systems

3.3 ELECTRICAL INTERFACE,

OPERATION, and INSTALLATION

This section is divided into two parts. The first part

discusses the interface and operation of the GS-120

system when the basic set (emitter and receiver) is

interfaced directly to the machine control circuitry by

means of the redundant solid state outputs.

The second section disc usses the interface when a ny

one of the various Tapeswitch control units is used.

The basic GS-120 system consists of an emitter and

receiver. The receiver unit provides two safety outputs.

These fail-safe outputs are solid-s tate PN P transistors

and are actively monitored and s hort-c irc uit protected.

The two outputs are independent of each other and

represent part of the redundancy of the overall light

curtain system. The outputs must always be in the

same state (i.e., both o utputs either on or off ). If one

output should fail i n the “on” position, the ot her output

will remain in the “off” position until the failure is

corrected. In order to maintain redundancy bo th outputs

must be interfaced to independent switching devices in

the machine control circuit (i.e., safety relays,

emergency stop relay packages, fail-safe PLC’S, etc.).

Both outputs must be used. The solid state ou tputs

can be interfaced directly to the machine control circuit

provided this circuitr y is compatible with the PNP-type

output. A number of manufacturers produce units

containing circuits of this type. Care should be taken to

ensure that the inputs of these units can accept t he PNP

outputs of the light curtain.

• The maximum current is 0.1 A.

• The output voltage, Ua , of each output is dependent

on the supply, Uv a nd the load and is given b y the

following expression Ua > Uv - 2v.

• If the solid state outputs are used directly, the

supply voltage to the light curtain (emitter and

receiver) must be c ommon to the supply voltage of

the device to which it will be interfaced.

• Both outputs must be used to maintain redundancy.

• Each output should be wired to independent switching

devices in the machine c ontrol circuit and SHOULD

NOT BE CONNECTED TOGETHER.

NOTE: The pair of solid state outputs are constantly

monitored and are designed to act as a single

of the

component in a fail-safe condition (i.e., if

outputs fails in the “on” position, the other output

will revert to the “off” position.

one

This output will remain “off” until the integri ty of th e

other output is restored. This level of integr ity mus t

be maintained throughout the machine control

circuit. It is the responsibility of the end user to

assure any fault within the safety circuit is detected

and that it puts the machine in a safe c o n d ition.

3.3.1 GENERAL

Both units must be suppl ied with 24 Vdc ± 20%. This

DC supply must be isolated by means of a safety

transformer which conforms to the requirements of

IEC61558-2-6. The emitter, receiver and interface unit

must use the same + 24V DC supply. The negative side

of the supply should be grounded and the cables should

be routed separately from power and motor drives.

The maximum cable length for each unit is 30 meters.

The power consumption is dependent on the protected

height of the system but is less than 12 VA.

The emitter and receiv er should be powered by a

common DC supply and connected to the system

ground. If power is removed from the emitter

only

the system may not automatically re-synchronize,

and may require power removal from the recei ver as

well in order to establ ish op tical communication and

synchronization. Power can be removed from the

receiver unit without any consequence to the

synchronization.

IMPORTANT

Power should be applied to both units at the

same time. If power is removed from the

emitter unit, power must also be removed

from the receiver unit.

3.3.2 EMITTER UNIT

3.3.2.1 General

The emitter unit has a five -pin male quick-disconnect

connector. Two pins for the DC supply, two fo r the test

input (see 3.3.2.2), and one for the grou nd. (protective

earth PE)

To connect to the emitter, a 5-pin female molded cable

assembly is necessary. This cable assembly is supplied

separately and is available in lengths of 15 feet (p/n

0972), 30 feet (p/n 0973), or 98 feet (p/n 0976). This

cable has an insulated j acket with color coded wires.

The cable has a fixed molded connector on one end and

flying leads at the other. The colors and corresponding

functions are shown in Figures 28 and 29.

TAPESWITCH CORPORATION Phone: 631-630-0442

100 Schmitt Boulevard

Farmingdale, New York 11735 www.tapeswitch.com

27 Fax: 631-630-0454

Release 7/2009 Ver. 1.0 Technical Manual: GS-120 Light Curtain Systems

Ground

Figure 28 – Emitter Connector

3.3.2.2 Test Input

On some machines, a test input is us ed to check the

interface between the phot o-electric saf ety device and

the machine. The input simulates the obstruction of the

curtain in order to c ycle the outp ut switchin g elem ents

and thereby expose an y fault before the next m achine

cycle. This input is appl ied during a safe part of the

machine cycle or at the end of the cycle.

If this function is used, a normally closed contact should

be connected as shown in Figure 29.

This contact must open for a minimum of 100ms. When

this contact is opened, th e light curtain safet y outputs

will be switched off and will remain off until the test

contact closes again and the curtain self-tests have

been successfully performed (assuming that the curtain

is not obstructed).

If the test input is not used, this input must be

jumpered.

NOTE: If the emitter cable is removed during

normal operation, the system will not return to

normal operation once the emitter is reconnected

until power is cycled on the receiver.

Figure 29 – Emitter Connections

3.3.3 RECEIVER UNIT

3.3.3.1 General

The GS-120 is availab le with two output m odes, PNP

and SSR, as shown in the order codes in section 1.3.

The PNP version has cross-monitored 24Vdc PNP

outputs, start/restart interlock and the ability to monitor

contacts from external devices (EDM). The SSR version

has volt-free contacts which are closed when the curtain

is clear, but does not have any start/restart interlock

function. This must be provided elsewhere in the safety

system. The receiver connector is shown in Figure 30.

The 24Vdc supply must have a 2A quick

blow in-line fuse fitted.

Figure 30 – Receiver Connector

TAPESWITCH CORPORATION Phone: 631-630-0442

100 Schmitt Boulevard

Farmingdale, New York 11735 www.tapeswitch.com

28 Fax: 631-630-0454

Release 7/2009 Ver. 1.0 Technical Manual: GS-120 Light Curtain Systems

Ground

3.3.3.2 PNP Version

3.3.3.2.1 Safety Outputs

This version has two 24 Vdc PNP outputs. The two

output signal switching devices (OSSDs) should be

wired to independent switching devices in the machine

control circuit. The OSSDs are solid-state de vices an d

are internally monitored and short-circuit protected. The

connections for the PNP version of the receiver are

shown in Figure 31.

The maximum current is 0.1A.

The output voltage, UA, of each OSSD is dependent on

the supply, UV, and the load which is given by the

following expression:

> UV - 2V

U

A

Figure 31- PNP Version Receiver Connections

3.3.3.2.2 Start/Restart and External Device

Monitoring (EDM)

In the PNP mode th e GS-120 can be set up for either

manual or autom atic start and restart. This functi on is

determined by the conn ections to the unit. In m anual

mode, the outputs will only switch on when the curtain is

clear and a reset s witc h is c losed and t hen opened . In

automatic mode the output s will be on whenever the

curtain is clear and off whenever the curtain is

obstructed.

The GS-120 also has the ability to monitor external

devices. This is achieved by using normally-closed

contacts of the external device and monitoring that they

are closed before allowing the outputs to switch from off

to on. The various wiring configurations for these

options are shown in Figures 32 to 35.

TAPESWITCH CORPORATION Phone: 631-630-0442

100 Schmitt Boulevard

Farmingdale, New York 11735 www.tapeswitch.com

Figure 32 – Auto Restart

Figure 33 - Auto Restart with EDM

Figure 34 – Manual Restart

29 Fax: 631-630-0454

Release 7/2009 Ver. 1.0 Technical Manual: GS-120 Light Curtain Systems

Ground

Figure 35 – Manual Restart with EDM

3.3.3.3 SSR Version

This version has two voltage-free solid-state outputs. It

operates in autom atic mode, so the outputs will be on

whenever the curtain is clear and off whenever the

curtain is obstructed. See Figure 36.

Figure 36 – SSR Version Wiring

TAPESWITCH CORPORATION Phone: 631-630-0442

100 Schmitt Boulevard

Farmingdale, New York 11735 www.tapeswitch.com

30 Fax: 631-630-0454

Release 7/2009 Ver. 1.0 Technical Manual: GS-120 Light Curtain Systems

3.3.4 INTERFACING TO A MACHINE

The interfacing of a l ight curtain to a machine can be

achieved by using discrete components or by means of

an interface unit such as the Tapeswitch SRUB.

All the relays shown are safety relays with positively

guided contacts. If this circuit is implemented using

discrete components, it is essential that this type of relay

is used.

3.3.4.1 PNP Version Manual Reset

It may be possible to connect the GS-120 directly to the

Machinery Primary Control Elements (MPCE) as shown

in Figure 37. The GS-120 provides the Start/Restart

function necessary to avoid unintended initiation of the

machine.

Figure 37 – PNP Version Manual Reset

Note: N/C contacts of K1 and K2 are used for

monitoring purposes. If EDM is carried out elsewher e,

the reset switch should be connected between pi n 2 and

pin 6 of the Receiver unit.

IMPORTANT

A number of manufacturers produce units containing

circuits of this type. Care should be taken to ensure that

the inputs of these units can accept the PNP outputs of

the light curtain.

TAPESWITCH CORPORATION Phone: 631-630-0442

100 Schmitt Boulevard

Farmingdale, New York 11735 www.tapeswitch.com

31 Fax: 631-630-0454

Release 7/2009 Ver. 1.0 Technical Manual: GS-120 Light Curtain Systems

3.3.4.2 PNP Version Auto Reset

The GS-120 can be used in Auto Restart mode as

shown in Figure 38. If this mode is selected, the Manual

Restart function must be provided elsewhere in the

machine safety control system (for example, in the

SRUB interface unit).

Note: The c onnection through 41 and 42 is used for

external monitoring (EDM). If an alternative safety relay

is used which does not have N/C contacts for

monitoring, then connect pin 2 to pin 6 on the Receiver

unit.

Figure 38 – PNP Version Auto Reset

IMPORTANT

A number of manufacturers produce units containing

circuits of this type. Care should be taken to ensure that

the inputs of these units can accept the PNP outputs of

the light curtain.

TAPESWITCH CORPORATION Phone: 631-630-0442

100 Schmitt Boulevard

Farmingdale, New York 11735 www.tapeswitch.com

32 Fax: 631-630-0454

Release 7/2009 Ver. 1.0 Technical Manual: GS-120 Light Curtain Systems

3.3.4.3 SSR Version

The interfacing of a GS-120 light curta in to a machine

can be achieved by means of an interface unit such as

the Pilz PNOZ 8. The circuit diagram for the PNOZ 8

and the typical c o nnec t ions to the GS-120 light curtain

and the machine are shown in Figure 39 below.

Figure 39 – SSR Version

IMPORTANT

A number of manufacturers produce units containing

circuits of thi s type. Care should be taken to ensure that

the inputs of these units can accept the volt-free outputs

of the light curtain, and that the outputs of the light

curtain are wired with one channel "pull up" and one

channel "pull down" so as to maintain the failure mode

integrity.

TAPESWITCH CORPORATION Phone: 631-630-0442

100 Schmitt Boulevard

Farmingdale, New York 11735 www.tapeswitch.com

33 Fax: 631-630-0454

Release 7/2009 Ver. 1.0 Technical Manual: GS-120 Light Curtain Systems

3.4 INITIAL CHECKING AND A LIGNMENT

The procedure for alignment is described below.

Apply power to the GS-120 system.

The amber indicator s on t h e emitter and recei ver u nits

should be lit. If either of the indicat ors is not lit, check

the wiring.

The yellow indicators on the em itter and the receiver

units should be in t he off state. If e ither of these two

indicators is flashing, there is a fault, contact your

Tapeswitch distributor. If the yellow indicator on the

emitter unit is on constantly, check the wiring as

described in sections 3.3.2 and 3.3.3.

The green indicator on the receiver unit should be lit, if

not, adjust the units into general alignment until the

green indicator comes on.

Adjust the units to optimum alignment as follows:

1. Slowly turn the emitter unit clockwise until the green

indicator on the receiver unit goes off and the red

indicator comes on. (Note this position.)

2. Then turn the em itter unit c ounter-cloc kwise, again

until the green ind icator goes of f and the red indicator

comes on. (Note this position.)

3. Set the emitter at the center of the two noted

positions.

4. Repeat steps 1, 2 and 3 but th is time turning the

receiver unit.

Using the test piece provided, obstruct the curtain. On

the receiver unit the green indicator should go off and

the red indicator comes on.

Move the test piece in an d out of the curtain several

times and check that the indicators change state

appropriately each time.

See section 5.2 of this m anual if the system does not

function as described above.

The installation of the machine can now be completed.

Before putting the machine into use, the complete

system (i.e. the machine and all its safeguarding

devices) should be commissioned by qualified personnel

and, as a minimum, the commissioning checks

described in section 5.1.1 of this manual should be

performed.

Periodic checks in accordance with section 5.1.2 should

be carried out at the prescribed intervals. Daily checks

to be performed on th e GS-120 system are detail ed in

section 5.1.3 of this m anual. In som e cases there are

specific statutory requirements concerning the

examination, inspectio n and test of a machine an d its

safety devices. It is for the user to determ ine if such

requirements exist f or the machine in question a nd to

ensure that those requirements are met.

TAPESWITCH CORPORATION Phone: 631-630-0442

100 Schmitt Boulevard

Farmingdale, New York 11735 www.tapeswitch.com

34 Fax: 631-630-0454

Release 7/2009 Ver. 1.0 Technical Manual: GS-120 Light Curtain Systems

4.0 INTERFACE AND AUXILIARY UNITS

4.1 GENERAL

In applications where the two PNP or solid state outputs

are not suitable for the machine control circuit, an

interface unit m ust be uti lized. T his interf ace unit m ay

be user supplied, provided it is compatible with either

the PNP or SSR outputs and has two channels. A

number of manufacturers produce units containing

circuits of this type. The interface unit must be de signed

to the same level of int egrit y as the GS-120 i n ord er to

maintain the same overall level of safety.

Several Tapeswitch interf a c e units are available whic h

offer options in configuring the input power source,

mounting package and type of electrical interface

desired. All of the units perform the actual switching of

the electrical circuit of the dangerous machine using

positively-guided saf ety relays. All of th e ac-powered

interface units (BSRSA and BSRUA-2) provide the

stepped-down +24 Vdc power for the GS-120 emitter

and receiver pair. The dc-powered interface units,

(SRUB an d SRUS), are powered b y an external +24

Vdc power supply and this supply must also power the

GS-120 emitter and receiv er pair. All of the interfac e

units provide isolation f rom the low am perage GS-120

solid state outputs (0.5 A each) and the potentially

higher amperage required by the machine control

circuitry. Each interface unit provides LED status

indicators. All LEDs will be discussed in the description

of the applicable interface units. These units are

described in the appendices of this document.

4.1.1 METHODS OF INTERFACING

All of the interface units have a m inim um of two saf ety

outputs. These outputs are to be interfaced with the

machine primary control elements (MPCEs). An

MPCE is defined as an e lectrically control led element

which directly controls the normal operating motion of a

machine such that it is the last (in time) to operate when

motion is initiated or arrested.

The safety output contacts of the interface unit must be

connected to a machine’s MPCEs in such a way that if

either of the safety output relays is switched off, then the

machine will be brought t o res t, r egardl es s of the state

of the other relay.

This gives assurance that the failure of a s ingle relay

cannot prevent the machin e from being stoppe d. The

safety output relays are cross-monitored within the

interface unit. This means any disparity between the

two relays will be detected. The machine will be

disabled until the cause of the disparity has been

removed. Such a disparity could be the loss of signal on

one of the two channels co ming from the light curt ain.

TAPESWITCH CORPORATION Phone: 631-630-0442

100 Schmitt Boulevard

Farmingdale, New York 11735 www.tapeswitch.com

The interface will only allow the safety relays to move to

the ON state if both channels are working correctly

together.

All interface units are provided with indicator lamps

which show the stat us of the interface. T he number,

color, meaning and location of the indicators may

change with the type of interface. All interfaces

however, have indicator s which specifically show the

commanded state of the output safety relays.

Both of these outputs must be used to take

advantage of the inherent redundancy of the

interface unit.

The two safety outputs are normally (NO). The outputs

are closed when no obstructions are in the light curtain

and no faults exist. Once the light curtain is broken the

outputs open. The state of the output may remain open

until a reset switch is applied (MANUAL RESET) or will

automatically close (AUTOMATIC RESET) once the

light curtain is cleared. Details of the resetting features

are discussed in the individual interface sections found

in the appendices.

The safety outputs can be used in several ways,

depending on the MPCEs found on the machine being

guarded. MPCE is the abbreviation for Machine

Primary Control Element. An MPCE is an electrically-

powered control device which directly controls the

guarded machines motion and is the final device in the

operating sequence when motion is either initi ated or

halted. This would be the main hydraulic control val ve

in a hydraulically controlled press. Some of the

common arrangements are described below:

• Normal risk m achine - These usual ly have a single

MPCE. In this case both normally open safety outputs

should be used together as shown in Figure 40.

• High risk machines - These should have 2 MPCEs. In

some countries, it is customary for both MPCEs to

operate in the sam e m ode. In th is c ase, eac h of the

normally open (NO) outputs controls a s i ngl e M PC E.

See Figure 41 for an illustration of the type of

interface. Any additional output contacts can be used

as a monitor, e.g. as an input to a PLC.

To protect the contacts of the safety output relays from

the effects of switching inductive loads, an appropria tely

rated power factor cor rection device must be inst alled

across t he MPCE coils. Fi gures 40 and 41 show Arc

Suppressors used for this pur pose. Arc Suppressors

are user supplied.

35 Fax: 631-630-0454

Release 7/2009 Ver. 1.0 Technical Manual: GS-120 Light Curtain Systems

Machine

Control

Voltage

Safety

Fuse

Safety

Output

1

Safety

Output

2

Arc

Suppressor

MPCE

1

Machine

Control

Voltage

Safety

Fuse

Safety

Output

1

MPCE

1

Arc

Suppressor

Safety

Fuse

Safety

Output

2

MPCE

2

Arc

Suppressor

CAUTION

Arc Suppressors must not be connected

across safety relay contacts.

Figure 40 - Interfacing a Machine with 1 MPCE

Figure 41 - Interfacing a Machine with Dual

SAFETY FUSES: It is good practice to protect the

safety r elays against welding due to a current s urge.

This can be done by current limiting designs in the

machine’s controls, or by simple fusing as shown in

Figure 40 and 41. The current through the safety

output contacts should be l imited to a level be low that

TAPESWITCH CORPORATION Phone: 631-630-0442

100 Schmitt Boulevard

Farmingdale, New York 11735 www.tapeswitch.com

Identical MPCEs

which could cause the c ontact to weld. Fuses with a

current rating less than that of the output contacts

should be used.

On the BSRSA Interface Unit, these safety (output

protection) fuses are par t of the unit. All of the other

interface units do not provide safety fuses (output

protection) and these fuses should be supplied

externally by the user.

4.1.2 SPECIAL INTERFACING CONSIDERATIONS

4.1.2.1 PNP Version Manual Reset

It may be possible to connect the GS-120 directly to the

Machinery Primary Control Elements (MPCE). The GS120 in this configuration provides the Start/Restart

function necessary to avoid unintended initiation of the

machine.

4.1.2.2 PNP Version Auto Reset

The GS-120 can be used in Auto Restar t m ode. If t his

mode is selected, the Manual Restart function must be

provided elsewhere in the machine safety control

system (for example, in the SRUB interface unit).

4.1.2.3 SSR Version

The interfacing of a GS-120 light curtain with SSR

outputs requires a controller that is compatible with

these devices. Care should be taken to ensure that the

inputs of this unit can accept the volt-free outputs of the

light curtain, and that the outputs of the light curtain are

wired with one channe l " pu l l up" and one channel "pull

down" so as to maintain the failure mode integrity.

36 Fax: 631-630-0454

Release 7/2009 Ver. 1.0 Technical Manual: GS-120 Light Curtain Systems

Figure 42

Connecting a GS-120 to an AS-i System

4.1.3 CONNECTIONS TO AN AS-i SYST E M

A GS-120 system c an be connected to an AS-i Safe

System using standard AS-i Safe I/O modules as shown

in Figure 42.

The connection of the Emitter and Receiver units to the

system is simply achieved by plugging into standard

AS-i components using the cables supplied.

Note: The power su pply leads of the GS-120 system

not

should

be connected di rectl y to the YELLOW AS-i

cable as this may cause AS-i data transmission

problems. It is recomm ended that this connection be

made using a decoupling network.

Alternatively the guard can be connected to the BLACK

AS-i cable (the auxiliary power cable).

TAPESWITCH CORPORATION Phone: 631-630-0442

100 Schmitt Boulevard

Farmingdale, New York 11735 www.tapeswitch.com

37 Fax: 631-630-0454

Release 7/2009 Ver. 1.0 Technical Manual: GS-120 Light Curtain Systems

5.0 PERIODIC CHECKING,

SERVICING, AND MAINTENANCE

5.1 PERIODIC CHECKING

5.1.1 COMMISSIONING CHECKS

The commissioning exam ination s hould be carried o ut

by persons who are competent and who possess all the

information supplied with the machine and its safety

equipment. The results of the examination sh ould be

recorded and copies of this record should be kept by the

user and the employer of the person performing the

examination. The person carrying out the examination

should ensure that the following general standard of

performance is met:

(a) It should not be possib l e f or the danger o us parts of

the machine to be set in motion while the light curtain is

penetrated.

(b) Penetration of the light curtain dur ing a dangerous

phase of the operation of the m achine shoul d result i n

the dangerous parts being arrested or, where

appropriate, assuming an otherwise safe condition,

before any part of a person can reac h th em . It shou ld

not be possible for the dangerous parts to be set in

motion until the curtain has been cleared, the safety

system has been restored to its normal condition, and

the machine controls have been reset.

The person performing the examination should also:

(c) Inspect the position of the light curtain to ensure that

it is set at the correct distance from the dangerous parts

of the machine as recorded on the machine information

label or plate.

(d) Ensure that additional safeguarding measures have

been provided where nec essary to prevent access to

the dangerous parts of the machine not protected by the

light curtain.

(e) Where appropriate, test the overall system response

time using a suita ble device and ensure that it is th e

same or less than that recorded on the machine

information label or plate.

(f) Test the detec tion capability of the light curtain as

described in section 5.1.4 of this manual.

(g) Examine the machine controls and c onnections to

the GS-120 system to ensure that the requirements

described in this manual a nd in the machine manual

have been met.

(h) Examine the stopping performance monitor (if

installed) to ensure that it is installed and functioning

correctly. Ensure that the means whereby the stopping

performance can be assessed by the operator is

indicating correctly.

(i) Test the muting arrangements (if installed).

(j) Examine brakes or clutches (if installed) as

recommended.

NOTE: No stopping performance monit or or mutin g

facility is provided with the basic GS-120 system

and there is no means provided for the connection

of such devices to the system. These devices may

however have been provided elsewhere in the

machine control system.

5.1.2 6 OR 12 MONTH PERIODIC CHECKS

These examinations should be carried out by competen t

persons. The results shou ld be recorded and a copy

kept by the user.

The person should ensure that the general standard of

performance as described in section 5.1.1 (a) and (b) is

achieved.

The person should perform the commissioning

inspections and tests detailed in sect ion 5.1.1. W hen

checking the stopping perform ance monitor, item (h),

any equally effective means of determining that the

overall system response time, as recorded on the

machine inform ation label or plate, is not exceed ed is

acceptable.

In addition the person should:

(a) Examine all switching elements in the switching

paths controlled by the ligh t curtain outputs to ensure

that they are functioning correctly and are not in need of

maintenance and or replacement.

(b) Inspect the machine to ensure that there are no

mechanical or structur al aspects which could prevent

the machine from stopping or assuming an otherwise

safe condition when called upon to do so.

(c) Examine and inspect t h e m achine controls and t he

connections to the GS-120 s ystem to ensure that no

modifications have b een made which cou ld adversely

affect that system, and that suitable modifications have

been correctly performed and properly recorded.

TAPESWITCH CORPORATION Phone: 631-630-0442

100 Schmitt Boulevard

Farmingdale, New York 11735 www.tapeswitch.com

38 Fax: 631-630-0454

Release 7/2009 Ver. 1.0 Technical Manual: GS-120 Light Curtain Systems

<150 mm

<150 mm

Test piece

5.1.3 DAILY/SETTING EXAMINATION

The following tests should be carried out daily by a

designated person appointed by the machine user. The

results should be r ecorded and a cop y shou ld be kept

on or near the machine. Specific statutory req uirements

may apply to certain types of machines. The desi gnated

person should:

(a) Check that access to the dangerous parts of the

machine is not possible from any direction not protected

by the light curtain and that side and rear guards are in

order.

(b) Check that the minimum distance from the

dangerous parts of the machinery to the light curtain is

not less than the distance stated on the machine