Page 1

user manual

Page 2

SAFETY WARNING

This equipment is designed for permanent installation. Disconnection from the mains supply is to be achieved by

isolation of the circuit to which it is connected.

Do not remove any covers, loosen any xings or allow items to enter any aperture.

Objects lled with liquids should not be placed on this apparatus.

The rear of this product can get hot. Avoid direct skin contact during operation and for at least 5 minutes after power

has been isolated.

To prevent injury this apparatus must be secured to the wall in accordance with the installation instructions.

AVERTISSEMENT DE SECURITE

Ce matériel est destiné à être installé de façon permanente. Toute coupure de l’alimentation secteur est a effectuer au

niveau de la prise où le matériel est raccordé.

Ne retirez pas les couvercles, ne desserrez pas les xations et ne laissez aucune pièce s’introduire dans les ouvertures.

Ne placez pas d’objets contenant du liquide à proximité de l’appareil.

La partie arrière de ce produit est susceptible de chauffer. Eviter tout contact direct avec la peau pendant fonctionnement

et au moins 5 minutes après coupure de l’alimentation secteur.

An de prévenir toute blessure cet appareil doit être xé au mur conformément aux instructions d’installation.

IMPORTANT SAFETY INSTRUCTIONS

1 Read these instructions.

2 Keep these instructions.

3 Heed all warnings.

4 Follow all instructions.

5 Do not use this apparatus near water.

6 Clean only with dry cloth.

7 Do not block any ventilation openings. Install in accordance with the manufacturer’s instructions.

8 Do not install near any heat sources such as radiators, heat registers, stoves or other apparatus (including

ampliers) that produce heat.

9 Only use attachments / accessories specied by the manufacturer.

10 Refer all servicing to qualied service personnel. Service is required when the apparatus has been damaged in any

way, such as, liquid has been spilled or objects have fallen into the apparatus, this apparatus has been exposed to

rain or moisture, does not operate normally, or has been dropped.

INSTALLATION INSTRUCTIONS

1 THIS PRODUCT MUST BE EARTHED. The safety ground terminal of the appliance must be connected to the

earthing terminal of the installation. The cord must be of maximum length 7.5 meters, rated SJ, SJT, or SJE, 10A

minimum and be marked VW-1.

2 The electrical power connection to this product is only to be made via the connector as supplied with the equipment.

and available from Tannoy under part number 3431-1150.

3 Wiring to this connector must conform with instructions in this manual, must only be made by suitably qualied per

sonnel and must comply with all local requirements.

4 Do not install this equipment in an enclosed space. Do not limit free ventilation and movement of air around the back

panel. Ensure that there is at least 100mm (4”) of space around all sides of the product for ventilation.

5 QFlex modules must only be joined or separated with the complete column laying at on the ground and

disconnected from the mains supply.

6 QFlex is designed and intended for use in non-domestic situations. Mains power is to be supplied from a permanent

hard wired feed. The feed for each QFlex must be protected by a fuse or circuit breaker rated at no more than 10A.

It must be possible to isolate the feed to each QFlex by means of a double pole switch with a minimum of 3mm con

tact separation.

Page 3

IMPORTANTES INSTRUCTIONS RELATIVES A LA SECURITE

1 Lire ces instructions.

2 Conserver ces instructions.

3 Tenir compte de tous les avertissements.

4 Respecter toutes les instructions.

5 Ne pas utiliser cet appareil a proximité d’eau.

6 Ne nettoyer qu’avec un chiffon sec.

7 Ne bloquer aucune ouverture de ventilation. Installer en suivant les instructions du fabricant.

8 Ne pas installer près de sources de chaleur, telles que radiateurs, enregistreurs de chaleur, fourneau, ou tout autre

appareil(ycomprisamplicateurs)quiproduisentdelachaleur.

9 Utiliseruniquementlesxations/accessoiresspéciésparlefabricant.

10 Conertoutentretienadupersonnelqualié.Unentretienestnécessairequandl’appareilaétéendommagéde

quelconque façon, notamment quand un liquide ou des corps étrangers sont tombés dans l’appareil, quand

l’appareil a été exposé à la pluie ou à l’humidité, ne fonctionne pas normalement, ou est tombé.

INSTRUCTIONS POUR L’INSTALLATION

1 CE PRODUIT DOIT ETRE RELIE A LA TERRE. La borne de terre de sécurité de l’appareil doit être connectée à la

borne de terre de l’installation. Le cordon ne doit pas dépasser 7.5 mètres de long, être de calibre SJ, SJT, or SJE,

10A minimum et avec un marquage VW-1.

2 La connexion secteur de ce produit doit être effectuée uniquement par l’intermédiaire du connecteur fourni avec

l’appareil, et disponible auprès de Tannoy sous le numéro de pièce 3431-1150.

3 Le câblage de ce connecteur doit être conforme aux instructions de ce manuel, être réalisé par du personnel quali

é,etenconformitéaveclesrèglesenvigueurlocalement.

4 Nepasinstallerceproduitdansunespaceconné.Nepasrestreindrelaventilationetlacirculationd’airautourdu

panneau arrière. Veiller à ce qu’il y ait un espace d’au moins 100 mm tout autour du produit pour sa ventilation.

5 Les éléments QFlex doivent être assemblés ou désassemblés uniquement quand la colonne est allongée sur le sol,

et déconnectée de l’alimentation secteur.

6 QFlex est conçu pour et est destiné à une utilisation excluant un usage domestique. L’alimentation secteur doit être

assurée au moyen d’un câblage non volant. L’alimentation de chaque QFlex doit être protégée par un fusible ou

coupe-circuit d’un calibre n’excédant pas 10A. Il doit être possible d’isoler chaque QFlex au moyen d’un commuta

teur à double circuit ayant des contacts distants d’au moins 3mm.

FOR CUSTOMERS IN EUROPE

This product complies with both the LVD (electrical safety) 73/23/EEC and EMC (electromagnetic compatibility) 89/336/

EEC directives issues by the commission of the European community.

Compliance with these directives implies conformity with the following European standards:

EN60065 Product safety

EN55103-1 EMC emissions

EN55103-2 EMC immunity

This product is intended for the following electromagnetic environments: E2; E3 & E4. Environment E1 (domestic) is

specically excluded.

FOR CUSTOMERS IN THE USA & CANADA

This product has been tested for electrical safety and complies with:

UL60065 7th edition 2003

CA /CSA C22.2 No.60065-03

This equipment has been designed to comply with the limits for a Class A digital device, pursuant to part 15 of the FCC

Rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is

operated in a commercial environment.

Industry Canada Class A emission compliance statement: This Class A digital apparatus complies with Canadian

ICES-003.

Avis de conformite’ a’ la re’glementation d’Industrie Canada. Cet appareil nume’rique de classe A est conforme a’ la

norme ICES-003.

Page 4

CONTENTS

1

8

INTRODUCTION

UNPACKING

2

3

SOFTWARE INSTALLATION & SETUP

3.1 BeamEngine Programme

3.2 MatLab Runtime Library MCR

3.3 QFlex BeamEngine Application

3.4 Updates

3.5 Uninstalling

4

INSTALLING THE MATLAB RUNTIME LIBARARY

INSTALLING THE BEAMENGINE APPLICATION

5

6

USING BEAMENGINE

6.1 Menu

6.2 Laying Out Venue Planes

6.3 Optimize Results

6.4 Adding Additional Venue Items

6.5 Probes

USING VNET SOFTWARE (PODWARE)

8.1 Overview

8.2 Layout

8.3 Menus

8.4 Toolbar

8.5 Communications

8.6 Launching a Panel

8.7 Controlling Devices – a quick overview

8.8 Parameter Synchronisation

8.9 Progress Bar

8.8 Navigation

8.9 The Selected Device

8.10 Device Context Menu

8.11 Control Panels

8.12 Loading Steering Data

8.13 Monicons

8.14 Controls

6.6 Saving Steering File

6.7 Balloon Data

6.8 BeamEngine – Frequently asked Questions

6.9 Some Design Tips

INSTALLING VNET SOFTWARE (PODWARE)

7

8.15 Filter Response Panels

8.16 Off-Line Operation

8.17 Saving and Recalling Data

8.18 Loading Factory Settings

8.19 Cloning a Device

8.20 Operating Mode

8.21 Device Properties

8.22 Device Firmware

8.23 Keyboard shortcuts

Page 5

HARDWARE CONFIGURATION (GENERAL INFORMATION)

9

ASSEMBLY INSTRUCTIONS

10

10.1 QFlex 8 & QFlex 16 Assembly

10.2 Wall Bracket Mounting Centres

- QFlex 8 & QFlex 16

10.3 QFlex 24 & QFlex 32 Assembly

10.4 Wall Bracket Mounting Centres

- QFlex 24 & QFlex 32

10.5 QFlex 40 Assembly

10.6 Wall Bracket Mounting Centres

- QFlex 40

10.7 QFlex 48 Assembly

10.8 Wall Bracket Mounting Centres

- QFlex 48

SYSTEM CONNECTIVITY

11

AUDIO CONNECTIONS

12

NETWORK CONNECTIONS

13

MAINS POWER

14

CONTROL INPUTS (SYSTEM INTEGRITY &

15

EMERGENCY PROVISION)

INDICATORS

16

SERVICE PARTS

17

TECHNICAL SPECIFICATIONS

18

WARRANTY

19

Page 6

1 INTRODUCTION

Congratulations on the purchase of your new QFlex loudspeaker.

QFlex is a range of self powered, digitally steerable loudspeaker arrays. With state of the art algorithms and dense

physical spacing of transducers, QFlex is the rst product of its kind to realize full range beam steering capabilities,

producing class leading performance for both vocal and music applications. To avoid shipping very long products, it

will be possible to assemble the components of a QFlex column on site.

QFlex products are small format, column-type loudspeaker systems with a user-variable vertical beamwidth pattern.

The loudspeakers can be used singly or combined in multiples.

The simple to use BeamEngine software allows accurate adjustment of coverage area from a xed, vertical mounting

location. In addition to excellent vocal performance, the QFlex range fully capable of full-range music applications and

can also be used in conjunction with any VNET™ subwoofer. Implementation of the network between nodes is via high

quality rugged Neutrik Ethercon connectors, which are compatible with standard RJ45 plugs, and CAT5 cable. Each

speaker has a unique address for auto-location on the network. System commissioning and ongoing venue network

control, incorporating real time diagnostics of electronics and drive unit, are all managed by the exclusive VNET™

software package.

This manual provides information about the design, conguration, and operation of QFlex products. It is intended to be

used in conjunction with the VNET™ & BeamEngine Windows software packages.

Please read this user manual to get the optimum performance from your QFlex loudspeaker system.

2 UNPACKING

Every Tannoy QFlex product is carefully tested and inspected before being packaged and leaving the factory. After

unpacking your loudspeaker, please inspect for any exterior physical damage, and save the carton and any relevant

packaging materials in case the loudspeaker again requires packing and shipping. In the event that damage has been

sustained in transit notify your dealer immediately. Each QFlex carton is marked to show each modules position in the

array. A detailed description can be found in the Hardware section of this manual.

3 SOFTWARE INSTALLATION & SETUP

QFlex loudspeakers are digitally controlled. A PC running BeamEngine and VNET software is needed during

installation and the commissioning process.

The BeamEngine programme can be obtained by contacting QFlex info@tannoy.com

VNET software and BeamEngine are powerful applications capable of running many complex windows

concurrently. They therefore require a computer with reasonable levels of resources.

For acceptable performance, the computer must have at least:

PC with >450MHz Pentium processor

32-bit Windows tm operating system (2000, XP, Vista)

128MB RAM

500MB Disk space

Screen with 1024 x 768 Pixel or better

CD-ROM drive or Internet access

RS232 or USB port

However, for large systems, larger RAM will make a difference to speed. QFlex makes use of the MatLab Runtime

Library MCR, which needs to be installed on your computer in order to run QFlex.

Page 7

3.1 BEAMENGINE PROGRAMME

There are two programme modules to install. For both the installation is fully automatic. However, please note

the following:-

Initialization time: Due to large data-les the installation may need a considerable time to load. Also, on the very rst

run of QFlex BeamEngine the MatLab Library needs to initialize, which cause a short delay.

Windows Vista: Do not install QFlex BeamEngine to the standard folder but elsewhere, for instance

C:\Tannoy\QFlex\.

Restricted User Rights: If you operate your computer under restricted user rights then it is best to install the \MatLab

Library rst and then to install QFlex BeamEngine. If you currently work with administrator rights on your PC the order of

installation does not matter.

MatLab owners: If you have already installed MatLab or a MatLab Runtime Library on your computer, the modules

should be of version 7.7. Otherwise install the provided package in parallel.

3.2 MATLAB RUNTIME LIBRARY MCR

The MatLab Runtime Library MCR needs to be installed separately. This MatLab Runtime Library is a special version

(v7.7) and is exclusively provided to you by Tannoy.

1. Log in as administrator, start the automatic installer by clicking on the link below and follow instructions.

2. Use the default settings.

3. Install MatLab Runtime Library v7.7

3.3 QFLEX BEAMENGINE APPLICATION

Install the QFlex BeamEngine module after the MatLab Library. The install is automatic. Under Vista it is recommended

to install into another directory than the one suggested (say “C:\Tannoy\QFlex\” for example).

1. Log in as administrator, start the automatic installer by clicking on the link below and follow instructions.

2. Install Tannoy QFlex

3.4 UNINSTALLING

Either go to Start Menu/Settings/Software or to the program-folder of QFlex, there double click unins000.exe

3.5 UPDATES

Install QFlex in the same location. The MatLab Library will not need to be reinstalled.

Page 8

4 INSTALLING THE MATLAB RUNTIME LIBARARY

Having downloaded the software, double click on the MCRInstaller_v77.exe

The following window will appear –

Click on “Run” to start the installer –

Choose the setup language and click ‘Ok’ to start the InstallShield wizard

The InstallShield window will appear – Click ‘Next’

Enter your credentials and click ‘Next’

Page 9

Approve the suggested le location by clicking on ‘Next’

Click on ‘Install’ to begin the Installation

The installation will begin. Due to the le size this may take some time

Click ‘Finish’ to complete the installation.

There is no need to start this programme as it resides behind

the BeamEngine programme. It will no longer be visible.

Page 10

5 INSTALLING THE BEAMENGINE APPLICATION

Having downloaded the software, double click on the QFlex_vXXXX.exe

The following window will appear.

The QFlex Setup wizard will start; click ‘Next’ to continue

Accept the terms of the licence agreement to continue with the installation.

Click ‘Next’ to continue.

Approve the suggested le location by clicking on ‘Next’

If you would like the setup programme to create a desktop icon check the box.

Click ‘Next’ to continue.

Page 11

Click on ‘Install’ to begin the Installation

Check ‘Launch QFlex’ if you wish to begin using the software immediately.

Click ‘Finish’ to complete the setup

.

Page 12

6 USING BEAMENGINE

Click on the QFlex icon which the installer left on your desktop.

On the very rst run of the program you will be prompted to select your preferred units of measurement. These settings

can be modied at any time in the menu options.

The following shows the default screen –

Page 13

6.1 MENU (File, Edit, Processing, Options, Help)

File

From here you can create a new project, open an existing and save a project.

A BeamEngine project has the le extension (.q)

Save a Beamsteering File (.bef)

Save a 3D Balloon le (.xhn) for export into acoustical simulation programmes.

Print a detailed project sheet. This includes Parameters, Project Notes & graphs.

‘Export’ generates a screenshot of your current project (.jpg)

Edit

From here you select your QFlex Model (Keyboard shortcut – F8)

Add menu item

Delete menu item

Processing

Optimize – Creates Beamsteering algorithm (Keyboard shortcut - CTRL + Enter)

Update Graphs – Regenerates graphics (Keyboard shortcut – SHIFT, CTRL + Enter)

Options

Preferences

Optimizer Tab

Default Property

Silent and Don’t Care is explained in the menu.

The Master Beta function

Master multiplication factor to apply to regularization factors beta given in global A.wf(woofer) and A.tw(tweeter).

Normally Masterbeta = 1, but it can be reduced to 0.1, trading some SPL for sharper directivity at the lower end of

each sub-array’s (tweeter or woofer) working range. It is recommended to use the default setting except in

exceptional circumstances

Fill Holes

With multiple primary venue items (multi-beam problems) performance can be improved by setting Fill Holes =1 (instead

of 0). Then the narrow gaps in the target directivity are lled up at low frequencies where they can’t be implemented

anyway. In some cases this produces better results than asking for the impossible. The results are marginal, so no need

to spend too much time here.

Page 14

Units Tab

Verify that you are using the correct measurement units

Misc Tab

By checking this box a shadow will be cast behind venue planes if they are raised above oor level

Help

Here you will nd programme info, including version number and a copy of this user manual in PDF format. The rst

step is to select your QFlex model, using the BeamEngine software is a simple and effective way of selecting the

correct model.

Which QFlex system you specify depends on a number of criteria:-

Distance: Farther areas you wish to reach will require a larger QFlex column.Typically, as a rule of thumb a QFlex 16

will be used to distances of 20m(66ft), and a QFlex 48 in excess of 80m(260ft)

Low Frequency Control: The larger the QFlex column, the more effective control at lower frequencies can be achieved.

This also goes for effective steering control at lower frequencies. QFlex 16 (700Hz) >>>> QFlex 48 (200Hz)

SPL Requirements: The larger QFlex arrays will have the ability to produce higher SPL levels.

For the purposes of this tutorial we will choose A QFlex 32

Page 15

6.2 LAYING OUT VENUE PLANES

1. Click on ADD to create a new venue plane(s)

2. Choose SPL to target this particular area from the loudspeaker.

NB. Other Options here are

Silent – This is basically a probe to view the out of beam attenuation on the SPL map.

Don’t Care - In the straight forward default case the steering algorithm will aim for silence in all unspecied directions, the user

can specify areas where avoiding areas does not matter, for example, areas of high absorption. This may improve results

elsewhere, but any differences will be marginal.

3. SPL (x1) is the front, and SPL (x2) is the rear of this specied venue plane. Specify your target/desired SPL here.

Specifying these levels has nothing to do with setting absolute volume levels. After optimization you will be notied if

there is enough headroom to reach your desired SPL. Manipulating these two levels allows you to adjust the intensity

of the sound beam across the specied venue plane. Normally the goal is to achieve an even SPL distribution across

the whole venue plane.

Hint: Where even coverage is required over large areas, splitting the venue plane into two sections may yield better results.

In this instance you are effectively creating two separate beams which you can manipulate independently, giving you more

control. Again, the goal is to achieve an even SPL distribution across the whole venue plane.

4. The rst X co-ordinate of the venue plane.

5. The Second X co-ordinate of the venue plane.

6. The First Y co-ordinate of the venue plane.

7. The Second Y co-ordinate of the venue plane.

(You may have a sitting or a standing audience. Remember to factor for the listening height when specifying the

Y coordinates.)

8. Here you can label your specied venue plane. This is especially helpful if you have multiple target areas.

9. Frequency Band – To view the beam steering characteristic at different frequencies you can view octave bands or the

following averages; Broad-Band(125Hz – 8kHz), Low-Band (125Hz - 1kHz), Mid-Band( 250Hz - 2kHz),

High-Band (1kHz – 8kHz)

Page 16

Note: Longer arrays will have better low frequency control characteristics

10. Set the height of the loudspeaker. The specied height is to the bottom of the array.

Hint: QFlex will invariably be installed in architecturally sensitive environments.The client or architect will most probably impose

restrictions on preferred mounting locations. Beware of mounting the loudspeaker too low. The venue will most probably be

empty when you demo or commission the project. If you are in a house of worship, remember that people stand up and sit

during a service. Make sure that when people stand they are not masking the sound at the back of the room.

11. Inclination – Not all mounting surfaces are plumb and straight. This feature will allow the programme to factor for any

inclinations in the mounting surface.

12. The SPL scale can be referenced against the resultant SPL maps.

13. Optimize: Will generate the steering algorithm based on the supplied information.

6.3 OPTIMIZE RESULTS

1. Resultant Beam based on target data. From here you can save the steering le and upload to the QFlex hardware

from the VNET software.

2. SPL distribution over target area. To further optimize this particular design the SPL intensity towards the back of the

room can be increased slightly to give a more even SPL distribution. Splitting the venue plane into two sections may

also yield better results. This effectively creates two separate beams which you can manipulate independently, giving

you additional control.

3. SPL Headroom. Indication of SPL headroom available in the design. This gure will show red if the specied SPL

cannot be achieved.

Page 17

6.4 ADDING ADDITIONAL VENUE ITEMS

1. Here we have added a second venue plane, in this case a balcony. BeamEngine will automatically target the second

venue plane (no need to specify opening angles or steering angles). Note that the intensity of the second beam has

been manually increased to mach the SPL of the rst venue plane. Both beams can be independently manipulated in

this way. Additional venue planes can be added as necessary.

2. By specifying a ‘Silent’ venue plane, in this example placing it on the roof, you can view the amount of ‘out of beam

attenuation’ at any point in the venue. “Reector” is labeled a surface if it normally points downwards, i.e. it is part of

the ceiling. “Cut” is labeled a surface if it is illuminated by the speaker only partly.

Page 18

6.5 PROBES

1. Click on the small grey box shown. Drag the line on the SPL key to draw the isobar into the display. The isobar

corresponds to the position on the SPL graph.

2. Click on the small grey box shown. Here you can drag and drop the crosshairs shown. Their corresponding

co-ordinates and SPL are shown directly below the SPL map.

3. Click on the small grey box shown. Drag the blue probe horizontally across the SPL graph. The SPL across each

venue plane is shown at 3a.

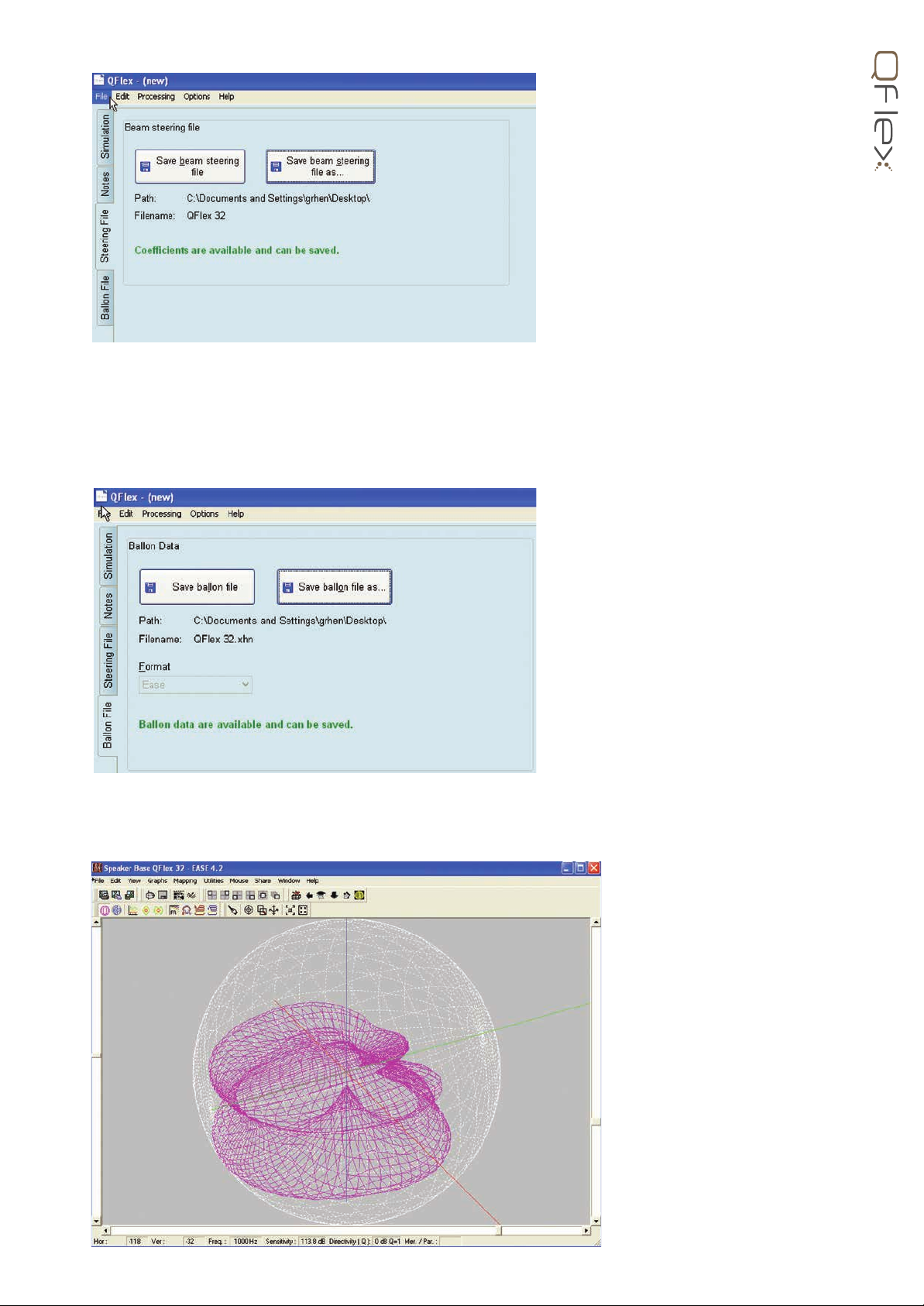

6.6 SAVING STEERING FILE

When you are ready to save your steering le, click on the ‘Steering File’ tab. The name of the le automatically defaults

to the QFlex model you are using. In this case ‘QFlex 32.bef’. A steering le is saved for each module in the array

and given an individual number. For example, when you save the steering le for a QFlex 32, two les will be saved

(QFlex32_box1.bef and QFlex32_box2.bef). Any number of steering les can be saved and quickly uploaded to your

QFlex hardware individually. Instructions for uploading your steering le are covered in the ‘Using Podware’ section.

Page 19

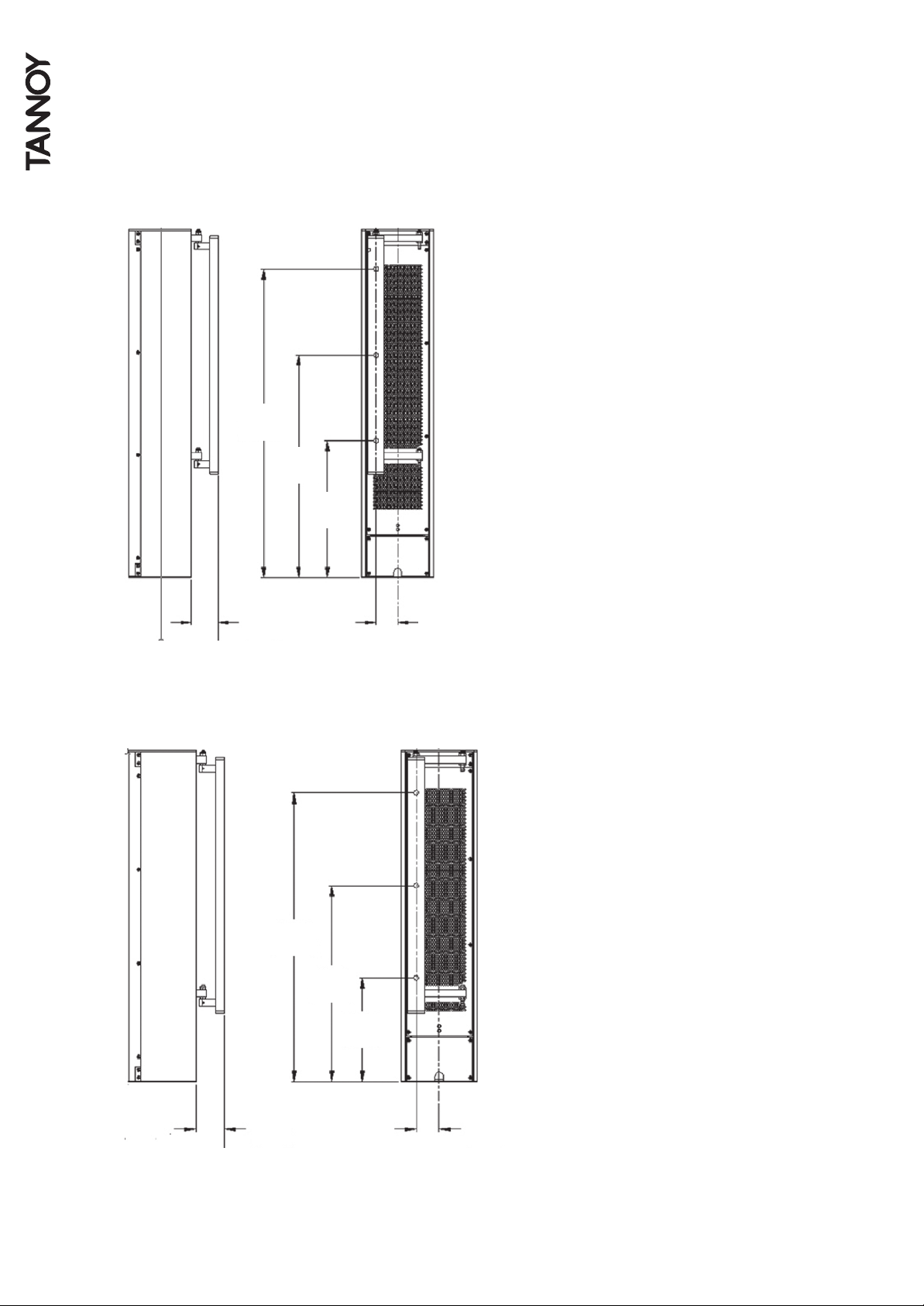

6.7 BALLOON DATA

EASE™ and CATT Acoustic™

Where more than one QFlex array is deployed in an installation it may be necessary or demanded to carry out a more

resolute acoustical analysis of the room. To properly evaluate QFlex coverage in 3D you can export a conguration le

from BeamEngine which can be used in Ease™ and CATT Acoustic™

Click on the ‘Balloon File’ tab.

The name of the le automatically defaults to the QFlex model you are using. In this case ‘QFlex32.xhn’ This name can

be modied. The le is saved in ASCII format and can be imported into the third party programme and the resultant

balloon data viewed.

Page 20

6.8 BEAMENGINE – FREQUENTLY ASKED QUESTIONS

Q. If I’m adjusting Master Beta, what LF driver utilization compromises do I suffer in adjusting to less than “1”?

A. Master multiplication factor to apply to regularization factors beta given in global A.wf(woofer) and A.tw(tweeter).

Normally masterbeta = 1, but it can be reduced to 0.1, trading some SPL for sharper directivity at the lower end of

eachsub-array’s(tweeterorwoofer)workingrange.Thedefaultsettingswillbeneinalmostallapplications.

Q. Why do some SPL plots of different surfaces further into the room start from the X=0 position?

A. The SPL-curves report the sound pressure along the venue items. For curves of ceiling venue items (pointing

downwards) it does not make sense to position these along the x-axis, so all ceiling items start at x=0.

Q. InoticedthatIcanskewthecoveragepatternofthearraybyputtingindifferingSPLvaluesforanySPLsurfaces.

Any caveats in doing so? I’m just trying to steer a bit more energy onto the balcony front where the sound booth

A. You can vary the intensity of each beam separately as well as adjust the intensity from the front to the rear of each

audience plane. Yo u should also treat the target SPL inputs (SPL (x1) & SPL (x2)) as a tool to vary the intensity of

the respective beams.

6.9 SOME DESIGN TIPS

InmanyapplicationsalargerQFlexmodelatthefrontofthebuildingwillsufce.AsingleQFlexmodelhasthecapability

of generating a number of independent beams and creating even SPL distribution over very large areas, so no need for

delay loudspeakers.

Beware of mounting the loudspeaker too low. The venue will most probably be empty when demonstrating or commission

the project. Remember that people stand up and sit. Make sure that when people stand they are not masking the sound

the back of the room.

at

For effective vocal reinforcement in venues with very long reverberation times, do not be tempted to use too small an

array. A QFlex 16 has effective steering control above 700Hz.The content of many vowel sounds occur below 700Hz. If

the RT60 is particularly high, consider using a larger QFlex array.

Even in highly reverberant environments QFlex is capable of directing sound in a laser like manner. Sometimes to create

some ambience it may be necessary to widen the beam slightly to create a natural sounding experience.

In very large venues where there may be features of the building which shadow the direct sound, for instance columns.

Using smaller delayed QFlex models may be necessary to provide complete coverage. Remember – there is 1000ms of

delay on board.

For more upbeat program materiel including music it may be necessary to compliment the QFlex with a subwoofer. As

part of the VNET family QFlex can be networked with a VNET Subwoofer if necessary.

Page 21

7 INSTALLING VNET SOFTWARE (PODWARE)

The latest version of Podware can be found at www.tannoy.com. Any new updates will automatically overwrite any

existing versions.

1. Having downloaded the software, double click on

the ‘Setup.exe icon. The welcome screen will appear.

Click <Next>

3.ConrmInstallation.Click<Next>

2. Select your destination Folder. Click <Next>

4. If you accept the licence agreement check

‘I Agree’ and Click <Next>

5. The programme will begin installing

6. Installation Complete

Page 22

8 USING VNET SOFTWARE (PODWARE)

Podware is a software package running under PC WindowsTM for setting up and controlling any Tannoy VNET device.

It is a clean Object Oriented package using the latest development technologies yielding intuitive ease of use and all the

features you have come to expect and more. Podware is used for conguring installations as well as the live control and

monitoring of devices during use. These devices may be connected individually using RS232 or USB. When participating

in a networked system, Podware can control many devices via RS485 and Ethernet.

Podware is a precision tool for system control and is capable of being congured to display single controls and indicators,

full interactive device panels or whole network views. Indeed, when networked, Podware can display information and

controls from multiple devices on the same page.

8.1 OVERVIEW

The VNET PodWare application will allow a PC computer running a 32-bit Windows

Vista, ME*, 98*) to monitor and control a number of compatible devices via communications network. The deceptively

simple intuitive user interface is PodWare’s outward appearance of a very powerful, thoroughly engineered protocol

engine, built on the latest software development technology.

PodWare can automatically discover devices connected to the network you tell it you would like to use. The connected

devices are then presented to you in an organised tree ready for you to select panels you would like to display and

manipulate

When devices are arranged in the main window, their default representation is a Monicon - an Icon which conveys basic

monitoring status indication. This Icon can usually then be opened up to the full control panel by clicking on a navigation

button.

Any number of Monicons and full panels may be displayed and organised on the screen automatically or manually. Each

device type usually has a predened Monicon and control panel associated with it, the latter containing controls for all

the parameters you can adjust within the device. Adjusting any of the controls on the panel whilst ‘on-line’ will cause

adjustments to be made in the relevant device in ‘real time’. A comprehensive set of features allow you to save and

retrieve stored parameter sets, manipulate ‘presets’, etc.

TM

operating system (NT, 2000, XP,

*Note that whilst operation with Windows

resource limitations these operating systems impose. If this is attempted, you should not attempt to run any other applications at the

same time as PodWare, and we would recommend that you only open one or two control panels at a time.

TM

98 or Millennium Edition is theoretically possible, this is not recommended because of the

8.2 LAYOUT

When PodWare is launched, its main window comprises three main areas:

A ‘tree’ panel on the left for navigating among devices and panel

A toolbar at the top with the most commonly used actions available at a single mouse click

A control panel area (the remainder of the window) for device Monicons and control panels.

The user may adjust the size of the application window by dragging the handle at the bottom-right of the main application

window. The ‘tree’ panel may be sized by dragging the split-line between the tree and the main control panel area.

Page 23

8.3 MENUS

The menu system is arranged like so:

File

Open - opens a le which contains parameters for the selected device

Save - saves the current settings for the selected device in the current le name

Save As - saves the current settings for the selected device under a new le name

Load Factory Settings – updates factory settings in the selected device (See Loading Factory Settings)

Open Device Clone – opens a le to clone the selected device

Save Device Clone – saves the settings of the selected device into a cloning le (See Cloning a Device)

Exit - closes the application

Preferences

Show Bandwidth As – Allows you to set the units used in Bandwidth controls

Show Delay As – Allows you to set the units used in Delay controls (See Controls)

Network

Go Online- Allows communication with devices on the network

Go Ofine - Stops communication with devices on the network

Com Port - Allows you to select which serial COM port you wish to use

Launch Panels - Launches the control panels for all the devices in the network

Device

Locate – to locate the selected device (e.g. wink the lights)

Update Firmware - update rmware in the selected device (See Device Firmware)

Add Device Panel – allows a panel for a device to be added to the layout off-line

Properties – Lists device details which may be of interest for maintenance (See The selected Device)

Panel

Tile Horizontally – arranges all the panels from left to right

Tile Vertically – arranges all the panels from top to bottom

Cascade – arranges all the panels in a heap from top-left to bottom-right

Help

Help topics – opens the help le (in your HTML viewer)

About this Application – shows copyright and version information

Some of these menu items have short-cuts using toolbar buttons. See Toolbar

Page 24

8.4 TOOLBAR

The toolbar provides the following one-click functions:

Open

Opens a le which contains parameters for the selected device. A dialogue will appear, inviting you to choose a le to open.

Save

Saves the current settings for the selected device. If you have previously opened or saved a le, the settings will be saved

in the same le name, otherwise, a dialogue will appear inviting you to enter a le name.If the settings have not changed

since you last saved or opened a le, the Icon will appear greyed out, indicating that a save is not necessary.

Online

Goes online/ofine to/from the network. If a device cannot be found, an error will be reported. While PodWare remains

on-line, this toolbar button is coloured green. It is red when off-line.

Locate

Flashes the indicators on the selected device (if online), to assist device identication, and as a quick check that

communications are working. This only works when on-line.

Mute All

Mutes (or Un-Mutes) every device in the system. When the speaker in the button is red, the system is muted. A green

speaker means un-muted. This has nothing to do with channel mutes, which operate completely independently. This state is

not saved in devices; a power cycle will cause a device to default to un-muted.

Launch All Panels

Launches the control panels for all of the devices on the network. This only work when on-line.

Help

Launches Help topics

If you place the mouse cursor over a toolbar, text ll appear describing the action of the button. If this text does not show,

click on the panel background.

See The Selected Device

8.5 COMMUNICATIONS

PodWare communicates with a device using a serial ‘COM’ port as a ‘network’ connection. This will usually be the COM port

associated with the RS232 Serial port on your computer. You need to select the appropriate COM port for this in the

Network menu.

If your computer does not have an RS232 serial port, a USB or Ethernet adapter may be used to create one. Such an

adaptor needs to create a ‘Virtual Com Port’ in order for it to be used with PodWare. Please refer to the installation

instructions supplied with the adaptor. We cannot guarantee that all adaptors will work correctly however. Please consult

your dealer for recommended adaptors.

It is strongly recommended that you use the dedicated Tannoy USB/232 interface (Tannoy part number 8001 4450). The

user manual & drivers for this device can be found at www.tannoy.com.

When a network connection is open and actively connected to one or more compatible devices, the system is said to be ‘On

Line’. Whilst On-line, you can control the connected devices in ‘real time’, and continuously receive status information from

the devices.

To go On-line, you can either select Device/Online from the menu, or press the Online toolbar button, which is a red triangle.

If all is well, the triangle will turn green, indicating that you are ‘On-line’.

Going Online

PodWare queries the network, searching for compatible devices. As PodWare nds each device, it will add it to the ‘Devices’

node of the Tree, along with text describing the model of the device, and the name of the device given by the user. Once all

devices has have been discovered, you are ready to start controlling the system by double-clicking a device icon in the Tree

to launch a control panel.(see Launching a Panel)

Page 25

If PodWare becomes unable to communicate with a device for some reason whilst on-line (such as a break in the

network cable), the corresponding icon for it in the Devices node of the Tree will appear in red, indicating that control and

monitoring on that device is invalid. Most devices will allow themselves to be ‘rediscovered’ automatically if such a cable

break is repaired.

8.6 LAUNCHING A PANEL

Once the application is On-Line, and there are one or more devices in the Devices node of the tree, a panel may be

launched for a given device in one of the following ways:

• By double-clicking on the appropriate Devices node of the Tree

• By dragging a Devices node to the Layout area of the main window

• By dragging a Devices node to the Panels node of the Tree

• By right-clicking on the Devices node and selecting Launch Panel from the context menu (see Device Context Menu)

• By selecting Launch All Panels, either from the Toolbar (see Toolbar), or from the Network menu (See Menus)

After a few seconds, the panel (or more usually, the reduced-size Monicon – see Monicons) will appear in the Layout part

of the main window. At the same time, an icon for the device will appear in the Panels node of the Tree.

Once the panel appears, the application will take a few seconds while it copies the settings in the device to the control

panel, as indicated by the progress bar at the bottom-right of the main window. (See Parameter Synchronisation)

This is now a fully functional real-time control panel for the connected device. A Monicon may be enlarged to a full-size

control panel by using navigation buttons. (See Navigation).

Several control panels may be launched onto the Layout, so that the user can monitor the operation of several devices

simultaneously. As each panel is added, another icon is added to the Layout node of the Tree, indicating the presence of

another panel in the Layout.

The Panel menu has features for arranging the panels into regular neat patterns if required (see Menus).

To locate a panel for a particular device, just double-click on its icon in the Panels node of the Tree. This will bring the

associated panel to the front, and highlight it (bring it into focus). (See Navigation).

A panel may be removed from the Layout by clicking on the ‘X’ in the top-right corner of the panel. This action will also

remove the device icon from the Panels node of the Tree. The panel may be launched back onto the Layout by double-

clicking on the Devices icon in the Tree.

Page 26

8.7 CONTROLLING DEVICES – A QUICK OVERVIEW

When online the tree menus will show the connected VNET speakers on the network. Double clicking on the model on

the tree view will open the control panel for each respective device. Each open panel will also appear on the tree view

under panels . When online, Podware gathers information from the connected devices. Any parameters which have been

adjusted by the user in previous sessions will be shown.

Each control panel can be positioned on the screen to represent its actual location position in the venue. When saving

data the control panels co-ordinates are also saved so that it appears in the same location on the screen when data is

recalled (see saving & recalling data).

The panels shown on the screenshot allows you to view what is going on inside the VNET product. As well as a mute

button, there is a limiter meter which indicate signal level relative to the limiter threshold setting, input level meter, draw

on the power supply, driver status indicators showing the status of each driver.

The arrow button (>>) at the top right hand side of the control panel will expand the control panel to reveal a host of

parameters which can be viewed & adjusted.

8.8 PARAMETER SYNCHRONISATION

PodWare aims to always ensure that the control settings in the virtual control panel are always a faithful representation of

the settings in the connected device. To achieve this, the parameters in the device are copied to the control panel when

going online. This takes a few seconds to complete (see Communications and Progress Bar). Whilst online, any changes

to the control settings will result in changes in the stored parameters in the devices, thus retaining synchronisation. When

a le is opened online, the new settings are not only set in the control panel; they are also transferred to the device

8.9 PROGRESS BAR

The area in the status bar at the bottom-right of the application window will indicate progress of some operations.

A coloured bar will extend to ll the extreme right-hand box, indicating progress from 0 to 100%, after which it will

disappear. While in progress, the text to the left of the bar will indicate what operation is being performed. “Loading”

will often be shown to indicate that the data is being transferred between the device and PodWare.

While the Progress Bar is showing activity

, it is best not to perform any other actions in PodWare.

8.10 NAVIGATION

The Tree view on the left-hand side of the screen allows you to view the system. The two main nodes in the Tree are

Devices, listing all the compatible devices found on the network, and Panels, listing all the control panels that have been

launched onto the Layout. Control panels may be launched by double-clicking on, or dragging a Devices node (see

Launching a Panel).

Clicking the ‘-’ on one of the main Tree nodes will close that branch, allowing you to remove some detail from the Tree.

Clicking the ‘+’ will restore the full detail.

Panels will often have navigation buttons for changing the amount of detail seen (and size of the panel). A Monicon panel

will have a ‘>’ button for expanding it into a full control panel. Similarly, a full panel will often have a ‘<’ button for reducing

the amount of detail (and panel size).

8.11 THE SELECTED DEVICE

The “Selected Device” is the device to which operations from the Device menu will be applied, and to which devicerelated toolbar button actions (such as Locate, Save, Open) will be applied.

If a device is selected in the Tree view (by clicking on a device node or a panel node so that the text of the node

highlights), then this is the selected device. If no device is selected in the tree, then the control panel in focus (the one

whose colour is different to the others) will be the selected device. If there are no panels in the layout, and no device is

selected in the Tree view, then no device is selected, and device-related operations will not work.

Page 27

8.12 DEVICE CONTEXT MENU

By right-clicking on the node of a device in the Tree, a ‘context menu’ will appear, providing you with the following

possible actions:

Launch Panel – Launches the control panel for this device

Rename Device – Allows the Device Name to be changed

Update Firmware - Update rmware in this device (See Device Firmware)

Locate Device – To locate this device (e.g. wink the lights)

Properties – Lists device details which may be of interest for maintenance

If you do not wish to select any actions from the context menu, it can be dismissed by pressing the ESC key, or by

clicking the mouse anywhere else in the application window.

8.13 CONTROL PANELS

Each panel will have a complete set of controls relating to the adjustable parameters within the device. Each control will

contain the current parameter value (See Parameter Synchronisation). In some panels, Tabs are used to distinguish

between different sections of the device.

Single parameters may be adjusted ‘live’ whilst ‘On-line’.

Also see Controls

Panels will often have a tool bar, with buttons for executing commonly used functions such as File Open, File Save,

Locate and Help (see ToolBar).

Main Control Panel

The EQ / Delay tab allows you to adjust the cabinet equalisation, High-pass lter, and delay.The cabinet equalisation

allows you to adjust the frequency and Gain (boost/cut) for each of the equalisation lters, and the bandwidth of the

parametric equalisers. The latter controls allow the responsiveness of the lters to be adjusted either as Octaves or Q,

depending on the setting of Preferences>Show Bandwidth As. There is also a Low-shelf and a High-shelf lter, each

with Frequency, Slope and Gain controls.A ‘Frequency Response’ curveshows the shape of each lter individually (by

colour), and the combined effect ofall equalisation (in white).

The Setup Tab - The steering le may also be loaded in this tab. See Loading Steering Data

The Properties/Options tab contains some properties of the loudspeaker. Here, you can enter a name for the

loudspeaker (such as “Front Left”), and a name for the conguration (such as “EQ 8-11-2008”). Also viewable in this tab

is the model name of the loudspeaker. The Maintenance area shows some details of how the loudspeaker has been

used, with various counts of use and abuse.

Page 28

The Logs area contains graphs of events against time, recording events over a period of up to three days. Since the

loudspeaker cannot record any events whilst powered-off, breaks in a log due to power-downs are indicated by a

discontinuity symbol ‘||’ in the log. The events recorded are: Thermal, which is the used thermal capacity, Amplier

Protect Gain, which is a measure of how much the loudspeaker is ‘dimming’ itself in order to protect itself from potential

damage, Driver Protection, which is a measure of how much the loudspeaker is ‘dimming’ itself in order to protect the

drivers from damage and Supply, which shows how the mains power voltage compares with nominal voltage. The data

in a log can be exported by right-clicking on the log to launch a context menu, and selecting “copy log data to clipboard”.

The data could then be pasted into a spreadsheet for further analysis. Your dealer may ask you to do this is you have

experienced a problem. Note that in addition to showing amplier protection due to over-heating, the Amp Protection log

will also show protection of individual ampliers if they attempt to drive into an open circuit (if a driver has ‘blown’). This

will be shown as a protection gain of approximately -9dB.

Power Save

At the bottom left hand corner of the control panel there is a power save button. Activating this button will shut down

the amplier into a lower-power standby mode. The DSP section remains active. If you set the Power Save control to

anything other than Manual, the loudspeaker will automatically go into power-save mode after a period without any audio

signal, the time being set by this control. Whenever a signal is applied in this mode, the loudspeaker will rapidly wake-up.

You can change the view to the MonIcon panel by clicking the “<<” button.

Page 29

8.14 LOADING STEERING DATA

Steering Files are generated in the BeamEngine software package (See Using BeamEngine)

The steering properties of the loudspeaker may be adjusted by loading a ‘Beam Engine File’ (*.bef) in the Setup tab in

the main control panel. When the ‘Open File’ button is clicked, a dialogue will allow you to load a new .bef le. If there is

more than one loudspeaker ‘box’ in the column, each .bef le produced by the beam design software will be for a given

box. The box number will usually be appended to the name of the le. The number of each box is shown to the right of

the device name in the Monicon. It is very important that each le is loaded to the appropriate box.

Note that when steering data is loaded into a loudspeaker, the data has to be stored internally, which takes a nite

time. To avoid loss of steering data, do not remove the power from a loudspeaker for at least ten seconds after loading

steering data. The same applies if you are loading a .dse Settings le which has steering data embedded into it.

Page 30

8.15 MONICONS

Monicons are a condensed representation of a device, which show some monitoring status information, but few or

no controls. Since these are quite small, they are a convenient way of arranging the devices on the main window in

a manner meaningful to the application. Clicking the ‘>’ button will cause the full control panel for the device to be

displayed. (See Navigation).

This allows you to view what is going on inside the loudspeaker at a glance. There is a pair of input signal level meters

showing the input signals, signal level meters for each group of drivers in the cabinet which indicate signal level relative

to the limiter settings, a thermal meter showing the used thermal capacity of the ampliers, and amplier status indicators

showing when an amplier is protecting itself from damage due to abnormal operating conditions, and Driver indicators

showing when the impedance of a driver is outside normal range, laid out in the same way as the physical drivers.

Generally, the indicators show green whilst all is well and red when something is wrong.

Note that the Input meter on a Master displays the absolute signal level (in dBu) present on the input connector, and

is unaffected by the input gain control. The input meter on a Slave displays the level of the signal passed to it by the

Master, relative to full-scale, and is effected by the input gain on the Master. You may also mute the loudspeaker, and see

the input gain. The gain can also be changed by typing a value into the Gain box. You can change the view to the main

panel by clicking the “>>” button. At the top of the MonIcon, the name of the device is shown, and to the right of this, the

number of the box so that each box may be identied in a multi-box column.

8.16 CONTROLS

Controls have standardised properties that allow them to work in a consistent way across various control panels for

different devices. Many controls will allow the mouse wheel to be used for ne adjustments, or the keyboard as an

alternative (see Keyboard Shortcuts). When using the keyboard or the mouse wheel, it is necessary to have the control

in question ‘in focus’. You can bring a control into focus either by tabbing to it (using the Tab key), or by clicking on it

with the mouse. Focus is often shown as a dotted rectangle around part of the control, or by the text in a control being

highlighted, or by a solid outline being added to a button. Some controls may allow the units of measure used for

displaying and adjusting values to be changed, such as Equaliser Bandwidths, which may be shown in Octaves or Q, or

Delays, which may be shown in distance or delay units. The units of measure are selected in the Preferences menu

(see Menus).

Drop-Down Selector boxes

These are for selecting one item from a number of possibilities in a list. Click the arrow on the right-hand end of the

control to cause it to display a list of the options. Click on the text for that option to select it. If there are many options to

choose from, a scroll-bar will be shown, allowing you to scroll up and down the list by clicking the scroll arrows. Note that

once the control is highlighted, the PGUP, PGDWN and Arrow keys or the mouse wheel may also be used to change the

selection.

Spin boxes

The value would normally be adjusted by clicking on the top button to increase the displayed value, or on the bottom

button to reduce the displayed value. Holding the mouse button whilst on a button will after a short delay cause the

repeat mechanism to repeatedly increment or decrement the value. Alternatively, values may be typed into the value box

directly. To do this, click in the value box and type in the new value. The value you type in may include a minus sign, a

decimal point, and/or an engineering multiplier, such as ‘k’ to signify a multiplication of 1000. This may appear at the end

of the typed string, or may be used instead of a decimal point (such as 6k2 to mean 6200). Some controls may

auto-range as the value changes. For example, delay controls in distance mode may change from mm to m as the

distance increases beyond 999mm. If you wish to type a value into such a control, then metres will be assumes unless

you specify mm (such as “53mm”). For the value to be accepted, you can either click outside the control (such as on

another control), or press the Enter key. Once s control button is highlighted, the PGUP, PGDWN and Arrow keys or the

mouse wheel may also be used to adjust the value.

Page 31

Buttons

Buttons generally have two states; depressed (active) and non-depressed (inactive). Generally, the button will apply the

condition that is labelled when it is depressed. The space bar may be used to activate a button which is in focus.

Radio buttons

These are laid out in mutually exclusive groups to select one of a number of options. Press the radio button to select it,

which will cause any other button in the group to be deselected. Once a control in the group is highlighted, the PGUP,

PGDWN and Arrow keys may also be used to change the selection.

Faders

Faders provide a linearly traversing button, which may be dragged using a pressed mouse to adjust the value. These

sometimes also have an associated value box for showing the numerical value of the parameter. Once the control is

highlighted, the PGUP and PGDWN keys may be used for coarse adjustment, and the Arrow keys or the mouse wheel

may be used to for ne adjustment.

8.17 FILTER RESPONSE PANELS

Some panels provide a graphical representation of the response of one or more of the lters/equalisers in the device.

These will usually consist of coloured semi-transparent lled areas representing individual lters, overlaid with a white

curve line representing the overall response of a bank of lters/equaliser sections.

When the associated lter parameters are adjusted, you will see the curves responding so they always show the current

response.

It will usually be possible to ‘drag’ the lter parameters with the computer mouse directly on the Response Panel. If you

click anywhere in a Response Panel, you will see a set of ‘drag handles’ appear at the apexes of the individual lter

response curves. These handles will usually have the same colour as the lter they relate to, and carry a number or letter

to assist identication.

To change a lter parameter, place the mouse pointer over the drag handle, then press and hold the left mouse button

while moving the mouse (vertically to change the lter gain, and horizontally to change the lter frequency). The lter

With/Slope/Order may be adjusted either using the mouse wheel, or by holding the keyboard shift key whilst dragging the

handle vertically.

The keyboard may also be used (see Keyboard Shortcuts).

Copy Graphics

To assist in preparing documentation etc, any response panel may be copied (to the Windows clipboard) by right-clicking

on the panel and selecting Copy Image to Clipboard. The bitmap image may then be pasted into another application

(such as word-processing), usually by selecting Edit>Paste in that application, or CTL+C.

Copy/Paste Settings

You can copy EQ settings from one channel to another on a given device, or copy EQ settings from one device to

another. To do this simply right-click on the source panel (the one you want to copy from) and select Copy EQ Settings.

Then on the destination response panel (the one you want to copy to), right-click and select Paste EQ Settings. You will

be alerted to any problems such as the destination response panel not having enough EQ bands to reproduce the source

EQ, or access to some or all of the bands being restricted due to security protection.

Page 32

8.18 OFF-LINE OPERATION

You may launch a control panel for a device whilst off-line be using the menu feature Device>Add Device Panel. Clicking

on this will cause a dialogue to be shown which allows you to choose the particular model of device you would like to add

to the layout. Once you have chosen the model, click the Add button. The application will then be busy for a few seconds

while the panel is constructed, after which it will appear in the Layout part of the window, and an icon for it will be added

in the Panel part of the Tree. More device panels may then be added by making further device model selections and

clicking Add. When you have added all the panels you need, click the Done button to dismiss the dialogue.

Off-line operation is useful either for demonstration or product familiarisation, or for creating setting les when a real

device is not available.

Settings made on an off-line panel may be saved to a settings le by clicking the le Save icon on the panel. Similarly, a

settings le may be loaded into the panel for further modication.

Note that when you go on-line to a network of devices, any off-line panels will rst be dismissed. You can of course load

a settings le you created ofine into a device when on-line (See Saving Data).

8.19 SAVING & RECALLING DATA

Device Data may be saved to disk or opened from disk. PodWare Device Settings les (with le extension .dse) contain

all the user data necessary to restore a device to exactly the same state as when the le was saved.

If the current settings have been changed since the last le save or le open, the Save Icon on the panel toolbar will be

shown in solid colour. If the settings are already safe, the Save icon appears grey.

If a le is opened when on-line to devices, the new data will be sent to the device, overwriting whatever was in the

device. A warning will be given before this is done. Data saved from one device can be reopened in another to save time

inputting data. (Assuming settings are to be duplicated).

When you save a le, you will be invited to include steering data in the le. If you do this, opening the le into the same

device or another device will reinstate the same steering settings.

If you do not include steering data, then the user settings such as EQ etc remain independent from steering data. If you

open a settings le which contains steering data, a warning will be given that the steering data will be overwritten.

PodWare will always try to protect your data, warning you if you are attempting an action that could cause loss of data.

8.20 LOADING FACTORY SETTINGS

Using the File>Load Factory Settings menu option, you can update the basic factory settings which might be issued in

future from Tannoy.

When you load factory settings into QFlex, the current user settings will be preserved since the factory settings will only

overwrite the factory DSP settings rather than the User DSP settings. Depending on what type of le is supplied, the

factory le may or may not include steering data. A warning will be given if you open a factory le which includes steering

data, since this will overwrite any existing steering data.

For further information on loading factory settings, please see the main application help.

This procedure will apply to the currently selected device (See The Selected Device). Once you have selected the menu

item, you will be guided to select a Device Factory (.dfa) le to load. If you have a control panel for the device in view,

this will automatically be dismissed for a time while loading takes place. The progress bar at the bottom-right of the

application indicates when the process has nished, after which your control panel will reappear if you had launched one.

8.21 CLONING A DEVICE

There are several different categories of settings within a device which are manipulated by the various le types. The

standard Device Settings le (.dse) will only manipulate those parameters which are under the control of the user.

More of the settings may be changed by loading Factory Settings (see Loading Factory Settings). However, to create a

completely duplicate device whose settings will be identical in every way, the Cloning facility may be used. To do this,

select the device which you wish to clone FROM (see The Selected Device), then use File>Save Device Clone.

Once you have selected the menu item, you will be guided to choose a Device CLone (.dcl) le name to save. If you

have a control panel for the device in view, this will automatically be dismissed for a time while saving takes place. The

progress bar at the bottom-right of the application indicates when the process has nished, after which your control panel

will reappear if you had launched one.

Now select the device you wish to clone TO, then use File>Open Device Clone. A similar process to that described

above will allow you to chose the .dcl le to open. Once the process is complete, the two devices will be identical.

Clearly for this to make sense, the two device should be of the same type.

Page 33

8.22 OPERATING MODE

A control input on the back of the loudspeaker allows you to select between two different sets of DSP settings (1 and 2)

– see system connectivity. The currently active Operating Mode is indicated by the ‘Active’ box in the OpMode group box

in the PodWare panel. You can select which Operating Mode you wish to edit by selecting the appropriate radio-button

in the OpMode group box. Both modes may be edited simultaneously by selecting ‘Edit Both’. Only when the Operating

Mode is the same as the edited mode will changes you make be heard. Note however that if you make adjustments

on the control panel when the active mode is different to the edit mode, the settings are changed and stored in the

loudspeaker, but you will not be able to hear the changes until the active mode is changed to the one you have edited. A

red indication will be shown in the OpMode group box when you are not listening to the mode you are editing.

Note that Parameter adjustments are automatically stored in the loudspeaker - it is not possible to do temporary changes

then store them separately.

Example - Op Mode 1 with a particular EQ setting.

Input B Muted

Example – Op Mode 2 with an EQ setting for emergency paging.

Page 34

Input A muted.

Page 35

Protection

Comprehensive protection features preserve the longevity of the ampliers and drivers by continuously monitoring

several critical parameters, and reducing the gain, or muting the ampliers either temporarily or permanently depending

on the nature and seriousness of the fault or misuse. The ampliers will recover and restart if at all possible, but may

remain shutdown if a serious fault persists.

Limiters deal with routine over-driving of the drivers, making sure that the drivers are not pushed too hard.

Minor faults are dealt with by slowly ‘dimming’ the loudspeaker, reducing the level to a sufcient degree and for a

sufcient time that the ampliers are able to recover gracefully without any user interaction. When the fault condition has

passed, the ampliers will slowly fade up to normal.

More serious faults may cause the ampliers to mute while they recover, after which they will automatically re-energise

and fade up, again without user interaction. If such a fault is found to be persistent however, the ampliers may shut

down permanently, ashing an indicator rapidly. A power cycle by the user is then required.

During power-up, the ampliers will remain muted for a short time while checks are made that all is well. During this time,

the Indicator will ash. The signal is then gently faded up.

Indication

Visible from the front of the loudspeaker is a Network indicator, which also winks for a few seconds when the ‘Locate’

feature is activated in PodWare. This allows you to conrm which control panel in PodWare is dealing with which physical

loudspeaker.

Summary of indication:

During Loudspeaker power-up: Indicator winks rapidly

Loudspeaker has detected a fault: Indicator winks rapidly

Locate feature activated in PodWare: Indicator winks

Mute All activated: Indicator winks slowly

8.23 DEVICE PROPERTIES

By selecting Device>Properties from the menu (see Menus), or by selecting Properties from the Device Context Menu

(see Device Context Menu), a dialogue will be shown listing some properties for the selected device (See The Selected

Device). These are as follows:

Model Name: The Model Name/Number the type of device is usually known as (e.g. “QFlex 16 Master”)

Device Name: The name given to this particular device by the user (e.g. “Left Proscenium”).This can usually be changed

in a control panel, or in the Device Context Menu (seeDevice Context Menu)

Settings Name: The name given to the current set of parameter settings (e.g. “Bright vocal”)

Firmware Model: A number describing the type of software running in the device.

Firmware Version: The version number of the rmware so you can tell if you have the latest. See Device Firmware

Handle: A 4-digit hexadecimal number which will uniquely identify this device on a network

Link Address: A hexadecimal number which the network will use for addressing this device.

Hardware Version: A number representing a variant of the hardware build of a given device type. This is rarely of

concern to the user, but you may be asked to quote this value when discussing a problem with your dealer.

When you have nished with the dialogue, just click the Done button.

Page 36

8.24 DEVICE FIRMWARE

Firmware is the software which runs inside the device. Most products which are controllable from PodWare have

rmware which can be updated by the user.

Firmware is uniquely identied by two things:

1. The Firmware Model Number. This is not the model number of the product, but a number which uniquely describes

the type of rmware used by the device. When updating rmware, the same rmware model must be used.

2. The Firmware Version Number. This describes the issue of the rmware update within a given model number. When

updating rmware, the latest rmware Version Number for a given rmware Model Number would normally be

selected. Firmware updates are usually supplied in .dfw (Device FirmWare) les. PodWare uses a .dfw le to load new

rmware into a device.

Firmware les are named like this: ****5678V1234.DFW

If you are using the very latest Version of Podware then you will be advised automatically when you go online if your

device requires a rmware update

You can inspect the rmware Model and Version in the Device Properties dialogue.

To update the rmware in a device, see Menus or Device Context Menus.

At the bottom right hand side of the screen a blue bar will show the progress of the rmware update. Do not power down

the unit or disconnect any network cable during a rmware update. During the update a red bar will show the progress

of the rmware update (bottom right of screen). The device will then power cycle automatically. The loudspeaker is now

ready for normal operation.

8.25 KEYBOARD SHORTCUTS

PodWare supports the following ‘shortcuts’:

Tab Move to next control

In value boxes:

CTL+C Copy

CTL+V Paste

CTL+X Cut

CTL+Z Undo

On Drop-down, Spin, Push, Fader and radio controls:

PgUp Increase value (coarsely)

PgDown Reduce value (coarsely)

Up/Right arrow Increase value (nely)

Down/Left arrow Reduce value (nely)

On push-button controls:

Space Activate

On Filter Response Panels:

PgUp Increase Width/Slope/Order value

PgDown Reduce Width/Slope/Order value

Up arrow Increase lter gain value

Down arrow Reduce lter gain value

Right arrow Increase lter frequency value

Left arrow Reduce lter frequency value

Tab Move to next lter

Shift Used with mouse drag to adjust Width/Slope/Order value

Page 37

9 HARDWARE CONFIGURATION (GENERL INFORMATION)

To avoid shipping very long products, QFlex products are modular, so it will be possible to assemble the components of a

QFlex product on site. Each QFlex module incorporates a mains power supply, DSP platform with VNET support, and

audio amplication.

All of the required joining hardware and bracketry is included with each QFlex purchase. If you have purchased a QFlex

8 or a QFlex 16 there are no connecting plates or other joining hardware. Each QFlex carton is marked to show each

modules position in the array.

QFlex modules must only be joined or separated with the complete column laying at on the ground and disconnected

from the mains supply.

There are 5 individual modules that make up the complete QFlex Range:

a. 8 channel master unit (80014910)

b. 8 channel slave unit (8001 4900)

c. 16 channel master unit (8001 4890)

d. 16 channel slave unit (top) (8001 4880)

e. 16 channel slave unit (bottom) (8001 4870)

Page 38

QFlex Range

8 16 24 32 40 48

The joining hardware parts are packed with the QFlex modules in

will be marked ‘HARDWARE’

The Table below shows the list of joining hardware parts and bracketry supplied with each QFlex model.

QFlex

product

QFlex 8 8004 0100 0 0 0 1

QFlex 16 8004 0110 0 0 0 1

QFlex 24 8004 0120 1 1 0 1

QFlex 32 8004 0130 1 1 0 1

QFlex 40 8004 0140 2 2 0 2

QFlex 48 8004 0150 2 3 1 2

A QFlex array will consist of either just a master unit (QFlex 8 or 16) or a master unit with up to three additional slave

units (QFlex 48)

The master unit will always be positioned at the bottom of any speaker column and will be slightly longer to

accommodate the connectors and power indicator.

The top of a slave unit will be the same as the top of the master unit to allow another slave unit to be mechanically

VNET™ command, returning to operating mode either upon the detection of audio or a ‘power up’ VNET™ command.

QFlex products have analog and AES* audio inputs, and use VNET™ for monitoring and control.

For mechanical integrity, thermal and EMC reasons, the electronics module is in a separate cavity from

the transducers.

QFlex products are designed to meet the safety requirements of UL60065 7th edition & EN60065 2002.

QFlex meet the EMC requirements of Fcc15a and EN55103* AES inputs will be included as standard in 2009

Product

number

Cabinet joining

plate with hinges

7600 1770

Joining plate - side

(inc 20 screws)

7600 1800

Joining plate

- rear

6883 0267

Wall

bracket

8001 5330

Page 39

10 ASSEMBLY INSTRUCTIONS

10.1 QFLEX 8 & QFLEX 16 ASSEMBLY

With a QFlex 8 and QFlex 16 all you need to do is remove the loudspeaker from the box and x the wall bracket as

shown below. The wall bracket can be hinged on the left or right pivot points. 3mm Allen grub screws allow the QFlex to

be locked at the desired horizontal angle.

Having the hinge points on either side of the QFlex column allow the loudspeaker to be rotated at 90 degrees to the

mounting structure allowing easy access to the input connector panel.

The installer must ensure that the mounting surface is capable of safely and securely supporting the loudspeaker. Seek

help from architects, structural engineers or other specialists if in any doubt.

Page 40

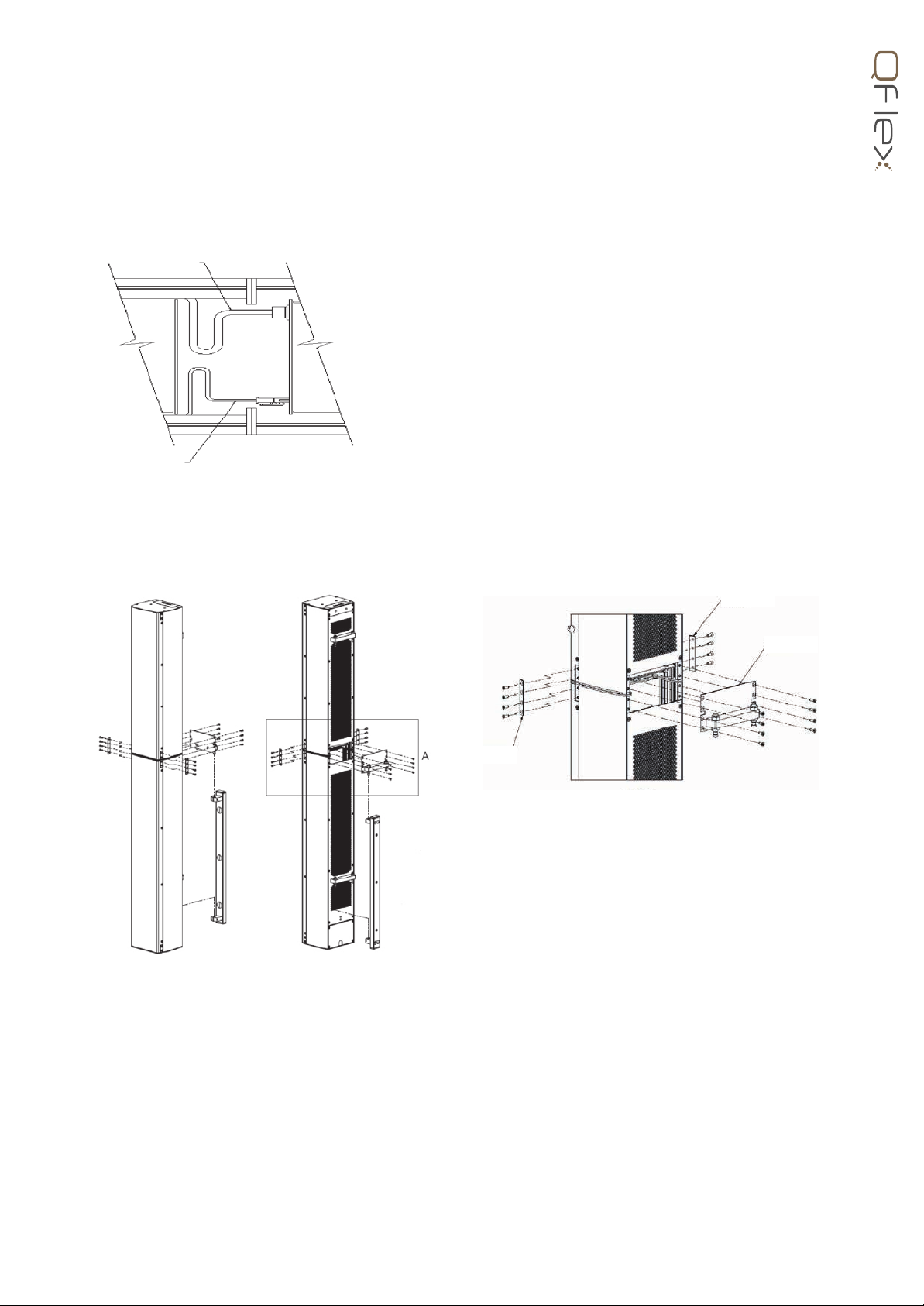

10.2 WALL BRACKET MOUNTING CENTRES - QFLEX 8 & QFLEX 16

QFlex must be wall mounted with the separately ordered mounting kit. The Wall bracket should be tted to the wall rst.

When you are satised with the mounting locations, x the bracket to the wall using the instructions supplied with the

bracket and ensuring that the installation complies with all local regulations.

QFlex 8

744.5

(29.31”)

537.0

(21.14”)

329.5

(12.97”)

QFlex 16

64.5.

(2.54”)

(25.53”)

52.0

(2.05”)

648.5

441.0

(17.36”)

233.5

(9.19”)

64.5

(2.54”)

52.0

(2.05”)

Page 41

10.3 QFLEX 24 & QFLEX 32 ASSEMBLY

It is recommended that you assemble the column horizontally on a at surface. Lay some cloth or cardboard on the

surface to avoid scratching the surface of the product during the assembly process.

In the hardware pack you will nd one wall bracket and joining hardware consisting of one heavy joining plate with hinge

points, two small link bars and M4 Phillips screws.

Place each module in its respective position on the assembly area keeping them slightly spaced apart. Take the ying

RJ45 connector in the lower module and insert it into the RJ45 socket in the upper module. Take the ying AC mains

connector in the lower module and insert it into the female connector in the upper module.

CAT 5

POWER CORD

Align the two columns together as shown below.

STAGE 2

STAGE 1

A

STAGE 3

Attach the joining plates in the three stages as shown. Only one wall

bracket it required to mount the two modules. For exibility the wall

bracket can be mounted to either the top or the bottom column. The

wall bracket can be hinged on the left or right pivot points. 3mm Allen

grub screws allow the QFlex to be locked at the desired

horizontal angle.

Having the hinge points on either side of the QFlex column allow the loudspeaker to be rotated at 90 degrees to the

mounting structure allowing easy access to the input connector panel.

The installer must ensure that the mounting surface is capable of safely and securely supporting the loudspeaker. Seek

help from architects, structural engineers or other specialists if in any doubt.

Page 42

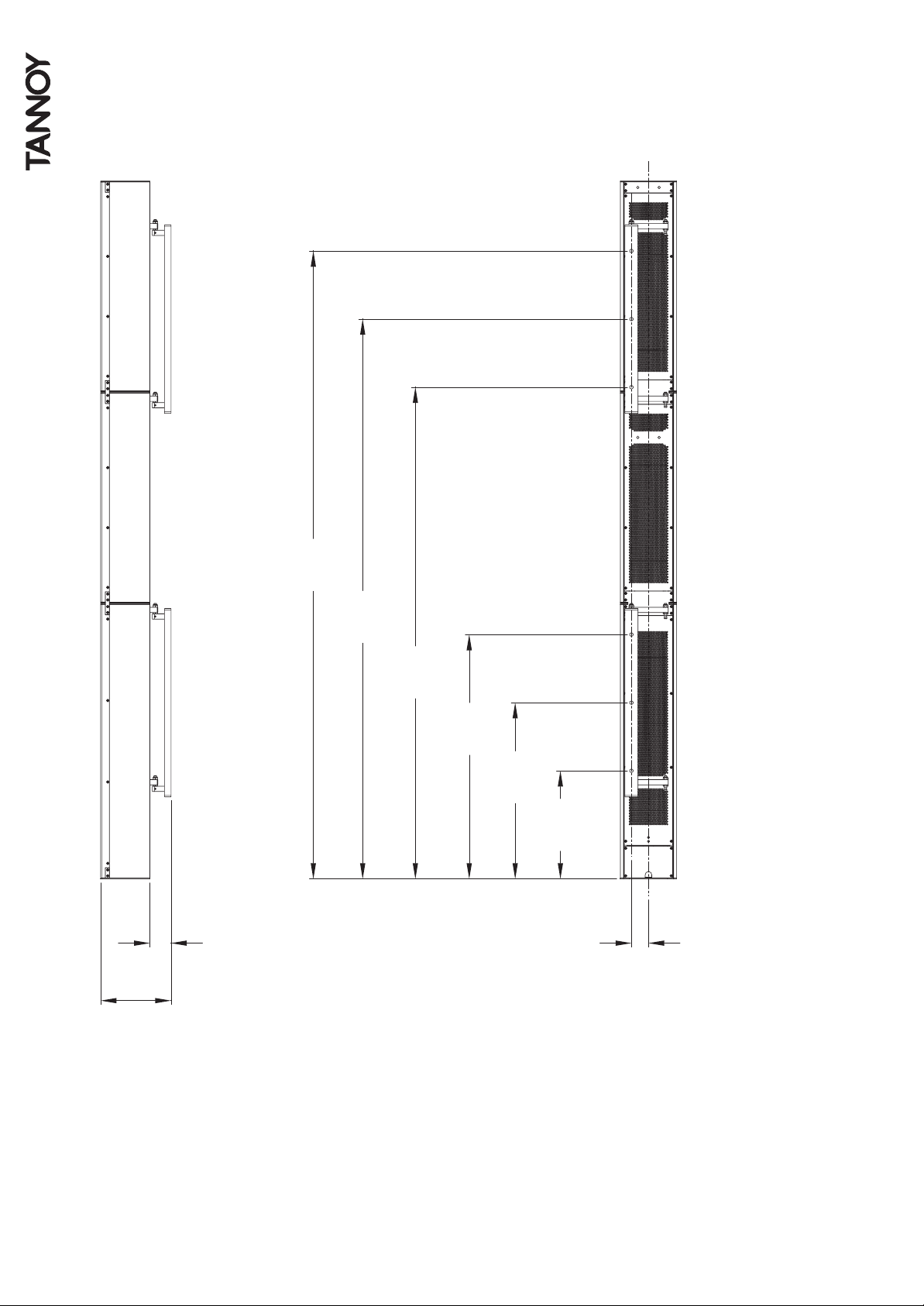

10.4 WALL BRACKET MOUNTING CENTRES - QFLEX 24 & QFLEX 32

QFlex must be wall mounted with the separately ordered mounting kit. The Wall bracket should be tted to the wall rst.

When you are satised with the mounting locations, x the bracket to the wall using the instructions supplied with the

bracket and ensuring that the installation complies with all local regulations.

QFlex 24

744.5

(29.31”)

537.0

(21.14”)

329.5

(12.87”)

QFlex 32

64.5.

(2.54”)

648.5

(25.83”)

441.0

(17.36”)

52.0

(2.05”)

233.5

(9.19”)

64.5

(2.54)

52.0

(2.05”)

Page 43

10.5 QFLEX 40 ASSEMBLY

It is recommended that you assemble the column horizontally on a at surface. Lay some cloth or cardboard on the

surface to avoid scratching the surface of the product during the assembly process.

In the hardware pack you will nd two wall brackets and joining hardware consisting of two heavy joining plates with

hinge points, four small link bars and M4 Phillips screws.

Place each module in its respective position on the assembly area keeping them slightly spaced apart. Take the ying

RJ45 connector in the lower module and insert it into the RJ45 socket in the middle module. Take the ying AC mains