Page 1

Page 2

For your own

the space provided. You

protection,

we urge youtorecord the serial numberofthis

will

find the serial number on the

bottomofthe unit.

unit

in

Serial

Number

.

Page 3

TERMS

AND

SOFTWARE

STORES

I.

CUSTOMER

A.

CUSTOMER

copiesofsoftware

capacity,

B,

CUSTOMER

the

II,

III.

IV.

V.

VI.

Equipment

LIMITED

WARRANTIES

A,

Foraperiodofninety

purchaseofthe

medium

to

purchasesofTandy

centers,

VOIdifthe

discovered

Computer

dealer

exclusive

refundofthe

replaceorrepair

B,

RADIO

exceptasprOVidedmthis

CUSTOMER'S

within

Software,

a

participating

C,

ExceptasproVided

warrantiesofany

o

EXCEPTASPROVIDED

WARRANTYOFMERCHANTABILITYORFITNESS

TO

THE

Some

applytoCUSTOMER

L1MITATIDNOFLIABILITY

A,

EXCEPTASPROVIDED

OR

ANY

ALLEGEDTOBE

LICENSEDORFURNISHEDBYRADIO

SERVICE,

THE

USEOROPERATIONOFTHE

LIABLE

ANY

BREACHOFTHIS

LEASE,

NOTWITHSTANDING

DAMAGES

THE

PARTICULAR

B,

RADIO

Software

No

action

more

than

RadiO

Shack

Some

limitation(s)orexcluslon(s)

SOFTWARE

RADIO

SHACK

subjecttothe

A.

Exceptasotherwise

B

Titletothe

CUSTOMER,

C,

CUSTOMER

tobefor

termmalonwhich

0,

CUSTOMER

~~1t;~r~s

E.

CUSTOMERispermittedtomake

additional

Software

limited

CUSTOMER

copyofthe

applicabletothird

G,

All

copyright

APPLICABILITYOFWARRANTY

A,

The

terms

saleofthe

conveys

B,

The

limifationsofliability

owner

STATE

LAW

The

warranties

have

other

fIghts

CONDITIONSOFSALE

PURCHASED

AND

RADIO

SHACK

OBLIGATIONS

assumes

full

responsibility

Included

capabiiitles,

versatility,

assumes

tuli

responSibility

and

Software

AND

CONDITIONSOFSALE

(90)

Equipment

upon

which

the

SoftwareisstoredISfree

retail

EquipmentorSoftware

dUring

Center,aRadio

for

repair,

remedyinthe

SHACK

thirty

The

DURATIONOFTHE

statesdonot

OTHER

LOSSOFBUSINESSORANTICIPATORY

FOR

LOSSOFPROFITS,ORANY

LICENSE,

INCURREDBYCUSTOMEROROTHERS

SHACK

a"sing

two

sales

statesdonot,

LICENSE

grantstoCUSTOMERanon-exclUSive,

followmg

mediumonwhich

may

useona

shall

specifically

copies

allowsabackup

numberofadditional

may

Software

notices

and

EqUipment

such

andorlicensorofthe

RIGHTS

granted

which

Equipmentbythe

stores,

and

the

stated

Shack

along

withacopyofthe

eventofa

purchase

price,atRADIO

expendabie

makesnowarrantyosto

paragraph,

exclusive

remedy,inthe

(3D)

calendar

defective

Software

Radio

Shack

hereinnoemployee,

natureonbehalfofRADIO

HEREIN,

allow

ilmltatlonsonhow

HEREIN,

PERSONORENTITY

CAUSED

WARRANTYORIN

USEORANTICIPATED

THE

ABOVE

"EQUIPMENT"OR"SOFTWARE"

shall

notbeliable

outofany

(2)

years

after

document

allow

proVisions:

providedinthiS

but

not

titletothe

use

Softwareona

multiuserornetwork

SoftwareIStobeused

not

use,

make,

providedmthis

are

reqUiredinthe

copytobe

resellordistribute

for

each

parties

recelvmg

shallberetamedonall

conditionsofthiS

and/or

Equipmenttoa

and

herein

give

vary

from

FROM

wifh

aretofunction,

Radio

Items,

daysofthe

franchiseeorRadiO

WRITIEN

DIRECTLYORINDIRECTlYBY"EQUIPMENT"OR"SOFTWARE"

claimed

for

the

may

copies

Software

statetostate

AND LICENSEOFTANDY

RADIO

SHACK

FRANCHISEESDRDEALERSATTHEIR

USA

the

EqUipmentorlicensed

and

other

calendar

RADIO

Shack

has

warranty

retail

defectISiimltedtothe

shalibereturnedtoa

RADIO

RAOID

"EQUIPMENT"OR"SOFTWARE."INNO

LIMITATIONS

for

breachofthiS

the

causeofaction

the

EqUipmentorSoftware,

limitationorexclusionatmCldentalorconsequential

not

applytoCUSTOMER,

Software

the

Softwareisrecorded

Software

muilluserornetwork

manufacture,orreproduce

additional

for

unmodified

one

soldordistributed,

copiesofthe

Warranty

Software

third

party

Warranty

the

original

COMPANY-OWNED

LIMITED

that

for

days

SHACK

been

period,

store,aparticipating

SHACK'S

Softwareislicensedonan

eventofa

dateofthe

LIMITED

SHACK

WITH

SHACK,

USEOFTHE

any

Software

operationofone

made,

CUSTOMER'S

LicensetoCUSTOMERortoatransaction

for

provisions

and

WARRANTY

this

computer

requirementsofCUSTOMER

the

condition

and

for

ItS

from

the

warrantstothe

from

original

franchisees

and

subjectedtoimproperorabnormal

the

defective

sales

documentoriease

election

the

deSign,

capability,

Software

RadiO

Shack

dealer

agent,

franchisee,

SHACK

SHACK

MAKESNOEXPRESS

FORAPARTICULAR

WARRANTIES

longanImplied

SHALL

RESPECTTOANY

INCLUDING,

PROFITSORCONSEQUENTIAL

INDIRECT,

SPECIAL,ORCONSEQUENTIAL

ANY

MANNER

"EQUIPMENT"OR"SOFTWARE."

AND

WARRANTIES,

SHALL

INVOLVED.

damages

causedbydelayIndeliveringorfurnishing

Warrantyortransactions

has

paid-up

License,

applicable

(cassette

system,orone

simultaneously,

License,

copiesatthe

However,

for

own

copiesofthe

Software

copiesofthe

are

applicableasbetween

leasetoCUSTOMER

herem

any

manufacturerofthe

CUSTOMER

COMPUTER

EQUIPMENT

COMPUTER

AUTHORIZED

hardware

purchased

separately

(the

"Software")

and

effectivenessofthe

installation,

dateofthe

customer

accruedormore

RadiO

Shack

orlgmai

manufactUring

dealersattheir

and

Radio

HAVENOLIABILITYORRESPONSIBILITYTOCUSTOMER

NOT

licensetouse

system

Customerisexpressly

computer

TASDOS

use,

The

from

Software,

shall

specific

CUSTOMER

defects,

from

Radio

EqUipment

RadiO

Shack

franchiseeora

agreement

correctionofthe

sale

expense

capacity,orsuitabillfy

"AS

IS"

manufacturing

Shack

sales

document

Shack

Computer

along

With

the

dealerorother

PURPOSEISLIMITEDINITS

SET

FORTH

warranty

iasts,sothe

LIABILITY,

BUT

NOT

ARISING

OUTOFOR

RADIO

EXCEED

THE

than

whichever

tirst

COPYright

and/or

diskette)orstored

onlyiteither,

copyofthiS

softwareispurchased

copiesofSoftware

Software

only

With

the

Software,

Software

proVided

prOVISionsofthis

CUSTOMER,

RADIO

Inuretothe

Equipment

legal

rights,

This

Shack

authorized

use,Ifa

mustbereturnedtoa

The

defectbyrepair,

RADIO

baSIS,

defect,isits

Center,aRadiO

sales

personISauthOrIZedtogive

WARRANTIES,

HEREIN,

LOSSORDAMAGE

LIMITED

EVENT

SHACK'S

AMOUNT

under

four

occurs,

the

TANDY

laws

shall

the

prohibited

for

backuporarchival

Software,

CUSTOMERISpermittedtomake

SHACK

benefitofRADIO

soldbyRadio

and

AND

CENTERS,

RETAIL

LOCATIONS

(the

"EqUipment"),

meefs

operafmg

environmentInwhich

sales

document

that

the

warrantyisonly

company-owned

locations,

manufactUring

participating

orlgmai

CUSTOMER'S

SHACK

hasnoobligation

for

useofthe

without

warranty,

repairorreplacement

received

upon

do~ument

AND

above

limitafion(s)

TO,

ANY

DAMAGES

SHALL

DAMAGES

CONNECTED

LIABILITY

PAIDBYCUSTOMER

this

Warranty

(4)

years

after

damages,sothe

Softwareonone

applytothe

(ROM)IStransferred

SoftwareISexpressly

except

for

useonone

from

but

onlytothe

CUSTOMER

Software

License

and

CUSTOMERtoeither

whereby

RadiO

SHACK,

Shack

the

original

and

the

specifications

received

and

applicable

computer

The

wdrranty

defect

RadiO

Radio

soie

repiacement

Software,

The

original

iicenseofthe

retali

ANY

IMPLIED

DURATION

may

CAUSED

SOLO,

LEASED,

FROM

SHACK

ARISING

OUT

THE

SALE,

and'or

maybebrought

the

dateatthe

computer

Software,

labeled

tor

each

node

computer

purposesorIf

extent

purchased

shall

also

Shack

sells

the

author,

CUSTOMER

upon

Shack

Shack

store,

above

may

4/87

EqUipment

Shack

INTERRUPTION

RESUlTING

RADIO

WITH

HEREUNDER

Equipment

disassembling

has

any

the

and

any

not

OR

OF

BE

OF

FOR

FOR

the

the

one

be

or

IS

IS

or

to

fa

0'

a

a

Page 4

This

The FCC Wants

equipment

that is in

radio and

It has been type

accordance

in

to provide reasonable

However, there is no

If

this

determinedbyturning

terference by one

generates and uses radio

strict

accordance

television

tested

with

the

equipment

or

with

reception.

and foundtocomply

specifications

protection

guarantee

does

cause

the

equipment

moreofthe

You

frequency

the

manufacturer's

in SUbpart JofPart 15ofFCC Rules,

against

that

interference

interferencetoradioortelevision

off

and on, the

following

with

such

interference

will

measures:

instructions,

to

energy.Ifnot

the

limits

for

not

occur

user

Is encouragedtotrytocorrect

Know

Installed and used properly,

It may cause

a Class B

in a

in a

particular

reception,

computing

which

residential

interference

device

are

designed

installation.

installation.

which

can be

to

the in-

• Reorient the receiving

• Relocate the

• Move the

Plug the

branch

This

equipment

pursuanttoSubpart JofPart15of

devices, terminals,

this

computer.

radio andTVreception.

computer

computer

computer

circuits.

has been

printers,

Operation

antenna

with

respecttothe receiver

away

from

intoadifferent

certifiedtocomply

etc.)

certifiedtocomply

with

non-certified

Dot Matrix Printer

© 1987

All

Reproductionoruse, without express written permission from Tandy Corporation and/or its licensor,

of any portion of this manual

reasonable efforts have

tion of this manual to assure its accuracy,

Corporation assumes no liability resulting from any

or

errors

of

IBM

Tandy and Scrips

omissions in this manual,orfrom the use

the information contained herein.

is

a registered

Business Machines, Corp.

Tandy Corporation.

the receiver

outletsothat

computer

and receiver areondifferent

Warning

with

the

limits

for

a Class B

FCC Rules.

DMP

Tandy

Rights

it

are registered trademarks of

Only

peripherals

with

peripheralsislikelytoresultininterference

the Class B

(computer

limits

132 Operation

Corporation

Reserved.

is

prohibited. While

been

taken in the prepara-

trademarkofInternational

computing

input/ouput

may be

attached

Manual:

Tandy

device,

to

to

2/86

10

9 8 7 6 5 4 3 2

Page 5

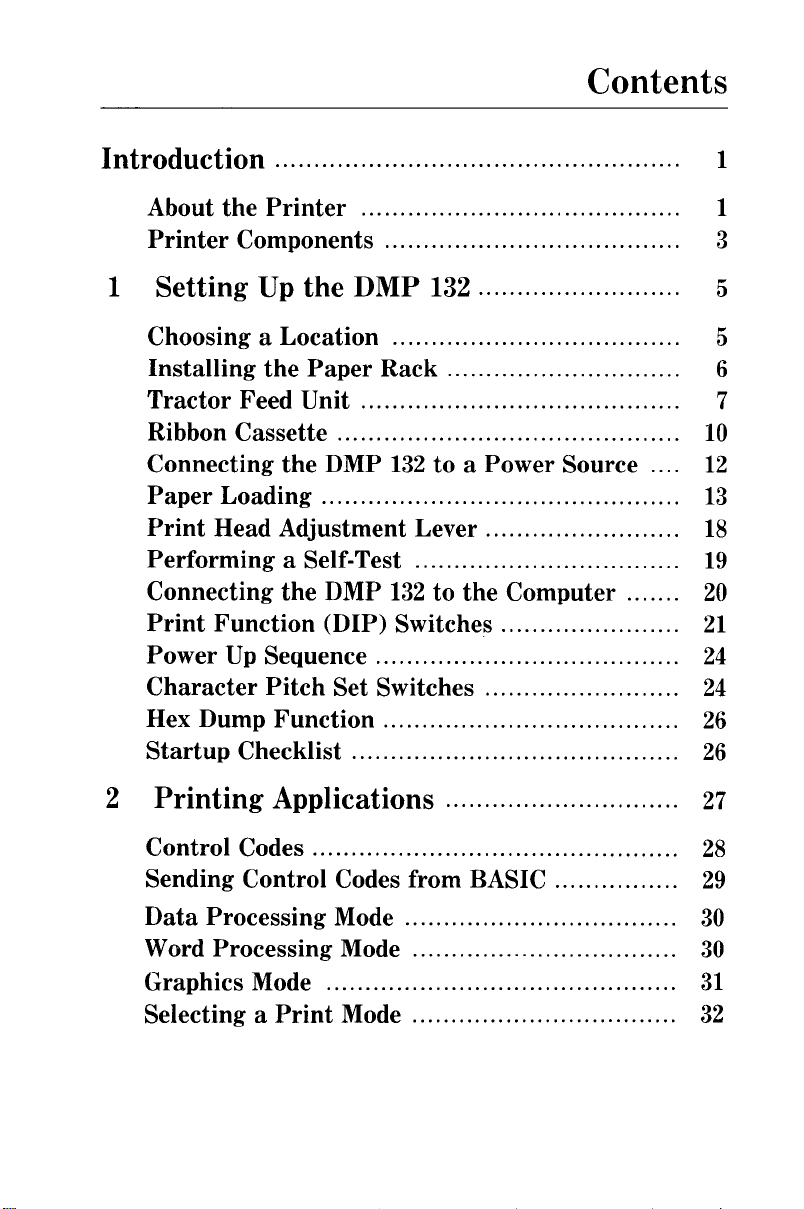

Contents

Introduction

About

Printer

1

Setting

Choosing a Location 5

Installing

Tractor

Ribbon Cassette

Connecting

Paper

Print

Performing

Connecting

Print

Power

Character

Hex Dump

Startup

the

Printer

Components 3

Up

the

DMP

the

Paper

Feed Unit 7

the

DMP

Loading

Head Adjustment Lever

a Self-Test

the

DMP

Function

Up

Sequence

Pitch

Checklist

(DIP)

Set Switches

Function

132

Rack 6

132toa Power Source

132tothe

Switches.......................

Computer

1

1

5

10

12

13

18

19

20

21

24

24

26

26

2

Printing

Control Codes

Sending Control Codes from BASIC

Data

Processing Mode

Word Processing Mode

Graphics Mode

Selecting a

Applications

Print

Mode

27

28

29

30

30

31

32

Page 6

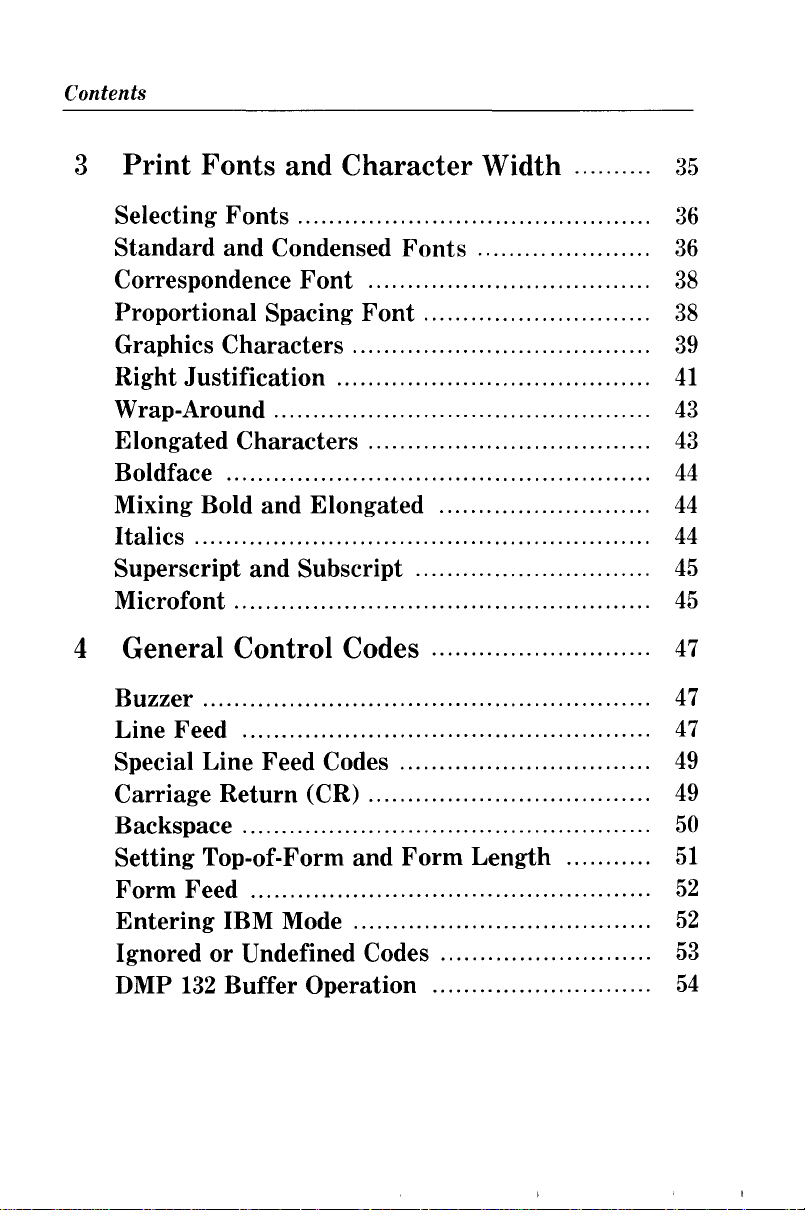

Contents

3

Print

Fonts

and

Character

Width

35

Selecting

Standard

Correspondence

Proportional Spacing

Graphics

Right

Wrap-Around

Elongated

Boldface

Mixing Bold

Italics..........................................................

Superscript

Microfont

Fonts

and Condensed

Font

Characters

Justification

Characters

and

and

Subscript

Fonts

Font

Elongated

4 General Control Codes

Buzzer

Line Feed

Special Line Feed Codes

Carriage

Backspace

Setting Top-of-Form

Form

Entering

Ignored

DMP

Return

Feed

IBM Mode

or

Undefined Codes

132

Buffer Operation

(CR)

and

Form

Length

36

36

38

38

39

41

43

43

44

44

44

45

45

47

47

47

49

49

50

51

52

52

53

54

Page 7

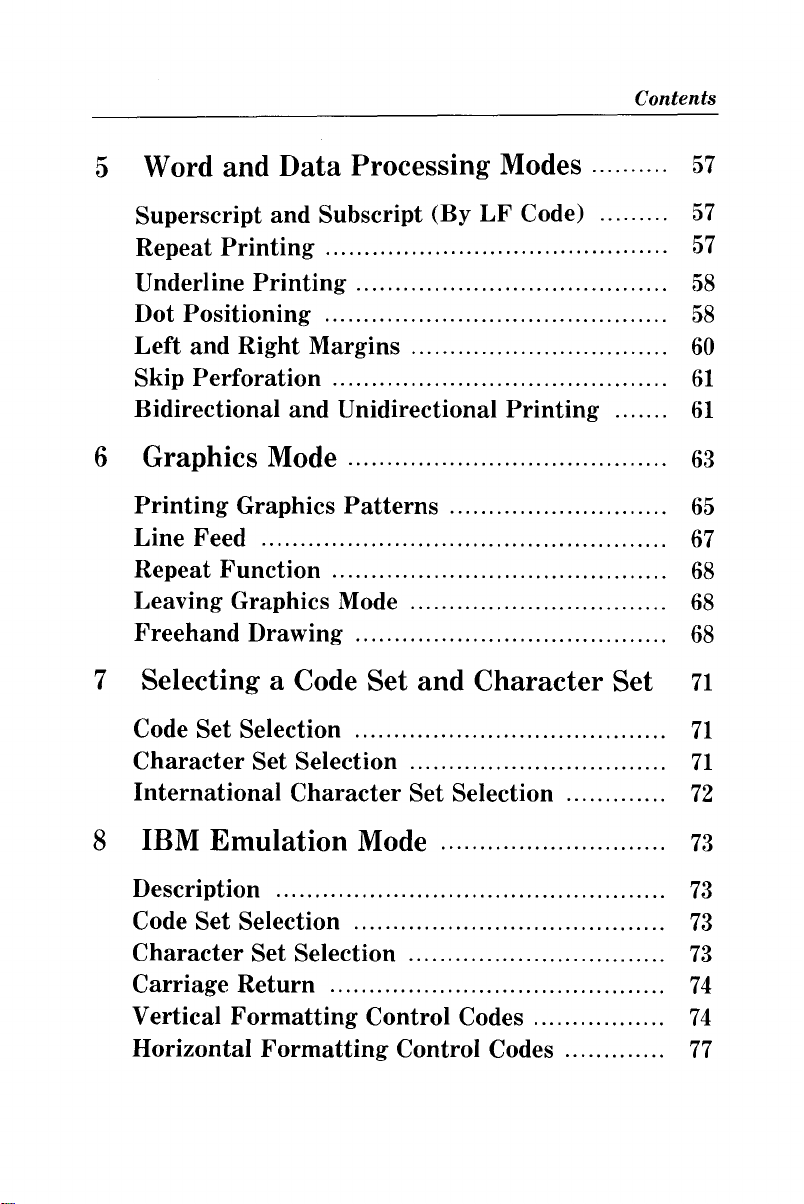

Contents

5 Word and

Superscript

Repeat

Underline

Dot

Positioning

Left

and

Skip

Perforation....................

Bidirectional

Data

and

Printing

Printing

Right

and

Processing Modes

Subscript (By

Margins

Unidirectional

6 Graphics Mode

Printing

Line

Repeat

Leaving Graphics Mode

Freehand

Graphics

Feed

Function

Drawing

Patterns

7 Selecting a Code Set

Code Set Selection

Character

International

Set Selection

Character

LF

Code)

Printing

and

Character

Set Selection

Set

57

57

57

58

58

60

61

61

63

65

67

68

68

68

71

71

71

72

8 IBM

Description

Code Set Selection

Character

Carriage

Vertical

Horizontal

Emulation

Return

Formatting

Mode

Set Selection

...........................................

Control

Formatting

Codes.................

Control Codes

73

73

73

73

74

74

77

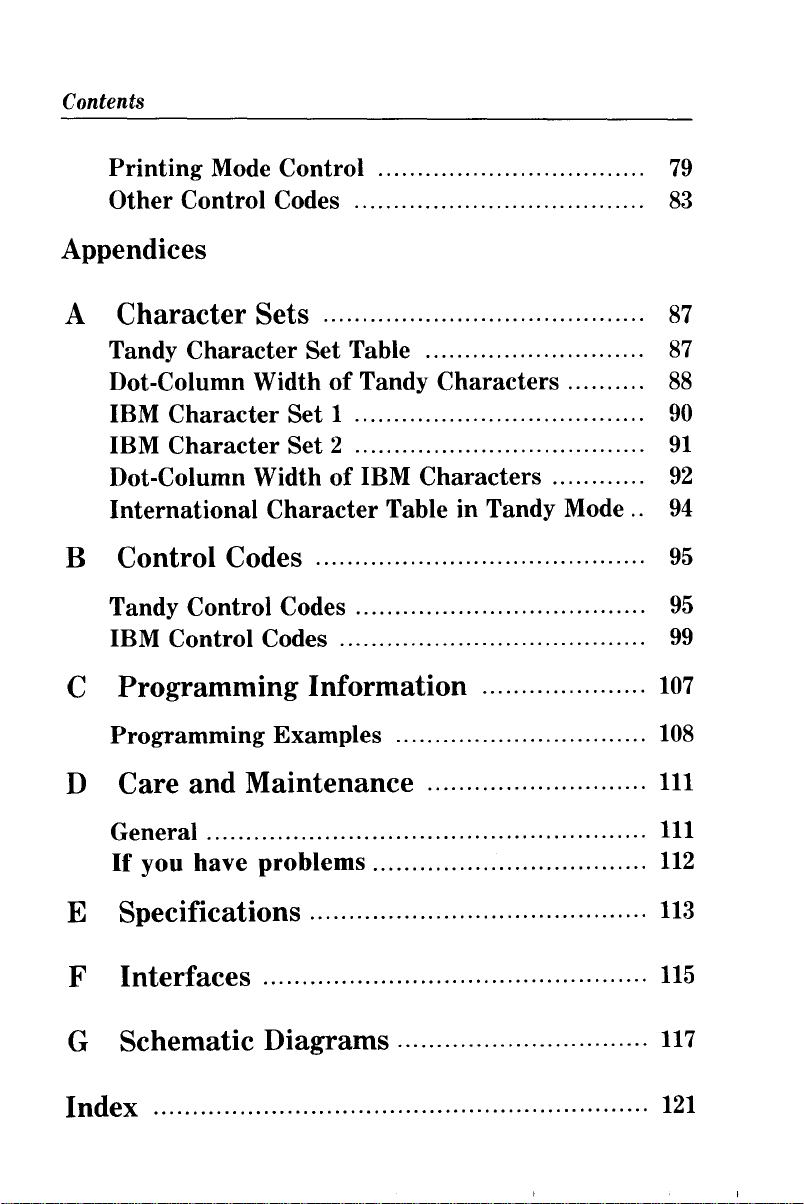

Page 8

Contents

Printing

Other

Mode Control

Control Codes

Appendices

Character

A

Tandy

Dot-Column WidthofTandy

IBM

IBM

Dot-Column WidthofIBM

International

Character

Character

Character

Sets

Set Table ......

Set 1

Set

2

Character

Characters

Characters

Table in Tandy Mode..

B Control Codes

Tandy Control Codes

IBM Control Codes

C Programming Information

Programming

Examples

.. .. ..... .. ..... ..

79

83

87

87

88

90

91

92

94

95

95

99

107

108

D Care and Maintenance

General

If

you

have

problems...................................

E Specifications...........................................

F

Interfaces.

..............................................

G Schematic Diagrams................................

Index

111

111

112

113

..

115

117

121

Page 9

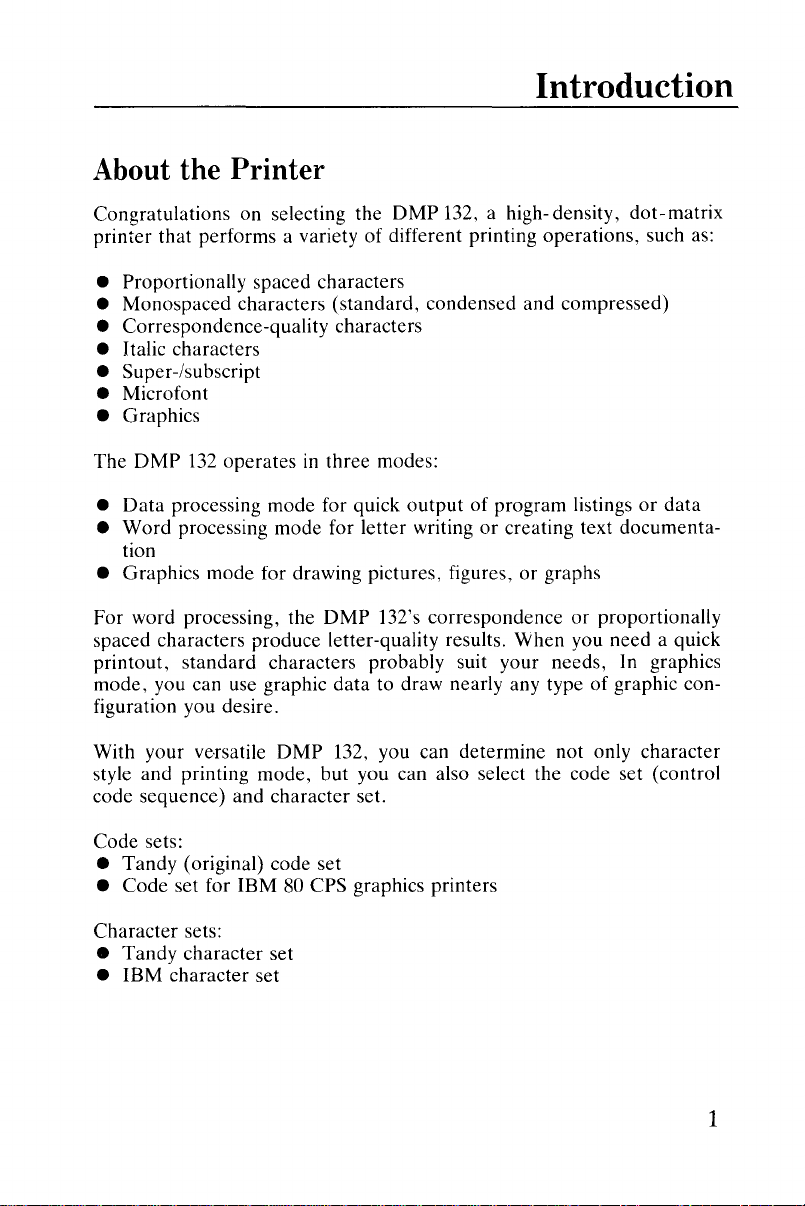

About the Printer

Introduction

Congratulations on selecting the

printer that performs a variety of different printing operations, such as:

• Proportionally spaced characters

• Monospaced characters (standard, condensed and compressed)

• Correspondence-quality characters

• Italic characters

• Super-/subscript

• Microfont

• Graphics

DMP

132

The

Data

•

•

Word

tion

• Graphics mode for drawing pictures, figures,

For

word processing, the

spaced characters produce letter-quality results. When you need a quick

printout, standard characters probably suit your needs,

mode, you can use graphic data to draw nearly any type of graphic con-

figuration you desire.

With your ve·rsatile

style and printing mode, but you can also select the code set (control

code sequence) and character set.

operatesinthree modes:

processing mode for quick

processing mode for letter writingorcreating text documenta-

DMP

DMP

DMP

132, a high-density,

output

132's correspondenceorproportionally

132, you can determine not only character

of program listingsordata

or

graphs

dot-matrix

In

graphics

Code sets:

• Tandy (original) code set

• Code set for IBM

Character sets:

• Tandy character set

• IBM character set

80

CPS graphics printers

1

Page 10

Introduction

You can use two typesofpaper

•

Tractorholes.

carbon

• Friction-fed, single-sheet

Other

• Full-orhalf-line feed

Underline

•

•

Buzzer

Automatic

•

•

Character

fed 4- inch

The

copies.

features

function.

or

10- inch

DMP 132 can also

typewriter

include:

and

capability.

paper

loading.

pitch

set

function

with the DMP 132:

computer

print

3/4or4/5 line feed.

fanfold forms with guide

one

original

paper.

andupto

two

non-

2

Page 11

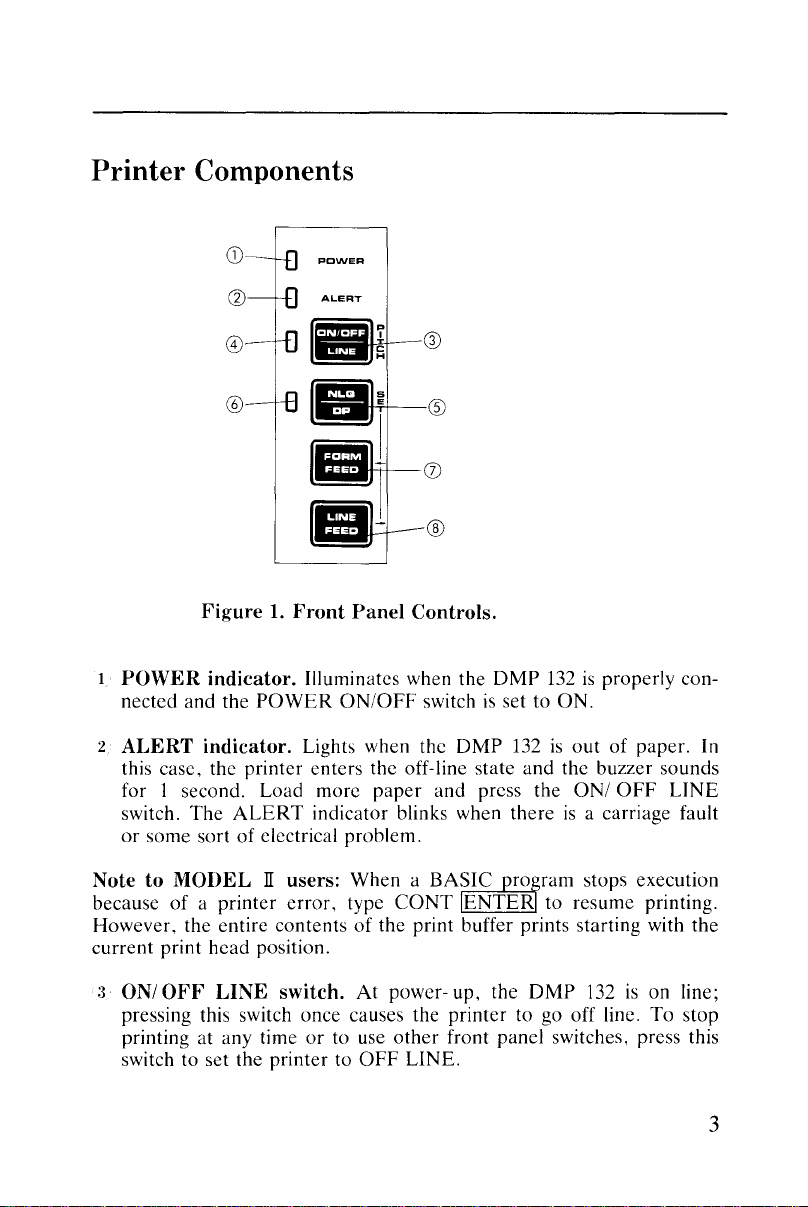

Printer Components

CD

o

®

-<-->-----

Figure1.Front

1

POWER

nected and the

2

ALERT

this case, the printer enters the off-line state

for I second. Load more

switch.

or

some sortofelectrical problem.

indicator. Illuminates when the

POWER

indicator. Lights when the

The

ALERT

Panel

ONIOFF switch

indicator blinks when thereisa carriage fault

NotetoMODELIIusers: When a

because

However, the entire contents

current

:3

of

a printer

print head position.

ONIOFF

pressing this switch once causes the

printing at any time

switch to set the

LINE

error,

switch.

printertoOFF

or

type

of

At

to use

®

Controls.

paper

and press the

BASIC

CaNT

the print buffer prints starting with

power- up, the

other

LINE.

DMP

132

is

properly con-

is

set to

ON.

DMP

132

is

outofpaper. In

and

the buzzer sounds

aNI

OFF

LINE

proram

JENTER to resume printing.

printer

front panel switches, press this

to go off line. To stop

stops execution

DMP

132

is

on line;

the

3

Page 12

Introduction

Press and hold this switch for one second while in on line mode to

enter the pitch-set mode.

Note: To print the remaining data

by

ing

pressing the

ON/OFF

using your computer software. Then, press the

132

to set the DMP

(V

ON/OFF

is

on line and ready to print. The indicator flickers in the pitch- set

LINE

to ON LINE.

indicator.

in

the buffer after you stopped print-

LINE switch, cancel the printing process

ON/OFF

LINE switch

When this indicatorison, the DMP

mode.

(~)

NLQlDP

Quality (NLQ)

selected, the

mode. This switch works only when the DMP

In

the pitch-set mode, pressing this switch sets the pitch.

6

NLQ

switch. Press this switch to select either the Near Letter

or

standard print mode. When the NLQ mode

NLQ

indicator lights. Press this switch again for standard

132isoff line.

indicator.

Illuminates when the DMP

132isin

the NLQ

mode.

7

FORM

next top-of-form position.

FEED

switch. Press this switch to advance the paper to the

It

is

effective only when the DMP

off line.

In the pitch-set mode, pressing this switch moves the print head to

the left.

132

132

is

is

8

LINE

FEED

switch. Press this switch to advance the paper one

line. Press and hold for continuous paper feed. This switch works

only when the DMP

132isoff line.

In the pitch-set mode, pressing this switch moves the print head to

the right.

4

Page 13

Setting

This

chapter

using it

• Choosing a location for the printer

• Installing the

• Installing/adjusting the tractor feed unit

• Installing

• Loading

• Connecting the printer to a power source

• Connecting the printer to your

• Powering up the printer

• Performing a self-test

Carefully unpack the

paper

rack. Keep the empty box and packing material in case you ever

need to transport the

shows you how to set up the

as

soon as possible. Setting up the printer involves:

paper

rack

or

replacing a ribbon

paper

DMP

132, being sure to locate the ribbon and the

DMP

132.

Up

computer

the DMP

DMP

132

so you can begin

132

1

Choosing a Location

When you choose the location for your printer, be sure to consider the

following:

The

•

•

• Space for paper.

• Noise generation.

Once you choose a location for

ting it up.

work surface. Place the printer on a sturdy surface.

The

length of the printer cable. This determines the distance from

the

computer

tractor-feed paper.

such as refrigerators

that you can place

Be

suretoleave enough room for smooth flow

Do

not place the printer

or

industrial equipment.

the

printer.

near

noise generators

the

printer, you are ready to begin set-

of

5

Page 14

SettingUpthe DMP

132

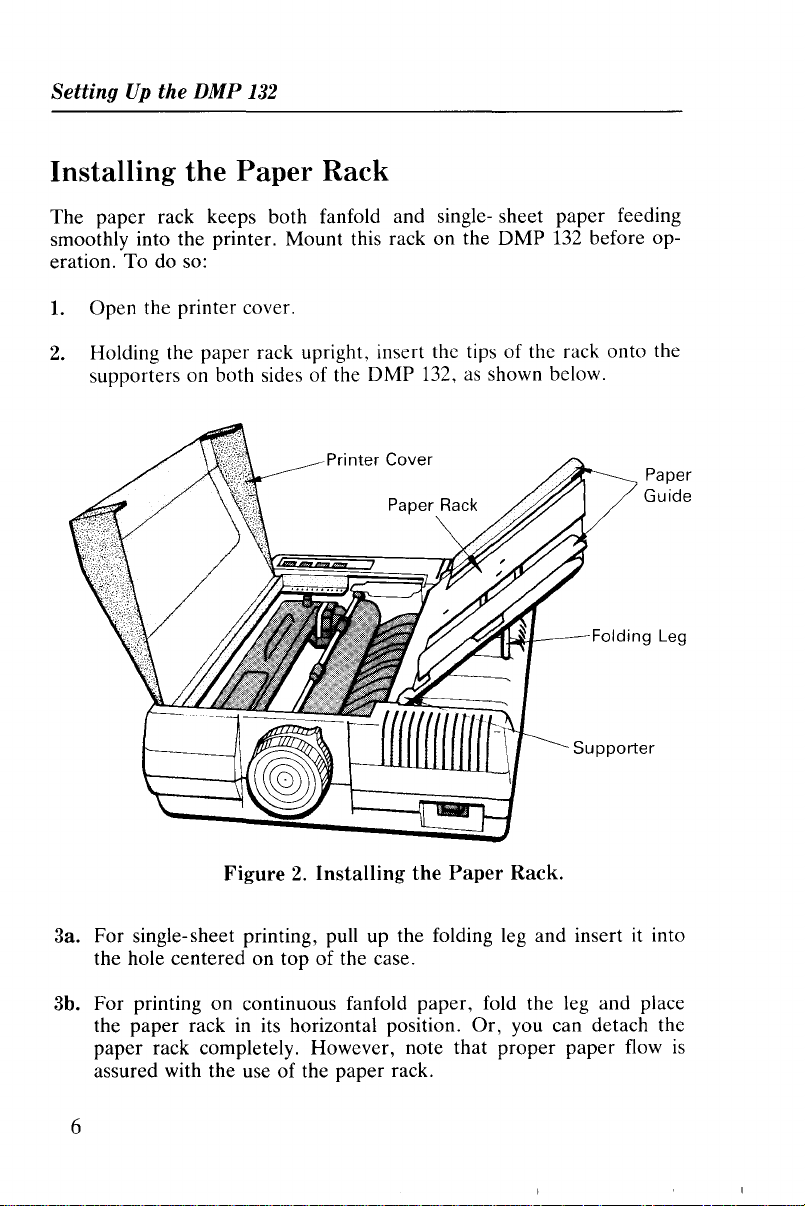

Installing the Paper Rack

The paper rack keeps both fanfold and single- sheet paper feeding

smoothly into the printer. Mount this rack on the DMP

eration. To do so:

1.

Open the printer cover.

2.

Holding the paper rack upright, insert the tips of the rack onto the

as

supporters on both sides of the DMP 132,

shown below.

132

before op-

Printer Cover

Paper Rack

Figure2.Installing

the

~,..~~_-

Paper

Rack.

Supporter

Paper

Guide

Folding Leg

3a. For single-sheet printing, pull up the folding leg and insert it into

the hole centered on top of the case.

3b. For printing on continuous fanfold paper, fold the leg and place

the paper rack in its horizontal position. Or, you can detach the

paper rack completely. However, note that proper paper flow

assured with the use of the paper rack.

is

6

Page 15

You

can adjust the

widths. Pull

Then

position it as you desire (within the range allowed). When using

narrow

range

empty switch

ting a single sheet, slide the right

paper

paper,

of

the

width.

the

paper

and

paper

left

paper

position the

guide. This ensures

also reduces the possibilityofpaper

rack's

paper

guide upward to removeitfrom the rack.

paper

paper

guides for

so that the left edgeiswithin the

proper

guidc to the left to match

paper

operationofthe

jam.

Tractor Feed Unit

Chapter 1

of

various

paper

Aftcr

set-

thc

You can use the

system.

(fanfold) that has guide holesonboth edges, while the

the friction feed system does not have these holes.

When

When the

DMP

The

you use the friction feed system, be sure to remove the tractor.

tractorisinstalled, the friction mechanismisreleased

132

might not feed the

DMP

132 with

differenceisthat

either

the

tractor

the tractor feed systemisused with

paper

properly.

feedorfriction feed

Installing the Tractor

1.

Be

2.

3.

sure the printer's

Remove

Turn

ward.

the

the

paper

paper

power

switchisoff.

rack and

loading knob forward to move the

open

the

printer

cover.

paper

paper

paper

used with

and

the

bail for-

7

Page 16

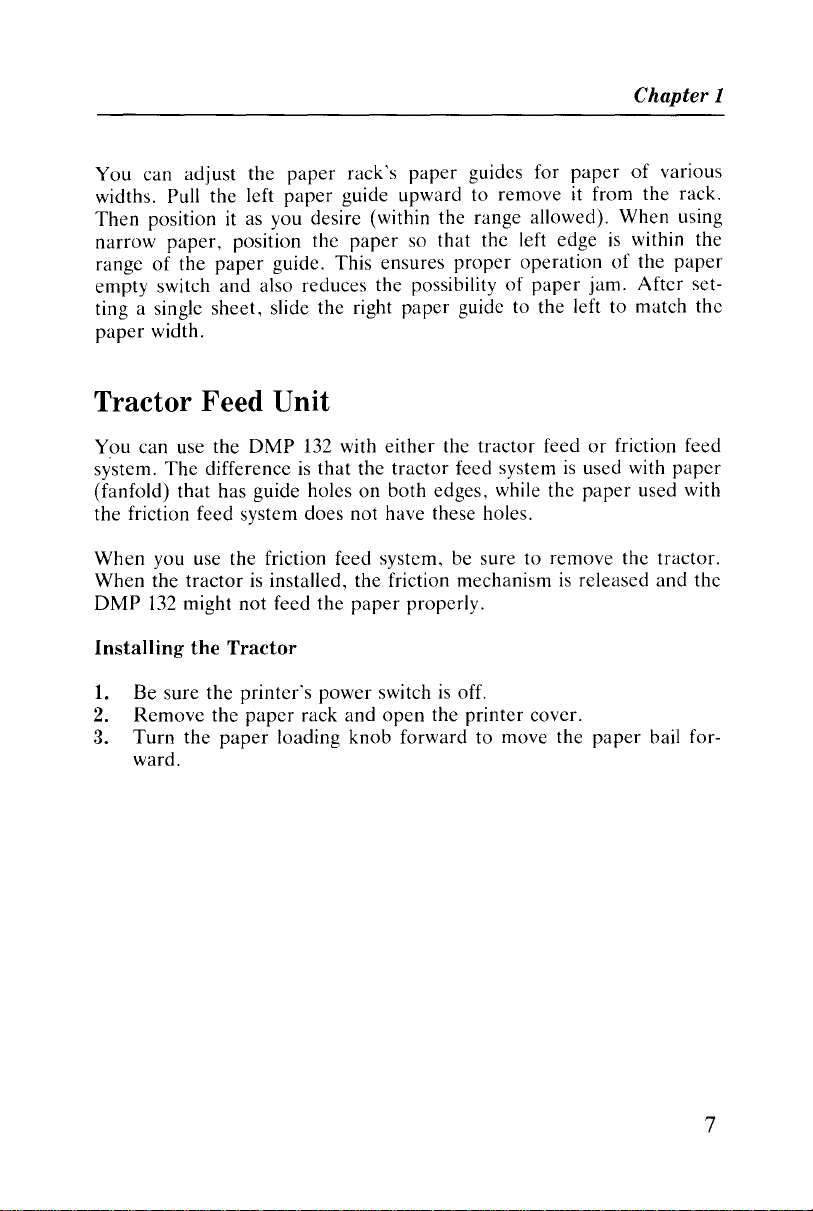

SettingUpthe DMP

132

Printer Cover Paper Rack

POWER Switch

Figure3.Right Side View.

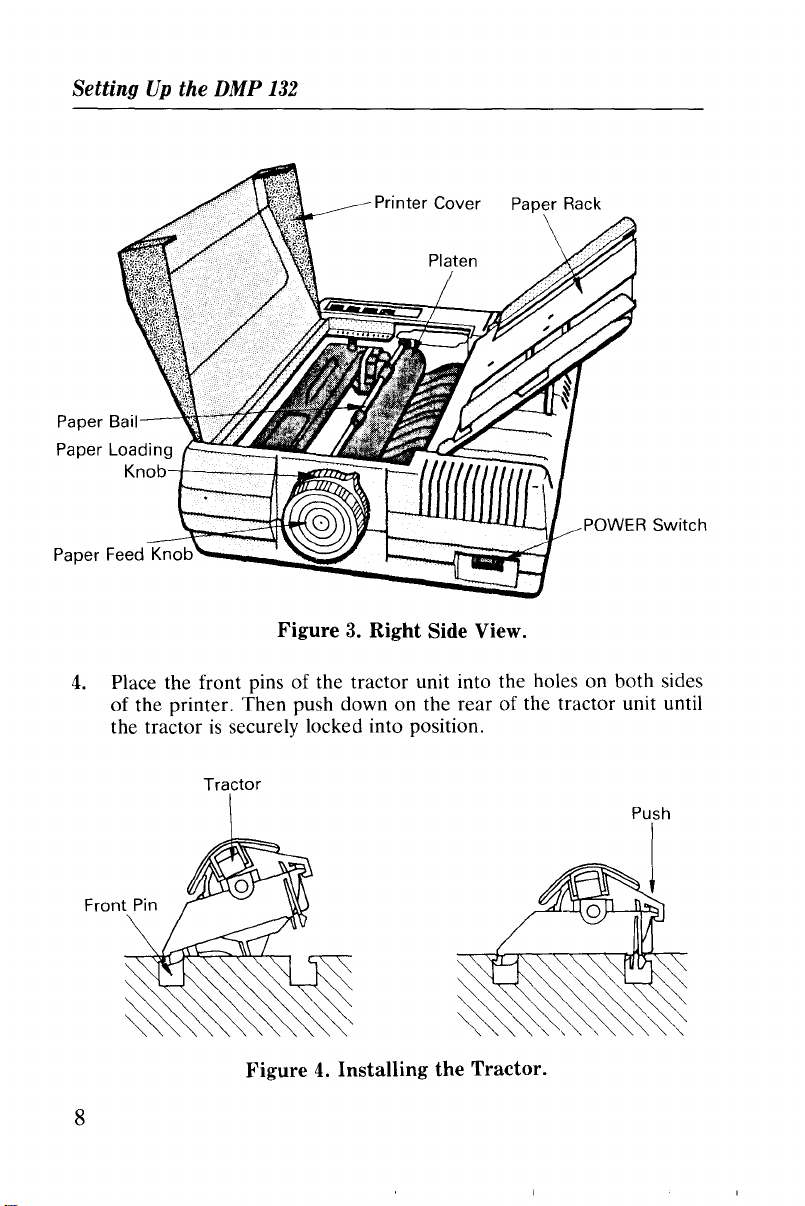

4.

Place the front pins of the tractor unit into the holes on both sides

of the printer. Then push down on the rear of the tractor unit until

is

the tractor

securely locked into position.

Tractor

Figure4.Installing the Tractor.

8

Page 17

Chapter 1

5. Turn the

the paper bail toward the platen.

6. Close the printer cover. Replace the

Removing

1.

Turn off the printer.

2.

Open

Turn

3.

toward the front.

4. Lift the tractor unit from the rear, then pull it upward.

5.

Turn

6.

Replace the paper rack and close the printer cover.

paper

loading knob backward (away from you) to move

paper

the

Tractor

the printer cover. Remove the

the

paper

loading knob toward you to move the

the paper loading knob away from you.

paper

rackifdesired.

rackifnecessary.

paper

bail

9

Page 18

Setting

Up

the DMP

132

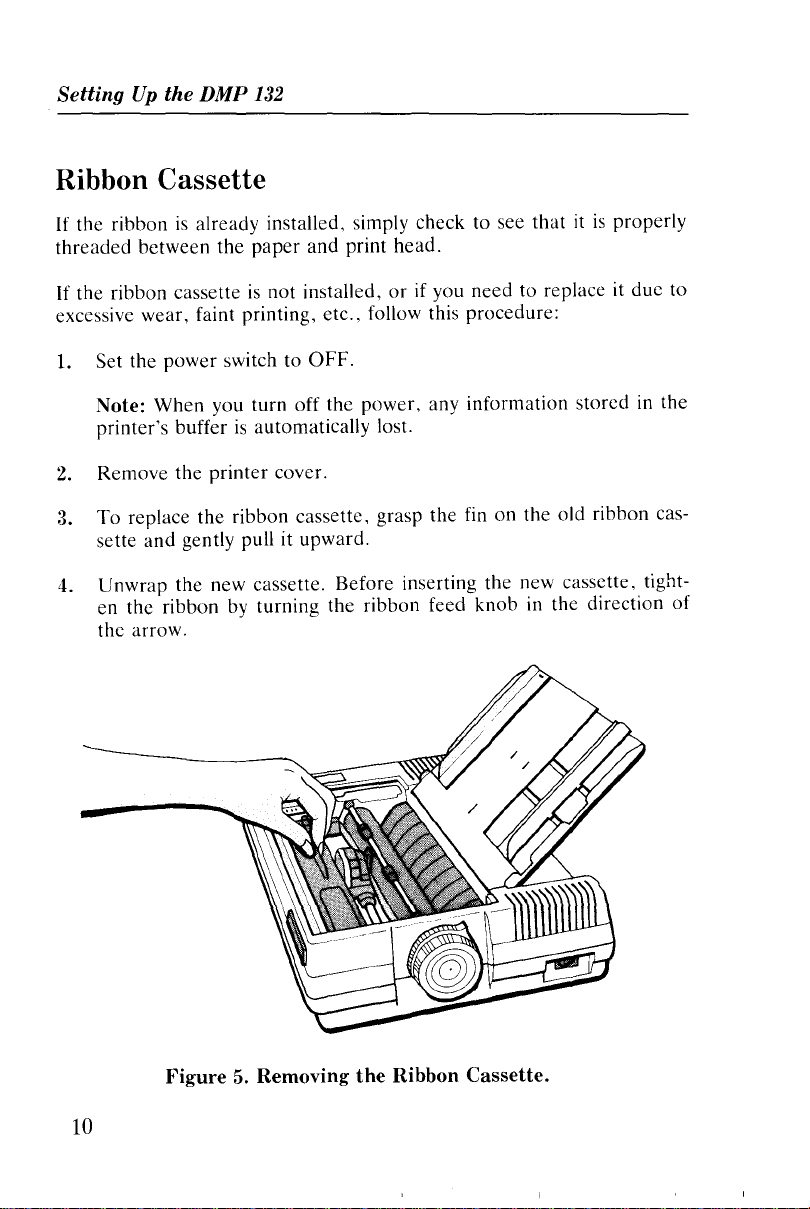

Ribbon Cassette

If

the ribbonisalready installed, simply check to see

threaded

If

the ribbon cassetteisnot installed,orif you need to replace it due to

excessive wear, faint printing, etc., follow this procedure:

1.

between

Set the power switch to

the

paper

and print head.

OFF.

Note: When you turn off the power, any information stored in the

is

printer's buffer

2.

Remove the printer cover.

3.

To

replace the ribbon cassette. grasp the fin on the old ribbon cas-

sette

and

gently pull it upward.

4. Unwrap the new cassette. Before inserting the new cassette. tighten the ribbon

the arrow.

automatically lost.

by

turning the ribbon feed knob in the direction of

thatitis

properly

10

Figure5.Removing

the

Ribbon

Cassette.

Page 19

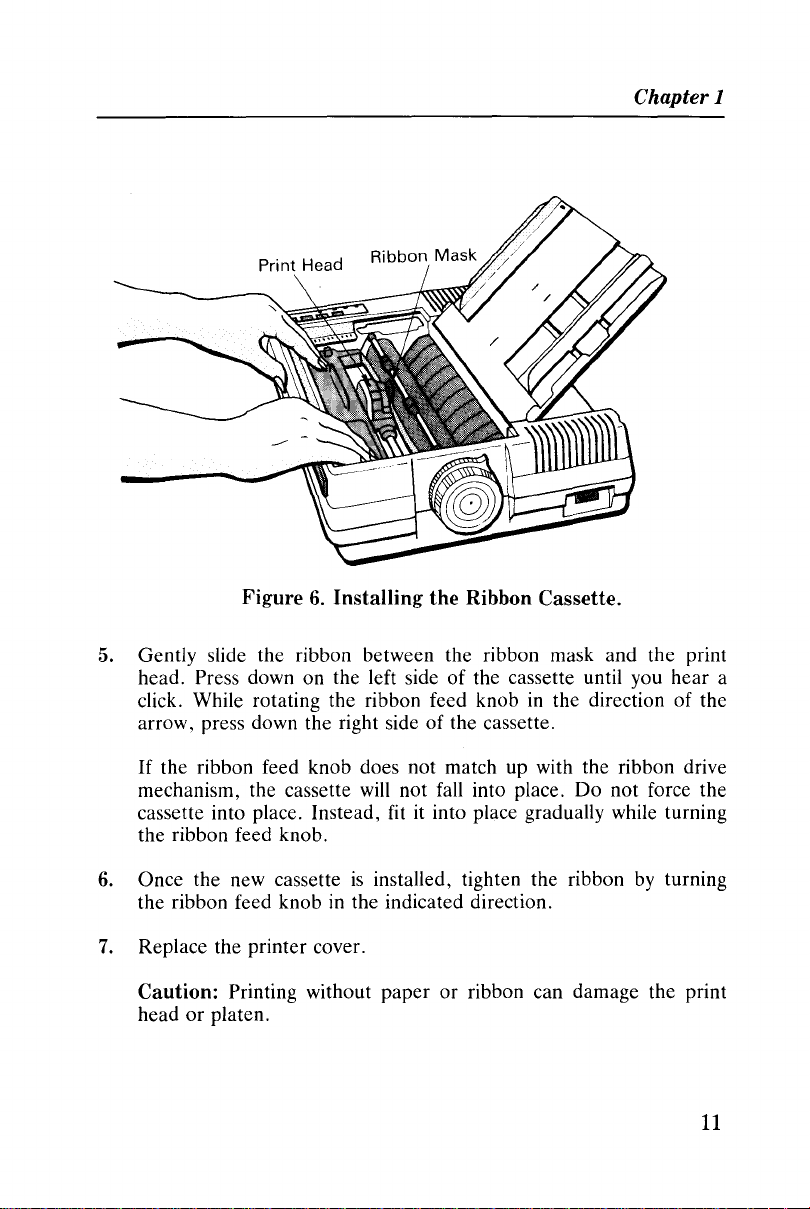

Chapter 1

Print Head

Figure6.Installing the Ribbon Cassette.

5. Gently slide the ribbon between the ribbon mask and the print

head. Press down on the left sideofthe cassette until you hear a

click. While rotating the ribbon feed knobinthe direction of the

arrow, press down the right sideofthe cassette.

If

the ribbon feed knob does not match up with the ribbon drive

mechanism, the cassette

cassette into place. Instead, fit it into place gradually while turning

the ribbon feed knob.

6. Once the new cassetteisinstalled, tighten the ribbon by turning

the ribbon feed knob in the indicated direction.

7.

Replace the printer cover.

will

not fall into place.

Do

not force the

Caution: Printing without paper or ribbon can damage the print

headorplaten.

11

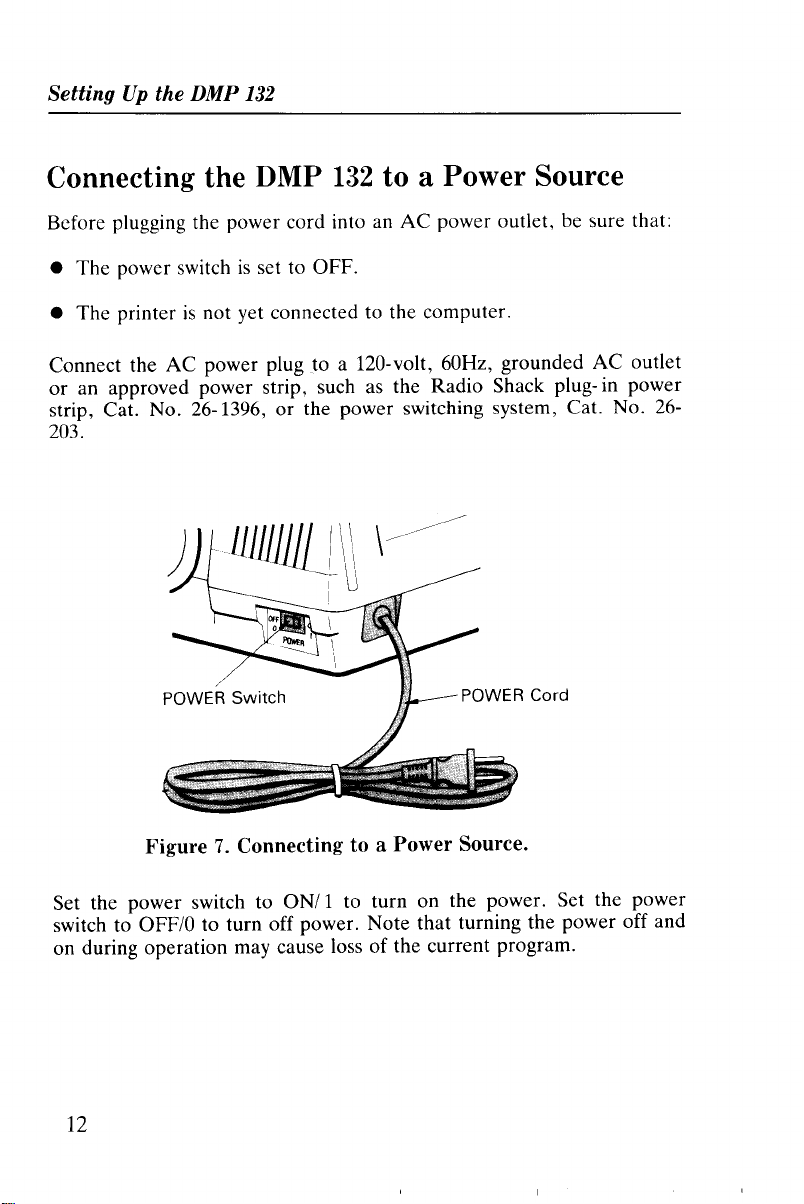

Page 20

SettingUpthe DMP

132

Connecting the DMP

Before plugging the power cord into an

is

• The power switch

• The printer

Connect the

or

an approved power strip, such as the Radio Shack plug- in power

strip, Cat. No. 26-1396,

203.

is

AC

set to OFF .

not yet connected to the computer.

power plug to a 120-volt, 60Hz, grounded

1II11111LI\\

132

to a Power Source

AC

power outlet, be sure that:

or

the power switching system, Cat. No.

\

......./

I

AC

outlet

26-

Figure7.Connecting to a Power Source.

Set the power switch to

switch to

on during operation may cause loss of the current program.

12

OFF/O

to turn off power. Note that turning the power off and

ONII

to turn on the power. Set the power

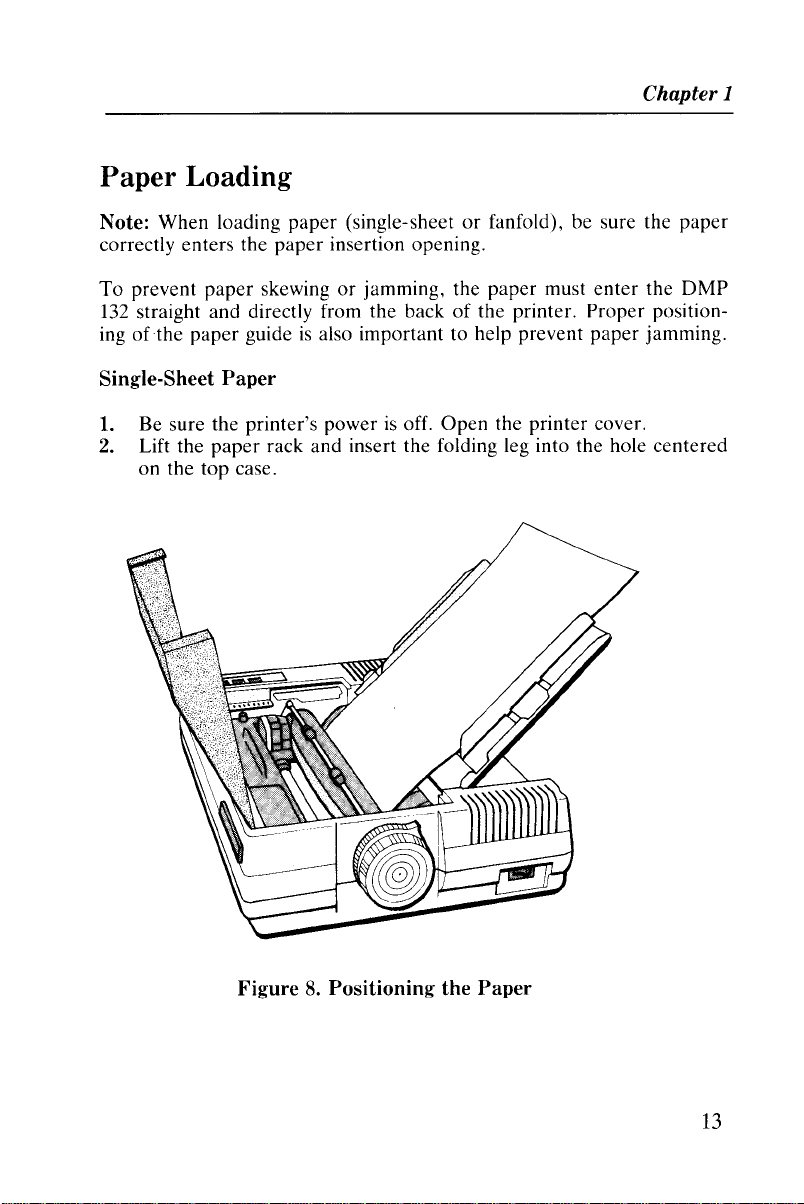

Page 21

Paper Loading

Chapter 1

Note: When loading paper (single-sheet

correctly enters the

To

prevent paper skewingorjamming, the paper must

132

straight and directly from the backofthe printer. Proper position-

ing

of

the paper guideisalso important to help prevent paper jamming.

paper

insertion opening.

or

fanfold), be sure the

enter

Single-Sheet Paper

1.

Be sure the printer's powerisoff.

2. Lift the

on the top case.

paper

rack and insert the folding leg into the hole centered

Open

the printer cover.

the

paper

DMP

Figure8.Positioning the Paper

13

Page 22

Setting

3. Position the paper on the paper rack, aligning it with the paper

4.

5.

6.

7.

Up

the DMP

guide. Since the auto-paper-loading system pulls the paper into the

printer, just placing the paper on the paper rack

you insert the paper into the opening, the

that the paperisalready in place and might not activate the autoloading mechanism.

Turn on the printer.

Turn the paper loading knob toward you. The paper automatically

advances to the print-start position.

If

Note:

system does not work. In such a case, remove the sheet and position it again to turn on the indicator.

Turn the paper loading knob away from you to return the paper

bail to the platen.

To align the paper, use the platen knoborthe front panel LINE

FEED

Verify that the paper bail

necessary.

the

switch (see "Printer Components") to advance the paper.

132

ALERT

is

sufficient.

DMP

132

might "think"

indicatorisnot lit, the auto- paper-loading

is

against the platen. Adjust the paper

If

as

Note: The paper bail MUST be against the platen for paper

adjustment.

8.

Set the print head adjustment lever located on the inside right of

the printer to the appropriate position. Refer to "Print Head

Adjustment Lever."

9.

Close the printer cover.

Hints

and

Tips on Single-Sheet

• With the paper properly installed, printing continues until the paper

passes the paper empty sensor. The printer then goes off line. Insert

another sheet and turn the paper loading knob to set the paper.

When the paper

DMP

132

continues printing where it left off.

isinplace, press the

Paper

Loading

ON/OFF

LINE switch and the

14

Page 23

•

If

you want to print

detects the

nottoexceed the bottom edgeofthe paper.

paper

end,

another

press the

few lines after the

ON/OFF

Fanfold Paper

The

DMP

132

accepts standard fanfold paper from 4 inches to10inches

wide. Before using fanfold

installed.

1.

2.

3.

4.

Referto"Tractor

Turn

off the power.

Open

the printer cover. Remove the

Turn

the

paper

away from the platen.

Feed

the

paper

into the printer through the

ing. Use the

appears between the platen and the print head.

paper

paper,

Feed

loading knob toward you to move the

feed knob to pull the

however, the tractor unit should be

Unit."

LINE

paper

rack temporarily.

paper

paper

Chapter 1

paper

empty sensor

switch. Be careful

paper

insertion open-

around

until it

bail

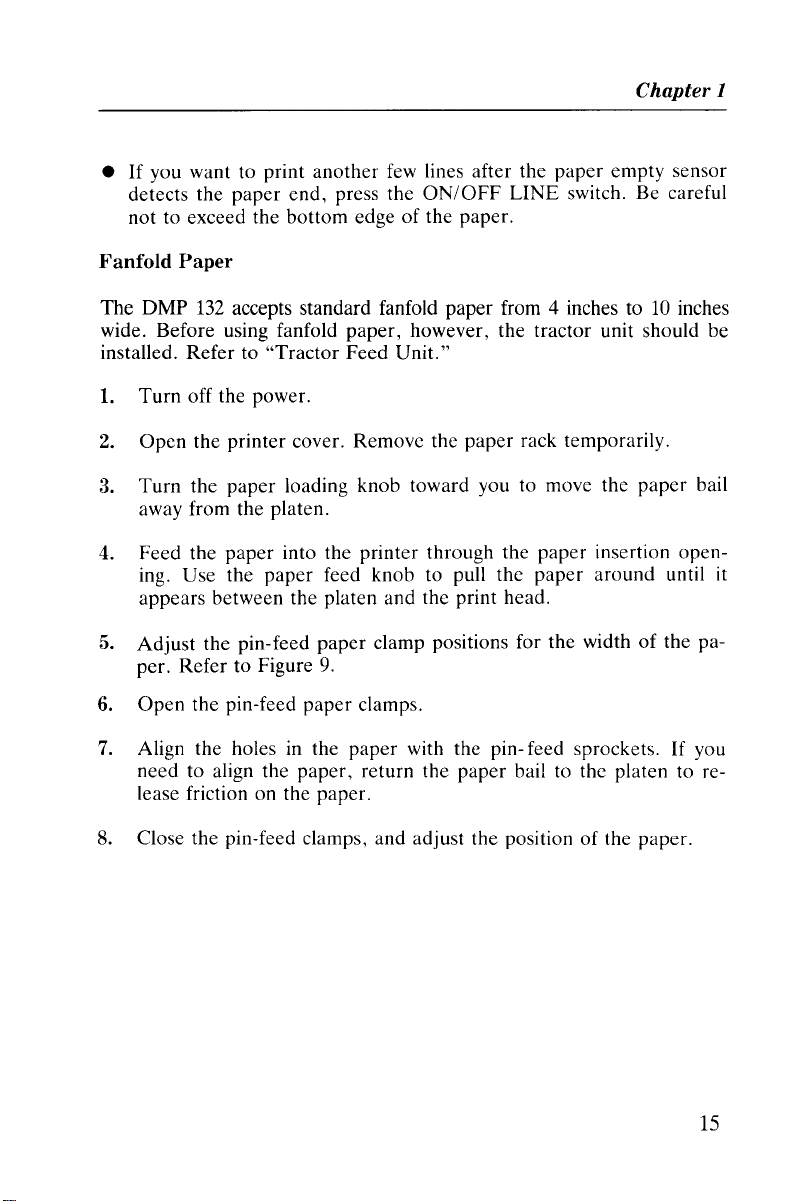

Adjust

5.

per.

6.

Open

7.

Align the holes in the

need to align the

lease friction on the paper.

8. Close the pin-feed clamps, and adjust the position of the paper.

the pin-feed

RefertoFigure

the

pin-feed

paper

9.

paper

paper,

clamp positions for

clamps.

paper

with the pin- feed sprockets.Ifyou

return the

paper

the

widthofthe pa-

bail to the platen to re-

15

Page 24

Setting

Up

the DMP

132

Pin-feed Paper Clamps

Figure9.Front

9.

Turn

the

paper

loading knob away from you to move the

bail toward the platen.

leased by setting the

that

you perform this step to

10. Set the print

the

printer.

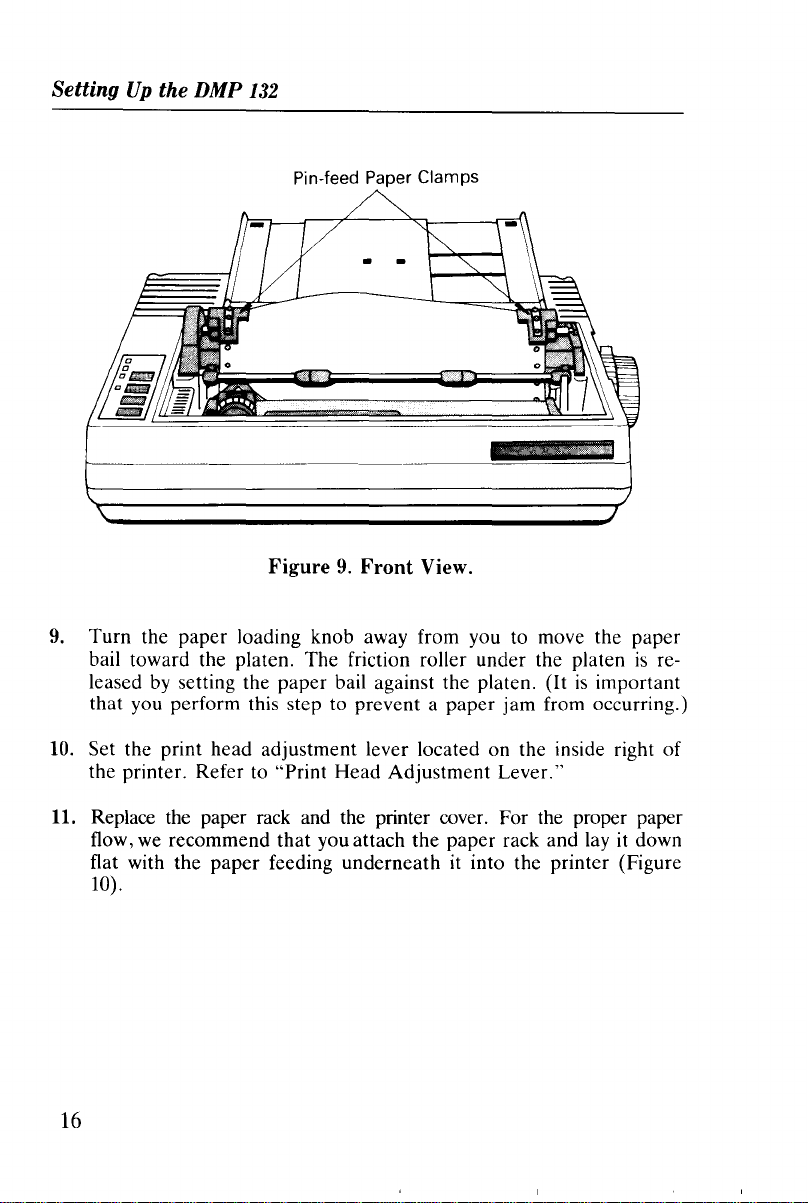

11. Replace the paper rack and the printer cover. For the proper paper

flow, we

flat with

10).

head

Referto"Print

recommend

the

paper

The

paper

bail against

adjustment

Head

that

you attach

feeding

friction roller under the platenisre-

preventapaper

underneath

View.

paper

the

platen. (Itisimportant

jam

from occurring.)

lever located on the inside right

Adjustment

the

Lever."

paper

rack and lay it down

it into the

printer

(Figure

16

of

Page 25

Tractor

Chapter 1

Rack

Print Head

Figure

If

fanfold paperiscorrectly loaded, it should enter between the body of

10.

Fanfold Paper Path.

the printer and the paper rack. Once the paper

on, check the

Components." Press the

illuminated.Ifthe

ALERT

ALERT

indicator on the front panel. Refer to "Printer

ON/OFF

LINE switch if the

lamp remains lit, the

Paper

is

loaded and power

ALERT

paperisprobably

Fanfold Paper

lamp

loaded incorrectly.

If

the

printer

ALERT

is

lamp does not illuminate after the paperisloaded, the

ready for operation.

Hints and Tips on Fanfold Paper Loading

is

is

• Be sure the paperispositioned so thatitcan travel through the

printer without binding.

Do

•

not let printed paper pile on top of unprinted paper. This can

cause the printed paper to be pulled into the paper insertion opening. This could jam the paper feed or damage the printer.

• When using fanfold paper, try to place the paper on the same level

as

the printer.

17

Page 26

Setting

Up

the DMP

132

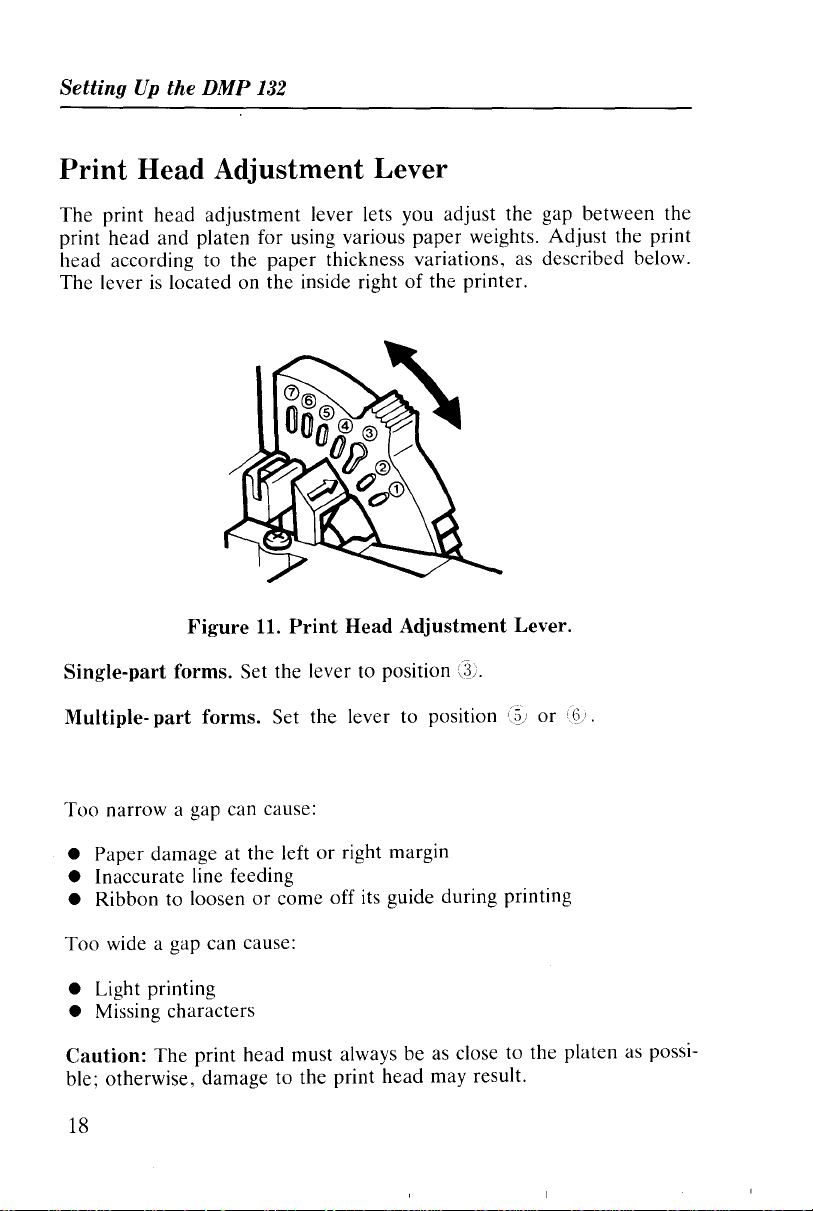

Print Head Adjustment Lever

The

print

head

adjustment

print

head

and platen for using various

head

according to

The

leverislocated on the inside rightofthe

the

lever lets you adjust the gap

paper

paper

thickness variations, as described below.

weights.

printer.

between

Adjust

the

the print

Figure

Single-part forms.

11.

Set the lever to position

Multiple- part forms. Set

Too

narrow a gap can cause:

Paper

•

• Inaccurate line feeding

• Ribbon to loosen

Too

• Light printing

• Missing characters

Caution:

ble; otherwise, damage to

damageatthe leftorright margin

or

come off its guide during printing

wide a gap can cause:

The

print

head

18

Print Head Adjustment Lever.

the

lever to position

must always be as closetothe platen as possi-

the

print

head

may result.

or

Page 27

If

smudging occurs, set the print

ting, by moving the lever toward the front of the printer.

head

adjustment lever to a higher set-

Performing a Self-Test

The

DMP

132 has a built-in self-test feature to check the print quality

and general printer operation before you begin using it.

the

Before running the self-test, be sure to load

paper

since the test prints from one end of the platen to the other.

DMP

Chapter 1

132 with lO-inch

Caution: Printing

the print head.

To

run the self-test:

1.

Press and hold either the

"Printer

2. Set the

ternal buzzer, the

programmed into

If

you press

font.

The

correspondence quality fontisused during

NLQ

switchispressed.

Printing continues until you press the

endisdetected.

on

the platen can shorten the life of the platen and

Components."

POWER

LINE

switch to ON. Starting with the soundofthe in-

DMP

the

FEED,

LINE

132 will print the ASCII96characters pre-

printer.

the

self- testisperformed in the

FEED

ON/OFF

switchorNLQ

the

LINE

switchorpaper

switch. See

standard

test when the

19

Page 28

Setting

Up

the DMP

132

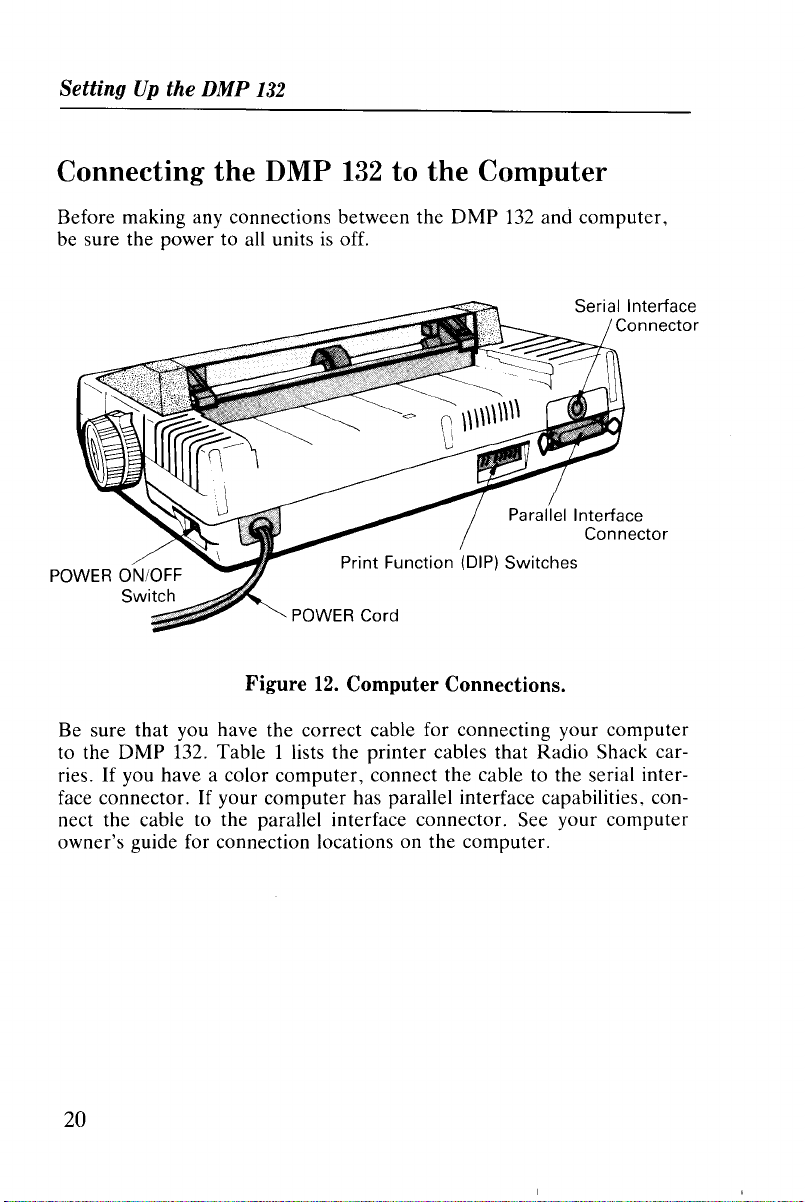

Connecting the DMP

Before making any connections between the

be sure the power to all units

Figure

Be sure that you have the correct cable for connecting your computer

DMP

to the

If

ries.

face connector.

nect the cable to the parallel interface connector. See your computer

owner's guide for connection locations on the computer.

132. Table 1 lists the printer cables that Radio Shack car-

you have a color computer, connect the cable to the serial inter-

If

your computer has parallel interface capabilities, con-

132

to the Computer

is

off.

POWER Cord

12.

Computer Connections.

DMP

132

and computer,

20

Page 29

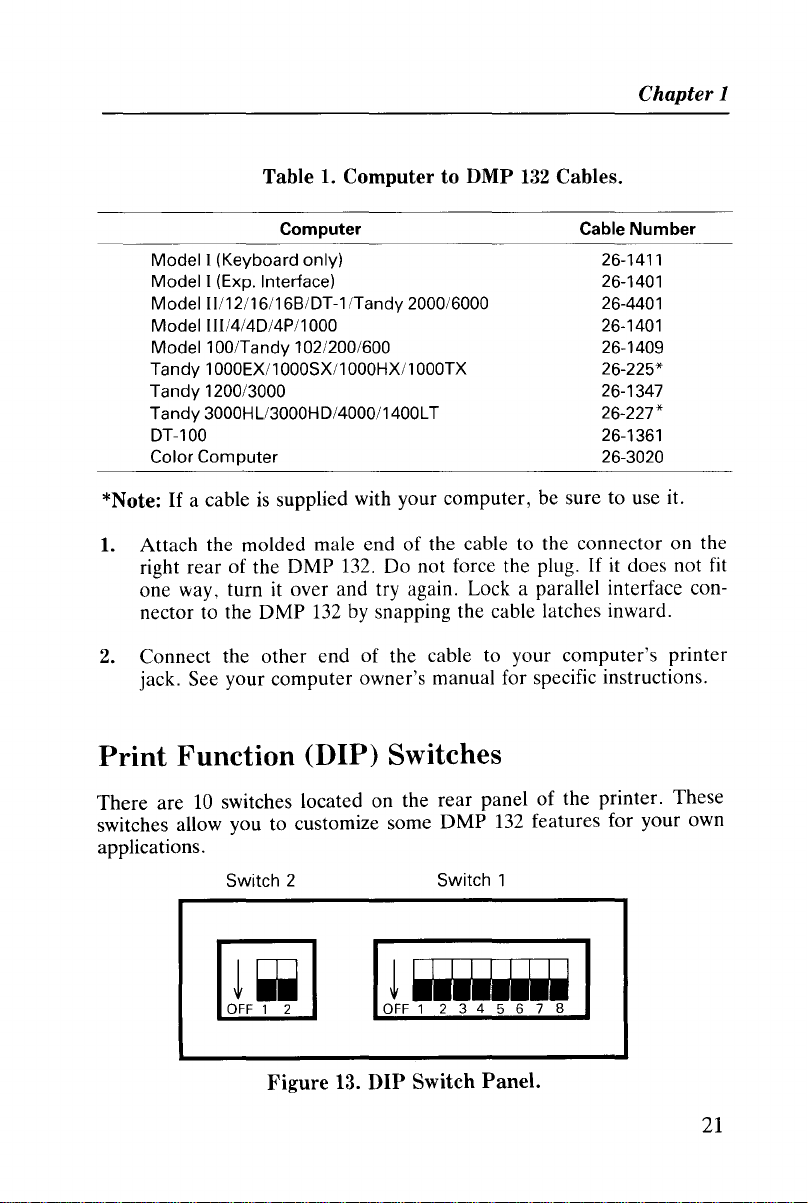

Chapter 1

Table 1. Computer to DMP

Computer

Model I (Keyboard only)

Model I (Exp. Interface)

Model I1/12/16/16BIDT-1 /Tandy 2000/6000

Model III/4/4D/4P/1000

Model100/Tandy

Tandy 1000EX/1 000SX/1 000HX/1

Tandy 1200/3000

Tandy

3000HLl3000HD/4000/1400LT

DT-100

Color

Computer

*Note:

If

a cableissupplied with your computer, be sure to use it.

102/200/600

OOOTX

132

Cables.

Cable

26-1411

26-1401

26-4401

26-1401

26-1409

26-225*

26-1347

26-227*

26-1361

26-3020

Number

1. Attach the molded male end of the cable to the connector on the

right rear of the

one way, turn it over and try again. Lock a parallel interface con-

nector to the

2. Connect the other end of the cable to your computer's printer

jack. See your computer owner's manual for specific instructions.

DMP

DMP

132.

Do

not force the plug.Ifit does not fit

132

by snapping the cable latches inward.

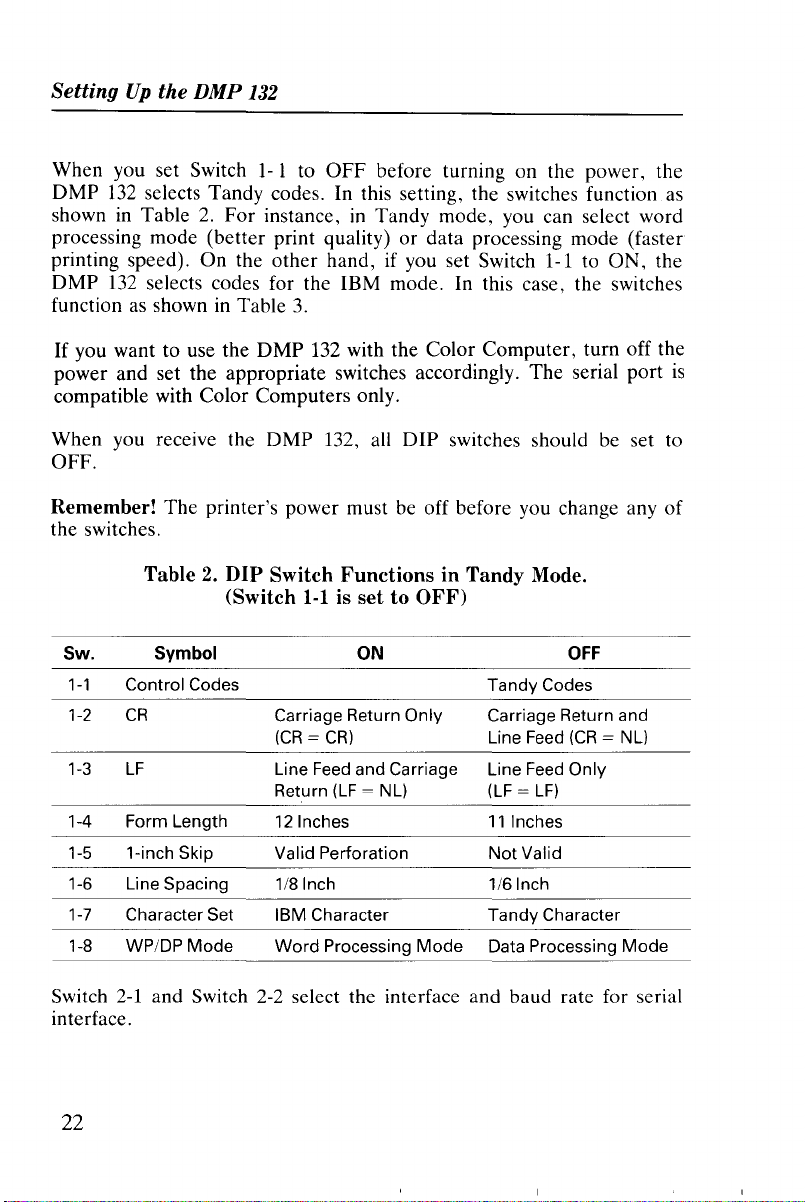

Print

There

switches allow you to customize some

applications.

Function

are10switches located on the

Switch 2

(DIP) Switches

1

.....

OFF

Figure

13.

DIP Switch Panel.

rear

panel of the printer. These

DMP

132

features for your own

Switch 1

1 2 3 4 5 6 7 8

21

Page 30

SettingUpthe DMP

132

When you set Switch1-1 to

DMP

132

selects Tandy codes. In this setting, the switches function

OFF

before turning on the power, the

as

showninTable2.For instance,inTandy mode, you can select word

processing mode (better print quality) or data processing mode (faster

printing speed). On the other hand, if you set Switch 1-1 to ON, the

132

DMP

function

If

you want to use the DMP

selects codes for the IBM mode. In this case, the switches

as

shown in Table

3.

132

with the Color Computer, turn off the

power and set the appropriate switches accordingly. The serial port

compatible with Color Computers only.

When you receive the DMP 132, all DIP switches should be set to

OFF.

Remember! The printer's power must be off before you change any of

the switches.

Table2.DIP

Sw. Symbol ON

1-1

Control Codes

1-2

CR

1-3

LF

1-4

Form Length

1-5

1-inch Skip

1-6 Line Spacing 1/8 Inch 1/6 Inch

1-7

Character Set IBM Character

1-8

WPIDP

Mode

Switch

(Switch

Carriage Return Only Carriage Return and

(CR=CR)

Line Feed and Carriage Line Feed Only

Return

12

Valid Perforation

Word

FunctionsinTandy Mode.

1-1

is settoOFF)

(LF

= NL)

Inches

Processing

Mode

Tandy Codes

Line Feed

(LF=LF)

11

Inches

Not

Valid

Tandy

Data Processing

OFF

(CR

= NL)

Character

Mode

is

Switch

interface.

22

2-1

and Switch

2-2

select the interface and baud rate for serial

Page 31

Chapter 1

Interface

Parallel

Serial

Serial

Serial 2400

Table3.DIP

Baud Rate

600

1200

Switch

(Switch

Sw. Symbol

1-1

Control Codes

1-2

CR

1-3

LF

1-4 Form Length

1-5 1-inch Skip Valid

Perforation

1-6 Line Spacing

1-7

Character Set IBM Character Set 2

1-8

Buffer Full

Codes

Carriage Return Only Carriage Return and

(CR=CR)

Line Feed and Carriage

Return

12

1/8 Inch

Carriage Return Only Carriage Return and

FunctionsinIBM

1-1issettoON)

ON

for

IBM

(LF

= NL)

Inches

Switch

2-1

OFF

OFF

ON

ON ON

2-2

OFF

ON

OFF

Mode.

OFF

Line Feed

Line Feed Only

(LF=LF)

11

NotValid

1/6 Inch

IBM Character Set 1

Line Feed

(CR

Inches

= NL)

Switch

interface.

Interface

Parallel

Serial

Serial

Serial

2-1

and Switch 2-2 select the interface

Baud Rate

600

1200

2400

and

baud rate for serial

Switch

2-1

OFF OFF

OFF

ON

ON

2-2

ON

OFF

ON

23

Page 32

SettingUpthe

DMP

132

Power

The specific power- up sequence depends on your computer. Consult

your computer owner's guide for details on powering up your computer

with peripheral devices, such

In any event, the

on.

It

is

computer.

nected but not turned on, the entire system might operate erratically.

Up

Sequence

POWER

essential that the

If

you turn the power onoroff,orif the

as

printers.

indicator remains lit while the

DMP

132 remains on when connected to the

DMP

DMP

132

is

132

con-

Character Pitch Set Switches

You can set the character pitchofthe

by

once you set the pitch

from the computer has no effect on the printing.

the pitch from the computer or your application software, do not set

the pitch by the front panel method, The default

pitch must he used. Turning the power off and then hack on restores the

pitch to default

CODE.

the front panel method, any control code

o

POWER

DMP

132; however, note that

If

you want to change

CODE

setting of

is

24

ON/OFF LINE

Indicator--

NLQ Indicator

Figure

o

14.

ALERT

Front

.-1--+------>

Panel.

PITCH

Switch

SET Switch

<-

Switch

Switch

Page 33

1.

Be sure the ON LINE indicatorislighted.

2.

Press and hold the PITCH

(ON/OFF

LINE indicator blinks.

Chapter1

LINE) switch until the

ON

3. Press the

--+

(LINE

FEED)

or+-(FORM

FEED)

switch to move

the print head to the position indicated on the printer cover you

as

wish to set

4.

Press the SET (NLO/DP) switch to set the character pitch.

PITCH

~ ~

SELECT

~~

Caracter Pitch

PICA 10

ELITE 12

CONDENSED 17

MICROFONT 17

PROPORTIONAL

a character pitch.

~

~

Figure 15.

Print

Printer

Examples.

-.~"-

~~L.'~'~~

2.b

abcdefghiJklmnopqrstuvwxyz

CONDENSED

.-.j

C

ije

17

Cover.

Print Example

..••

IJ:·::lrGlll::l~rl:l)~S

f i;lh i

.j

k 1

mnopqr'=:.

tu'/!;.}: :\/:::

When the

CODEisselected, you can change the character pitch

sending control codes from the computer.

by

25

Page 34

Setting

Up

the

DMP

132

Hex Dump Function

The

DMP

132 can print the hexadecimal values for data transmitted to

it. This modeisuseful for checking exactly what informationisbeing

received by the

power to the

FEED

switch.

DMP

DMP

132

132.

To

implement this function, turn on the

while simultaneously holding down the

FORM

Before printing, be sure that lO-inch

avoid printingonthe platen. Then press the

the program that you want to check.

To

exit hex dump mode, turn the printer off and then on again.

paperisloaded in the

ON-LINE

switch and run

DMP

132 to

Start-up Checklist

The checklist that follows reminds youofthe things you should do each

time you use the

prepare to use the printer.

w Is the power off?

w Does the printer have enough paper?

w Is the ribbon installed?

w

Is

the printer connected to a power source?

w

Is

the printer connected to the computer?

w Are the

w Turn power on and perform self-test. Does the printer pass the self-

test?

DMP

132. Be sure to check the list each time you

DIP

switch positions correct?

26

Page 35

The

DMP

132isdesigned for three distinct applications:

•

Data

processing

• Word processing

• Graphics

Printing Applications

2

The DMP

computer - one for each application. The three response patterns,

modes, have many similarities, but each has its own unique features.

Data

The only difference between these two modes

line feed commands - commands that determine the direction and distance the paper

• In the word processing mode, each line feed command causes an

immediate paper advancement. Word processing programs (such as

SCRIPSIT®) use immediate line feeds for superscripts, subscripts,

and

• In the data processing mode, a line feed command other than five

special line feed commands (see page

ate line feed. Instead, line feeds are stored

along with other data. When a line

mands stored

paper feed.

In both data processing and word processing modes, the DMP

print in different fonts (type styles) and pitches (character spacing).

One font

spaced character set.

132

has three different responses to software codes from the

processing and word processing modes are for printing characters.

is

in the way they handle

is

fed.

other

special printing styles.

49) does not cause an immediin

the printer's memory

is

printed, the line feed com-

in

memory determine the direction and pitch of ·the

132

can

is

the proportional character set and anotheristhe mono-

or

• Proportionally spaced characters have variable widths.

an M takes up more space than an

create professional-looking documents.

• Monospaced characters are so named because each character

allotted the same space width. This uniformity makes this font preferable for tables and charts that require vertical alignment.

I.

Use proportional characters to

For

example,

is

27

Page 36

Printing Applications

Charactersinthe various fonts are createdina dot- matrix pattern.

Monospaced characters use an

proportionally spaced characters use a matrix

n depends on the width

of

11

by 9 and a

the character being printed.)

of

23

n by

by

18

matrix, while

18.

(The value

of

The print pitch (character spacing)isdesignated by the space the

132

puts between each printed character. The font selectedisalso a

factorindetermining the pitch. Consequently, you must thinkofpitch

in

termsofthe numberofcharacters printed

and 17CPI for normal printing, and 5CPI, 6CPI, and 8.5CPI for elongated printing.

The graphics mode can be used to create custom letterheads, designs,

and special fonts. However, many control codes which can be used in

data processing and word processing modes cannot be usedingraphics

mode. The

send such a code; it simply ignores the code. This includes control

codes that change line feed pitch and direction.

To ensure full coverageofthe paper in graphics mode, the line feed

lengthofthe LF code (10 Dec.)isfixed at 7/72 inch. The five special

line feeds canbeexecuted by dynamic

DMP

132

does not give you an

per

inch - IOCPI, 12CPI,

error

message when you

paper

movement commands.

DMP

Control Codes

Before you proceed, consider how the computer communicates with the

printer.

All informationissent to the

decimal (00- FF hexadecimal). The printer interprets these numbers

according to the American Standard Code for Inforntation Interchange,

commonly referred to as the ASCII code. (See Appendix A for a list

ASCII codes.) Most numbers

bers,orsymbols. However, the numbers 0-31, as well as some special

sequencesofcode numbers, are used to "control" various printer functions. These control codes let you change character sets, select print

modes, underline, superscript, subscript, and perform

functions.

DMP

132

as numbers between 0 and

(or

codes) are printedasletters, num-

other

255

special

of

28

Page 37

Chapter 2

The control codes have different meanings, depending on the current

print mode.

X.

The next few sections demonstrate how some of the control codes

activate various printer functions.

If

a codeisnot recognizedbythe printer,itis

printed

as

Sending Control Codes from BASIC

Some printer features are activatedbya single code, but many func-

or

tions require a sequence of two

sequences begin with decimal

The ESC code notifies the printer that a special sequence

The next code(s) sent determines which printer feature

BASIC, use CHR$ ( ) to send these codes to the printer.

For instance, set up the

and enter BASIC in the normal way.

Then, type and run the following program:

10

REM

20

LPRINT "DATA

30

LPRINT

"MODE"

27

DMP

"jCHR$(27)CHR$(28)j"PROCESSING"

more codes. Most multiple- code

referred toasthe ESC (escape) code.

is

on its way.

is

selected. In

132inTandy modeasdescribed earlier,

Note: The command LPRINT

DMP

to the

PRINT-2, for LPRINT.

Roll the paper forward and look at the results. The word

printed over part of the word

CHR$(28) tell the printer to change the forward line feed to half its

normal distance. The chart in Appendix B shows the various code sequences understood

132.Ifyou are using a Tandy Color Computer, substitute

by

the

is

used in the examples that send codes

DATA.

DMP

Why? The codes CHR$(27) and

132.

MODE

Tandy Computer Code Set

The Tandy computer code setisthe default DMP

is

ly, this code set

Tandy computer, the DMP

processing, and graphics printing modes,

DMP

132

control codes.

used on Tandy computer systems. When you use a

132

lets you use the data processing, word

as

132

code set. Usual-

wellasthe other original

29

Page 38

Printing Applications

Code Set

When you select the code set for IBM, the

80 CPS graphics printer's code set.

you can use the

IBM-compatible systems without code conversion and get the same results as you would with an IBM printer. Detailed information

Chapter

Character

The

character sets as well.

ified ASCII, 64

others are the IBM character sets 1 and

set at any time.

Data

How can you tell which mode the

on? Some reflection on the program you previously

you need to know.

Line feed commands are executed immediately in word processing

(WP) mode, but not

quence did not cause a half- forward line feed until after the first line

was printed. Thus, the printer must be in

feed stays

mode). To see this, type:

for

IBM

DMP

132

with the IBM personal

7, "Selecting a Code Set and

Set

OMP

132

not only has two kindsofcode sets, but three kinds

Oneisa Tandy character set (96 ASCII, 4 mod-

European

Processing

in

effect until further notice

Mode

in

data processing (OP) mode.

If

you select this operation mode,

Character

symbol, and

OMP

DMP

132 emulates the IBM

computer

Set."

30

block graphics), and the

2.

You can use any character

132isin

OP

(another

when itisfirst turned

entered

The

mode.

And

characteristicofOP

system

tells you all

(27, 28) se-

this new line

is

or

in

of

LLIST

The

Word

If

you executed the same program in WP mode, the line feed would

have occurred immediately after the word

and try it. To

ITNTE~

short line feedisstill there.

Processing

enter

Mode

WP

mode, change line10to:

DATA.

Go

into WP mode

30

Page 39

10

LPRINT CHR$(20):REM

and run the program.

CHR$(20)

SELECTS

Chapter 2

WP

MODE

As you can see, the line feed

Note that in WP mode, the

LUST

once.

IENTERI to prove that the half- forward line feed occurs only

The

line feed then returns to normal.

is

immediately executed.

new line feedisonly temporary. Type

Graphics Mode

Graphics modeisvery different from the other two printer modes.

one thing, in graphics mode the

opposed to the ordinary 1/6" pitch in WP and

only a few WP and

letters and symbols, for example, are ignored by the

is

in graphics mode. Instead, numeric data from

into dot patterns for the print head. This lets you produce graphic

printouts

For

10

20

30

40

and run the program.

of

charts, graphs, logos, andsoon.

a quick look at this mode, change your test program to:

LPR1NT

FOR

1=128

LPRINT

NEXT

DP

features are available in graphics mode. Normal

CHR$(18)

TO

CHR$(!);

255

LF

code (10 Dec.) feeds

DP

paper

modes. Furthermore,

DMP

132

128to255istranslated

For

7/72"

when it

as

DMP

132

CHR$(18) puts the

through

Type

again to be sure you are no longeringraphics mode.

255

are interpretedasdot patterns.

LPRINT

CHR$(30) IENTERI to return to WP mode. Try

into graphics mode. The numbers

128

LUST

33

Page 40

Printing Applications

Selecting a Print Mode

To move from one mode to another, refer to Table 4 for the required

_

-,

Page 41

Print Fonts and Character Widths 3

The

DMP

132

has four distinct print (character) fonts:

• Standard and condensed

• Correspondence (NLQ)

• Proportional

• Graphics

Each font

is

created with a unique dot pattern laid outina grid,

or

matrix.

The character styles differ in the size of the matrix and the way in

which individual characters are created within the matrix.

132

Table 5 shows that the DMP

•

10

CPI

•

12

CPI

• 17 CPI

Table5.Character

Font

Style

Standard

Condensed

Correspondence

(NLQ)

Proportional n x

Remember that the

Matrix Size

11x18

11

x 9

23x18

DMP

setting to receive character select control codes.

other than

CODE

by

using the front panel switch, the set character

has three basic dot pitches:

Widths

18

and

Densities.

Pitch

Normal 10 CPl/Elongated 5

Normal12CPl/Elongated 6

Normal

Normal10CPl/Elongated 5

Normal

Variable Width (canbeElongated)

17

CPl/Elongated 8.5

12

CPl/Elongated 6

132 must be set to the default

If

you set the pitch to

CODE

CPI

CPI

CPI

CPI

CPI

pitch

pitch stays valid even if you send control codes from the computer.

35

Page 42

Print

Fonts and Character Widths

If

you change a fontina line without changing the dot pitch, the line

For

prints continuously without pausing.

not pause while changing from proportional printing to correspondence

10

CPI because both use the same dot density.

of

the density

one, the

printing in the new character style. When condensed characters are

printed on the same line with

because

when you change from standard to condensed characters.

the new style characterisdifferent from the preceding

DMP

132

prints the current buffer contents and then resumes

other

of

the changingofthe dot density.

example, the

On

characters, some dot spaceisleft

For

example, this happens

the

DMP

other

132

does

hand, if

Selecting Fonts

You can select character fonts by using the control codes from the com-

NLQ

puter, as well as by using the control panel

switch.

A font style stays in effect until you choose

graphics mode does not change the font.

to the last active font upon leaving graphics mode.

another

The

font style. Entering

DMP

132

simply returns

Standard and Condensed Fonts

Standard characters are composedofan11by 9 dot matrix. The character pitch

tween each character

This font prints in three character widths:

• Standard-IO characters per inch (CPI)

• Standard-12 CPI

• Condensed-17 CPI

You can elongate each

width), which gives you half as many characters

six

different print widths.

To

see the different print widths available, print a few sample lines.

Type this BASIC program:

36

is

determined either by the space the

or

by the dot pitch.

of

these widths (print characters at double-

DMP

132

per

inch and a total

puts be-

of

Page 43

NEW

IENTERI

110

F$="STANDARD

120

N=19:W$="10

130

N=23:W$="12

140

N=20:W$="17

230

240

250

LPRINT

LPRINT

RETURN

CHR$(27)jCHR$(19):STOP

CHR$(27)jCHR$(N)jF$j"CHARACTERS

Then, run the program.

AND

CONDENSED"

CPI":GOSUB

CPI":GOSUB

CPI":GOSUB

Chapter 3

240

240

240

"iW$

STANDARD

STANDARD

STANDARD

The subroutine

DMP 132. Line

ram execution.

Send

27

27

27

27

27

27 29

27

27

27

27

276601

276600

278301

278300

27

27

AND

AND

CONDENSED

CHR$(

19

18

17

23

20

14

15

31

32

88

77

AND

CONDENSED

CONDENSED

CHARACTERS

CHARACTERS12CPI

10

CHARACTERS17CPI

in

Line

240

sends the required control codes to the

230

returns to normal character width and stops prog-

Table6.Font

):

Style Change Commands.

If

you

want:

Standard-10

Correspondence-10

Proportional

Standard-12

Condensed-17

Correspondence-12

Start Elongation

End Elongation

Start Bold

End Bold

Start Italics

End Italics

Start Subscript

Start Superscript

End Sub-/Superscript

Microfont

Print Example

AE:Chijk

ABCh1jk

ABCh1jk

A8Chi j k

ABChijk

ABChljk

AE:C:hi

AE:Ct-,

ABChijk

AE:Chijk

A8Chi

A8Chijk

ADChlJk

A8ChlJk

ABChijk

118ChlU.

CPI

j k

i j k

-ik

37

Page 44

Print

Fonts and Character Widths

Correspondence Font

The second character setisa23by18dot matrix character set for cor-

10

respondence

from. standard-l0

ty.

(23

dots wide fits in the same space as11dots wide.) You can elon-

gate correspondence print to 5 and 6 CPI.

• Correspondence-lO CPI

• Correspondence-12 CPI

and12CPI. The characters have different total widths

or12characters, but print with the condensed densi-

Correspondence characters appear to be the same

ters in normal width, but they are an entirely unique character style.

As an example, add these lines to the program, and then compare the

two styles.

150

F$="CORRESPONDENCE

160

!{=29:W$="12

Run the program.

STANDARD

STANDARD

STANDARD

AND

AND

AND

CONDENSED

CORRESPONDENCE

CORRESPONDENCE

You can see the differences between the characters. The correspond-

is

ence style

support proportional characters.

good for use with word processing programs that do not

CPI":GOSUB

CONDENSED

CONDENSED

CHARACTERS17CPI

CHARACTERS

CHARACTERS12CPI

":N=18:W$="10

240

CHARACTERS

CHARACTERS12CPI

10

as

CPI":GOSUB

cpr

standard charac-

240

10

cpr

Proportional Spacing Font

The third character setisthe proportionally spaced character set. This

font

is

also different from the

width varies from character to character.

11

dots (including two columns of blank dots to allow space between

to

the characters).

other

two fonts, and the character matrix

The

widths vary from 3 dots

38

Page 45

To

see an exampleofthis font, add this line to the program.

170

F$="PROPORTIONAL

180

W$="VARIABLE

Run the program.

":N=17

PITCH":

GOSUB

240

Chapter

3

STANDARD

STANDARD

STANDARD

CORRESPONDENCE

CORRESPONDENCE

PROPORTIONAL

Proportional characters add a quality look to word processing documents by eliminating wide gaps between characters. You can also elongate these characters to twice their normal width.

AND

AND

CONDENSED

AND

CONDENSED

CONDENSED

CHARACTERS

CHARACTERS12CPI

CHARACTERS17CPI

CHARACTERS

CHARACTERS12CPI

CHARACTERS

VARIABLE

10

CPI

10

PITCH

CPI

Graphics Characters

The fourth character setisused for block graphics printing. The characters can be normal10CPI width,12CPI widthorcondensed17CPI.

This setisnot fully compatible with the screen graphicsofmost Tandy

computers. Rather, itisa unique character set.

To

see that the various character widths do not affect graphics charac-

ters, add these lines to the program:

190

N=19:W$="10

200

GOSUB

210

N=23:W$="12

220

N=20:W$="17

260

FOR

270

LPRINT:RETURN

240:

1=224

CPI":F$="GRAPHIC

GOSUB

260

CPI":GOSUB

CPI":GOSUB

TO

254:

LPRINT

":LPRINT

240:

GOSUB

240:GOSUB

260

260

CHR$(I)j:NEXT

I

39

Page 46

Print

Fonts and Character Widths

Run the program.

STANDARD

STANDARD

STANDARD

CORRESPONDENCE

CORRESPONDENCE

PROPORTIONAL

GRAPHIC

1ft

m.

..'"

GRAPHIC

••••••-.,j

GRAPHIC

Since the normal line-to-line spacingis1/6

the graphics characters are 6 dots high, you can create continuous vertical graphics by using the half forward line feed (CHR$(27);

CHR$(28)).

10

20

30

40

50

60

70

80

90

CHARACTERS17CPI

• I

LPRINT

FOR

FOR

READ

NEXT

NEXT

DATA

DATA

DATA

AND

AND

CDNDENSED

AND

CONDENSED

CONDENSED

CHARACTERS17CPI

CHARACTERS

CHARACTERS

CHARACTERS12CPI

10

CHARACTERS12CPI

CHARACTERS

CHARACTERS

...........

.111

DII"""1IIDI",,,,1lIlIlRI

r----.

VARIABLE

10 CPI

..,..

I-

I

LJ...L..j

+p"

CHARACTERS12CPI

llr'

Add

I11""'III-8,...-,..,..

r-,.,.fILJ.q+'A

these lines to the program and run it.

I-

I

U...L..J

-+J'"

A"'IIi..

CHR$(27);CHR$(28)1

R=l

TO

3

C=l

TO

7

N:LPRINT

CHR$(N);

C:LPRINT

R:LPRINT

CHR$(27);CHR$(54);

241,243,241,224,241,243,241

224,244,241,241,241,249,224

241,248,241,224,241,248,241:STOP

CPI

PITCH

..4"'111h...

inch,or12

10 CPI

dots high, and

After you print the results, delete lines10through

40

90.

Page 47

Wrap-Around

The

DMP

132isa dot-addressable printer.

termined

per

word processing mode is:

• Standard-1O=960

• Standard-12=1l52

• Condensed-17=1918

• Correspondence-lO=1920

• Correspondence-12=2304

If

the lengthoftext the

line

feed, and the "leftover" character(s)

next line. This

not by the

line.

The

numberofaddressable dots

(or

the right margin if it has

is

numberofcharacters but by the

called wrap-around.

DMP

132 receives exceeds the limitofdots

been

is

printed at the beginningofthe

Elongated Characters

You

can elongate any font to twice its normal width.

Therefore,

per

line in

set), the

line lengthisde-

numberofdots

data

processing

printer

inserts a line

Chapter 3

or

per

Table8.Elongated Printing.

Send CHR$( ):

27

14

15

27

Enter

the codes to start

times within a line in any mode.

and

Start elongation

End elongation

end

elongated characters any

To:

number

of

43

Page 48

Print Fonts and Character Widths

Boldface

The printer produces boldface characters by widening each character's

line width horizontally.

Send

CHR$( ):

27

31

27

32

Table9.Bold

Printing.

To:

Start bold

End bold

printing

printing

When the printer receives a (27,31) code sequence, it begins bold character printing at the next character it receives.

Mixing Bold

and

Elongated

You can activate both bold and elongated characters at the same time.

Italics

You can print any font on a "slant."

Table

10.

Italic

Printing.

Send

27

27

CHR$( ):

66

1

66

0

To:

Start italic

End italic

printing

printing

The printer starts printing italic characters at the first character it encounters after receiving the (27

If

the printer receives a super-/subscript command during italic charac-

ter

printing, the

DMP

132

66

1) code sequence.

prints the current buffer contents and then

enters the super-/subscript printing mode.

44

Page 49

Chapter 3

Superscript

and

Subscript

In superscript and subscript, character heightiscutinhalf. In superscript character printing, the character prints on the upper half of the

line. In subscript, the character prints on the lower half of the line.

Table

11.

Super-/Subscript

Send

CHR$( ):

27

83

0

27

83

1

27

88

When the printer receives a (27830)or(27831)

Printing.

To:

Start superscript

Start subscript

End super-/subscript

printing

printing

code sequence, sub-

printing

sequent characters printinsuperscriptorsubscript until the printer receives a (27 88) code.Itthen returns to the font that wasinuse before

entering super-/subscript character printing.

The printing speedorhorizontal dot resolutionisfixed at17CPr.

The

underline positionisnot changed.

Microfont

In the microfont mode, all printouts areinsuperscript, with half forward line feeds (1/12 inch)inWP mode,orhalf the designated line

pitchinDP

mode.

Table

12.

Send

CHR$( ):

27

77

Microfont

Printing.

Start

To:

microfont

Microfont stops when you send another font select command, such as

CHR$(27);CHR$(19);orCHR$(27);CHR$(23). (See Table 6 for

other

character style change commands.)

45

Page 50

Print

Fonts and Character Widths

As with superscript, printing pitch for

CPI.

the

microfont

modeisfixedto17

46

Page 51

Buzzer

General Control Codes 4

In IBM