Tandy CM-8, 26-3215 Service Manual

TANDY®

\ .

erv1ce

Color

Monitor

CM-8

for

Color

Computer

3

Catalog

Number

:

26-3215

CUSTOM

MANUFACTURED

FOR

RADIO

SHACK, A DIVISION

OF

TANDY

CORPORATION

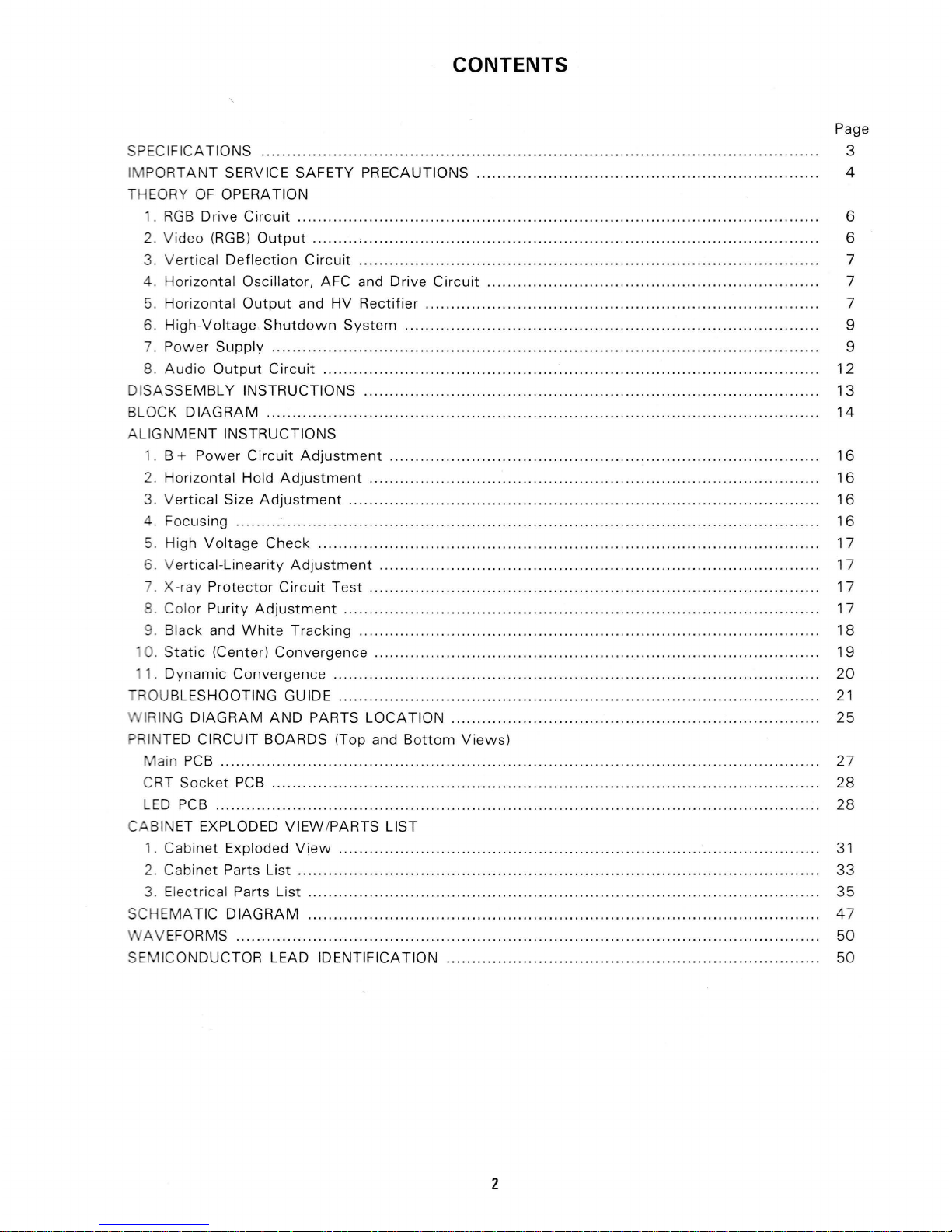

CONTENTS

Page

SPECIFICATIONS

..

. . . . . ... . .... .... .. .... ..

....... ..... ... . . . ... . ... . .

..

. . ....

....... ..

. .

....

. .... .. .. . . ... . .

..

. . . .

..

..... ... 3

I

POR

TANT

SERVICE SAFETY PRECAUTIONS ......... ...... .

......

.......

....

....

.....

...................

.... .. 4

TH

EORY

OF

OPERATION

1.

RGB

Drive

Circuit

...

......

...

....

.......

.......

..... ... .. .. ......

................

...

.........................

.. .

......

. 6

2.

Vi

deo (RGB)

Output

.. ..

.....

,. ...

........

........ ......

.........

........................ .

....

.. ...

.....

.....

......

....

6

3.

Vertical

Deflection

Circuit

................

............... .....

.......

...

....

.......

.. ........ ...... ...........

.....

. 7

4.

Horizontal

Oscillator, AFC and Drive

Circuit

...

.....

...

......

....

...........

....

..............

......

........

. 7

5.

Horizontal

Output

and HV

Rectifier

..... ............. ... ....

.....

........ .

.....

...

.....

........

...........

....

.. 7

6.

High-Voltage

Shutdown

System ....

.....

............ . ... ....

..........

.. ...... ....... ..

.........

..... .

..........

9

7.

Power

Supply

............

.....

...... ......... .

....

............ .. . .... ...............................

...

.................

9

8.

Audio

Output

Circuit

.. .... .

....

.....

......

..............

.. . .

.......

..............

.. ...

.....

......

....

............

....

12

DISASSEMBLY INSTRUCTIONS

.....

.... ... ....... .........

..

.. . . ... ....

......

.... ..... .. ... .. .....

............

.........

13

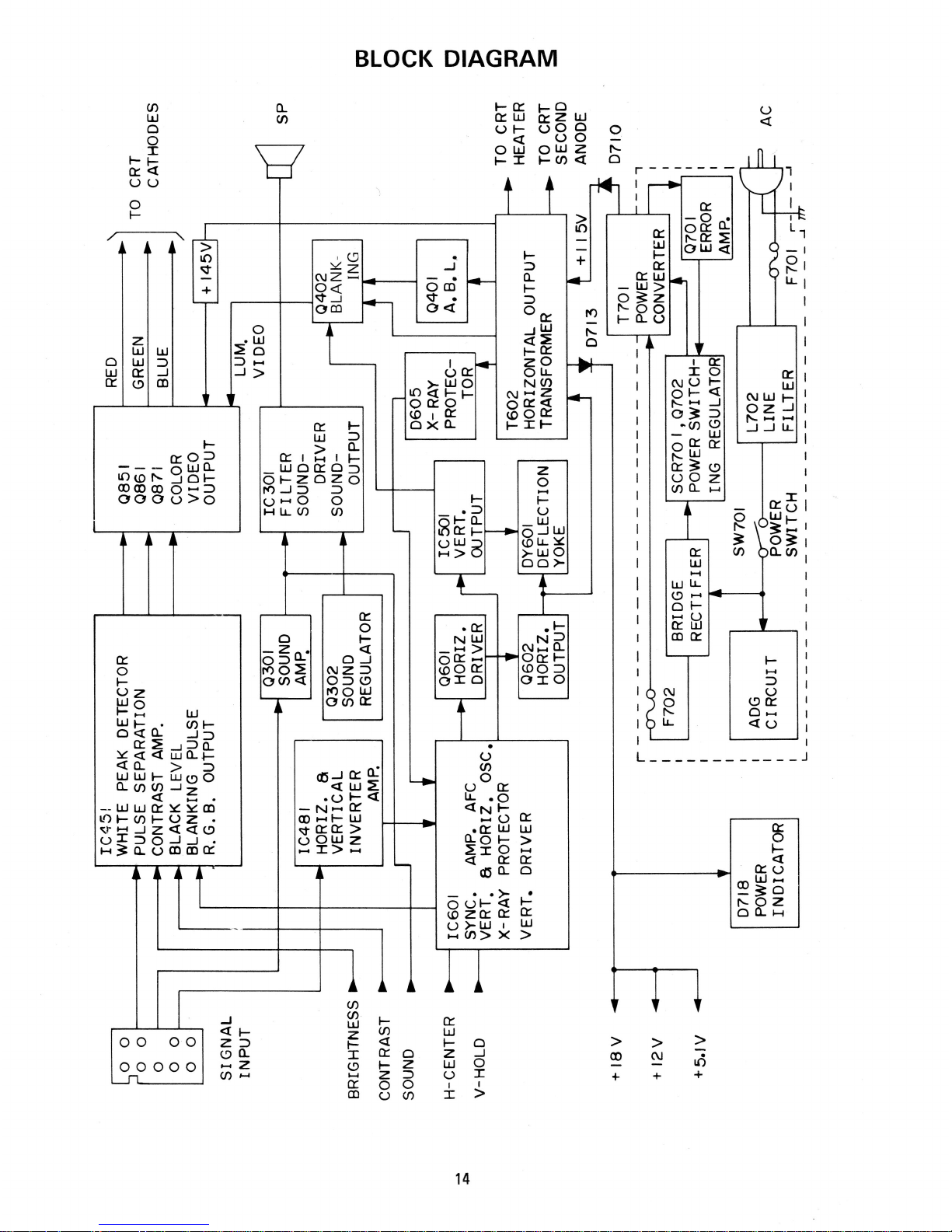

BLOCK

DIAGRAM

.....

.......

.....

.....

........

.....

......

.......

...

..........................

.. .. ..... ..

...........

....

......

14

AL

IGNMENT INSTRUCTIONS

1. B +

Power

Circuit

Adjustment

. . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . .. .. . .. .. .. .. .. .. .. .. .. .. .. . . .. .. . . . .

16

2. Horizontal Hold

Adjustment

. . . . . . . . . . . . .. .

..

. . . .. . . . .. . . . . . .. . . . . .. .

..

..

..

. . .. . . . . .

..

. .

..

. . .... . . . .

.. . ..

. . .... . . . . .

16

3. Vertical Size

Adjustment

....

....

.... .

..

........... ......... ........ .......

........

.....

.......

.....

.....

.....

.... ...

16

4. Focusing . . . .

..

. . . . . .. . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . .

..

..

..

. . . . . .. . . . . . . . .. . . . . . . . . .

.. . ..

. . . . . . .. . . . 1 6

5. High

Voltage

Check

....

........

.......

..

......

......

......

................

.....................

...

...................

17

6. V

ertical-Linearity

Adjustment

.. .....

..

..... . ...... .....

.......... ............

.....

.............

.........

.. .........

17

7. X-ray Protector

Circuit

Test

.... .. ... .. ........... ..... ... .. ... ....................

.......

.......

..........

.........

17

. Color

Purity

Adjustment

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 7

9.

Black and

White

Tracking

. . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 8

0.

Static

(Center)

Convergence

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . .. . . . . . . . . . .. . . . . . . . . . . . . . . . 1 9

. Dy

namic

Convergence

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . .

..

. . . . . . . .

20

OU

BLESHOOTING GUIDE

...........

.........

........

...........

..... .. ..........

.....

.......

....

..... ..

......

..... ....

21

I

RI G DIAGRAM

AND

PARTS

LOCATION

....

....

..... .. ..................

.....

.....

...

............

....

........

..

25

I

TED

CIRCUIT BOARDS (Top and

Bottom

Views)

ain

PCB

...... ... ..

.........

........

...............

..........

........

.... ........

....

..... .... ...

.....

...... .........

....

....

27

CRT

Socket

PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

28

L

ED

PCB

.............. ............. ..

..................

.... .. ..

..........

...... ...... ....

.....

....

.......

...... .... .. ..

.......

28

CA

BINET EXPLODED VIEW/PARTS LIST

1.

Cabinet

Exploded

View

. .. . . . ..... .. . . . . . . . .

....

..... ... . . ......... .. ... . .. .... .. .... ... ....

......

....

..

...

..

. . . . .. . .

31

2. Cab

inet

Parts

List

............ ... ..........

......

...................

....

..... ....... ........... ... ....

.........

.. .. .. ...

33

3. Electrical Parts

List

........

......

....... ...

.............

.... ....... .. ...... .

.............

....

......

................

....

35

SCHEMATIC DI

AGRAM

...... ... .. .. ........ .....

.......

............ ....... ..... ......

.......................

.........

....

. 4 7

AV

EFORMS .................

.....

..........

....

.......

.....

.....

....... .... .. ....... ... ..

.....

...

.....

.....

........

.....

..... 50

SE !CONDUCTOR

LEAD IDENTIFICATION .... ............. ..

.......

.... .. .

..........

...

....

....... ... ..

........... 50

2

SPECIFICATIONS

1 .

Power

2.

AC

3.

Input signal

a)

RGB

b)

Synchronous

c)

Audio

4.

Resolution

a)

Horizontal

b)

Vertical

5.

Brightness

6.

Display

7.

High

8.

Picture

a)

Horizontal

b)

Vertical

9.

Synchronous

a)

Horizontal

Vertical

b)

10.

Screen

input

input

video

color

voltage

linearity

pitch

Description Nominal

AC 1 20V, 60Hz

current

0.75A

RGB

level,

separate

positive

T.T.L. level ,

(default)

480

dots

(non -

interlaced)

(pull-in range)

225

All

23

15.

59

. 7

0.52

lines

colors

kV /Oµ.A

701

kHz

Hz

mm

analog

(default)

positive

going

Limit

+

10%

-30%

0.8 -2.0Vp-p

4.0 -

1.0Vp

30

27.5

10%

10% max

+300

-400

-7

5.0Vp-p

-p

fl.

min. (white

kV

max./Oµ.A

max

.

.

H

z

Hz

(at

75

peak)

ohm)

Note:

exceed

still

might

Nominal

and

some

be

specs

considered

may

represent

drop

the

slightly

acceptable

design

below

; in

specs;

these

no

specs.

case

should a unit

all

units

Limit

should

specs

perform

be able

represent

to

to

approximate

the

absolute

less

than

these -some

worst

within

any

condition

limit

spec

will

that

.

3

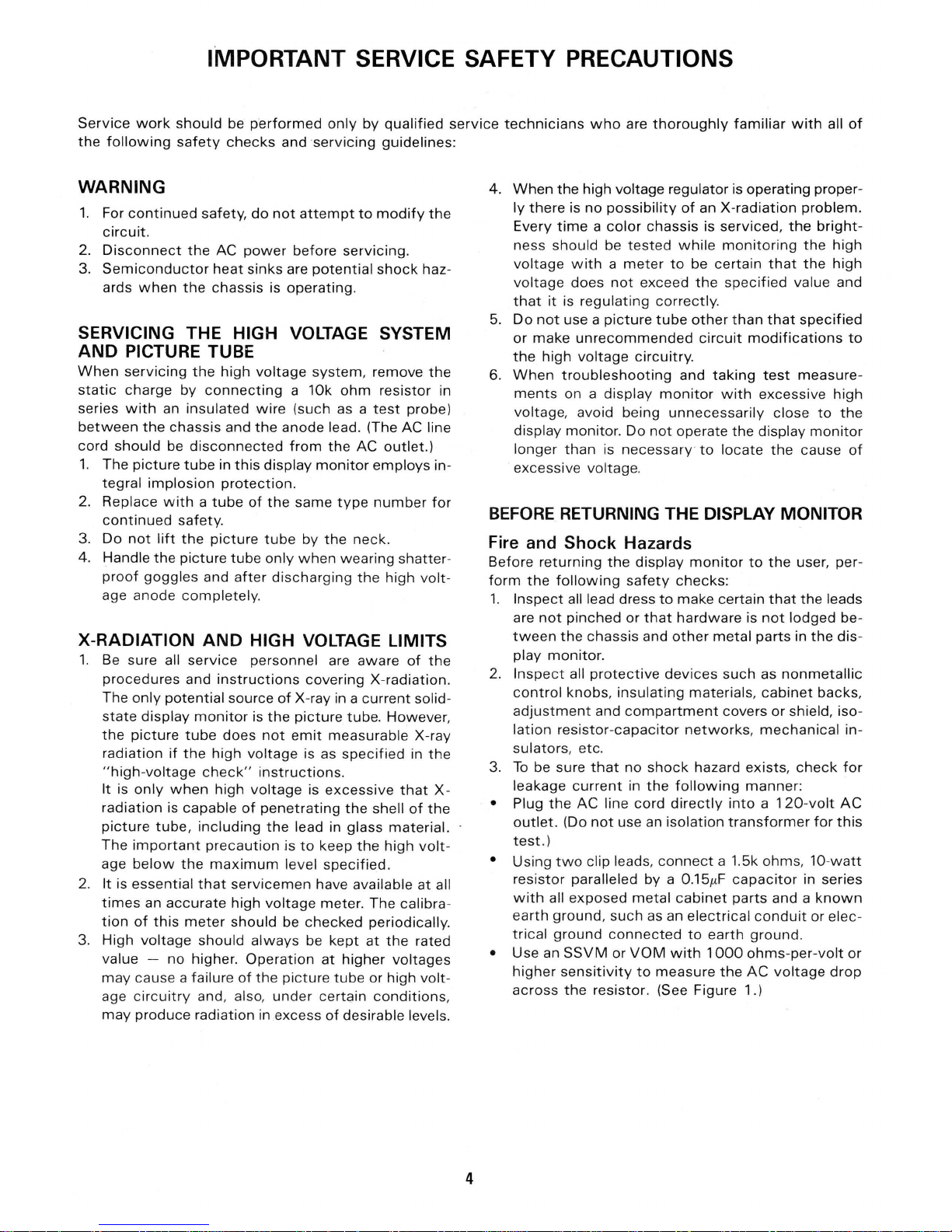

IMPORTANT SERVICE SAFETY PRECAUTIONS

Service

work

should

be

performed

only

by

qualified

service

technicians

who

are

thoroughly

familiar

with

all

of

the

following

safety

checks

and

servicing

guidelines:

WARNING

1.

For

continued

safety,

do

not

attempt

to

modify

the

circuit.

2.

Disconnect

the

AC

power

before

servicing.

3.

Semiconductor

heat

sinks are

potential

shock

haz-

ards

when

the

chassis is

operating.

SERVICING

THE

HIGH

VOLTAGE SYSTEM

AND

PICTURE TUBE

When

servicing

the

high

voltage

system,

remove

the

static

charge by

connecting

a 10k

ohm

resistor in

series

with

an

insulated

wire

(such as a

test

probe)

between

the

chassis and

the

anode lead. (The AC line

cord

should

be

disconnected

from

the

AC

outlet.)

1.

The

picture

tube

in

this

display

monitor

employs

in-

tegral

implosion

protection.

2.

Replace

with a tube

of

the

same

type

number

for

continued

safety.

3.

Do

not

lift

the

picture

tube

by

the

neck

.

4. Handle

the

picture

tube

only

when

wearing shatter-

proof

goggles

and

after

discharging

the

high

volt-

age anode

completely.

X-RADIATION

AND

HIGH

VOLTAGE LIMITS

1.

Be

sure all

service

personnel are aware

of

the

procedures

and

instructions

covering X-radiation.

The

only

potential source

of

X-ray

in a current

solid-

state

display

monitor

is

the

picture

tube. However,

the

picture

tube

does

not

emit

measurable

X-ray

radiation

if

the

high

voltage

is as

specified

in

the

"

high-voltage

check"

instructions

.

It is

only

when

high

voltage

is

excessive

that

X-

radiation

is

capable

of

penetrating

the

shell

of

the

picture

tube,

including

the

lead

in

glass

material.

The

important

precaution

.is

to

keep

the

high

volt-

age

below

the

maximum

level

specified.

2.

It is essential

that

servicemen

have available

at

all

times

an

accurate

high

voltage

meter.

The

calibra-

tion

of

this

meter

should be

checked

periodically.

3.

High

voltage

should

always

be

kept

at

the

rated

value - no higher.

Operation

at

higher

voltages

may

cause a failure

of

the

picture

tube

or

high

volt

-

age

circuitry

and , also,

under

certain

conditions

,

may

produce

radiation in excess

of

desirable levels.

4

4.

When

the

high voltage regulator

is

operating proper-

ly

there

is

no

possibility

of

an

X-radiation

problem.

Every

time a color

chassis

is serviced,

the

bright-

ness should be

tested

while

monitoring

the

high

voltage

with a meter

to

be

certain

that

the

high

voltage

does

not

exceed

the

specified

value and

that

it

is

regulating

correctly

.

5.

Do

not

use a

picture

tube

other

than

that

specified

or

make

unrecommended

circuit

modifications

to

the

high

voltage

circuitry

.

6.

When

troubleshooting

and

taking

test

measure-

ments

on a

display

monitor

with

excessive

high

voltage, avoid being

unnecessarily

close

to

the

display

monitor. Do

not

operate

the

display

monitor

longer

than

is

necessary

to

locate

the

cause

of

excessive voltage.

BEFORE

RETURNING THE DISPLAY MONITOR

Fire and Shock Hazards

Before

returning

the

display

monitor

to

the

user, per-

form

the

following

safety

checks

:

1.

Inspect

all lead dress

to

make certain

that

the

leads

are

not

pinched

or

that

hardware

is

not

lodged

be-

tween

the

chassis

and

other

metal

parts

in

the

dis-

play

monitor.

2.

Inspect

all

protective

devices

such

as

nonmetallic

control

knobs,

insulating

materials,

cabinet

backs,

adjustment

and

compartment

covers or shield, iso -

lation

resistor-capacitor

networks,

mechanical

in-

sulators, etc.

3.

To

be sure

that

no

shock

hazard

exists, check

for

leakage

current

in

the

following

manner:

• Plug

the

AC

line cord

directly

into a 120-volt

AC

outlet.

(Do

not

use an isolation

transformer

for

this

test

.)

•

•

Using

two

clip leads,

connect

a 1.5k ohms,

10-watt

resistor

paralleled by a 0.15µF

capacitor

in series

with

all

exposed

metal

cabinet

parts

and a

known

earth

ground,

such

as an

electrical

conduit

or elec-

trical

ground

connected

to

earth

ground.

Use an

SSVM

or

VOM

with

1000

ohms-per-volt

or

higher

sensitivity

to

measure

the

AC

voltage

drop

across

the

resistor.

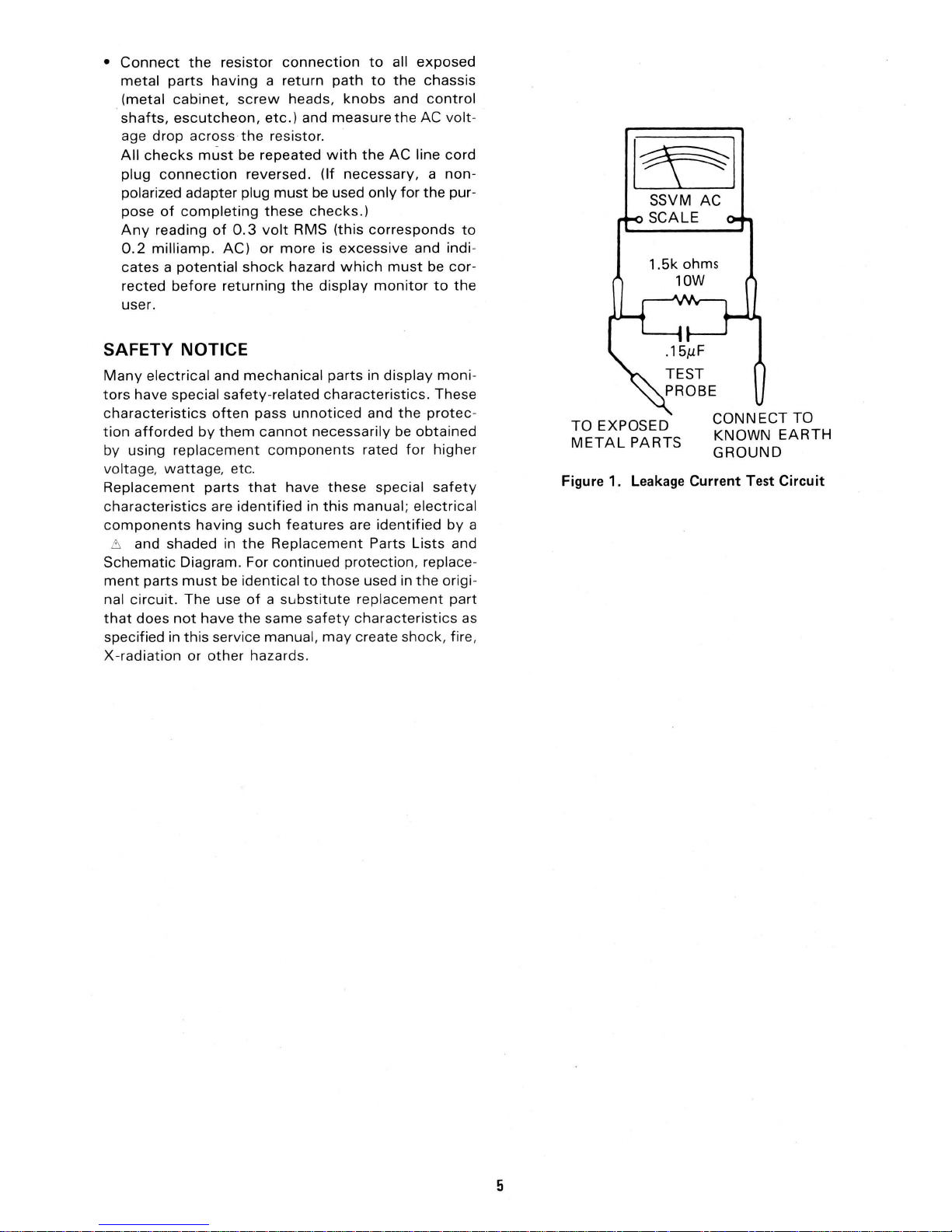

(See Figure 1 . )

•

Connect

the

resistor

connection

to

all

exposed

metal

parts

having a return

path

to

the

chassis

(metal

cabinet,

screw

heads,

knobs

and

control

shafts,

escutcheon,

etc.)

and

measure

the

AC

volt

-

age

drop

across

the

resistor.

All

checks

must

be

repeated

with

the

AC

line

cord

plug

connection

reversed. (If

necessary, a non-

polarized adapter plug

must

be

used

only

for

the

pur-

pose

of

completing

these

checks.)

Any

reading

of

0. 3

volt

RMS (this

corresponds

to

0.2

milliamp.

AC)

or

more

is

excessive

and

indi-

cates a potential

shock

hazard

which

must

be

cor-

rected

before

returning

the

display

monitor

to

the

user.

SAFETY NOTICE

Many

electrical

and

mechanical

parts

in

display

moni-

tors

have special

safety-related

characteristics.

These

characteristics

often

pass

unnoticed

and

the

protec-

tion

afforded

by

them

cannot

necessarily

be

obtained

by

using

replacement

components

rated

for

higher

voltage,

wattage,

etc.

Replacement

parts

that

have

these

special

safety

characteristics

are

identified

in

this

manual;

electrical

components

having

such

features

are

identified

by

a

6 and shaded in

the

Replacement

Parts

Lists

and

Schematic

Diagram. For continued

protection,

replace-

ment

parts

must

be

identical

to

those

used in

the

origi-

nal

circuit.

The

use

of a substitute

replacement

part

that

does

not

have

the

same

safety

characteristics

as

specified in

this

service manual,

may

create

shock

, fire,

X-radiation

or

other

hazards.

5

SSVM

AC

SCALE

TO EXPOSED

METAL

PARTS

CONNECT

TO

KNOWN

EARTH

GROUND

Figure 1.

Leakage

Current Test Circuit

THEORY

OF

OPERATION

1.

RGB

Drive Circuit

IC451 is a linear

IC

to

amplify

the

RGB

signals.

The DC

restoration

system

of

IC451 provides

control

of

the

simultaneous

amplitude

(contrast)

and DC level

(brightness)

of

RGB

.

The

synchronizing

signal, as a DC restoration pulse, is

fed

from

pin @

of

IC601

to

pins @ and @

of

IC451.

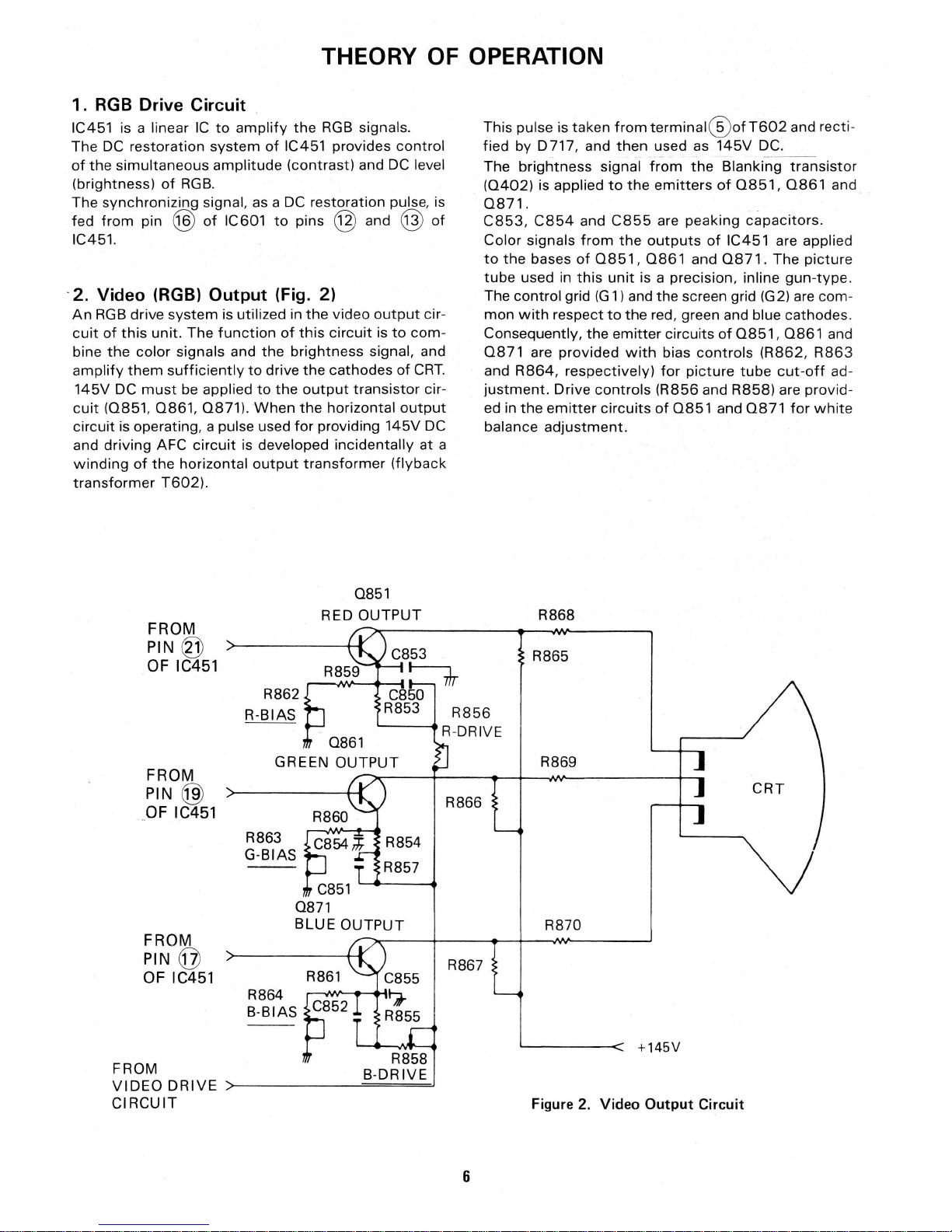

· 2. Video (RGB) Output (Fig. 2)

An

RGB

drive

system

is

util

ized in

the

video

output

cir-

cuit

of

this

unit. The

function

of

this

circuit

is

to

com-

bine

the

color

signals and

the

brightness

signal, and

amplify

them

sufficiently

to

drive

the

cathodes

of

CRT.

145V

DC

must

be applied

to

the

output

transistor

cir-

cuit

(0851,

0861,

0871).

When

the

horizontal

output

circuit

is operating, a pulse used

for

providing

145V

DC

and

driving

AFC

circuit

is developed

incidentally

at a

winding

of

the

horizontal

output

transformer

(flyback

transformer

T602).

0851

RED

OUTPUT

FROM

PIN@

OF

IC451

R862

R-BIAS

This pulse is taken

from

terminal@ofT602

and recti-

fied by

D717

, and

then

used as

145V

DC.

--··-

-

The

brightness

signal

from

the

Blanking

transistor

(0402)

is applied

to

the

emitters

of

0851,

0861

and

0871.

C853,

C854

and

C855

are

peaking

capacitors.

Color signals

from

the

outputs

of

IC451 are applied

to

the

bases

of

0851, 0861

and

0871

. The

picture

tube

used in

this

unit

is a precision, inline

gun-type.

The control grid

(G

1)

and the screen grid (G2) are com-

mon

with

respect

to

the

red, green and blue cathodes.

Consequently, the

emitter

circuits

of

0851,

0861

and

0871

are

provided

with

bias

controls

(R862, R863

and

R864,

respectively)

for

picture

tube

cut-off

ad-

justment.

Drive

controls

(R856

and

R858)

are provid-

ed in

the

emitter

circuits

of

0851

and

0871

for

white

balance

adjustment.

R868

R865

R856

0861

R-DRIVE

R869

FROM

PIN@)

CRT

R866

OF

IC451

R863

G-BIAS

C851

0871

BLUE

OUTPUT

R870

FROM

PIN@

R867

OF

IC451

R861

R864

C852

B-BIAS

---

+145V

FROM

R858

B-DRIVE

VIDEO

DRIVE

CIRCUIT

Figure 2.

Video

Output

Circuit

6

3.

Vertical Deflection Circuit

The

vertical

to

plied

Pin @

oscillator

controlled

be

varied

obtained

between

The

oscillator

through a buffer

0 , is

The

sawtooth

an

AC

The

output

(R

507)

The

verti

tegrating

sawtooth

4.

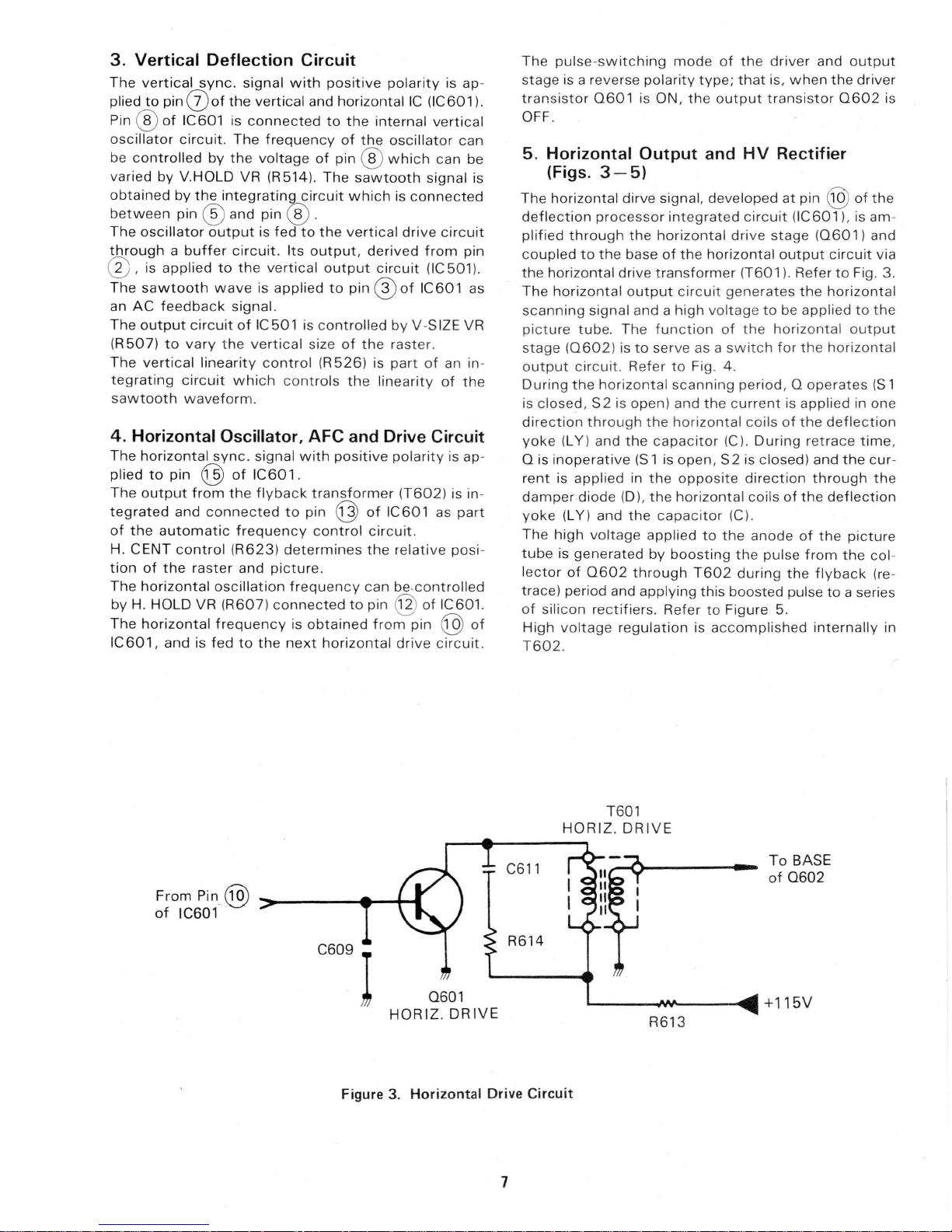

Horizontal Oscillator, AFC and Drive Circuit

The

horizontal

to

plied

The

output

tegrated

of

the

H.

CENT

tion

of

The

horizontal

by H. HOLD VR

The

horizontal

IC601, and

sync.

signal

pin

0of

the

vertical

of

IC601 is

circuit.

by

V.HOLD VR (R514).

by

the

pin @

applied

feedba

circuit

to

vary

ca l

linearity

circuit

waveform

pin @

from

and

automatic

control

the

raster

is

connected

The

by

the

voltage

integrating

and

pin @ . . . . .

output

ck

connected

fed

is

circuit.

to

the

wave

is

signal.

of

IC

the

vertical

control

which

.

sync.

signal

of

IC601

the

flyback

frequency

(R623)

and

oscillation

(R607)

frequency

to

the

with

and

frequency

of

The

circuit

fed

to

the

Its

output,

vertical

applied

501

is

controlled

size

(R

controls

with

.

transformer

to

pin @

control

determines

picture.

frequ

connected

is

obtained

next

horizontal

positive

horizontal

to

the

of

the

pin @

sawtooth

which

vertical

derived

output

to

pin@

of

the

526)

the

positive

of

circuit.

the

ency

can be.

to

pin @

polarity

IC

internal

oscillator

which

is

connected

drive

circuit

of

by

V-S IZE VR

raster

is

part

line

arity

polarity

(T602)

IC601

relative

from

pin @

drive

from

IC601

of

controlled

of

is ap-

(IC601

vertical

can

can

signal

c1rcu1t

(IC 501

.

an in -

of

is ap-

is in-

as

part

posi

IC601.

circuit.

be

is

pin

).

as

the

of

The

stage

transistor

).

OFF.

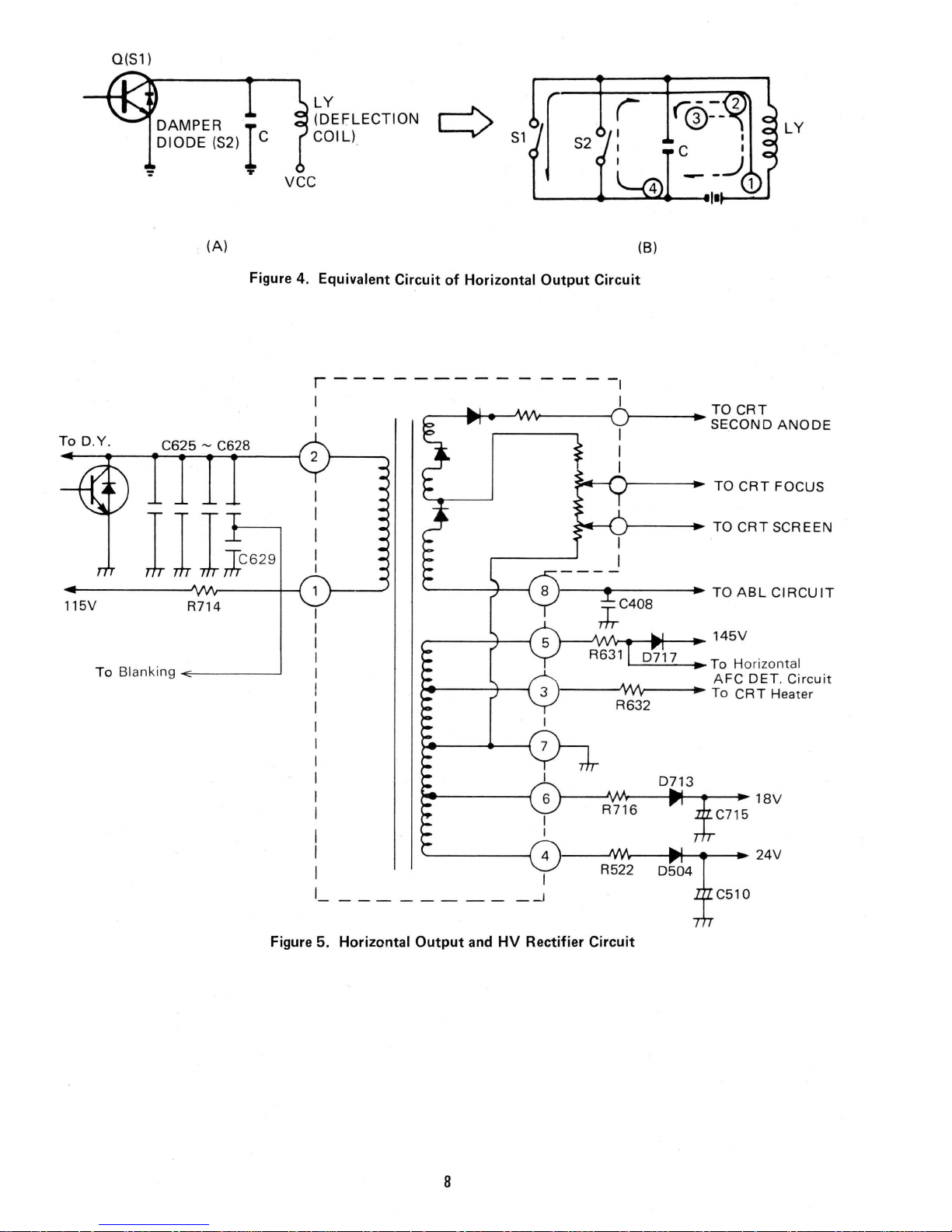

5. Horizontal Output and

The

deflection

plified

coupled

the

The

scanning

picture

stage

output

During

is

direction

yoke

O is

rent

damper

yoke

The

-

tube

lector

trace) period and

of

High

T602.

pulse-switching

is a reverse

0601

(Figs.

horizontal

horizontal

horizontal

closed,

inoperati

silicon

3-5)

processor

through

to

the

signal

tube. The

(0602)

circuit.

the

horizontal

S2

through

(LY)

and

ve

is

applied

diode

(LY) and

high

voltage

is

generated

of

0602

rectifiers. Refer

voltage

drive

is

regulation

mode

polarity

is ON,

dirve signal,

the

base

output

and a

is

to

Refer

open)

the

(S

in

(D),

the

through

applying

the

integrated

horizontal

of

the

transformer

circuit

high

function

serve as a

to

scanning

and

the

horizontal

capacitor

1 is

open,

the

opposite

the

horizontal

capacitor

applied

by

boosting

of

the

type;

that

output

transistor

HV

developed

circuit

drive

horizontal

(T601

generates

voltage

Fig. 4.

the

to

T602 during

this

to

is

accomplished

to

of

the

switch

period, 0 operates

current

coils

(C).

During

S2

is

closed)

direction

coils

(C).

the

anode

the

pulse

boosted

Figure

driver

is,

and

when

Rectifier

at

pin @

(IC601

stage

(0601)

output

).

Refer

the

be

applied

horizontal

for

the

is

applied

of

the

retrace

and

through

of

the

of

the

from

the

flyback

pulse

5.

internally

output

the

driver

0602

of

the

),

is

am-

and

circuit

horizontal

horizontal

deflection

deflection

to

to

Fig. 3.

to

output

in one

time

the

picture

the

a series

via

the

(S

cur

the

co l-

(re

is

1

,

-

-

in

From

Pin.@

of

IC601

C609 l

HORIZ. DRIVE

C611

R614

0601

HOR IZ. DR

IVE

Figure 3. Horizontal Drive Circuit

7

T60

1

R613

To

of

BASE

0602

O(S1)

To

D.Y.

DAMPER I

DIODE

':'

C625 - C628

(S2)

(A)

.,.

C

LY

(DEFLECTION

COIL)

vcc

c::)

s1J

I

r

r

52

1:

L@I--

"'----------"4---·1·---

Figure 4. Equivalent Circuit of Horizontal Output Circuit

r---

1

(B)

i------TO

)-------

1-----

r@=--

2

c - :

_ _)1

CRT

SE.COND

TO

CRT

TO

CRT

LY

ANODE

FOCUS

SCREEN

115V

To

Blanking

R714

~

---

~

I_

---

Figure 5. Horizontal Output

---

--

and

1----'Vlt1----

l----JV.,..,_---1t-.....-__,~18V

HV

Rectifier Circuit

'------To

AFC

To

C715

C510

H

orizontal

DET

CRT

Heater

. Circuit

8

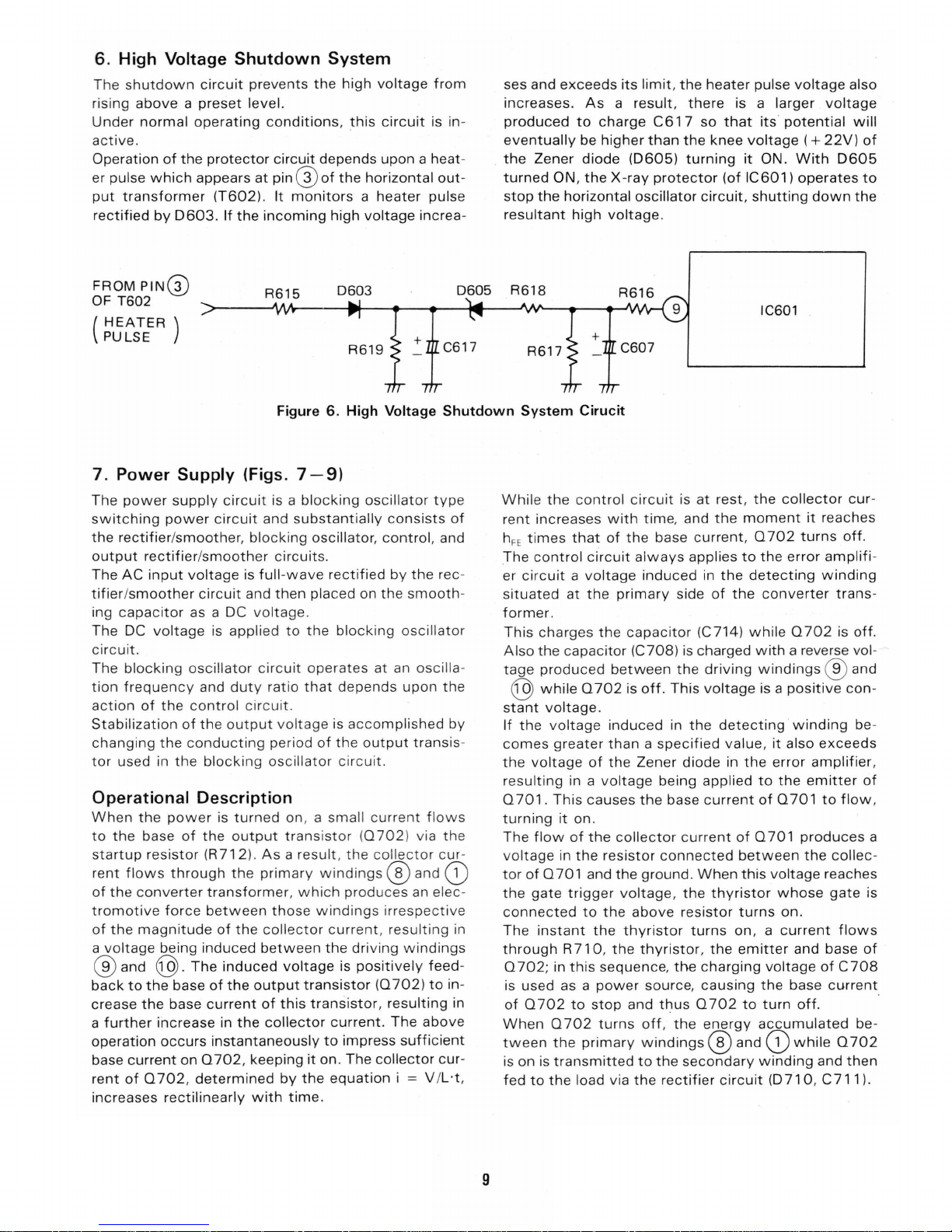

6.

High

Voltage

Shutdown

System

The

shutdown

circuit

prevents

the

high

voltage

from

rising

above a preset

level.

Under

normal

operating

conditions,

this

circuit

is inactive.

Operation

of

the

protector

circuit

depends

upon a heat

-

er

pulse

which

appears

at

pin@

of

the

horizontal

out

-

put

transformer

(T602). It

monitors a heater

pulse

rectified

by

0603. If

the

incoming

high

voltage

increa-

R615

0603 0605

ses

and

exceeds

its

limit, the

heater

pulse

voltage

also

increases.

As a result,

there

is a

larger

voltage

produced

to

charge

C617

so

that

its

potential

will

eventually

be

higher

than

the

knee

voltage

( +

22V)

of

the

Zener

diode

(0605)

turning

it

ON.

With

D605

turned

ON,

the

X-r

ay

protector

(of

IC601)

operates

to

stop

the

horizontal

oscillator

circuit,

shutting

down

the

resultant

high

voltage.

R618

FROM

PIN@

OF

T602

~~-91~--41>----41>-----4--~-l\.IV'-~---~----'VVI

IC601

(

HEATER

)

PULSE

R619

+

+

C617

C607

Figure

6.

High

Voltage

Shutdown

System

Cirucit

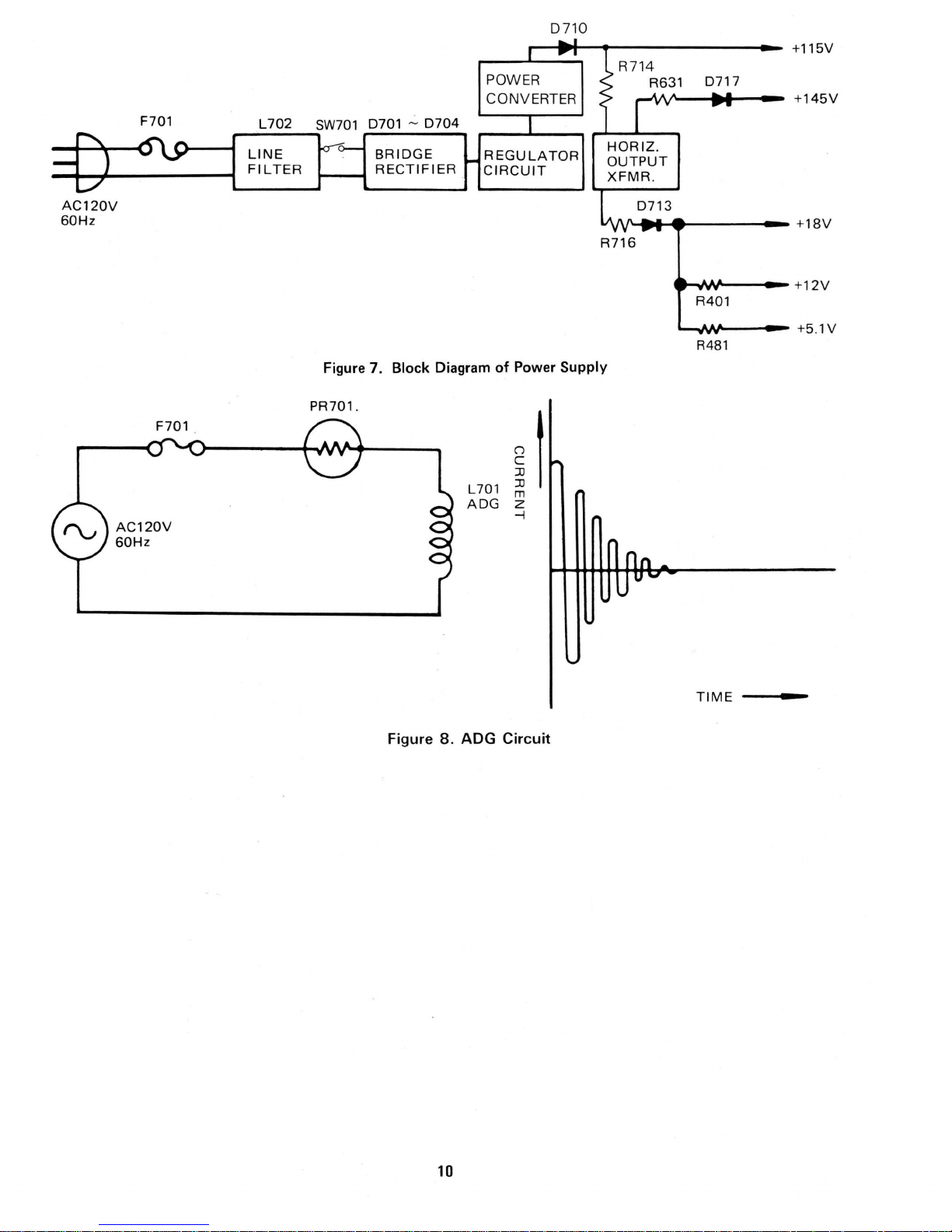

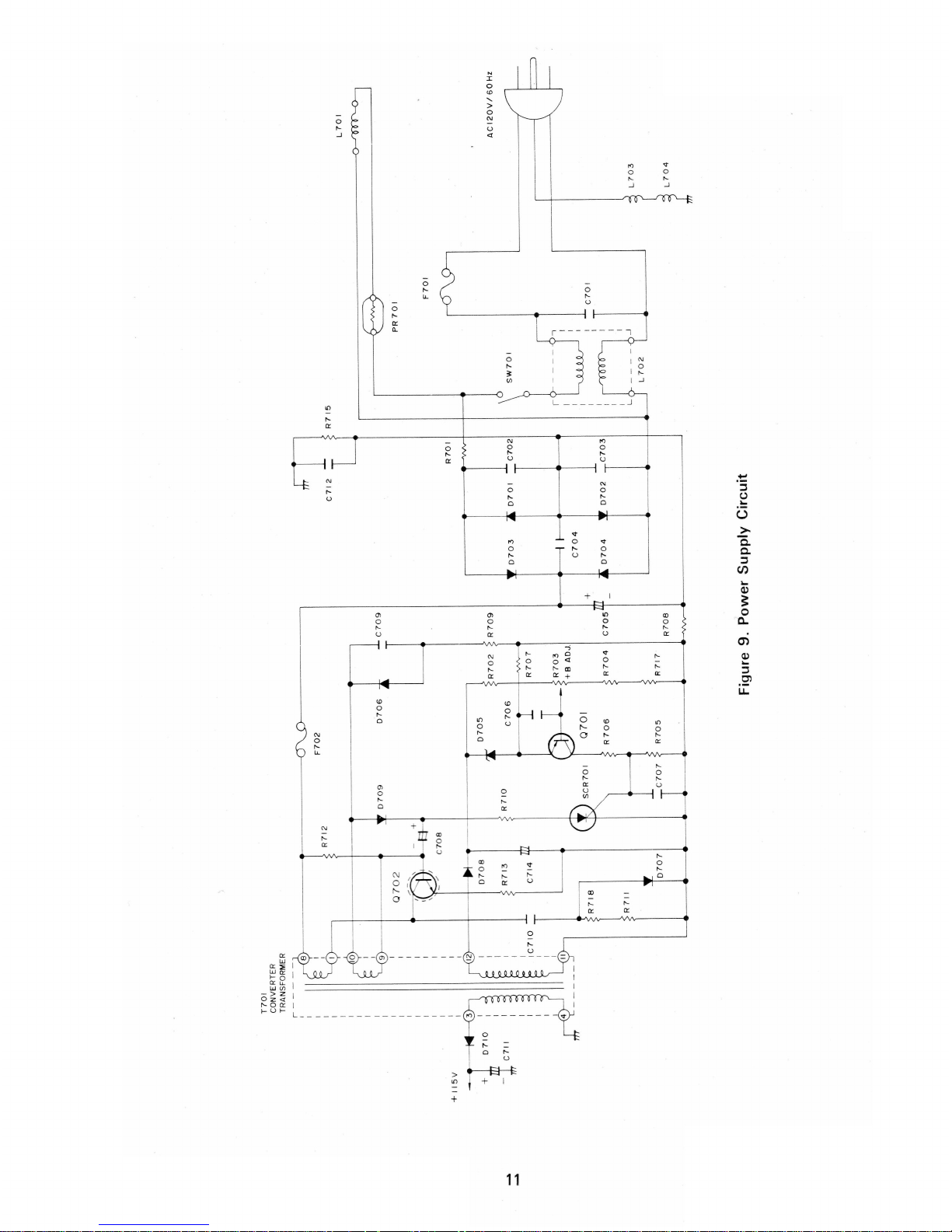

7.

Power

Supply

(Figs.

7-9)

The

power

supply

circuit

is a

blocking

oscillator

type

switching

power

circuit

and

substantially

consists

of

the

rectifier/smoother, blocking

oscillator,

control,

and

output

rectifier/smooth

er

circuits.

The

AC

input

voltage

is

full-wave rectified

by

the

rec

-

tifier/smoother

circuit

and

then

placed

on

the

smooth-

ing

capacitor

as a DC

voltage.

The

DC

voltage

is

appli

ed

to

the

blocking

oscillator

circuit

.

The

blocking

oscillator

circuit

operates

at

an

oscilla

-

ti

on

frequency

and

duty

ratio

that

depends

upon

the

action

of

the

control

circuit.

St

abilization

of

the output

voltage

is

accomplished

by

changing

the

conducting

period

of

the output transis-

tor

used

in

the

blocking

oscillator circuit.

Operational

Description

When

the

power

is

turned on, a

small

current

flows

to

the

base

of

the

output

transistor

(0

702

) via t he

startup

resistor (R712

).

As a result, the

collector cur-

rent

flows

through

the pri

mary

windings@

and

Q)

of

the

converter

transformer, whi

ch

produ

ce s an elec -

tromotive

force

between

those

windings irrespective

of

the

magnitude

of

the

collector

current,

resulting

in

a

voltage

being

indu

ced

between

the

driving windings

@

and

@.

The

induced

voltage

is

positively

feed-

back

to

the

base

of

the

output

transistor

(0

702) to

in-

crease

the

base

current

of

this

transistor, resulting

in

a

further

increase

in

the

collector

current.

The

above

operation

occurs

instantaneously

to

impress

sufficient

base

current

on 0 702, keeping

it

on.

The

collector

cur

-

rent

of 0 702, determined

by

the

equation

i = V /L ·t,

increases

rectilinearly

with

time.

9

While

the

control

circuit

is

at

rest, the

collector

cur

-

rent

increases

with

time, and

the

moment

it

reaches

h

FE

times

that

of

the

base

current, 0 702

turns

off.

.

The

control

circuit

always

applies

to

the

error

amplifi

-

er

circuit a voltage

induced

in

the

detecting

winding

situated

at

the

primary

side

of

the

converter

trans

-

former

.

This

charges

the

capacitor

(C714)

while

0702

is

off

.

Also

the

capacitor (C708)

is

cha

rged

with

a reverse vol-

ta

ge

produced

between

the

driving

windings

@

and

@

while 0 702

is

off. This

voltage

is a

positive

con-

stant

voltage

.

If

the

voltage

induced

in

the

detecting

winding

be -

comes

greater

than a specified

value,

it

also

exceeds

the

voltage

of the

Zener

diode

in

the

error

amplifier,

resulting

in a

voltage

being

applied

to

the

emitter

of

0701. This

causes

the

base

current

of

0701

to

flow

,

turning

it on.

The

flow

of

the

collector

current of

0701

produces

a

voltage

in

the

resistor

connected

between

the

collec

-

tor

of

0701

and

the

ground. When

this

voltage

reaches

the

gate

trigger

voltage, the

thyristor

whose

gate

is

connected

to

the

above

resistor

turns on.

The instant

the

thyristor

turns on, a

current

flows

through

R710, the

thyristor, the

emitter

and

base

of

0

702

; in

this

sequence, the

charging

voltage

of C 708

is

used

as a

power

source, causing

the

base

current

.

of 0 702

to

stop

and

thus 0 702

to

turn

off.

When Q 702

turns

off,

the

energy

accumulated

be-

tween

the

primary

windings@

and

G)

while

0702

is

on

is

transmitted

to

the

secondary

winding

and

then

fed

to

the

load

via

the

rectifier

circuit

(D

71

0, C 711).

AC120V

60Hz

F701

F701

L702

LINE

FILTER

SW701

Figure 7.

PR701 .

POWER

CONVERTER

0701

,...:,

0704

BRIDGE

RECTIFIER

Block Diagram of Power Supply

REGULATOR

CIRCUIT

0710

R714

HORIZ.

OUTPUT

XFMR

R716

R631

.

0717

R401

R481

+115V

+145V

+18

V

+12V

+5.1V

AC120V

60Hz

Figure 8 .

L701

ADG

ADG

~

f

m

z

--i

Circuit

TIME

---

10

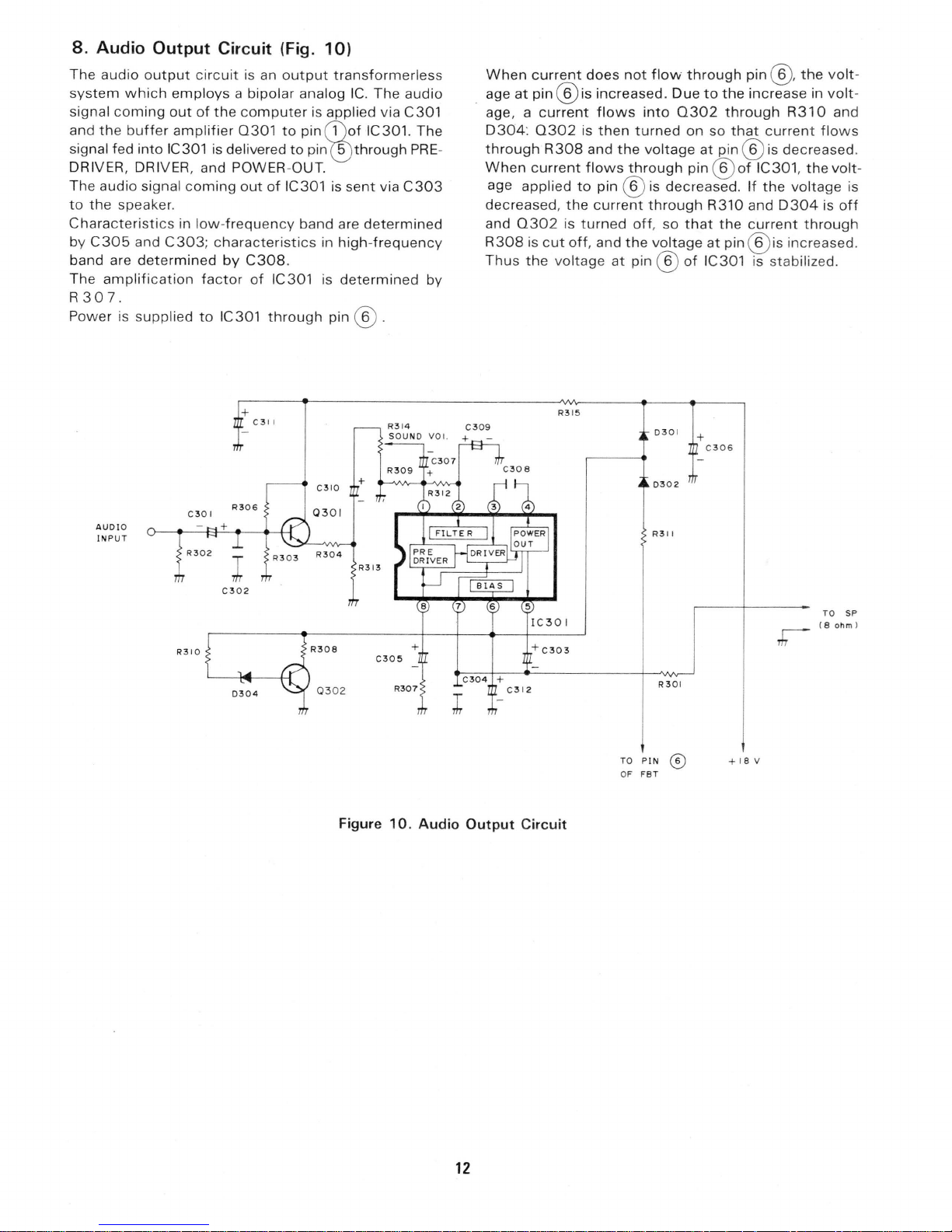

8.

Audio Output Circuit (Fig.

The audio

system

signal

and

signal fed into

DR

IVER, DRIVER, and POWER-OUT.

The audio signal

to

the

Characteristi

by

C305

band are

The

30

R

Power

output

which

coming

the

buffer

employs

out

amplifier

IC301

speaker.

cs in

and

C303; characteristi

determined

amplification

7.

is

supplied

circuit

of

the

is

delivered

coming

low

-frequ e

by

factor

to

IC301

is an

a bipolar analog

computer

0301

out

of

ncy

C308

of

IC301 is

through

+

C3 1 I

10)

output

to

IC301 is

transformerless

is

applied via C301

pin(Dof

to

pin ®

band are

cs in

high-frequency

.

determined

pin

IC.

The

IC301. The

through

sent

via

determined

@.

R3

SOUN D

audio

PRE

C303

by

14

VOi.

-

C3

When

current

age

at

pin@

age, a

current

D304: 0302

through

When

R308

current

age applied

decreased,

and

0302

R308

is

cut

Thus

the

09

does

is increased.

flows

is

then

and

flows

to

pin @

the cur

is

turned

off

, and

volt

age

R3

15

not

turned

the

through

rent

off

the

at

pin @

flow

Due

into

0302

voltage

is

decreased

through

, so

voltage

0 3 0 1

03

0 2

through

on so

pin @

that

of

+

pin

@,

to

the

increase in

through

that

at

pin@ is decreased .

of

. If

R310 and

the

at

pin @ is increase d.

R310

current

IC301 ,

the

D304

current

IC301 is stabilized.

C3 0 6

the

volt

volt

and

flows

the

volt

voltage

is

through

-

-

-

is

off

R310

03

02

Figure 10. Audio Output Circuit

TO

OF

PIN

FBT

R3

1 I

TO SP

( 8 ohm )

R3

01

®

+1

a v

12

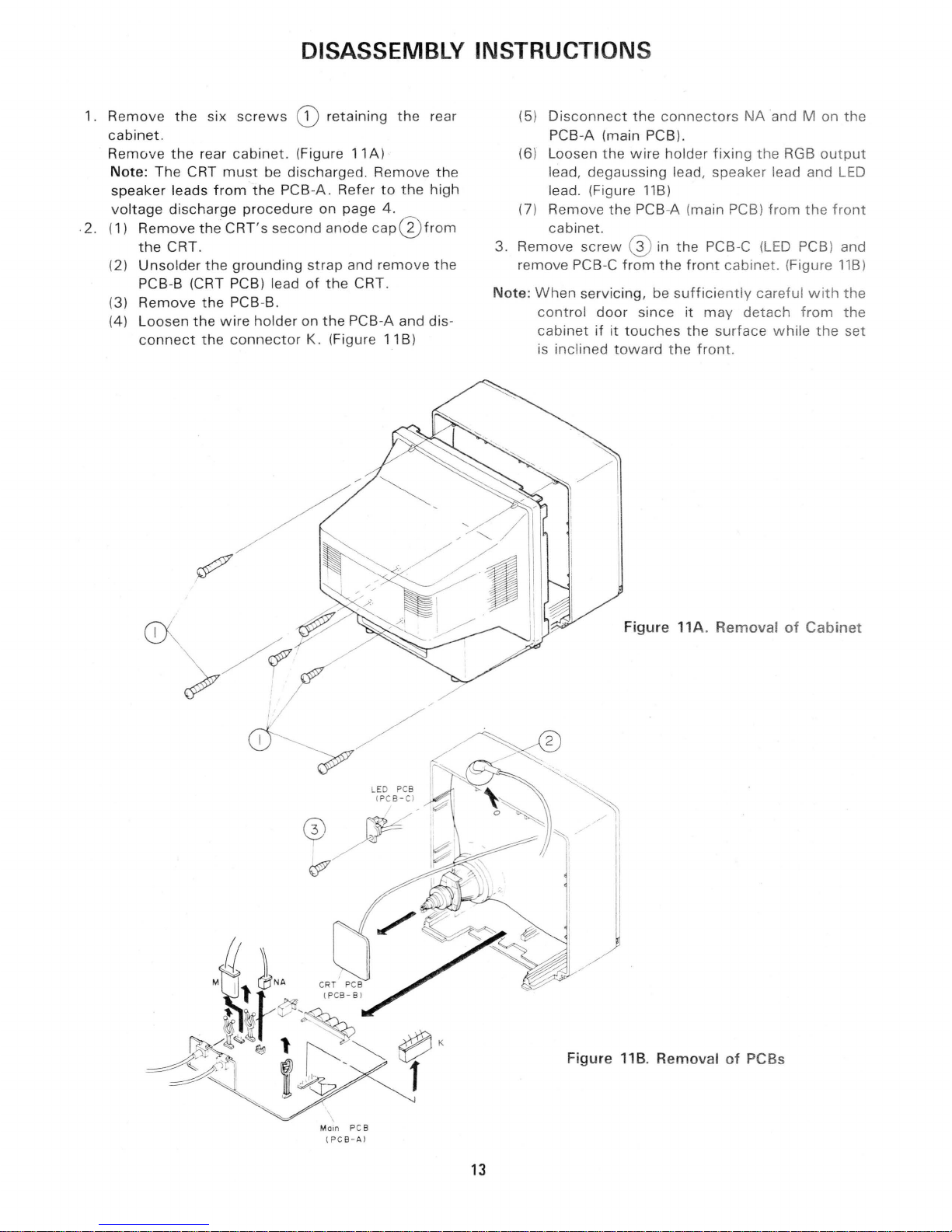

DISASSEMBLY INSTRUCTIONS

1.

Remove

the

six

screws

Q)

retaining

the

rear

cabinet.

Remo ve

the rear

cabinet.

(Figure

11A)

Note: The CRT

must

be

discharged

. Remove

the

speaker

leads

from

the

PCB-A. Refer

to

the

high

voltage

discharge

procedure

on page 4.

.2. (1)

Remove the

CRT's

second anode cap @

from

the

CRT .

(2)

Unso

lder

the

grounding

strap

and

remove

the

PCB

-B

(CRT PCB) lead

of

the

CRT.

(3)

Remove

the

PCB-B.

(4) Loosen

the

wire

holder

on

the

PCB-A and dis-

connect

the

connector

K. (Figure 11B)

'

\

Ma

in

PC 8

( P CB- A l

13

(5)

Disconnect

the

conn

ect

ors

NA

and M on

the

PCB-A (main PCB).

(6) Loosen

the

wire

hold er fi

xing

the

RGB

output

lead,

degaussing

lead, speaker lead and

LED

lead. (Figure 118)

(7) Remove

the

PCB-A (

main

PCB)

from

the

fron

t

cabinet

.

3. Remove

screw

@ in

the

PCB

-C

(LED PC

B)

and

remove

PCB-C

from

the

front

cabinet. (Figure 118)

Note:

When

servicing, be

suff

ici

ently

careful

with

the

control

door

since

it may

detach

from

the

cabinet

if

it

touches

the surface while

the

set

is inclined

toward

the front.

Figu

re

11A. Removal

of

Cabinet

Figure

11B.

Removal of PCBs

Loading...

Loading...