Page 1

Owner’s Manual

Page 2

Page 3

Contents

5 The Prestige Dual Concentric™

Gold Reference

6 Tannoy - A Short History

8 Over 80 Years of Audio Innovation

18 Unpacking Instructions

20 Initial Positioning

22 Cable Choice

23 Amplifier Choice

24 Connection in Single Wire Mode

26 Connection in Bi-Wire Mode

28 Bi - Amp Mode

30 Connection of Earth or ‘Ground’ Lead

31 Grille Removal

32 Loudspeaker System Adjustment

34 Tannoy Dual Concentric Drive Unit

35 Running In

36 The High Frequency Section

37 The Low Frequency Section

38 The Magnetic Circuit

39 Alcomax Magnet

40 The Crossover Network

41 Care of the Cabinet

42 Tannoy Quality

43 Fault Finding

44 Warranty

46 Technical Specifications

3

Page 4

4

Page 5

The Prestige Dual Concentric™ Gold Reference

Thank you for investing in high performance

loudspeakers incorporating Tannoy’s world

renowned Dual Concentric driver technology.

First developed and patented by Tannoy’s Chief

Engineer, Ronnie H Rackham in 1947, the 15”

Monitor Black offered class leading performance

from a true full bandwidth point source transducer.

As the most accurate loudspeaker available,

initial usage was as a calibration instrument

for microphones, before finding favour as

monitors in the most famous recording studios

in the world, and with major radio and television

broadcasters. This heritage has underpinned

Tannoy’s global success in audiophile and

professional loudspeakers for over 65 years.

Over this period of time, evolution and

development of the Dual Concentric concept

has seen the technology continue as the preferred

choice of audiophiles, recording engineers and

musicians around the world. This has been as a result

of implementing new materials and developing

bespoke manufacturing processes. While today,

the designs benefit from advanced computer

aided design and software modelling, we have not

lost sight of the traditional values that form the

most musically rewarding loudspeakers available.

Building on the strengths of the drivers launched

in 2006 as part of the Prestige SE series, the Gold

Reference DC drivers benefit from technologies

developed from Tannoy’s Kingdom Royal flagship

speaker project. These include new HF compression

driver assemblies with Mylar™ roll surrounds

and new cone materials which blend traditional

paper pulp fibres with advanced synthetic microstrands to give a dynamic bass performance with

a low colouration midrange. Along with a number

of other revisions across the series, the Gold

Reference Dual Concentric drivers and the Prestige

GR loudspeakers represent Tannoy’s most refined

and accomplished loudspeakers to date, while

remaining faithful to the original design principles.

5

Page 6

Tannoy - A Short History

In the early days of broadcasting, radio sets

needed both low and high voltage DC power

that had to be supplied by batteries. The lead

acid batteries used in the radio sets of the time

needed regular recharging.

In London, in 1926, Guy R. Fountain perfected

a new type of electrical rectifier with the aim of

designing a charger more suitable for use in the

house. His rectifier consisted of two dissimilar

metals held in a special electrolyte solution.

One metal was Tantalum and the other an alloy

of Lead. So successful was this invention that

Guy Fountain founded a British Company called

Tannoy (a contraction of the words ‘Tantalum’

and ‘Alloy’). Tannoy began to diversify and

soon became internationally known and highly

regarded in all aspects of sound reproduction.

Moving coil loudspeakers with DC energised

magnets began Tannoy’s continued success

in terms of technology. A discrete two-way

6

loudspeaker system followed in 1933, and

shortly after a range of microphones and

loudspeakers capable of high power handling.

Tannoy has always been at the forefront of

the communications revolution, developing its

own equipment and production technology.

The company built a wealth of knowledge and

experience, which has proved invaluable in the

development of loudspeakers for a truly wide

range of applications.

Guy Fountain retired from the company in

1974 but the Tannoy Company continues

his philosophy dedicated to the accurate

and realistic reproduction of music for both

enthusiasts and professionals around the world.

Tannoy is now part of the TC Group, whose

goal is to design, produce and distribute the

best engineered, most recognised and respected

brands of audio products in the world.

Page 7

7

Page 8

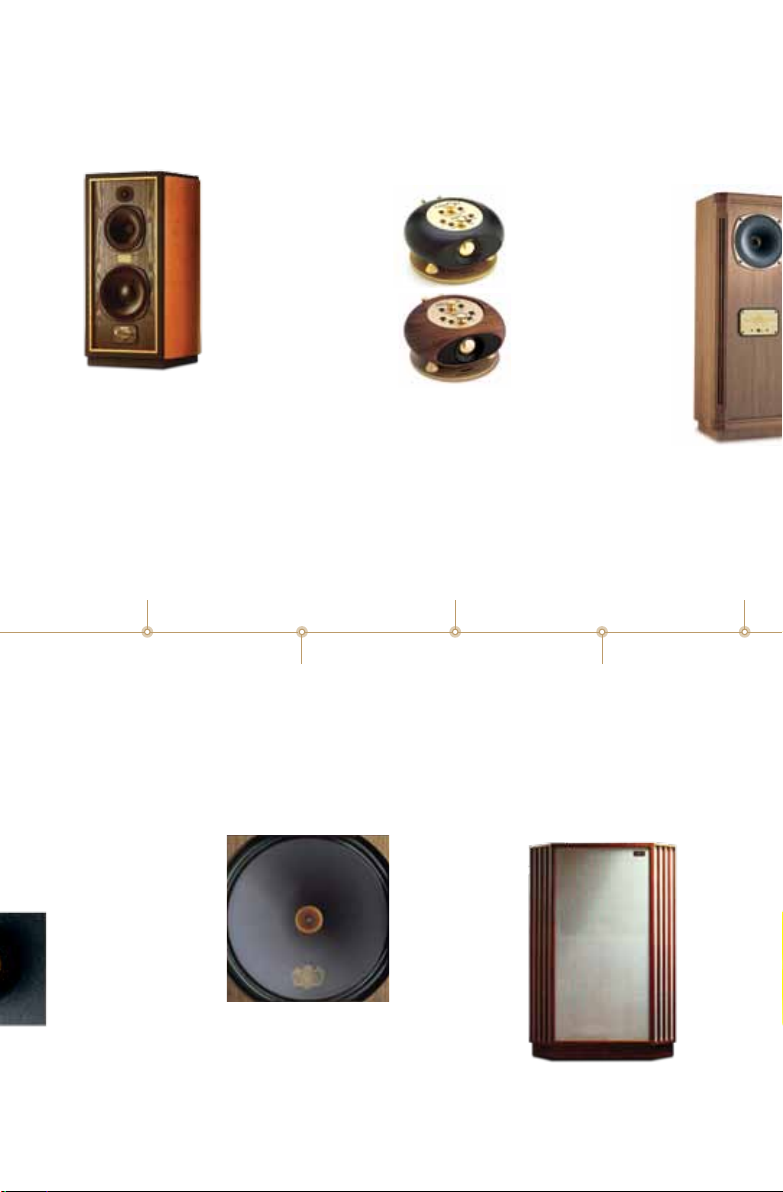

Over 80 Years of Audio Innovation

Tannoy has been involved with audio related manufacturing in the

UK for more than 80 years. The company’s core business is, and

always has been, loudspeaker design and manufacturing. For nearly

40 years, the hub of this activity has been in Scotland where the

company’s headquarters and manufacturing facility are located.

Few companies’ products have such a profound

impact on our lives that their names enter the

dictionary as generic descriptions for their

inventions. The word Tannoy is synonymous

with sound, recognised not only as a proprietary

Brand name in the Oxford English Dictionary

but also defined as a word that is commonly

used within the English language:

to call (someone) by public address system.

Audio related manufacturing commenced at

Tannoy in the late 1920’s at a time when other

landmark industry events were beginning to

8

v. trans.,

take place. This era saw the first commercial

electrical recording by HMV and, soon

after that, the first release of records from

The Decca Record Company. At the same

time the company became interested in the

world of Public Address and early in 1930

Tannoy won a contract to supply the most

famous circus in Europe, Bertram Mills, with

a sound reinforcement system. From that time

onwards the company never looked back.

Page 9

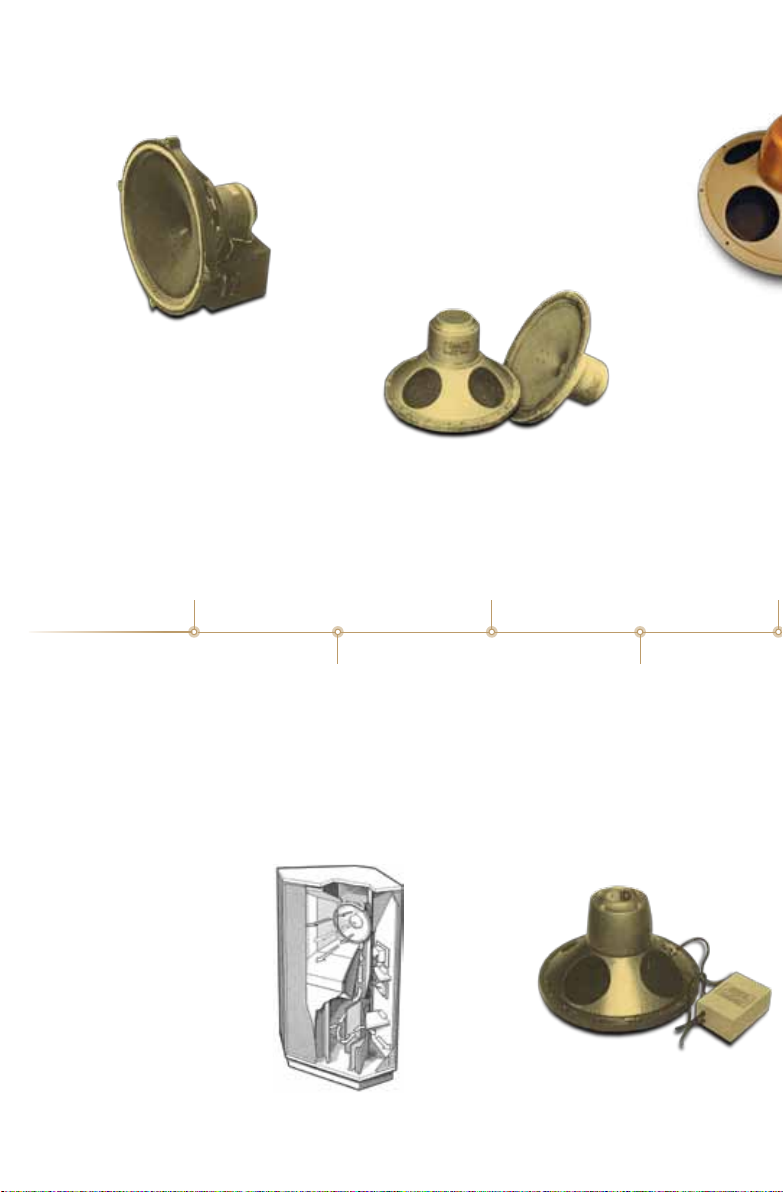

Introduction of the

15” Monitor Black and

12” version later with an

Alnico magnet system, where

uniquely the high frequency

compression driver horn flare was

continued by the shape of the bass

cone, giving previously unheard of

low colouration levels.

Introduction of

12in Monitor Silver -

the first Canterbury enclosure.

Monitor Gold series, with

slightly lower sensitivity to suit

smaller enclosures and with new

compression driver rear chamber

using an advanced thermoset

moulding, still used to this day.

Along with some of the existing

designs, the Monitor Gold

enclosures, Lancaster and IIILZ were

some of the most famous enclosures.

1947

1953

Upgraded to Monitor Silver,

with more open chassis and separate

crossover, initially in the famous

compound horn Autograph cabinet

and later corner GRF.

9

1955

1967

1958

Introduction of Monitor Red in 15”

and 12” variants, with a 10” model

appearing three years later. The ‘Red’

offered improved power handling

over the silver and were used in the

famous Monitor Red cabinets.

Page 10

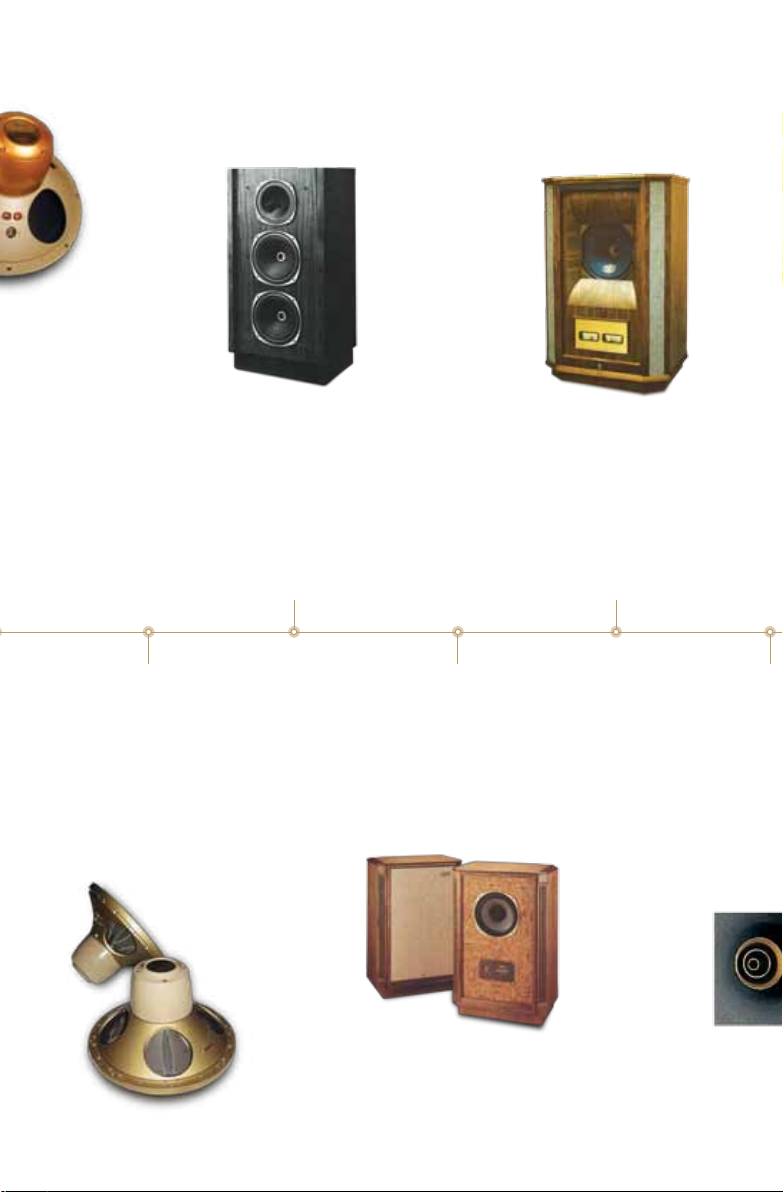

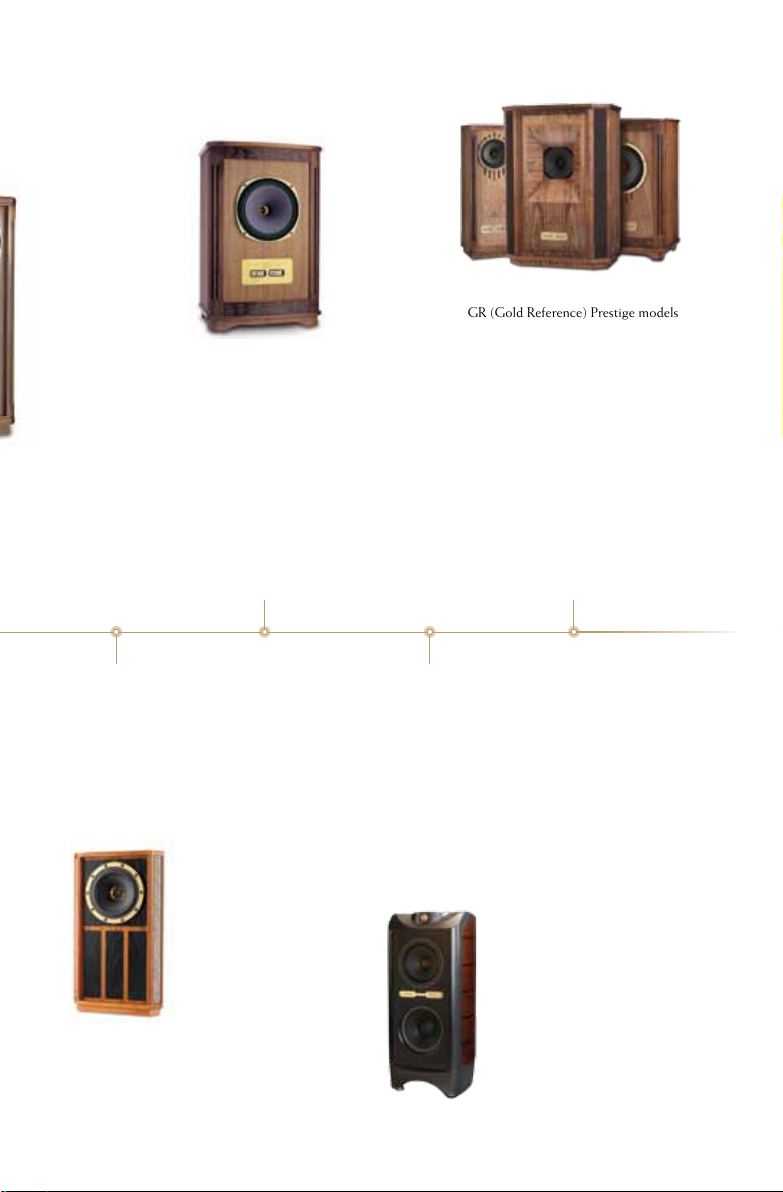

Pioneering use of Anisotropic

Barium Ferrite (ABF) magnets to

replace Alnico on the Mk. 2 HPD’s

bringing, amongst others, the

imposing Buckingham and Windsor

monitors.

Westminster Royal sees a return

to Alnico magnets, and a larger

high rigidity birch ply cabinet.

Canterbury 12 and 15 follow a

year later.

19 74

High Performance Dual (HPD)

series introduced, with a foam

low frequency surround, and

strengthening ribs on the rear of the

cone, a feature still used on our

new 15” Prestige drivers.

1978

1982

First Prestige range, featuring

Westminster, GRF Memory, Stirling

and Edinburgh, was set to conquer

the Japanese audiophile market.

10

1987

1992

Tulip Waveguide (TW) Prestige

series introduces, with Stirling,

Edinburgh, GRFM and Westminster,

using ferrite magnets. The

Westminster Royal and Canterbury

models continued to use Alnico

magnets.

Page 11

Kingdom flagship introduced, with

18” bass driver, 12” SuperDual

and 1” SuperTweeterTM.

Smaller 15” bass/ 12” Dual version

a year later, and 12” bass combined

with 10” Dual model in 2000.

TM

ST100 and ST200 SuperTweeters

introduced, to complement wide

bandwith sources such as

SACD, and enhance the

Prestige listening experience.

Sandringham, Kensington and

Yorkminster HE models added, with

8, 10 and 12” drivers respectively.

1997

1998/9

HE (Hard Edge) versions of the

Prestige Dual Concentric driver

featuring twin-roll fabric surround.

2000

2003

2001

Return of the famous Autograph

(with HE cone surround).

Produced as a special limited

edition for selected markets.

Page 12

Prestige upgraded to SE

(Special Edition) status, featuring

Westminster Royal, Canterbury,

Yorkminster Royal, Kensington, Turnberry

and Stirling. Featuring PCOCC

carefully chosen selection of audiophile

components, to deliver optimal tonality

and transparency.

TM

and a

GR (Gold Reference) Prestige models

introduced. Westminster Royal, Canterbury

and Kensington feature technology

pioneered with the Kingdom Royal, such

as optimally terminated Mylar compression

driver surrounds and cryogenic crossover,

while Turnberry and Stirling models feature

new computer optimised crossovers, backed

up by extensive listening tests. All models

display an unsurpassed quality of cabinet

work and trim detail.

2005

Autograph Mini, with 4” cone

introduced, the smallest Dual

Concentric ever but with a

surprisingly large presentation.

2006/7

2013

2010

Kingdom Royal flagship

loudspeaker launched, with 15”

bass, 12” Dual and 1” magnesium

SuperTweeter, building upon the

SE cable and crossover component

philosophy, but enhanced with

cryogenic treatment.

6481 0637/210813

12

Page 13

Timeline

Pull Out

Page 14

Heritage, tradition and timeless styling...

Page 15

Page 16

Page 17

17

Page 18

Unpacking Instructions

Examine all pieces of packing material and

inspect the carton for signs of external damage.

If there is evidence of excessive damage to

the packaging and resulting damage to the

loudspeaker inform the carrier and supplier

immediately. Always keep the packing in such

circumstances for subsequent examination.

Unfasten the bottom of the carton. Fold the

end leaves out of the way and remove the

packing tray to reveal the plinth and bottom

of the loudspeaker cabinet. Locate and remove

from the carton the accessories pack carefully.

Turn the carton and loudspeaker over so that

the cabinet now stands on the floor inside

the carton. Lift the carton upwards to reveal

the loudspeaker.

Tannoy strongly suggests that you store the

complete packaging set for possible future use.

18

Check the contents of the accessories pack for

the pair of loudspeakers as follows:

• Bi-wire links (x4)

• Carpet spikes (x8)

• Lock nuts (x8)

• Metal cups (x8)

• Tin of wood wax (x1)

• Grille key (x1)

Page 19

19

Page 20

Initial Positioning

Locate the loudspeakers so that the favourite

listening position is approximately 15° from

the axes of the cabinets. The axes of both

cabinets should intersect at a point slightly

in front of the listening position. Remember

that the proximity of the loudspeakers to

walls and corners will affect the sound. Some

experimentation will probably be needed

to fine-tune the stereo image depth and

low frequency sound quality. Close to wall

positions and room corners have the effect of

increasing very low frequency sound energy.

Reflective adjacent walls may upset the stereo

image by causing unwanted reflections.

In order to experience the best acoustic

performance and fully realise their exceptional

stereo image depth capabilities, the

loudspeakers should ideally be used at least 1m

from any sidewall or reflective surface and at

least 0.5 m away from a rear wall.

20

Inserts are provided in the base of the speakers

for down spikes that give maximum stability.

The spikes provided should be screwed into

the base of the loudspeakers. When the

loudspeaker is installed in its upright position,

the spikes should pass between the weave

of your carpet to contact the floor beneath.

Adjust the spikes for maximum stability then

tighten the lock nuts firmly, but without using

undue force.

For polished wooden floors and other delicate

surfaces, metal cups are provided to place under

the spikes.

Page 21

1.0 M OR MORE

0.5 M OR MORE0.5 M OR MORE

2.0 M to 4.5 M

1.0 M OR MORE

21

Page 22

Cable Choice

Always use the best quality of cable available

within your budget. High quality audio

signals passing from the amplifier to the

loudspeaker are unusual in their demands

on the cable. Wide dynamic range and wide

bandwidth information has to coexist with

the ability to transmit peak currents of at

least 10 amps, without incurring any loss or

signal impairment. This explains why the

sound quality of the music reproduced by the

loudspeakers is so dependent on the physical

properties of the cables connecting them to

the amplifier. It also explains why bi-wiring is

the preferred connection method, so that low

frequency and high frequency signals do not

have to share the same cable.

We would recommend that you always keep

the cable runs the same length for each

speaker. Remember that cable construction

can affect the sound quality so be prepared to

experiment to find a cable that suits your ear

and audio system. Please consult your dealer

for further advice on choosing cables.

22

Page 23

Amplifier Choice

Consult the product specification section

within this manual as this clearly shows

the acceptable power range for amplifier

matching to your speakers. The high peak

power handling of Tannoy loudspeakers

permits responsible use with more powerful

amplifiers - Please read the Warranty

conditions (page 44).

As with all loudspeaker systems, the power

handling is a function of voice coil thermal

capacity. Care should be taken to avoid

overdriving any amplifier, as this will cause

output overload resulting in ‘clipping’ or

distortion within the output signal. This can

cause damage to the speakers if done for any

extended period.

Generally an amplifier of higher power that

is running hard, but free of distortion, will

pose less risk of damage to the loudspeaker

than a lower power amplifier continually

clipping. Remember also that a high powered

amplifier running at less than 90% of output

power generally sounds a great deal better

than a lower powered example struggling

to achieve 100%. An amplifier with

insufficient drive capability will not allow

the full performance of the loudspeakers to

be realised.

Some users may have a preference for low

power valve (tube) amplifiers which are

below the recommended minimum amplifier

power. While this does not cause potential

for damage, consideration should be given

to musical preferences, maximum listening

levels and room size.

23

Page 24

TO 'GROUND' OR

'EARTH' CONNECTION

ON AMPLIFIER (OPTIONAL)

LINKS IN PLACE

Connection in Single Wire Mode

TO RIGHT

SPEAKER

- + -

+

L R

POWER AMPLIFIER

Before proceeding, ensure amplifier is switched

off (applies to all methods of connection).

First link the HF+ terminal to the LF+ terminal

and HF- terminal to the LF- terminal, using the

links provided in the accessories pack.

For optimum performance in single wire

mode, loudspeaker cable connections from the

amplifier should be made to the high frequency

(HF) terminals of the loudspeaker:

The positive (plus) terminal on the amplifier

left channel (marked + or coloured red) must

be connected to the positive HF terminal on

the left speaker. The left speaker is the one on

the left as you look at the stereo pair from your

listening position.

The negative (minus) terminal on the amplifier

left channel (marked - or coloured black) must

be connected to the negative HF terminal on

the left speaker.

24

Repeat this connection process for the right

speaker. Remember that the positive (+ or

red) on the amplifier must be connected to

the positive (+ or red) on the speaker and the

negative (- or black) to negative.

Select a signal source, such as a CD player,

switch on the amplifier and slowly turn up the

volume control to check that both loudspeakers

are reproducing bass and treble information.

Page 25

25

Page 26

LINKS REMOVED

Connection in Bi-Wire Mode

POWER AMPLIFIER

TO 'GROUND' OR

'EARTH' CONNECTION

ON AMPLIFIER (OPTIONAL)

TO RIGHT

SPEAKER

+ -

L

+ -

R

Please note in bi-wire mode that the link

cables should not be used. Best results will

be obtained with a specially designed bi-wire

speaker cable.

If your amplifier is not equipped with two sets

of output terminals, at the amplifier end of the

cables, twist the Left LF+ (positive) and the

Left HF+ (positive) together. Connect these

to the amplifier Left channel positive terminal

marked + (plus) or coloured red.

Twist the Left LF- (negative) and the HF(negative) cables together and connect them

to the amplifier Left channel negative terminal

marked - (minus) or coloured black.

At the loudspeaker end connect the cables

labelled Left LF+ and Left LF- to the left

hand loudspeaker LF terminals, ensuring

that you note the polarity markings on the

cable sheathing.

26

Then proceed to connect the Left HF+

and Left HF- to the HF terminals on the

same loudspeaker.

Repeat this process to connect the right hand

loudspeaker to the amplifier right channel

output, once again ensuring that polarity is

correct throughout.

Page 27

27

Page 28

LINKS REMOVED

Bi - Amp Mode

Bi-amping extends the principle of bi-wiring

one stage further. In this connection option

separate power amplifiers are used for bass and

treble signals in each loudspeaker. Four mono

(or two stereo) amplifiers of the same type are

required for a stereo pair of loudspeakers.

-+L-+

R

HIGH FREQUENCY

POWER AMPLIFIER

LOW FREQUENCY

POWER AMPLIFIER

L-R

-

+

TO RIGHT

SPEAKER

+

SPEAKER

TO RIGHT

If two stereo amplifiers are used, it is

recommended that one amplifier supply bass

information to left and right loudspeakers and

the other, the treble information.

It is important not to use the link cables on the

terminal panel, otherwise amplifier damage

may result.

28

Page 29

29

Page 30

Connection of Earth

or ‘Ground’ Lead

To optimise performance further, use a

shielded or screened loudspeaker cable in

order to reduce unwanted radio frequency

interference. The screening termination

should be connected to the earth or ground

(green) terminal on the loudspeaker and to the

ground or earth connection on the amplifier.

Alternatively, if you are not using a screened

loudspeaker cable but wish to utilise the

earthing facility, run a single cable between

the loudspeaker and amplifier earth terminals.

30

Page 31

Grille Removal

Special acoustically transparent cloth is

used in the grilles. However, for ultimate

fidelity the enthusiast will find it is best to

use these loudspeakers with their grilles

removed during listening. Grille removal

is also necessary for access to the front

panel controls.

The front grille is removed using the key

provided. Turn the key in the key slot and

pull the bottom of the grille away from the

cabinet. The grille will drop down from its

upper location. Take care not to damage the

wooden lower part of the cabinet. To replace

the grille engage the top of the grille into the

slot in the cabinet and push the grill into the

recess and lock in position.

31

Page 32

Loudspeaker System Adjustment

Each loudspeaker is fitted with two

controls located on the front baffle beneath

the detachable grille. These high current

switch blocks are labelled ROLL OFF and

ENERGY. They can be used to compensate

for the varied acoustic characteristics of

listening rooms. The controls should be

adjusted with the amplifier tone controls

in the ‘flat’ or uncompensated position.

Each loudspeaker should be adjusted

individually. Rotating the amplifier balance

control, to select first one loudspeaker and

then the other, most easily achieves this.

The Energy control has five positions. It

allows the output of the high frequency

compression drive unit to be increased or

decreased from the linear or ‘flat’ position

over a frequency band from approximately

1 kHz to 27 kHz.

The Roll Off control has five positions

(+2, level, -2, -4 and -6 dB per octave)

32

and provides adjustment at extreme high

frequencies from 5 kHz to 27 kHz.

The Energy control has a shelving effect

whereas the roll off control increases or

decreases the slope of the extreme high

frequency response.

The flattest, most linear response from

the loudspeaker will be obtained with

both controls set at the LEVEL position,

and this position should be used for initial

listening tests. If the overall quality

of the high frequency sound seems too

prominent the –1.5 or –3 positions for

the Energy control should be tried. If the

sound appears subdued in the treble region

+1.5 or +3 settings may be preferred.

Once the energy control setting has

been established the Roll Off control

can be adjusted to reduce or slightly

increase the extreme high frequency

content if necessary.

Page 33

Remember the changes that can be made by

moving either control from one position to

another are subtle. They may not easily be

heard if the programme material has very

little content in the frequency band under

consideration. Choose a well-balanced

piece of music with a full spectrum of sound.

The correct setting will be found when the

loudspeakers are no longer evident and only

the musical performance is heard.

33

Page 34

Tannoy Dual Concentric Drive Unit

One of the unique advantages of the Tannoy

Dual Concentric principle is that the low and

high frequency sound radiation is generated

on the same axis. The high frequency unit is

mounted behind and concentrically with the

low frequency unit. High frequency sound

radiates from the centre of the low frequency

unit through a carefully designed high

frequency exponential horn. Low and high

frequencies are therefore fully integrated

at source. It is this feature that gives the

Dual Concentric driver such unique sound

reproduction qualities.

There are other significant benefits. The

high frequency unit does not obstruct the

low frequency unit in any way (a unique

feature when compared with other so called

coaxial systems). Polar dispersion of sound is

symmetrical in both horizontal and vertical

planes. By careful crossover network design

the virtual acoustic sources of the high and

34

low frequency units can be made to occupy

the same point on the axis. Therefore the

total sound appears to emanate from a single

point source located slightly behind the

drive unit. This means that the loudspeakers,

when fed from a high quality stereo source,

can recreate a full and accurate stereo image.

Page 35

Running In

Like all loudspeakers, the drive unit in your

Prestige GR speaker requires a while to reach

optimum performance as the stresses in the

materials relax, especially in the suspension

system. For this reason, it is beneficial

to run the system at fairly high levels at

normal room temperature for approximately

20 hours to achieve best results.

35

Page 36

The High

Frequency Section

The high frequency driver consists of a wide

dynamic range compression unit giving

superb transient performance with a smooth

uncoloured response. The compression unit

feeds acoustic power through a multiple

phase compensating device to the throat of a

solid steel acoustic horn. This horn provides

an acoustic impedance transformation to

match the compression unit radiation into

the listening environment.

An aluminium / magnesium alloy diaphragm,

formed by a specially developed five-stage

process, produces a piston with a very high

stiffness to mass ratio. Optimum molecular

grain structure gives long-term durability.

Dome energy is terminated by a specially

developed Mylar vented surround. A very

low mass precision aluminium coil provides

the driving force for the diaphragm, with

fine multi-stranded copper lead out wires to

ensure reliability. A rear damped acoustic

cavity controls the compression driver

response and ensures further correct acoustic

impedance matching to the horn throat.

The response of the compression horn

driver extends more than two full octaves

below the crossover frequency to eliminate

colourations that can arise through operation

over the fundamental resonance region.

36

Page 37

The Low

Frequency Section

The low frequency section of the

Dual Concentric driver has exceptional

power handling and dynamic range. The

low frequency cone piston is produced from

selected paper pulp with synthetic fibre

micro-strand additives. This is specially

treated to absorb internal resonance modes.

The twin roll fabric surround is also damped

and shaped correctly to terminate the moving

cone and provide optimum compliance and

linearity at large excursions. The cone piston

is driven by a high power motor system

consisting of a four-layer coil suspended

in a precision magnetic air gap. The coil

is wound with a special high temperature

adhesive system and individually cured to

ensure reliable operation at high peak power

inputs. The shape of the low frequency cone

is arranged to provide optimum dispersion

of audio frequencies at both the high

and low ends of the spectrum. The cone

flare continues the high frequency horn

profile to ensure a smooth transition at the

crossover point.

37

Page 38

The Magnetic Circuit

An Alcomax 3 high energy magnet provides

flux generation for both high frequency and

low frequency driving motors. Precision air

gaps contain the magnetic flux surrounding

each coil. The high frequency air gap has a

unique shunt member to apportion the total

magnetic flux in the correct ratio between

low and high frequency units. This gives an

optimum acoustic balance. Precision machined,

low carbon steel pole pieces ensure unsaturated

operation, linear flux fields and a high heat

sinking capability. High power inputs can

therefore be handled with minimum change of

impedance due to temperature effects. A very

robust, high quality, precision pressure die cast

chassis locates the whole magnet assembly and

positions the moving parts with high accuracy.

The chassis is clamped to the front baffle by

10 mounting bolts. This provides long term

reliability without interfering with the acoustic

radiation from the individual sections.

38

Page 39

Alcomax Magnet

Alcomax 3 is an unusually high energy

permanent magnet. The unusual iron / nickel

alloy is doped with cobalt, aluminium and

other rare metals to produce a magnetic

material with very special properties. Alcomax

3 has a high remanent magnetism and energy

product. In other words, it magnetises to a

high level and retains that unusual degree of

magnetisation. Alcomax 3 is also an electrical

conductor, so damps any non-linear eddy

current losses in the magnetic circuit giving

reduced midrange distortion. These properties

give the Dual Concentric drive unit using an

Alcomax 3 magnet an exceptionally clean

transient response and increased sensitivity.

39

Page 40

The Crossover Network

During the design of the crossover network the

acoustic, mechanical and electrical interactions

of the high and low frequency sections have

been fully analysed. The crossover is therefore

an integral part of the design of the system. The

crossover network provides complex equalisation

in both amplitude and phase for each section and

fully integrates the response at the crossover point.

All components are high precision, low-loss and

thermally stable. Specially damped polypropylene

audiophile capacitors are used, together with

non-inductive thick film resistors and low loss

laminated core inductors. A unique shunt element

technique controls the motional impedance of the

high frequency unit.

All components in the crossover network are

hard wired to eliminate unwanted metal-to-metal

contact and ensure freedom from vibration.

The components are laid out to minimise inter

component coupling and are placed well away

from the driver magnetic field. Top quality

40

PCOCC™ 99.9999% purity copper wiring is

used throughout, with 99.99% purity silver link

wires on the crossover boards. High current

switch blocks with gold plated screw terminals

permit user adjustment of high frequency sound

radiation to suit differing listening environments.

Speaker terminals are WBT Nextgen™, mounted

on a specially designed non resonant acrylic panel.

Finally, the complete crossover assemblies are

deep cryogenically treated (DCT) to relieve

component, conductor and solder joint stresses

at crystal structure level for smoother, more

natural sound.

The complementary design of crossover and

drive units means that the loudspeaker system as

a whole behaves as a minimum phase system over

the audio band. Therefore the acoustic sources of

the high and low frequency sections are aligned

in time and space to ensure accurate reproduction

of stereo images.

Page 41

Care of the Cabinet

The cabinet is finished to exacting standards

utilising carefully selected solid hardwood

mouldings and matching real wood veneers.

The wood should only be cleaned with

a dry cloth or with a light application of

quality non-silicone furniture polish such

as the specialist Tannoy wax supplied in

the accessory pack. Take care not to get

polish on the grille cloth or lacquered

front baffle.

In common with all solid wood furniture,

exposure to extremes of heat, cold and

varying humidity will cause the wood to

ease slightly. Therefore it is recommended

that the loudspeaker is protected from

environmental extremes to guard against

any such occurrence. Any wood will change

colour when subjected to the UV content of

ambient light and dry out over time, hence

the need to ‘feed’ the wood with the wax

provided periodically.

41

Page 42

Tannoy Quality

An important part of Tannoy’s design

philosophy is to produce loudspeakers with

a level of performance beyond the most

exacting specifications of contemporary

source equipment.

Loudspeaker design is no longer a ‘black art’.

It is now possible to use computers to model

designs and predict results. Comprehensive

test equipment is used to pinpoint problems

with cabinets or drive units and anechoic

chambers help in producing accurate

measurements. Computer aided design

(CAD) and sophisticated test equipment

are used extensively at Tannoy but we

always remember that listening tests must

be the final judge, and considerable time is

expended in this pursuit.

Tannoy follows a policy of stringent quality

control procedures using sophisticated

measurement facilities. Strict quality control

42

is more easily achieved because all Prestige

loudspeakers are built in-house at the Tannoy

factory in Scotland. All drive units are designed

and manufactured by Tannoy. All incoming

parts are thoroughly tested to ensure that they

are within our demanding tolerances. For over

85 years Tannoy has strived to ensure that every

loudspeaker it makes exceeds both our exacting

standards and our customers’ high expectations.

Page 43

Fault Finding

Tannoy loudspeakers are designed and

manufactured to be reliable. When a fault

occurs in a hi-fi system the effect is always

heard through the loudspeakers although

they may not be the source of the fault. It is

important to trace the cause of the problem

as accurately as possible.

A fault heard on one source (only CD or

tape for instance) is most unlikely to be a

loudspeaker problem. Loudspeakers do not

generate hum, hiss or rumble although high

quality, wide-bandwidth loudspeakers may

emphasise such problems.

43

Page 44

Warranty

No maintenance of this Prestige GR

loudspeaker is necessary, except to periodically

wax polish the natural wood of the cabinet

- see under Cabinet Care.

Please register your new loudspeaker online at

www.tannoy.com.

All of our products have been produced and

tested with care and precision to give first

class service and exceptional reliability.

All passive components are guaranteed for a

period of five years from the date of purchase

from an authorized Tannoy dealer. All active

and electronic components are guaranteed for

a period of two years from the date of purchase

from an authorized Tannoy dealer. Misuse,

overload or accidental damage to Tannoy

passive or active and electronic components

are not covered by this warranty.

44

If at any time during this warranty period

the equipment proves to be defective for any

reason other than accident, misuse, neglect,

unauthorised modification or fair wear and tear,

we will repair any such manufacturing defect

or, at our option, replace it without charge for

labour, parts or return carriage.

If you suspect a problem with a Tannoy product

then, in the first instance, discuss it with

your Tannoy dealer. If you require further

assistance then we ask that you deal directly

with your local Tannoy distributor. If you

cannot locate your distributor please contact

Customer Services, Tannoy Limited, at the

address given opposite.

Page 45

Customer Services

Tannoy Ltd.

Rosehall Industrial Estate

Coatbridge

North Lanarkshire

Scotland

ML5 4TF

Telephone: +44 1236 420199

Fax: +44 1236 428230

Website: www.support.tannoy.com

Do not ship any product to Tannoy without

previous authorisation.

Our policy commits us to incorporating

improvements to our products through

continuous research and development. Please

confirm current specifications for critical

applications with your supplier.

45

Page 46

Technical Specifications

Performance

Recommended Amplifier Power

Continuous power handling

Peak power handling

Sensitivity

Nominal Impedance

Minimum Impedance

Frequency Response

Dispersion

Dual Concentric Drive Unit

Low Frequency

High Frequency

Crossover

Crossover Type

Crossover Frequency

Adjustments

20 to 250 watt per channel

125 watt RMS

500 watt

93 dB (2.83 volt @ 1 m)

8 ohm

5 ohm

29 Hz - 27 kHz (-6 dB)

90 degrees conical

250 mm (10”) with paper pulp cone and twin roll

impregnated fabric surround.

52 mm (2”) round wire voice coil

52 mm (2”) aluminium/magnesium alloy dome

with round voice coil

Bi-wired, hard-wired passive, low loss. Time compensated.

2nd order low pass. 2nd order high pass.

Deep cryogenically treated

1.1 kHz

+/-3 dB over 1.1 kHz to 27 kHz shelving

+ 2 dB to -6 dB per octave over 5 kHz to 27 kHz slope

Cabinet

Enclosure Type

Volume

Dimensions (H x W x D)

Construction

46

Distributed port

105 litres (3.7 cu. ft.)

1100 x 406 x 338 mm (43.31 x 15.98 x 13.31”)

Particle board with high density birch ply baffle and

rear panel, 18 mm (10.71”) thickness. Internally cross

braced and heavily damped

Page 47

47

Page 48

Tannoy Limited - product designed in the United Kingdom.

Tannoy adopts a policy of continuous improvement and product specification is subject to change.

Dual Concentric, High Performance Dual (HPD), Tulip WaveGuide, SuperDual and SuperTweeter

are trademarks of Tannoy Limited.

All other trademarks remain the property of their respective owners.

Copyright © 2013 Tannoy Limited. All rights reserved.

6481 0624/210813

Page 49

Page 50

Tannoy.com

Loading...

Loading...