OEM

OPERATING

AND

SERVICE

MANUAL

TM848-1

AND

TM848-2

DISK

DRIVES

48

TRACKS

PER

INCH

'anCion

CORPORATION

20320

PRAIRIE STREET

CHATSWORTH, CA

91311

TELEPHONE

NO.: (213)

993-6644

TWX NO.:

910

494

1721

TEL.EX NO.:

194794

COPYRIGHT

1982

TANDON CORPORATION

The

information

containedinthis

documentisthe

property

of

Tandon Corporation. It may

notbeduplicated

in fullorpart

by

any

person

without

prior

written

approval. The material in

this

documentisprovided

for

informational

purposes,

andissubject

to

changebyTandon Corporation.

Sectoon

Number

SECTION

I

TABLE

OF

CONTENTS

TitleofSection

INTRODUCTION

TOTHETM848

FAMILYOF

DISKDRIVES

Page

Number

1.

1.1

1.2

1.3

1.4

1.5

1.6

1.7

1.8

1.9

1.10

1.10.1

1.10.2

1.10.3

1.11

1.12

1.13

1.14

1.15

1.15.1

1.15.2

1.15.3

1.15.4

1.15.5

1.16

1.16.1

1.16.2

1.17

1.17.1

1.17.2

1.17.3

1.18

1.19

1.19.1

1.19.2

1.19.3

1.19.4

1.19.5

1.19.6

1.19.7

1.19.8

1.19.9

1.19.10

1.19.11

1.19.12

1.19.13

1.19.14

1.19.15

1.19.16

1.19.17

Introduction

1-1

PurposeOfThe

Drive

1-1

Physical

DescriptionofThe

Drive

1-1

Functional

DescriptionofThe

Drive

1-1

Diskettes

1-2

Mechanical

and

Electrical

Sepcifications

1-2

Power

Requirements

1-2

Interface

Circuit

Specifications

1-2

Incoming

Inspection

Checks

and

Procedures

1-2

Interface

Connections

1-5

Mounting

The

Drive.." " ,

1-5

Hardware

"1-6

Dust

Cover.

1-6

Cooling

System

Requirements

1-6

Diskette

Care,

Handling

and

Storage

1-6

Write

Protect.

1-7

OperationofThe

Drive

1-7

OrganizationofThe

Drive

1-7

ComponentsofThe

Drive

'"

1-7

Index

Pulse

" , "

1-8

Drive

Status

Logic

"

1-8

Spindle

Drive

System

1-9

Positioner

Control

"

1-9

Data

Electronics

1-9

Interface

Electronics

"

'"

1-12

Interface

Connector

Pin

Assignments,

P13

1-12

Power

Connector

Pin

Assignments

1-12

Terminated

Lines

1-14

Input

Line

Terminations

From

Removable

Resistor

Pack

1-14

Drive

Select.

1-14

Program

Shunt

1-14

DS

and

HL

Power

Save

Options

1-17

User-Selectable

Options

1-17

Drive

Select

DS1--DS4

,

1-18

Side

Select

Options

Using

Drive

Select

18--48

1-18

In

Use

From

Drive

Select

1-18

In

Use

From

Head

Load

"

'"

1-18

Ready

Alternate

Output

Pad

1-18

Radial

Ready..'"

'"

1-19

Ready

Modified

1-19

Radial

Index

"

1-19

I

ndex

Alternate

Output

Pad

1-20

In

Use

Altenate

Output

Pad

1-20

Diskette

Lever

Lock

Latch

Option

1-20

Disk

Change

1-20

Two-Sided

Diskette

Installed

1-20

Stepper

Power

From

Drive

Select

1-21

Stepper

Power

From

Head

Load

Line

, 1-21

Head

Load

Alternate

Output

Pad

Option

1-21

Radial

Head

Load

Signal

Option

1-21

Section

Number

TitleofSection

Page

Number

1.19.18

1.19.19

1.19.20

1.19.21

1.19.22

Inhibit

Write When

Write

Protected

, 1-21

Allow

Write

When

Write

Protected

1-21

Head

Side

Select

Options

S1-S3

,

1-22

Spindle

Motor

Control

Options

M1 -

M4

1-22

Motor

Control

Select

Options

MC1 -

MC4

1-22

SECTION

II

MAINTENANCE

CHECKS

AND

ADJUSTMENTS

2.

Introduction

2-1

2.1

Spindle

Drive

Motor

Checks

and

Adjustments

2-1

2.1.1 Long-Term Drive

Motor

Speed

Checks

and

Adjustments

,

2-1

2.2

Cats

Eye

Alignment

Check

and

Adjustment

2-2

2.2.1

Cats

Eye

Alignment

Check

2-4

2.3

Head

Carriage

Adjustment

2-5

2.4

Index

Sensor

Checks

and

Adjustments

2-6

2.4.1 Index-To-Data Burst

Checks

2-6

2.4.2

Index

Sensor

Adjustment

, 2-7

2.4.3

Index

Pulse Width

Check

2-8

2.5 Track

00

Sensor

Check

and

Adjustment

2-8

2.6

Amplitude

Check

2-9

2.7

Azimuth

Check

2-10

2.8

Load

Arm

Adjustment

2-10

SECTION

III

PRINTED

CIRCUIT

BOARD

OPERATION

3.

3.1

3.2

3.3

3.4

Introduction

3-1

Physical

DescriptionofThe

Circuit

Board

3-1

Interface

Electronics

Specifications

3-1

Input

Control

Lines

3-2

Output

Control

Lines

3-7

SECTION

IV

TROUBLESHOOTING

GUIDE

4.

4.1

4.1

4.3

4.4

4.5

4.6

4.7

Introduction

" "

.,

"..4-1

Not

Ready

and/or

No

Index

,..4-2

Will

Not

SeekorRestore

4-2

Will

Not

Write

4-3

Will

Not

Read

4-3

Activity

L.E.D.

Inoperative

4-3

No

Track00Sensor

Indication

4-4

Drive

Motor

Will

Not

Start

When

Door

Latched

4-4

SECTION V REPLACEMENT PROCEDURES

5.

Introduction

5-1

5.1

Drive

Belt

5-1

5.2 Drive

Motor

5-2

5.3

Circuit

Board 5-3

5.4

Cone

Assembly

5-4

5.5

Diskette

Lever

, " 5-6

5.6

Bridge

Assembly

5-6

5.7 Bezel 5-8

ii

Section

Number

TitleofSection

Page

Number

5,8

5,9

5,10

5,'11

5,12

5,13

5,'14

5,'15

5,'16

5,'17

5.'18

ActivityL,E,

D",.

, " , " , . ,","""

, . ,.,, . "

., .,",..

, . , ,, . ,. , "

",.,, 5-9

Load

Arm

Assembly,.,..

, , , ,. , ,, . , ,, , ,, , .,

...

, , , ,. , ., , . , , , , ,. , ,. , . ,.., . , .

5-10

Track00Sensor

Assembly,

,, , ,, , ,. , , ,, . ,, , . ,, . ,. , . , ,..,.., , . , ., , ., , , .

5-10

Write

Protect

Sensor

Assembly,

,, , ,. , ,, , , ,, , ., , . ,. ,..,.., 5-11

Door

Switch

Assembly.., , , ,.., , . , ,, , , , ,

5-12

Index

Sensor

Assembly.,.,.., , , .,.,, "..,

5-12

Diskette

Ejector

Assembly

, , , ,,.., , , , , ,

5-14

Load

Resistor

Assembly,

, , , ,. , ,, , .,,.., , , . ,

5-15

Stepper

Band,

, , , , , , , , , ,..,, ,

5-16

Stepper

Motor

Assembly

,.,,.., , ,

.,

, , ,

5-18

Head

Carriage

Assembly""

..

"",

..

" , , ,

5-19

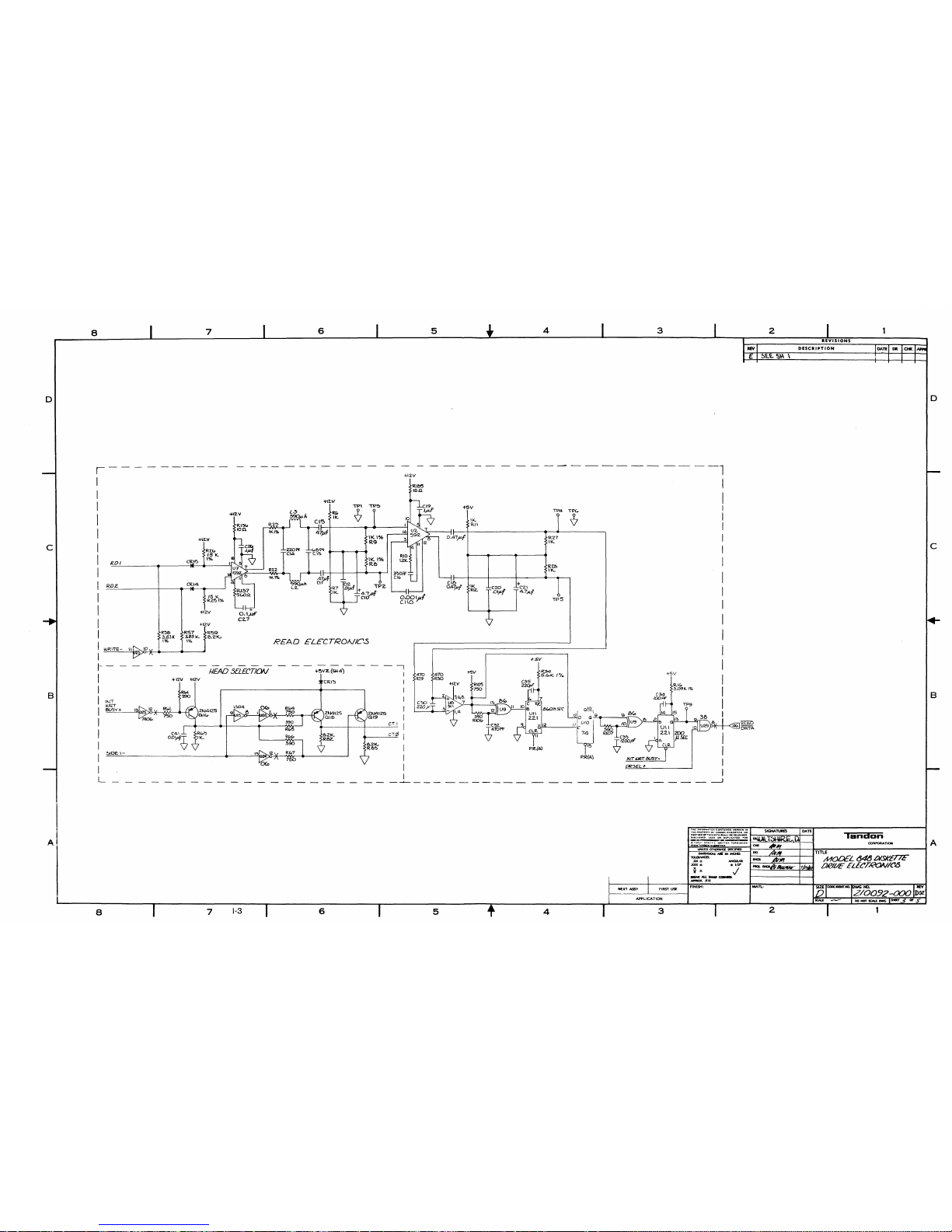

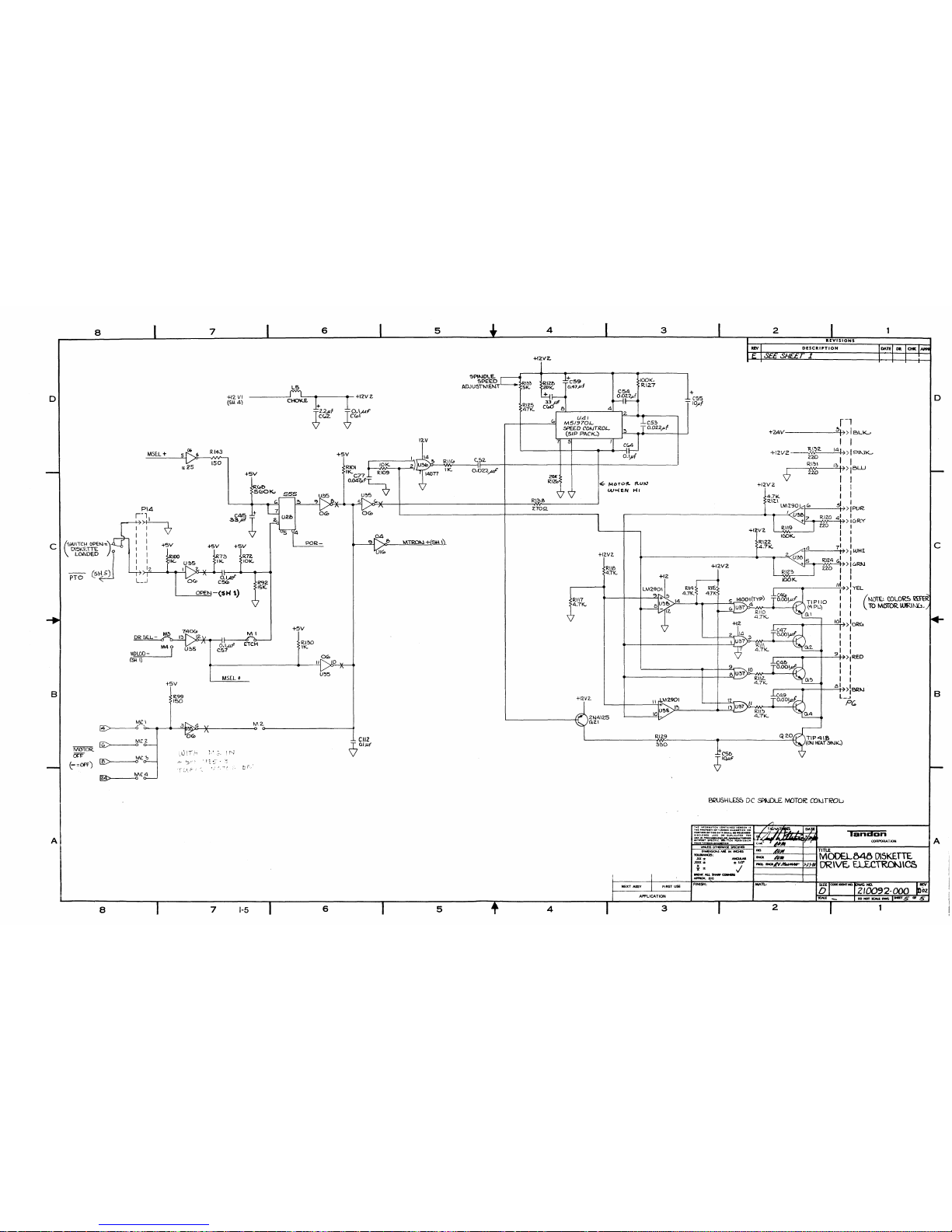

APPENDIX I PRINTED CIRCUIT BOARD SCHEMATICS AND

ASSEMBLY

DRAWiNGS"",

".,."",

, " , ,

1-1

APPENDIXIIRECOMMENDED

SPARE PARTS LIST , ".., ,

11-1

iii

LIST

OF

ILLUSTRATIONS

FIGURES

Figure

Number

TitleofFigure

Page

Number

1-1

TM848

Disk

Drive

Mounting

Configuration

" 1-6

1-2

TM848

Disk

Drive

Functional

Block

Diagram " 1-9

1-3 FM

Recording

Magnetization

Profiles

1-10

1-4

Write

Operation

Timing Diagram 1-11

1-5 Read Timing Diagram

1-12

1-6

Circuit

Board

Assembly

" " '

1-15

1-7

General

Control

and

Data Timing

Requirements

,..,

1-16

1-8 Radial Ready

Installation.." " "

1-19

1-9 Radial I

ndex

Installation

1-20

1-10

Radial

Head

Load

Signal. 1-21

2-1

Circuit

Board

Assembly

2-2

2-2

Hub

Center

Line

and

Track

Locations

2-3

2-3

Cats

Eye Pattern 2-4

2-4

Head

Module

Retaining

and

Cam

Screws

2-5

2-5

Index-to-Data

Burst.." , 2-7

2-6

Index

Sensor's

Retaining

Screw

and

Adjustment.

2-7

2-7

Negative

Going

Pulse

Width

2-8

2-8

Track

00

Sensor

2-9

2-9

Optimum

Head

Azimuth

Alignment.

2-11

2-10

Head

Azimuth

Alignment

Acceptable

Lower

Limits

2-11

2-11

Head

Azimuth

Alignment

Acceptable

Upper

Limits

, 2-12

2-12

Load

Arm Adjustment,

Front

View 2-12

3-1

Printed

Circuit

Board

3-1

3-2

Interface

Configuration

3-1

3-3

S~lect

Lines

Schematic

Diagram 3-2

3-4

Write

Data

Circuit

Block

Diagram 3-6

3-5 Trim Erase Diagram 3-8

3-6 Side

Select

Schematic

Diagram 3-9

3-7

Index

Schematic

Diagram , 3-11

3-8 Waveform

at

Test Point7,Soft

Sectored

3-11

3-9

Track

00

Schematic

Diagram

3-12

3-10

Write

Protect

Schematic

Diagram " "

3-13

3-11 Read

Circuit

Block

Diagram " "

3-14

3-12

Read

Data

Schematic

Diagram

3-15

5-1

Drive

Belt

and

Spindle

5-2

5-2 Drive

Motor

and

Related Parts 5-3

5-3

Circuit

Board

Mounting

Screws

" 5-4

5-4

Cone

Assembly

Key Parts 5-5

5-5

Cone

Assembly

Parts 5-5

5-6

Diskette

Lever

Key

Parts 5-6

5-7

Diskette

Lever

Adjustment

5-7

5-8

Bridge

Assembly

Key

Parts " 5-7

5-9

Bridge

Assembly

Additional

Key

Parts " 5-8

iv

Figure

Number

TitleofFigure

FIGURES

Page

Number

5-10

Bezel

and

Related Parts 5-8

5-1

"I

Activity

L.

E.

D.

Key

Parts 5-9

5-12

Load

Arm

Assembly

Key

Parts

5-10

5-13

Track00Sensor

Assembly

Key

Parts 5-11

5-14

Write

Protect

Sensor

Assembly

Key

Parts

5-12

5-15

Door

Switch

Assembly

Key

Parts

5-13

5-16

Index

Sensor

Assembly

Key

Parts, Top View

5-13

5-17

Index

Sensor

Assembly

Key

Parts,

Bottom

View

5-14

5

5-18

Diskette

Ejector

Assembly

Key

Parts ,

5-15

5-19

Load

Resistor

Assembly

and

Key

Parts

5-16

5-20

Stepper

Band

Key

Parts

5-17

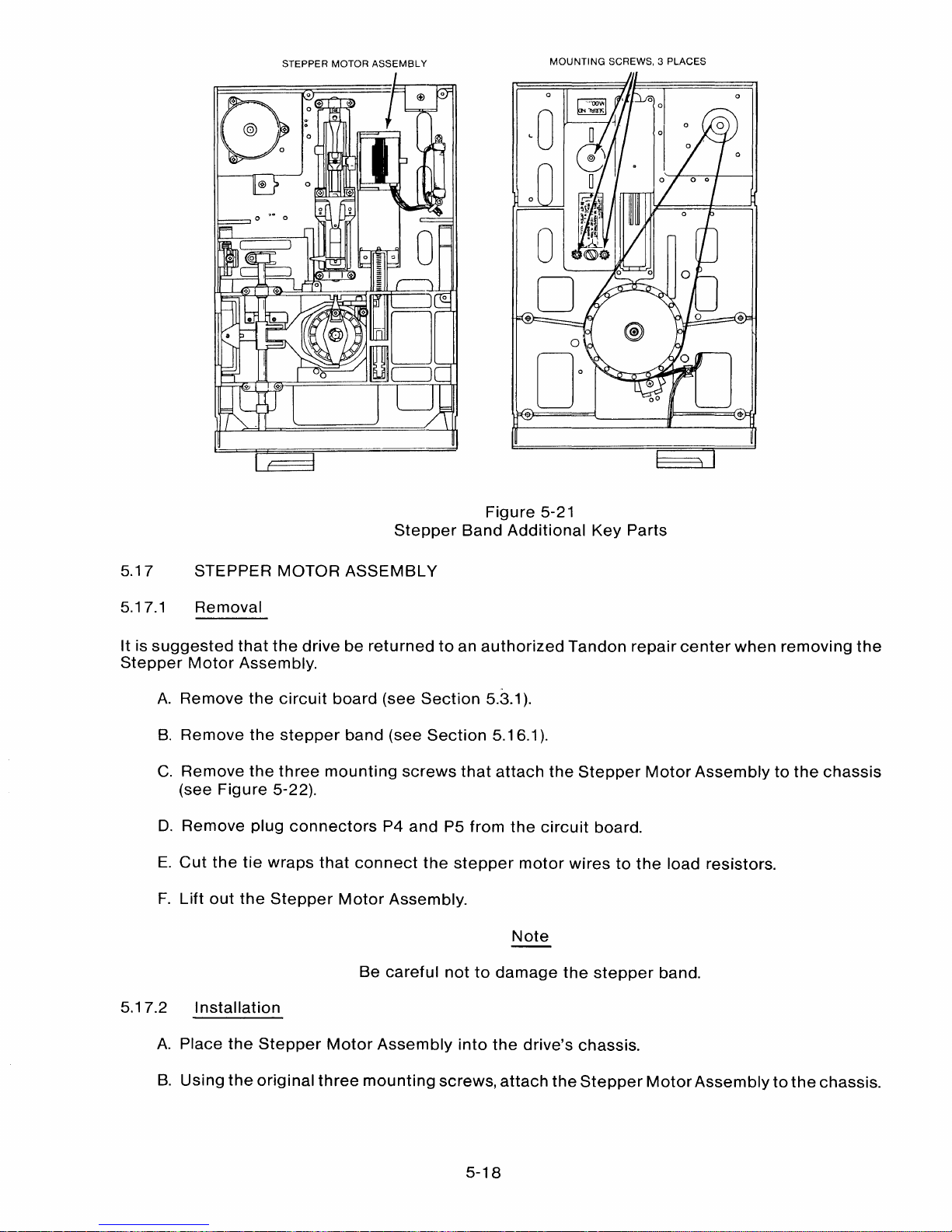

5-21

Stepper

Band

Additional

Key

Parts

5-18

5-22

Stepper

Motor

Assembly

Key

Parts

5-19

5-23

Head

Carriage

Assembly

Key

Parts

5-20

TABLES

Table

Number

TitleofTable

Page

Number

1-1

1-2

1-3

1-4

1-5

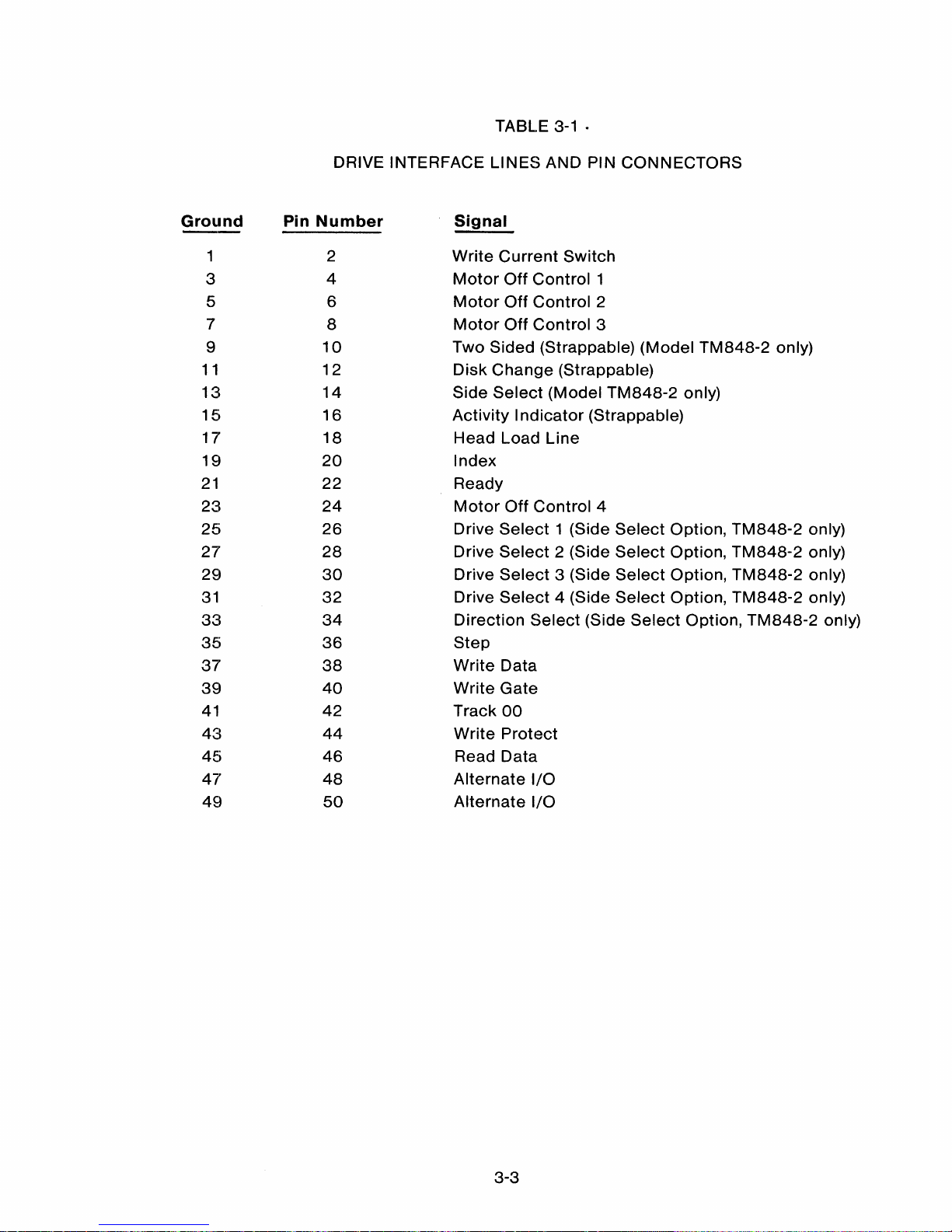

3-1

3-2

Mechanical

and

Electrical

Specifications

1-3

Power

Requirements

1-4

Interface

Connector

Pin

Assingments

1-13

Power

Connector

Pin

Assignments

1-14

Options

1-17

Drive

Interface

Lines

and

Pin

Connectors

'"

,

3-3

Stepper

Logic

Truth Table

3-5

v

SECTION

I

INTRODUCTION

TO

THE

TM848

FAMILY

OF

DISK

DRIVES

1.

INTRODUCTION

This

section

containsadescriptionofthe

physical and

functional

specifications

forthe

TM848-1

and-

2

disk

drives,48tracks

per

inch (TPI),

manufacturedbyTandon

Corporation.

1.1

PURPOSE

OF

THE DRIVE

The drive is an

eight-inch

disk

memory

designed

for

random

access

data

entry, storage,and retrieval

applications. These

applications

typically

are

intelligent

terminal

controllers,

microcomputers,

word

processing

systems,

data

communications

systems,

error

logging,

microprogram

loading, point-of-

sale terminals,

and

Winchester

back

ups.

The drive is

capableofrecording

and reading

digital

data, using FM,

and

MFM.

1.2 PHYSICAL DESCRIPTION

OF

THE DRIVE

The drive

canbemountedinany

verticalorhorizontal

plane. However,

when

mounted

horizontally,

the

printed

circuit

board

must

be up.

The

spindleisbelt

drivenbya

brushless

D.C.

motor

withanintegral

tachometer.

The

servo

control

circuit,

suitably

sized pulleys, and

the

tachometer

control

the

speedofthe

spindle. The Read/Write,

double-sided

head

assemblyispositionedbymeansofa

stepper

motor,

split

band,

and

a pulley.

The

Read/Write/Erase

head

assembly

is a

glass-bonded

manganese/zinc

ceramic

structure.Ithas a

life in

excessof20,000

hours.

For

diskette

loading,

operator

access

is provide via a

slot

locatedonthe

frontofthe

drive.

The

electronic

componentsofthe

drive are

mounted

on a

circuit

board

assembly

locatedinthe

chassis.

Power

and

interface

signalsarerouted

through

connectors

that

plug

into

the

back

ofthe

drive.

1.3 FUNCTIONAL DESCRIPTION

OF

THE DRIVE

The drive is

fully

self-contained.

It requires

no

operator

intervention

during

normal operation. The

drive

consistsofa

spindle

drive

system, a head

positioning

system,

andaread/write/erase

system.

The TM848-1 is a

single-sided

drive. The

TM848-2

is a

double-sided

drive. The

only

difference

between

the

two

drives is

the

numberofheads. The

circuit

boardisidenticalinboth

models.

When

the

diskette

lever

is opened,

accessisprovided

for

the

insertionofa

diskette.

The

diskette

is

accurately

positionedbyplastic

guides.The

disk

positionisensuredbythe

backstop

and

disk

ejector.

Closing

the

diskette

lever

activates

the

cone/clamp

system,

resultingincenteringofthe

diskette

and

clampingofthe

diskettetothe

drive hub. The

drive

hub

is drivenata

constant

speedof360

RPMbya

servo-controlled

brushlessD.C.

motor. The head is

loaded

into

contact

with

the

recording

medium

whenever

the

diskette

lever

is latched.

1-1

The head is

positioned

over

the

desired

trackbymeansofa

stepper

motor/band

assembly

and

its

associated

electronics. This

positioner

employs

a 3.6

degree

rotationtocauseaone-track

linear

movement.

Whenawrite-protected

disketteisinserted

into

the

drive,

the

Write

Protect

sensor

disables

the

write

electronicsofthe

drive,

andaWrite

Protect

status

output

signal is availabletothe

interface.

When

performingawrite

operation, a

0.013-inch

wide

(nominal)

data

track

is recorded. This

track

is

then

tunnel

erasedto0.012

inch

(nominal).

Data

recovery

electronics

include

a low-level head amplifier, a

differentiator,azero

crossing

detector,

and

digitizing

circuits.

No

data-clock

separation

is provided.

In addition,

the

drive is

supplied

with

the

following

sensor

systems:

1.Atrack00sensor

that

senses

when

the

Head

Carriage

AssemblyispositionedatTrack

00.

2.

The

two

index

sensors, eachofwhich

consistsofa L.E.D.

light

source

andaphototransistor,

are

positionedsothat

a signal is

generated

whenaindex

holeisdetected.

The drive can

determine

whether

asingle-ordouble-sided

diskette

is installed. This

output

signalis

present

at

the

interface.

3.

The

Write

Protect

sensor

disables

the

drive's

write

electronics

wheneverawrite-enable

tab

is

removed from

the

diskette

(see

Section

1.12).

1.4 DISKETTES

The drive

usesastandard

eight-inch

diskette.

Diskette$

are available

withasingle

index

hole

orwith

index

and

sector

holes.

They

also are available

double-orsingle-sided.

Single

index

hole

diskettes

are used

when

sector

informationispre-recordedonthe

diskette

(soft

sectoring).

Multiple

index

hole

diskettes

provide

sector

pulsesbymeansofthe

index

sensor

and

electronics

(hard sectoring).

1.5

MECHANICAL

AND ELECTRICAL SPECIFICATIONS

The

mechanical

and

electrical

specificationsofthe

drive are listed in Table 1-1.

1.6 POWER REQUIREMENTS

The

power

requirementsofthe

drive

are

listed

in Table 1-2.

1.7 INTERFACE CIRCUIT SPECIFICATIONS

The

interface

circuits

are

designedsothatadisconnected

wire

results

in a false signal.

Levels:

True

=

+0.4V,maximum

False

=

+2.4V,minimum

1.8

INCOMING

INSPECTION

CHECKS

AND PROCEDURES

There are

two

kindsofrecommended

incoming

inspection

checks

and

procedures:

static

and

dynamic

ones.

The

static

incoming

inspection

checks

include

the

minimum

steps

that

should

be

takentoensure

that

the

driveisoperational

when

received.

1-2

TABLE

1-1

MECHANICAL

AND

ELECTRICAL

SPECIFICATIONS

MECHANICAL

Height:

2.30

inches

Width: 8

inches

ELECTRICAL

+ 5 V

D.C.Power:

+24VD.C.Power:

Selected

Motor

On:

Deselected:

Spindle

Motor:

Start

Current

Surge:

ENVIRONMENTAL

Operating

Temperature:

Storage

Temperature:

Wet

Bulb

Temperature:

Noncondensing

Operating

Humidity:

RELIABILITY

MTBF:

MTTR:

Error

Rates:

Soft

Read:

Hard

Read:

Seek

Errors:

PERFORMANCE

Head

Wear

Guarantee:

NumberofTracks:

Track-To-

Track

Access

Time:

Head

Settling

Time:

Average

Access

Time,

including

head

settling

time:

Motor

Start

Time:

Disk

Rotational

Speed:

I

nstantaneous

Speed

Variation:

Flux

Changes

Per

Inch,

Inside

Track:

Transfer

Rates:

Unformatted

Recording

Capacity:

IBM

Format

Recording

Capacity:

Recording

Method:

1-3

Length:

13.125

inches

behind

front

panel

Weight:

5.5

pounds

+5

volts

± 5 percent,

0.75

amp

typical

+24

volts±10

percent

0.75

amp

typical

0.20

amp

typical

OAO

amp

typical

2.5 amps,

400

msec

on,

24

volts

total

4.4°Cto46°C

(40°Fto115°F)

-40°C

to

71°C

(-40°F

to

160°F)

26°C (78°F)

maximum

20-to-80

percent

10,000

power-on

hours

30

minutes

1 in

109bits

1 in

1012bits

1 in

106seeks

15,000

media

hours

77

for

TM848-1;

154

for

TM848-2,

77

per

surface

3

milliseconds

15

milliseconds

91

milliseconds

700

milliseconds

360

RPM

± 1.0

percent

6536

FCI,

Side0,both

models;

6818

FCI,

Side1,TM848-2

only

250K

BPS

single

density,

500K

BPS

double

density

0.8 M

Bytes

per

disk,

single

density,

double-sided

drive

1.6

MBytes

per

disk,

double

density,

double-sided

drive

0.6

MBytes,

single

density,

double-sided

drive

1.2 MBytes,

double

density,

double-sided

drive

FM

single

density, MFM

double

density

TABLE 1-2

POWER REQUIREMENTS

1.

+5

Volts:

0.70

Amps

typical

2.

+24

Volts:

After

motor

start

interval

Spindle

Motor

0.35

Amps

typical

Stepper

Motor

0.40

Amps

typical

Electronics

0.17 Amps

typical

Total

0.92

Amps

typical

3.

+24

Volts:

During

motor

start

interval

a.

Configured

for

stepper

motor

enabled

during

motor

start.

2.5 Amps

typical

surge.

2.5

(j)

2.0

a..

~

~

~

1.5

z

w

a:

a:

1.0

::::>

()

0.5

"

\..

100

200

300

400

TIME (MILLISECONDS)

b.

Configured

for

stepper

motor

disabled

until

motor

comes

up

to

speed.

2.1

Amps

typical

surge.

500

600

600

500

400

300

200

100

I STEPPER MOTOR

ENABLED

"

V

~

I

•

2.5

en

2.0

a..

~

~

~

1.5

z

w

a:

a:

1.0

::::>

()

0.5

TIME (MILLISECONDS)

1-4

A.

Inspect

the

shipping

package

for

obvious

damage.

B.

Open

the

shipping

container,

and

remove

the

drive.

C.Inspect

the

drive's overall appearance. Ensure

that

there

arenoscratches

on

the

bezel.

D.

Ensure

that

all

internal

connectors

are

seated

properly.

E.

Turn

the

diskette

lever

counterclockwise,

and

remove

the

shipping

diskette.

F.

Insertablank

diskette,

close,

and

then

open

the

diskette

lever. The

diskette

should

eject.

G.

Insertablank

diskette,

and

manually

turn

the

spindle

pulley.Itshould

rotate

freely.

The

dynamic

incoming

inspection

procedures

include:

A.

Connect

the

drivetoan

exerciserorcomputer

tester

capableofseeking,writing,

and

reading.

B.

Power

up

the

test

equipment,

and

apply

powertothe

drive.

C.

Select

the

drive,

and

ensure

that

the

Activity

L.E.D.

located

on

the

bezel

illuminates.

D.Insertawork

diskette

and

write/verify

from Track00to

Track

76.

Ensure

that

there

are

no

errors.

E.

I

nsertadiskette

written

previouslyonanother

drive. Read

this

diskette,

and

ensure

that

there

arenodata

errors. If

excessive

errors

occur,

check

the

disketteonthe

driveonwhichitwas

written.

F.Ifthe

drive passes all

the

checks

listed

above, it is operational. If not, review

Section

II.

1.9 INTERFACE

CONNECTIONS

Signal

connections

for

the

drive are

made

via a

user-supplied

50-pin,

flat

ribbon

connector

(3M

Scotchflex

3415). This

connector

mates

directly

with

the

circuit

board

connectoratthe

rearofthe

drive. TheD.C.

power

connector

is a six-pin

connector

(Amp

Mate-N-Lok

Part

Number

1-480270-0),

which

mates

with

the

connectoratthe

rearofthe

drive.

Thesignal

connector

harness

shouldbeof

the

flat

ribbon

ortwisted

pair

type, havea maximum

length

of

ten

feet,

and

have a

22-to-28

gauge

conductor

compatible

with

the

connector

thatistobeused.

Power

connections

should

be

made

with

18-AWG cable, minimum.

1.10

MOUNTING

THE DRIVE

The drive has

been

designedtomountinany

plane,

Le.:

upright, horizontal,orvertical. The

only

restrictionisthat

the

printed

circuit

board

sideofthe

chassis

mustbeuppermost

when

the

drive is

mounted

horizontally.

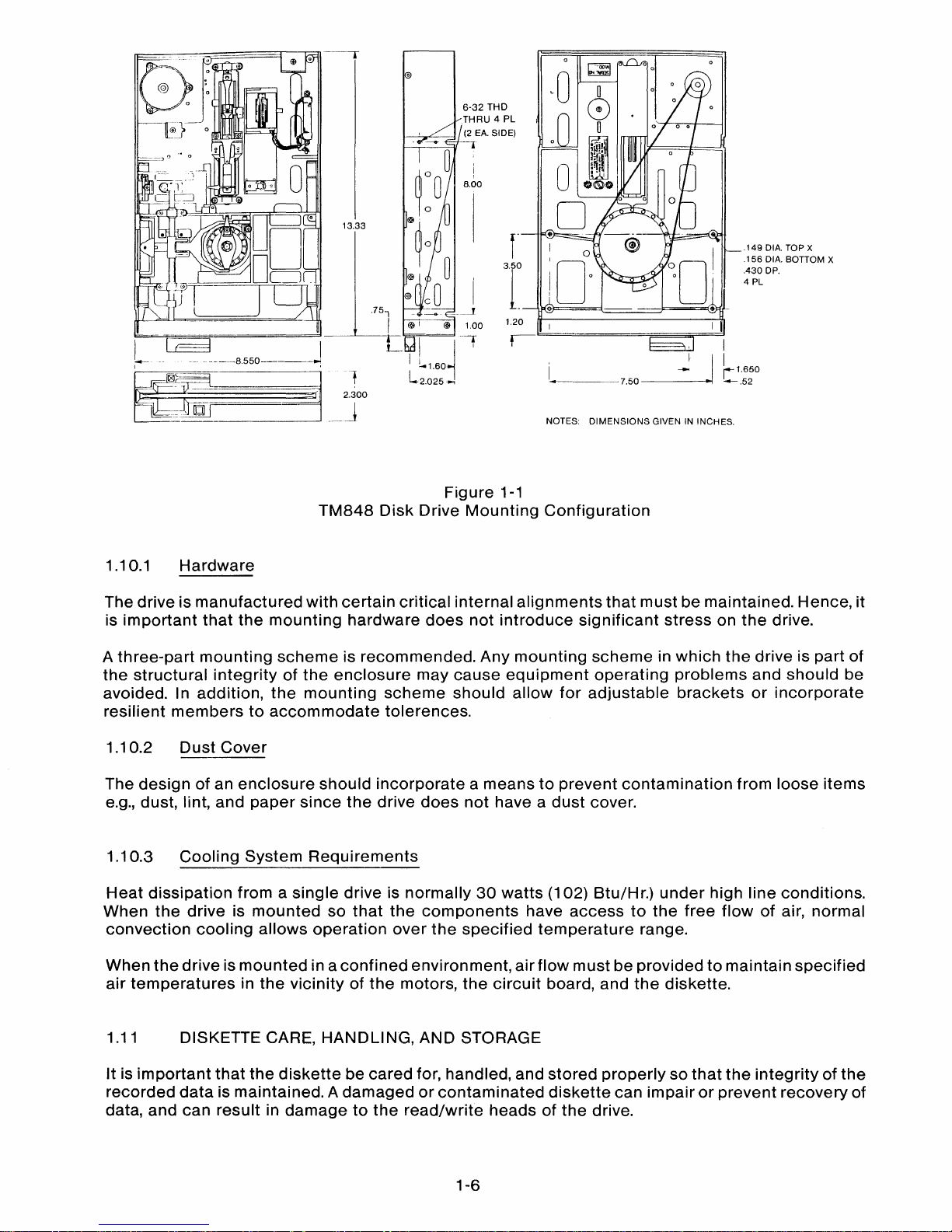

Eight

holes

are

provided

for

mounting:

twooneach

side

and

fouronthe

bottom

of

the

housing

(see Figure 1-1). The

two

on each

side

are

tapped

for

8-32

screws. The

four

mounting

holesonthe

bottom

require

8-32

thread

forming

screws.

Optional

straps

areavailabletopermit

attaching

two

drives

together

for

installationinstandard

width

drive openings.

1-5

---

0"

~-

°

F_}-

0r.!l\'l.

~1P.iI1r=--'t1

13.33

[(

J I

~-

-··------8.550----~

e

~

..

+

6-32 THO

THRU 4 PL

(2

EA.

SIDE)

I---r-'-~

-,

8.00

.149

DIA. TOP X

.156

DIA.

BOnOM

X

.430DP.

4 PL

I

L----7.50---~.1

t

1

..

::

0

NOTES:

DIMENSIONS

GIVENININCHES.

1.10.1

Hardware

Figure

1-1

TM848

Disk

Drive

Mounting

Configuration

The

driveismanufactured

with

certain

critical

internal

alignments

that

mustbemaintained.

Hence,

it

is

important

that

the

mounting

hardware

does

not

introduce

significant

stress

on

the

drive.

A

three-part

mounting

schemeisrecommended.

Any

mounting

schemeinwhich

the

driveispart

of

the

structural

integrityofthe

enclosure

may

cause

equipment

operating

problems

and

should

be

avoided.

In

addition,

the

mounting

scheme

should

allow

for

adjustable

brackets

or

incorporate

resilient

memberstoaccommodate

tolerences.

1.10.2

Dust

Cover

The

designofan

enclosure

should

incorporateameanstoprevent

contamination

from

loose

items

e.g.,

dust,

lint,

and

paper

since

the

drive

does

not

haveadust

cover.

1.10.3

Cooling

System

Requirements

Heat

dissipation

fromasingle

driveisnormally

30

watts

(102)

Btu/Hr.)

under

high

line

conditions.

When

the

driveismounted

so

that

the

components

have

access

to

the

free

flowofair,

normal

convection

cooling

allows

operation

over

the

specified

temperature

range.

When

the

driveismounted

in a

confined

environment,

air

flow

mustbeprovidedtomaintain

specified

air

temperatures

in

the

vicinityofthe

motors,

the

circuit

board,

and

the

diskette.

1.11

DISKETTE

CARE,

HANDLING,

AND

STORAGE

It

is

important

that

the

diskette

be

cared

for,

handled,

and

stored

properlysothat

the

integrityofthe

recorded

dataismaintained.Adamagedorcontaminated

diskette

can

impairorprevent

recovery

of

data,

and

can

resultindamagetothe

read/write

headsofthe

drive.

1-6

The

following

list

contains

information

on

how

the

diskette

can be

cared

for, handled,

and

stored.

1.

Keep

the

diskette

away

from

magnetic

fields.

2.

Do

not

touch

the

precision

surfaceofthe

diskette

with

fingers.

3.

Insert

the

diskette

carefully

into

the

drive

until

the

backstopisencountered.

4.

Do

not

bendorfold

the

diskette.

Ei.

Put

the

diskette

into

its

jacket

when

it is

not

in use.

6.

Store

the

disketteattemperatures

between1DoC

and 52°Cor50°F

and

125°F.

1.12 WRITE PROTECT

The drive is

equipped

withaWrite

Protect

Sensor

Assembly.This

sensor

operatesinconjunction

with

a

diskette

that

has a

slot

cutinthe

protective

jacket.

When

the

slot

is uncovered,

the

disketteiswrite

protected.

The

slot

mustbecoveredtowriteonthe

diskette.

An

option

is available on

the

board

for

defeating

the

write

protect

sensor.

1.13 OPERATION

OF

THE DRIVE

The drive

consistsofthe

mechanical

and

electrical

components

necessarytorecord

andtoread

digital

dataona

diskette.

User-providedD.C.

powerat+24

volts

and+5voltsisrequired

foroperation

of

the

drive.

1.14 ORGANIZATION

OF

THE DRIVE

All

electrical

subassembliesinthe

drive

are

constructed

with

leads

that

terminate

in

multipin

connectors,

enabling

the

individual

assembliestobe removed.

The

heads

are

connectedtothe

circuit

board

via

cables

that

terminate

in five-pin

female

connectors

and

their

associated

male

sockets

that

are

located

in

close

proximity

to

the

read/write

data

electronics.

Interface

signals

and

power

are

provided

via

connectorsatthe

rearofthe

drive.

1.15

COMPONENTS

OF

THE DRIVE

The drive

consistsofsix

functional

groups:

'1.

Index

Pulse

Shaper

2.

Drive

Status

Logic

A.

Write

Protect

B.

Track

00

Sensor

C.

Double-sided

Disk

D.

Ready

E.

Disk

Change

1-7

3.

Spindle

Drive

Control

4.

Carriage

Position

Control

5.

Write/Erase

Control

6.

Read

Amplifier

and

Digitizer

Figure

1-2

is a

functional

block

diagramofthe

drive.Itshouldbereferredtoin

conjunction

with

the

following

sections.

The

datainthe

ensuing

figuresisprimarily

representedinsimplified

form.

1.15.1

Index

Pulse

An

index

pulseisprovidedtothe

user

system

via

the

index

pulse

interface

line.

The

index

circuitry

consistsofan

indexL.E.

D.,anindex

phototransistor,

andapulse

shaping

network.Asthe

index

hole

in

the

disk

passesanindex

L.E.D.

phototransistor

combination,

light

from

the

L.E.D.

strikes

the

index

phototransistor,

causingitto

conduct.

The

signal

from

the

index

phototransistorispassedonto

the

pulse

shaping

n~twork,

which

producesapulse

for

each

hole

detected.

This

pulseispresentedtothe

useronthe

index

pulse

interface

line.

1.15.2

Drive

Status

Logic

There

are

five

drive

status

logic

lines:

Write

Protect,

Track00Sensor,

Two-Sided

Ready

and

Disk

Change.

A.

Write

Protect

A

write

protect

signalisprovidedtothe

user's

system

via

the

write

protect

interface

line.

The

write

protect

circuitry

consistsofa

write

protect

sensor

and

circuitry

that

routes

the

signal

thatisproduced.

Whenawrite

protected

disketteisinsertedinthe

drive,

the

sensorisactivated

and

the

logic

disables

the

write

electronics

and

supplies

the

status

signaltothe

interface.

B.

Track

00

Sensor

The

levelonthe

Track

00

interface

line

is a

functionofthe

positionofthe

head

assembly.

When

the

headispositionedatTrack00and

the

stepper

motorisat

the

home

position,atrue

(low) level

signalisgeneratedatthe

interface.

C.

Two-Sided

Disk

This

signalislow

(true)

when

the

driveisselected

and

has

detected

the

presenceofthe

Index

Two

holeinthe

diskette

currently

installed.

D.

Ready

This

signalistrue

when

Drive

Selectislow

(true)ifthe

spindle

driveisuptospeed

and

the

driveisreadytoread

and

write.

E.

Disk

Change

This

signalistrue

when

Drive

Selectislow

(true) if

the

diskette

lever

has

been

movedtothe

open

position

after

the

previous

drive

select

went

false.

1-8

1.15.3

Spindle Drive System

The spindle drive system consists of a spindle assembly driven through a drive belt by a brushless

D.C. motor/tachometer.

The servo electronics required for speed control are located on the printed circuit board.

The control circuitry contains an interface

control

line.

When

the drive motor control interface line

is

false (high), the drive motorisallowed to come up to speed.

READY

CONTROL

INDEX

LOGIC

DISK

CHANGE

TWO SIDED

WRITE PROTECT

TRACK

00

IN USE

SIDE SELECT

HEAD CARRIAGE

DRIVE SELECT

AND STEPPER

BAND

ASSEMBLY

SPINDLE

MOTOR

CONTROL

MOTOR

CONTROL

WRITE GATE

WRITE

WRITE DATA

LOGIC

CURRENT

SWITCH

READ READ DATA

LOGIC

DIRECTION

STEPPER

MOTOR

CONTROL

STEP

Figure

1-2

TM848

Disk Drive Functional Block Diagram

1.15.4

Positioner Control

The head positioning system uses a bipolar-driven motor drive, which changes

one

phase for each

track advancement of the read/write carriage. In addition to the logic necessary for motor control, a

gateisprovided that inhibits positioner motion during a write operation.

1.15.5 Data Electronics

Information can be recorded

on

the diskette by using a double-frequencycode. Figure

1-3

illustrates

the magnetization profiles

in

each bit cell for the number sequence shown for FM recording.

1-9

BIT

PATTERN----,

BIT

CELL""""

I 1 I 1

I I I

I I I

WRITE

DATA

o

I

I

1

I

C D

ic

D IC C I

D

C

ICC

D

1

I

I

I

I I I

I I I I I I

I I I

\:f.=k:1

,-,t;fl:f

~t:A1

I f I

MAGNETIZATION

1:

1

I I -

~

.

~

--'I

I

~

I I

IIIIIIIIIII~II

M~NEnCELEMEN~

~

I

r--rTt4

I I

Figure 1-3

FM

Recording

Magnetization

Profiles

The

erase

gaps

provide a

guard

band

on

either

sideofthe

recorded

track.

All

signals

requiredtocontrol

the

data

electronics

are providedbythe

user

system

and

are

shown

in

the

TM848

drive

functional

block

diagram (see

Figure

1-2). These

control

signals

are:

1.

Select

2.

Write

Gate

3.

Write

Data

4.

Side

Select

5.

Write

Current

Switch

Composite

read

dataissenttothe

user

system

via

the

Read

Data

interface

line.

A.

Data

Recording

The

write

electronics

consist

ofaswitchable

write

current

source, a

write

waveform

generator,

an erase

current

source,

the

trim erase

control

logic, and

the

head

selection

logic

(see

Appendix

I).

The

read/write

windingonthe

head is

center-tapped.

Duringawrite

operation,

current

from

the

write

current

source

flowsinalternate

halvesofthe

winding,

under

controlofthe

write

waveform generator.

The

conditions

required

for

recording,

i.e.

drive ready

must

be

established

by

the

user's

system, as follows:

1.

Drive

speed

stabilization

occurs

700

milliseconds

after

the

drive

motor

is started.

2.

Subsequenttoany

read/write

operation,

the

positioner

must

be

allowedtosettle. This

requires18milliseconds

maximum

after

the

last

step

pulse

is initiated,

i.e.,3milliseconds

for

the

step

motion

and

15

milliseconds

for

settling.

3.

The

foregoing

operations

can be overlapped, if required.

Figure

1-4

illustrates

the

timing

diagram

forawrite

operation. At t =0,

when

the

unit

is ready,

the

write

gate

interface

line

goes

true. This

enables

the

write

current

source.

Write

current

is

switched

via

the

write

current

switch

interface

linetoa

lower

valuebythe

user's

controller

at

Track 43.

1-10

The Trim Erase

control

goes

true

190

microseconds

after

the

Write

Enable

interface

line

since

the

trim erase

gaps

are

behind

the

read/write

gap. It

shouldbenoted

that

this

value is

optimized

between

the

requirementsatTrack00andatTrack

76,sothat

the

effectofthe

trim

erase

gaps

on previous

information

is minimized.

Figure

1-4

shows

the

informationonthe

write

data

interface

line

and

the

outputofthe

write

waveform

generator,

which

togglesonthe

leading

edgeofevery

write

data

pulse.

A maximum

of4microseconds

between

write

gate

going

true

and

the

first

write

data

pulse

is

only

requirediffaithful

reproductionofthe

first

write

data

transition

is signifcant.

At

the

endofrecording,atleast

one

additional

pulseonthe

write

data

line

mustbeinserted

after

the

last

significant

write

data

pulsetoavoid

excessive

peak

shift

effects.

3.

10MAPEAKTO PEAK, TRACK 0 TO

TRACK42; 7.5 MAPEAK

TO

PEAK,

TRACK

43

TO TRACK 77.

4.

2 USEC

MINIMUM

4 USEC MAXIMUM

I

I

NOTES:

1.

T = 0 =

700

MILLISECONDS

AFTER DRIVE MOTOR

STARTS OR

20

MILLISECONDS

AFTER LAST STEP

PULSE, WHICHEVER IS THE LATEST TIME.

2.

UNSYCHRONIZED

Figure

1-4

Write

Operation

Timing Diagram

NOTE 2

I

~

I

~50usec""

I I

~-""""""-----""---"""~:;-"'I~

~---tl----;---+----

........-

.......

-~

.......

I

~~

I I

WRITE

WAVEFORM

GENERATOR

WRITE

CURRENT

INTERNAL WRITE

BUSY

TRIM ERASE

WRITE GATE

The

durationofa

write

operation

is from

the

true

going

edgeofwrite

gatetothe

false

going

edge

of

erase. This is

indicatedbythe

internal

write

busy

waveform

shown

(see Figure 1-4).

The Read

electronics

consist

of:

1.

Read

Switch/Side

Select

2.

Read

Preamplifier

3.

Filter

4.

Differentiatior

5.

Time

Domain

Filter

and

Digitizer

The read

switch

is usedtoisolate

the

read

amplifier

from

the

voltage

excursion

across

the

head

duringawrite

operation. The

side

select

is usedtoenable

oneofthe

read/write/erase

heads.

Thedrive

must

be in a ready

condition

before

readingcan begin.As

with

the

data

recording

operation,

this

ready

condition

must

be

established

by

the

user

system. In

addition

to

the

requirements

establishedinthis

section, a periodof100

microsecondsisnecessary

after

a trim

erase

operation

occurstoallow

the

read

amplifiertosettle

after

the

transient

causedbythe

read

switch

returning

to

the

read mode.

1-11

The

output

signal from

the

read/write

headisamplifiedbya read

preamplifier

and

filteredbya low-

pass

linear

phase

filtertoremove

noise

(see Figure 1-5). The

linear

output

from

the

filter

is passed

to

the

differentiator,which

generates

awaveform

whose

zero

crossovers

correspondtothe

peaksofthe

Read signal. This signal is then fedtothe zero crossing detector and digitizer.

LINEAR OUTPUT FROM FILTER

OUTPUT FROM DIFFERENTIATOR

READ DATA INTERFACE

t

t

==

0

Figure 1-5

Read Timing Diagram

Note

T= 0 is

definedas250

milliseconds

after

drive

motor

starts,or20

milliseconds

afterastep

command,or100

microseconds

afterterminationofwrite

busy,

whicheveristhe

latest

time.

The

zero

crossover

detector

and

digitizer

circuitry

generatea200

nanosecond

read

data

pulse,

correspondingtoeach

peakofthe

read signal. The

composite

read

data

signal is

senttothe

user

system via

the

read

data

interface

line.

1.16 INTERFACE ELECTRONICS

All

interface

signals

are TTL compatible.

Logic

true

(low) is

+0.4

volt maximum,

logic

false (high) is

+2.4

volts

minimum. The maximum

interface

cable

lengthisten

feet.Itis

recommended

that

the

interface

cable

be flat ribbon

cable

that

has a

characteristic

impedenceof100

ohms.

1.16.1

Interface

Connector

Pin Assignments, P13

The

interface

connector

pin assignments, P13, are listed in Table 1-3.

1.16.2

Power

Connector

Pin

Assignments

The

power

connector

pin

assignments

are listed in Table 1-4.

1-12

TABLE

1-3

INTERFACE

CONNECTOR

PIN

ASSIGNMENTS

Ground

---

1

3

5

7

9

"11

'13

"15

"17

'19

:21

:23

:25

27

29

31

33

35

37

39

41

43

45

47

49

Pin

Number

2

4

6

8

10

12

14

16

18

20

22

24

26

28

30

32

34

36

38

40

42

44

46

48

50

Signal

Write

Current

Switch

Motor

Off

Control

1

Motor

Off

Control

2

Motor

Off

Control

3

Two

Sided

(option)

(Model

TM848-2

only)

Disk

Change

(option)

Side

Select

(Model

TM848-2

only)

ActivityIndicator

(option)

Head

Load

Index

Ready

Motor

Off

Control

4

Drive

Select1(Side

Select

Option,

TM848-2

only)

Drive

Select2(Side

Select

Option,

TM848-2

only)

Drive

Select3(Side

Select

Option,

TM848-2

only)

Drive

Select4(Side

Select

Option,

TM848-2

only)

Direction

Select

(Side

Select

Option,

TM848-2

only)

Step

Write

Data

Write

Gate

Track

00

Write

Protect

Read

Data

Alternate

I/O

Alternate

I/O

1-13

TABLE 1-4

POWER CONNECTOR PIN

ASSIGNMENTS

Pin

1

6

3

2

5

1.17 TERMINATED LINES

Supply

Voltage

24VD.C.

Return

Return

Return

5V

D.

C.

1.17.1

Input

Line

Terminations

From Removable Resistor Pack

The drive

has

the

capabilityofterminating

the

following

input

lines:

1.

Write

Current

Switch

2.

Write

Data

3.

Write

Gate

4.

Side

Select

(TM848-2

only)

5.

Direction

6.

Step

7.

Head

Load

These

input

lines

are

individually

terminated

througha150

ohm

resistor

pack

thatisinstalledinthe

dip

socket

locatedatintegrated

circuit

location

RP1. In a single-drive system,

this

resistor

pack

shouldbeinstalledtoprovide

the

proper

terminations. In a multiple-drive system,

only

the

last drive

on

the

interfaceisto

be terminated. All

other

drivesonthe

interface

must

have

the

resistor

pack

removed (see

Figure

1-6).

1.17.2 Drive

Select

The

Select

lines

provide

a meansofselecting

and

deselecting

a drive. These

four

Iines·-OS1

through

DS4--allow

independent

selectionofuptofour

drives

attachedtothe

controller.

When

the

signal

logic

level is

true

(low),

the

drive

electronics

are

activated

and

the

drive is

conditionedtorespondtoStep

orto

Read/Write

commands.When

the

signal

logic

level isfalse(high),

the

input

control

lines

and

the

output

status

lines

are disabled.

The drive

select

addressisdetermined

by

a movable

shorting

plug

installed

on

the

circuit

board.

Select

lines

one

through

four

provide a

meansofdaisy

chaining

a maximumoffour

drivestoa

controller.Onlyonelinecan betrue(low) at a time.An undefined operation might result iftwo

or

moreunits

areassigned

the

sameaddressoriftwoormoreselect linesare in the true(low) state simultaneously (see

Figure

1-7). A

select

line

must

remain

stableinthe

true

(low)

state

until

the

execution

if a

Step

or

Read/Write

commandiscompleted.

1.17.3 Program Shunt

The program shunt is AMP Part Number 435704-8. The program shunt positions are programmed by

cutting

the

particular

shunt. The program

shunt

is installed in a

dip

socket. At

the

user's option,

the

program

shunt

may

be removed

and

replacedbya

dip

switch. Pins 8 and 9ofthe

program

shunt

are

not

used.

See

Table 1-5

fora

listingofthe

program shunts.

1-14

R133

o

P6

P14

M2

00

o

o

00

00

CI:(J)

CI:O

~P4

~P5

M3

0-0

o

M4

2SCH)

DC

00

00

RI

TP11 G 0 TP12

ALTERNATE TEST POINT, INDEX TRIGGERING

R33

I

00

y

~

NP

@O~S2

OS1

g~O:

WP

P2

P3

Pi0

Pi

P11

P12

TP5

t

TP4ooopT6

TP2

TP1

1

o

~o

TP3

P8

pg

00

DSi

1b

0

000S2

2b

0

000S3

3b

0

000S4

4b

0

o

OTP8

OTP10

gOL

P7

MC3

2 j

MC2~C'gMC1

S2

0

IT

S

1

D 0 S2

o

C g

MC4g

RP1

o

TP9

P13

50

TP7

o

......

I

......

01

Figure 1-6

Circuit Board Assembly

D.C. POWER

MOTOR OFF

CONTROL

DRIVE SELECT

---l

r-

500

NSEC. MINIMUM

0,8 SEC

MAXIMUM

..

_

STATUS

OUTPUTS VALID

-

........

"'1--

500

NSEC'MINIMUM

---.:.J

L 1 USEC MINIMUM

~-------

..

DIRECTION

SELECT

I---

550

USEC.

MINIMUM'

4 USEC.

MAXIMUM

I--

100

USEC. MAXIMUM

U3 MILLISECONDS

MINIMUM

1 USEC. J

l--

MINIMU~~

I---

100

NSEC MINIMUM.

...

---------

....

--

...

~~

.-U

I---

18

MSEC. MINIMUM

1--------_

......

-....

..-------'\,,...---.

~

VALID

READ DATA

WRITE DATA

SIDE SELECT

WRITE GATE

Figure 1-7

General Control and Data Timing Requirements

1-16

1.18

OS

AND

HL

POWER SAVE OPTIONS

The

driveis

setupwith

theHLoption

in. This

stepper

power

from head load

line

option

supplies

power

to

the

stepper

motor

when

the

head load

line

goes

low

(true),

which

resultsinlower

stand-by

current

consumption.

As

shipped

from

the

factory, HL is installed

but

will remove

power

from

the

stepper

motor

when

the

driveisdeselected.

There

should

be a

20

millisecond

wait

after

a Drive

Select

command

is given in

ordertoallow

the

step

motor

electronicstosettle.

The

stepper

power

from drive select,

OS

option,

allows

the

usertoremoveD.C.

power

from

the

stepper

motor

using driveselect,

which

resultsinlower

stand-by

current

consumption.

This

option

is

implemented

by

installing

OS,

and

cutting

HL.

1.19 USER SELECTABLE OPTIONS

The

descriptionofuser

selectable

options

should

be used in

conjunction

with

the

following

list

of

options

that

are

available

for

model

numbers

TM848-1 and

TM848-2

(see Table 1-5).

TABLE 1-5

OPTIONS

AS

SHIPPED

TRACE

Shunt/Pin

Not

OPTION

DESIGNATOR

Locations

Installed

Installed

Drive Se

lect

DS1-DS4

DS1

Side

Select

Options

using Drive

Select

1B-4B

X

In Use, Drive

Select

Z

U3,1-16

X

In Use,

Head

Load

Y

X

Ready

Alternate

Output

Pad

R

U3,

7-10

X

Radial Ready

RR

X

Ready,

Modified

RM

X

Radial

Index

RI

X

Index,

Alternate

Output

Pad

I

U3,6-11

X

In Use,

Alternate

Output

Pad

0 X

Diskette

Lever

Lock

Latch

Option

DL X

Disk

Change

DC X

Two-Sided

Diskette

Installed

2S X

Stepper

Power

from Drive

Select

OS

X

Stepper

Power

from

Head

Load

Line

HL

U3,2-15

X

Head

Load

Alternate

Output

Pad

C

X

Radial

Head

Load

Signal

A

U3,3-14

X

Radial

Head

Load Signal

B

U3,4-13

X

Radial

Head

Load

Signal

X

U3,5-12

X

I

nhibit

Write

When

Write

Protected

WP

X

Allow

Write

When

Write

Protected

NP X

Head

Side

Select

Options

S1-S3

S2

Spindle

Motor

Control

Options

M1-M4

M1,

M3

M2,

M4

Motor

Control

Select

MC1-MC4

MC1

1-17

1.19.1

Drive

Select

OS

1-DS4

This

option

allows

the

usertodaisy

chain

uptofour

drives,

andtoenable

one

driveatat

time.

Drive

selectisimplementedbyshorting

oneofthe

four

connections,

usingashorting

plug.

The

drive

comes

equipped

from

the

factory

with

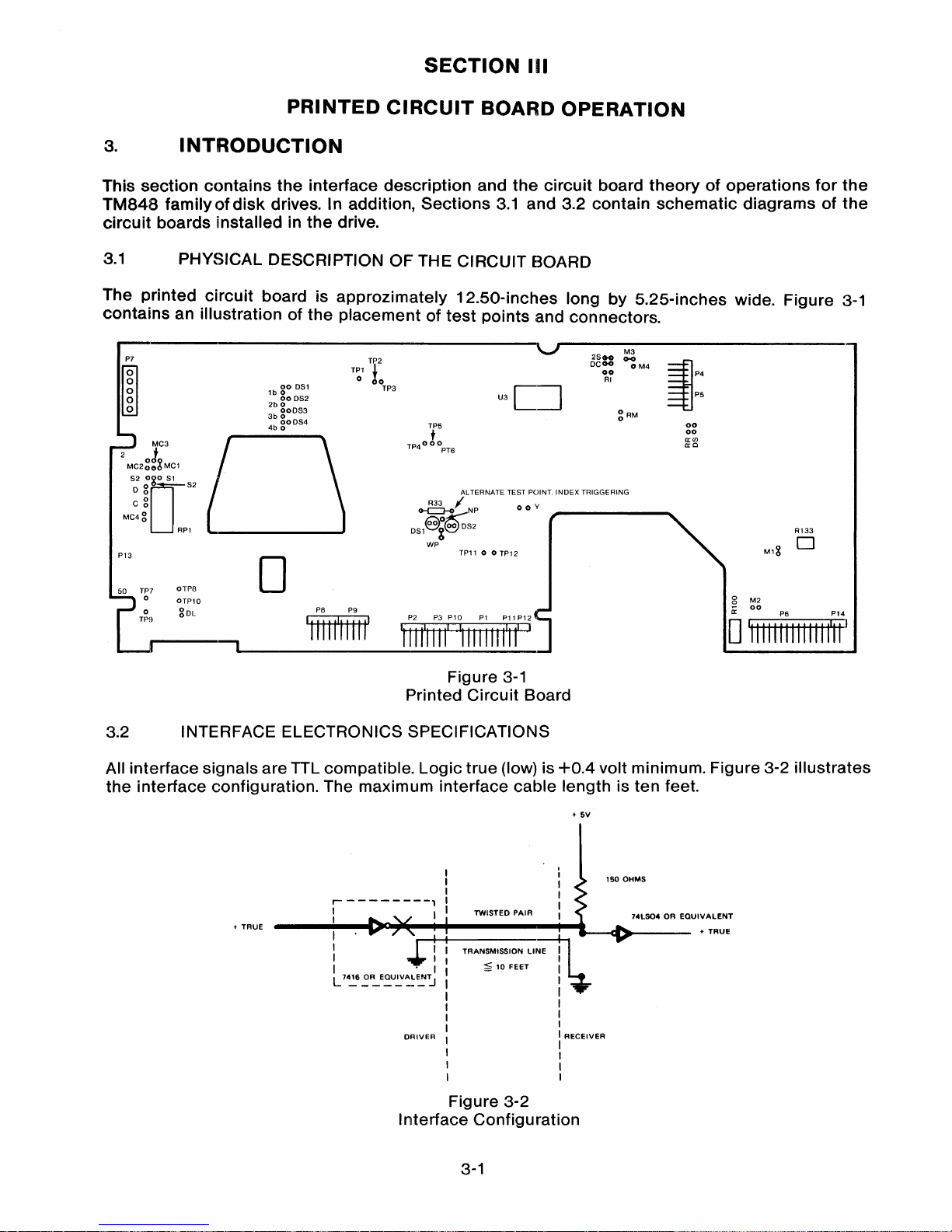

OS1

installed.

All

outputs

are

gated

with

drive

select,asset-up

at

the

factory.

1.19.2

Side

Select

Options

Using

Drive

Select

18--48

This

option

allows

the

usertoselect

the

headtobe

used

with

drive

select.

Side

Select

options

are

implementedbyremoving

the

shorting

plug

from

the

DS1-DS4

option

pads,

installing

Pins18-48,

and

connecting

the

shorting

plugtothe

desired

18-48

pins. S2

shouldbeetch

cut,

and

S3

installed

(see

Section

1.18).

1.19.3 In

Use

From

Drive

Select

(Z)

This

option

allows

the

usertoenable

the

activity

L.E.D.

when

the

driveisselected.

In

Use

From

Drive

Selectisfactory

installed.

1.19.4 In

Use

From

Head

Load

(Y)

This

option

allows

the

usertouse

the

head

load

linetoenable

the

Activity

L.E.D.

In

Use

From

Head

Loadisimplemented

by

punching

out

OptionZbetween

Pins 1

and

16ofU3. A

jumper

must

be

installedatlocation

Y.

1.19.5

Ready

Alternate

Output

Pad

(R)

This

low

going

signalisderivedbygating

the

internal

ready

and

drive

selecttogive

the

controller

a

true

(low)

ready

statusofthe

drive

.

. The

Ready

Alternate

Output

Pad is

factory

installed.

1.19.6 Radial

Ready

(RR)

This

option

allows

the

usertomonitor

the

ready

statusofall

drives

without

selecting

them.

This

option

cannot

be

used

concurrently

with

individual

motor

control

lines

for

each

drive.

(see

Figure

1-8).

Radial

Readyisimplementedbypunching

out

OptionRbetween

Pins 7

and10of

U3,byetch

cutting

RR,

thenbyrunningawire

from

U4, Pin 3tothe

desired

alternate

output

lines4,6,8,

and

24.

1-18

RI4

+5

~99

150

+5V

ETCH CUT

PROGRAM

SHUNT

PINS

7-10

ARE

OPENED

/'

OREDY+

RADIAL

READY

STATUS

TO USER

CONTROLLER

RM

'9

ETCH CUT

~-~~4

~

IREADY

-

,--

.........

--

~'3_SE_L_+_.

---~'--o-------'

RR

Figure

1-8

Radial Ready

Installation

Note

MC1

through

MC4

cannot

be used as radial

motor

control

when

using

this

option.

1.19.7

Ready,

Modified

(RM)

This

option

allows

the

drivetowriteonthe

upper

surfaceofa

single-sided

diskette. It

prevents

the

drivefrom

making

Ready

become

false

when

the

upper

surfaceofa

single-sided

diskete

isselected.

To

implement

this

option,

connectajumperatthe

RM pads.

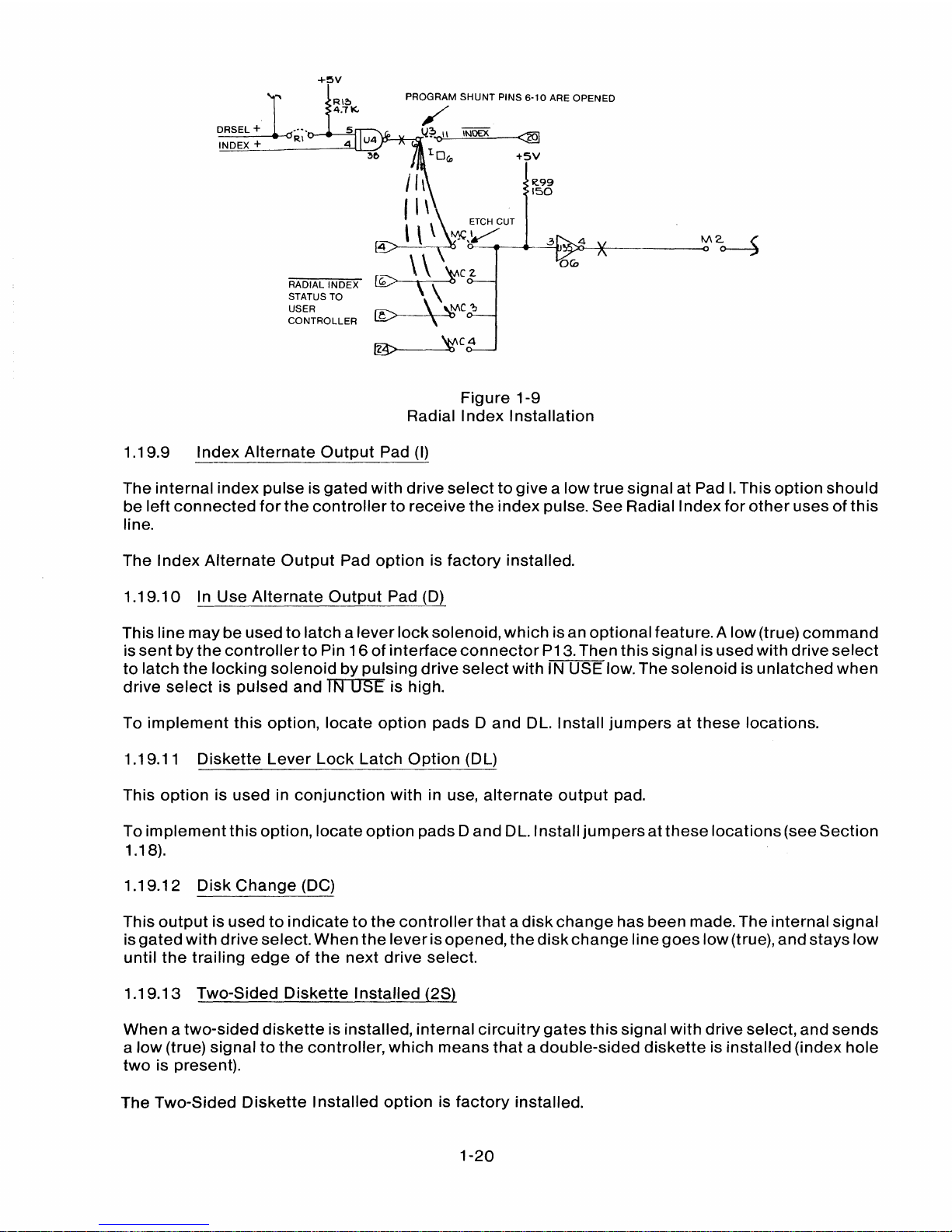

1.19.8

Radial

Index

(RI)

This

option

uses

the

alternate

I/O

lines

for

radial

index

lines.This

option

allows

the

userto

monitor

the

indexofeach

drive

independentofdrive select. This

option

cannot

be used

concurrently

with

radial

ready,

or

with

independent

motor

control.

Radial

Indexisimplementedbyremoving

the

shunt

bridge

at U3, Pins 6

and

11, by

etch

cutting

radial

index,

andbyrunningawire

from U4, Pin6,to

the

appropriate

alternate

I/O

lines.IfuseofMC1 is

desired,

interface

line

20

may be used as

one

index

line. In

this

case,

the

shunt

pack, U3, 6-11,

remains

intact

on

one

drive, (see

Figure

1-9).

1-19

R.99

150

+~v

~

R\~

4.71(.

DRSEL + .... 5

INDEX

+

R\

D--e--=i

4

RADIAL INDEX

STATUS TO

USER

CONTROLLER

PROGRAM

SHUNT

PINS

6-10

ARE OPENED

/

1,l~"OI\

INDEX

QQ]

'LOCo

+5V

1/\

~\

'~

'\

ET_CH

CUT

\

t"f;,V

~

2-

[4

Q--

~It_-3r2!~X:------~

~

rr---, \ \

1fC

2.

OeD

~

\\

CD

','oMC

~

fM>

't'C4

Figure

1-9

Radial I

ndex

Installation

1.19.9

Index

Alternate

Output

Pad (I)

The

internal

index

pulse is

gated

with

drive

selecttogivealow

true

signalatPadI.This

option

should

be

left

connected

for

the

controllertoreceive

the

index

pulse.

See

Radial

Index

for

other

usesofthis

line.

The

Index

Alternate

Output

Pad

optionisfactory

installed.

1.19.10 In Use

Alternate

Output

Pad (D)

This linemaybeused

to

latchalever

lock

solenoid,

which

isan

optional

feature. A

low

(true)

command

is

sentbythe

controllerto

Pin16of

interface

connector

P13.Then

this

signal is

used

with

drive

select

to

latch

the

locking

solenoidbypulsing

drive

select

with IN USE low. The

solenoidisunlatched

when

drive

selectispulsed

and

IN

USE

is high.

To

implement

this

option,

locate

option

pads D

and

DL. Install

jumpersatthese

locations.

1.19.11

Diskette

Lever

Lock

Latch

Option

(DL)

This

option

is used in

conjunction

with

in use,

alternate

output

pad.

To

implement

this

option,

locate

option

padsD

and

DL.lnstall

jumpersatthese

locations

(see

Section

1.18).

1.19.12

Disk

Change

(DC)

This

output

is usedtoindicatetothe

controller

thatadisk

change

has

been

made. The

internal

signal

is

gated

with

driveselect.When

the

lever

isopened,

the

disk

change

line

goes

low

(true),

and

stays

low

until

the

trailing

edgeofthe

next

drive select.

1.19.13 Two-Sided

Diskette

Installed

(2S)

When a

two-sided

diskette

is installed,

internal

circuitry

gates

this

signal

with

driveselect,

and

sends

a

low

(true) signaltothe

controller,

which

means

thatadouble-sided

disketteisinstalled

(index hole

two

is present).

The Two-Sided

Diskette

Installed

optionisfactory

installed.

1-20

1.19.14

Stepper

Power

From Drive

Select

(OS)

This

option

allows

the

usertoremoveD.C.

power

from

the

stepper

motor

using

drive

select,

which

resultsinlower

stand-by

current

consumption.

The

Stepper

Power

From Drive

Select

optionisimplemented

by

installing

OS,

and

cutting

HL.

1.19.15

Stepper

Power

From

Head

Load

Line

(HL)

This

option

supplies

powertothe

stepper

motor

when

the

head load line

goes

low

(true).This

results

in

lower

stand-by

current

consumption.

This

optionisfactory

installed.

OS

must

be removed

for

proper

operation.

1.19.16

Head

Load

Alternate

Output

Pad

Option

C

This

option

allows

the

userto

loadand

unload

the

headload

solenoid

(optional) and,

along

with

the

HL

and Y options,

enables

the

stepper

motor

and

lights

the

Activity

L.E.D.,

respectively.

Head

load is

accomplished

by

connecting

both

option

padsClocated

near

interface

connector

P13.

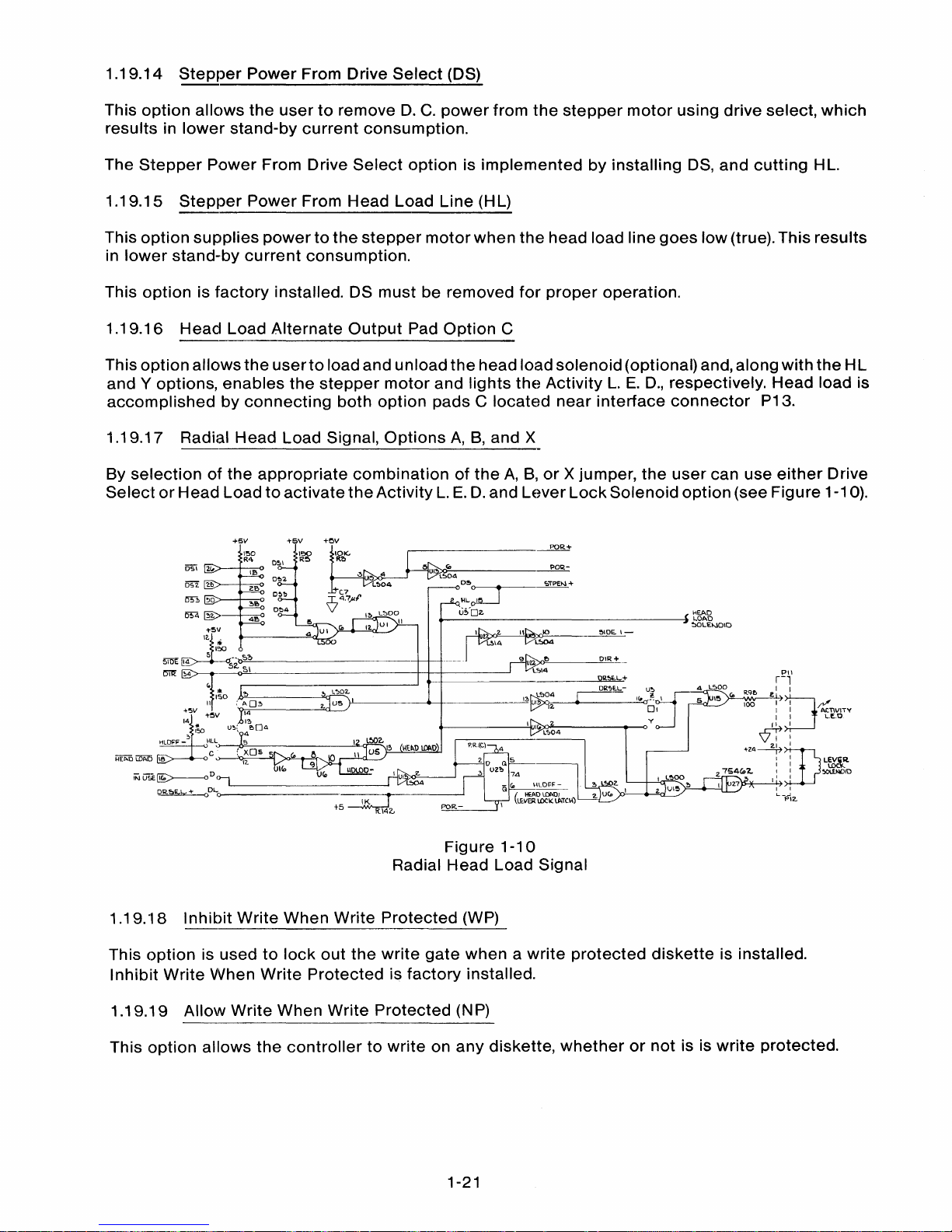

1.19.17 Radial

Head

Load

Signal,

Options

A,

B, and X

By

selectionofthe

appropriate

combinationofthe

A,B,or

Xjumper,

the

user

can use

either

Drive

SelectorHead

Loadtoactivate

the

Activity

L.E.D.

and

Lever

Lock

Solenoid

option

(see

Figure

1-10).

DIR±..._

OIl.~L..+

10 SlOE.

\-

W';ll..-

U,>

c==

I(,cr!!:'

0,

y

r#)O.O'----

__

--<>

POR.-

(i>

POR-

L504

D~

':iTI>El<.l+

H~;=r---

....-_uS_'O_z,

----ll

~getDID

,.--______

POR+

+SV

+5V

+ov

I~O

\'::>0

R4

RO

';f,~

5iDE

~--<1;i=:)'O'------------t-t--+_···_·,

~:14

,,"'_---O-,5~1

----------1--+-+-------'

ISO

tr~'------"'<1~

,.......L';,OZ.

11:1'.03

z.

US

)-'-1

---------+----~

+5V

+5V

14

14

I~

U~:,

4e04

5

Figure

1-10

Radial

Head

Load Signal

1.19.-18

Inhibit

Write

When

Write

Protected

(WP)

This

option

is usedtolock

out

the

write

gate

whenawrite

protected

diskette

is installed.

Inhibit

Write

VVhen

Write

Protectedisfactory

installed.

1.19.19

Allow

Write

When

Write

Protected(NP)

This

option

allows

the

controllertowriteonany

diskette,

whetherornot

is is

write

protected.

1-21

Note

This

option

does

not

stop

the

write

protect

signal from being

sentonthe

interface

line.

This

optionisimplementedbycutting

WP,

andbyinstalling NP.

1.19.20

Head

Side

Select

Options

S1--S3

This

option

allows

headstobe

selectedbyside

select, driveselect,

orthe

direction

control

signal.The

drive

comes

with

side

select, S2, installed.

To

use

the

drive

select

linetoenable

the

heads,

cut

S2

and

install S3

along

with

the

proper

18-48

jumper

that

is used with S3 (see

18-48).

For

head

selection

using

Direction

Select,

cut

S2, and install

S1.

1.19.21

Spindle

Motor

Control

OptionsM1--M4

M1 is usedtoenable

the

motor

off

delay

timer. When

this

jumper

is installed,

the

drive

motor

is

enabled

and

disabledbyeither

the

drive

select

(M3)orhead load (M4) commands. A

20-second

turn

turn

off

delayofthe

spindle

motorisactivated

on

the

trailing

edgeofthe