Page 1

iQ SERIES

USER MANUAL

iQ 10/15

Page 2

Page 3

CONTENTS

1. Introduction

2. Unpacking

3. Connectors/Cabling

4. Amplification & Power Handling

5. Operation

6. Equalisation

7. Arraying

8. Dimensions

9. Rigging & Suspension

General Safety Advice

SECUR ET – VEB Eyebolt

Suspension Truss

10. Performance Data

11. Technical Specifications

12. System Configuration & OEM Controllers

System Parameters

13. Recommended Service Parts & Accessories

14. Warranty

15. Declaration of Conformity

Page 4

4

1. Introduction

Thank you for purchasing Tannoy PowerDual™ iQ 10/15

As part of the HDSR

TM

product group, the iQ range is the next generation of high

intelligibility sound reinforcement loudspeakers from Tannoy. High Definition Sound

Reinforcement (HDSR

TM

) products specifically designed to provide high intelligibility

audio reproduction in such locations as houses of worship, performing arts centres,

auditoria, stadiums and larger music venues; in fact, any public space where high

performance, high definition sound can enhance the listening experience.

Using a 250mm (10”) version of Tannoy’s own unique, point source and constant

directivity PowerDual™ driver, the iQ 10/15 is a single cabinet full range system

incorporating a 15” horn loaded bass driver. This high efficiency bass driver,

functioning from 43Hz to 180kHz, has been optimally designed to acoustically match

the iQ10 HF/MF section to deliver high definition sound reinforcement at low

frequencies. This is mounted in the lower section of the enclosure and is horn-loaded

to deliver increased efficiency and improved LF output.

The HF/MF section, covering a frequency range from 180Hz to 18kHz, uses the

amalgamation of the exceptional PowerDual™ driver with the Funktion One Research

patented Axhead™ horn technology to provide a controlled 60° horizontal and 40°

vertical dispersion pattern. Exclusively this unique combination incorporates the High

Frequency element of the PowerDual™ into the Axhead™ phase plug itself; providing

not only a point source time coherent design, but a valuable reduction in overall size

as no separate HF horn is necessary as in other ‘phase plug’ designs

This compact high power sound reinforcement solution is ideal for live or fixed

installation music and speech sound reinforcement applications. The construction of

the cabinet is exceptionally robust, using 18mm birch plywood throughout, and is

equipped with carrying handles, extensive rigging and pull back points in order to

facilitate the use of various flying options. A full-length foam-covered powder coated

perforated steel grille is provided. The trapezoid angles of the enclosure facilitate the

creation of optimized-coverage arrays.

The system may be installed in the standard LF and passive HF/MF bi-amp

configuration or alternatively, as an option, set up in fully tri-amp mode.

Comprehensive system control may be provided by the addition of the TannoyTDX1

or TDX2 digital loudspeaker management systems.

2. Unpacking

Every Tannoy iQ10/15 is carefully tested and inspected before packing. After

unpacking, please inspect your iQ10 for any damage sustained during transit. In the

unlikely event of any damage, would you please notify your dealer immediately and

retain your shipping carton, as your dealer may ask the faulty unit to be returned for

inspection.

3. Connectors/Cabling

The iQ 10/15 is fitted with two 4-pole Speakon™ connectors. Speakon™ has the

following advantages over EP and XLR type connectors: All terminations are

solderless, making life easier at the time of installation or when field servicing is

required. Contacts will accept 6 sq. mm wire with an outside diameter of up to 15 mm

and a current rating of 30 Amps.

The pins of the Speakon™ sockets, marked input/output on the rear of the speaker,

are paralleled within the enclosure.

Page 5

5

Tannoy has adopted the following wiring standard for the iQ 10/15: -

SPEAKON™

CONNECTOR

SIGNAL

Pin 1+ LF Positive

Pin 1- LF Negative

Pin 2+ MF/HF Positive

Pin 2- MF/HF Negative

For a worldwide list of Neutrik distributors see

http://www.neutrik.com/

*A custom termination panel is available for tri-amp operation

Cable choice consists mainly of selecting the correct cross sectional area in relation

to the cable length and the load impedance. A small cross sectional area would

increase the cables series resistance, inducing power loss and response variations

(damping factor).

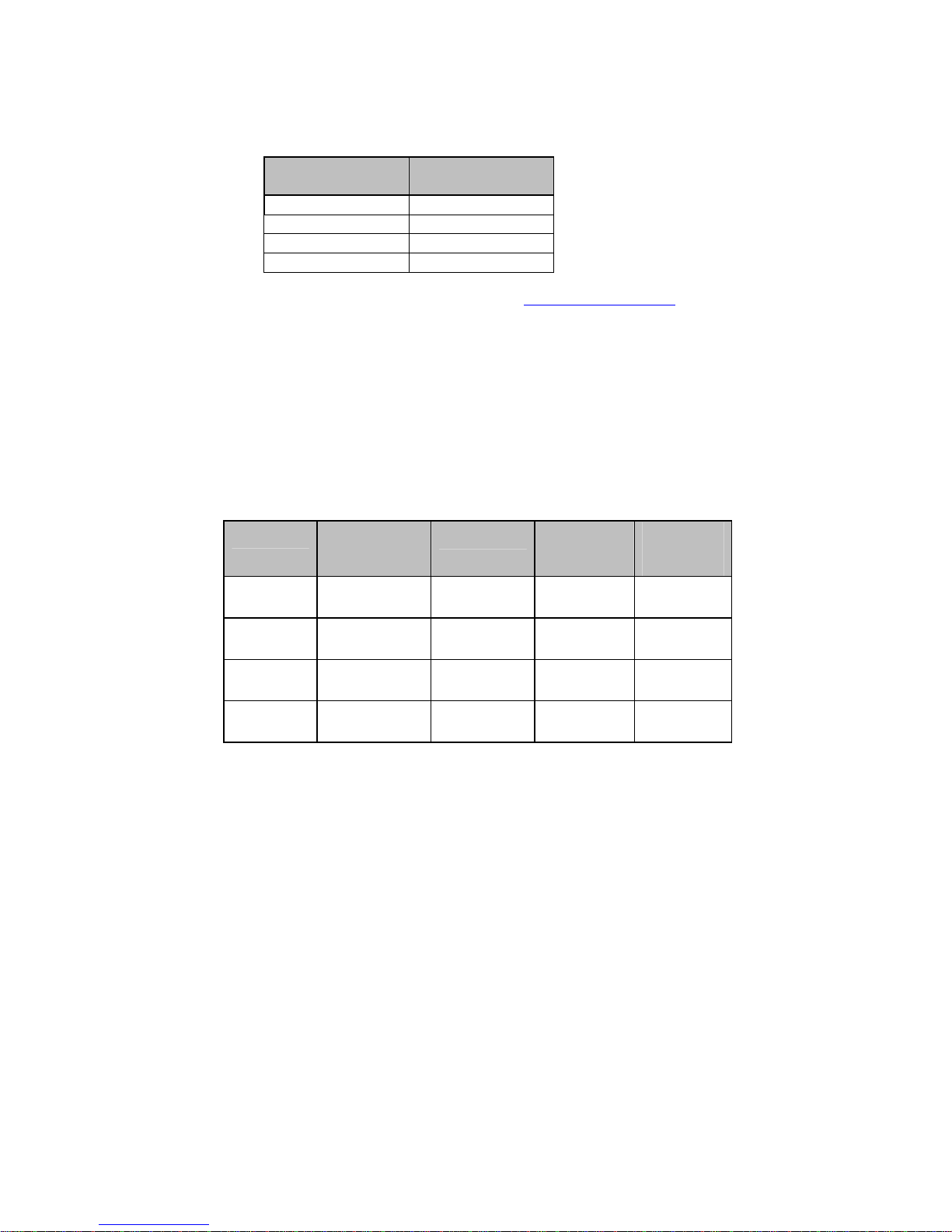

Connectors should be wired with a minimum of 2.5 sq. mm (12 gauge) cable. This will

be perfectly satisfactory under normal conditions. In the case of very long cable runs

the wire size should exceed this, refer to the following table for guidance: -

CABLE RUN

(m)

C.S.A. OF EACH

CONDUCTOR

(mm)

CABLE

RESISTANCE Ω

% POWER

LOSS

INTO 8Ω LOAD

% POWER

LOSS

INTO 4Ω

LOAD

10 2.5

4.0

6.0

0.14

0.09

0.06

1.7

1.1

0.73

3.5

2.2

1.5

25 2.5

4.0

6.0

0.35

0.22

0.14

4.3

2.7

1.8

8.6

5.4

3.6

50 2.5

4.0

6.0

0.69

0.43

0.29

8.6

5.4

3.6

17.0

11.0

7.2

100 2.5

4.0

6.0

1.38

0.86

0.58

17.0

11.0

7.2

35.0

22.0

14.0

4. Amplification & Power Handling

As with all professional loudspeaker systems, the power handling is a function of

voice coil thermal capacity. Care should be taken to avoid running the amplifier into

clip (clipping is the end result of overdriving any amplifier). Damage to the

loudspeaker will be sustained if the amplifier is driven into clip for any extended

period of time. Headroom of at least 3dB should be allowed. When evaluating an

amplifier, it is important to take into account its behaviour under low impedance load

conditions. A loudspeaker system is highly reactive and with transient signals it can

require more current than the nominal impedance would indicate.

Generally, a higher power amplifier running free of distortion will do less damage to

the loudspeaker than a lower power amplifier continually clipping. It is also worth

remembering that a high powered amplifier running at less than 90% of output power

generally sounds a lot better than a lower power amplifier running at 100%. An

amplifier with insufficient drive capability will not allow the full performance of the

loudspeaker to be realised.

It is important when using different manufacturers amplifiers in a single installation

that they have very closely matched gains, the variation should be less than +/-

0.5dB. This precaution is important to the overall system balance when only a single

compressor/limiter or active crossover is being used with multiple cabinets; it is

therefore recommended that the same amplifiers be used throughout.

Page 6

5. Operation

For optimal performance, the iQ 10/15 has been designed to operate in conjunction

with the Tannoy TDX1 & TDX2 System Controllers, and iQ18B bass unit for extended

bass performance. The TDX controllers have been factory preset to provide the

recommended eq, crossover points, and overall system balance. Please refer to the

TDX1 & TDX2 manual for operation.

If you intend using an alternative loudspeaker management system (e.g. BSS™,

KlarkTeknik™, XTA™ etc) please refer to section 12 of this manual.

6. Equalisation

Over equalisation can reduce system headroom, and introduce phase distortion

resulting in greater problems than cures. If equalisation is required then it should be

applied gently and smoothly. Violent equalisation will be detrimental to the overall

sound quality.

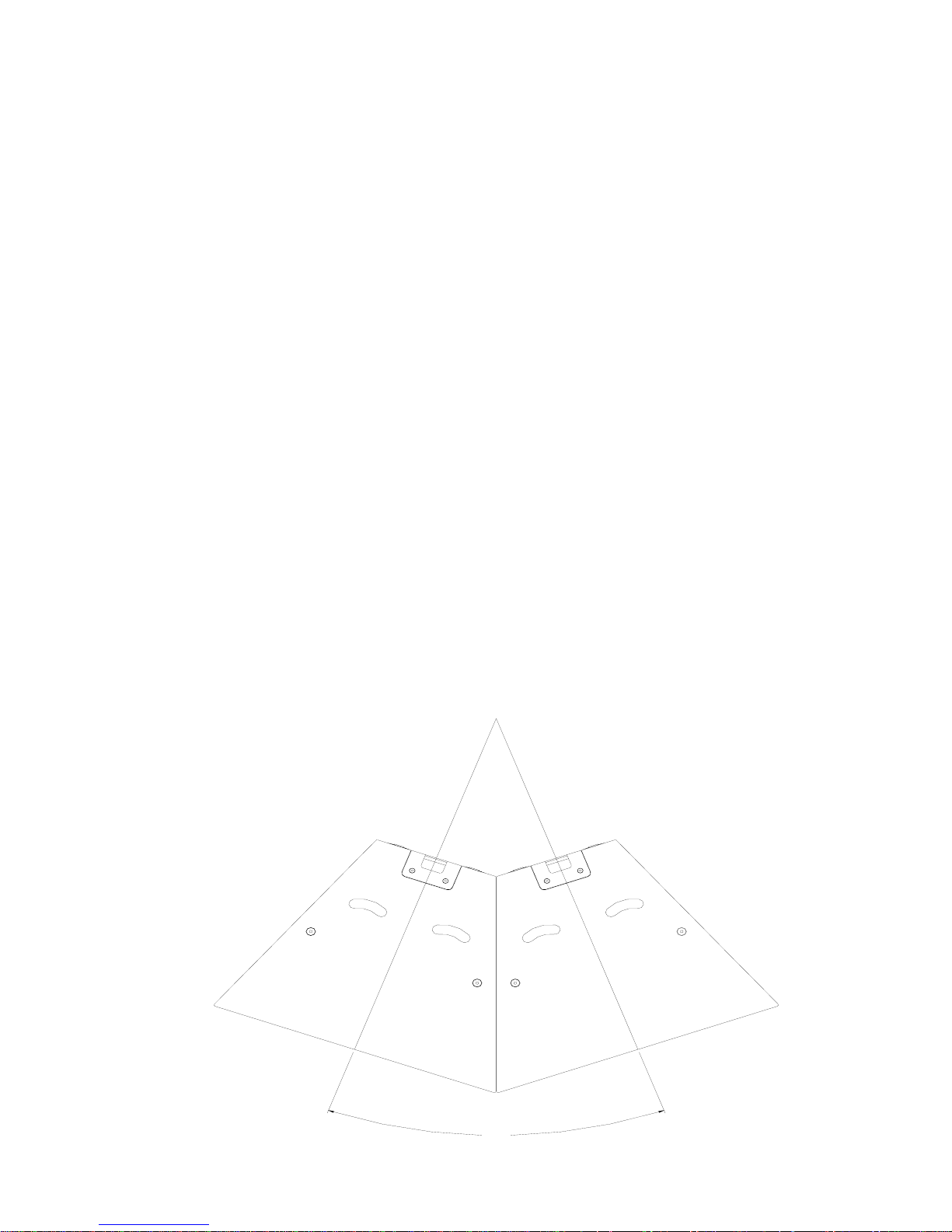

7. Arraying

Comb filtering is a phenomenon, which cannot be cured by equalisation. Small

alterations to loudspeaker positions can have the effect of minimising problematic

combing frequencies. Arrays should be constructed so that the individual coverage

patterns of each loudspeaker combine with minimal overlap. The design of the

iQ 10/15 cabinet greatly simplifies the creation of effective arrays, allowing seamless

wide (120 degree) horizontal coverage using two loudspeakers wit hout the need for

tedious experimentation.

By placing the iQ 10/15 cabinets as shown in the diagram below, minimal dispersion

pattern overlap is achieved, guaranteeing an extraordinarily smooth transition.

6

8.

40°

Page 7

8. Dimensions

1116.0

680.0

540.0

7

Page 8

9. Rigging & Suspension

General Safety Advice

The Tannoy Professional hardware covered in this guide has been desi gned to offer

quick, simple, cost effective and secure solutions for mounting specific Tannoy

Professional loudspeakers. This hardware has been designed and manufactured with

a high safety load factor for its specific role. To ensure the safest possible use of the

hardware covered in this guide, it must be assembled in strict accordance with the

instructions specified. The information relating to the assembly and the safe use of

these accessories must be understood and followed. The installation of Tannoy

Professional loudspeakers using the dedicated hardware should only ever be carried

out by fully qualified installers, in accordance with all the required safety codes and

standards that are applied at the place of installation.

WARNING: As the legal requirements for flying change from country to country,

please consult you local safety standards office before installing any product. We also

recommend that you thoroughly check any laws and bylaws prior to commencing

work.

Tannoy Professional hardware has been designed for use with specific Tannoy

Professional loudspeakers, and is not designed or intended for use with any other

Tannoy Professional products, or any other devices. Using Tannoy Professional

hardware for any purpose other than that indicated in this guide is considered to be

improper use. Such use can be very dangerous as overloading, modifying,

assembling in anyway other than that clearly stated in the manual, or damaging

Tannoy Professional hardware will compromise safety.

The component parts of any Tannoy Professional hardware device must only be

assembled using the accessory kits supplied and in strict compliance with the user

manual. The use of other accessories or non-approved methods of assembly may

result in an unsafe hardware system by reducing the load safety factor. Welding, or

any other method of permanently fixing hardware components together or to the

integral fixing points in the cabinet should never be used.

Whenever a Tannoy Professional loudspeaker is fixed to a surface using a Tannoy

Professional hardware device, the installer must ensure that the surface is capable of

safely and securely supporting the load. The hardware employed must be safely,

securely, and in accordance with the manual, attached both to the loudspeaker and

also to the surface in question, using only the fixing holes provided as standard and

covered in the manual. Secure fixings to the building structure are vital. Seek help

from architects, structural engineers or other specialists if in any doubt.

All loudspeakers flown in theatres, nightclubs, conference centre or other places of

work and entertainment must, be provided with an independent, correctly rated and

securely attached secondary safety – in addition to the principle hardware device.

This secondary safety must prevent the loudspeaker from dropping more than

150mm (6”) should the principle hardware device fail.

!

8

Page 9

SECUR ET – VEB Eyebolt

!

The Tannoy iQ 10/15 loudspeaker can be flown

with high quality VEB M10 eyebolts with collar to

BS4278:1984. The loudspeakers are equipped

with internal steel braces, which also double as

the flying points, and accept VEB M10 eyebolts.

To install the VEB M10 eyebolts remove the

original M10 counter sunk screws from the

locations you wish to install the VEB M10

eyebolts. Then replace these counter sunk M10

screws with the VEB M10 eyebolts. The kelping

brackets on the rear of the cabinet should only

be used for tilting the loudspeaker to the desired

angle.

Important: It is imperative for safety reasons

that two eyebolts linked to two independently

fixed straps are used per cabinet.

Never attempt to use formed eyebolts i.e.

formed from a steel rod and bent into an eye.

9

Page 10

SINGLE iQ SUSPENSION TRUSS (By ATM

™

)

The iQ suspension truss is an economical solution to suspending a single purpose

loudspeaker array from two or three fixed structural attachment points. The iQ Suspension

Truss is designed to hold the loudspeakers at the optimum splay angle to optimize cluster

performance. Most Suspension Trusses are equipped with two suspension rails with multiple

attachment holes that travel from front to back across the top of the array, allowing

manipulation of the center of gravity of the cluster to achieve down tilt without a pull strap.

Features:

• Optimized fixed splay angle

• Adjustable tilt

• Fast multiple enclosure rigging system

• Economical

• Low profile, clean looking array

iQ Suspension Truss

The iQ Suspension Truss is a "semi-custom" product line that is built to order. Please contact

your Tannoy or ATM Fly-Ware dealer with the loudspeaker model numbers along with the

array application.

Full assembly instructions for the iQ Suspension Truss accompany the product.

10

Page 11

Typical Suspension Truss applications –

2 x iQ 10/15

2 x iQ 10C & 2 x iQ 10/15

11

Page 12

10. Performance Data

FREQUENCY RESPONSE

Anechoic System Frequency Response, 1 watt (MF/HF) @ 1 metre on axis

INPUT IMPEDANCE

Impedance (Passive MF/HF only)

Page 13

High Frequency (Tri-amp option)

13

Anechoic Frequency Response, 1 watt (HF) @ 1 metre on axis

Impedance (HF only)

Page 14

Mid Frequency (Tri-amp option)

A comprehensive range of measurements including off axis frequency response curves, octave & third

octave polar diagrams (single & two cabinet arrays) and beamwidth plots as well as Ease™ data can be

downloaded from

http://www.tannoy.com/

Impedance (MF only)

Anechoic Frequency Response, 1 watt (MF) @ 1 metre on axis

14

Page 15

11. Technical Specifications

Frequency Response (1) +/- 3dB 49Hz - 19kHz

-10dB Point 43Hz

Nominal Dispersion 60

o

x 40

o

(H x V)

Driver Compliment MF/HF – 1 x 250mm (10”) PowerDual™

LF - 1 x 380mm (15”)

Configurations Bi-amp (standard) - LF & Passive MF/HF

Tri-amp (optional)

Components LF Midrange High Frequency

Frequency Band (3) 43Hz – 180Hz 180Hz – 2.77kHz 2.77kHz – 19kHz

Sensitivity (1) 101dB 107dB 110dB

Power Handling (2) 400W (average) 175W (average) 50W (average)

800W (programme) 350W (programme) 100W (programme)

1600W (Peak) 700W (peak) 200W (peak)

Impedance 8Ω 16Ω 16Ω

Maximum SPL (3) 127dB (average) 129dB (average) 127dB (average)

133 (peak) 135dB (peak) 133dB (peak)

DI Averaged (PCQ) 11.0, 500 Hz - 16 kHz

@ 1kHz (ISO) 12.6

@ 2kHz (ISO) 12.2

@ 4kHz (ISO) 9.5

@ 8kHz (ISO) 11.5

@ 16kHz (ISO) 12.3

Q Averaged (PCQ) 13.5, 500 Hz - 16 kHz

@ 1kHz (ISO) 18.3

@ 2kHz (ISO) 16.7

@ 4kHz (ISO) 8.8

@ 8kHz (ISO) 14

@ 16kHz (ISO) 16.9

Crossover Active 180Hz, Passive 2.6kHz (standard model)

4th order high pass, 4th order low pass

Enclosure 18mm multi-ply birch plywood

Finish Textured black paint (optional in white)

Protective Grille Foam covered, powder coated perforated steel

Connectors 2 x Speakon NL4MP in/out (standard model)

4 x Speakon NL4MP (optional tri-amp model)

Fittings 8 x M10 inserts & 2 pullback points

4 x Recessed Carrying handles

Dimensions 1116mm x 680mm x 540mm

(43

15/16” x 26 ¾” x 21 ¼”)

Weight 69kg (152.1 lbs)

NOTES: (1) Average over stated bandwidth. Measured at 1m on axis.

(2) Long term power handling capacity as defined in EIA standard RS - 426A.

(3) Unweighted pink noise input, measured at 1m in an anechoic chamber

The iQ 10/15 is designed for use with the Tannoy TDX1 & TDX2 digital system controller, which provide a preset configuration of

Crossover frequencies, relative output levels, and system equalization for optimum performance. Should you intend using an alternative

Loudspeaker management system, these parameters can be accessed from the Tannoy website –

www.tannoy.com - or can be found in this

IQ 10/15 user manual

.

Tannoy operates a policy of continuous research and development. The introduction of new materials or manufacturing methods will always equal or exceed the publis

h

which Tannoy reserves the right to alter without prior notice.

Please verify the latest specifications when dealing with critical applications.

Unique Funktion One Axhead Technology (UK patent number GB2270606) is incorporated into

Tannoy iQ Series SuperDual

TM

products by agreement with Funkton One Research

Page 16

16

12. System Configurations & OEM Controllers

Passive or Biamp?

The iQ 10/15 is supplied as standard for bi-amp operation, therefore there is no

internal passive crossover network between the LF & Mid/High units. The Bi-amp

controller parameters below must be adhered to for optimum performance.

An optional iQ 10/15 (tri-amp version) can be ordered.

A loudspeaker driven in Bi-amp mode offers a number of performance advantages,

such as increased system headroom. Audio program materiel is made up of many

different frequencies and harmonics. In music materiel, most of the energy is in the

low frequencies, with less in the highs. When both high and low frequencies are

present in a signal, the stronger low frequencies can use up amp power, leaving little

or no reserve for the highs, so they are more likely to cause the power amplifier to

clip. In a Biamp driven system, a smaller amp can handle high frequencies, LF amp

clipping is less of a factor, and less overall amplifier capacity is needed due to the

efficiency improvement in the absence of a passive crossover.

Bi-amp System Parameters (iQ 10/15)

Parameter Unit/Name Low Section Mid/High Section

Gain

(dB) +5 0

Delay*

(ms) 0 0

Polarity

Positive Positive

HPF

Freq (Hz) 39.8 180

Slope (dB/oct) 24 24

Filter Shape Butterworth Linkwitz Riley

LPF

Freq (Hz) 180 Thru

Slope (dB/oct) 24 NA

Filter Shape Linkwitz Riley NA

Freq (Hz) 60.1 2000

Level (dB) +4 -4

Type Parametric Parametric

PEQ 1

Q / Bandwidth 2 / 0.5 0.8 / 1.25

Freq (Hz) 141.3

Level (dB) -5

Type Parametric

PEQ 2

Q / Bandwidth 2 / 0.5

Page 17

17

13. iQ 10/15 Service Parts and Accessories

Part Number Description

7900 0607 Driver Kit Type 2519 (MF)

7900 0609 Recone Kit Type 2519 (MF)

7900 0608 Driver Kit Type 0278 (HF)

7900 0610 Diaphragm Type 0278 (HF)

8001 2820 VEB – Secur ET – Eyebolts M10

8000 3630 TDX1 Digital System Controller 60-250V – UK

8000 3631 TDX1 Digital System Controller 60-250V – EUR

8000 3632 TDX1 Digital System Controller 60-250V – USA

8000 0727 TDX2 Digital loudspeaker management system 60-250V - UK

8000 0728 TDX2 Digital loudspeaker management system 60-250V - EUR

8000 0729 TDX2 Digital loudspeaker management system 60-250V – USA

14. Warranty

No maintenance of the iQ 10/15 loudspeaker is necessary.

All Tannoy professional loudspeaker products are covered by a 5 year warranty from

the date of manufacture subject to the absence of misuse, overload or accidental

damage. Claims will not be considered is the serial number has been altered or

removed. A Tannoy Professional dealer or service agent should only carry out work

under warranty. This warranty in no way affects your statutory rights. For further

information, please contact your dealer or distributor in your country. If you cannot

locate your distributor, please contact Customer Services, Tannoy Ltd at the address

given below.

Customer Services

Tannoy Ltd.

Coatbridge

ML5 4TF

Scotland

Telephone: 01236 420199 (National)

+44 1236 420199 (International)

Fax: 01236 428230 (National)

+44 1236 428230 (International)

E-Mail:

service@tannoy.com

Website: www.tannoy.com

DO NOT SHIP ANY PRODUCT TO TANNOY WITHOUT PREVIOUS AUTHORISATION

Our policy commits us to incorporating improvements to our products through

continuous research and development. Please confirm current specifications for

critical applications with your supplier.

Page 18

15. Declaration of Conformity

The following apparatus is/are manufactured in the United Kingdom

by Tannoy Ltd of Rosehall Industrial estate, Coatbridge, Scotland,

ML5 4TF and conform(s) to the protection requirements of the

European Electromagnetic Compatibility Standards and Directives

relevant to Domestic Electrical Equipment. The apparatus is

designed and constructed such that electromagnetic disturbances

generated do not exceed levels allowing radio and

telecommunications equipment and other apparatus to operate as

intended, and, the apparatus has an adequate level of intrinsic

immunity to electromagnetic disturbance to enable operation as

specified and intended. This Equipment conforms to the

requirements of the EMC Directive 89/336/EEC, amended by

92/31/EEC and 93/68/EEC and the requirements of the low voltage

directive 73/23/EEC, amended by 93/68/EEC.

Details of the Apparatus: Tannoy Contractor Loudspeaker

Model Number: iQ10/15

Associated Technical File: EMCIQ10/15

Applicable Standards: EN 55103 –1:1996 Emission

EN 55103 –2:1996 Immunity

Electrical Safety: EN 60065:1993

Signed:

Position: Engineering Director – Professional Products

Tannoy Professional

Date: 11/10/2004

For Tannoy Ltd

18

Page 19

Page 20

Β

Tannoy Loudspeakers are manufactured in Great Britain by:

Tannoy Ltd, Rosehall Industrial Estate, Coatbridge,

Strathclyde, ML5 4TF, SCOTLAND

Telephone: +44 (0) 1236 420199

Fax: +44 (0)1236 428230

Tannoy North America Inc, Suite 1. 335 Gage Avenue, Kitchener, Ontario, CANADA, N2M 5E1

Telephone: (519) 745 1158

Fax: (519) 745 2364

Issue 1.0 Part No. 6481 0430

GH June 27, 2004

20

Loading...

Loading...