1\

~'

'anaon

"

'-

"

'"'--.

'-

.".,'''.

'-'"

TAN

DON MAGNETICS CORPORATION

9333

OSO

AVENUE

CHATSWORTH, CALIFORNIA 91311

(213) 993-6644

TM

100

DISK DRIVE

OPERATING & SERVICE MANUAL

023-6017

TABLE

OF

CONTENTS

PROPRIETARY NOTICE

Information contained in this document

MAGNETICS CORPORATION and may

or in part

by

any

person without prior written approval of TANDON

MAGNETICS CORPORATION. Itisprovided asanaidtothe

with no guarantee, written

with regard

to

©copyright

any specification.

1979

or

implied, that the documentisaccurate

TANDONMAGNETICS CORPORATION

is

copyrightbyTANOON

not

be duplicated in full

usef

SECTION

Introduction Purpose of Equipment

Description Diskettes Mechanical

Uncrating

Mounting

Protect

SECTION

Introduction

GENERAL DESCRIPTION

I

tbe

Disk Drive Physical Checkout

the

Disk Drive·. . . Diskette Handling and Storage . . . Loading

...

DC

Power Requirements.

II

THEORYOFOPERATION. . . . . . . . . . . . . . . . . . . . . . . . .

...

Organization

olthe

Disk Drive

AND

SPECIFICATIONS. . . . . . . . . . . .

...

Physical Description of Equipment

and

Electrical Specifications

...

Interface Connections

...

Functional Block Diagram Description

...

Write Protect . . . Track00Switch . . . Spindle Drive . . . Positioner Control

SECTION

Figure

Figure 2

Figure 3

Figure 4

Figure 5

Figure 6

Figure 7

Figure 8

Figure 9

Figure 10

Figure

Figure

Figure 13

Figur.'4

Figure 15

III

Introduction

Board Test Points

..•

1

TM

Recording Medium. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0

Outline TM100 Disk Drive. . . . . . . 0 • 0 • • • 0 • • • • • • • • • • • • • • • • • • 0 • •

Diskette

Diskette Access . . . • • . . . . . 0 • • • 0 0 • • • • • • • • • • • • • • • • • • • • • • • • • • 0 7

Write Protect

TM100

FM .Aecording . 0 • • • • • • • • • • • • • • • • • • • • • • • • 0

Write Timing Diagram 0 • • • • • • • • • • • • • • 0 • • • • • • • • • • • • • • • • • • • • • • • 12

Read Timing

11

logic

12

Servo P.C.B.A

Interface Configuration. . .

Catseye Pattern. . . . . . . 0 • 0 • • 0 • • 0 • • • • 0 • • • • • • • • • • 0 • • 0 • • • • • • • • •

IndextoData . 0

OPERATION

Physical Description of PCBA's

...

Option Select

100

Disk Drive : . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

eare

FunctionatBlock

.........................•...............

...

...

Adjustment

liST

OF

ILLUSTRATIONS

and

Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tab

. . . . . . . . . . . . 0 • • • • • • • • • • • • • •

Diagram 0

Interface Electronics Specifications

•••••••••••••••••••

Diagram 0 • • • • • • • • • • • • • • • • • • • • • • • 0 0 • • • • • 13

PoC.B.A

.•..

0

••••••••••

••••••••••••••••••••••••••••••••••••••••

.'.

. . . . . . . 0 • • • • • • • • • • • • • • • • • • • • • • • • 0 •

0

••••••••••••••••••

0

••••••••••••

...

Interface Specifications .

...

the

...

Functional

Chassis Ground .

Diskette . . . Write

...

Index

Data Electronics

...

••

•••••••••••

•••

• 0 • • • • • • • • • • • • •

0••0••0

0 • 0

0

•••••

••••••••

•••••

..

..

...

Circuit

..

••

••

..

0 8

0

1

9

14

1

3

5

6

10

11

14

15

15

20

21

LIST

OF

TABLES

Table - Mechanical

Table - Interface Connector Pin Assignments,

and

Electrical Specifications. . . 0 0 • • • 0 • • • • • • • • • • • 0 • • • 0 • 0 •o.4

Jl/P1

Table - Power Connector Pin Assignment 0

0

••••••

••••••••••••••••••

0

•••••••

0 0

•••••

16

0

••

16

SECTION I

GENERAL DESCRIPTION AND SPECIFICATIONS

1.1 INTRODUCTION

This section provides

TANDON MAGNETICS CORPORATION.

1.2

PURPOSEOFTHE DRIVE

The

TM100

retrieval applications. These applications typically are intelligent terminal controllers, micro-computers.

processing systems,

terminals.

The

TM100iscapableofrecording

1.3

PHYSICAL DESCRIPTIONOFTHE DRIVE

The

TM100

when

however,

The

spindleisbelt

and

pulleys,

positionedbymeansofa

The

read/write/erase

20,000

hours.

Operator

access

The

electronic

the

chassis,

connectors

the

which

the

physical

Disk Driveisa

data

communications

Disk Driveisshown

mounted

horizontally,

drivenbyademotor

the

tachometer

for

componentsofthe

other

plug

control

stepper

head

assemblyisa glass-bonded ferrite/ceramic

diskette

loading is provided via a slot

(servo) is

directly

and

functional specifications for

"MINI"

Disk Memory designed for

systems.

and

reading digital

in Figure 1.

motor,

Drive are

mountedatthe

into

the

The

the

printed

with an integral tachometer.

the

speedofthe

split

band,

mountedontwo

rearofthe

logic PCBA.

the

random

error

logging, micro-program loading.

data

usingFM,

Drives

canbemountedinany

circuit logic

spindle.

and

a suitablv sized

locatedatthe

unit.

MFM,orM2FM

board

mustbeuppermost.

The

The

read/write double-sided

structure

PCDA's,

Power

and

TM100

Disk Drive.

access

verticalorhorizontal plane;

servo

control

puney.

which has a fife in excess

frontofthe

oneofwhich Hogic)islocated above

interfacesignals are

manufactured

data

entry,

storage,

and

pointofsale

techniques.

circuit, suitably sized

head

assembly

unit.

routed

and

word

through

by

is

of

TM

100 DISK

Fig. 1

DRIVE

(,f"-"'-'~

1.4

The Disk Drive.isfuttyself-contained

Drive consists of a spindle drive system, a head positioning system, and read/write/erase system.

When the front latch

place by plastic guides, and the front latch. Inlout location

back stopisencountered.

Closing the front latch activates the conelclamp system resulting in centeringofthe

the diskettetothe drive hub. The drive

motor. In operation, the magnetic headisloaded intocontact with the recordingmedium whenever the front

latch

is

The magnetic headispositioned over·the desired track by meansofa4-phase stepper motor/ba,nd assembly

and

its associated electronics. This positioner employsa one-step

When a write-protected

electronics of the Drive andanappropriate signal is appliedtothe interface.

When performing a

then tunnel erasedto0,30

Data recovery electronics include a low-level read amplifier, differentiator, zero-crossing detector,

digitizing circuits.

No

data decoding facilities are provided in the basic Drive.

The Drive

1.5

TheTM100

or

hole

Diskettes with a single hole are used when secto.rinformationisprerecorded on the diskette. Multiple hole

diskettes provide sector informationbymeans of the index sensor

Figure 2 is a simpUfied drawingofthe

medium

the jacket,

1.6

MECHANICAL·AND ELECTRICAL SPECIFICATIONS

The mechanical

1.7

INTERFACE

Levels: True

The interface circuits are designed so

1.8

UNCRATING THE DISK DRIVE

The Disk Drive is shipped

damage during shipment. The

Drive.

(1) Place the containerona flat work surface.

(2) Remove the outer cardboard sleeve from around the Inner container.

(3) Remove theupper half

(4) Remove the Disk Drivefrom the lower halfofthe inner container.

(5) Check thecontentsofthe

\

FUNCTIOhl"\L DESCRIPTIONOFTHE

is

opened, accessisprovided for the insertionofa diskette. The disketteispositioned in

closed.

disketteisinserted into

write operation, a 0,33

mOl

(0.012 inch) Cnominal).

is

also supplied with

(1)

A Track 00 switch which senses when the Head/Carriage assembly

(2)

The index sensor, which consistsofan

that when

resolution device which can distinguish holes placed close together, i.e., Index-Sector holes in a

hard sectored diskette.

(3) The write-protect sensor disable

to

DISKETTES

multiple holes.

is

a flexible magnetic disk enclosed in a protective Jacket. The protected disk, free to

False

possible.damage; notify the carrier immediatelyIfany damageIsnoted.

an

index hole is detected, a digital signal is guaranteed. The index sensor usedisa high

the disketteCsee section

uses a standard

is

continuously cleaned by

and

electrical specifications for the

SPECifiCATIONS

II:

+O.4v(maximum)

= +2.4v (minimum)

the.

.1.

133.4mm

that

ina

protective container which, whenbulk packaged, minimizes the possibility

follOWing

of

the

shippingcontainer against the packing

DRIVE

and

requires'no operator intervention during normal operation. The

is

ensured·when the disketteisinserted until a

diskette

hubisdrivenata constant speedof300

the

mOl

(0.013-inch) (nominal)

following sensor systems:

LED'Ught source

the

Disk Drive electronics whenever a write-protect

16 and figure 6).

(5.25

inch) diskette. These diskettesare available with a single Index

diskette used with the Disk Drive. It

th,

soft fabric liningofthe Jacket during normal operation.

Disk~rive

a disconnected wire results in a false signal.

procedure describes

inner-container.

rotationtocause a 1-treck Unear' movement.

Ddve, the write;;protect senior disables

andphototransistor,

andelectronicl.

are given in Table 1.

thetecommended

rpmbya servo controlled dc

data

track is recorded. This ,track

is

canbesaenthat

method

sUp.

Investigate

and

positionedatTrack

is positioned such

tabisapplied

this recording

rotate

for uncfatlng

the

contents

clamping

the

within

the

write

and

.,.

Disk

for

6.30I0,25

3fi6mm

ul'40

of

--J~~

'NCIIl .

.,

11

..

-lI

1015I0.0'

mm

'NCIII

T

i

'33,4

10m

(5?5

E~

(0

is

e-

\1)(;

dO

+1·

~~

I!:?

INC'"

L

::.~;

,'::...

:;.~:

:~~H'

LINER

of

1.9

PHYSICAL CHECKOUT

Before applying powertothe unit, the following inspection shouldbeperformed:

(1)

Front'atch.

head arm raises.

(2) Ensure

(3) Manually rotate the drive hub. The

(4) Check

(5) Check for debris

Check that the

that

the front panelissecure.

that

PCBA's are secure. Check that the connectors are firmly seated.

or

foreign material between the heads and remove same.

RECORDING MEDIUM

Fig. 2

front

latch opens

hub

should rotate freely.

..1

•I

and

closes. Note that when the doorisopened, the

TABLE 1

MECHANICAL AND ELECTRICAL SPECIFICATIONS

Media

Tracks per inch

Number of Tracks

Dimensions

Height

Width

Depth

Weight

Temperature

(Exclusive

Operating

Non-operating

Relative Humidity

(Exclusive

Operating

Non-operating

Seek Time

Head Setting Time

Error Rate

Head

Media

Disk Speed

Instantaneous Speed Variation

Start/Stop

Transfer

Bits/Disk (unformatted)

Recording Modes (typicaU

Power +12

life

life

Time

Rate

of

of

Media)

Media)

Industrv-compatible 5%-inch diskette

48

80

85,85mm(3.38 inches)

149,10mm(5.87 inchest

203,2

2.04

100eto44°C

-40°Cto7,oe

20%to80% (Non-condensing)

5%

5 msec track

15 msec (last track addressed)

20,000

3.6x106passes Per track

300

~

250/150

FM

MFM

2.00

FM,MFM,MMfM

+5v dc

(40

per

side)

mm

(8.0) inches

Kg

(4.5 IbsJ

(GOoFto112°F)

(-400F

to

95% (Non-condensing)

to

track

per

109(recoverable)

10'2(non-recoverable)

per

106(seeks)

per

hOUfS

(normal use'

rpm:!: 1.5% (long term)

3.0%

msec (maximum)

125K bits/sec

250K bits/sec

million (FM)

de~O.6v

±0.25v,

900

ma AVE.

600maAV

to

16ooF)

E.

1.10

INTERFACE CONNECTIONS

Signal connections for

3463-0001

The dc power connector

the

and

The

Power connections

connector

1.11 CHASSIS GROUND

To

ac lug, 'Clcated

1.12 MOUNTING THE DISK DRIVE

The

The only mounting restriction

uppermost side. Tapped holes

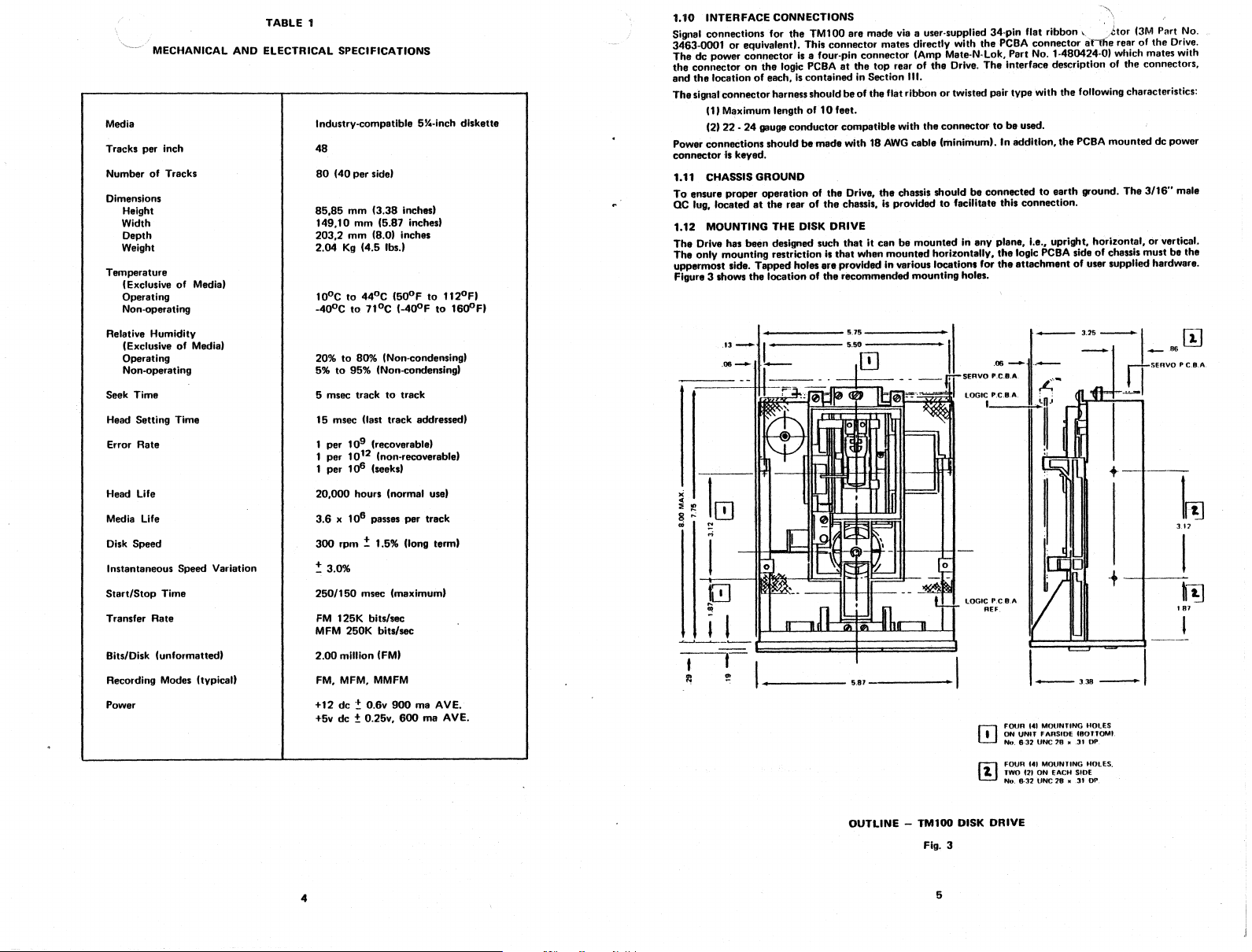

Figure 3 shows

or

connectoronthe

the

locationofeach,Iscontained in Section

signal connectorharnessshouldbeof the flat ribbonortwisted pair type with the following characteristics:

(1)M~ximum

(2)

22 -24gauge

lskeyed.

ensure proPer

Drive has

13__'"

.06

.-...,

the

equiva'end.

operationofthe

at

been

the

~-.....-

i

TM100 are made via a user·supplied 34-pin flat ribbon\.,

This connector mates directly with

is

a four-pin connector (Amp Mate-N-Lok, Part No. 1,.480424-0) which mates with

logic PCBAatthe

length

of10

conductor

shou'dbemade wit,h18 AWGcable (minimum).Inaddition,

the

rearofthe

designed such

locationofthe

I

is

.feprovidedin

top

rearofthe

",.

feet.

compatible with

Drive,

chassis,

that

it canbemounted

that

when

recommended mounting holes.

5,75

5.50

.m

the

the

chassis shouldbeconnectedtoearth

'sprovided

mounted

horizontally,

various loc:;ations for

thePCBA

Drive.

The

connectortobe

·to

facilitate this connection.

in any plane, i.e., upright, horizontal, or vertical.

•

'itor

connector anile rear of

interface description of the connectors,

used.

the

PCBA

ground. The 3116" male

the

logic

peBA

the

attachmentofuser supplied hardware.

sideofchassis must be the

(3M

mounteddcpower

+-t-t·

~

1

m

I

~

,..;

I

lOGIC

lLD

CIO

~jJL---II'

It

gill

"'IF'

UUII

" • I

REF.

PC8.A

.--,

.~

~

• 5,81 •

OJ

r;l

~

L-3~-1

FOUR. ,•. t

MOUNTING

,.ONUNIT

No,

6·32

UNe18" .31

FOUR '4t. MOUNTING. HOLES.

TWO

f2t ON

No,

6·32

tJNe28" .31

HOLES

FARStOEC80lTOMt.

EACH

SlOE

OP

OP

Part No.

the

Drive.

fiJ

3.12

I

,~

Hn

I

OUTLINE

4

- TM100 DISK

Fig. 3

5

DRIVE

1.12.1 HARDWA.

The Disk Driveismanufactured with certain critical internal alignments that mustbemaintained. Therefore,

it

is

important

Any mounting scheme

Mounting schemes should allow for adjustable brackets or incorporate resilient members

tolerances.

Mounting schemes involving more than three mounting points should

that

the mounting hardware does not introduce significant stressonthe Drive.

in

which the Driveispart of the structural .intergrity of the enclosureisnot

be

avoided.

permitted.

to

accommodate

1.12.2OUST COVER

Since the Disk Driveisnot provided with a dust cover, the design ofanenclosure should incorporate a means

to

prevent contamination from loose items, e.g., dust, lint, paper chad, etc.

1.12.3COOLING

Heat dissipation from a single Disk Driveisnormally15watts (51 Btu/Hr) under

the

Drivels mounted so

allowsoperation over the specified temperature range.

When the Driveismounted in a confined environment, air flow must be providedtomalntain specified air

temperatures in

1.12.40RIVE

In additiontothe cooling requirements specified in Paragraph 1.12.3, a minimum separationof26,4mm

(1

inch) between· Drivesisrecommended. Thisisrequiredtoavoid electrical interference between the motors

of one

at

least 1,52 mm (O.060-inch) thickisplaced between units. However, useofthis steel sheet may increase the

cooling requirements.

SEPARATION

Drive and the magnetic head of another Drive. Closer mountingisallowableIfa gounded sheetofsteel

1.13 DISKETTE

It

·is

important

maintained. A damaged

damage

to

the read/write heads.

that

the components have accesstothe free flow

the

vicinity of the motors, PCBA's,

HANDLING

that

the diskettebehandled

AND

STORAGE

or

contaminated diskette can impairorprevent recoveryofdata

and

and

stored properly so

diskette.

that

hi",Uneconditions.

ofafr,normal

the integrityofthe recorded

convection cooting

and can result in

When

data

Figure 2 illustrates the physical configuration of the diskette. The diskette is an oxide coated, flexible mylar

disk, 130,2

protective jacket. Read/write/erase head access

drive

Figure 4 provides some helpful

to

handling should

mm

(6.125

inches) in diameter, andisenclosed in

hub

and

diskette index hole are also provided.

assure trouble-free operation and enhance the service life of the diskette, the following procedures for

be

observed:

hi~lts

on the care and handlingofthe

is

made through an aperture in the jacket. Openings for the

an

133,4

mm x

133,4

Disk Drive and diskettes. Additionally,

/

mm(5.25x

5.25-inch)

Return the diskettetothe protective jacket when not in use.

Avoid exposing the diskettetoany mangetizing force in excess of50oersted.

NOTE

The50oersted levelofmagnetizing forceisreached

of

approxilnately76mm

motors,

generators, transformers.

Do not

stare

the diskette in direct sunlight as warping could resutt.

Do

not

use a lead pencit or ballpoint pentowrite on the label.

on

the label.

1.14

LOADING

Diskette. loadingisaccomplished by inserting the properly oriented diskette. into the front slot provided.

Access

tathe

THE DISKETTE

diskette loading

slotisobtained by opening the front latch. See Figure 5.

(3 inches)

from

at

a typical source, e.g.,

a distance

Use

a felt tip

pen

and mark IightiV

The diskette should· be carefully inserted untit the diskette jacketissolidly against the backstop.

CAUTION

DAMAGE

RESULT

NOT

is

RECOVERY OF THE RECORDED DATA.

TO THE CENTER HOLE

IF

THE DOOR IS CLOSED WHEN THE IJISKETTE IS

PROPERLY INSERTED. THIS WILL PREVENT

IN

THE DISKETTEMAY

RELIABLE

00

NOT TOUCH PRECISION SURFACE

WITH YOUR FINGERS

FIEt-OS.

Wlnt

CARE BENDING

MAY

AWAV

.

FROM

DAMAGE

KEE'

DISKETTE

MAGNEnC

UANOLE

AND FOLDING

DISkETTE

DISKETTE CARE

TO AVOID DAMAGE TO THE DISKETTE

AND TO YOUR DRIVE, INSERT

CAREFUllY

ENCOUNTERED

RETURN

lUE

WHEN NOT

OISKETllS

,00

10

5l'1C

Q

to"

10

I2S

AND

HANDLING

Fig. 4

UNTtl

BACKSTOP IS

OISKETtEfOITS

I.N

USE

SltOULOBESTORED

f

OI$KUTE

JACKel

At

"'"

"""''-

",-

'\.'.".

DISKETTE

Fig. 5

ACCESS

1.15 WRITE

The Disk Driveisequipped with a write

diskette having a slot

When the slot

to

writeonthe

t,~",eCT

cut

in the protective jacket.

is

covered with a self-adhesive tab,

diskettE!. Figure 6 illustrates

WRln

PROffcr

TAO

~

@

o

O·

,-

1.16

DC

POWER REQUIREMENTS

+12:!:O.6vdc:

+6 :!:O.25v de:

900MA

600

MA

(MAX

(MAX

protect

switch assembly. This sensor operates in conjunction with a

The

location of the slotisshown in Figure 6.

the

disketteiswrite protected. The slot must be uncovered

howtoinstan a

fOlO

OVER

OACI<

Fig. 6

<lOOmv

-I!--'-

P.P. ripple

-------11

INDEX ACCESS HOLE

WRITE PROTECT TAB

AVE.)

AVE'),

tabtocover

the

slot.

OJ

@.

-~

o

Of

Ol<;t<fl

f[

I--

356

mrn

";t4

'NCH'

6.30

r

IO'~

INCH,

Tf

96.5

mm

"~lNC"'

....",..

TAO

",,,n

SECTION

II

THEORY OF OPERATION

2.1

INTRODUCTION

This section provides a

TM100 Disk Drive.

The

Disk Drive consists of

ana

diskette.DCpower

ba.sic

description of

the

mechanical

at

+12 v and + 5v (provided

and

the

operationofthe TANOON MAGNETICS CORPORATION

electrical

components

by

the

necessarytorecord and read digital data

user)isrequired for operation.

2.2 ORGANIZATION OF THE DISK DRIVE

All

electrical subassemblies in the Disk Drive are constructed with leads which terminate in 4 or 5 pin

connectors. enabling the individual.assemblies

The magnetic heads are connected

associated male sockets which are localed in close

Interface signals

signals are presented in Section

and

power are provided via connectorsatthe

to

til

of this manual.

to

be removed.

the

PCBA via cables terminated in 5-pin female connectors and its

proxi.mityto

the

read/write

rear of the Drive. Detailed description of these

data

electronics.

2.3 FUNCTIONAL BLOCK DIAGRAM DESCRIPTION

Figure 7isfunctional block diagramofthe

the

following discu$sion:

The

identificationofthe elementsofthis discussion

associated figures are related

only

representedinsimplified

The Disk Drive

con$ists of

the

following functional groups:

TM

100

Disk Drive

NOTE

to

the actual schematic

forminthis section.

and

$hould be referredtoin conjunctionwith

and

the

and

are

* Index Pulse Shaper

* Write Protect Sensor

* Track 00 Sensor

• Spindle Drive Control

* Carriage Position Control

• Write/Erase Control

and

• Read Amplifier

2.5 INDEX

An index pulse is providedtothe

consists of an Index LED, Index

disk passes

Transistor causing it

Network which produces a pulse for each hole detected. This pulse

PULSE Interface tine.

2.6

A Write Protect signalisprovidedtothe user system via the WRITE PROTECT interface tine. The write

protect

When a write

write

2.1

The level

the

and

2.8 SPINDLE DRIVE

The Spindle Drive system consists of a spindle assembly drivenbya

through a drive belt.

Associated with the spindle drive

The control circuitry also includes a current limiter

ENABLE interface line

drive

the

Index LED/Photo Transistor combination, light from

to

WRITE PROTECT

circuitry consists of a Write Protect Sensor

protected

~Iectronics

TRACK"

head.ispositionedatTrack0.and

senttothe

motor

and

supplies the status signaltothe

SWITCH

on

the TRACK00interface lineisa function of

user.

exceeds

1.3

Digitizer

user system via

Photo

Transistor,

conduct.

The

signal from

disf<etteisinserted in

the

motor

is

true,

the

drive

ampere,

motorisallowedtocomeupto

the

current limit circuitry disables

the

INDEX PULSE interface line. The index circuitry

and

a Pulse Shaping Network.Asthe index hole in

the

Index

Photo

Transistorispassedtothe Pulse Shaping

is

and

circuitry'toroute

the

drive,

the

sensorisactivated and

interface.

the

stepper

motorisat

are

the

servo electronics required for control.

and

position of the magnetic head assembly. When

the home position, a true levelisgenerated

an interface control line. When the DRIVE MOTOR

the

the

LED strikes the Index Photo

presentedtothe

the

dcmotor-tachometer

speed. When

motor

drive.

useronthe

signal produced.

the

the

current through the

INDEX

logic disables the

combination

the

8

9

DC

STEPPER MOTOR

INlHtfACE

CONTUOl

<4.._-_._--

IND[)(

PlltSf-

WHITE

"Honel

.-----'

TM

100

FUNCTIONAL BLOCK DIAGRAM

Fig. 7

2.9

POSITIONER CONTROL

The Head Positioning system utilizes a four-phase stepper

track advancement

provided as an element for inhibiting positioner

2.10

DATA

Information can be recordedonthe diskette using a double-frequency code. Figure 8 illustrates the

magnetization prQfiles in each bit cell for the number sequence shown.

The erase gaps provide

tolerances in track positioning.

All

signals requiredtocontrol the data electronics are providedbVthe user system and are shown in

diagram, Figure

of

the Read/Writecarriage. In additiontothe logic necessary for motion

motion

ELECTRONICS

an

erased guard bandoneither side of the recorded track..·T

7. These control signals are:

motor

drive

w"ichchanges

during a write operation.

one

phase for each

contro',

a gate

....isaccommodat«!s

the

block

• SELECT

• WRITE.ENABLE

DATA

SIDESELECT

The READ

• WRITE

*

DATA

composite signalissenttothe user system via the interface.

the

-H

BIT

CEll~_

I 1 I 1

BITPATT£RN

NWRITEOATA

MAGNETIZATION • 1

,i

MAGNETIC

El~MENTS

I • I

I I I

I I I

I ! I

>(

Y'

)"'

>f Y .

I

I

1-

I I

I •

I •

7)(

/ :

If

¥

....

G·;:.f

II

'i

F M RECORDING

Fig. 8

2.10.1

DATA

RECORDING

ReferringtoFigure 7, it

Write Waveform Generator, Erase Current Source, Trim Erase Control Logic,

The read/write winding

Write Current Source flow in alternate halves of the winding under control of the Write Waveform Generator.

Before recordinr can begin, certain conditions must be satisfied. The conditions required for recording

O.e.,

unit ready must be establishedbVthe

CH

Drlvespeed stabilization. This condition will exist

(2) Subsequent

total after the last step pulseisinitiated, i.e., 5 msec for the step motion and 15 msec for settling.

is

Figure 9 shows the relevant timing diagram for a write operation. At t

ENABLE interface line goes true, this enables the Write Current Source.

the

Since

the WAITE ENABLE interface line.Itshouldbenoted

at

Figure

Generator which togglesonthe leading edge of every WAITE

Note that a minimumof4 usee end a maximum

WRITE

At

I"

last significant WRITE

The TRIM ERASE signa' must remain true for

thataUrecorded

.I

and

The

TRIM ERASE. This

trim erase gaps are behind the read/write gap, the TRIM ERASE control goes true

Track0.and Track 34 so

9 shows the information

DATA

pulseisonly requirediffaithful reproduction

the

endofrecording,atleast

34.

durationofa write operationisfrom

c~n

be seen

that

the Write Electronics consist of a Write/Erase Current Source and

on

the magnetic headiscenter-tapped. During a write operation, current from the

us,er

system as follows:

250

msec after starting the drive motor.

to

any step operation, the positioner must be allowedtosettle. This requires

NOTE

Allofthe foregoing operations can be overlapped,ifrequired.

that

that

the effectofthe trim erase gapsonprevious informati.onisminimized.

on

the WRITE

DATA

of8

one

DATA

data

are trim erased.·This valueisagain optimized between the requirementsatTracks

Is

indicated by the internal WRITE BUSY waveform shown.

additional pulseonthe WRITE

pu'setoavoid excessive peak shift effects.

800

the

true-going edgeofWRITE ENABLEtothe false-going edge of

this valueisoptimited between the requirements

interface line,

DATA

usecbetween WRITE ENABLE going true

olthe

usec after the termination of WRITE ENABLEtoensure

::::

0 when the

and

the

pulse.

first WRITE

DATA

a'1d

Head Select Logic.

unit

is

readv, the

output

of theWrite Waveform

DATA

transitionissignificant

line must be inserted after the

390

and

20msec

WR

ITE

usee after

the first

0.

WAITE ENABLE

'RIM

ERASE

INTERNAL

WAllE

BUSY

NWAITEOATA

WAITE

WAVEFORM

GENERATOR

WRITE

CURRENT

,~0

NOTE 1

f NOTE 1

,

I

390

~

sees~'

I

I I 1 1 I

'J-;

I I

It·

I I I

I I I

I I 1

1i--f~1

I

,--L

r-"J

~

800

users

s--r

S.

I t

S~

~

I

r-:--t

t I

-..J

I

~

I

LINEAR OUTPUT FROM

OUTPUT FROM DIFFERENTIATOR

READ DATA INTERFACE

FitTER

NOTES: t = 0 =250 MILLISECONDS AFTER DRIVE MOTOR STARTS,

t

t =0

OR

20

MILLISECONDS AFTER STEP COMMAND,

100

u SECONDS AFTER TERMINATION OF WRITE

BUSY, (WHICHEVER

IS

THE LATEST TIME)

OR

NOTES

2.10.2

DATA REPRODUCTION

The Read Electronicsconsist of

I~0

~250

M'LLISECONOS

STAATSOR2OMIlliSECONOS

PULSE,

4WH'CHEVER'STHE

WRITE TIMING DIAGRAM

the

following:

AFTER

OAIVE

AFTER

LATEST TIME)

Fig. 9

MOlOA

LAST STEP

UNSYNCHRON'ZEO

8.5

MI\

PEAKTOPEAK

.. u

SECONOS

M'NIMUM,

8 "

S£CONOS

* Read Switch/Side Select

* Read Amplifier

* Filter

* Differentia tor

* Comparator

The Read Switch

during a write operation. The side select

Before reading

ready condition must

Paragraph 2.10.1 a

Read Amplifiertosettle after

Referring

filteredtoremove noisebya linear phase Filter. The linear outpUt from

Differentiator which generates 8 waveform whose zero crossovers correspondtothe peaksofthe

signal. This

The Comparator

the

interface line.

to

signatisthen fedtothe

read signal. This Composite Read Data signal is

and

Digitizer

is

usedtoisolate the Read Amplifier from

can

begin,

the

Drive mustbein a ready condition. As

be

established by the user system. In additiontothe

100

usee delay must exist from

the

Figure 10,

the

output

and

Digitizer circuitry generates a 1usee READ

is

usedtoenable

transient caused by the Read Switch returningtothe

signal from.

Comparator

the

voltage excursion across the magnetic head

oneofthe

the

trailing edge of

the

read/write headisamplified

and

Digitizer circuit.

then

read/write/erase heads.

with

DATA

senttothe

the

data

recording operation, this

requirernents established in

the

TAIMERASEsignattoallow

pulse correspondingtoeach

user system via

Read

mode.

bya

read amplifier

the

Filterispassedtothe

the

READ DATA

MAXIMUM

peak

READ TIMING DIAGRAM

Fig. 10

the

and

read

of

l'

SECTION

III

OPERATION

3.1 INTRODUCTION

This section

TM100 Disk Drive. Also presented are schematic diagrams of

3.2

The

servo

illustrate

J3

READ/WRITE

HEAD

contains

the

interface description

PHYSICAL DESCRIPTIONOFTHE PCBA's

logic PCBAisapproximately

PCBA

is

approximately 127mm(6.0 inches) long

the

placementoftest

~~

:>%

CONNECTORS'RM

P5

0:

WQ

~~

..1%

P6

146

points

mm

(5.75 inches) tong by

and

connectors.

and

the

mechanical/electrical adjustments necessary for

by38mm

TP2 •

o

TPI •

TPI,

•

C48~~~)(i~

%Zzzz25!.

PROGRAMMABLE

SHUNT

SOCKET

HE.

Jl

,NTERfACE

CONNECTiON CONNECTIONS

/

.TP5

1Pl.

.UNUSEO

I}O

INTERfACE

TPH

1P9

I

II·

••

P6

,.p,o.

~~

%..

~

a

t

..

~y

~~~Y-CONNECTOR

~'..

TERMINATOR I n 0 0 0 I

SOCKET'2F1

ii

LOGIC P.C.B.A.

Fig.

11

the

PCB

• TP8

TN

. - . -

~o

~

:~

!

A's installed in

146

mm

(1.5 inches) wide. Figures

TP4 •

TP10

TP3 •

the

(6.75 inches) wide,

•

o

AI

T~13

/

%SERYO

p"mpl3

','-

:

~

c(

~

~

.•.

I

" .

..•.--.

:1

,

-',

Disk Drive.

11

STEPPER

MOTOR

J2.

J4

POWfR

the

and'

the

and

12

~ER'

o

o

R4 SPINDLE

SPEED CONTROL

3.3

INTERFACE ELECTRONICS SPECIFICATIONS

All

Interface signals are

(minimum). Figure 13 illustrates

It

Is

recommended

«>hans

Cor

equivalent twisted pairs).

Interface

connector

3.3.1 INPUT CONTROL LINES (SeeTable

3.3.1.1 SELECT LINES (NDS1-NDS4)

The

SELECT lines provide a meansofselecting

standard) select

(low).

the

commands. When

A SELECT line

command

The

daisy-chaining a maximumoffour

An undefined operation might result if two.

SELECT

Disk Drive electronics are activated

is completed.

Disk Drive addressisdeterminedbya Select

lines

areinthe

+

TRUE

TTL

compatible. Logic

that

pin

oneofthe

the

must

the

the

interface cablebeflat ribbon cable, with a characteristic impedanceof100

assignments

four Disk Drives

logic level is falseChigh).

remain stable in

true

Clow)

r

--------1

I

'""

I

I

I

I . I

L

'~6

~~E~:V~~~

interface configuration. Maximum interfacecable length is10feet.

and

power

the

Disk Drivestoa controller. Only

state

simultaneously.

'"

~

+'

DRIVER

INTERFACE CONFIGURATION

SERVO JUMPER

DRIVE MOTOR

SERVO P.C.B.A.

Fig.

12

true·

(low) is +0.4v (maximum), logic false (high) is +2.4v

connector

pin

assignments are given in Table 2

2.

and

deselecting a Disk Drive. These four lines (NDSO-NDS3

attachedtothe

and

the

the

input

true

Clow)

Shuntonthe

or

more

TWISTED

I

TRANSMISStON

Fig.

controller. When

Driveisconditionedtorespondtosteporread/write

control

lines

state

until

the

PCBA. SELECT lines 0-3 provide a means

.LINE

t

I

I

I

I

I

t

I

I

REeEtVER

I

I

I

I

one

.5V

units

~,

10

are assigned

PAIR

FEET

the

signal logic levelistrue

and

output

status tines are disabled.

executionofa steporread/write

line

canbetrue

the

same addressorif

150

OHMS

14lS04OREOU.VAlENT

13

and

Table 3.

(low)ata time.

twoormore

•

TRUE

of

INTERFACE CONNECTOR PIN ASSIGNMENTS.

Ground

1

3

5 6

9

11

13 14

15

17

19

21

23

31

-

-

Ground

7

25

27

29

33

TABLE 2

Controller-to-Disk Drive

Signa'

2

4

10

12

16

18

20

22

24

32

Disk Drive-to- Controller

Signal

8

26

28

30

34

POWER CONN,ECTOR PIN ASSIGNMENT

Pin

1

2

3

4

Description

Connector

(Spare)

SELECT 3 (NOS3)

SELECT 0 (NDSO)

SELECT 1 (NDS1)

SELECT 2 (NDS2)

DRIVE-MOTOR ENABLE (NMOTORON)

DIRECTION

STEP (NSTEP)

WRITE DATA (NWRITEDATA)

WRITE GATE (NWRITEGATE)

SIDE SELECT (NSIOE SELECT)

Description (Mnemonic)

INDEX (NINDEX/SECTOR)

TRACK

WRITE PROTECT (NWRITEPROTECT)

READ

Connector

TABLE 3

Supply Voltage

+12v

Return(+12v

Return

+5v

de

00

DATA

de

C+5v

(Mnemonic)

clamp

(NTRK00J

Clamp

det

J1/P1

(NREADDATAJ

de)

3.3.1.2

When

and

stop

3.3.1.3

Whe'n

Hne

line

true

the

the

STEP pulse

initiatedonthe

DRIVE MOTOR ENABLE (NMOTORON) ,

this signal line logic leve' goes

stabilizes in 'ess

DIRECTION

the

Disk Driveisselected, a

initiates

when

a STEP pulse is issued.

(low)

state

DIRECTION

DIRECTION line

and

than

and

the

access

motion.

when

a STEP pulse is issued.

line

isinthefa1se

shouldbestable 0.1 usec

remain

stable

trailing edgeofthe

250

true

msec. When

STEP Lines(2Lines)

true

(low) pulse

The

directionofmotionisdeterminedbythe

The

motion

(highl

until

0.1 usee

STEP pulse.

3.3.1.4 WRITE DATA (NWRITEDATA)

When

the

the

WRITE ENABLE line (see Paragraph 3.3.1.5).

For each high-to-Iow transistiononthe

This causes a

When

Write Data signa1).itis

zeros,beequaltothe

when

3.3.1.5

When this signal is

This signat

input

first

first significant WRITE

restrictions

the

When a

Irrespective

3.3.1.6

When this signal is

false (high) side 0ofthe

This

3.3.2

3.3.2.1 INDEX (NtNDEX/SECTORI

The

beginningofa trac·k.

The

The

Drives.

3.3.2.2

When

write

from Track

3.3.2.3

When

The

Disk Driveisselected, this interface line provides

switchingofthe

the

double-frequency

writingaUones,

WRITE ENABt.E CNWRITEGATE)

line. It is generally

WRtTEDATA

WRITE ENABLE signal. When

write·protected

SIDE SELECT (NSIDESELECT»

signatis

OUTPUT STATUS (See Table

INDEX signalisprovided

durationofan

leading edgeofan

TRACK.e(NTRK")

the

Disk Driveisselected,

headispositionedatTrack 00.

00.

WRITE PROTECT (NWRITEPROTECT)

the

Oisk Driveisselected, this signal line 'ogic level goes

write electronics

write

currentinthe

·nux

changetobe

true

turnsonwrite

pulse. However,

exist

for

the

of

the

stateofthe

true

best

implemented in sychronization

The

INDEX pulse is nominally

INDEX pulse

are

storedonthe

type

recommended

nominal

shouldbeequaltotwice

data

(lowtthe

currentinthe

recommended

DATA

pulse

relationship

diskette is installed in a

WRITE ENABLE LINE.

(low) side 1ofthe

diskisselected. This signal

once

INDEX line remains in

the

internally disabled

WRITE DATA line, a flux change is

encoding techniqueisused

that

rate

write

that

the

should

between

the

WRITE ENABLE line is false (high). all write electronics

2»

each revolution

must

TRACK00interface signal indicatestothe

The

(low),

the

drive

the

logic level goes false (high),

is towards

The

state

after

heads.

The

disk.

the

±0.1

percent.

the

electronics

read/write head. Data is

changesofstateonthe

separation

notbeless

the

least significant WRITE DATA pulse

diskisselected

4.0

msec.

alwaysbeusedtoensure

TRACK 00signal remains

when

the

motor

CDIR)

eNSTEP)

withatime

directionofmotion

when

(minimum.

the

write electronics

repetitionofthe

nominal

are

between

TM100

mustbestable duringanentire

with

the

(200

the

true

disketteiswrite

duration

the

centerofthe

a STEP

pulse

before

trailing edgeofthe

the

bit-serial WRITE DATA pulses

Cin

The

repetition

data

prepared

for writing

written

the

teadingedgeofWRITE ENABLE

than

4 usee

Disk Drive,

forread/write

device select line signal. (See Paragraph 3.3.1.1 J

msec, nominal)toindicatetothe

(low)

state

true

(low)

acceleratestoits

is away from

is issued.Toensure

the

mustbeconditioned

which

high-to-Iow transitions,

rateofthe

rate,

±O.1

WRITE ENABLE line

and

for

diskette

true

(low) until

when

protected.

nomin~T;~eed

the

Disk Drive deceleratestoa

greater

than

logic

diskifthe

data

under

not

the

the

stateofthe

DIRECTION lineisin

trailing edgeofthe

STEPpufse.

producedatthe

and

clock form

percent.

data

(read electronics disabled).

controlofthe

greater

write electronics

operations. When

readorwrite

durationofthe

interchangeability

controller

the

the

disketteiswrite

of

300

rpm

200

nseconthe

the

centerofthe

proper

The

access

for writingbythe

when

high-to-Iow transitions,

occur

than

8 usec.

and

the

between

that

headismovedaway

STEP

DIRECTION

disk

positioning

corresponding

motion

that

control

head

write gap.

the

combined

writing

WRITE

DATA

before

and

The

same

termination

are

disabled.

are

disabled

the

signal

operation.

controller

INDEX pulse.

the

Disk

the

read/

protected.

the

the

the

aU

of

is

if

is

NOTE

It

;s recommended that the write data line be inactive whenever

Write Enable

When

the

performed.Itis

signal is

16

levelonthis lineisfalse (high),

recommended

true

(low)_

is

fillse (i.e., read stateJ.

the

con

the

trotter

that

write

electronics are enabled

not

issue a

write

17

command

and

when

the

write

the

WRITE PROTECT

operation

can

be

3:~~3.2.4

This interface line transmits the readback data

for each flux

of 1 usec for

The leading edge of the READ

the diskette surface.

REAL

,/A

(NREADDATA'

to

transition recordedonthe medium. The READ

eachf'ux

change recorded.

DATA

output

the controller when the Driveisselected.Itprovides a pulse

pulse represents the true positions for

DATA

output

line goes true

Uow)

the

flux transistions

3.4 CIRCUIT BOARD TEST POINTS

that

the

logic

and

The following test point description assumes

Drive and

3.4.1 LOGIC GROUND (TP6)

Digital

3.4.2 DIFFERENTIATED READ SIGNAL (TP3, TP4)

.These test points are providedto.observe the differential

differentiated read signal.

3.4.3 READ

The

3.4.4 INDEX PULSE (TP7)

With a standard soft sectQred diskette installed, the signal

every

3.4.5. AMPLIFIED READ SIGNAL (TP1.

These test points are providedtoobserve the differential

3.4.6 MOTOR ON (TP13)

This signal

3.4.7 TRACK

This signalislow true when the carriageispositionedattrack 01

3.4.8 ANALOG GROUND

Analog groundreference pointisprovided for measuring read/writewaveforms.

3.4.9 (TP11) NOT FOR USE

3.4.10 STEP PULSE (TP12,

When stepping

3.4.11 WRITE PROTECT SWITCH (TP9)

When a write protected diskette

that

the Driveisin an operational mode with 8 diskette installed.

logic

groundisreferencedatTP6.

DATA

output

200

msec.

SINGLE SHOT (TP5)

of the single shot used in

is

low true for

It

(TPI'

inor.out

the

read sectionisnominally 1.0 usec for each flux transistion detected.

TP2)

the

"motor

on"

condition.

CTP10)

the·signalisa high going pulse for each step of the carriage.

is

installed in the Drive the signal is high.

servo peDA's are installed in a TM100 Disk

outputofthe second stage· amplifier

ishigh going pulse nominally 3.5 msec in.duration

outputofthe first stageofread signal amplification.

and

the step

motor

phaseiscorrect.

3.5 OPTION SELECT

3.5.1 INPUT LINE TERMINATIONS

The TM100 has been provided with

• Motor On

• Direction Select

tne capabilityofterminating the input lines listed below:

* Step

* Write Data

• Side Select

These lines are terminated through a 160

In a singte drive system this resistor pack should be kept in placetoprovide the proper terminations.

In a multiple drive system (Program Shunt position

terminated. All other drivesonthe i·nterface must have the resistor pack removed.

3.5.2 DRIVE SELECT

The TM100 as shipped from the

modified by the usertooperate with

activate the multiplex option

IF. This will allow the multiplexingofthe

1-4

by

ohm

factory;s

other

cutting.the

resistor pack installed in a dip socketlocatedatIC

"MX"

open. only

configuredtooperate in a single drive system. It can be easily

drives in a multiplexed multiple drive system.

·'MX"position

I/O

lines.

of the programmable shunt locatedinIe

the

last driveonthe

interfaceisto

for a duration

and

location 2F.

The

user can

location

In

amultipl.e

Drive. Select 2 and Drive Select 3) are provided so

interface

the Drive with its Drive Select

on

The program shunt,IClocation 1E,positions

Drive Seleet

on

the interfacetobe addressed as drive

leave"OS1"

The program shunt

number 435105. The shunt

dip switch. The user may also choose

Forth's

drive system (program shunt position

istobe used. In addition, Drive Select 4isprovided as an option. In this mode of operation, only

tine will activate the I/O lines for a unique drive. Asanexample,ifthe user

intact.

service

contact

is

AMP

your local

Une

active will respondtothe input Unesand gate the

#1,

part

number 436704-7. The shunt positions canbecut

is

installed in a dip socket andatthe user's option be removed and replaced by a

to

have the program shunts pre-programed and/or color coded by

AMP

representative.

"OS1",

he must

"MX"

open) the three input

that

the using system may select which driveonthe

"052"

and

"OS3",

cut

program shunt positions

lin~$/(Orive

output

tines.

aretobe

usedtoselect which

wants

"OS2"

and

using AMP's tool part

the first drive

Select

"OS3",

AMP.

1,

and

3.6 ADJUSTMENT

3.6.1 CE ALIGNMENT

The CE alignment procedure locates the magnetic

centerline, thus assuring accurate track location. This adjustmentisnecessary·onty after service, or for

suspected diskette·interchange problems.

3.6.1.1 DISK DRIVE·PREPATATION

(H

Apply the necessary power and controltoturnonthe Disk Drive.

(2) Insert a CE Alignment Diskette (Oysan Part No. 224-2A or equivalent) into the drive and close

the front latch.

(3) Attach oscilloscope lignat probes to·test points

tPl0.

Adjust

the

on

the leading. edge of the Index. pulseatTP7 with sync probe ground clipatTP6.

3.6.1.2 RADIAL TRACK ALIGNMENT

(1'

SelectHO"

(2. Loosen·

C3'

(4'

(5t

(6'

(7) Check H01 ensureslobes are within 80%ofeach other.

3.8.1.3 INDEX SENSOR ALIGNMENT

(1)

(2lPerform

(3)

(4'

(5) Referringtofigure

(6)

be

(do

atthe

top

Follow instructions accompanying the CE Diskette.

Manually

observed. Carefully rotate the cam untit the cats-eye

Secure

the

After securing the module screw, verify Step (4). Repeat as required.

Position the Index sensortocenteroftrave'; lightly tighten retaining screw.

Perform fifteen step

Set oscilloscope horizontal time baseto50

2

msec

pulse. Adjustment may be made with the use of a flat-bladed screwdriver placed between the

photo

transitor mounting block and chassis as required.

Secure retaining screw on the

readjust as necessary.

oscilloscopetoread differentially

....

not

remove' the two module retaining screwsonthe

rearofmodute.

rotate

the cam

at

the

module by tightening the

CE

alignment as requiredtolocate thecats-eye pattern (refertoParagraph 3.7.1.2'.

out

commandstoposition thecarriagetoTrack

15.

burst (ecordedatTrack'1occurs 200

adjust

read/writ.

rearofthe modula until the cats-eye pattern shown in Figure 14

t3'

retaining screws, previously loosened.

photo

transistor mounting block until the first transistion of the

photo

headatthe proper radial distance from the

TP1

and

TP2. Place ground clip of signal probes

(A

+ B with Binverted). Sync the oscilloscope

bottom

of the chassis,

pattern

has equal.· amplitudes.

'1.

usee

per division.

!50

usee

after the leading edgeofthe . Index

transistor mounting block

and

and

the

verify burst location;

hub

to

one

is

18

EOUAl

CON

AMPltTUO£

TRACK

'6.

l'

't,'

TIME SCALE20mslOtV

TIME SCALE

...20mslOIV.

CATSEVE

Fig. 14

PATTERN

ONE

IS8~OF THE OTHER

U MtL

OFF

TRACKJ

3.6.2

TRACK"

(1

t

ApplV

(2) Insert

C3J

Position the carriagetothe radiai alignment track. Confirm the position by observing the cats-eye

patter'n.

(4)11 adjustment

Track"Bracket.

••

Adjustment Screw (located

without forcing it.

(&) Position the carriage

(6)

Rotate the Track

rotate the screw clockwise'

(7)

Tighten the retaining screwperviously loosened.

3.6.3 WRITE

(1)

'flsert a nOfl-write protected diskette· partially (halfway) into the Drive.

(2)

Ensure

(3)

Insert diskette fully·against diskette

deactivated.

(4)

Adjust switch by loosening the retainingscrew, removing switch assembly and setting switch higher

or

'ower as required.

3.6.4

DRIVE

(1)

Apply

(2)

Insert drskette:

(3)

Ensure

14)

Adjust Speed

lighting.

INOEXJ'tO

O'ATA

Fig. 15

SWITCH

the necessary power

and

contro'toturn

on

the- Drive.

theCEAlignment Diskette into the drive and close the

is

PROTECT

SWITCHES

that

the switchisactuf,lted.

required, remove

retighten slightlytoprovide some frictiononthe bracket

to

Track"

...

Adjustment Screw clockwise-very

theCEOiskette.

atth'

rearofthe

loosen

chassis) counter-clockwise as far

by performing repetitive step

(same directiont exact.ly one hall turn.

back

stop

and

close the front latch. Ensure that theswitch

MOTOR SPEED

nt?~essary

power

andcootroltoturnonthe drive.

that

Qri~e

,Motor Enabht-lineisactive.

·Control.potentiomete~

.(on servo peDA) until timing diskisstationary in fluorescent

hont

the retaining screw

out

pulses.

.'ow1y-until

the switch "clicks". Then

latch.

and

on

rotate

the base

the Track

as

It

of

the

will go

is

20

21

Loading...

Loading...