TAOS TSL2014 Datasheet

TSL2014

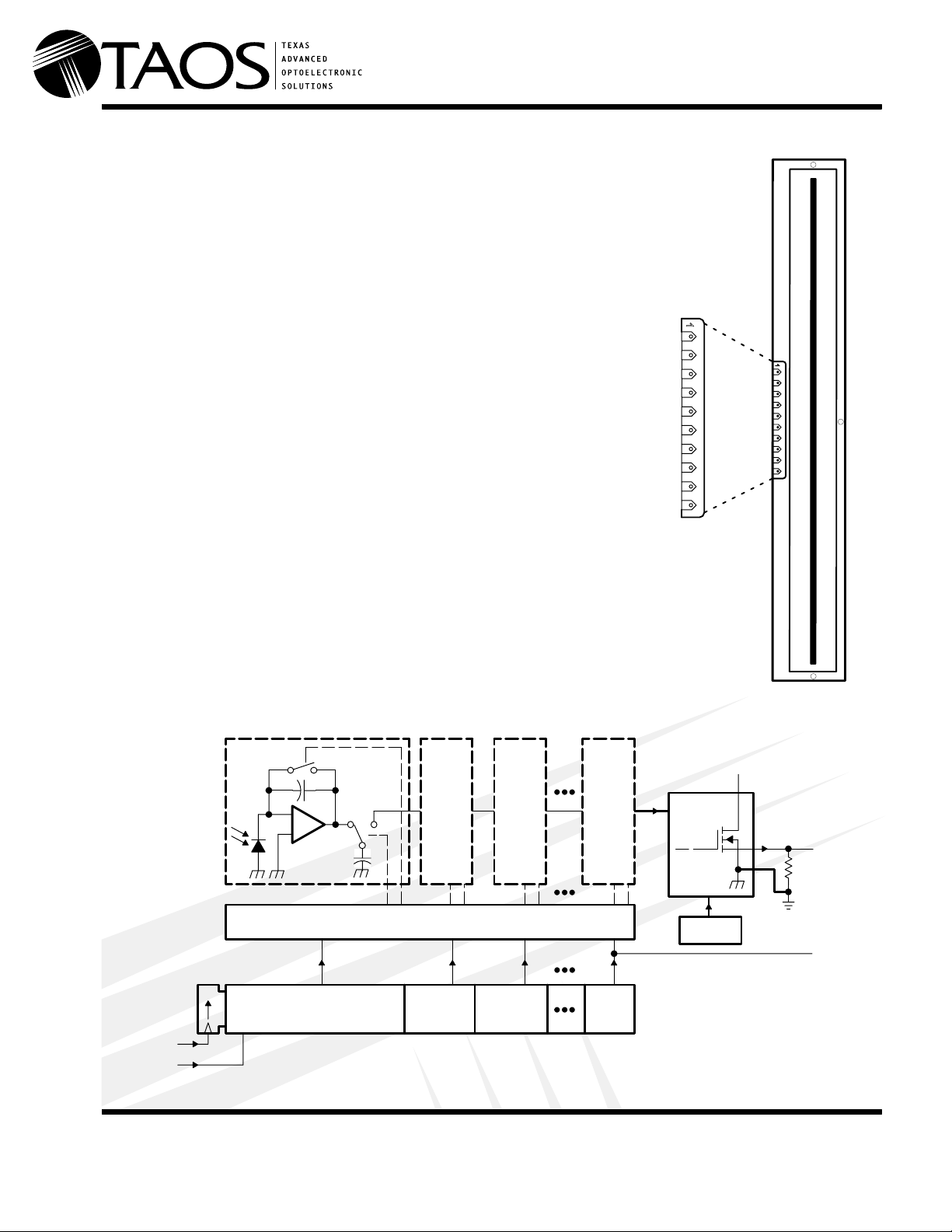

896 1 LINEAR SENSOR ARRAY

TAOS040 – AUGUST 2002

896 × 1 Sensor-Element Organization

200 Dots-Per-Inch (DPI) Sensor Pitch

High Linearity and Uniformity

Wide Dynamic Range...2000:1 (66 dB)

Output Referenced to Ground

Low Image Lag . . . 0.5% Typ

Operation to 5 MHz

Single 5-V Supply

112 mm Active Length

Description

The TSL2014 linear sensor array consists of two

sections of 448 photodiodes and associated charge

amplifier circuitry that can be connected to form a

contiguous 896 × 1 array. The pixels measure 120 µm

(H) by 70 µm (W) with 125-µm center-to-center spacing

and 55-µm spacing between pixels. Operation is

simplified by internal control logic that requires only a

serial-input (SI) signal and a clock.

The TSL2014 is intended for use in a wide variety of

applications including mark detection and code

reading, optical character recognition (OCR) and

contact imaging, edge detection and positioning as well

as optical linear and rotary encoding.

V

DD

SI1 2

AO1 3

SO1 4

SI2 5

CLK 6

GND 7

AO2 8

SO2 9

V

10

DD

PACKAGE

(TOP VIEW)

1

Functional Block Diagram (each section)

Pixel 1 (449)

Integrator

Reset

_

+

Sample/

Output

Switch Control Logic

CLK 448-Bit Shift Register

SI1 (SI2)

The

LUMENOLOGY

Company

Texas Advanced Optoelectronic Solutions Inc.

800 Jupiter Road, Suite 205 Plano, TX 75074 (972) 673-0759

Pixel

2

(450)

www.taosinc.com

Pixel

(451)

3

Q3Q2Q1

Pixel

448

(896)

Analog

Bus

Q448 (896)

Output

Amplifier

Gain Trim

V

DD

AO1

(AO2)

R

L

External

Load

SO1

(SO2)

Copyright 2002, TAOS Inc.

1

TSL2014

896 1 LINEAR SENSOR ARRAY

TAOS040 – AUGUST 2002

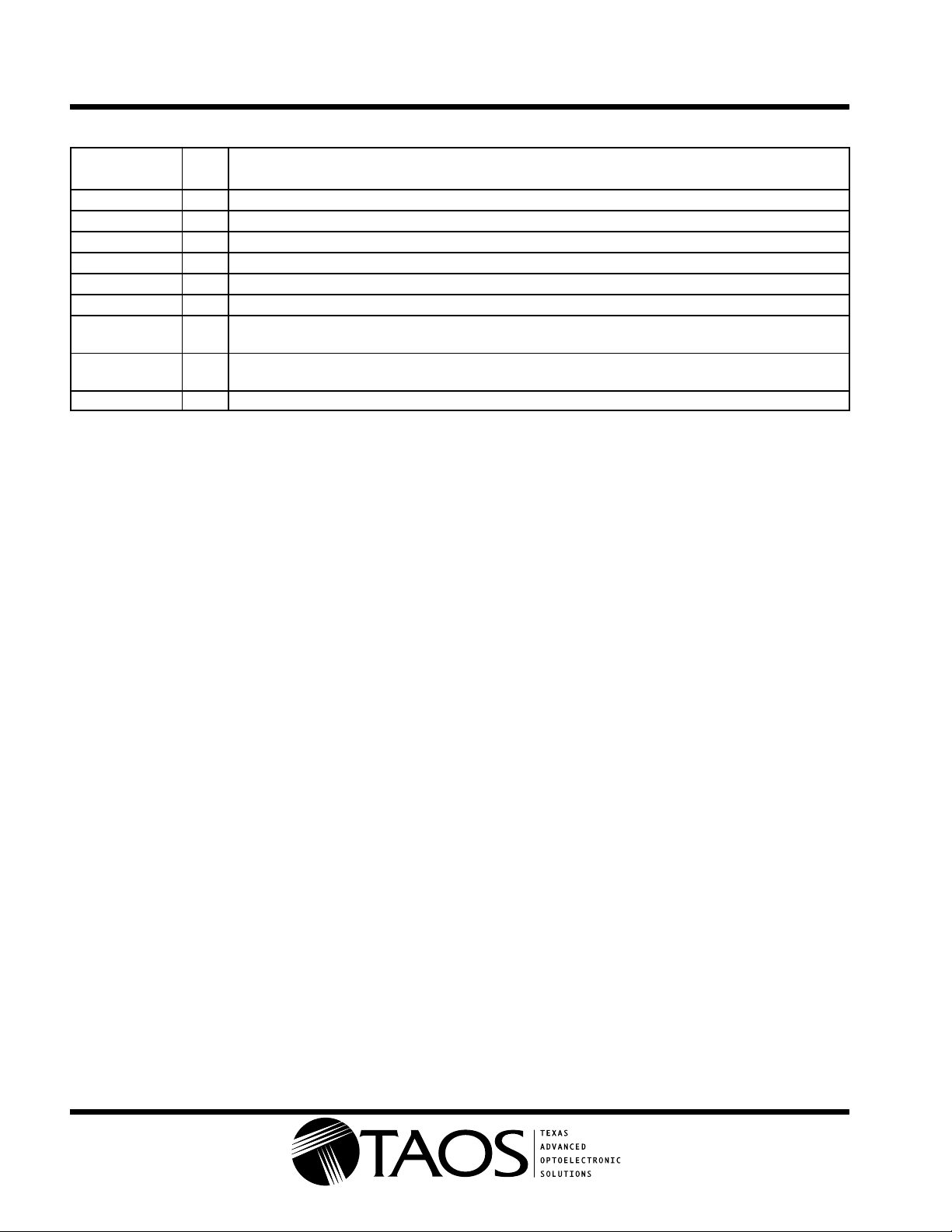

Terminal Functions

TERMINAL

NAME NO.

AO1 3 O Analog output of section 1.

AO2 8 O Analog output of section 2.

CLK 6 I Clock. The clock controls the charge transfer, pixel output and reset.

GND 7 Ground (substrate). All voltages are referenced to GND.

SI1 2 I Serial input (section 1). SI1 defines the start of the data-out sequence.

SI2 5 I Serial input (section 2). SI2 defines the start of the data-out sequence.

SO1 4 O

SO2 9 O

VDD 1, 10 Supply voltage. Supply voltage for both analog and digital circuits.

I/O DESCRIPTION

Serial output (section 1). SO1 signals the end of the data out sequence and provides a signal to drive the input

of section 2 (SI2) in serial mode.

Serial output (section 2). SO2 signals the end of the data out sequence and provides a signal to drive the input

of another device for cascading.

Detailed Description

The sensor consists of 896 photodiodes arranged in a linear array. Light energy impinging on a photodiode

generates photocurrent, which is integrated by the active integration circuitry associated with that pixel. During

the integration period, a sampling capacitor connects to the output of the integrator through an analog switch.

The amount of charge accumulated at each pixel is directly proportional to the light intensity and the integration

time. The integration time is the interval between two consecutive output periods.

The output and reset of the integrators is controlled by two 448-bit shift registers and reset logic. A 448-pixel

output cycle is initiated by clocking in a logic 1 into the SI input of a section for one positive going clock edge

(see Figures1 and 2)†. The two 448-pixel sections may be operated independently using a single clock input

or connected in series to form a 896-pixel array. Each section has an independent output (AO), which may be

connected together for the 896-pixel function.

When operating in the 896-pixel mode, as the SI pulse is clocked through the 896-bit shift register, the charge

on the sampling capacitor of each pixel is sequentially connected to a charge-coupled output amplifier that

generates a voltage output, AO. When the bit position goes low, the pixel integrator is reset. On the 897th clock

rising edge, the SI pulse is clocked out of the shift register (S2) and the output assumes a high-impedance state.

Note that this 897th clock pulse is required to terminate the output of the 896th pixel and return the internal logic

to a known state. A subsequent SI pulse can be presented as early as the 898th clock pulse, thereby initiating

another pixel output cycle.

The voltage developed at analog output (AO) is given by:

V

= V

out

+ (Re) (Ee) (t

drk

)

int

where:

V

out

V

drk

R

E

e

t

int

is the analog output voltage for white condition

is the analog output voltage for dark condition

is the device responsivity for a given wavelength of light given in V/(µJ/cm2)

e

is the incident irradiance in µW/cm

2

is integration time in seconds

AO is driven by a source follower that requires an external pulldown resistor (330-Ω typical). The output is

nominally 0 V for no light input, 2 V for normal white-level, and 3.4 V for saturation light level. When the device

is not in the output phase, AO is in a high impedance state.

A 0.1 µF bypass capacitor should be connected between VDD and ground as close as possible to the device.

†

For proper operation, after meeting the minimum hold time condition, SI must go low before the next rising edge of the clock.

Copyright 2002, TAOS Inc.

The

LUMENOLOGY

Company

2

www.taosinc.com

TSL2014

896 1 LINEAR SENSOR ARRAY

TAOS040 – AUGUST 2002

Absolute Maximum Ratings

†

Supply voltage range, VDD –0.3 V to 6 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Input voltage range, VI –0.3 V to VDD + 0.3V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Input clamp current, IIK (VI < 0 or VI > VDD) –20 mA to 20 mA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Output clamp current, IOK (VO < 0 or VO > VDD) –25 mA to 25 mA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Voltage range applied to any output in the high impedance or

power-off state, VO –0.3 V to VDD + 0.3V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Continuous output current, I

(V

= 0 to VDD) –25 mA to 25 mA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

O

O

Continuous current through VDD or GND –150 mA to 150 mA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Analog output current range, IO –25 mA to 25 mA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating free-air temperature range, TA –25°C to 85°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Storage temperature range, T

–25°C to 85°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

stg

Lead temperature on solder pads for 10 seconds 260°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ESD tolerance, human body model 2000 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

†

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and

functional operation of the device at these or any other conditions beyond those indicated under “Recommended Operating Conditions” is not

implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

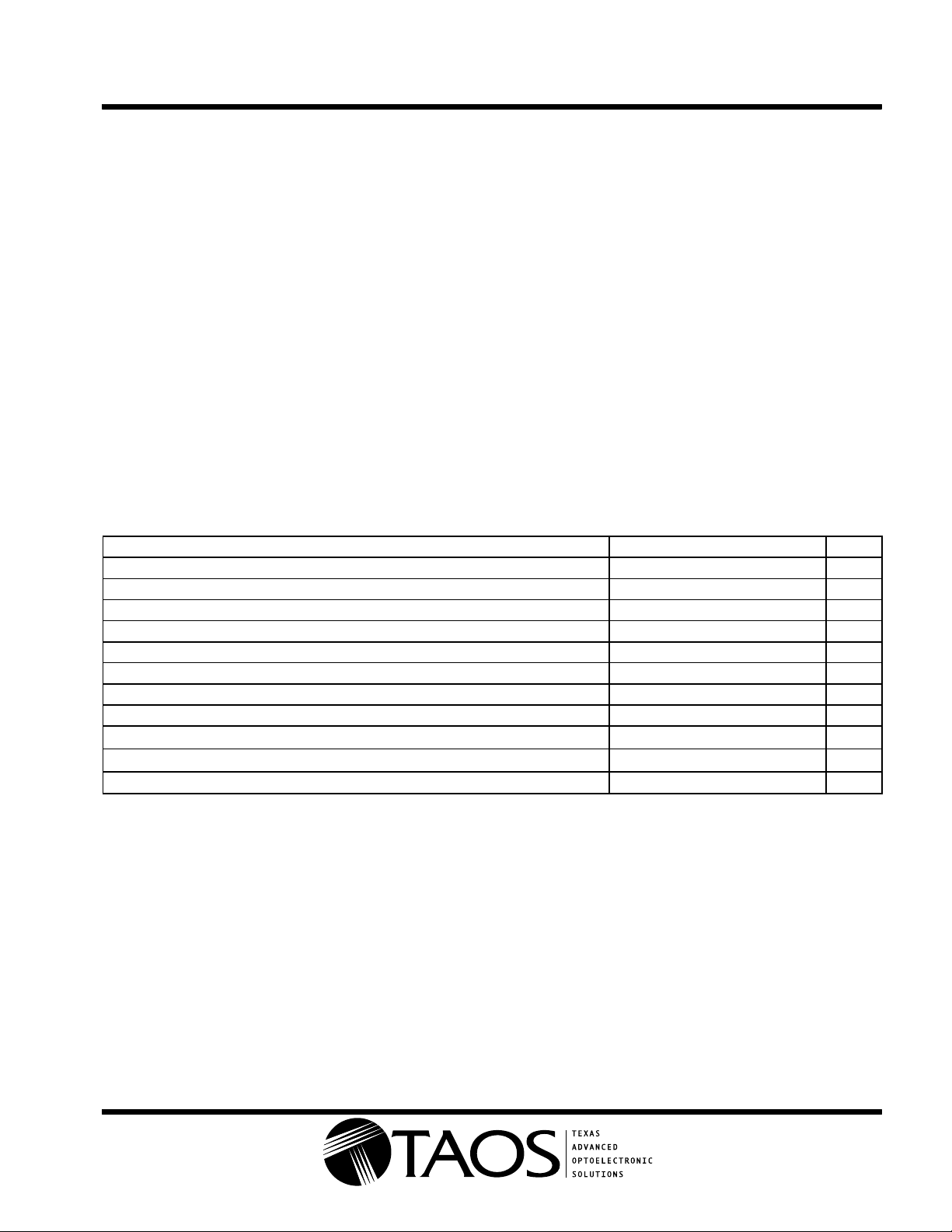

Recommended Operating Conditions (see Figure 1 and Figure 2)

MIN NOM MAX UNIT

Supply voltage, V

Input voltage, V

High-level input voltage, V

Low-level input voltage, V

Wavelength of light source, λ 400 1000 nm

Clock frequency, f

Sensor integration time, serial t

Sensor integration time, parallel t

Operating free-air temperature, T

Load resistance, R

Load capacitance, C

DD

I

IH

IL

clock

int

int

A

L

L

4.5 5 5.5 V

0 V

2 V

0 0.8 V

5 5000 kHz

0.1792 100 ms

0.090 100 ms

0 70 °C

300 4700 Ω

DD

DD

330 pF

V

V

The

LUMENOLOGY

Company

www.taosinc.com

Copyright 2002, TAOS Inc.

3

Loading...

Loading...