TAOS TSL3301 Datasheet

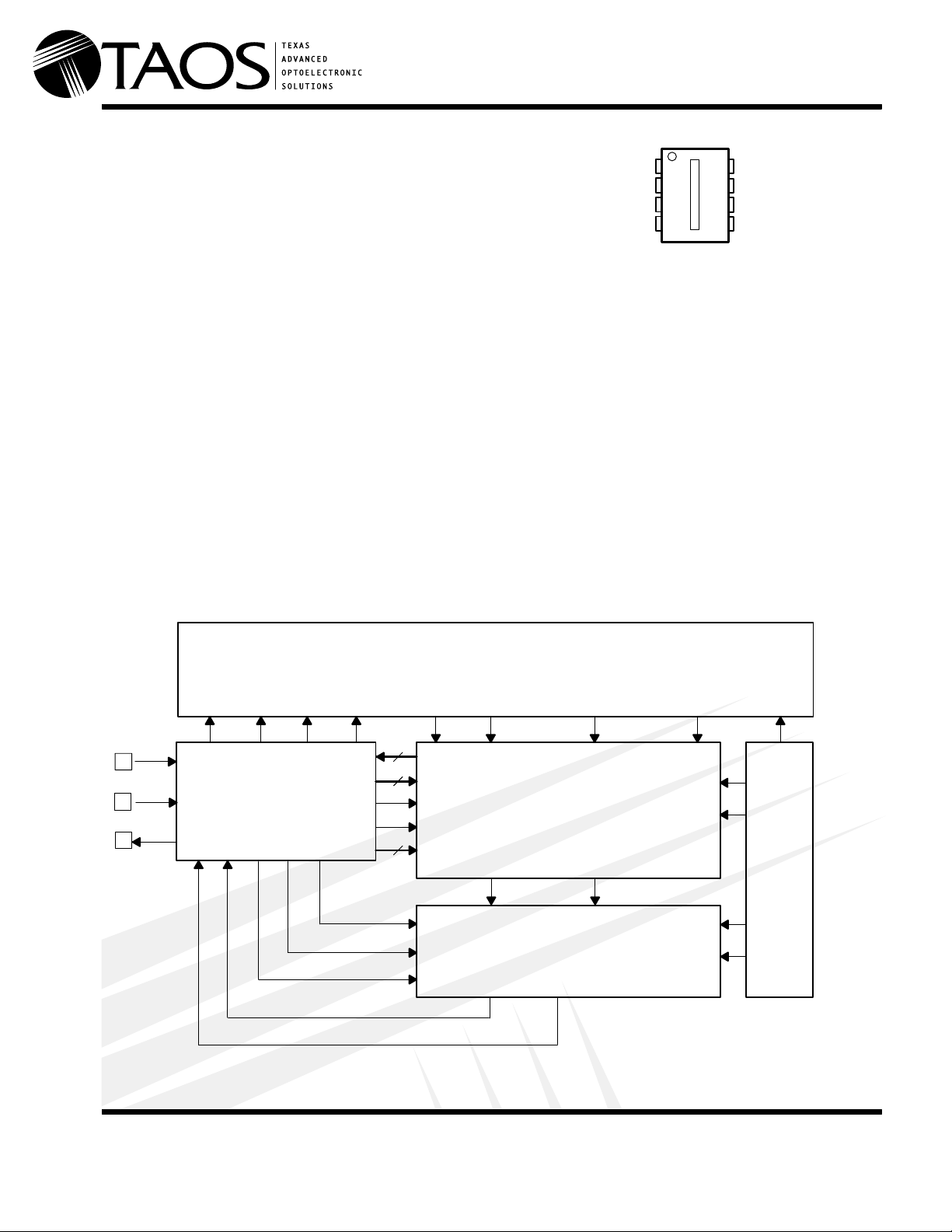

TSL3301

102 × 1 LINEAR OPTICAL SENSOR ARRAY

WITH ANALOGTODIGITAL CONVERTER

TAOS026 – FEBRUARY 2001

102 × 1 Sensor Element Organization

(TOP VIEW)

300 Dots-per-Inch Pixel Pitch

High Sensitivity

On-Chip 8-Bit Analog-to-Digital Conversion

Three-Zone Programmable Offset (Dark Level) and Gain

SCLK

VDD

SDIN

SDOUT

1

2

3

4

NC

8

GND

7

GND

6

NC

5

High Speed Serial Interface

1 MHz Pixel Rate

NC – No internal connection

Single 3-V to 5.5-V Supply

Description

The TSL3301 is a high-sensitivity 300-dpi, linear optical sensor array with integrated 8-bit analog-to-digital

converters. The array consists of 102 pixels, each measuring 85 µm (H) by 77 µm (W) and spaced on 85 µm

centers. Associated with each pixel is a charge integrator/amplifier and sample-hold circuit. All pixels have

concurrent integration periods and sampling times. The array is split into three 34-pixel zones, with each zone

having programmable gain and offset levels. Data communication is accomplished through a three-wire serial

interface.

Intended for use in high performance, cost-sensitive scanner applications, the TSL3301 is based on a linear

sensor array die that has expanded capability, including multi-die addressing and cascade options. Please

contact TAOS for additional information on die and multi-die package availability.

Functional Block Diagram

PIXCLK SI HOLD ZERO LEFT EVEN RIGHT ODD RIGHT EVEN IREF

SCLK

SDIN

SDOUT

DIGITAL I/O

AND

CONTROL

PIXEL ARRAY WITH INTEGRATORS AND S–H

(51-bit shift register)

8

DB<7:0>

5

ADDR<4:0>

READ

WRITE

3

SECTOR

RESET/SAMPLE

START

ADCLK

OUTPUT CHARGE-TO-

VOLTAGE CONVERTER

WITH PROGRAMMABLE

GAINS AND OFFSETS

DUAL 8–BIT

SA ADC

VREF

IREF

BIAS

BLOCK

VREF

IREF

www.taosinc.com

Texas Advanced Optoelectronic Solutions Inc.

800 Jupiter Road, Suite 205 Plano, TX 75074 (972) 673-0759

Copyright 2001, TAOS Inc.

1

TSL3301

102 × 1 LINEAR OPTICAL SENSOR ARRAY

WITH ANALOGTODIGITAL CONVERTER

TAOS026 – FEBRUARY 2001

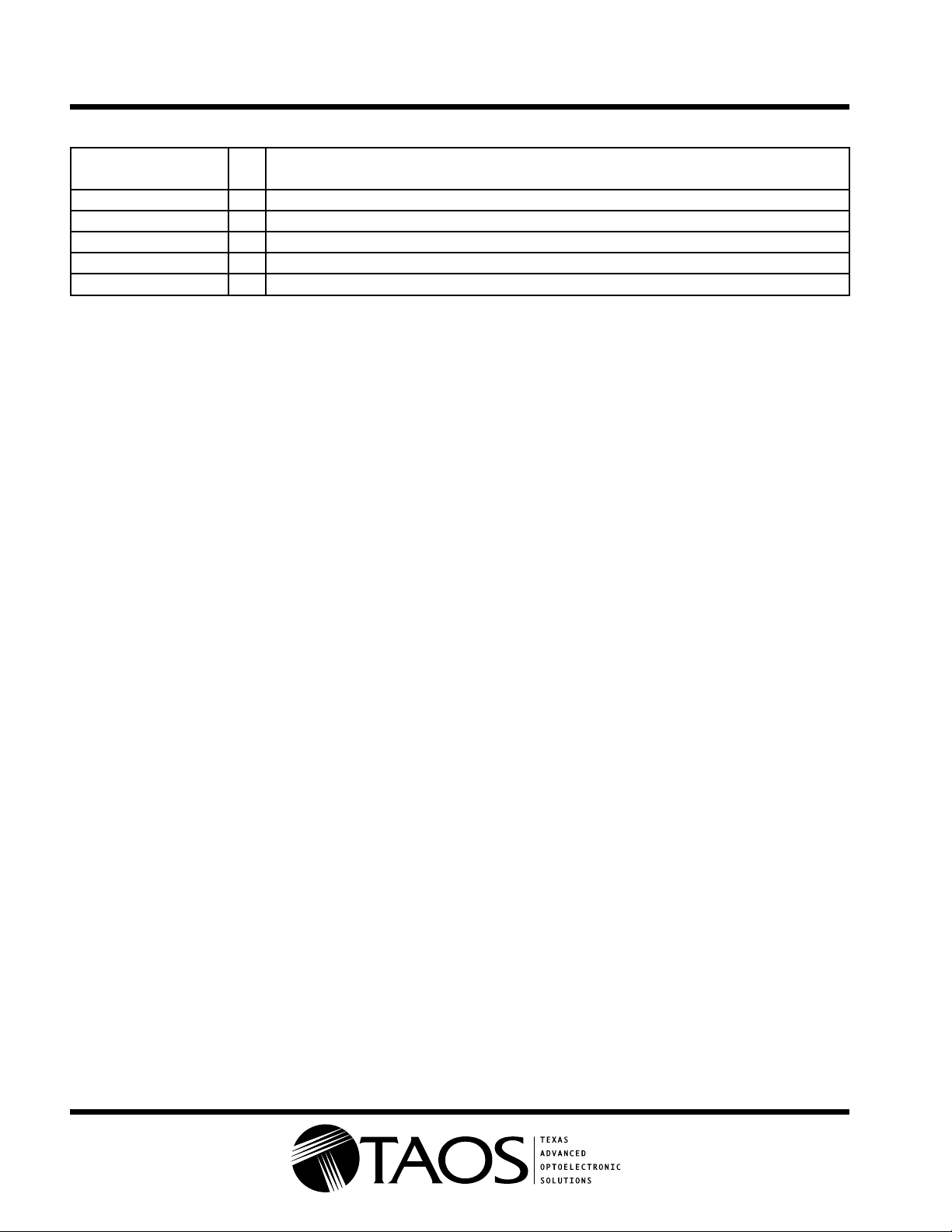

Terminal Functions

TERMINAL

NAME NO.

GND 6, 7 Ground

SCLK 1 I System clock input for serial I/O and all internal logic.

SDIN 3 I Serial data input. Data is clocked in on the rising edge of SCLK.

SDOUT 4 O Serial data output. Data is clocked out on the falling edge of SCLK.

V

DD

I/O DESCRIPTION

2 Positive supply voltage.

Detailed Description

The TSL3301 is a 102 × 1 linear optical array with onboard A/D conversion. It communicates over a serial digital

interface and operates over a 3 V to 5.5 V range. The array is divided into three 34-pixel zones (left, center, and

right), with each zone having programmable gain and offset (dark signal) correction.

The sensor consists of 102 photodiodes, also called pixels, arranged in a linear array. Light energy impinging

on a pixel generates a photocurrent, which is then integrated by the active integration circuitry associated with

that pixel. During the integration period, a sampling capacitor connects to the output of the integrator through

an analog switch. The amount of charge accumulated at each pixel is directly proportional to the light intensity

(Ee) on that pixel and to the integration time (t

approximately 300 electrons.

Integration, sampling, output, and reset of the integrators are performed by the control logic in response to

commands input via the SDIN pin. Data is read out on the SDOUT pin. A normal sequence of operation consists

of a pixel reset (

(

SAMPLEInt

RESET

), start of integration (

), and pixel output (

READPixel

the integrators from the reset state and defines the beginning of the integration period. Sampling the integrators

ends the integration period and stores the charge accumulated in each pixel in a sample and hold circuit.

Reading the pixels causes the sampled value of each pixel to be converted to 8-bit digital format and output on

the SDOUT pin. All 102 pixels are output sequentially unless interrupted by an abort (

or reset by a

RESET

command.

). At maximum programmed gain, one LSB corresponds to

int

STARTInt

), integration period, sampling of integrators

). Reset sets all the integrators to zero. Start of integration releases

ABORTPixel

) command

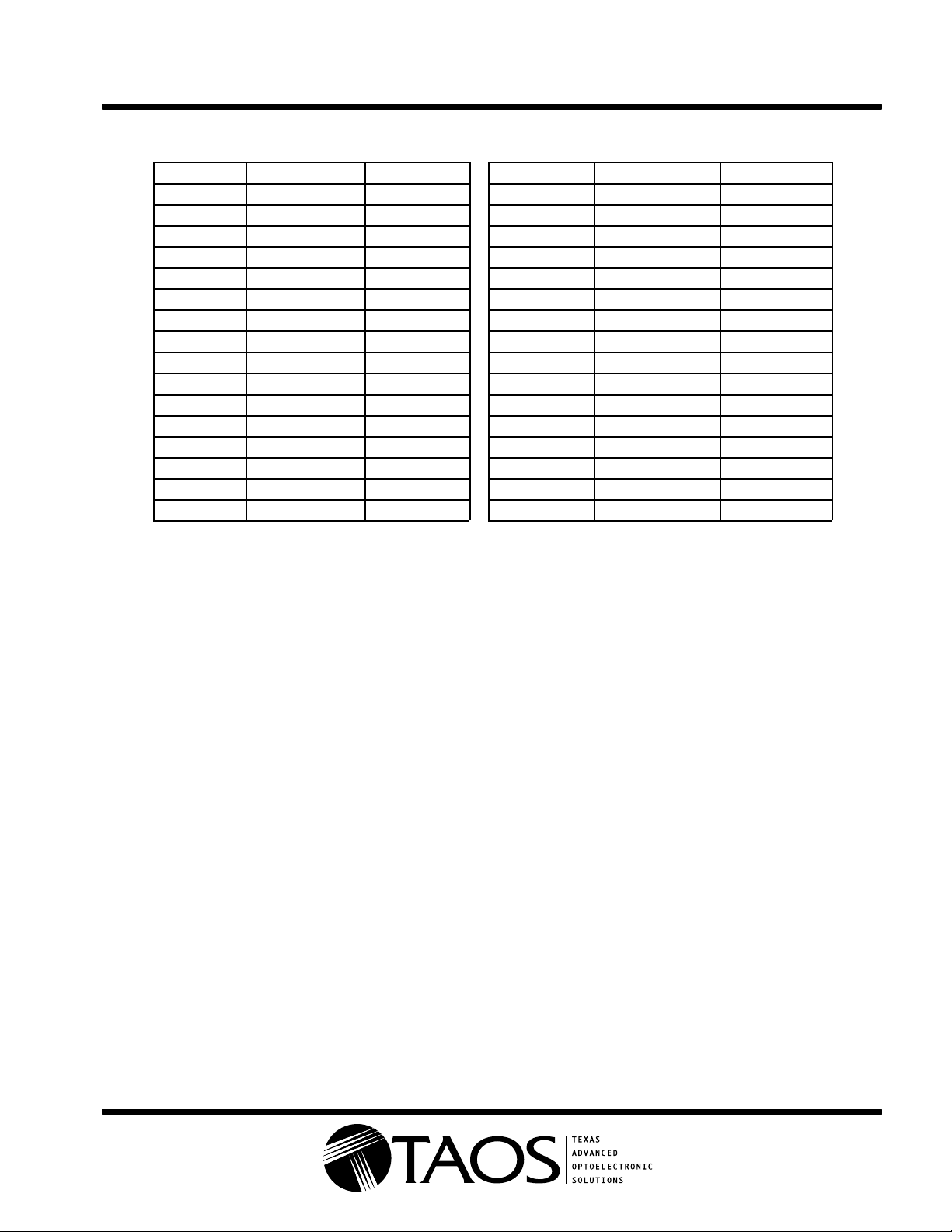

Gain adjustment is controlled by three 5-bit DACs, one for each of the the three zones. Table 1 lists the gain

settings and the corresponding pixel values. Offset is affected by the gain setting and may have to be adjusted

after gain changes are made.

Offset correction is controlled by three 8-bit sign-magnitude† DACs and is performed in the analog domain prior

to the digital conversion. There is a separate offset DAC for each of the three zones. Codes 0h – 7Fh correspond

to positive offset values and codes 80h – FFh correspond to negative offset values.

The offset correction is proportional to the gain setting. At minimal gain, one LSB of the offset DAC corresponds

to approximately 1/3 LSB of the device output, and at maximum gain, to about 1 LSB of the device output.

Note that the gain and offset registers are in indeterminate states after power up and must be set by the controller

as required.

†

Sign-magnitude is a binary representation in which the most significant bit (MSB) is used to represent the sign of the number, with the remaining

bits representing the magnitude. An MSB of 1 indicates a negative number.

Copyright 2001, TAOS Inc.

2

www.taosinc.com

102 × 1 LINEAR OPTICAL SENSOR ARRAY

WITH ANALOGTODIGITAL CONVERTER

TAOS026 – FEBRUARY 2001

Table 1. Gain Settings and Results

GAIN CODE RELATIVE GAIN % INCREASE GAIN CODE RELATIVE GAIN % INCREASE

0 1 16 1.52 3.23

1 1.02 2.17 17 1.57 3.33

2 1.05 2.22 18 1.62 3.45

3 1.07 2.27 19 1.68 3.57

4 1.09 2.33 20 1.74 3.70

5 1.12 2.38 21 1.81 3.85

6 1.15 2.44 22 1.88 4.00

7 1.18 2.50 23 1.96 4.17

8 1.21 2.56 24 2.05 4.35

9 1.24 2.63 25 2.14 4.55

10 1.27 2.70 26 2.24 4.76

11 1.31 2.78 27 2.35 5.00

12 1.34 2.86 28 2.48 5.26

13 1.38 2.94 29 2.61 5.56

14 1.43 3.03 30 2.77 5.88

15 1.47 3.13 31 2.94 6.25

TSL3301

Serial interface

The serial interface follows a USART format, with start bit, 8 data bits and one or more stop bits. Data is clocked

in synchronously on the rising edge of SCLK and clocked out on the falling edge of SCLK. Stop bits are not

required on the input. When clocking data out continuously (i.e., reading out pixels) there will be one stop bit

between data words.

The receive and transmit state machines are independent, which means commands can be issued while

reading data. This feature allows starting new integration cycles while reading data. Note that this allows

undefined conditions so care must be taken not to issue commands that will cause outputs (such as register

read) while reading out data. For instance, issuing a register read command while reading out image data will

result in garbage out. Likewise, it is possible to change offset and gain registers during a readout, which can

give unpredictable results.

It is not necessary to have a continuously active clock, but a minimum of 6 clocks is required after any command

has been issued to ensure that the corresponding internal logic actions have been completed. When reading

register contents, there will be a 4-clock delay from the completion of the

the register contents are output. When reading out pixel values, there will be a 44-clock delay from completion

of the

READPixel

to have 22 clocks to complete the pixel reset cycle (see

command until the first pixel data is output. When sampling pixel information it is necessary

Imaging

below).

REGRead

command before

www.taosinc.com

Copyright 2001, TAOS Inc.

3

TSL3301

102 × 1 LINEAR OPTICAL SENSOR ARRAY

WITH ANALOGTODIGITAL CONVERTER

TAOS026 – FEBRUARY 2001

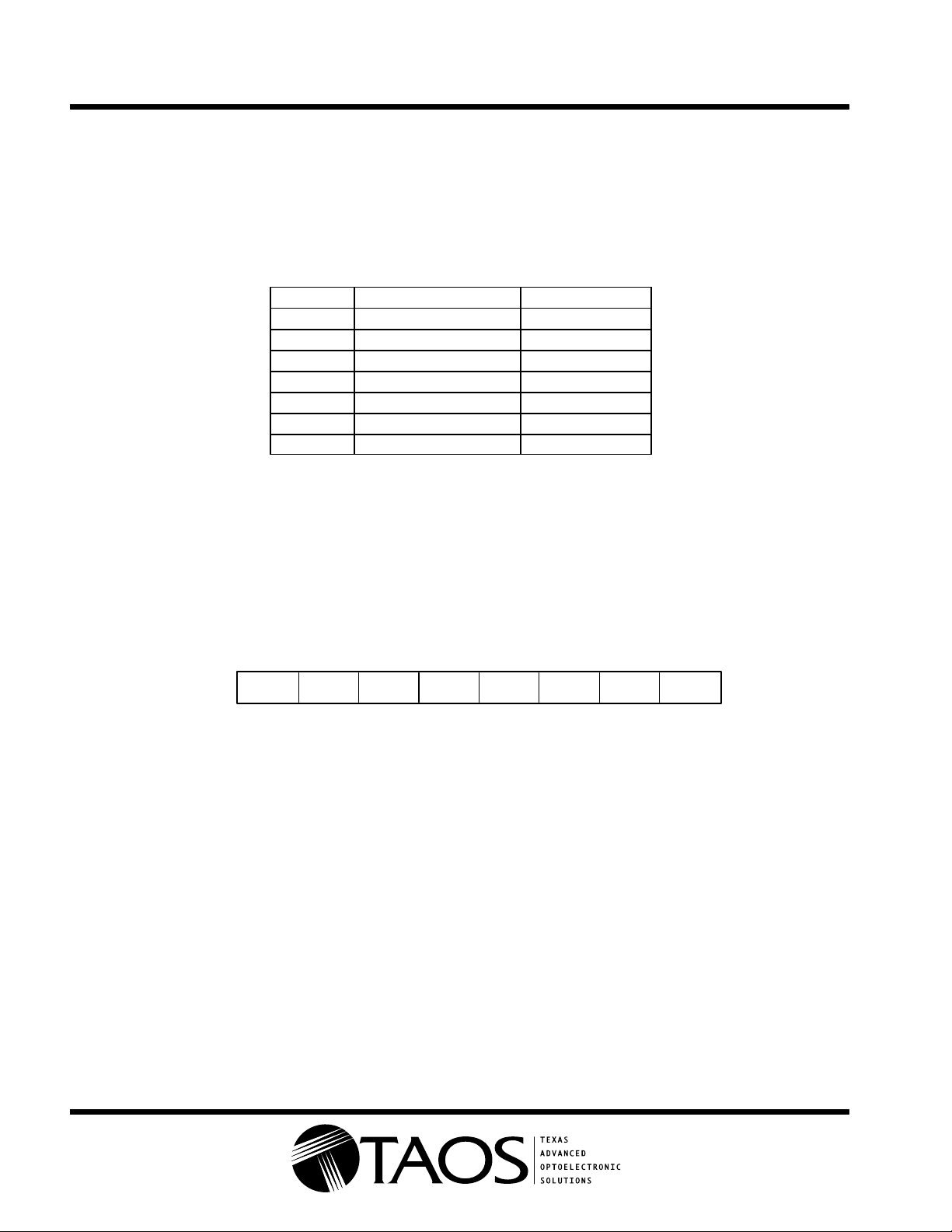

Register address map

The TSL3301 contains seven registers as defined in Table 2. Data in these registers may be written to or read

from using the

converters (ADC). Three other registers allow the offset of the system to be adjusted. Together the gain and

offset registers are used to maximize the achievable dynamic range.

REGWrite

and

REGRead

commands. Three registers control the gain of the analog-to-digital

Table 2. Register Address Map

ADDRESS REGISTER DESCRIPTION REGISTER WIDTH

0x00 Left (pixels 0–33) offset 8

0x01 Left (pixels 0–33) gain 5

0x02 Center (pixels 34–67) offset 8

0x03 Center (pixels 34–67) gain 5

0x04 Right (pixels 68–101) offset 8

0x05 Right (pixels 68–101) gain 5

0x1F Mode 8

The offset registers are 8-bit sign-magnitude values and the gain registers are 5-bit values. The programmed

offset correction is applied to the sampled energy, and then the gain is applied. (i.e., the gain will affect the offset

correction.) These registers allow the user to maximize the dynamic range achievable in the given system.

The last register is the mode register. Bits in this register select the sleep mode as well as options for multichip

arrays and production testing. Note that test and multichip options do not apply to the 8-pin packaged device.

Users should always write zeros into the production test and multichip control bits.

654321

0x1F

SLP = Sleep Mode:

1

places device into sleep mode

0

places device in normal operating mode

P2 MODE0 0 SLP P1 P0 C1 C0

C1, C0 selects multichip options (should be written

P2 to P0 are factory test bits (should be written

07

0

)

0

)

Figure 1. Mode Register Bit Assignments

Copyright 2001, TAOS Inc.

4

www.taosinc.com

Command description

TSL3301

102 × 1 LINEAR OPTICAL SENSOR ARRAY

WITH ANALOGTODIGITAL CONVERTER

TAOS026 – FEBRUARY 2001

The TSL3301 is a

slave

device that reacts strictly to commands received from the digital controller. These

commands cause the device to perform functions such as reset, integrate, sample, etc. Table 3 summarizes

the command types and formats and Table 4 lists the command set for the TSL3301. Each command is

described in more detail below.

Table 3. Command Type and Format Summary

COMMAND TYPE FORMAT

Action command < Command byte >

Register write < Command byte > < Data byte >

Table 4. TSL3301 Command Set

COMMAND DESCRIPTION

IRESET Interface Reset

RESET Reset Integration and read blocks

DETReset Reset determine unique address block

STARTInt Start pixel integration

SAMPLEInt Stop light integration and sample results

READPixel Dump serial the contents of each sampled integrator

ABORTPixel Abort any READPixel operation in progress

READHold Combination of SAMPLEInt and READPixel commands

READHoldNStart Combination of SAMPLEInt, READPixel and STARTInt commands

REGWrite Write a gain, offset, or mode register

REGRead Read a gain, offset, or mode register

www.taosinc.com

Copyright 2001, TAOS Inc.

5

Loading...

Loading...