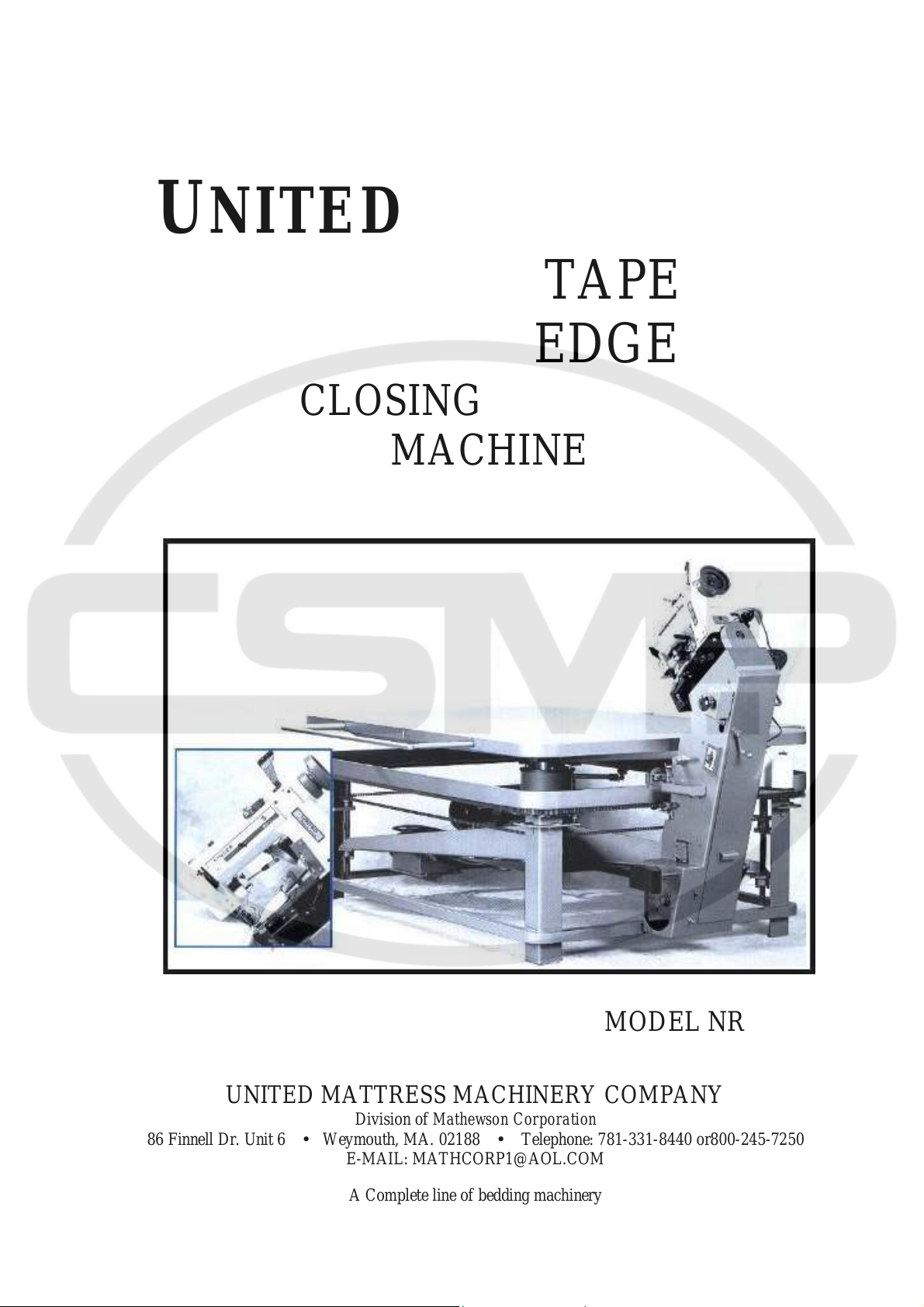

Tape Edge Machines UNITED MATTRESS MACHINERY User Manual

U

NITED

TAPE

EDGE

CLOSING

MACHINE

MODEL NR

UNITED MATTRESS MACHINERY COMPANY

Division of

Mathewson Corporation

86 Finnell Dr. Unit 6y Weymouth, MA. 02188

y

Telephone: 781-331-8440 or800-245-7250

E-MAIL: MATHCORP1@AOL.COM

A Complete line of bedding machinery

UNITED

MATTRESS MACHINERY

U

NITED

MODEL

NR

®

TAPE EDGE

CLOSING MACHINE

OPERATING AND PARTS MANUAL

MATHEWSON

CORPORATION

UNITED

MATTRESS MACHINERY

86

FINNELL

DRIVE

WEYMOUTH,

MA 02188

USA

TEL: 781

-

331-8440

FAX: 781

-

331-8870

E-Ma

il: mathcorp

1@aol

.com

©

Mathewson

Corporation 1999 All Rights Reserved

OPERATING MANUAL

TABLE OF CONTENTS

FORWARD

.........................................................................

ASSEMBLY INSTRUCTIONS

.........................................................

Table

...........................................................................

Carriage

........................................................................

Sewing Head

.....................................................................

Work Light

......................................................................

Threading

.......................................................................

Electrical Connections

..............................................................

Table Motor

.....................................................................

Overhead Swivel

..................................................................

Starting Machine

..................................................................

Adjustments

......................................................................

Looper

Adjustment

................................................................

OPERATING INSTRUCTIONS

........................................................

SPECIAL OPTIONAL FEATURES

.....................................................

Piping Attachment

..................................................................

Extension Bars

....................................................................

Under Table Swivel

.................................................................

Variable Speed

....................................................................

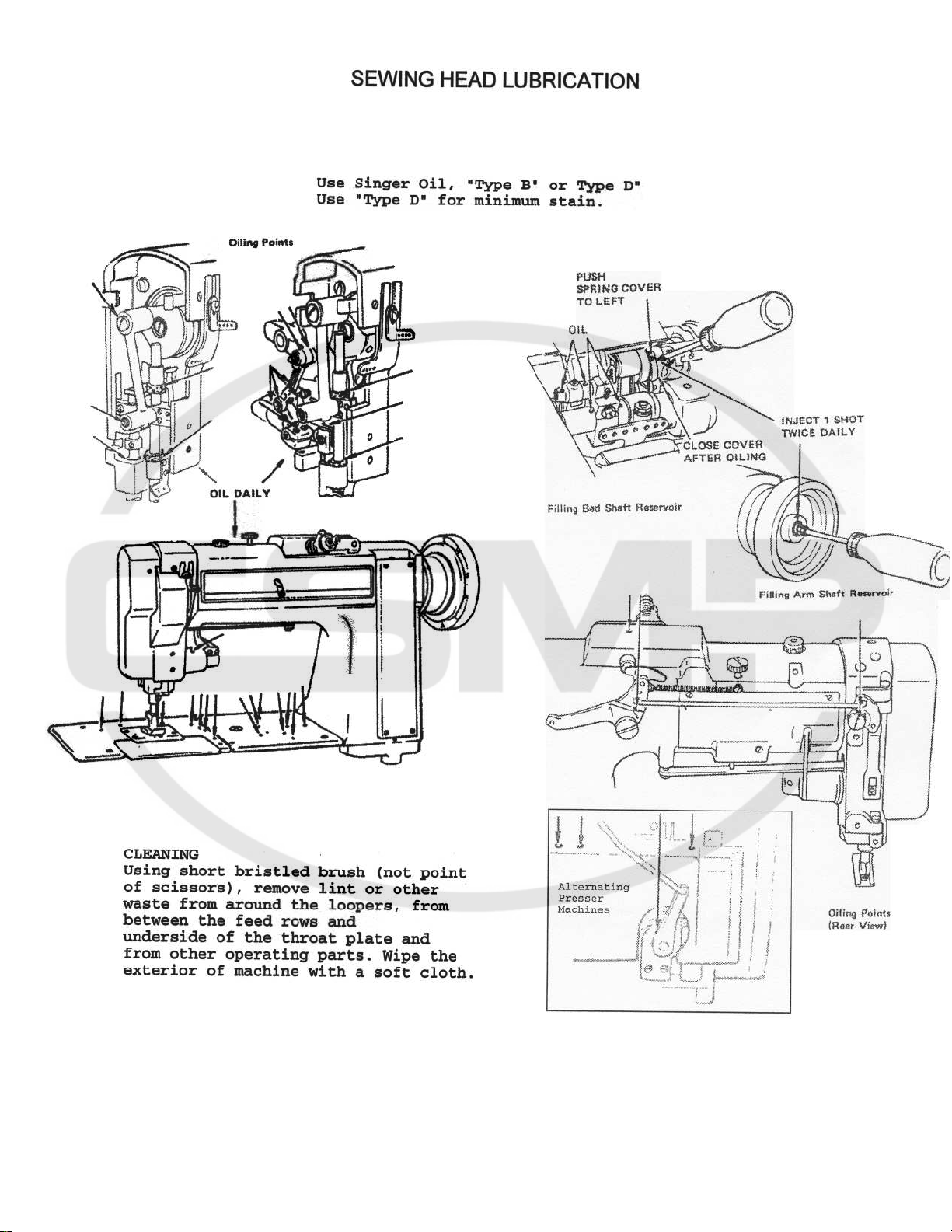

SEWING HEAD LUBRICATION

......................................................

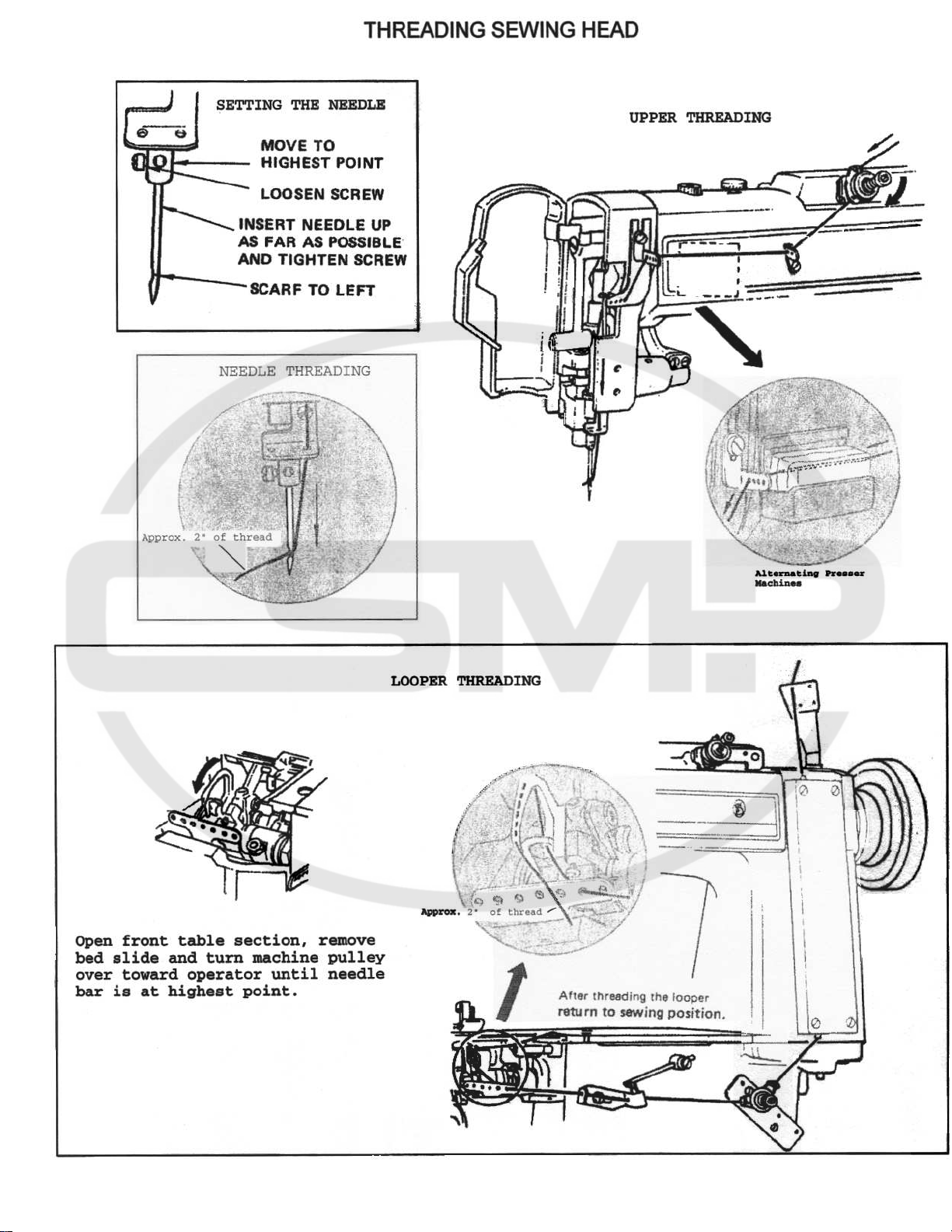

THREADING SEWING HEAD

........................................................

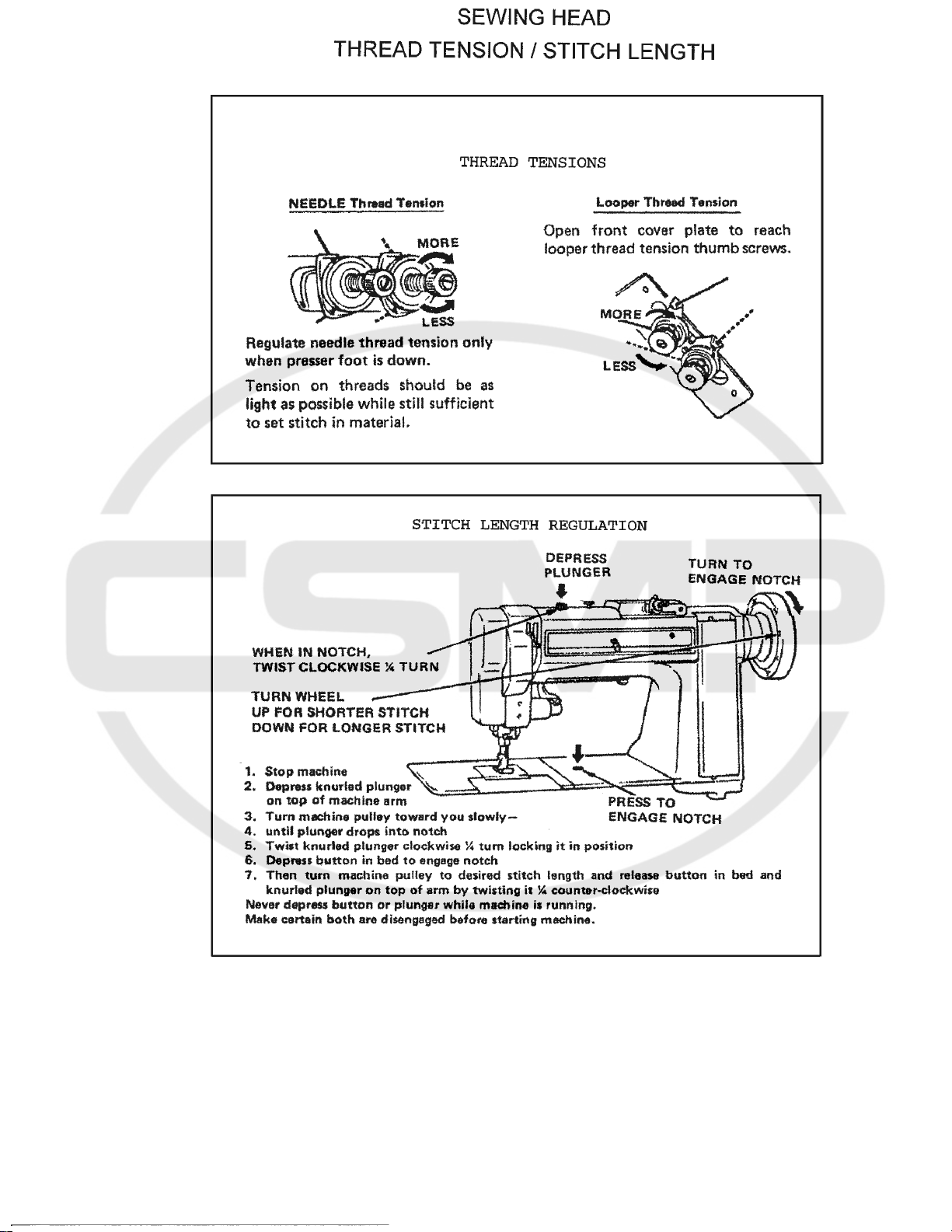

SEWING HEAD THREAD TENSION/STITCH LENGTH

.................................

MACHINERY WARRANTY

..........................................................

PARTS WARRANTY

.................................................................

PARTS MANUAL

Plate

Page

SEWING HEAD

1.

Front Assembly Sewing Arm

..............................................

4

2.

Upper Shaft Assembly

...................................................

8

3.

External Parts Sewing Arm

..............................................

12

4.

External Parts Sewing Arm

..............................................

14

5.

External Parts Sewing Arm

..............................................

16

6.

Front Assembly Sewing Bed

.............................................

18

7.

Lower Shaft Assembly

.................................................

22

8.

External Parts Sewing Bed (Binder list page 28)

..............................

26

9.

Cross Shaft in Sewing Bed

..............................................

30

Plate

Page

TABLE & CARRIAGE

10.

Old Style Gear Box Assembly

............................................

32

10A.

New Style Gear Box Assembly

...........................................

34

11.

Castor Assembly

......................................................

36

12.

Main Drive Assembly

..................................................

40

13.

Main Drive Assembly

..................................................

44

14.

Main Drive Assembly

..................................................

46

15.

Main Drive Assembly

..................................................

48

16.

Machine Traverse Speed Adjustment

......................................

52

17.

Table

...............................................................

54

18.

Table

...............................................................

56

19.

Overhead Swivel Assembly

..............................................

58

20.

Sewing Head Drive Belt Path

............................................

60

20.

Lubrication Chart

.....................................................

60

21.

NR Table Electrical Schematic

1ph

110v Motor

..............................

61

21A.

NR Table Electrical Schematic

1ph

220v Motor

..............................

62

21B.

NR Table Electrical Schematic

3ph

230/460v Motor

..........................

63

22.

NR Carriage Assembly Electrical Schematic

................................

64

23.

(plate reserved)

24.

Piping Attachment

.....................................................

66

25.

(plate reserved)

Variable Speed Drive

..................................................

69

26.

Variable Speed Drive Brake Potentiometer Assembly

..........................

71

27.

Variable Speed Drive Component Locations/Control Side

......................

72

28.

Variable Speed Drive Carriage Internal Parts

................................

73

29.

Variable Speed Drive Control Panel Assembly

...............................

74

30.

Variable Speed Drive Guard Group

.......................................

75

31.

Variable Speed Tilt Head Assembly

.......................................

76

32.

Variable Speed Drive Electrical Schematic

..................................

77

33.

Variable Speed Drive Proximity Switch Actuator

.............................

78

34.

Variable Speed Drive Proximity Switch

....................................

79

35.

Under Table Swivel Top and Side Views

...................................

81

36.

Under Table Swivel Slip Ring Assembly

...................................

82

37.

Under Table Swivel Isometric View

.......................................

83

PARTS INDEX

.....................................................

85

This heavy duty machine is shipped to you in a

single crate, with the completely assembled table

on a skid, and bo

xed with the

carriage and

sewing head each strapped to it. The accessories

are w

r

apped a

nd packed in a separate box inside

the shi

pp

ing box

.

TABLE

Set up the table in it

’s proper location. inst

a

ll the

adjusting screws provided, at the bottom of each

leg to level the table.

CARRIAGE

To assemble the carriage to the table, first

remove the roller and stud from the bracket at

upper track level. This roller normally runs

against the narrow inside (back) face of the upper

track. It must be removed to get the carriage on

the track. When the carriage has been lifted on

the track, running on its caster rollers, replace the

roller and stud, this roller adjusts the backlash in

the carriage gear and is

pre-set

at the factory by

means of the two set screws and

locknuts

in the

front of the carriage mounting brackets. After

mounting the carriage

on the table, check for proper backlash by

r

eaching through the back of the carriage and

turning the drive gear side to side. The gear

should only have enough play to be just barely

noticeable.

The machine has been tested at the factory and

no other adjustments are needed.

SEWING HEAD

Attach the sewing head to the carriage, by means

of the four hex head screws provided. These are

put in from the bottom, and on two of them a

little reaching under the carriage upper tilt plate

will have to be done.

F

asten the sewing head drive belt (round belt)

over the pulley and feed over idler pulley and

sewing head pulley. Then replace the drive wheel

cover and sewing head belt guard.

WORK LIGHT

The

work

-

light bracket is fastened on the side of

the head opposite the operator's position. Two

screws for fastening the bracket will be found in

place. The wire to plug in the work light should

be fastened in two places with

plastic

clips

before

plugging it into the lower outlet on the carriage.

PLEASE READ THIS MANUAL THOROUGHLY BEFORE OPERATING THE MACHINE

ASSEMBLY INSTRUCTIONS

This construction manual and parts catalog

contains all the necessary information on

installation, operation, care and maintenance

of the United Model NR Tape Edge Closing

Machine.

The design of this machine is the result of a

continuous development program to provide

you with modern production equipment to

help make better products ... faster and at

less cost.

To insure the successful operation of the

machine it should be kept well lubricated and

as clean as possible.

OPERATING MANUAL

FOREWORD

(The top outlet is for the main power wire

coming down from the swivel.) Both these plugs

(connectors) are of the twist

-

on type, requiring a

short twist to lock them in place.

THREADING

Next, fasten the (lower) thread cone platter and

the (upper) tape reel on the same side of the

carriage, away from the table. A rubber guide

loop for the main power wire is attached to the

head with the same screw used to fasten the tape

reel.

Three thread guides, consisting of a wire with a

loop at each end are fastened to the carriage and

sewing head below the tape reel. The right

-

hand

(needle) thread uses two thread guides, a long

one on the carriage and a shorter one on the head;

the latter to the left to by

-

pass the reel. The

looper

thread, further to the left, uses only one

(long) thread guide on the carriage. These guide

the two threads to the bracket on top of the head.

The

looper

thread (on the left) passes from the

bracket down through a tube provided. Just

thread any needle to the thread and use it as a

weight to pass the thread down through the tube

to its lower tension post.

The other (needle) thread goes from the upper

tension post over various thread guides across the

top of the head and down the nose to the needle.

The sewing head comes to you fully threaded, so

please observe the various thread guides. For

further threading information, see page x of this

section.

ELECTRICAL CONNECTIONS

ALL ELECTRICAL CONNECTIONS

SHOULD BE MADE BY A QUALIFIED

ELECTRICIAN

TABLE MOTOR

Connect from floor under the table to eliminate

exposed wires.

O

VER

HEAD SWIVEL

Fasten the overhead swivel (banjo) to the ceiling

from 7' to 10' above the floor level. The swivel

wire is

brought down and threaded through a rubber

loop, which is fastened to the head below the tape

reel with one of the tape reel screws. Be sure the

"ground" wire is properly connected. The swivel

wire is plugged in and twisted (locked) in place

on the upper one of the two connectors on the

side of the carriage.

STARTING MACHINE

It is advisable to first turn it over by hand, to be

sure everything is in order before turning on the

power.

Be sure carriage moves freely along the rail

before starting the machine.

Press your right knee against the foam rubber

pad on the clutch control, flip the start switch to

on, and then move the clutch handle to the

horizontal position.

ATTENTION:

Movement of the clutch handle to the

horizontal position without depressing the

clutch knee pad will result in severe damage to

the carriage drive and void the warranty.

ADJUSTMENTS

The machine is designed to tape-sew the full

circumference of the mattress, to sew the

complete panels to the boxing.

It will also close the ends of the mattresses filled

on a filling machine with or without tape. When

finishing a seam with tape, cut it off just behind

the needle and sew it off to complete the

unbroken tape continuity around the mattress

edge. To

rethread

the tape into the binder, if

necessary, cut it off on a long bias to create a

point on the tape for easier threading.

The United heavy-duty head on this machine

sews without bobbins, without interruption for

the length of the thread cones. Owing to the

special construction of the sewing head, it sews

with walking feet up very close to the end of the

arm, with the tape always under compression and

requiring a minimum of effort for the operator to

pull the boxing and the panel into sewing position

in the binder.

A soft 30/3 cord thread is recommended for both

the needle and the

looper.

Either left twist or right

twist thread can be used.

For the piping attachment, a 24/3 cord thread is

recommended for the needle only.

LOOPER

ADJUSTMENT

(The following instructions take place of and

supersede those in the green Singer booklet.)

To time and position the "United" sewing

machine

looper,

set the machine to the desired

stitch length. Loosen the

Looper

Carrier Crank

Clamping Nut (#201524E) sufficiently to be able

to tap the

Looper

Carrier from position. Set

looper

timing mark

(L.T.)

on machine pulley

opposite the arrow on the front of the arm. Tap

the

looper

carrier until the

looper

point is at the

center of the needle.

Turn the machine pulley until the letter "G" is

opposite the arrow on the front of the arm. At

this position the

looper

point should again be at

the center of the needle. If it is not, adjust the

timing of the

looper

crank by adjusting the

looper

timing screw, until the point of the

looper

is at

the center of the needle at both the above

described position of the machine pulley.

("L.T."

opposite arrow and "G" opposite arrow.)

When this position is obtained, securely tighten

the

looper

carrier crank clamping nut. The

looper

will now be timed and positioned correctly.

About 7' x 10' floor space is needed for operating

the machine. A combination of the angle setting

(tilt) of the sewing head, plus the power

adjustment of the table height, permits closing

mattresses and cushions from 1" up to

ll¼"

box,

or knife edge cushions and pads.

When the clutch handle, located to the left of the

starting switch, is vertical (upright), the carriage

is not in gear and will not move forward when the

power is turned on. When this same handle is

pulled to a horizontal position, the machine

carriage is in gear and will move forward when

the sewing head starts to function.

CAUTION:

Movement of the clutch handle to

the horizontal position without depressing the

clutch knee pad will result in severe damage to

the carriage drive and void the warranty.

There is a plunger type locking device just below

the clutch handle which locks the carriage tight in

place when it is desired to use the sewing head in

a stationary position, viz: for closing cushions or

similar smaller articles.

In general operation of this equipment, to stop

the whole mechanism, both sewing head and

forward motion carriage, press the right knee

against the foam rubber pad on the knee control.

This will leave both the operator's hands free to

guide the sewing.

To start the whole mechanism forward, sewing,

remove the knee pressure slowly from the knee

control.

For the mattress closing operation, have a fully

assembled mattress on the machine table with

both the hemmed panels temporarily fastened to

the hemmed boxing with 3" upholstery pins - six

pins per panel will do. Use the

finger-tip

table

height control to regulate for the proper sewing

height by merely pulling the cord at any point

around the table. Pull to the right to raise the

mattress; to the left to lower it. Limit switches

prevent the table from raising or lowering too far.

Before starting to sew, grasp the panel firmly

with the left hand, the boxing with the right,

aiming the

two together so that the edges are in

the binder. A special lever on the sewing head

will lock the presser foot in the upper (open)

position so that the panel and boxing can be

pushed into the binder without difficulty.

To release the presser foot from the upper (raised

and locked) position, the operator needs only to

push the lever with his elbow, so that it

disengages from its lock notch and closes down

on the material to be sewn. The sewing head can

then be turned over by hand to push the needle

through the goods to be ready for sewing.

Have everything ready to sew, with the right knee

pushed up against the foam rubber knee pad, and

then turn on the power. Withdraw the knee

pressure gradually, permitting the carriage to

start forward, sewing as it goes along. To stop

the machine, apply positive pressure with the

right knee on the foam rubber pad again, which

disengages the clutch and stops the machine.

A new operator should be given a mattress to

practice on for a day. He should sew up one

panel, rip off the tape. and then do it again, until

he has the "feel" of the machine. He should

practice on the first panel until he acquires the

knack of sewing and then try the second panel,

which will be tighter.

In the beginning the operator will sew for as long

as he can hold the panel and the boxing, and then

stop the machine (with the knee control) until he

can get another firm hold. The technique of a

good tape edge closing operator is to pull upward

to get the panel and the boxing under the needle,

into the binder, but not to pull forward. When

the two hands have the panel and boxing well

into the binder and are holding it several inches

ahead of the needle, shift the hold to the right

hand and move the left hand for a new hold

further to the front;

OPERATING INSTRUCTIONS

at the same time being ready to move the right

hand forward to a new hold the minute the

sewing mechanism has closed the mattress (with

tape) thus far.

As some experience is gained, longer stretches of

tape will be sewn without stopping the machine.

Note that the binder and presser feet are right at

the far end of the sewing arm, flush with the

edge, which makes it easier to pull the panel and

boxing up into sewing position. As more

experience is gained, this feature will aid and

encourage

non-stop

sewing for the length of the

straight seams, and facilitate sewing around the

corners.

Mattresses with Marshall (muslin pocket) type

spring units are quite soft and therefore easy to

close. Those requiring the most effort are the

ones selling under various names identifying

them as extra firm. These are particularly tight

after the half-way-around point on the second

panel when everything tightens up. At this point

it is essential for the operator to use his left

elbow to draw the panel towards the needle, to

ease the pressure at the point of sewing.

Most good operators use this elbow technique on

all mattresses, and by so doing have been able to

improve their sewing speed. A combination

crawling fingers and the elbow technique aids

non-stop

sewing on the long seams, especially on

this machine with its special features to

encourage such speed sewing.

The machine is equipped with two motors. One is

in the bottom of the carriage to drive the carriage

and

sewing machine. The second is under the table to

raise or lower the table top. Motors are installed

according to the customer's electrical

specifications.

See instructions attached to the carriage.

SPECIAL OPTIONAL FEATURES

PIPING ATTACHMENT

A piping attachment is available, at an extra

price, for the United Model NR Tape Edge

Machine. It consists of a bracket for holding the

12 lb. roll of roving, guide piece to feed the

roving into the needle, and a binder for using

1-7/16" tape.

This attachment produces the effect of a

miniature roll edge, and adds height to the box of

the mattress. If the original machine is purchased

with this piping attachment, there is no problem

for the user to figure out the feed of the roving.

The tape goes into the binder from the binder

platen just as any other tape would, and is

hand-fed into the binder by cutting off the tape on

the bias to create a point for easier handling.

All machines are drilled in the factory for this

piping attachment, so it can be put on with the

aid of an instruction blueprint (NR-465)

furnished when sold separately for later

attaching.

SPECIAL NOTE: When the piping attachment is

used, we recommend changing from a 30/3 to a

24/3 cord thread on the needle. Machines

furnished with the piping attachment as original

equipment also have a standard 7/8" tape binder

and pivot arm furnished as a separate unit.

The two binders with their pivot arms are

interchangeable so that the machine can be used

for either a piping or a plain tape.

To change over from one attachment to another,

simply remove the knurled-head pivot screw,

replace the one attachment and its arm with the

other, and the machine is ready to sew. Of

course, the different size tape (with or without

the roving) has to be fed into the binder. To do

this quickly, cut the tape on the bias with scissors

to create a long (tapered) point, which will feed

into the binder easily.

EXTENSION BARS

The special optional extension rack for oversize

mattresses easily slides out 18" on either side to

give extra support for King and other oversize

mattresses. Locks out of the way when working

on standard sizes.

UNDER TABLE SWIVEL

The United under table swivel not only gives you

trouble free operation, but it eliminates all

overhead cords or swivels. Just plug in the power

inlet cord and you are ready to start operating.

VARIABLE SPEED

The optional variable speed system controls the

speed of travel of the carriage and sewing head as

they move along the table.

There are two knobs at the operator station, one

for controlling the speed of the carriage along the

straight portion of the table and the other to set

the speed of the carriage as it travels through the

corners. Speeds for straight and corner travel are

independent.

The speeds selected depend on the skill and

experience of the operator.

Please note:

The carriage should not be

subjected to shock as it enters the corners. Be

sure to set the speed so that the carriage enters

the corners smoothly.

Travel speed is also controlled by means of the

foam rubber knee pad.

The carriage can be

stopped by exerting "inward" pressure on the

knee pad. Reducing the inward pressure on the

knee pad allows the carriage to reach the travel

speed set at the operator's station.

The variable speed electrical/ electronic

components are enclosed under a cover guard

located on the side of the carriage opposite the

operator's station. The major electronic

component under this guard is

Zener

master

controller. Please refer to the

Zener

instruction

manual for trouble shooting.

U

NITED

MATTRESS MACHINERY

STANDARD CONDITION OF SALE

MACHINERY WARRANTY

Mathewson

Corporation, United Mattress Machinery Division (the SELLER), warrants all new equipment

to be free from defects in material or workmanship for 120 days from date of installation. The obligation

under the WARRANTY is limited to the replacement or repair, at the SELLER'S factory, of parts which

shall appear to the SELLER, upon inspection, to have been so defective. This WARRANTY does not

obligate the SELLER to bear the cost of labor or transportation charges in connection with the replacement

or repair of defective parts. This WARRANTY shall not apply to any equipment which has been repaired

or altered without the SELLER'S authorization, nor shall it apply to any equipment which has been subject

to misuse, neglect or accident. With respect to any component or accessory purchased by the SELLER and

incorporated into any equipment, the WARRANTY of the manufacturer thereof shall apply and no other.

The SELLER shall in no event be liable for consequential damages or loss of prospective profits.

SELLER MAKES NO OTHER WARRANTY OF ANY KIND WHATEVER, EXPRESS OR IMPLIED;

AND ALL WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE WHICH EXCEED THE ABOVE

-

MENTIONED OBLIGATION ARE DISCLAIMED BY

SELLER AND EXCLUDED FROM THIS AGREEMENT.

Purchase Orders are accepted only when acknowledged in writing by the SELLER at

Weymouth,

Massachusetts, by its stated officers. No other employee, agent or salesman has authority to waive or vary

and term of the order, to take oral orders or make any sales on any other terms. Any agreement made shall

be governed by the laws of Massachusetts. Purchase Orders, after acceptance, are not cancelable except

by mutual agreement.

The SELLER reserves the right to make changes in design or add improvements to equipment at any time,

without incurring any obligation to install the same on equipment previously delivered.

DELIVERY

Shipping dates are approximate and are subject to the prompt receipt of all necessary information.

The SELLER shall not be liable for delays in delivery or

non-delivery,

in whole or in part, due to causes

beyond its reasonable control; due to acts of God, acts of the Purchaser, acts of civil or military authority,

priorities, fires, strikes, floods, epidemics, war, riot, delays in transportation or car shortages, or inability

due to causes beyond its reasonable control to obtain necessary labor, materials, components or

manufacturing facilities. In the event of any such delay, the date of delivery shall be extended for a period

equal to the time lost by reason of the delay.

U

NITED

MATTRESS MACHINERY

STANDARD CONDITION OF SALE

PARTS WARRANTY

Mathewson

Corporation, United Mattress Machinery Division (the SELLER), warrants all new parts to be

free from defects in material or workmanship for 90 days from date of shipment. The obligation under the

WARRANTY is limited to the replacement or repair, at the SELLER'S factory, of parts which shall appear

to the SELLER, upon inspection, to have been so defective. This WARRANTY does not obligate the

SELLER to bear the cost of labor or transportation charges in connection with the replacement or repair of

defective parts. This WARRANTY shall not apply to any equipment which has been repaired or altered

without the SELLER'S authorization, nor shall it apply to any equipment which has been subject to misuse,

neglect or accident. With respect to any component or accessory purchased by the SELLER and

incorporated into any equipment, the WARRANTY of the manufacturer thereof shall apply and no other.

The SELLER shall in no event be liable for consequential damages or loss of prospective profits.

SELLER MAKES NO OTHER WARRANTY OF ANY KIND WHATEVER, EXPRESS OR IMPLIED;

AND ALL WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE WHICH EXCEED THE ABOVE

-

MENTIONED OBLIGATION ARE DISCLAIMED BY

SELLER AND EXCLUDED FROM THIS AGREEMENT.

Purchase Orders are accepted only when acknowledged in writing by the SELLER at

Weymouth,

Massachusetts, by its stated officers. No other employee, agent or salesman has authority to waive or vary

and term of the order, to take oral orders or make any sales on any other terms. Any agreement made shall

be governed by the laws of Massachusetts. Purchase Orders, after acceptance, are not cancelable except

by mutual agreement.

The SELLER reserves the right to make changes in design or add improvements to equipment at any time,

without incurring any obligation to install the same on equipment previously delivered.

DELIVERY

Shipping dates are approximate and are subject to the prompt receipt of all necessary information.

The SELLER shall not be liable for delays in delivery or

non-delivery,

in whole or in part, due to causes

beyond its reasonable control; due to acts of God, acts of the Purchaser, acts of civil or military authority,

priorities, fires, strikes, floods, epidemics, war, riot, delays in transportation or car shortages, or inability

due to causes beyond its reasonable control to obtain necessary labor, materials, components or

manufacturing facilities. In the event of any such delay, the date of delivery shall be extended for a period

equal to the time lost by reason of the delay.

U

NITED

MATTRESS MACHINERY

PARTS MANUAL

Plate

Page

S

EWING HEAD

1

Front Assembly Sewing Arm

..............................................

4

2

Upper Shaft Assembly

...................................................

8

3

External Parts Sewing Arm

..............................................

12

4

External Parts Sewing Arm

..............................................

14

5

External Parts Sewing Arm

..............................................

16

6

Front Assembly Sewing Bed

.............................................

18

7

Lower Shaft Assembly

.................................................

22

8

External Parts Sewing Bed (Binder list page 28)

..............................

26

9

Cross Shaft in Sewing Bed

..............................................

30

TABLE & CARRIAGE

10

Old Style Gear Box Assembly

............................................

32

10A

New Style Gear Box Assembly

...........................................

34

11

Castor Assembly

......................................................

36

12

Main Drive Assembly

..................................................

40

13

Main Drive Assembly

..................................................

44

14

Main Drive Assembly

..................................................

46

15

Main Drive Assembly

..................................................

48

16

Machine Traverse Speed Adjustment

......................................

52

17

Table

...............................................................

54

18

Table

...............................................................

56

19

Overhead Swivel Assembly

..............................................

58

20

Sewing Head Drive Belt Path

............................................

60

20

Lubrication Chart

.....................................................

60

21

NR Table Electrical Schematic

1ph

110v Motor

..............................

61

21A

NR Table Electrical Schematic

1ph

220v Motor

..............................

62

21B

NR Table Electrical Schematic

3ph

230/460v Motor

..........................

63

22

NR Carriage Assembly Electrical Schematic

................................

64

23

(plate reserved)

24

Piping Attachment

.....................................................

66

25

(plate reserved)

Variable Speed Drive

..................................................

69

26

Variable Speed Drive Brake Potentiometer Assembly

..........................

71

27

Variable Speed Drive Component Locations/Control Side

......................

72

28

Variable Speed Drive Carriage Internal Parts

................................

73

29

Variable Speed Drive Control Panel Assembly

...............................

74

30

Variable Speed Drive Guard Group

.......................................

75

31

Variable Speed Tilt Head Assembly

.......................................

76

32

Variable Speed Drive Electrical Schematic

..................................

77

33

Variable Speed Drive Proximity Switch Actuator

.............................

78

34

Variable Speed Drive Proximity Switch

....................................

79

35

Under Table Swivel Top and Side Views

...................................

81

36

Under Table Swivel Slip Ring Assembly

...................................

82

37

Under Table Swivel Isometric View

.......................................

83

PARTS INDEX

.....................................................

85

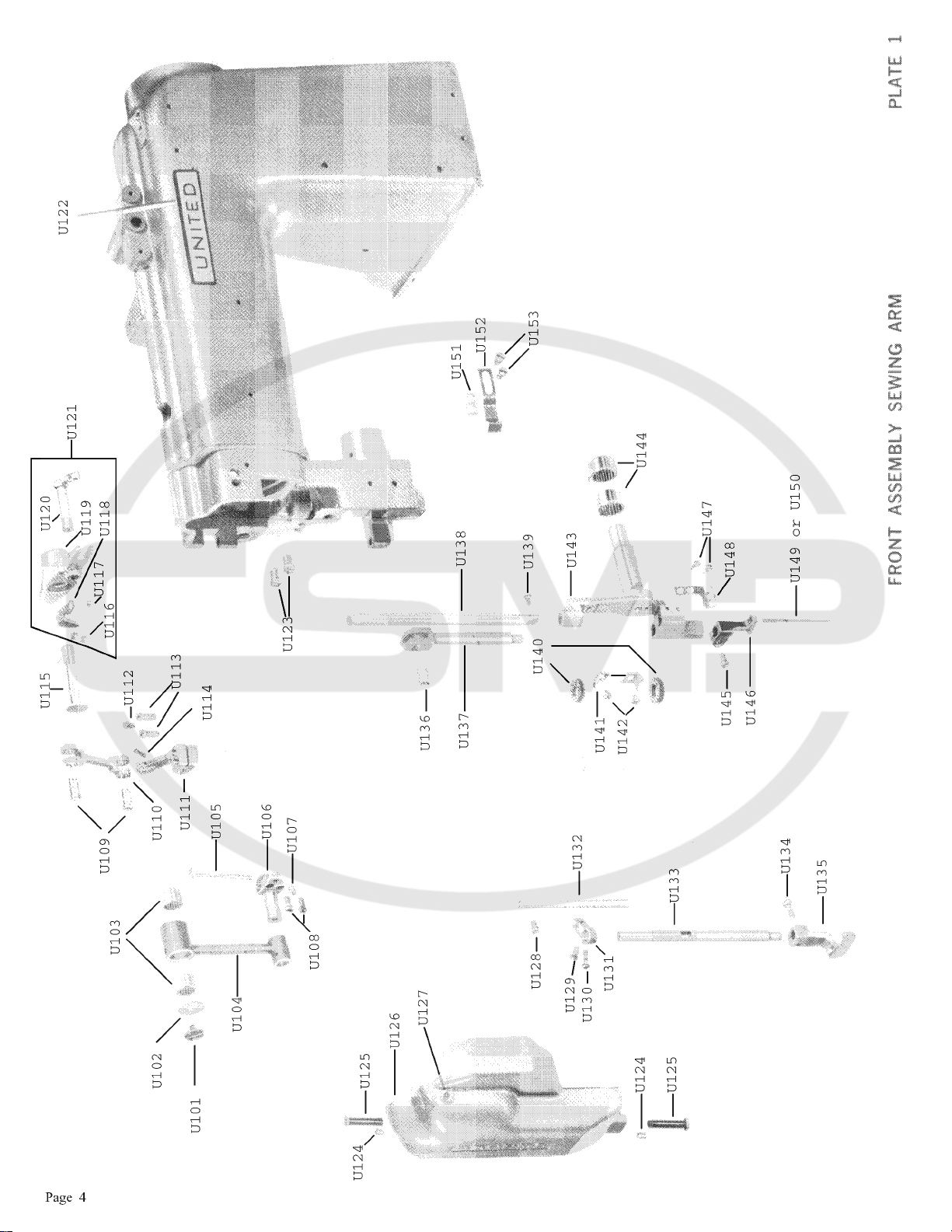

UNITED MATTRESS MACHINERY

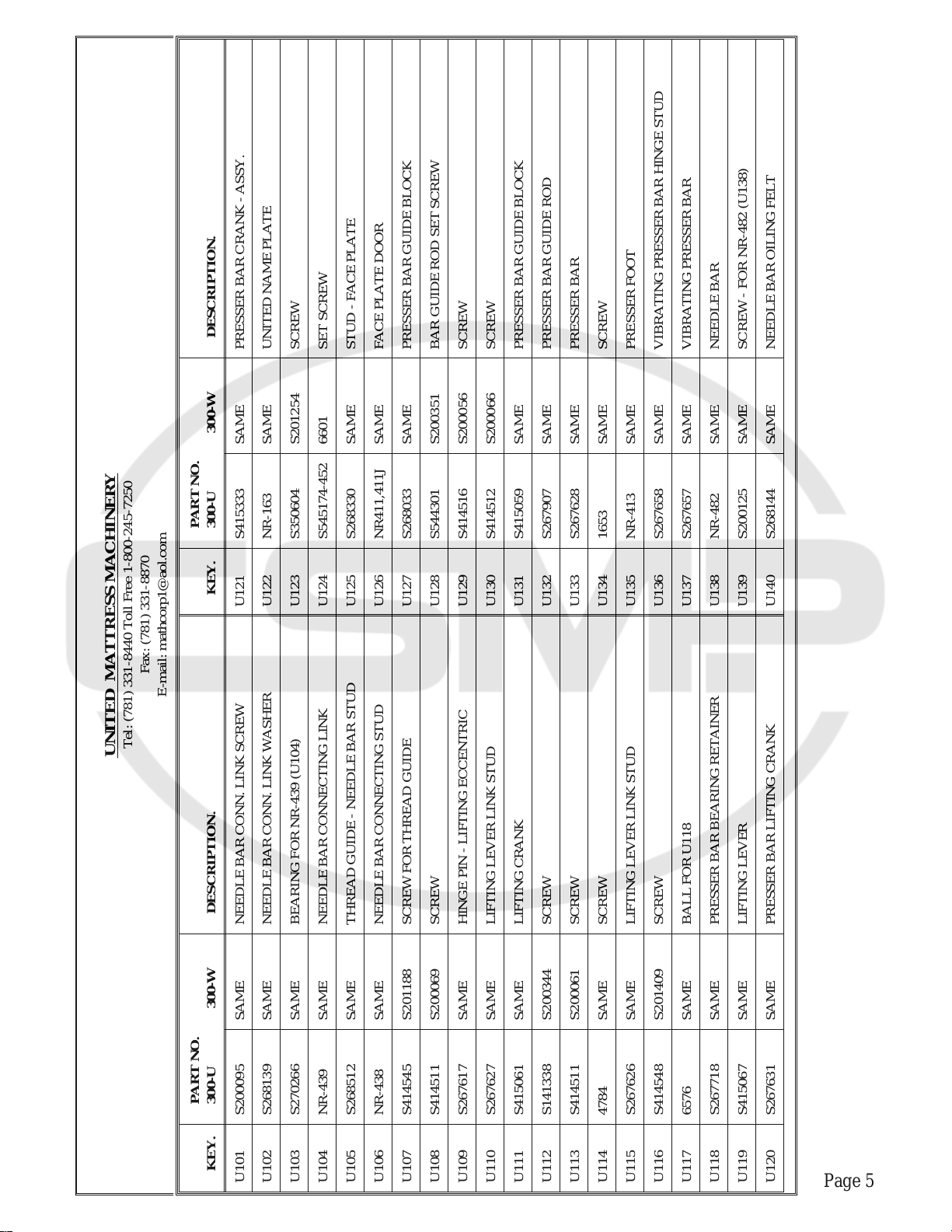

PLATE 1

FRONT ASSEMBLY SEWING ARM

Page.

3

NEEDLE BAR OILING FELT

SAME

S268144

U140

PRESSER BAR LIFTING CRANK

SAME

S267631

U120

SCREW - FOR NR-482 (U138)

SAME

S200125

U139

LIFTING LEVER

SAME

S415067

U119

NEEDLE BAR

SAME

NR-482

U138

PRESSER BAR BEARING RETAINER

SAME

S267718

U118

VIBRATING PRESSER BAR

SAME

S267657

U137

BALL FOR U118

SAME

6576

U117

VIBRATING PRESSER BAR HINGE STUD

SAME

S267658

U136

SCREW

S201409

S414548

U116

PRESSER FOOT

SAME

NR-413

U135

LIFTING LEVER LINK STUD

SAM

E

S267626

U115

SCREW

SAME

1653

U134

SCREW

SAME

4784

U114

PRESSER BAR

SAME

S267628

U133

SCREW

S200061

S414511

U113

PRESSER BAR GUIDE ROD

SAME

S267907

U132

SCREW

S200344

S141338

U112

PRESSER BAR GUIDE BLOCK

SAME

S415059

U131

LIFTING CRANK

SAME

S415061

U111

SCREW

S200066

S414512

U130

LIFTING LEVER LINK STUD

SAME

S267627

U110

SCREW

S200056

S414516

U129

HINGE PIN - LIFTING ECCENTRIC

SAME

S267617

U109

BAR GUIDE ROD SET SCREW

S200351

S544301

U128

SCREW

S200069

S414511

U108

PRESSER BAR GUIDE BLOCK

SAME

S268033

U127

SCREW FOR THREAD GUI

D

E

S201188

S414545

U107

FACE PLATE DOOR

SAME

NR411

,

411

J

U126

NEEDLE BAR CONNECTI

N

G ST

UD

SAME

NR-438

U106

STUD - FACE PLATE

SAME

S268330

U125

THREAD GUIDE - NEEDLE BAR STUD

SAME

S268512

U105

SET SCREW

6601

S545174-452

U124

NEEDLE BAR CONN

EC

TING LINK

SAME

NR-439

U104

SCREW

S201254

S350604

U123

BEARING FOR NR-439 (U104)

SAME

S270266

U103

UNITED NAME PLATE

SAME

NR-163

U122

NEEDLE BAR CONN. LINK WASHER

SAME

S268139

U102

PRESSER BAR CRANK -

ASSY

.

SAME

S415333

U121

NEEDLE BAR CONN. LINK SCREW

SAME

S200095

U101

DESCRIPTION.

300-W

PART NO.

300-U

KEY.

DESCRIPTION.

300-W

PART NO.

300-U

KEY.

UNITED MATTRESS MACHINERY

Tel: (781) 331-8440 Toll Free 1-800-24

5

-7250

Fax: (781) 331-8870

E-mail:

mathcorp1@aol.com

Page 5

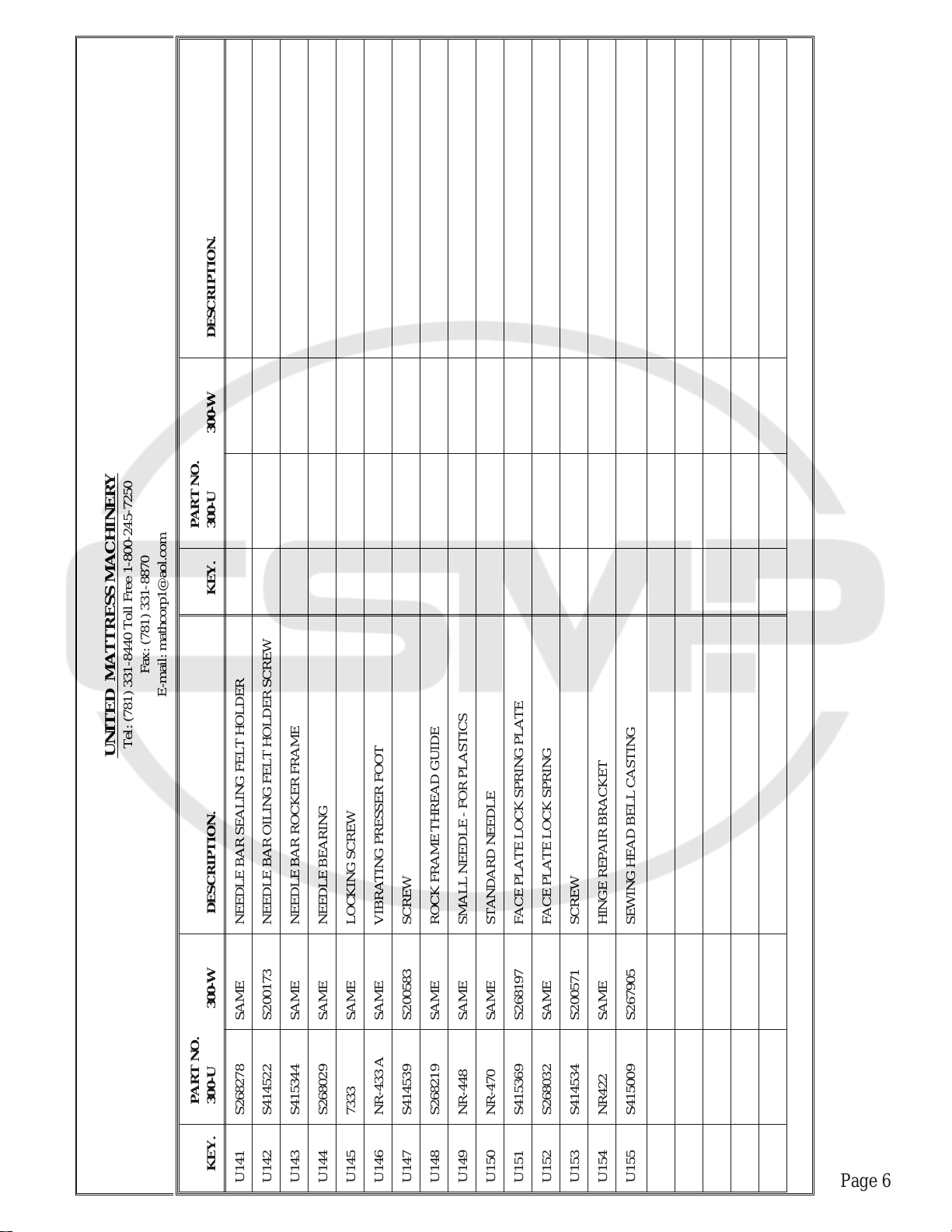

SEWING HEAD BELL CASTING

S267905

S415009

U155

HINGE REPAIR BRACKET

SAME

NR422

U154

SCREW

S200571

S414534

U153

FACE PLATE LOCK SPRING

SAME

S268032

U152

FACE PLATE LOCK SPRING PLATE

S268197

S415369

U151

STANDARD NEEDLE

SAME

NR-470

U150

SMALL NEEDLE - FOR PLASTICS

SAME

NR-448

U149

RO

CK FRAME THREAD GUIDE

SAME

S268219

U148

SCREW

S200583

S414539

U147

VIBRATING PRESSER FOOT

S

A

ME

NR-433 A

U146

LOCKING SCREW

SAME

7333

U145

NEEDLE BEARING

SAME

S268029

U144

NEEDLE BAR ROCKER FRAME

SAME

S415344

U143

NEEDLE BAR OILING FELT HOLDER SCREW

S200173

S414522

U142

NEEDLE BAR SEALING FELT HOLDER

SAME

S268278

U141

DESCRIPTION.

300-W

PART NO.

300-U

KEY.

DESCRIPTION.

300-W

PART NO.

300-U

KEY.

UNITED MATTRESS MACHINERY

Tel: (781) 331-8440 Toll Free 1-800-24

5

-7250

Fax: (781) 331-8870

E-mail:

mathcorp1@aol.com

Page 6

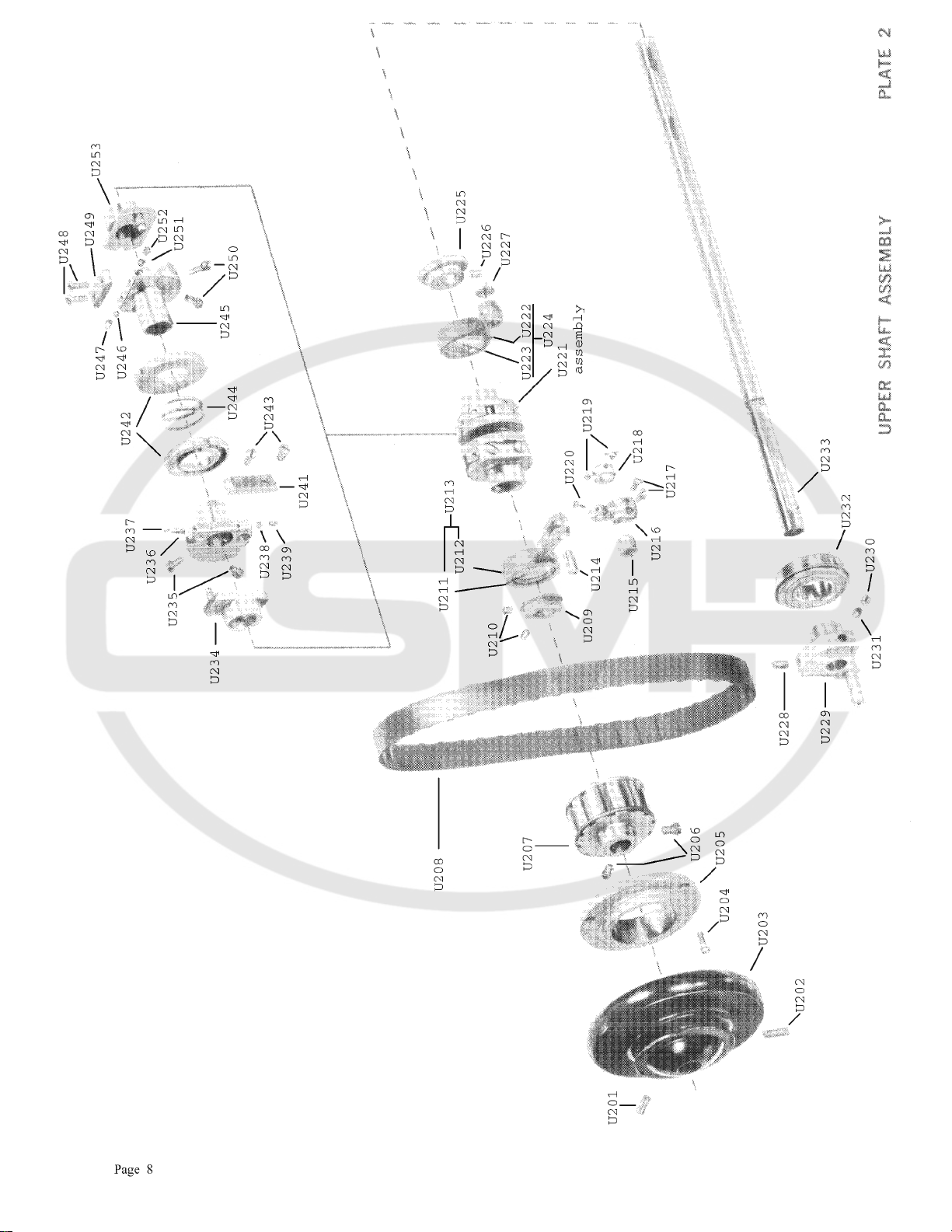

UNITED MATTRESS MACHINERY

PLATE 2

UPPER SHAFT ASSEMBLY

Page. 7

LIFTING ECCENTRIC FLANGE

SAME

S

415077

U240

SCREW

S201063

S414543

U220

SET SCREW

S350477

S414557

U239

SET SCREW

SAME

6526

U219

BRASS PACKING

SAME

S241763

U238

COLLAR

SAME

NR-429

U218

SET SCREW

S350477

S414557

U237

SCREW

S200058

S414509

U217

BRASS PACKI

N

G

SAME

S241763

U236

LIFING

ECCENTRIC CRA

N

K

SAME

S415069

U216

SCREW

S350467

S414555

U235

BEARING

SAME

S267110

U215

LIFTING ECCE

N

TRIC

SAME

S268064

U234

LINK ECC

ENTRIC HINGE PIN

SAME

S267617

U214

ARM SHAFT ASSEMBLY

SAME

S415128

U233

LIFTING ECCENTRIC CONNECTION

A

S

S

Y

.

SAME

S268493

U213

ARM SHAFT BALL BEARING

SAME

S32848

U232

LIFTING

ECCENR

IC

CONNECTION

SAME

S268492

U212

SCREW

S201222

S549024

U231

NEEDLE BEARING

SAME

S415368

U211

SCREW

S200346

S544358

U230

SCREW

6266

S414529

U210

NEEDLE BAR CRANK

SAME

S415137

U229

LIFTING ECCENTRIC SPACING COLLAR

SAME

NR-641

U209

SCREW

S200346

S500272

U228

BELT - ARM SHAFT - TI

MING ASSE

MBLY

SAME

NR-494

U208

CAP SCREW

S200123

S545297

U227

ARM SHAFT TIMING PULLEY

SAME

NR-491

U207

SCREW

6266

S414529

U226

SCREW

S201254

S414546

U206

LIFTING ECCENTRIC SPACING COLLAR

SAME

NR-641

U225

ARM SHAFT BEARING HOUSING

SAME

S268004

U205

CONNECTOR ASSEM

BLY

SAME

S268061

U224

SCREW

S20047

S544336

U204

NEEDLE BEARING

SAME

S415368

U223

HAND WHEEL ASSEMBLY

SAME

S415153

U203

CONNECTOR

SAME

S268060

U222

BALANCE WHEEL POSITION SCREW

S200342

S414526

U202

TOP SHAFT ECCENTRIC ASSE

MBLY

SAME

S415075

U221

BALANCE WHEEL LOCK SCREW

S200347

S414525

U201

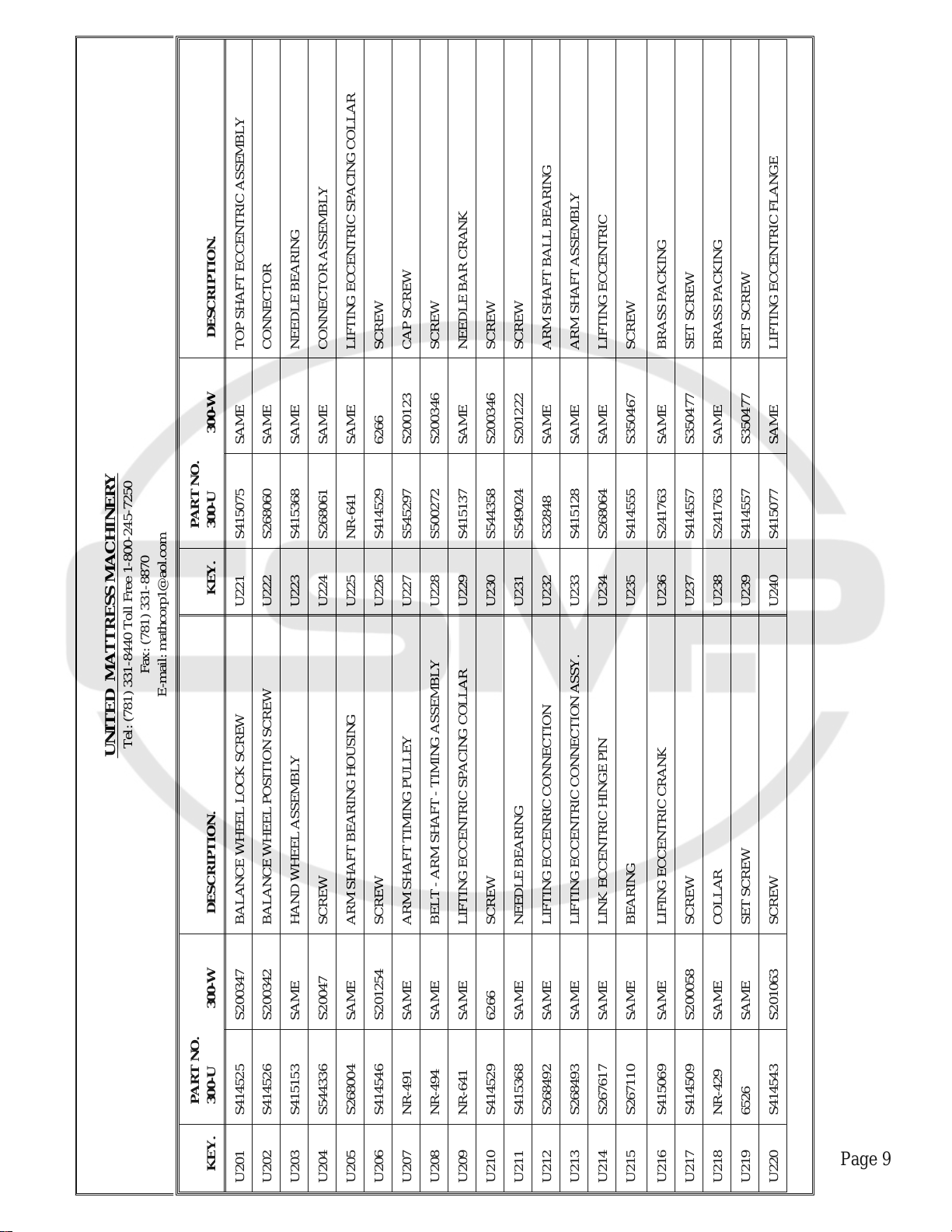

DESCRIPTION.

300-W

PART NO.

300-U

KEY.

DESCRIPTION.

300-W

PART NO.

300-U

KEY.

UNITED MATTRESS MACHINERY

Tel: (781) 331-8440 Toll Free 1-800-24

5

-7250

Fax: (781) 331-8870

E-mail:

mathcorp1@aol.com

Page 9

HANDWHEEL

BEARING

SAME

S272142

U253

LIFTING ECCEN

T

R

IC

SAME

S268064

U253

SET SCREW

S350477

S414557

U252

BRASS PACKING

SAME

S241763

U251

SCREW

S350467

S414555

U250

GIB

SAME

S267623

U249

SCREW

S350548

S544286

U248

SET SCREW

S350477

S414557

U247

BRASS PACKING

SAME

S241763

U246

LIFTING ECCENTRIC FLANGE

SAME

S415079

U245

ADJUSTING DISC SPRING

SAME

S267618

U244

SCREW

S350548

S374098

U243

ADJUSTING FLAN

GE

SAME

S268065

U242

GIB

SAME

S267623

U241

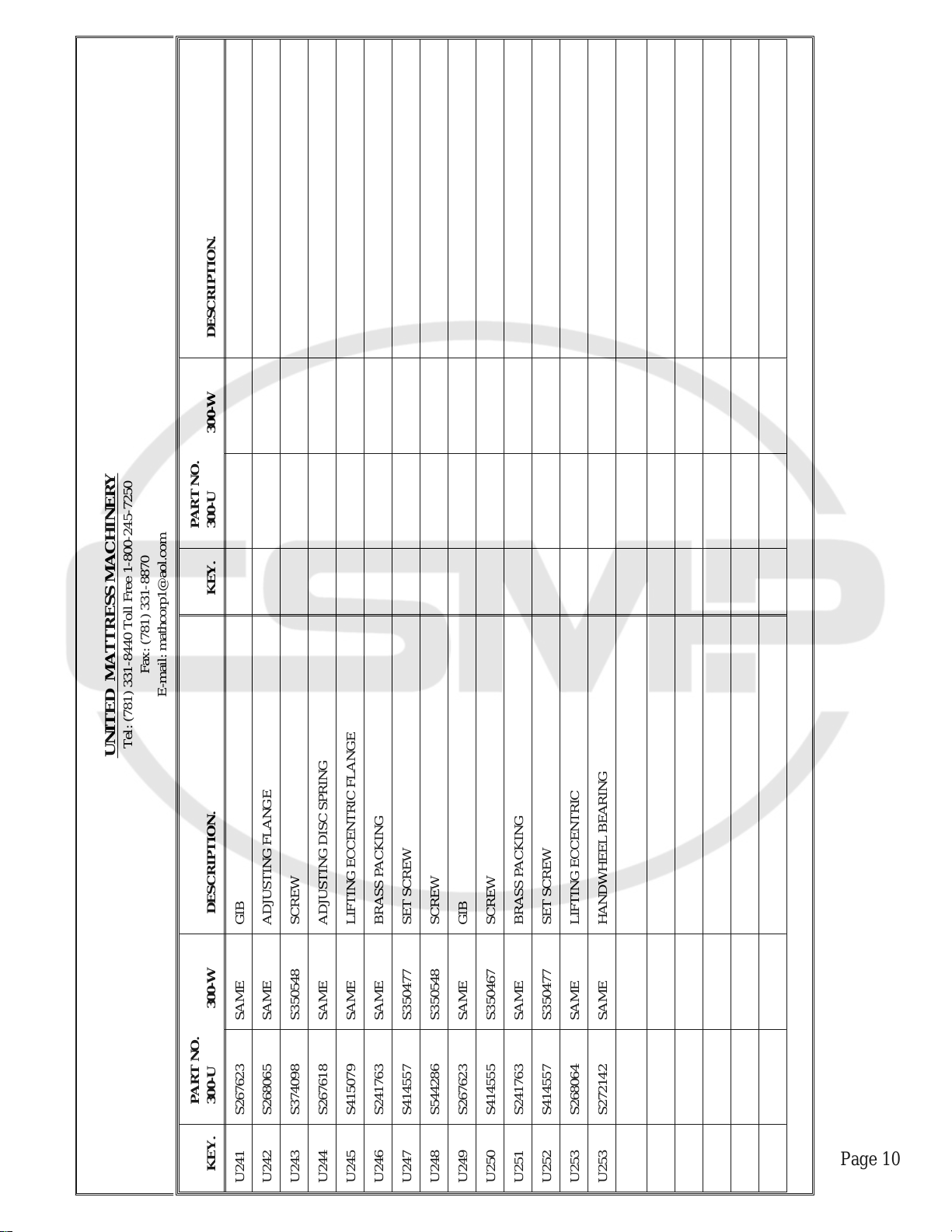

DESCRIPTION.

300-W

PART NO.

300-U

KEY.

DESCRIPTION.

300-W

PART NO.

300-U

KEY.

UNITED MATTRESS MACHINERY

Tel: (781) 331-8440 Toll Free 1-800-24

5

-7250

Fax: (781) 331-8870

E-mail:

mathcorp1@aol.com

Page 10

UNITED MATTRESS MACHINERY

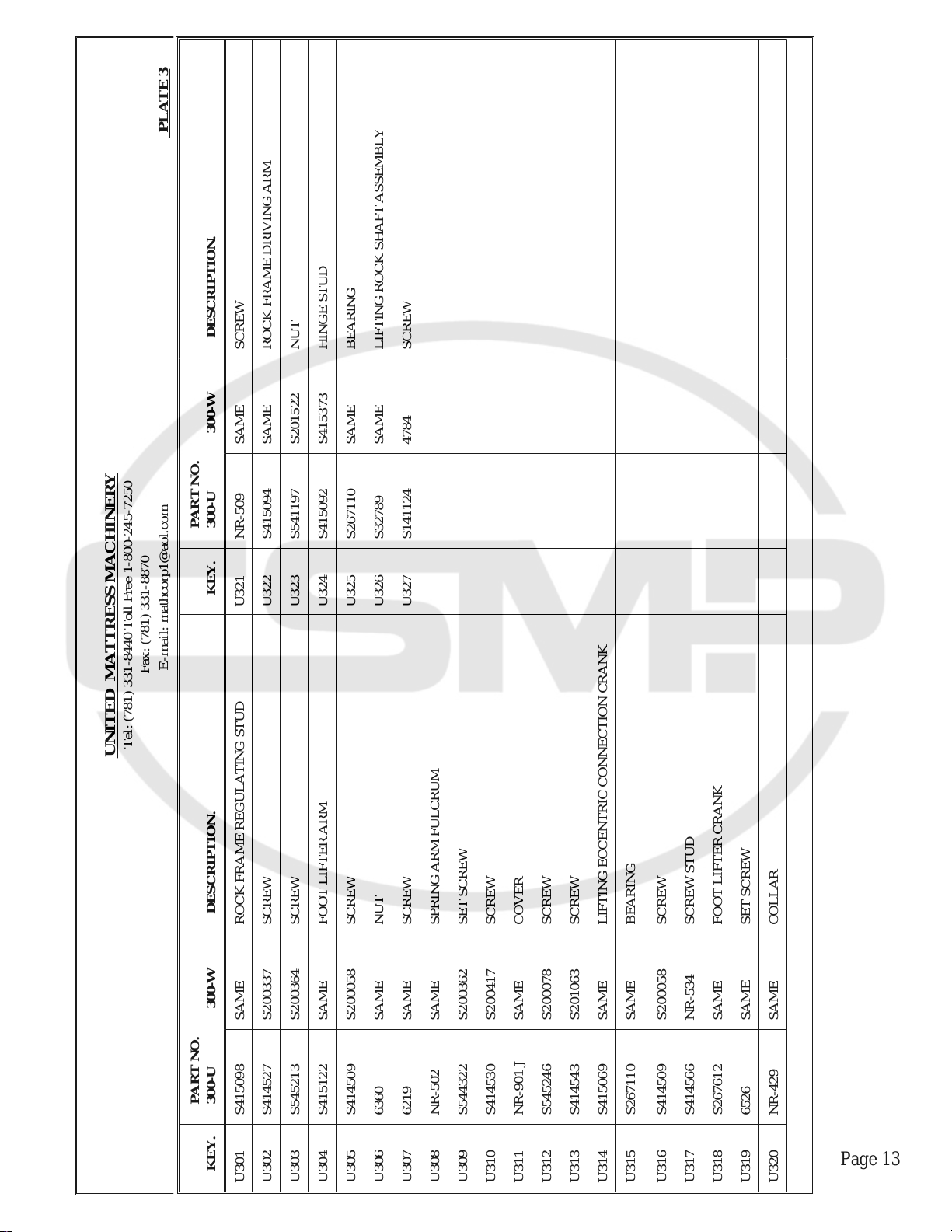

PLATE 3

EXTERNAL PARTS SEWING ARM

Page.11

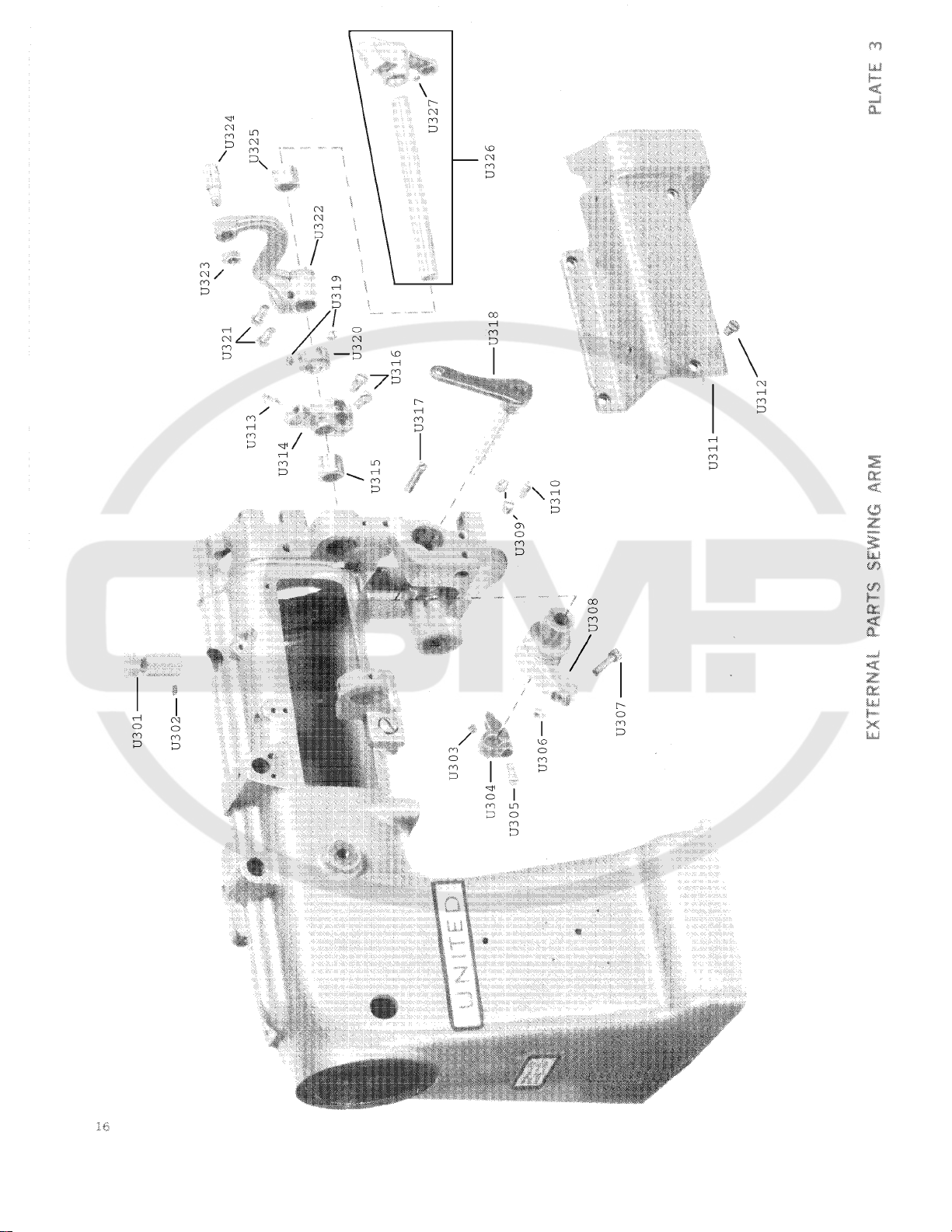

COLLAR

SAME

NR-429

U320

SET SCREW

SAME

6526

U319

FOOT LIFTER CRANK

SAME

S267612

U318

SCREW STUD

NR-534

S414566

U317

SCREW

S200058

S414509

U316

BEARING

SAME

S267110

U315

LIFTING ECCENTRIC CONN

EC

TION CRAN

K

SAME

S415069

U314

SCREW

S201063

S414543

U313

SCREW

S200078

S545246

U312

COVER

SAME

NR-901 J

U311

SCREW

S200417

S414530

U310

SET SCREW

S200362

S544322

U309

SPRING ARM FULCRUM

SAME

NR-502

U308

SCREW

4784

S141124

U327

SCREW

SAME

6219

U307

LIFTING RO

CK SHA

FT ASSEMBLY

SAME

S32789

U326

NUT

SAME

6360

U306

BEARING

SAME

S267110

U325

SCREW

S200058

S414509

U305

HINGE STUD

S415373

S415092

U324

FOOT LIFTER ARM

SAME

S415122

U304

NUT

S201522

S541197

U323

SCREW

S200364

S545213

U303

ROCK FRAME DRI

VING ARM

SAME

S415094

U322

SCREW

S200337

S414527

U302

SCREW

SAME

NR-509

U321

ROCK FRAME RE

G

ULATING ST

UD

SAME

S415098

U301

DESCRIPTION.

300-W

PART NO.

300-U

KEY.

DESCRIPTION.

300-W

PART NO.

300-U

KEY.

UNITED MATTRESS MACHINERY

Tel: (781) 331-8440 Toll Free 1-800-24

5

-7250

Fax: (781) 331-8870

E-mail:

mathcorp1@aol.com

PLATE 3

Page 13

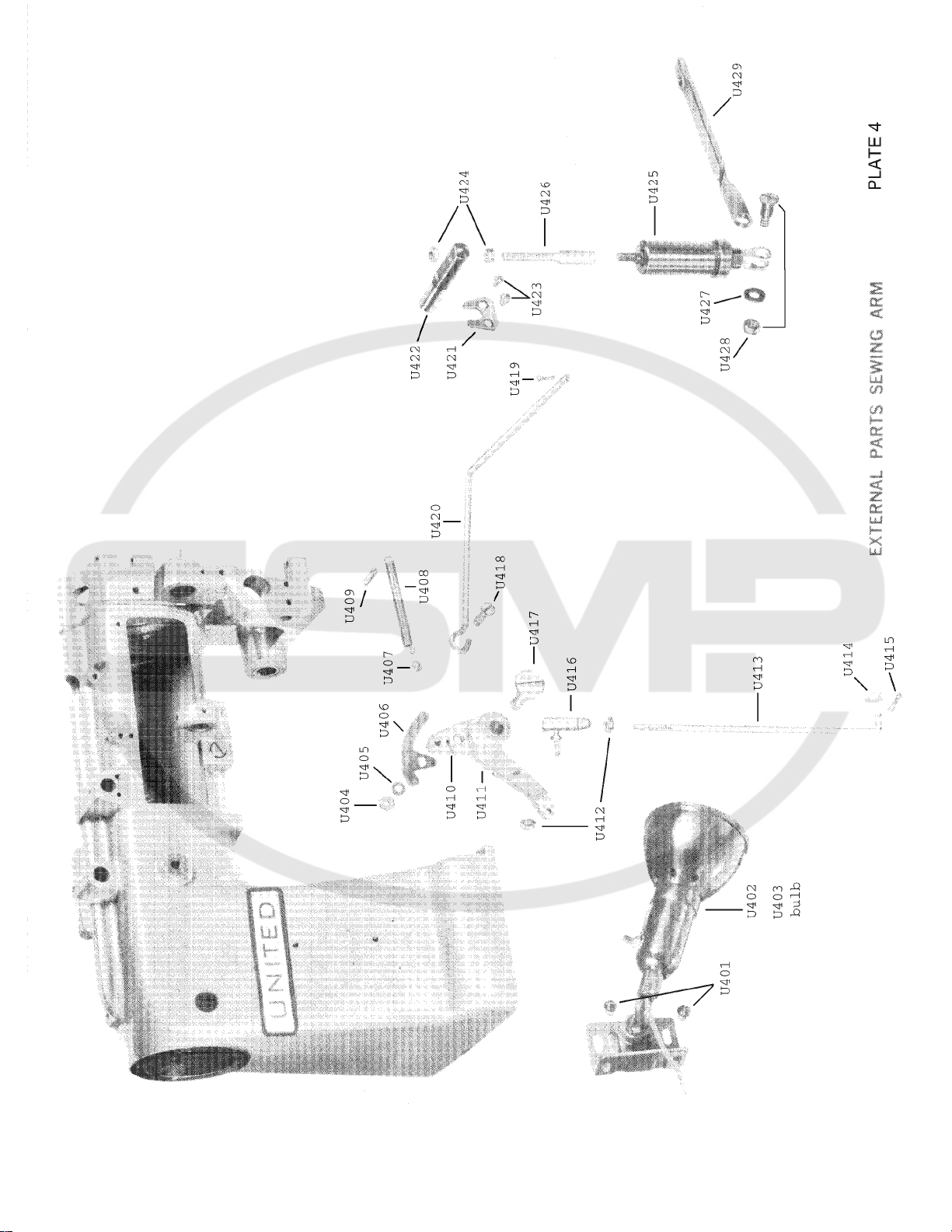

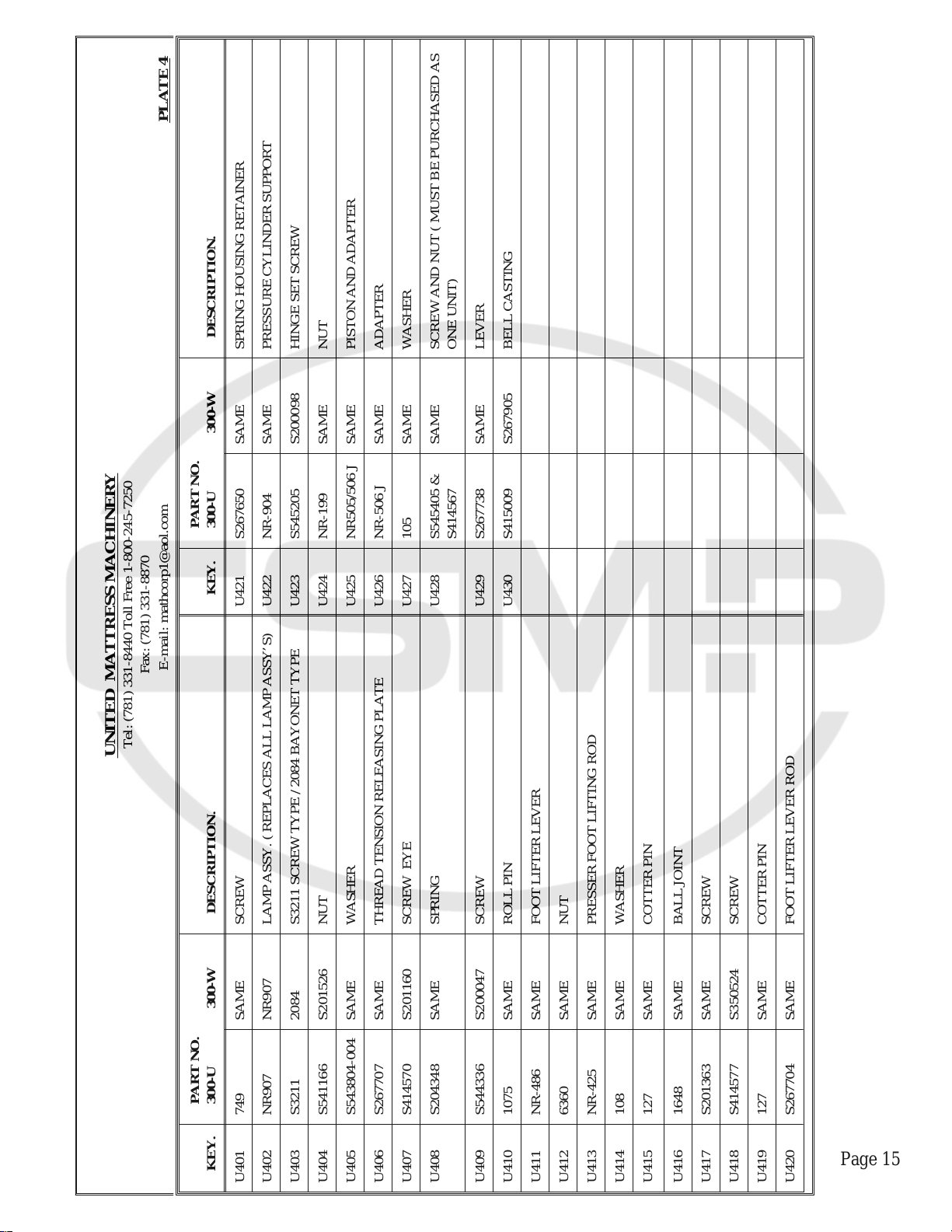

UNITED MATTRESS MACHINERY

PLATE 4

EXTERNAL PARTS SEWING ARM

FOOT LIFTER LEVER ROD

SAME

S267704

U420

COTTER PIN

SAME

127

U419

SCREW

S350524

S414577

U418

SCREW

SAME

S201363

U417

BALL JOINT

SAME

1648

U416

COTTER PIN

SAME

127

U415

WASHER

SAME

108

U414

PRESSER FOOT LIFTING ROD

SAME

NR-425

U413

NUT

SAME

6360

U412

FOOT LIFTER LEVER

SAME

NR-486

U411

BELL CASTING

S267905

S415009

U430

ROLL PIN

SAME

1075

U410

LEVER

SAME

S267738

U429

SCREW

S200047

S544336

U409

SCREW AND NUT ( MUST BE PURCHASED AS

ONE UNIT)

SAME

S545405 &

S414567

U428

SPRING

SAME

S204348

U408

WASHER

SAME

105

U427

SCR

EW EYE

S201160

S414570

U407

ADAPTER

SAME

NR-506 J

U426

THREAD TENSION RELEAS

ING PLATE

SAME

S267707

U406

PISTON AND ADAPTER

SAME

NR505/506

J

U425

WASHER

SAME

S543804-004

U405

NUT

SAME

NR-199

U424

NUT

S201526

S541166

U404

HINGE SET SCREW

S200098

S545205

U423

S3211 SCREW TYPE / 2084 BAYONET TYP

E

2084

S3211

U403

PRESSU

RE CYLINDER SUPPORT

SAME

NR-904

U422

LAMP

ASSY.

( REPLAC

E

S ALL LAMP

ASSY

’

S

)

NR907

NR90

7

U402

SPRING HOUSING RETAINER

SAME

S267650

U421

SCREW

SAME

749

U401

DESCRIPTION.

300-W

PART NO.

300-U

KEY.

DESCRIPTION.

300-W

PART NO.

300-U

KEY.

UNITED MATTRESS MACHINERY

Tel: (781) 331-8440 Toll Free 1-800-24

5

-7250

Fax: (781) 331-8870

E-mail:

mathcorp1@aol.com

PLATE 4

Page 15

Loading...

Loading...