Page 1

IInnssttaallllaattiioonn aannd

d

TTaannddbbeerrgg LLTTO

O22

Auuttoollooaaddeerr

A

UUsseerr’’ss MMaannuuaal

l

Date: August 18, 2003

Document Number: 432778

Revision:01

Be sure to read this manual before using this product.

Carefully store this manual after reading.

CAUTION:

Page 2

Trademarks

Linear Tape-Open, LTO and Ultrium are trademarks of Hewlett-Packard, IBM

Corporation and Seagate Technology.

Microsoft, Windows, Windows NT, and its logo are registered trademarks of Microsoft

Corporation in the United States and other countries.

Other brands and product names appearing herein may be trademarks or registered trademarks

of their respective owners.

FCC Class B Notice

This device complies with Part 15 of FCC Rules. Operation is subject to the following two

conditions:

1. This device may not cause harmful interference.

2. This device must accept any interference received, including interference that may cause

undesired operation.

Note:

This equipment has been tested and founded to comply with the limits for a class B digital

device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable

protection against harmful interference in a residential installation. This equipment generates,

uses and can radiate radio frequency energy and, if not installed and used in accordance with the

instructions, may cause harmful Interference to radio communications. However, there is no

guarantee that interference will not occur in a particular installation. If this equipment does

cause harmful Interference to radio or television reception, which can be determined by turning

the equipment off and on, the user is encouraged to try to correct the interference by one or

more of the following measures:

・Reorient or relocate the receiving antenna

・Increase the separation between the equipment and receiver

・Connect the equipment into an outlet on a circuit different from that to which the receiver is

connected.

・Consult the dealer or an experienced radio / television technician for help.

CAUTIONS:

(1) All rights reserved.

(2) The contents of this document may be changed without prior notice.

(3) No part of this document may be reproduced without the permission of Tandberg.

(4) Though the contents of this manual are thoroughly prepared, please contact the dealer you

purchased if you have any questions, or if mistakes or omissions are found.

(5) Tandberg shall not be held liable for the effect of operations, regardless of item (4).

Page 3

Keep this operation manual on hand so that you can refer to it when needed. Be sure to read

“Safety Precautions” before using this product.

Safety Precautions- Be sure to read this section before using this product. –

Safety Descriptions

This manual describes dangers that may be caused by ignoring the cautions and the ways to

avoid those dangers. Warning labels are attached on the components that may cause danger.

“Warning” and “caution” terms are used for warning labels to describe the degree of the

danger.

WARNING

CAUTION

The following three types of symbols are used for warnings and cautions. The meaning of each

symbol is described below.

This symbol indicates that danger could be

Attention

Prohibited

action

Mandatory

action

(Description example in this manual)

Term indicating the degree of danger Details of caution to avoid danger

CAUTION

Symbol prompting the caution

caused if instructions are ignored. The

figure in the symbol indicates details of the

danger.

This symbol indicates prohibited action. The

figure in the symbol or near the symbol

indicates details of the prohibited action.

This symbol indicates mandatory action.

The figure in the symbol indicates details of

the mandatory action. The mandatory action

is required to avoid danger.

Only plug into specified electric outlet.

Plug the power supply cable into an electric outlet on the wall

with specified voltage and power supply. Fire or electric leak may

be caused if power supply other than the one specified is used.

This indicates a hazard that could lead to death or

serious injury in the event of improper handling.

This indicates a hazard that could lead to burns, injury,

or property damage in the event of improper handling.

(Ex)

(CAUTION:

Electric shock)

(Ex)

(Do not

disassemble.)

(Ex)

(Unplug)

- i -

Page 4

Symbols and Their Meanings Used in This Manual

and Warning Labels

Attention

Indicates the risk of an electric

shock.

Indicates non-specific, general

Prohibited action

Indicates non-specific, general

action that is prohibited.

Indicates non-specific, general

action that is prohibited.

Mandatory action

Unplug the power supply plug

of the Autoloader from an

electric outlet. An electric

shock or fire may result.

Indicates the risk of smoke or

fire.

Do not disassemble, repair or

modify. An electric shock or

fire may result.

Indicates non-specific, general

user’s action. Follow the

instructions.

- ii -

Page 5

Safety Cautions

Read and understand warnings, cautions and instructions described below in order to use this

product safely. For descriptions of symbols used below, refer to the aforementioned “Safety

Description.”

General Cautions

WARNING

Do not use when smoke,

foul smell or abnormal noise are emitted.

If smoke, foul smell or abnormal noise is given off, immediately turn

off the power switch and pull out the power plug from the outlet.

Then, contact the dealer you purchased this device from or the

maintenance service company. Using the device under such

circumstances may cause a fire.

Do not insert metal strip or wire.

Do not insert foreign substances such as metal strips or wire in the air

inlet or cartridge slot as electric shock may occur.

CAUTION

Do not allow water or foreign substances into the device.

Do not place water and other liquid or pins, clips and other foreign

substances into the device because it may cause a fire, an electric

shock or failure. If any of them are placed into the device, immediately

turn the power off and pull out the power plug from the outlet. Do

not attempt to disassemble this device.Contact our dealers or

maintenance service companies.

- iii -

Page 6

Cautions for power source or power cable

WARNING

Do not handle the power plug with wet hands.

Do not connect/disconnect the plug with wet hands. Otherwise, an

electric shock may occur.

CAUTION

Do not insert the plug

into the outlet other than the one specified.

Use the wall outlet of specified voltage and power source. Use of

power sources other than the one specified may cause a fire or

electrical leakage.

Do not apply starburst wiring.

This device may overheat when current exceeds the rated value,

which may cause a fire.

Do not insert the plug halfway.

Insert the plug to the end. Inserting halfway generates heat from the

loose connection and may cause a fire. The plug also generates heat

when dust or droplets adhere to the inserting part, which may cause a

fire.

Do not use the power cable other than the one specified.

Do not use the power cable other than the one attached to the device

May cause a fire when current exceeds the rated value.

In addition, to prevent from an electric shock or a fire caused by

damage of the power cable, do not perform the following actions.

・Pulling the power cable

・Pinching the power cable

・Bending the power cable

・Pouring chemicals on the power cable

・Twisting the power cable

・Placing items on the power cable

・Bundling the power cable

・Modifying, processing or repairing the power cable

・Fixing the power cable with staples, etc.

Do not use a damaged power cable (replace damaged power cable

with one with the same specification. For replacement, contact the

dealer from whom you purchased this device or a maintenance service company).

- iv -

Page 7

Cautions for installing, transporting, storing, and connecting

CAUTION

Do not lift the device alone.

This device weights 18 kg. Lifting it alone may injure your back. Be

sure to transport or move the device with two persons.

Do not install in location other than the one specified.

Do not install this device in the location listed below or other than the

location specified in this manual as a fire may occur.

・Dusty place

・Humid place such as near a hot water supply

・Install where exposed to direct sunlight

・Unstable place

Do not cover the air inlet

Do not cover the fan on the back panel and air inlet on the front panel

of the device as internal temperatures will rise, resulting in a fire or

an electric shock as well as operation error.

Do not connect/disconnect the interface cable with the plug still

inserted in the outlet.

Remove the power cable from the outlet before

connecting/disconnecting the interface cable. Touching cables or

connectors while the power cable is connected may lead to an electric

shock or a fire due to a short-circuit, even if the power is OFF.

Do not use an interface cable other than the one specified.

Use an interface cable specified by TD and connect it after

checking the device or connector. Using an interface cable other than

the one specified or connecting the cable to the wrong connection

point may lead to a fire due to a short-circuit.

Follow the instructions described below for handling and connecting

the interface cable.

・Do not step on the cable

・Do not place items on the cable

・Do not use the device with the cable connected loosely

・Do not use a damaged cable

・Do not use a damaged cable connector

・Be sure to lock the fastening screws

- v -

Page 8

Cautions of maintenance

WARNING

Do not disassemble, repair or modify by yourself.

Never disassemble, repair or modify this device. Doing so results in

the danger of an electric shock or a fire as well as operation error of

the device.

Do not clean the device with the plug still inserted in the outlet.

Turn the power off and remove the power cable from the outlet

before cleaning. Touching parts inside the device while the power

cable is connected may lead to an electric shock, even if the power is

OFF.

Pull out the power plug and wipe with a dry cloth from time to time

to remove dust. If a dusty cord catches droplets, heat will be

generated, which may cause a fire.

CAUTION

Do not insert the connecting parts halfway.

Insert the power cable or interface cable to the end. Inserting halfway

generates heat due to a loose connection and may cause a fire.

Do not touch the broken LCD.

LCD contains liquid which is harmful to the human body. If the

liquid leaking from the broken LCD is taken into the mouse, wash it

out immediately and consult with a doctor. If the liquid adheres to the

skin or gets into the eyes, wash with water for 15 minutes or more

and consult with a doctor. When removing the LCD for separating

and disposal, contact our dealers or maintenance service companies.

- vi -

Page 9

Cautions during operation

CAUTION

Caution: Suction.

Do not place hands or hair close to the cooling fan on the back panel

while operating the device as hands may be pinched or hair may be

sucked in.

Do not insert hands inside the transporter, as it may cause an electric

shock or injury.

Do not touch the device when there is lightning.

If there is possibility of lightning, pull out the power plug from the

outlet. In case lightning strikes before pulling out the power plug,

do not touch the device, including cables, as it may cause a fire or an

electric shock.

Do not allow pets to approach the device.

Do not allow pets and other animals to approach the device.

Excrement or hair entering the device may cause a fire or an electric

shock.

Do not use cellular phones, PHS (personal handy-phone system)

or pagers near the device.

Turn off cellular phones, PHS or pagers near the device as its electric

waves may cause an operation error.

- vii -

Page 10

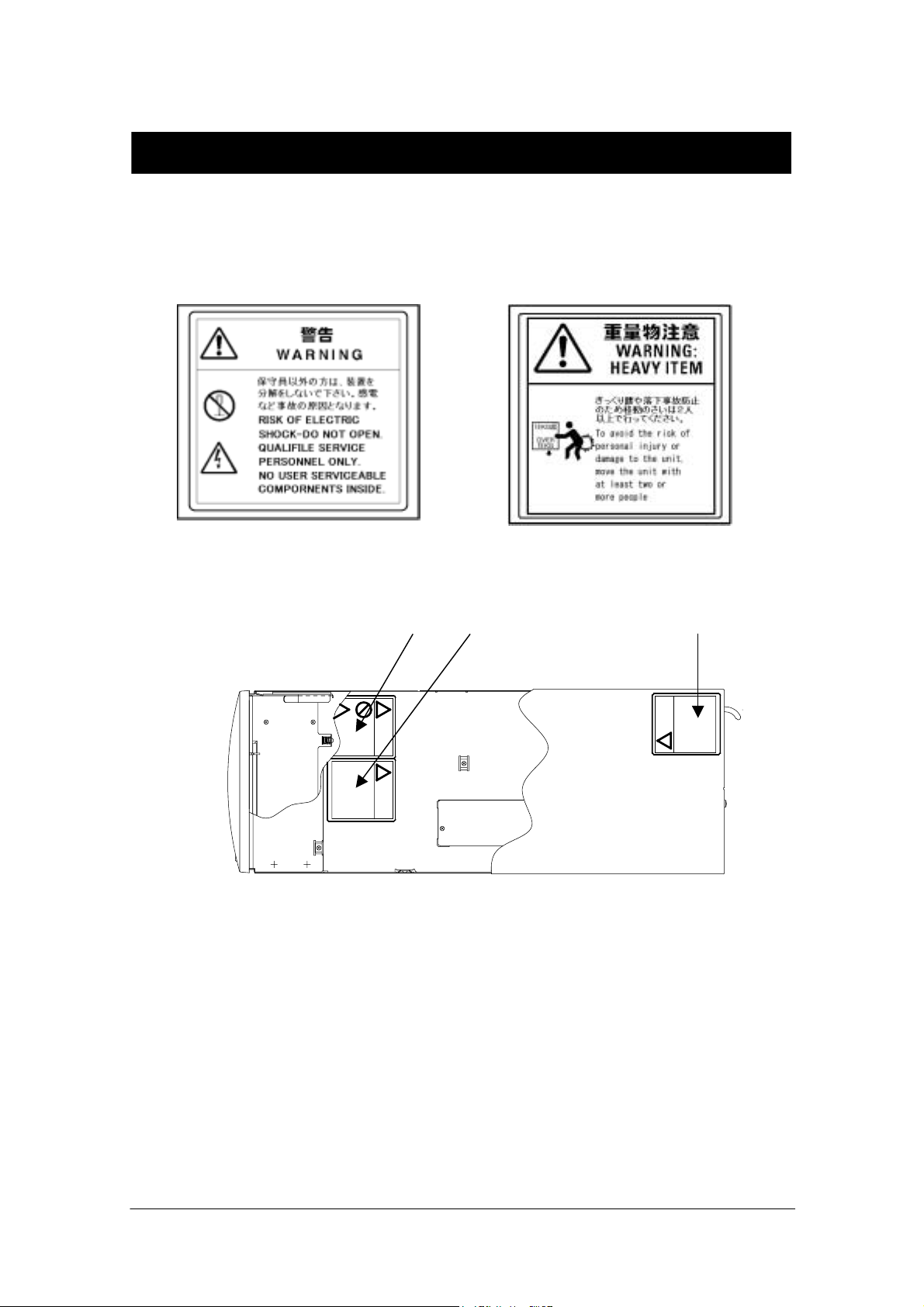

WARNING Label

WARNING labels are affixed to or around the parts where latent dangers exist so that customers

are always aware of the dangers when operating the device (therefore, do not remove or soil the

labels). If any of the labels are not affixed, peeling off or stained, contact our dealers.

FigureⅠ WARNING Label ①FigureⅡ WARNING Label ②

FigureⅢ Top view of the Tandberg LTO2 Autoloader

・ WARNING Label ① and ② are affixed on the front top of internal frame in advance,

because this autoloader might be converted from a standalone model into rack mount model.

① ② ②

- viii -

Page 11

Revision History

This Revision History provides a concise publication record of this manual. It lists the manual

revision levels, release dates, and reasons for the revisions.

Document No. / Rev Level / Date

432778 / 01 / 2003-08-13

- ix -

Page 12

Contents

Safety Precautions- Be sure to read this section before using this product. –............i

Safety Descriptions .................................................................................................................... i

Symbols and Their Meanings Used in This Manual and Warning Labels ................................ii

Safety Cautions ........................................................................................................................iii

General Cautions..................................................................................................................iii

Cautions for power source or power cable...........................................................................iv

Cautions for installing, transporting, storing, and connecting...............................................v

Cautions of maintenance...................................................................................................... vi

Cautions during operation...................................................................................................vii

WARNING Label...................................................................................................................viii

Revision History............................................................................................................. ix

Introduction ..................................................................................................................xii

Organization of this manual...................................................................................................xiii

Symbols used in this manual..................................................................................................xiv

Chapter1 Tandberg LTO2 Autoloader ...................................................................... 1

1.1 Overview of theTandberg LTO2 Autoloader ......................................................................1

1.2 Names an d Functions of the Parts....................................................................................... 2

1.2.1 Front Panel of the Tandberg LTO2. Autoloader............................................................ 2

1.2.2 Rear Panel of the Tandberg LTO2 Autoloader ........................................................... 4

1.2.3 Liquid Crystal Display.................................................................................................5

1.3 Handling Precautions .......................................................................................................... 6

1.3.1 Main Unit..................................................................................................................... 6

1.3.2 Data Cartridges............................................................................................................. 6

1.4 Transfer or Disposal of the Device......................................................................................6

1.5 Contents of the Carton......................................................................................................... 7

Chapter2 Setup............................................................................................................ 8

2.1 Preparation Before Use ....................................................................................................... 8

2.2 SCSI Cable Connections.....................................................................................................9

2.3 AC Power Cable Connection.............................................................................................10

2.4 Switching ON the Power Switch and the Power-On Sequence.........................................12

2.5 SCSI ID Setting.................................................................................................................12

2.6 Starting and Closing the System ....................................................................................... 13

Chapter 3 Operation ................................................................................................. 14

3.1 Removal of the Magazine ................................................................................................. 14

3.2 Loading the Magazine.......................................................................................................15

3.3 Loading the Cartridge........................................................................................................16

3.3.1 Loading to the Magazine............................................................................................ 16

3.3.2 Loading to the Fixed Slots ......................................................................................... 17

3.4 Removal and Insertion of the Cartridges........................................................................... 19

3.4.1 Removal from and Insertion to the Magazine............................................................ 19

3.4.2 Removal from and Insertion to the Fixed Slots.......................................................... 20

3.5 Operation of the Panel Keys.............................................................................................. 21

3.5.1 Organization of the Front Panel Switches..................................................................21

3.5.2 Functions of the Switches ..........................................................................................21

3.5.3 Slot Logical Numbers.................................................................................................21

3.5.4 Panel Operation Procedure.........................................................................................22

3.5.5 Menu Tree ..................................................................................................................24

- x -

Page 13

3.6 Setting the SCSI ID........................................................................................................... 26

3.6.1 Checking the SCSI ID................................................................................................ 26

3.6.2 Changing the SCSI ID................................................................................................ 27

3.7 Using the Emergency Release Key...................................................................................30

Chapter 4 Cartridges................................................................................................. 31

4.1 Cartridges..........................................................................................................................31

4.1.1 Data Cartridge............................................................................................................32

4.1.2 Cleaning Cartridge ..................................................................................................... 32

4.2 Write-Protect Switch.........................................................................................................33

4.3 Bar Code Label..................................................................................................................34

4.4 Handling Precautions ........................................................................................................ 35

4.4.1 Usage Precautions......................................................................................................35

4.4.2 General Precautions....................................................................................................35

4.4.3 Standards for Prohibition of Use................................................................................ 36

4.4.4 Service Life................................................................................................................36

4.4.5 Storage of Data Cartridges.........................................................................................36

Chapter 5 Daily Maintenance................................................................................... 37

5.1 Cleaning ............................................................................................................................ 37

5.1.1 Cleaning of the Drive Head........................................................................................ 37

5.1.2 Cleaning the Roller inside of the transporter..............................................................39

5.1.3 Cleaning of the Main Unit.......................................................................................... 51

5.1.4 Cleaning of the magazine...........................................................................................52

5.1.5 Cleaning of the cartridge............................................................................................ 52

5.2 Movement and Shipping of the Autoloader ......................................................................53

Chapter 6 Troubleshooting....................................................................................... 54

6.1 Other Matters to Check.....................................................................................................60

6.2 When Requesting Maintenance......................................................................................... 60

Appendix A Specifications ........................................................................................61

Appendix B Optional Items and Supplies ............................................................... 63

Appendix C Error Code............................................................................................ 64

- xi -

Page 14

Introduction

Tandberg LTO2 Autoloader is an external memory device that has been developed for the

file systems of servers and other equipment. This large capacity, high-performance streaming

cartridge tape device is designed for use in medium intermediate to top-level computer systems.

This manual describes the overview, operation, maintenance method, regular maintenance, and

troubleshooting of this device so as to avoid maintenance faults.

Please keep this manual in a safe place so that it may be easily referred to when necessary.

- xii -

Page 15

Organization of this manual

This section describes the organization of this manual and an overview of each chapter. Use it

when you would like to find out something about this device.

Chapter 1 Tandberg LTO2 Autoloader

This chapter describes the features of the Autoloader as well as the package contents and

the names of the parts. It also covers precautions for handling and storage. (See the

description at the beginning of the manual concerning precautions for the safe handling of

the device.)

Chapter 2 Setup

This chapter presents a step-by-step explanation of the procedure from the connection of

the Autoloader to a server or workstation all the way to bringing it up to a usable

condition. The procedure should be followed for proper installation. There is also a

description of the rack mounting method.

Chapter 3 Operation

In this chapter, a description is provided of the TD Autoloader LTO2 operation, front

panel menu organization, and the method of inserting the data cartridge.

Chapter 4 Cartridges

This chapter describes the method of handling the data cartridge that is used in the

Autoloader as well as handling precautions.

Chapter 5 Daily Maintenance

The cleaning method and precautions to take when moving and storing the Tandberg LTO2

Autoloader are described so that the Autoloader can be maintained in the best condition

for whenever it is used.

Chapter 6 Troubleshooting

Should the Autoloader fail to operate properly, please check the details described in this

chapter before assuming a breakdown has occurred. If the problem persists, please

request servicing from a repair company.

Appendix A Specifications

The specifications of the Tandberg LTO2 Autoloader and the data cartridge are listed here.

Appendix B Optional Items and Supplies

Optional items and supplies are listed here.

Appendix C Error Code

This section lists the Autoloader error codes and treatment method.

- xiii -

Page 16

Symbols used in this manual

Symbols used in this manual

The following symbols are used to indicate cautions or tips for operations. (For symbols related

to safety precautions, please refer to the descriptions aforementioned.)

Important

Indicates handling methods of this product, software operational instructions,

or special notes.

Tip

Indicates helpful and useful information.

- xiv -

Page 17

Chapter1 Tandberg LTO2 Autoloader

Some preliminary information about the Tandberg LTO2 Autoloader is presented here before

installation and handling.

1.1 Overview of the Tandberg LTO2 Autoloader

This is a high-performance, high-capacity data storage device that is connected to the supported

host to provide additional host storage. The Autoloader is designed to run an unattended backup

and is furnished with the following functions.

・ The LTO2 Autoloader has one built-in LTO Ultrium tape drive that reads and writes data

and a robot mechanism that handles up to 10 cartridges (w/BCR

・ The LTO2 Autoloader is equipped with a Ultra160 Low Voltage Differential(LVD) interface

and functions as a device having two different IDs on a single SCSI bus.

・ The maximum transfer rate (at the time of reading/writing) of the LTO2 Autoloader when

operating in the non-compression mode is 35 MB/s. The maximum transfer rate (at the

time of reading/writing) in the compression mode (with a compression of 2 times)

is 70 MB/s.

・ The amount of data that can be stored on a LTO2 data cartridge is a maximum of 200 GB

in the non-compression mode and 400 GB (with a compression of 2 times) in the

compression mode. The Tandberg LTO2 Autoloader permits the storage of a maximum

of 2 TB of data on 10 LTO2 data cartridges in the non-compression mode and a maximum

of 4 TB (with a compression of 2 times) in the compression mode.

・ The optional Tandberg LTO2 Autoloader Rack Mounting Kit is required to mount the

(rack mount type of the) Tandberg LTO2 Autoloader into a rack

・ The optional Tandberg LTO2 Autoloader Rack Mounting Kit allows two (rack mount

type of the) Tandberg LTO2 Autoloader units to be mounted with only one kit.

・ A vacant 5U portion of space is required to mount the (rack mount type of the) Tandberg

LTO2 Autoloader in a rack.

Important

*1

: up to 9).

*2

1*: Performance of the LTO2 Autoloader including Bar Code Reader model

We can provide you the Tandberg LTO2 Autoloader with the Bar Code

Reader which hereafter called Autoloader w/BCR.TheAutoloader w/BCR

requires a free slot used to swap cartridge during the inventory scan process.

Thus the maximum cartridge capacity of the Autoloader w/BCR is changed

from 10 to 9. But if you will prefer to use 10 cartridges, the BCR function

will be changed disable.

In this case, please contact your nearest Customer Support Center.

*2: Tandberg LTO2 Autoloader is a standalone model. To mount this autoloader into a rack,

you must convert this autoloader to a rack mount model. This is easily accomplished by using the

LTO2 Autoloader Rack Mounting Kit.

- 1 -

Page 18

①

⑤

⑦

④

⑥

1.2 Names and Functions of the Parts

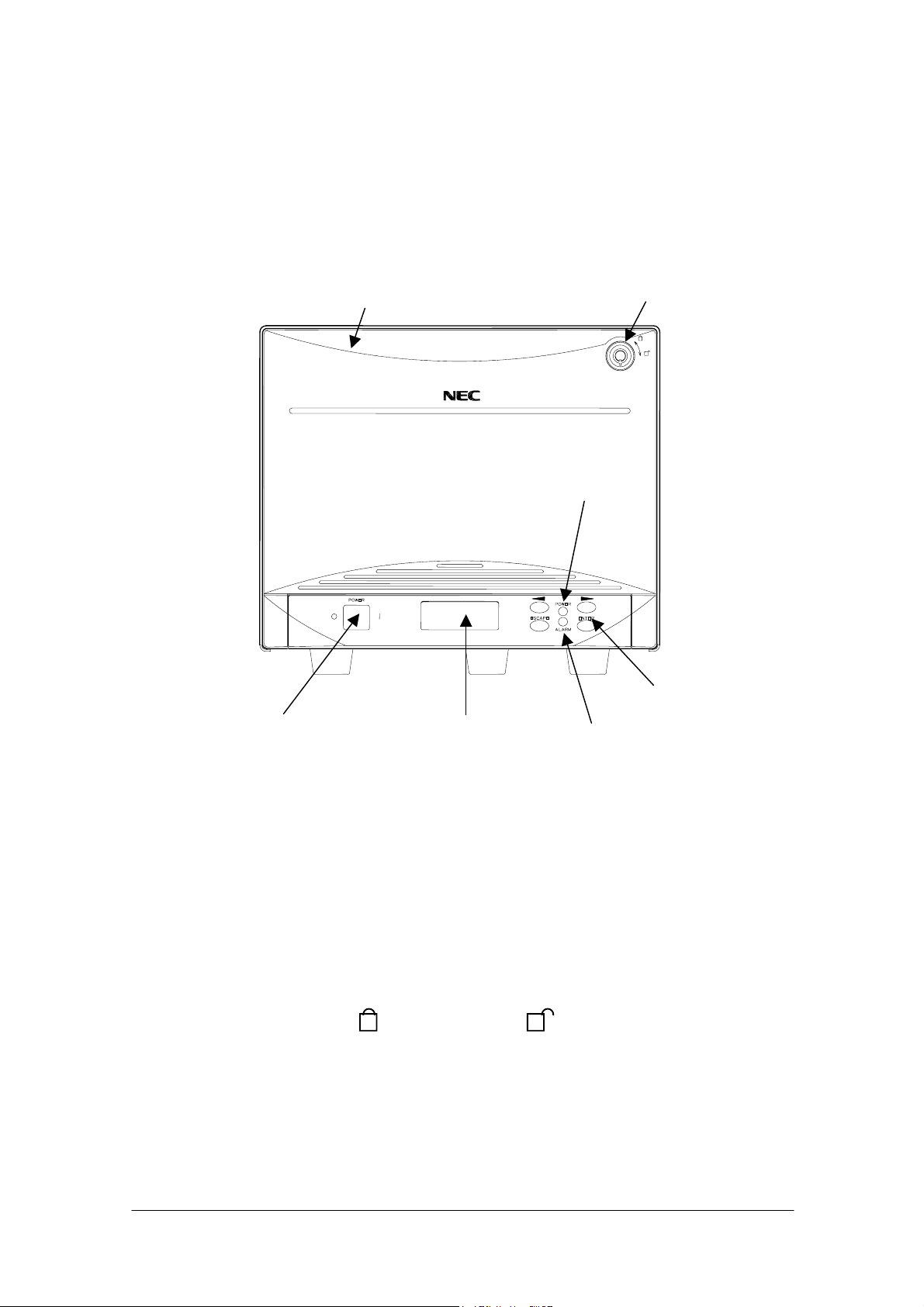

This section describes the names and functions of the Tandberg LTO2 Autoloader parts.

1.2.1 Front Panel of the Tandberg LTO2 Autoloader

③

Figure 1-1 Front Panel of the LTO2 Autoloader

①Front door

This door prevents the intrusion of foreign objects. While the power is ON, unlock the door

lock with the door lock key supplied with the main unit.

② Key lock

The front door is locked with the door lock key supplied with the main unit.

Pushing in the key and turning it clockwise 90 degrees will release the lock. The unit should

normally be used with the door locked.

Door Locked. Door Open.

③ Power switch

This switch switches the power of the Autoloader on and off.

A press on the right side ( | ) switches the power ON and a press on the left side (○)

switches the power OFF.

②

- 2 -

Page 19

④ Liquid Crystal Display

This liquid crystal display (LCD) is organized in 2 lines of 10 characters, and 11 icon

characters. It displays the status of the Autoloader, menus, and error information.

⑤ Alarm LED

This LED lights (in red) should some kind of fault arise in the Autoloader.

⑥ Power LED

This LED lights (in green) when the power is supplied and the power switch is ON; it is

unlit when the power is OFF.

⑦ Panel keys

・ (arrow) key : Moves forward through the menu.

・ (arrow) key : Moves backward through the menu.

・ ENTER key : Defines and executes the displayed menu or operation

command.

・ ESCAPE key : Cancels the execution of the selected command, or returns to

the previous screen of the selected menu.

- 3 -

Page 20

②

③

1.2.2 Rear Panel of the Tandberg LTO2 Autoloader

① AC Power connector

This connector supplies power to this device.

Plug in the AC power cable supplied with the main unit.

② SCSI connector

These connectors are used to connect a SCSI interface that controls this device.

Connect the SCSI cable of the server, workstation, or other equipment.

③ Filter Element

The Filter Element is the air filter to clean the inside of the Autoloader.

①

Figure 1-2 Rear Panel of the LTO2 Autoloader

- 4 -

Page 21

1.2.3 Liquid Crystal Display

The display is a liquid crystal display (LCD) that indicates the status of the Autoloader,

menus, and error information. The display is organized in 2 lines, each able to display up

to 10 characters.

Lighting of any of the 11 icon characters indicates the corresponding slot number when a

cartridge is housed in a magazine and fixed slots. The lock symbol will also light when

the front door is locked with the door lock key supplied with the main unit. The icon will

cease to be illuminated when the door lock is unlocked.

Figure 1-3 Liquid Crystal Display (LCD)

- 5 -

Page 22

1.3 Handling Precautions

To operate this device properly, please observe the following precautions.

1.3.1 Main Unit

● Cooling fans are attached to the rear panel of the Autoloader. Do not use the unit in

places where the fans will be obstructed or there is poor air circulation. The

Autoloader should not be stored or used in extremely hot locations or in locations

having severe temperature changes.

The Autoloader is built with precision electronic components. Do not subject the

●

Autoloader to shock or either use or store it in locations that are exposed to vibration.

Do not use or store the Autoloader in locations where chemical vapors are dispersed

●

in the air or where the unit will come into contact with chemicals.

Do not move or transport the Autoloader while the power is ON.

●

Do not use or store the Autoloader with a heavy object on top of it.

●

Do not switch off the power while the Autoloader is operating.

●

To insert or remove a magazine, first check that the Autoloader is in a condition that

●

will allow insertion or removal of the magazine.

Only insert a cartridge into a magazine, nothing else.

●

Be sure to use the (rack mount) Tandberg LTO2 Autoloader mounted in a rack .

●

mounting requires the Tandberg LTO2 Autoloader Rack Mounting Kit.)

(Rack

1.3.2 Cartridges

● The data cartridge that should be used is the TD LTO1 Data Cartridge (TD P/N:

432630-1) and the TD LTO2 Data Cartridge (TD P/N:

432744).

The cleaning cartridge that should be used is the TD LTO Universal Cleaning Cartridge (TD P/N:

●

432631)

See Chapter 4 for other precautions.

●

1.4 Transfer or Disposal of the Device

● When disposing of this device along with the consumables and accessories, please

follow the national and municipal guidelines for disposal.

●

When transferring this device to another party, please include all items including this

manual.

- 6 -

Page 23

1.5 Contents of the Carton

Open the carton and check that all of the following items are included. In the unlikely event that

something is missing or damaged, please contact your store of purchase.

Installation and

User’s Manual

Preparation guide before powering

on the Autoloader

Important

Main unit

AC power cable

Emergency release key

(x 1)

Check the “Lock Block” condition

Figure 1-4 Contents of the Carton

Roller cleaner set

Filter Element

Terminator (dual LVD/SE)

Door lock key

(x 2)

・The carton and cushioning material will be used when moving or storing the

device and should be kept safely for such times.

・Should this device be transferred to another party, please be sure to include

this instruction manual.

- 7 -

Page 24

Chapter2 Setup

This chapter describes the procedure for connecting the Autoloader to a basic processing device

such as a server or workstation.

Important

Maintenance personnel will perform the rack installation or removal work for

the Tandberg LTO2 Autoloader.

2.1 Preparation Before Use

Before using the Autoloader, remove the transporter locking screw that is a type of thumbscrew

located at the left side of the decorative cover.

Important

Remove the transporter locking screw before switching ON the power switch.

Switching ON the power while the transporter locking screw is still attached

could result in damage to the Autoloader.

Removal of the Transporter Locking Screw and Instruction TAG

1. To loosen this screw turn to counterclockwise by hand.

2. Remove the Instruction TAG with the Transporter Locking Screw (see figure 2-1).

3. As the Transporter Locking Screw will be needed to ship or move the Autoloader, insert

it into the hole and tighten to keep it (see figure 2-2).

Transporter Locking Screw

Instruction TAG

Figure 2-1 Removal of the Transporter Locking Screw and Instruction TAG

- 8 -

Page 25

Figure 2-2 Storing the Transporter Locking Screw for later use

2.2 SCSI Cable Connections

CAUTION

The Autoloader is connected to the server/workstation (or other SCSI device) with a SCSI cable.

The SCSI connector of the Autoloader is located on the rear panel.

To the next SCSI device

Before starting the installation of this device, be certain to

unplug the power plug of the server, workstation, or other

processing equipment. Working on the unit while the power

plug is left connected to the power outlet could result in

electrical shock.

Terminator

Figure 2-3 SCSI Cable Connections

From the host computer

- 9 -

Page 26

When the SCSI connections end with this device (i.e., when connection to a separate device is

not made from the left-side connector), be certain to connect the terminator supplied with the

main unit. Failure to connect the terminator will result in improper operation of all connected

SCSI devices.

When connections are made to other SCSI devices with the Autoloader connected in an

intermediate position, connection to the next SCSI device is made from the left-side connector.

Be certain to attach the terminator to the SCSI device positioned at the farthest end of the chain

of devices that are connected by SCSI cable.

Please refer to the manuals supplied with the server/workstation and SCSI devices for

information about the method of connection to server/workstations and other SCSI devices.

Note that the SCSI cable is sold separately. Please purchase a SCSI cable that suits the connectors

of the Autoloader, the equipment to be connected, as well as the SCSI interface specifications.

Important

Once cable connections are completed, check that there are no kinks in the

connections. SCSI cable connectors are equipped with screws for securing the

connection. Please check that the connectors have been securely fastened with

the screws.

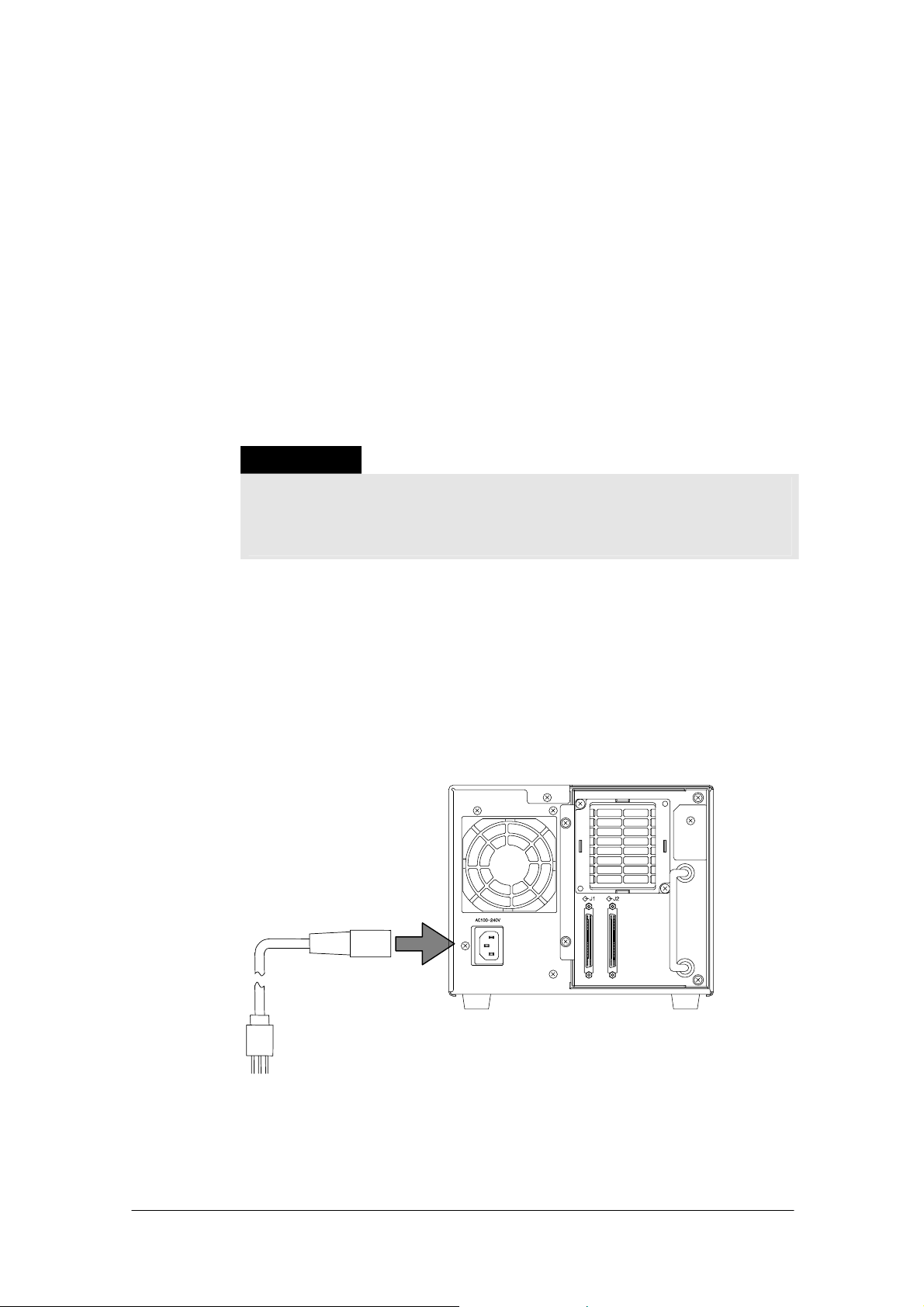

2.3 AC Power Cable Connection

When the connection to the signal cable or terminating connector is completed, check that the

power switch is OFF (switched to the " { " side).

After checking it, plug the AC power cord supplied with the main unit into the AC power

connector of this device. Ensure that the plug is inserted completely.

AC power cable

Connect to the external AC power outlet

Figure 2-4 AC Power Cable Connection

- 10 -

Page 27

2.4 Attaching and removing the Filter Element

Attach the Filter Element to the rear panel of the Autoloader as shown in Figure 2-5.

Remove the Filter Element from the rear panel of the Autoloader as shown in Figure 2-5.

Replace the Filter Element every 6 months.

Figure 2-5 Attaching and removing a Filter Element

Attaching

Removing

- 11 -

Page 28

2.5 Switching ON the Power Switch and the Power-On

Sequence

Switching ON the power of the Autoloader executes an automatic power-on sequence.

1. Connect the AC power cable.

2. Press the right side ( | ) of the Autoloader front panel power switch to switch the power ON.

3. When the power is supplied, the POWER LED lights in green and the power-on test starts.

4. When the power-on test ends normally, "READY" and "DRV empty" are alternately

displayed on the top level of the LCD.

Power switch

Figure 2-6 Powering on the LTO2 Autoloader

2.6 SCSI ID Setting

Please check that the SCSI ID of the Autoloader is not already being used by a

server/workstation or another SCSI device. (Prior to shipping from the factory, the SCSI ID of

the Autoloader was set as described below.)

See "3.6 Setting the SCSI ID" for information about how to check the SCSI IDs that have been

set and for the method of changing them when required.

Important

The Autoloader and the tape drive must each have an independent SCSI ID.

This device has a specification that does not allow duplication of the tape drive

and Autoloader IDs. Please check that the IDs of other SCSI devices on the

same SCSI bus do not duplicate the IDs of the tape drive and the Autoloader.

SCSI ID at time of factory shipping

● Tape drive : (1)

● Autoloader : (0)

- 12 -

Page 29

2.7 Start and Shutdown of the System

When the SCSI ID settings have been completed, switch on the power of the server/workstation

and the other devices and start the system.

To start the system, switch ON the power in the order of the Autoloader (along with the

peripherals connected to the server/workstation) and then the server/workstation.

Important

If the data cartridge is loaded into the tape drive before starting the system, the

reading/writing of data recorded on the data cartridge may not be performed

properly.

To shut down the system, switch OFF the power in the order of the server/workstation and then the

Autoloader (along with the peripherals connected to the server/workstation).

Important

・Before shutting down the system, check that a data cartridge is not loaded in the

tape drive. If the system is shut down while the data cartridge is still loaded in

the tape drive, the next time the system is started, the reading/writing of data

recorded on the data cartridge may not be performed properly or this could

cause damage to the data cartridge or this device.

・Do not shut down or restart the system while this device is operating. Check

that this device is stopped before closing down or restarting the system.

Important

If an error message is shown as "Unreadable Media" on the PC console’s

screen without front panel LED lighting solid red during the following

operations, Inventory, Erase, Backup, Restore and etc., please retry the same

operation. Also if the cartridge remains in the drive, please eject the cartridge

from the drive by manual operation (refer “3.5 Operation of the Panel Keys”)

before retrying the operation.

- 13 -

Page 30

Chapter 3 Operation

In this chapter, a description is provided of the operation methods that should be known for the

daily use of the Autoloader as well as information about the LCD indications.

3.1 Removal of the Magazine

Follow the procedure described below to remove the magazine from the Autoloader.

1. Check that the power of the Autoloader is ON.

Tip

The Autoloader has a double locking mechanism comprising a door lock and

an electronic lock. When the power is in the OFF condition, the electronic lock

is activated by a solenoid and the door cannot be opened. When it is necessary

to open the door while the power is in the OFF condition, use the emergency

release key that has been supplied. See “3.8 Using the Emergency Release

Key” for information describing the use of the emergency release key.

2. Use the door lock key supplied with the main unit to release the door lock, then open the front

door.

Tip

The Autoloader is designed so that the electronic lock operation will again be

activated if the front door is not opened within 10 seconds following the

release of the door lock with the door lock key. Should the door become locked

again, follow this same procedure to release the door lock and then open the

front door within 10 seconds.

3. Refer to the diagram affixed to the inside of the front door and press down on the lock lever

located at the lower left to release the magazine lock (see figure 3-1).

4. Pull out the magazine that has protruded (see figure 3-2).

Figure 3-1 Lock Lever Figure 3-2 Pulling out the Magazine

- 14 -

Page 31

3.2 Loading the Magazine

Follow the procedure described below to load the magazine into the Autoloader.

1. Check that the power of the Autoloader is ON.

Tip

The Autoloader has a double locking mechanism comprising a key operated

door lock and an electronic lock. When the power is in the OFF condition, the

electronic lock is activated by a solenoid and the door cannot be opened. When

it is necessary to open the door while the power is in the OFF condition, use

the emergency release key that has been supplied. See “3.8 Using the

Emergency Release Key” for information describing the use of the emergency

release key.

2. Use the door lock key supplied with the main unit to release the door lock, then open the front

door.

Tip

The Autoloader is designed so that the electronic lock operation will again be

activated if the front door is not opened within 10 seconds following the

release of the door lock with the door lock key. Should the door become locked

again, follow this same procedure to release the door lock and then open the

front door within 10 seconds.

3. Set the magazine as indicated in the figure and press the PUSH mark portion back until it

locks with a click sound.

4. Close the front door and lock it using the door lock key supplied with the main unit.

Figure 3-3 Loading the Magazine

- 15 -

Page 32

3.3 Loading the Cartridge

This section describes the method of loading the cartridges.

In this device the slot numbers are assigned to the magazine and internal fixed slots as

illustrated below.

(Top of device)

Important

Drive

Figure 3-4 Slot Logical Numbers

10

9

8

7

6

5

4

3

2

1

Front of device Rear of device

The Tandberg LTO2 Autoloader w/BCR requires a free slot used to swap

cartridge during the inventory scan process. Thus the maximum cartridge

capacity of the Autoloader w/BCR is changed from 10 to 9 and you can not

use slot 10 that is a free slot. But if you prefer to use 10 cartridges, the

BCR function neet be disabled.

In this case, please contact your nearest Customer Support Center.

3.3.1 Loading to Magazine

A maximum of 7 cartridges can be loaded into the magazine.

Follow the procedure described below to load the cartridges into the magazine.

1. Load the cartridges into the magazine in the proper orientation as shown in the figure 3-5.

(The insertion direction is marked on the label on the side of the magazine.)

2. A "click" locking sound will be heard when the cartridge is inserted to the back. Up to seven

cartridges can be mounted on a magazine.

Perform the following procedures to mount a cartridge on a magazine:

Tip

When inserting the cartridge, be certain to push it in until it locks with a

"click." If the cartridge is not properly locked, it could fall out from the

magazine.

- 16 -

Page 33

Figure 3-5 Loading the Magazine

3.3.2 Loading to the Fixed Slots

A maximum of 3 cartridges can be loaded to the fixed slots inside the Autoloader.

Operation of the Autoloader front panel keys permits automatic loading of the cartridges from

the magazine to the fixed slots. Loading is possible between the following slots at this time.

Slots involved with cartridge movement when loading

Slot 5 → Slot 8

Slot 6 → Slot 9

Slot 7 → Slot 10.

Important

For using the Tandberg LTO2 Autoloader w/BCR's optional

In using the TD LTO2 Autoloader w/BCR, slot 10 must be a free slot

used to swap a cartridge during the inventory scan process. When you load

the 2 cartridges to the fixed slots, i.e. slot 8 and slot 9, you can insert the

cartridges into slot 5 and slot 6 only.

Operation Examples

The operation procedure and display indications are described when loading the cartridges of

slot numbers 5 to 7 within the magazine to slot 8 to 10 among the fixed slots. See "3.5

Operation of the Panel Keys" for information about detailed panel operations.

Operation 1

Display: "READY" and "DRV empty" are alternately displayed.

Switch ON the power and wait for the completion of the power-on test.

- 17 -

Page 34

Operation 2 Press the "ENTER" key.

Display: STATUS

Operation 3

Press the "arrow" key and select the LOAD command.

Display: LOAD

Operation 4

Press the "ENTER" key and define the command.

Display: Load Drv?

Operation 5

Press the "arrow" key and select "Load Slt?" .

Display: Load Slt?

Operation 6

Press the "ENTER" key and execute the command.

Display: Complete (when the command ends normally.)

Err. xxxxxx (when an error occurs. xxxxxx is the error code.)

Tip

• Loading by command is valid only when slots 8 to 10 among the fixed slots

are all vacant slots.

• When loading by command is executed, all cartridges housed in slots 5 to 7

within the magazine are moved to fixed slots.

Important

For using the Tandberg LTO2 Autoloader w/BCR

In using the LTO2 Autoloader w/BCR, slot 10 must be a free slot used

to swap a cartridge during the inventory scan process. When you load the 2

cartridges to the fixed slots, i.e. slot 8 and slot 9, you can insert the cartridges

into slot 5 and slot 6 only. If a cartridge is in slot 7, loading command is

failed and error message of "S10 forBCR" is displayed on the LCD.Then,

you remove the cartridge fro slot7 manually, and retry the loading command.

- 18 -

Page 35

3.4 Removal and Insertion of the Cartridges

The method by which cartridges are removed and inserted is described here.

3.4.1 Removal from and Insertion to the Magazine

1. Hold the magazine body steady and press the center portion of the cartridge. A "click" sound

is heard and the lock is released.

2. Remove the cartridge.

Figure 3-6 Removal and Insertion of Cartridges (7-Slots)

Tip

When removing or inserting cartridges, keep your finger against the cartridge

when pressing on the center portion so that the cartridge does not fall out.

- 19 -

Page 36

3.4.2 Removal from and Insertion to the Fixed Slots

Operation 1

Remove the cartridges that are housed in the fixed slots (i.e., slot 8 to

10). (The cartridges will move to slot 5 to 7 within the magazine at this

time.)

Operation 2

Operation 3

Operation 4 Press the "ENTER" key.

Display: STATUS

Operation 5

Display: EJECT

Operation 6

Display: Eject Drv?

Operation 7

Display: Eject Slot?

Operation 8

Reload a magazine into the main unit that has vacant slots for slot 5 to

7.

Lock the front door and wait for "READY" to be displayed.

Press the "arrow" key and select the EJECT command.

Press the "ENTER" key and define the command.

Press the "arrow" key and select "Eject Slot?" .

Press the "ENTER" key and execute the command.

Operation 9

•Ejecting by command is valid only when slot numbers 5 to 7 among the

magazine slots are all vacant slots.

•When ejecting by command is executed, all cartridges housed in slot numbers

8 to 10 within the fixed slots are moved to the magazine.

Display: Complete (when the command ends normally.)

Err. xxxxxx (when an error occurs. xxxxxx is the error code.)

When required, remove the magazine and remove the cartridges of slot

5 to 7 which have been moved.

Tip

- 20 -

Page 37

3.5 Operation of the Panel Keys

3.5.1 Organization of the Front Panel Switches

The arrangement of switches as viewed from in front of the front panel is as illustrated below.

ESCAPE ENTER

Figure 3-7 Front Panel Switches

3.5.2 Functions of the Switches

The functions of the various switches are described below.

key(arrow key) : Moves forward through the menu.

key(arrow key) : Moves backward through the menu.

ENTER key : Defines and executes the displayed menu or operation

command.

ESCAPE key : Cancels the execution of the selected command, or returns to

the previous screen of the selected menu.

3.5.3 Slot Logical Numbers

In the Autoloader, logical numbers such as the following are assigned to the slots that house the

cartridges upon execution of the operation command.

(Top of device)

Drive

Figure 3-8 Slot Logical Numbers

10

9

8

- 21 -

7

6

5

4

3

2

1

Front of device Rear of device

Page 38

Important

The LTO2 Autoloader w/BCR requires a free slot used to swap cartridge

during the inventory scan process. Thus the maximum cartridge capacity of

the LTO2 Autoloader w/BCR is changed from 10 to 9. But if you prefer

to use 10 cartridges, the BCR function will need to be changed disabled.

In this case, please contact your nearest Customer Support Center.

3.5.4 Panel Operation Procedure

1. Press the right side ( | ) of the Autoloader power switch to switch the power ON.

2. When the power is supplied, the POWER LED lights in green and the power-on test starts.

3. When the power-on test ends, "READY" is displayed on the LCD.

4. Press the ENTER key and enter the main menu.

5. Press the arrow key and select the command. (The menu scrolls.)

6. Press the ENTER key and define the selected command.

7. Refer to “3.5.5 Menu Tree” and follow the system of operation commands to repeat

aforementioned

Steps 5 and 6, select the command to be executed, and define it.

8. To cancel the defined command during this procedure, press the ESCAPE key.

(A press of the ESCAPE key results in a return to the previous menu.)

9. Press the ENTER key and execute the menu.

- 22 -

Page 39

Operation Examples

The operation procedure and LCD indications are described below when loading the cartridge

housed in slot 7 into the drive.

Operation 1

Display: "READY" and "DRV empty" are alternately displayed.

Operation 2

Display: STATUS

Operation 3

Display: LOAD

Operation 4

Display: Load Drv?

Operation 5

Switch ON the power and wait for the completion of the power-on test.

Press the ENTER key.

Press the arrow key and select the "LOAD" command.

Press the ENTER key and define the command.

Press the ENTER key and define the command.

Display: Frm Slt 1?

Operation 6

Display: Frm Slt 7?

Operation 7

Press the arrow key and select "Slt 7".

Press the ENTER key and execute the command.

Display: Complete (when the command ends normally.)

Err. xxxxxx (when an error occurs. xxxxxx is the error code.)

- 23 -

Page 40

3.5.5 Menu Tree

1 Main Menu

STATUS EJECT UNLOCK LOAD SCSI ID RET RY MODE M AINTENANC

READY

2 Menu Commands

1) STATUS

(Permits a check of the different types of status.)

Slt 1? Slt 10? Drive ? Ma ga zine ?

STATUS

2) EJECT

(Permits ejecting a cartridge from the drive and houses the cartridge in an empty slot.)

To Slt 1? To Slt 10?

Important

EJECT

Eject Drv? Eject Slt?

Do not use this command during a reading / writing operation.

3) UNLOCK

(Cancels the front door software key lock.)

UNLOCK

Unlock?

- 24 -

Page 41

4) LOAD

(Permits loading a cartridge from an arbitrary slot to the drive.)

LOAD

Load Drv? Load Slt?

Frm Slt 1? Frm Slt10?

5) SCSI ID

(Permits setting, changing, and checking of the drive and Autoloader SCSI ID.)

SCSI ID

View ID?

Set ID?

Lib. ID?

Drv. ID?

Lib.ID 0? Lib.ID 15?

Drv.ID 0? Drv.ID 15?

6) RETRY MODE

RETRYMODE

NotSupport

7) MAINTENANC

(You can check or change the CLNROL function.)

CLEANROL?

RCLNMODE?

View?

Disable? RtyCnt10? RtyCnt15? RtyCnt20? RtyCnt25?

MAINTENANC

Set?

Revision?

Lib.Rev? Drv.Rev?

BCRMODE?

View? Set?

Disable? Enable?

- 25 -

Page 42

3.6 Setting the SCSI ID

This command sets the SCSI ID of the Autoloader in conjunction with SCSI devices such as the

server/workstation that is to be connected.

The following SCSI IDs are assigned to this device as default values prior to shipping from the

factory.

SCSI IDs at time of factory shipping:

• Tape drive : (1)

• Autoloader : (0)

Important

The Autoloader and the tape drive must each have an independent SCSI ID.

This device has a specification that does not allow duplication of the tape drive

and Autoloader IDs. Please check that the IDs of other SCSI devices on the

same SCSI bus do not duplicate the IDs of the tape drive and the Autoloader.

Checking the SCSI ID and the method of changing it are described in this section.

3.6.1 Checking the SCSI ID

Operation 1

Display: "READY" and "DRV empty" are alternately displayed.

Operation 2

Display: STATUS

Operation 3

Display: SCSI ID

Operation 4

Display; View ID?

Operation 5

Switch ON the power and wait for the completion of the power-on test.

Press the ENTER key.

Press the arrow key and select the "SCSI ID" command .

Press the ENTER key and define the command.

Press the ENTER key and define the command.

Display: L.0 D.1

Tip

When checking the SCSI ID, the Autoloader is displayed as "L" and the tape

drive as "D".

- 26 -

Page 43

3.6.2 Changing the SCSI ID

Operation Example 1

The operation procedure and LCD indications are described below when changing the SCSI ID

of the Autoloader from 0 to 1.

Operation 1

Display: "READY" and "DRV empty" are alternately displayed.

Operation 2

Display: STATUS

Operation 3

Display: SCSI ID

Operation 4

Switch ON the power and wait for the completion of the power-on test.

Press the ENTER key.

Press the arrow key and select the "SCSI ID" command.

Press the ENTER key and define the command.

Display: View ID?

Operation 5

Display: Set ID?

Operation 6

Display: Lib.ID?

Operation 7

Display: Lib. ID 0?

Operation 8

Display: Lib. ID 1?

Operation 9

Display: Complete

Operation 10

Operation 11

Press the arrow key and select the "Set ID" command.

Press the ENTER key and define the command.

Press the ENTER key and define the command.

Press the arrow key and select the "Lib. ID1" command.

Press the "ENTER" key and define the command.

Set the power switch of this device to OFF.

Switch the power of this device ON again.

- 27 -

Page 44

Operation 12

Display: "READY" and "DRV empty" are alternately displayed.

Operation 13

When changing the SCSI ID, the Autoloader is displayed as "Lib." and the

tape drive as "Drv."

Important

When changing the SCSI ID of this device, be certain to execute a restart of

this device, the server/workstation, and any other devices. Note that the restart

of the server/workstation and the other devices should be executed after

checking the "READY" display of this device.

See "2.6 Starting and Closing the System" for information about the power-on

sequence.

Wait for the completion of the power-on test.

Check the "READY" display and then switch on the power of the

server/workstation and the other devices to restart the system.

Tip

Tip

Operation Example 2

The operation procedure and LCD indications are described below when changing the SCSI ID

of the tape drive from 1 to 5.

Operation 1

Display: "READY" and "DRV empty" are alternately displayed.

Operation 2

Display: STATUS

Operation 3

Display: SCSI ID

Operation 4

Display; View ID?

Operation 5

Switch ON the power and wait for the completion of the power-on test.

Press the ENTER key.

Press the arrow key and select the "SCSI ID" command.

Press the ENTER key and define the command.

Press the arrow key and select "Set ID" command.

Display: Set ID?

- 28 -

Page 45

Operation 6

Display; Lib.ID?

Operation 7

Display: Drv. ID?

Operation 8

Display; Drv. ID 0?

Operation 9

Display: Drv. ID 5?

Operation 10

Display: Complete

Operation 11

Operation 12

Operation 13

Press the ENTER key and define the command.

Press the arrow key and select "Drv. ID?" command.

Press the ENTER key and define the command.

Press the arrow key and select "Drv. ID 5" command.

Press the ENTER key and define the command.

Set the power switch of this device to OFF.

Switch the power of this device ON again.

Wait for the completion of the power-on test.

Display: "READY" and "DRV empty" are alternately displayed

Operation 14

Check the "READY" display and then switch on the power of the

server/workstation and the other devices to restart the system.

Important

When changing the SCSI ID of this device, be certain to execute a restart of

this device, the server/workstation, and any other devices. Note that the restart

of the server/workstation and the other devices should be executed after

checking the "READY" display of this device.

- 29 -

Page 46

3.7 Using the Emergency Release Key

As touched upon at the beginning of this chapter, this device has a double lock mechanism

comprising a key operated door lock and a solenoid operated electronic lock. When the power is

in the OFF condition, the electronic lock is activated and the door cannot be opened.

To release the door lock at the time of a power outage or emergency, release the electronic lock

by following this procedure.

1. Release the door lock as usual by using the door lock key supplied with the main unit.

2. Insert the release key (supplied with the main unit) into the electronic lock release key

insertion slot at the top of the main unit.

3. Press down the electronic lock key lightly and open the door at the same time.

Emergency Release Key supplied with the main unit

Figure 3-9 Using the Emergency Release Key

- 30 -

Page 47

Chapter 4 Cartridges

4.1 Cartridges

The Tandberg LTO2 Autoloader uses the following types of LTO cartridges.

・ TD P/N : 432744 LTO2 Data Cartridge

・ TD P/N : 432630-1 LTO1 Data Cartridge

・ TD P/N : 432631 LTO Universal Cleaning Cartridge

To ensure that your Tandberg LTO2 Autoloader conforms to our specifications for reliability, use

only the above cartridges. Below figure shows the overview of a cartridge and its components.

Write-protect switch

Label area

Insertion guide

Leader pin

Cartridge door

Figure 4-1 LTO Cartridge

- 31 -

Page 48

4.1.1 Data Cartridge

The Data Cartridge contains 1/2-inch MP (metal-particle) tape.

The cartridge door protects the tape from contamination when the cartridge is out of the

drive.

The write-protect switch prevents data from the accidental erasure of data.

The label area provides a location for placing a label. A label that extends outside of the

recessed area can cause loading problems in the tape drive.

The insertion guide is a large, notched area that prevents users from inserting the cartridge

incorrectly.

4.1.2 Cleaning Cartridge

The Tandberg LTO2 Autoloader itself determines when a drive head needs to be cleaned. It

alerts you displaying "REQ clean" on the LCD. The cleaning cartridge is valid for 50 uses. .

Important

If you insert a cleaning cartridge when the tape drive does not need to be

cleaned or if you insert a cleaning cartridge that has expired, the tape drive

will eject the cleaning cartridge automatically.

- 32 -

Page 49

t

4.2 Write-Protect Switch

Each LTO data cartridge has a write-protect switch that can be used to prevent accidental

erasure of data. Before inserting the data cartridge into the tape drive, position the write-protect

switch on the front of the cartridge. The position of the write-protect switch is shown below.

・ Move the write-protect switch to the left to disable write protection.

This means that data can be written to the data cartridge unless software write-protect

is in effect..

・ Move the write-protect switch to the right to enable write protection.

This means that data can not be written to the data cartridge.

Write-Protect Switch

Write EnableWrite Protec

Figure 4-2 Setting the Write-protect Switch

- 33 -

Page 50

4.3 Bar Code Label

The bar code label contains;

・ A volume serial number that you can read.

・ A bar code label that the Tandberg LTO2 Autoloader can read.

When appling a bar code labels to a cartridge position the bar code label only

in the recessed label area (see below figure). A bar code label that extends outside of this

recessed area can cause reading problems in the internal LTO drive or the robotics of the TD LTO2 Autoloader.

Sample Bar Code Label on the cartridge

Figure 4-3 Sample Bar Code Label on the Cartridge

Tip

Do not place any type of mark on the white space area at either end of the bar

code. A mark in this area may prevent the Tandberg LTO2 Autoloader from

reading the bar code label.

Using Bar Code Labels Precautions

When using a bar code labels, please observe the following precautions.

・ Use only TANDBERG DATA-supplied bar code labels.

・ Do not re-use a bar code label or re-apply a used bar code label over an existing label.

・ Before you apply a new bar code label, remove the old label by gently pulling it.

・ Remove the bar code label from the label sheet carefully. Do not stretch the bar code

label or cause the edges to curl.

・ Position the bar code label within the recessed label area..

・ Do not place other autoloader readable bar code labels on other surfaces of the

cartridge. They may interfere with the ability of the bar code reader to read the bar

code.

- 34 -

Page 51

4.4 Handling Precautions

This section describes precautions to take when handling the data cartridge.

4.4.1 Usage Precautions

□ Before use

- Open the cartridge door and check that the reader pin is locked.

- Do not use a data cartridge that is damaged, misshapen, or bent.

- When using a data cartridge that has been stored under conditions other than the

operation temperature and humidity conditions of the Autoloader, bring the cartridge into

the environment in which it will be used for a period at least as long as the time that it

was exposed to under conditions outside the operation temperature and humidity

conditions (i.e.24 hours maximum) and then use. When the temperature difference is

great between the storage and operation locations at this time, do not move the cartridge

at once, rather, take care so that the temperature change is in the order of 10°C per hour

and allow the data cartridge to adapt to the temperature of the operation location.

□ When loading to magazine and fixed slots

- Please insert the data cartridge securely. (See Chapter 3 for details.) Firmly close the

protective case from which the data cartridge was removed and store it in a clean place

□ After use

- Be sure to return the used cartridge to the protective case and store it in a dust-free place

The cartridge can be stored either horizontally or vertically.

□ Disposal Method

- When disposing the cartridge, please follow the national and municipal guidelines for disposal.

4.4.2 General Precautions

□ Do not touch the tape medium (i.e. the magnetic surface).

□ Do not bring the cartridge close to objects that produce a magnetic field.

□ Do not place the cartridge where it will be exposed to direct sunlight or near heaters.

□ Do not subject the cartridge to strong shocks.

□ Avoid handling the cartridge while eating and drinking or smoking. Also be careful not to

allow the cartridge to come into contact with thinners, alcohol, beverages

□ Be sure to return the cartridge to the case after use.

□ Insert the cartridge into the magazine carefully.

□ The data cartridge is sensitive to dirt and dust.

- 35 -

Page 52

4.4.3 Standards for Prohibition of Use

When circumstances correspond to any of the following items, the continued use of that

cartridge is prohibited. Exchange to a new data cartridge is necessary.

□ When the data cartridge is subjected to a strong shock such as being dropped and it sustains

damage.

□ When the recording surface becomes soiled with liquid such as a soft drink, coffee, or tea, or

a solvent, metal dust, tobacco ashes, or other contaminants.

Tip

Use of a data cartridge that falls under the aforementioned description may

damage the heads or the device, or make it dirty and may cause breakdown of

the device. If the soiled or damaged heads go unnoticed and the device is

used as is with a new data cartridge, the new data cartridge will become soiled

or scratched and the damage may spread.

4.4.4 Service Life

The life of the data cartridge will vary depending on the environment in which it is used and the

following matters should be taken into consideration. (The service life may become shorter

than the guideline depending on the environment in which it is used including such factors as

temperature, humidity, and dust.)

□ When a new data cartridge is used, a control number is assigned. It will probably be convenient

to enter that number on the label of the data cartridge.

□ Create a data cartridge control number ledger, record the days used, and estimate the number

of years used and the cycles used.

□ Periodically check the control ledger and marked labels of the data cartridges and dispose of

the data cartridges when they have been used for a long time and their reliability is low such

as when there is an occurrence of write and read errors.

4.4.5 Storage of Data Cartridges

Please observe the determined storage conditions and always keep the storage location clean.

□ We recommend that the data cartridges be kept in the write protect condition.

□ When cartridges are to be stored over a long period, we recommend that the data is read

periodically to check that the backup data can be restored.

□ In consideration of an unlikely but disastrous event, we recommend storage of data

cartridges at a location remote from the system.

- 36 -

Page 53

Chapter 5 Daily Maintenance

A method of maintenance is described so that the Autoloader can be maintained in the best

condition for whenever it is used.

WARNING

In the unlikely event that this device should break down, or if a

strange sound or strange smell were to arise, immediately set

the power switch to OFF and disconnect the plug of this

device's power cable from the power outlet to prevent a

short-circuit of a circuit portion or an electrical shock.

5.1 Cleaning

This section describes the method of cleaning the Autoloader and the internal heads.

5.1.1 Cleaning of the Drive Head

Cleaning is important and removes dirt from the surface of the magnetic heads which arises

from tape travel and from the dust of the operating environment. Continued writing and reading

with dirty heads will result in the loss of proper writing and reading operations, shortened data

cartridge life, scratched tape surfaces that will make the tape unusable, and other faults.

Important

The LTO cleaning cartridge (TD P/N 432631) is exhausted after it

has performed 50 cleanings. Replace the cleaning cartridge when it has

performed 50 cleanings.

- 37 -

Page 54

5.1.1.1 Manually Cleaning of the Drive Head

Operation 1

Operation 2

Operation 3

Display: DRV full

Operation 4

Display: STATUS

Operation 5

Load the cleaning cartridge supplied with the main unit into any of the

slots. The cleaning cartridge is housed in slot number 5 in this example.

Use the panel keys to load the cleaning cartridge into the drive.

(Cleaning will start automatically.)

Display: cleaning (Displayed during cleaning.)

When cleaning is completed, "DRV full" is displayed.

Press the ENTER key.

Press the arrow key and select the "EJECT" command.

Display: EJECT

Operation 6

Display: Eject Drv?

Operation 6

Display: To Slot 1?

Operation 7

Operation 8

Press the ENTER key and define the "EJECT" command.

Press the ENTER key and define the command.

Press the arrow key and select "To Slot 5?".

Display: To Slot 5?

Press the ENTER key and select the command.

Display: Complete (when the command ends normally.)

Err. xxxxxx (when an error occurs. xxxxxx is the error code.)

- 38 -

Page 55

5.1.2 Cleaning the Roller inside of the transporter

When the Alarm LED is blinking and "REQ CLNROL" message is displayed on the LCD, the

Autoloader is requiring to clean the Roller inside of the transporter, hereafter called

CLNROL-function.

As been described above, this Autoloader will teach you the time when it cleans automatically.

But if you prefer not to use this function, it is possible to change the setting.

The Autoloader must be in maintenance mode to check or change the setting of this function.

5.1.2.1 Checking the CLNROL- function

The method of checking the CLNROL-function is described in this section.

Default CLNROL-function setting : Enable

Operation 1

Switch ON the power and wait for the completion of power-on test.

Display: READY and DRV empty are alternately displayed.

Operation 2

Display: STATUS

Operation 3

Display : MAINTENANC

Operation 4

If you press the allow key, the number is up or down. If you press the enter

key, the number is decided and the cursor move to the next digit. If you have made a

mistake, press the escape key. All number you have entered are canceled.

Operation 5

Press the ENTER key.

Press the arrow key and select the MAINTENANC command

Press the ENTER key and define the command.

Display (line 1): PASSWORD

Display (line 2): 0000000000

Tip

In this condition, press the ENTER key and set the above password.

Display (line 2): RCLN MODE?

Operation 6

Display (line 2): View?

Press the ENTER key and define the command.

- 39 -

Page 56

Operation 7 Press the ENTER key and define the command.

Display (line 2): Enable ( or Disable) and

RtyCnt XX are alternately displayed.

5.1.2.2 Setting the CLNROL- function Disable

If you would like to set the CLNROL- function disable, follow the procedure described below.

Important

In normal operation, please use the default settings.

Operation 1

Display: READY and DRV empty are alternately displayed.

Operation 2

Display: STATUS

Operation 3

Switch ON the power and wait for the completion of power-on test.

Press the ENTER key.

Press the arrow key and select the MAINTENANC command

Display : MAINTENANC

Operation 4

If you press the allow key, the number is up or down. If you press the enter

key, the number is decided and the cursor move to the next digit. If you have made a

mistake, press the escape key. All number you have entered are canceled.

Operation 5

Display (line 2): RCLN MODE?

Operation 6

Display (line 2): View?

Press the ENTER key and define the command.

Display (line 1): PASSWORD

Display (line 2): 0000000000

Tip

In this condition, press the ENTER key and set the above password.

Press the ENTER key and define the command.

- 40 -

Page 57

Operation 7 Press the arrow key and select the Set ?.

Display (line 2): Set ?

Operation 8

Display (line 2): Disable?

Operation 9

Display (line 2): Complete