Page 1

I N S T A L L A T I O N M A N U A L

CVS 4 CVS 6

Tannoy has a policy of continuous improvement and this specification sheet provides the latest information at the time of printing.

All specifications may be subject to further change. Please contact the Tannoy website for the latest information.

Tannoy United Kingdom T: 00 44 (0) 1236 420199 E: enquiries@tannoy.com

Tannoy North America T: 00 1 (519) 745 1158 E: inquiries@tannoyna.com

Tannoy Deutschland T: 00 49 (180) 1111 881 E: info@tannoy.com

Tannoy France T: 00 33 (0)1 7036 7473 E: ventes@tannoy.com

Tannoy adopts a policy of continuous improvement and product specification is subject to change.

REVISION DATE: 4TH

JULY 200

7

6481 0487

CVS 4 TEMPLATE CUTOUT SIZE: 180mm

CVS 6 TEMPLATE CUTOUT SIZE: 250mm

Page 2

CONTENTS

1. INTRODUCTION

INTRODUCTION

1

2

UNPACKING

3

SAFETY NOTICES

4

PRODUCT FEATURE IDENTIFICATION

5

ACCESSORIES

6

INSTALLATION GUIDE

6.1

MECHANICAL INSTALLATION GUIDE FOR SUSPENDED CEILINGS

6.2

MECHANICAL INSTALLATION GUIDE FOR SHEET-ROCK CEILINGS

6.3

MECHANICAL INSTALLATION INSTRUCTIONS FOR OPTIONAL PLASTER RING

7

WIRING AND SETTING UP

Thank you for purchasing this Tannoy Ceiling loudspeaker. This product range is suited for highlevel music and speech reinforcement applications requiring exceptional sonic quality with uncompromised

reliability.

2. UNPACKING

Every Tannoy product and accessory is carefully inspected before packing. After unpacking, please

inspect your product to make sure no damage has occurred in transit. In the unlikely event of any

damage, would you please notify your dealer immediately and retain your shipping carton, as your

dealer may ask you to return the faulty unit to him for inspection.

Each CVS loudspeaker is packed in pairs and provided with the following accessories as standard;

C Ring, tile-bridge kit, grille, cut-out template, and paint mask. A plaster (mud) ring is also available

as an optional extra.

3. SAFETY NOTICES

Some regional construction codes require the use of a secondary method of securing loudspeakers

in ceiling to provide security of a back up support. A secondary support line should be attached from

the safety loop on the rear of the product to a source point on the ceiling. Please consult the relevant

construction codes in your region.

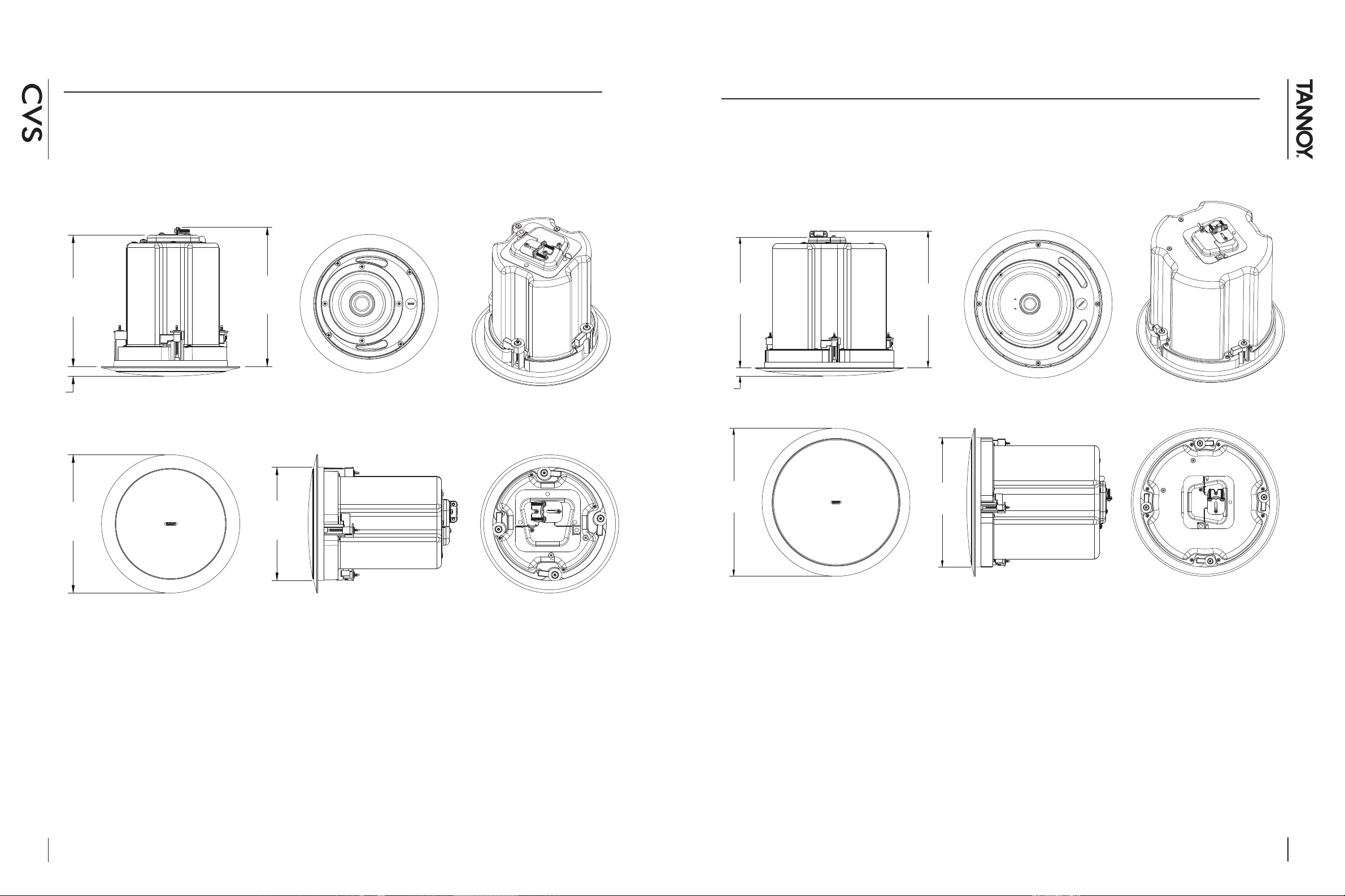

DIMENSIONS

8

CVS 4 DIMENSIONS

8.1

CVS 6 DIMENSIONS

8.2

TECHNICAL SPECIFICATIONS

9

PAINTING10

WARRANTY

11

DECLARATION OF CONFORMITY

12

When using a power driver to install the product it is essential to use the correct torque level settings

to avoid over tightening and damage to the ceiling material or clamps.

Recommended torque setting: 1.5Nm

Tannoy will not be held responsible for any damages caused by the improper installation of these

loudspeakers.

Electrical Safety Notice: to comply with the standard UL1480, metal-clad flexible conduit (BX) is

required for connection to the terminal block for proper earth grounding.

SAFETY NOTE:

In order to comply with relevant fire safety regulations (i.e. BS 5839:1998), it is required that in the event of fire,

that failure of the circuit to which the loudspeaker is connected does not occur before evacuation of the building is

complete. Suitable measures include: a) use of terminal blocks (for connection to primary) with a melting point of not less than 650°C, for example

constructed from ceramic materials;

c) use of terminal blocks of a lower melting point but protected with thermal insulation;

d) use of terminal blocks such that, on melting, an open-circuit or a short-circuit does not occur.

2

3

Page 3

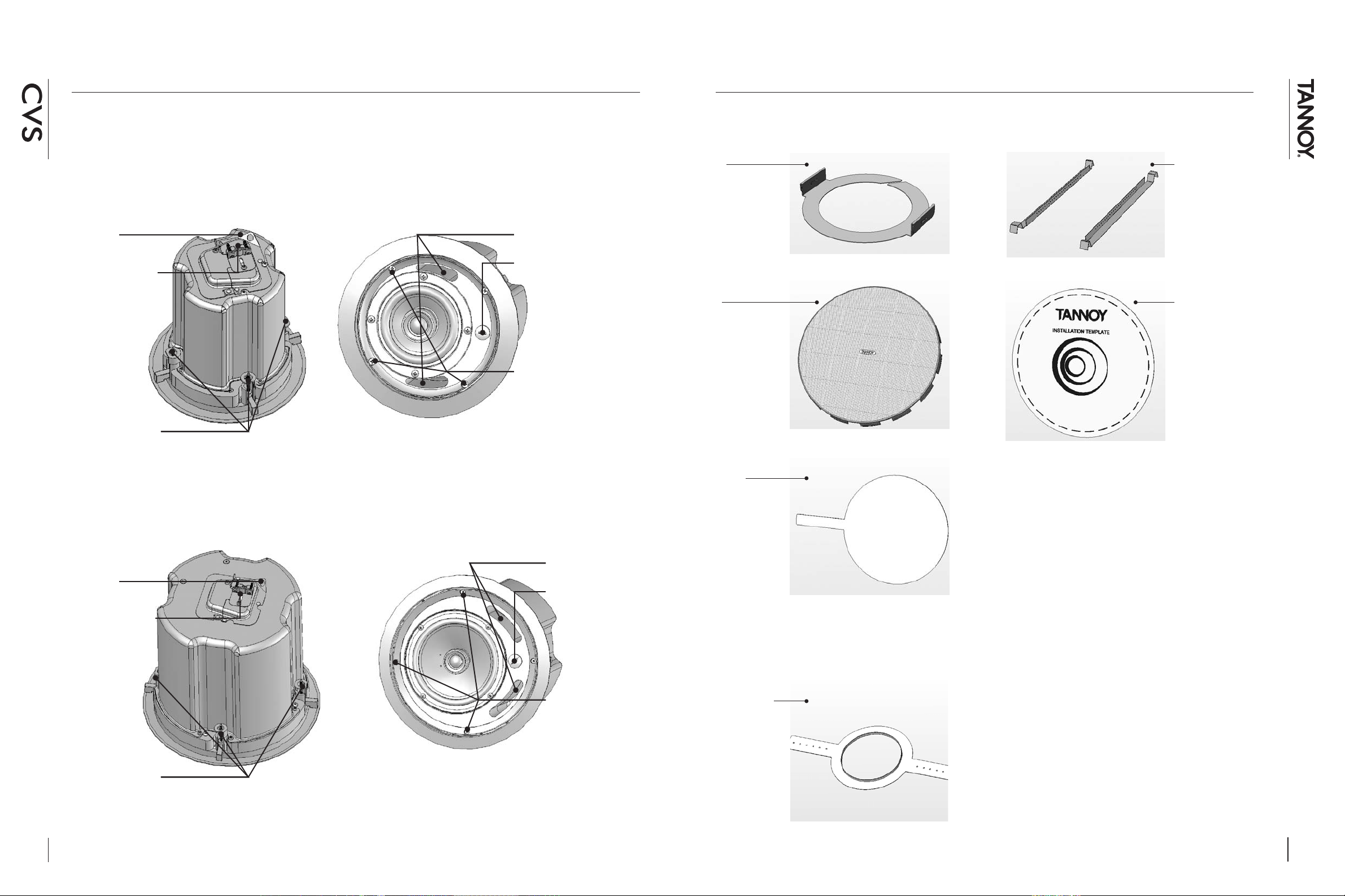

4. PRODUCT FEATURE IDENTIFICATION: 5. ACCESSORIES:

CVS 4

Safety Tab

Conduit/Cable Clamp

Mounting Wings

Standard Accessories

C-Ring Tile bridge kit

Note: A tile bridge kit

must always be used

when installing into

suspended ceiling tiles

Tuning Ports

Rotary Switch

Grille Cut-out template

Screws for

mounting wings

CVS 6

Safety Tab

Conduit/Cable Clamp

Mounting Wings

Tuning Ports

Rotary Switch

Screws for

mounting wings

Paint Mask

Optional Accessories

Plaster (Mud) Ring

4

5

Page 4

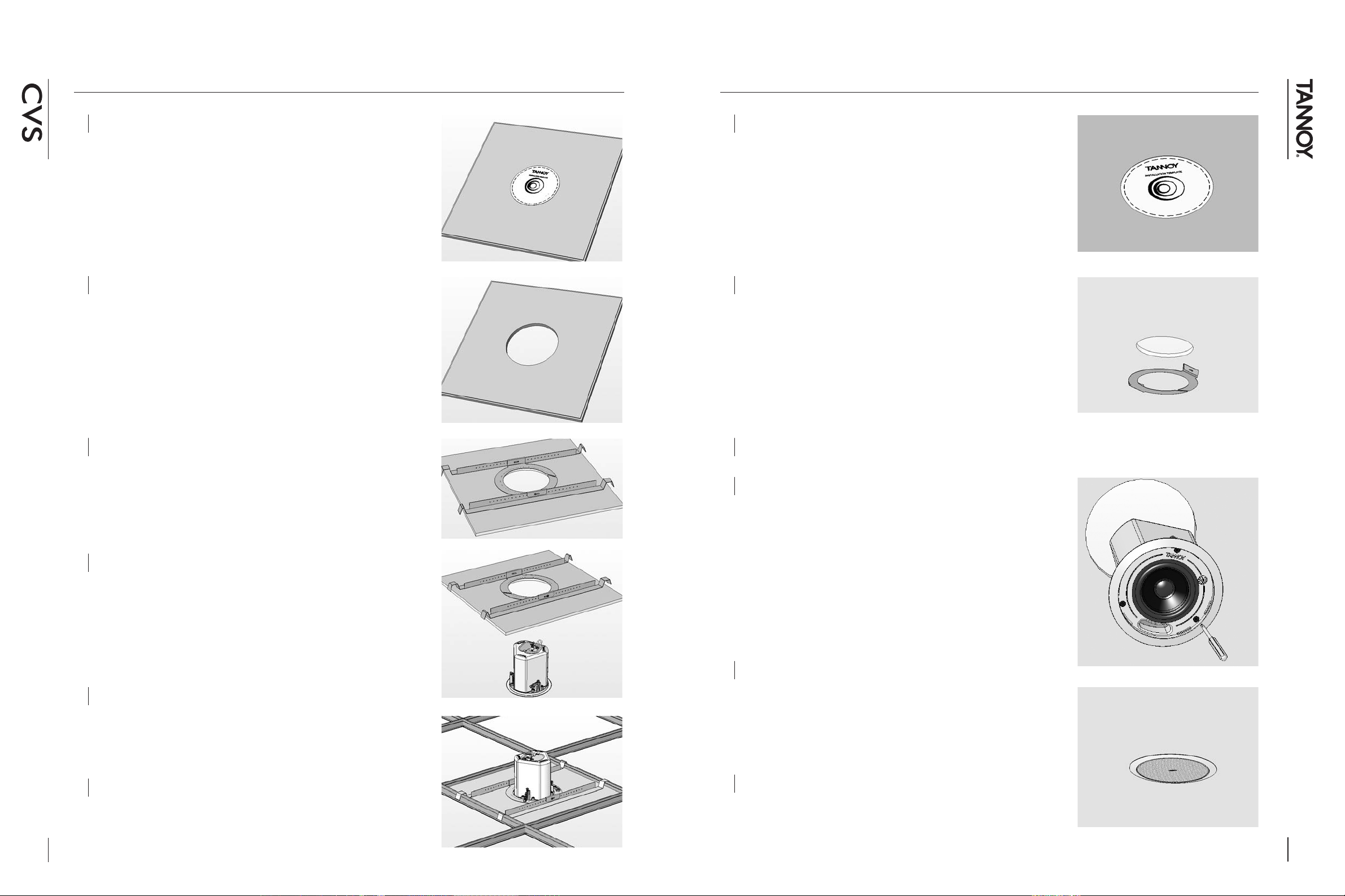

6.1 MECHANICAL INSTALLATION GUIDE FOR SUSPENDED CEILINGS

6.2 MECHANICAL INSTALLATION GUIDE FOR SHEET-ROCK (PLASTER BOARD) CEILINGS

Remove the ceiling tile from its frame and place it on a flat surface. Mark the

1

cut-out area on the ceiling tile by tracing around the template provided.

Cut out the hole in the ceiling tile using a circular saw or pad saw.

2

Place the C-ring and tile-bridge on top of the ceiling panel, aligning the C-ring over the

3

hole, and screw the C-ring to the tile bridge using the fixings provided.

Mark the cut-out area on the ceiling by tracing around the template provided.

1

Cut out the hole in the ceiling using a circular saw or pad saw, then slide the

2

C-ring into the ceiling, aligning it over the cut-out hole).

Go to section 7 for wiring and set-up instructions then return to point 4 below.

3

Slide the speaker assembly through the hole and turn the screws on the front of the

4

speaker to extend the mounting wings. Tighten the screws until a firm grip is achieved.

If using a power driver, Tannoy recommends a torque setting of 1.5Nm.

DO NOT OVERTIGHTEN!

Slide the tile panel back into the suspended ceiling. The tile bridge ends will catch over

5

the railings, supporting the weight of the speaker.

Connect a Secondary Support Line to safety tab. Some construction codes require use

6

of this secondary support point, which should connect to a separate secure support point

using a suitable support line. Consult construction codes in your region.

Slide the speaker assembly through the hole and turn the screws to extend the mounting

4

wings. Tighten the screws until a firm grip is achieved.

If using a power driver, Tannoy recommends a torque setting of 1.5Nm.

DO NOT OVERTIGHTEN!

Connect a Secondary Support Line to safety tab. Some construction codes require use

5

of this secondary support point, which should connect to a separate secure support point

using a suitable support line. Consult construction codes in your region.

Insert grille by pushing it onto the speaker.

6

Go to section 7 for instructions on wiring and set-up instructions.

6

7

Page 5

6.3 MECHANICAL INSTALLATION INSTRUCTIONS FOR OPTIONAL PLASTER RING:

7. WIRING AND SETTING UP:

An optional plaster (mud) ring bracket is available from Tannoy. This bracket is designed to be pre-installed into newly

constructed, non-suspended ceilings.

Nail or screw the plaster ring to the joists.

1

Lay the speaker wiring to where the speaker will be fitted and complete the

2

plastering work on the ceiling.

Cut out the hole in the ceiling using a circular saw or pad saw.

3

Open the wiring cover at the back of the speaker can to access the Euro type connector

1

plug and socket.

For connection to an amplifier, use pins 1 and 2:

2

• Pin 1 is positive

• Pin 2 is negative

For connection to additional speakers in a distributed line,

pins 3 and 4 are in parallel where:

• Pin 3 is negative

• Pin 4 is positive

Go to section 7 for instructions on wiring then return to point 5 below.

4

Slide the speaker assembly through the hole and turn the screws to extend the mounting

5

wings. Tighten the screws until a firm grip is achieved.

If using a power driver, Tannoy recommends a torque setting of 1.5Nm.

DO NOT OVERTIGHTEN!

Connect a Secondary Support Line to safety tab. Some construction codes require use

6

of this secondary support point, which should connect to a separate secure support point

using a suitable support line. Consult construction codes in your region.

Insert grille by pushing it onto the speaker.

7

Close the wiring cover and tighten both screws on the cable clamp. Use the rotary

3

switch located on the front of the unit to select whether you wish to use the speaker in

a low-impedance or distributed-line application.

THE SPEAKER IS SUPPLIED IN LOW IMPEDANCE MODE. NEVER CONNECT THE

SPEAKER TO A 70/100 VOLT AMPLIFIER WHILE IT IS SET FOR LOW IMPEDANCE.

4

The CVS 4 is fitted with a 30W transformer. When used in distributed-line systems, the

transformer can be tapped at 30W, 15W and 7.5W, with an additional 3.75W tapping

for 70.7V line systems.

The CVS 6 is fitted with a 60W transformer. When used in distributed-line systems, the

5

transformer can be tapped at 60W, 30W, and 15W, with an additional 7.5W tapping for

70.7V line systems.

8

9

Page 6

8.1 CVS 4 DIMENSIONS:

8.2 CVS 6 DIMENSIONS:

14.7

[0.58"]

CVS 4 TEMPLATE CUTOUT SIZE: 180mm

202.5

[7.97"]

214.9

[8.46"]

CVS 6 TEMPLATE CUTOUT SIZE: 250mm

246.5

[9.70"]

15.9

[0.63"]

[10.18"]

258.5

ø213.0

[8.39"]

ø174.8

[6.88"]

ø279.6

[11.01"]

ø244.6

[9.63"]

10

11

Page 7

CVS4

CVS6

TECHNICAL SPECIFICATIONS

System

Frequency Response (-3dB)

Frequency Range (-10dB)

System Sensitivity (1W @1m)

Nominal Coverage Angle

Coverage Angle (1kHz to 6kHz)

Directivity Factor (Q)

Directivity Index (DI)

Rated Maximum SPL

Power Handling

Average

Programme

Peak

Recommended Amplifier Power

Nominal Impedance

Transformer Taps

(via front rotary switch)

70V

100V

Distortion

1% Full Power

250Hz

1kHz

10kHz

10% Full Power

250Hz

1kHz

10kHz

Crossover Point

Notes

(1) Average over stated Bandwidth. Measured in an IEC baffle in an Anechoic Chamber

(2) Unweighted Pink noise input, measured at 1m on axis"

(3) Long term power handling capacity as defined in EIA - 426B test

(3)

CVS4

(1)

85Hz - 19kHz

(1)

77Hz - 22kHz

(2)

87dB (1W = 2.45V for 6Ω)

90 degrees conical

102 degrees

5.6 averaged 1kHz to 6kHz

7.1 averaged 1kHz to 6kHz

103dB (average)

109dB (peak)

40W

80W

160W

80W @ 6Ω

6Ω

30W / 15W / 7.5W / 3.75W / OFF

& low impedance operation

30W / 15W / 7.5W / OFF

& low impedance operation

2nd Harmonic 3rd Harmonic

0.231% 0.112%

0.229% 0.253%

0.163% 0.025%

2nd Harmonic 3rd Harmonic

0.99% 0.169%

0.816% 0.323%

0.444% 0.027%

2.7kHz

Transducers

Low Frequency

High Frequency

Physical

Enclosure

Back can

Baffle

Grille

Safety Features

Clamping Design

Back Can Options

Cable Entry Options

Connectors

Safety Agency Ratings

Hole Cutout Diameter

Dimensions

Bezel diameter

Front of ceiling to

rear of back can

Front of ceiling to

top of safety loop

Net Weight (ea)

Included Accessories

Optional Accessories

100mm (4.00") Mineral Loaded

19mm (0.75")

Zinc plated steel

Reflex loaded UL 94V-0 rated ABS

Steel, with weather resistant coating

Safety ring located at rear of enclosure

for load bearing safety bond

Security toggle clamp

Cable clamp & squeeze connector for

conduit up to 22mm

Removable locking connector with sctrew

terminals with "loop through" facility

UL-1480, UL-2043, CE

180mm

213.0mm (8.39”)

202.5mm (7.97”)

214.9mm (8.46”)

2.60kg

C Ring, tile bridge, paint mask,

cutout template, grille

Plaster (mud) ring

TECHNICAL SPECIFICATIONS

System

Frequency Response (-3dB)

Frequency Range (-10dB)

System Sensitivity (1W @1m)

Nominal Coverage Angle

Coverage Angle (1kHz to 6kHz)

Directivity Factor (Q)

Directivity Index (DI)

Rated Maximum SPL

Power Handling

Average

Programme

Peak

Recommended Amplifier Power

Nominal Impedance

Transformer Taps

(via front rotary switch)

70V

100V

Distortion

1% Full Power

250Hz

1kHz

10kHz

10% Full Power

250Hz

1kHz

10kHz

Crossover Point

Notes

(1) Average over stated Bandwidth. Measured in an IEC baffle in an Anechoic Chamber

(2) Unweighted Pink noise input, measured at 1m on axis

(3) Long term power handling capacity as defined in EIA - 426B test

(3)

CVS6

(1)

79Hz - 21kHz

(1)

60Hz - 24kHz

(2)

91dB (1W = 2.45V for 6Ω)

90 degrees conical

93 degrees

7.7 averaged 1kHz to 6kHz

8 averaged 1kHz to 6kHz

109dB (average)

115dB (peak)

60W

120W

240W

120W @ 6Ω

6Ω

60W / 30W / 15W / 7.5W / OFF

& low impedance operation

60W / 30W / 15W / OFF

& low impedance operation

2nd Harmonic 3rd Harmonic

0.439% 0.140%

0.396% 0.458%

0.235% 0.023%

2nd Harmonic 3rd Harmonic

1.16% 0.214%

1.014% 0.685%

0.944% 0.047%

2.5kHz

Transducers

Low Frequency

High Frequency

Physical

Enclosure

Back can

Baffle

Grille

Safety Features

Clamping Design

Back Can

Cable Entry Options

Connectors

Safety Agency Ratings

Hole Cutout Diameter

Dimensions

Bezel diameter

Front of ceiling to

rear of back can

Front of ceiling to

top of safety loop

Net Weight (ea)

Included Accessories

Optional Accessories

150mm (6.00") Mineral Loaded

polypropylene ICT™

19mm (0.75")

Zinc plated steel

Reflex loaded UL 94V-0 rated ABS

Steel, with weather resistant coating

Safety ring located at rear of enclosure

for load bearing safety bond

Security toggle clamp

Cable clamp & squeeze connector for

conduit up to 22mm

Removable locking connector with sctrew

terminals with "loop through" facility

UL-1480, UL-2043, CE

250mm

279.5mm (11.01”)

246.5mm (9.70”)

258.5mm (10.18”)

4.75kg

C Ring, tile bridge, paint mask,

cutout template, grille

Plaster (mud) ring

12

13

Page 8

10. PAINTING

If desired, the grille and baffle panel may be painted to match the surrounding décor.

Painting the baffle:

Carefully mask off the driver assembly using the paint-mask provided to ensure that the paint does not come into

contact with the cone and roll surround.

Apply several thin coats of paint – this will provide a better finish than one overly thick coat.

Painting the grille:

Carefully remove the acoustically transparent foam from the reverse side of the grille.

Paint the grille and then replace the foam - several thin coats of paint will provide a better finish than one

overly thick coat.

Re-bond the foam to the grille over the entire area using a light spray-adhesive to avoid audible resonances.

11. WARRANTY

No maintenance of the CVS loudspeaker is necessary.

All Tannoy professional loudspeaker products are covered by a 5 year warranty from the date of manufacture

subject to the absence of misuse, overload or accidental damage. Claims will not be considered if the serial

number has been altered or removed. Work under warranty should only be carried out by a Tannoy Professional

dealer or service agent. This warranty in no way affects your statutory rights. For further information please

contact your dealer or distributor in your country. If you cannot locate your distributor please contact Customer

Services, Tannoy Ltd at the address given below.

12. DECLARATION OF CONFORMITY:

The following apparatus is/are manufactured in China for Tannoy

Ltd of Rosehall Industrial estate, Coatbridge, Scotland, ML5 4TF

and conform(s) to the protection requirements of the European

Electromagnetic Compatibility Standards and Directives relevant

to Domestic Electrical Equipment. The apparatus is designed

and constructed such that electromagnetic disturbances generated

do not exceed levels allowing radio and telecommunications

equipment and other apparatus to operate as intended, and, the

apparatus has an adequate level of intrinsic immunity to

electromagnetic disturbance to enable operation as specified

and intended. This equipment conforms to the requirements of

the EMC Directive 89/336/EEC, amended by 92/31/EEC and the

requirements of the Low Voltage Directive 73/23/EEC, amended

by 93/68/EEC.

Details of the Apparatus: Tannoy Contractor Loudspeaker

Model Numbers: CVS 4

CVS 6

Customer Services

Tannoy Ltd.

Rosehall Industrial Estate

Coatbridge

Strathclyde

ML5 4TF

Scotland

Tel: 01236 420199 (National)

+44 1236 420199 (International)

Fax: 01236 428230 (National)

+44 1236 428230 (International)

E-mail: enquiries@tannoy.com

DO NOT SHIP ANY PRODUCT TO TANNOY WITHOUT PREVIOUS AUTHORISATION

Our policy commits us to incorporating improvements to our products through continuous research

and development. Please confirm current specifications for critical applications with your supplier.

Applicable Standards: EN55103-1 1996 Emission

EN55103-2 1996 Immunity

Electrical Safety EN 60065: 1993

Signed:

Position: Commercial Engineering Director

Tannoy Professional

Date: 15/05/2006

For Tannoy Ltd

14

15

Loading...

Loading...