Page 1

CMS55 ICT

USER MANUAL

Page 2

CONTENTS

1. Introduction

2. Unpacking

i. CMS55 ICT (Loudspeaker, Baffle & Transformer)

ii CMS 55 BC (Ceiling Can)

iii CMS 55 TB (Tile Bridge Assembly)

3. Assembly instructions

4. Voltage & Power Selection

5. Equalisation

6. Dimensions

7. Technical Specifications

8. Performance Data

9. Recommended Service Parts & Accessories

10. Warranty

11. Declaration of Conformity

HOLE CUT-OUT SIZE – 208mm

Page 3

1. Introduction

The Tannoy CMS55 ICT Ceiling Monitor System is suited for high level music

and speech reinforcement applications requiring exceptional sonic quality with

uncompromised reliability. Achieving fast, simple and cost effective installation in

new and existing buildings, this versatile design has addressed the two most

common failures of background music and sound reinforcement systems, which

are firstly the tweeter, and secondly the crossover. With the revolutionary design

of the ICT™ drive unit, neither of the above criteria applies, assuring you years

of trouble free use.

ICT™ or Inductive Coupling Technology utilises a wireless electromagnetic tweeter

that does not require a crossover and can not be burned out from heavy or abusive

use. The 1” aluminium high frequency dome has a deep drawn skirt which sits on the

inside of the low frequency voice coil in the same magnetic gap. The skirt is like a

single shorted turn, which is induced with high frequency information generated by the

low frequency voice coil, which is fed a full bandwidth signal. The ICT™ dome is at the

heart of our 5” ceiling transducer which utilises a moulded plastic cone and nitryl

rubber surround to further enhance it’s durability and long term reliability.

The ICT driver is housed in a rugged aluminium ceiling enclosure that has been

optimally tuned to achieve maximum bass response and tonal balance.

The CMS55 ICT is powered by Tannoy’s THP 30 multi-tap transformer that provides

high system sensitivity, a wide bandwidth and dynamic range, with very low insertion

loss. For critical applications provision has been made for the CMS55 ICT to accept

the THP 60, a 60W multi-tap transformer.

2. Unpacking

Every Tannoy CMS55 ICT and accessory is carefully inspected before packing. After

unpacking, please inspect for any exterior physical damage, and save the carton and

any relevant packaging materials in case the loudspeaker again requires packing and

shipping. In the event that damage has been sustained in transit notify your dealer

immediately.

The complete CMS55 ICT package consists of three major components all packaged

and supplied as individual items: -

i. CMS55 ICT (Loudspeaker, Baffle & Transformer, Part No. 8000 0748)

ii CMS 55 BC (Ceiling Can, Part No. 8000 0749)

iii CMS 55 TB (Tile Bridge Assembly, Part No. 8000 0750)

Please check the contents of each package before assembly.

Page 4

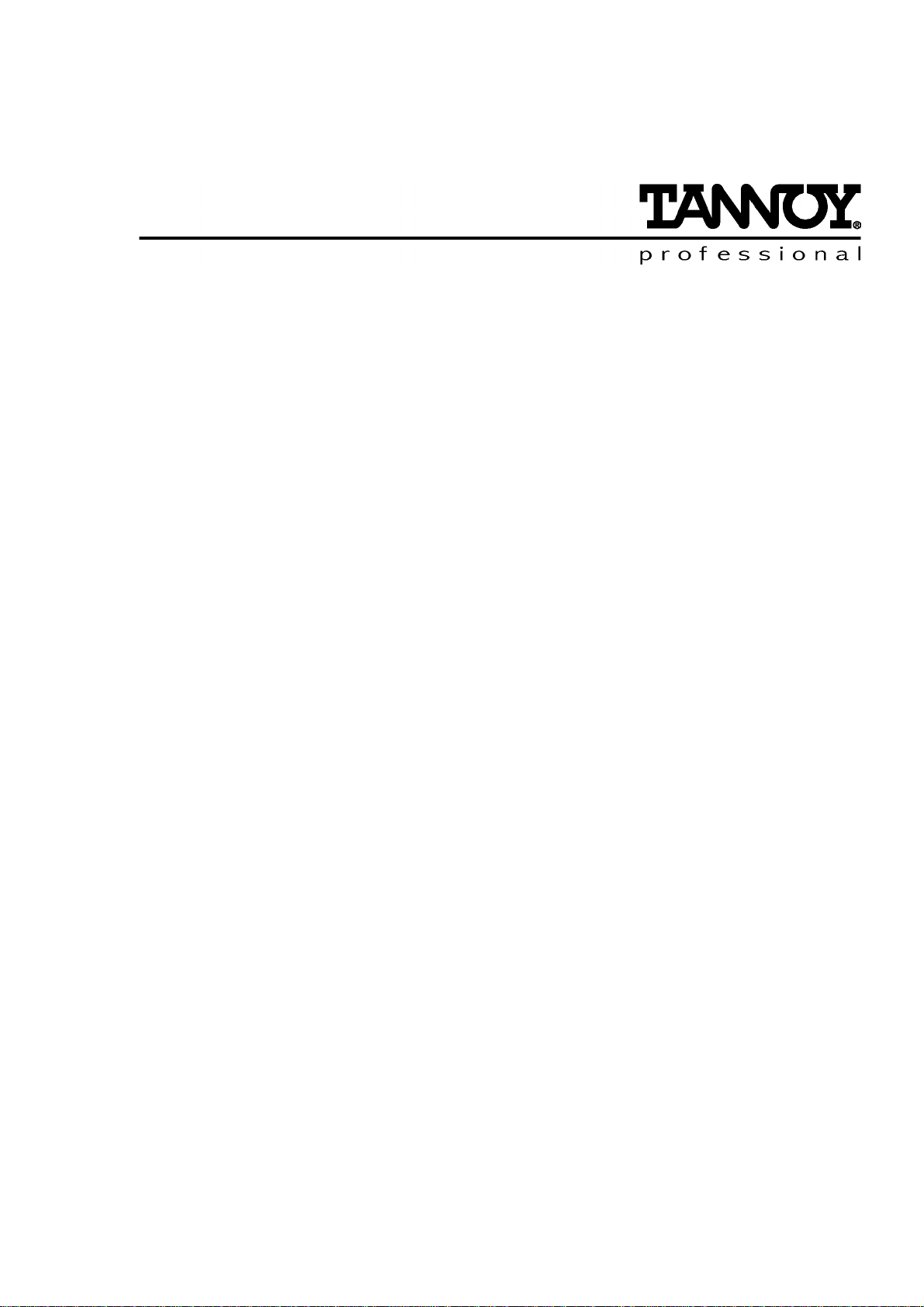

i. CMS55 ICT Loudspeaker, Baffle & Transformer

Contents:-

Baffle Assembly - Complete

Wadding Material

Baffle assembly

ii Ceiling Can

Contents:-

Back Can

C-Ring

2 x Sliding Clamp & Fixings

C-Ring

Back Can

Sliding Clamp

Page 5

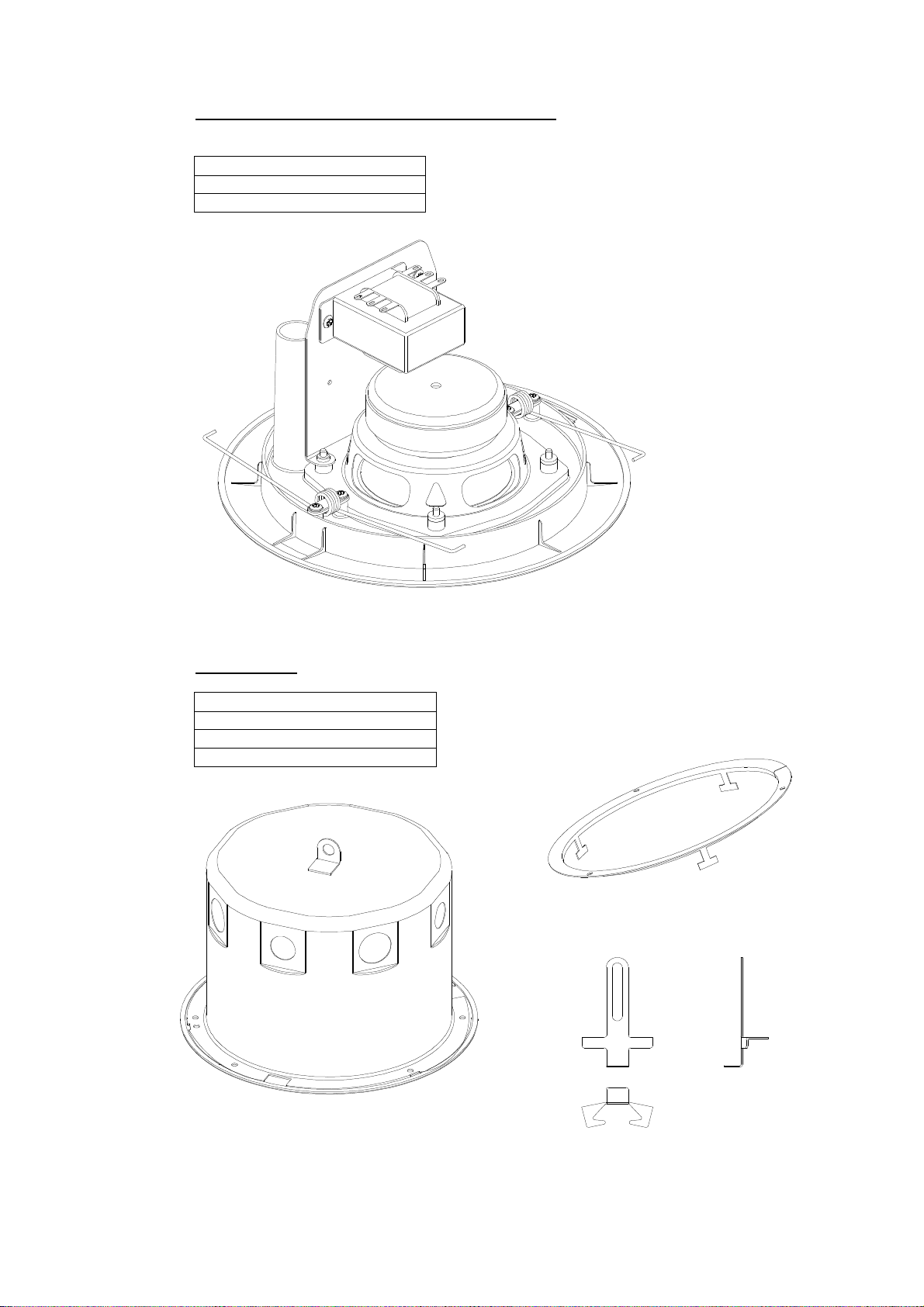

iii Tile Bridge Assembly

Contents:-

Tile Bridge

2 x Large Tile Support (angle)

2 x Small Tile Support (angle)

2 x Right Angle Bracket

2 x Sliding Clamp & Fixings

Tile Bridge (shown with tile supports assembled)

Right Angle Bracket

3. Assembly Instructions

There are 4 methods of assembly depending on application: i Baffle assembly and back can, back can fitted from above ceiling.

ii Baffle assembly and back can with c-ring. The use of the c-ring facilitates

installation from below the ceiling, where access is not possible from above.

iii Baffle assembly, back can and tile bridge.

iv Baffle assembly with tile bridge.

Sliding Clamp

Ceiling hole cut-out size – 208 mm

Page 6

i Baffle assembly and back can, back can fitted from above ceiling.

Fig a.

Fig b. Fig c.

Fit the sliding clamps to the M8 studs as shown in Fig b. do not tighten the wing nuts

at this stage. Place the back can over the hole and use the sliding clamp to sandwich

the roof material, tighten the wing nut to hold the back can firmly in position. Place the

wadding material that comes with the baffle assembly into the back can.

Important: Connect the safety cable to the rear of the transformer plate.

After connecting to the transformer (see section 4) squeeze the retaining springs

together as shown in fig c. Still holding the springs together place them into the sliding

clamp and gently push the baffle into position. There is an anchor point fitted to the

top of the back can (fig a.). For added safety this should be used.

The C-ring is not used for this method of installation and can be discarded.

There are 8 knock-out holes in the back-can (4 x 22mm & 4 x 28mm). When installing

conduit ensure the glands are airtight.

Page 7

ii Baffle assembly and back can with c-ring

Fig e.

Fit the sliding clamps to the M8 studs as shown in Fig b., push the sliding clamp until it

stops hard against the flange of the back can and fits into the indent, tighten the wing

nuts at this stage. Place the wadding material that comes with the baffle assembly into

the back can.

Important: Connect the safety cable to the rear of the transformer plate.

Place the three spring clips supplied over the screwholes on the c-ring (fig e.). The cring is split to facilitate positioning from below the ceiling if necessary. After positioning

the c-ring, bend the tabs back to secure the c-ring in place, push the back can through

the ceiling hole, ensure the tabs on the c-ring line up with the three indents on the

back can rim. Insert the three machined screws through the holes in the back can

flange and into the spring clips on the c-ring (fig e.). After connecting to the

transformer (see section 4) squeeze the retaining springs together as shown in fig c.,

still holding the springs together place them into the sliding clamp and gently push the

baffle into position. There is an anchor point fitted to the top of the back can (fig a.),

for added safety this should be used.

Page 8

iii Baffle assembly, back can and tile bridge.

Fig f.

Fit sliding clamps to the M8 studs in the back can as shown in Fig b. do not tighten the

wing nuts at this stage. Assemble the Tile Bridge as shown in Fig f. The spikes

highlighted in fig g. below can be bent at right angles to hold the assembly in position

before fixing the tile supports in position permanently. The back can is fixed into

position by rotating the can until the holes on the can flange line up with dimples on

the Tile Bridge (fig g.). Use the sliding clamp to sandwich the roof material, tighten the

wing nut to hold the back can and Tile Bridge firmly in position. Place the wadding

material that comes with the baffle assembly into the back can.

Important: Connect the safety cable to the rear of the transformer plate.

After connecting to the transformer (see section 4) squeeze the retaining springs

together as shown in fig c. Still holding the springs together place them into the sliding

clamp and gently push the baffle into position. There is an anchor point fitted to the

top of the back can (fig a.). For added safety this should be used.

The C-ring is not used for this method of installation and can be discarded.

Fig g.

Page 9

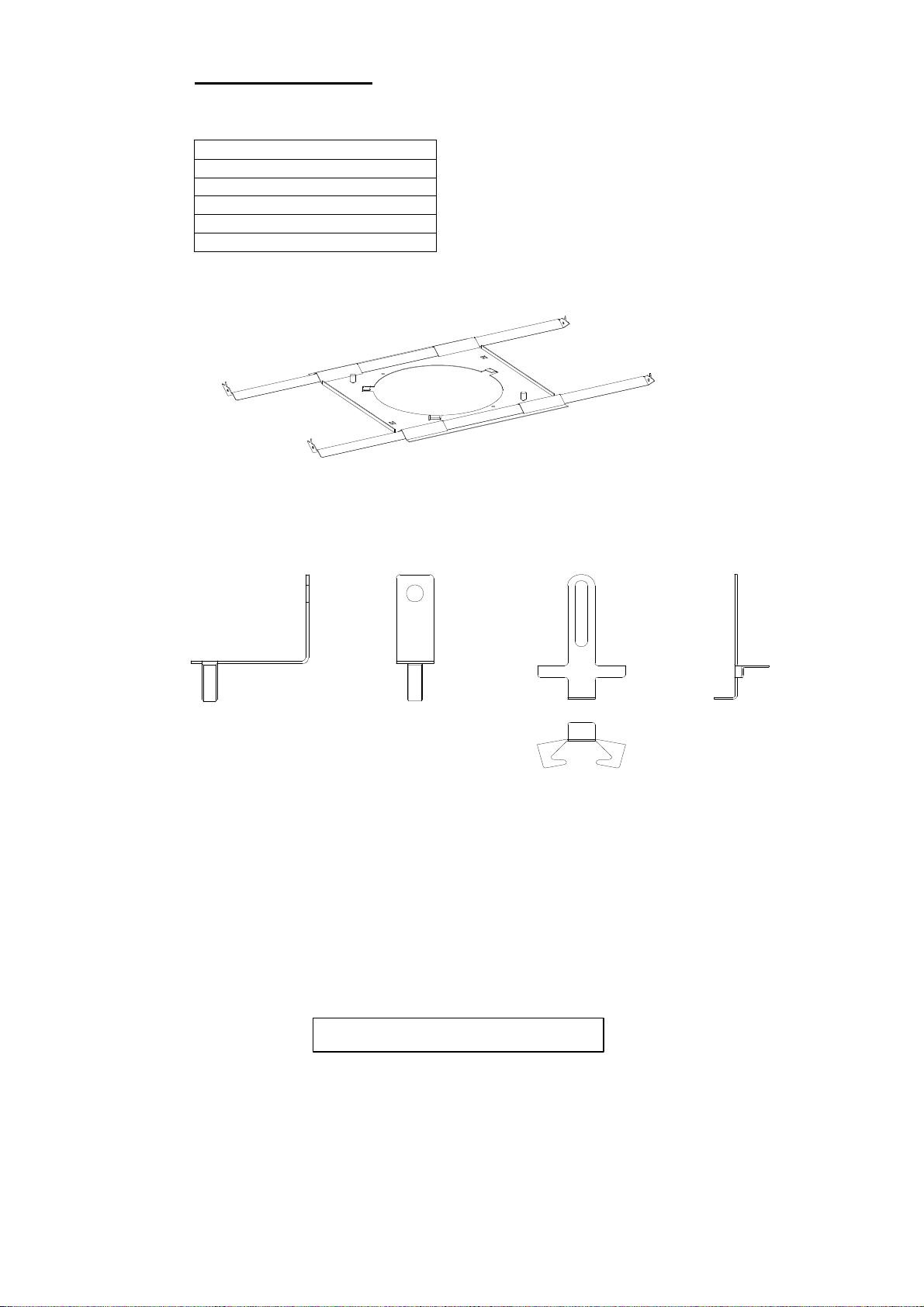

iv Baffle assembly with tile bridge

Fix the right angle brackets to the M8 studs on the tile bridge as shown in fig h.

Assemble the tile bridge and fit the sliding clamps to the right angle brackets as

shown in fig j. below. The spikes highlighted in fig g. can be bent at right angles to

hold the assembly in position before fixing the tile supports in position permanently.

Use the sliding clamp to sandwich the roof material, tighten the wing nut to hold the

tile bridge firmly in position. After connecting to the transformer (see section 4)

squeeze the retaining springs together as shown in fig c. Still holding the springs

together place them into the sliding clamp and gently push the baffle into position.

Fig h.

Fig j.

Page 10

4. Voltage & Power Selection

After deciding on a 70.7 or 100 volt system, determine the maximum power in watts

needed at each speaker location. The Tannoy THP30 transformer can be tapped at

30w, 15w, 7.5w, & 3.75 w. When the relevant tappings have been selected add the

individual wattages required at all speakers and select an amplifier with a rating equal

to or exceeding the total wattage required. All of the transformer primaries should be

connected in parallel to the output of this amplifier. If for example, you select the 7.5watt transformer tap, it means that at full rated amplifier output the speaker will

receive the full 7.5 watts. If the amplifier gain is reduced each speaker will receive a

proportional amount of power, maintaining the overall system balance.

When calculating amplifier wattage requirements for a system, it is recommended that

a generous wattage safety margin (3dB of headroom) be left so that the system does

not have to operate continuously at its full rated output.

Make sure the red cable (amplifier

end) is connected to the respective

voltage rating on the primary. The

black cable is connected to the

‘common’ on the transformer

primary.

When you have selected the desired

operating wattage, the brown wire

connected to the positive terminal of

the loudspeaker should be connected

to the relevant wattage tapping on

the transformer secondary. The blue

wire connected to the negative

terminal of the loudspeaker drive unit

is connected to the ‘common’ on the

transformer secondary.

Low impedance operation - If

required the CMS55 ICT can be used

as a conventional loudspeaker by

simply bypassing the THP30

transformer and connecting the

amplifier output to the loudspeaker

terminals.

THP30 transformer

In order to comply with relevant fire safety regulations (i.e. BS 5839:1998), it

is required that in the event of fire, that failure of the circuit to which the

loudspeaker is connected does not occur before evacuation of the building is

complete. Suitable measures include: -

a) use of terminal blocks (for connection to primary) with a melting point of

not less than 650°C, for example constructed from ceramic materials;

c) use of terminal blocks of a lower melting point but protected with thermal

insulation;

d) use of terminal blocks such that, on melting, an open-circuit or a short-

circuit does not occur.

Page 11

5. Equalisation

170.2

149.0

The CMS55 ICT is designed to need no equalisation or correction to overcome

system limitations. As a result, it will only need equalisation to compensate for difficult

acoustic environments.

Excess equalisation can reduce system headroom, and introduce phase distortion

resulting in greater problems than it cures. If equalisation is required then it should be

applied gently and smoothly. Violent equalisation will be detrimental to the overall

sound quality. If the loudspeakers were being used consistently at high levels it would

be beneficial to introduce a high-pass filter at 50Hz to protect the loudspeaker from

any unnecessary subsonic frequencies

6. Dimensions

245.0

202.4

Page 12

7. Technical Specifications

System Type Vented, full range ICT™ loudspeaker system

Frequency Response (1) +/- 3dB 80Hz - 20kHz

Power Handling(2) 60 watt

Sensitivity (1) 2.83 volt @ 1m 89 dB

Maximum SPL (3) @ 1m 103 dB (with THP 30 Transformer)

106 dB (@ 8Ω)

Impedance Nominal 8.0 ohm

Minimum 6.1 ohm

DI Averaged (PCQ) 7.8, 500 Hz – 16 kHz

@ 1kHz (ISO) 5.7

@ 2kHz (ISO) 6.8

@ 4kHz (ISO) 8.4

@ 8kHz (ISO) 9.5

@ 16kHz(ISO) 12.6

Q Averaged (PCQ) 7.5, 500 Hz - 16 kHz

@ 1kHz (ISO) 3.7

@ 2kHz (ISO) 4.8

@ 4kHz (ISO) 6.9

@ 8kHz (ISO) 8.9

@ 16kHz (ISO) 18.2

Driver Complement 1 x 5” (130mm) full range, ICT™ Point Source

Enclosure 4.3 litres, vented (in back can)

Finish White

System Weight (in back can) 1.75 kg

Dimensions Can height: 150mm

Baffle Diameter: 245mm

Hole cutout size: 208mm

Accessories Tile Bridge (optional)

NOTES: (1) Average over stated bandwidth. Measured at 1m on axis, in an anechoic chamber.

Tannoy operates a policy of continuous research and development. The introduction of new materials or manufacturing

methods will always equal or exceed the published specifications which Tannoy reserve the right to alter without prior notice.

Please verify the latest specifications when dealing with critical applications.

(2) Long term power handling capacity as defined in EIA standard RS - 426A.

(3) Unweighted pink noise input, measured at 1m.

Page 13

8. Performance Data

FREQUENCY RESPONSE IMPEDANCE

4 kHz

16 kHz

Page 14

9. CMS55 ICT Recommended Service Parts & Accessories

Part Number Description

7900 0538 Driver Kit – 1212 5”ICT

7600 0963 Transformer/Plate Assembly

8000 0748 CMS55 ICT (Loudspeaker, Baffle & Transformer)

8000 0749 CMS55 BC (Ceiling Can)

8000 0750 CMS55 TB (Tile Bridge Assembly)

10. Warranty

No maintenance of the CMS55 ICT loudspeaker is necessary.

All Tannoy professional loudspeaker products are covered by a 5 year warranty from

the date of manufacture subject to the absence of misuse, overload or accidental

damage. Claims will not be considered is the serial number has been altered or

removed. Work under warranty should only be carried out by a Tannoy Professional

dealer or service agent. This warranty in no way affects your statutory rights. For

further information please contact your dealer or distributor in your country. If you

cannot locate your distributor please contact Customer Services, Tannoy Ltd at the

address given below.

Customer Services

Tannoy Ltd.

Rosehall Industrial Estate

Coatbridge

Strathclyde

ML5 4TF

Scotland

Telephone: 01236 420199 (National)

+44 1236 420199 (International)

Fax: 01236 428230 (National)

+44 1236 428230 (International)

e-mail: prosales@tannoy.com

DO NOT SHIP ANY PRODUCT TO TANNOY WITHOUT PREVIOUS AUTHORISATION

Our policy commits us to incorporating improvements to our products through

continuous research and development. Please confirm current specifications for

critical applications with your supplier.

EASE Data for Tannoy Professional products available on request.

Page 15

Declaration of Conformity

The following apparatus is/are manufactured in the United Kingdom by Tannoy Ltd of

Rosehall Industrial estate, Coatbridge, Scotland, ML5 4TF and conform(s) to the

protection requirements of the European Electromagnetic Compatibility Standards

and Directives relevant to Domestic Electrical Equipment. The apparatus is designed

and constructed such that electromagnetic disturbances generated do not exceed

levels allowing radio and telecommunications equipment and other apparatus to

operate as intended, and, the apparatus has an adequate level of intrinsic immunity

to electromagnetic disturbance to enable operation as specified and intended.

Details of the Apparatus: Tannoy Monitor Loudspeaker

Model Number: CMS55 ICT

Associated Technical File: EMC CMS55 ICT

Applicable Standards: EN 50081-1 Emission

EN 50082-1 Immunity

Signed:

Position: Technical Manager

Tannoy Professional

Date: 22nd Feb 1999

For Tannoy Ltd

Page 16

Tannoy Loudspeakers are manufactured

in Great Britain by :

Tannoy Ltd, Rosehall Industrial Estate, Coatbridge,

Strathclyde, ML5 4TF, SCOTLAND

Telephone: +44 (0)1236 420199 Fax: +44 (0)1236 428230

Internet: http://www.tannoy.com

TGI/Tannoy, 300 Gage Avenue, Kitchener, Ontario, CANADA, N2M 2C8

Telephone: (519) 745 1158 Fax: (519) 745 2364

Tannoy Nederland BV, Anthonetta Kuijlstraat 19, 3066 GS, Rotterdam THE NETHERLANDS

Telephone: (010) 2860554 Fax: (010) 2860431

Tannoy is a member of the Group of Companies Issue 1 Part No. 6481 0314

GH 10 FEB 1999

Loading...

Loading...