Page 1

Tandberg

DLT VS160

Tape Drive

Installation and

Operations Manual

TANDBERG DATA ASA

P.O. Box 134 Kjelsås

N-0411 OSLO, NORWAY

Phone + 47 22 18 90 90

Telefax + 47 22 18 95 50

© Tandberg Data ASA

Part No. 432679-01

January 2003

Page 2

Related Publications

Part No. Title

432679-01 DLT VS160 and VS160e Product Specification

TBD DLT VS160 SCSI Reference Manual

This publication may describe designs for which patents are granted or pending. By publishing this information, Tandberg Data ASA conveys no license

under any patent or any other rights.

Every effort has been made to avoid errors in text and diagrams. However,

Tandberg Data ASA assumes no responsibility for any errors, which may

appear in this publication.

It is the policy of Tandberg Data ASA to improve products as new techniques

and components become available. Tandberg Data ASA therefore reserves the

right to change specifications at any time.

We would appreciate any comments on this publication.

"DLT VS, DLTtape and the DLTtape logo are trademarks or registered trademarks of

Quantum Corporation."

Page 3

Table of Contents

1 Introduction 1-1

1.1 Overview 1-1

1.2 DLT VS160 Drive Overview 1-1

1.2.1 Features 1-1

1.2.2 Obtaining Drivers and Firmware Upgrades 1-2

1.3 Scope of This Manual 1-2

2 Installing Your Tandberg DLT VS160 Drive 2-1

2.1 Chapter Overview 2-1

2.2 Preparation 2-1

2.2.1 SCSI Requirements 2-1

2.2.2 Before You Start 2-1

2.3 Installing your Tandberg DLT VS160 Tabletop Drive 2-2

2.3.1 Installation Overview 2-2

2.3.2 Unpacking your Drive and Selecting a Location 2-3

2.3.2.1 Unpacking your Drive 2-3

2.3.2.2 Selecting a Location for your Drive 2-3

2.3.3 Setting the SCSI ID 2-4

2.3.4 When to Use Termination 2-5

2.3.5 Terminator Power 2-5

2.3.6 Connecting the Cables 2-5

2.4 Installing your Tandberg DLT VS160 Internal Drive 2-9

2.4.1 Installation Overview 2-9

2.4.2 Unpacking your Drive 2-10

2.4.3 Configuration 2-10

2.4.3.1 Setting the SCSI ID 2-10

2.4.3.2 When to Use Termination 2-11

2.4.4 Installing your DLT VS160 Internal Drive 2-13

2.5 Installing the Device Drivers 2-19

2.5.1 Microsoft® Windows NT® 4.0: 2-19

2.5.2 Microsoft® Windows® 2000: 2-19

3 Using Your Tandberg DLT VS160 Drive 3-1

3.1 Chapter Overview 3-1

3.2 Front Panel Controls and Indicators 3-1

Tandberg DLT VS160 Installation and Operations Manual i

Page 4

Tandberg Data Table of Contents

3.2.1 Key to Indicators 3-1

3.2.1.1 Indicator Activity During

Power-On Self-Test (POST) 3-2

3.2.1.2 Indicator Activity During Normal Operation:

Ready LED 3-3

3.2.1.3 Indicator Activity During Normal Operation:

Fault/Clean/Media LEDs 3-3

3.2.2 Unload/Eject Button Features 3-4

3.2.2.1 Unload/Eject Button Feature Description 3-5

3.3 Using Cartridges 3-6

3.3.1 Loading a Cartridge 3-6

3.3.2 Unloading a Cartridge 3-7

3.3.3 Cartridge Write-Protect Switch 3-8

3.3.4 Caring for your Cartridges 3-8

3.3.5 Using the Cleaning Cartridge 3-9

4 Troubleshooting 4-1

4.1 Obtaining Drivers and Firmware Upgrades 4-1

4.2 Troubleshooting the Drive 4-1

4.2.1 Power-On Self-Test (POST) and

Drive Connectivity Failure 4-1

4.2.2 If the Drive Becomes Unresponsive 4-9

4.2.3 Drive Makes Noises During System Startup 4-9

4.2.4 Drive Failures During Backup or Restore Operations 4-9

4.2.5 Tape-Backup Software Errors 4-10

ii Tandberg DLT VS160 Installation and Operations Manual

Page 5

1 Introduction

1.1 Overview

This chapter introduces your Tandberg DLT VS160 Internal

Drive, Tandberg DLT VS160 Tabletop Drive, and this

Installation and Operations Manual.

1.2 DLT VS160 Drive Overview

Your Tandberg DLT VS160 Drive is a value-priced, highreliability, high-capacity linear streaming cartridge tape drive

designed for use on entry to midrange computing platforms.

With a combination of data compression and compaction, the

DLT VS160 Drive offers a formatted cartridge capacity of 80GB

(160GB assuming a 2:1 compression ratio) and a sustained user

data transfer rate of 8 MB/s (up to 16 MB/s with 2:1

compression). The capacity you realize in practice depends on

the data set, which affects the actual compression ratio.

Your DLT VS160 Drive is built on a 5¼-inch, half-height formfactor, using a ½-inch tape. Its design includes a four-channel

read/write head, Lempel-Ziv (DLZ) high-efficiency hardware

data compression, and tape-mark directory to achieve fast data

throughput and data access times.

1.2.1 Features

Your DLT VS160 Drive has the following features:

Supported formats: DLT VS160 (read/write using DLTtape

•

VS1 Media cartridges), DLT1/VS80 (read only using

DLTtape™ IV cartridges)

Uses DLTtape VS1 Media

•

5.25-inch half-height form-factor

•

Formatted cartridge capacity of 80GB native, 160GB

•

compressed

Sustained user data transfer rate of 8 MB/s native, up to 16

•

MB/s with compression*

Requires a wide-ultra, Ultra2, Ultra160, or Ultra3, Low-

•

Voltage Differential (LVD) or Single-Ended (SE) SCSI bus

Tandberg DLT VS160 Installation and Operations Manual 1-1

Page 6

Tandberg Data Introduction

* Assumes 2:1 compression ratio. The capacity and data

transfer rates realized in practice depend on the data set, which

determines the actual compression ratio.

1.2.2 Obtaining Drivers and Firmware Upgrades

If the tape backup software does not detect the tape drive or to

obtain the latest operating system drivers and/or firmware

upgrades, visit:

www.tandberg.com

1.3 Scope of This Manual

This Installation and Operations Manual is intended to provide

all the information you need to install and use your Tandberg

DLT VS160 Internal Drive or Tandberg DLT VS160 Tabletop

Drive.

1-2 Tandberg DLT VS160 Installation and Operations Manual

Page 7

2 Installing Your Tandberg DLT

VS160 Drive

2.1 Chapter Overview

This chapter explains how to configure and install your

Tandberg DLT VS160 Tabletop Drive or Tandberg DLT VS160

Internal Drive. Configuration and installation are not difficult

and require only that you follow the steps and instructions

presented in this chapter.

2.2 Preparation

This section helps you prepare to install your DLT VS160

Tabletop Drive or DLT VS160 Internal Drive.

2.2.1 SCSI Requirements

Your DLT VS160 Drive (tabletop and internal) incorporates a

wide-ultra 160 Low-Voltage Differential (LVD) SCSI bus, but

may also be attached to a Single-Ended (SE) SCSI bus.

Make sure your SCSI host adapter or controller supports these

standards. If you connect the drive to an SE SCSI bus or if

there are SE devices attached to the same SCSI bus, the drive's

performance is limited to the maximum data transfer speed

and maximum cable lengths of the SE bus. The DLT VS160 is

not compatible with a standard differential (Diff) or HighVoltage Differential (HVD) SCSI bus. If you attach the drive to

a narrow (50-pin) SCSI bus, you must use a customer-supplied

68-pin to 50-pin adapter that terminates the unused 18 pins.

These adapters are sometimes labeled "high-byte termination."

Make sure the total length of the SCSI bus does not exceed the

ANSI SCSI standard of 19 feet (6 meters) for an SE bus, 40 feet

(12 meters) for an LVD SCSI bus with multiple devices, or 82

feet (25 meters) for an LVD SCSI bus with a single device.

2.2.2 Before You Start

Installing your DLT VS160 Tabletop Drive requires no special

tools. You will need a ballpoint pen to change the SCSI ID

switch on the rear panel of the drive. Installing your DLT

VS160 Internal Drive requires only the usual tools needed to

Tandberg DLT VS160 Installation and Operations Manual 2-1

Page 8

Tandberg Data Installing Your Tandberg DLT VS160 Drive

install an internal drive in the computer you have chosen to

house the DLT VS160.

If you are installing a DLT VS160 Internal Drive, refer to page

2-9 for instructions.

2.3 Installing your Tandberg DLT VS160 Tabletop Drive

This section contains step-by-step instructions for installing

your DLT VS160 Tabletop Drive.

2.3.1 Installation Overview

Installing your DLT VS160 Tabletop Drive is fast and easy

when you follow the instructions in this section in the order

presented. Installing your DLT VS160 Tabletop Drive consists

of the following steps, covered in the next few sections:

1. Unpack and check your drive for shipping damage.

2. Select a location near the server or workstation that is to be

the host for your DLT VS160 Tabletop Drive.

3. Set the SCSI ID for your DLT VS160 Tabletop Drive, if

necessary.

4. Shut down and turn off the server or workstation that is to

host your DLT VS160 Tabletop Drive. Remove the power

cable from the selected server or workstation. Turn off and

remove the power cables from all devices attached to the

selected server or workstation.

5. Install an LVD/SE SCSI host adapter in the server or

workstation that is to be the host for your drive, if

necessary.

6. Attach the SCSI cable to your DLT VS160 Tabletop Drive

and SCSI host adapter.

7. Install the terminator on your DLT VS160 Tabletop Drive if

it is the last or only device on the SCSI bus.

8. Attach the power cable to your DLT VS160 Tabletop Drive,

server or workstation, and all attached devices, plug in the

power cable to the nearest power outlet, and turn on all

devices.

9. Check your DLT VS160 Tabletop Drive to make sure it is

working properly.

2-2 Tandberg DLT VS160 Installation and Operations Manual

Page 9

Tandberg Data Installing Your Tandberg DLT VS160 Drive

2.3.2 Unpacking your Drive and Selecting a Location

Before you begin, clear a desk or table so that you can unpack

your DLT VS160 Tabletop Drive. You also need to select a

location near the server or workstation that is to host your

drive.

Note: If the room in which you are working differs from the

temperature at which your DLT VS160 Tabletop Drive was

shipped or stored by 30° F (15° C) or more, let the drive

acclimate to the surrounding environment for at least 12 hours

before opening the shipping carton.

2.3.2.1 Unpacking your Drive

Before you do anything else, unpack and inspect your DLT

VS160 Tabletop Drive for shipping damage. If you notice any

damage, report it both to Tandberg and the shipping company

immediately.

Note: Save the packing materials in case you need to move or

ship your drive in the future. You must ship your DLT VS160

Tabletop Drive in the original or equivalent packing materials

or your warranty may be invalidated.

2.3.2.2 Selecting a Location for your Drive

Select a location for your DLT VS160 Tabletop Drive that is

flat, sturdy, level, and close to the host server or workstation. A

desk or table-top is most suitable. Regardless of the location

you choose for your DLT VS160 Tabletop Drive, make sure the

environment is free from dust and excessive temperature and

humidity. See the DLT VS160 Product Specification manual for

acceptable operating temperature and humidity limits.

Be sure to follow these additional guidelines when selecting a

location for your DLT VS160 Tabletop Drive:

Allow at least 6 inches (15.2 cm) behind the drive for proper

•

cooling.

Avoid locations near printers or photocopy machines, both of

•

which produce paper fiber and other types of dust and

airborne contaminants.

Do not place your drive on the floor.

•

Tandberg DLT VS160 Installation and Operations Manual 2-3

Page 10

Tandberg Data Installing Your Tandberg DLT VS160 Drive

Avoid locations near generators, electric motors, audio

•

speakers, or other sources of magnetic fields. Magnetic

fields can adversely affect your drive and media.

2.3.3 Setting the SCSI ID

Regardless of the number of SCSI devices attached to the

server or workstation that is to be the host for your DLT VS160

Tabletop Drive, each device must have a unique SCSI ID.

Check the SCSI IDs on all other devices on the selected server

or workstation, including the SCSI host adapter, and select an

unused SCSI ID for your DLT VS160 Tabletop Drive. The

factory default SCSI ID is 5. If the drive’s factory default SCSI

ID is not being used by another device on the same SCSI bus,

you do not need to change the SCSI ID.

SCSI ID

Switch

Power Switch

68-pin highdensity SCSI

connectors

Power Cable

Connector

Figure 2-1: DLT VS160 Tabletop Drive Rear Panel Layout

Note: If you plan to attach the drive to a narrow (50-pin) SCSI

bus, you can only use IDs 0 through 7.

To set the SCSI ID on your DLT VS160 Tabletop Drive, use a

small screwdriver or ball-point pen to press the button above

the SCSI ID display to select the next lower SCSI ID. Press the

button below the SCSI ID display to select the next higher

SCSI ID. Each time you press one of these buttons, the SCSI ID

increases or decreases by one. Press the appropriate button

until the desired SCSI ID appears on the switch display.

Press here to decrease

SCSI ID

Press here to increase SCSI

ID

Figure 2-2: SCSI ID Switch

2-4 Tandberg DLT VS160 Installation and Operations Manual

Page 11

Tandberg Data Installing Your Tandberg DLT VS160 Drive

After you change the SCSI ID, turn the drive off and on again

to activate the new SCSI ID. Then restart the host server or

rescan the SCSI bus so the server can recognize the drive at the

new SCSI ID.

2.3.4 When to Use Termination

If your DLT VS160 Tabletop Drive is the only SCSI device on

the selected server or workstation other than the SCSI host

adapter, or it is the last physical device on the SCSI bus (at the

end of the SCSI cable), it must be terminated. If another SCSI

device is the last device on the SCSI bus, confirm that it is

properly terminated and do not terminate your DLT VS160

drive. Regardless of which device is used to terminate the SCSI

bus, it must have power applied and be turned on for proper

termination to occur.

To terminate your DLT VS160 Tabletop Drive, locate the

terminator in the accessories package and press it firmly into

either of the two SCSI connectors on the rear panel of the drive.

Secure the terminator by tightening the screws until snug. See

Figure 2-4 for an example.

2.3.5 Terminator Power

At least one device on the SCSI bus must supply terminator

power (TERMPWR). The factory default for the DLT VS160

Tabletop Drive is TERMPWR enabled, which is the

recommended setting. It is acceptable for more than one device

on the SCSI bus to provide TERMPWR. Only an authorized

service provider can disable the DLT VS160 Tabletop Drive

TERMPWR setting.

2.3.6 Connecting the Cables

This is the final installation stage, which requires that you

attach the SCSI and power cables to your DLT VS160 Tabletop

Drive.

Note: If the selected server or workstation does not already

have an installed SCSI host adapter, install one now. For more

information on SCSI host adapter requirements, see page 2-1.

To connect the SCSI and power cables to your DLT VS160

Tabletop Drive, follow these steps:

1. Shut down the operating system and turn off the selected

server or workstation. Turn off all attached accessory

Tandberg DLT VS160 Installation and Operations Manual 2-5

Page 12

Tandberg Data Installing Your Tandberg DLT VS160 Drive

devices, such as printers and other SCSI devices. Remove

the power cable from the host server or workstation and all

attached accessory devices. Failure to follow these

instructions may result in damage to your DLT VS160

Tabletop Drive or other devices.

Do not move on to step 2 until you have shut down

the operating system and turned off the server or

workstation that is to be the host for your DLT

VS160 Tabletop Drive. Turn off all attached

accessory devices, such as printers and other SCSI

devices. Remove the power cables from the host

server or workstation and all attached accessory

devices.

2. Locate the SCSI cable in the accessories package.

3. Attach one end of the SCSI cable to one of the connectors on

the rear panel of your DLT VS160 Tabletop Drive.

2-6 Tandberg DLT VS160 Installation and Operations Manual

Page 13

Tandberg Data Installing Your Tandberg DLT VS160 Drive

4. Attach the other end of the SCSI cable to the connector on

your SCSI host adapter or to the connector on the previous

SCSI device on the SCSI bus.

SCSI Host Adapter

DLT VS160 SCSI Cable

To Next SCSI Device

To SCSI Host Adapter

Figure 2-3: Attach SCSI Cable to Server or Workstation or to

Previous SCSI Device

Tandberg DLT VS160 Installation and Operations Manual 2-7

Page 14

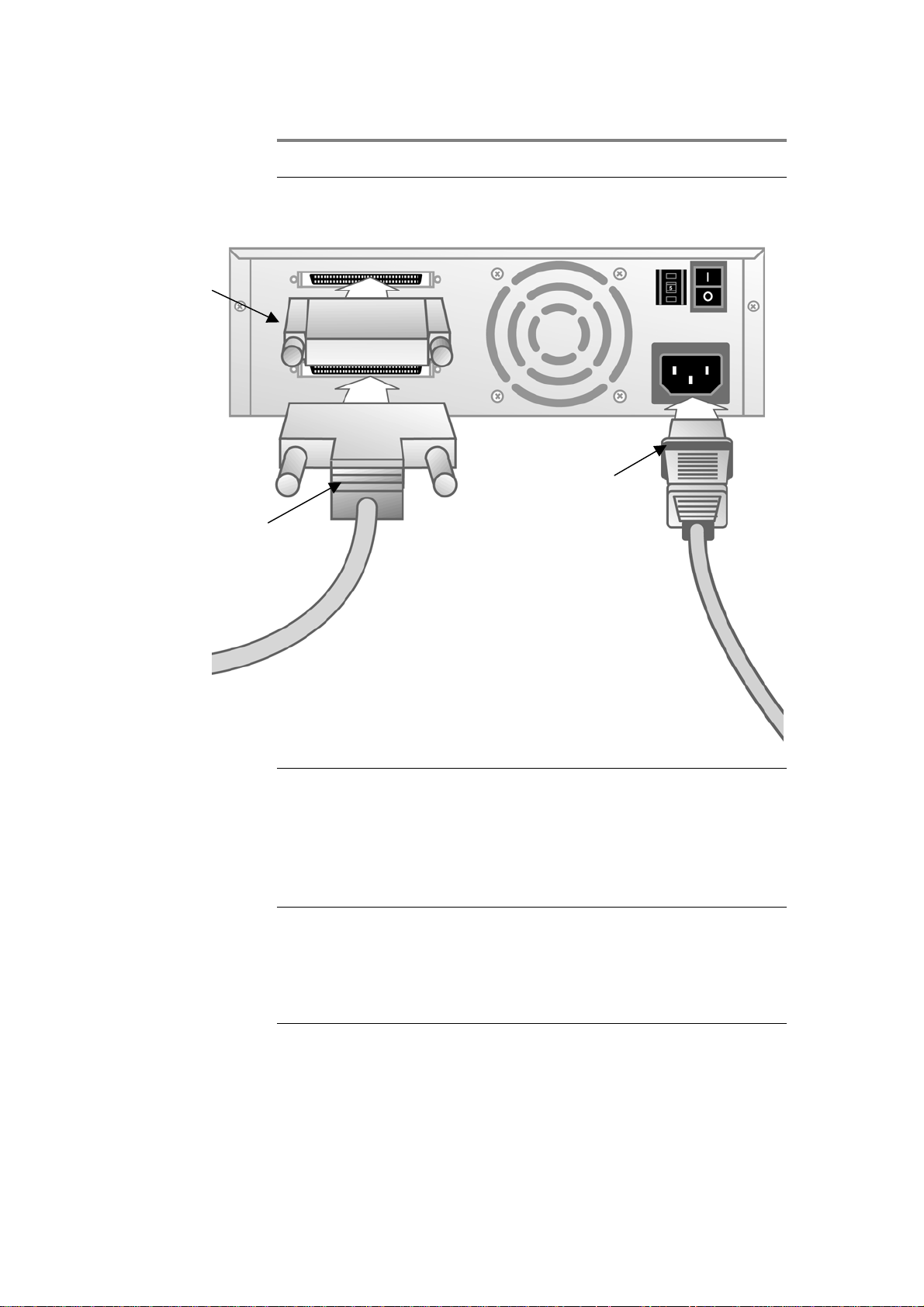

Terminator

(or cable to

next SCSI

device)

DLT VS160 SCSI

Cable

To computer or

previous SCSI device

Tandberg Data Installing Your Tandberg DLT VS160 Drive

Note: Figure 2-3 does not show a terminator because none of

Power Cable

the three drives are at the end of the SCSI bus.

Figure 2-4: Attach Terminator (if necessary), SCSI, and Power

Cables to your Drive

5. Secure the SCSI cable connectors by tightening the screws

until snug.

Note: If the supplied SCSI cable does not fit the connector on

your SCSI host adapter, you either have an incompatible SCSI

host adapter or you need to purchase a cable adapter. Contact

Tandberg or your SCSI host adapter manufacturer for

information.

6. Make sure the power switch on the rear panel of your DLT

VS160 Tabletop Drive is in the OFF position. Attach the

female connector on the power cable to the power connector

on the rear panel of the drive.

2-8 Tandberg DLT VS160 Installation and Operations Manual

Page 15

Tandberg Data Installing Your Tandberg DLT VS160 Drive

Use caution when plugging the power cord into an

electrical outlet. Hazardous voltages are present in

the sockets of the outlet.

7. Plug in the power cable to a nearby power outlet.

8. Attach the power cables to the host server or workstation

and all attached devices.

9. Turn on your DLT VS160 Tabletop Drive and any other

devices you turned off earlier.

10. Turn on the host server or workstation and allow its

operating system to start.

Turn to page 3-2 to learn about your DLT VS160 Tabletop

Drive’s self-test and initialization features.

2.4 Installing your Tandberg DLT

VS160 Internal Drive

This section contains step-by-step instructions for installing

your DLT VS160 Internal Drive.

2.4.1 Installation Overview

Installing your DLT VS160 Internal Drive is fast and easy

when you follow the instructions in this section in the order

presented. Installing your DLT VS160 Internal Drive consists

of the following steps, covered in the next few sections:

1. Unpack and check your drive for shipping damage.

2. Select a server or workstation that is to be the host for your

DLT VS160 Internal Drive.

3. Set the SCSI ID for your DLT VS160 Internal Drive, if

necessary.

4. Shut down and turn off the server or workstation that is to

host your DLT VS160 Internal Drive. Remove the power

cable from the selected server or workstation. Turn off and

remove the power cables from all devices attached to the

selected server or workstation.

5. Remove the cover from the selected server or workstation as

explained in the server’s or workstation’s manuals.

Tandberg DLT VS160 Installation and Operations Manual 2-9

Page 16

Tandberg Data Installing Your Tandberg DLT VS160 Drive

6. Install an LVD/SE SCSI host adapter in the server or

workstation that is to be the host for your drive, if

necessary.

7. Install your DLT VS160 Internal Drive in an open drive

bay.

8. Attach the SCSI ribbon cable to your DLT VS160 Internal

Drive and SCSI host adapter.

9. Install an active LVD/SE terminator on the SCSI ribbon

cable if your DLT VS160 Internal Drive if it is the last or

only device on the SCSI bus.

10. Attach a power cable to your DLT VS160 Internal Drive.

11. Secure your DLT VS160 Internal Drive in the selected

server or workstation.

12. Install the server or workstation's cover, attach power

cables to all devices, and turn on the server or workstation

and other devices.

13. Check your DLT VS160 Internal Drive to make sure it is

working properly.

2.4.2 Unpacking your Drive

Before you do anything else, unpack and inspect your DLT

VS160 Internal Drive for shipping damage. If you notice any

damage, report it both to Tandberg and the shipping company

immediately.

Note: Save the packing materials in case you need to move or

ship your drive in the future. You must ship your DLT VS160

Internal Drive in the original or equivalent packing materials

or your warranty may be invalidated.

2.4.3 Configuration

Configuring your DLT VS160 Internal Drive is fast and easy.

You only need to select a unique SCSI ID and decide if your

drive needs to be terminated. The following sections explain

how to configure your drive.

2.4.3.1 Setting the SCSI ID

Regardless of the number of SCSI devices attached to the

server or workstation that is to be the host for your DLT VS160

Internal Drive, each device must have a unique SCSI ID. Check

the SCSI IDs on all other devices on the selected server or

2-10 Tandberg DLT VS160 Installation and Operations Manual

Page 17

Tandberg Data Installing Your Tandberg DLT VS160 Drive

workstation, including the SCSI host adapter, and select an

unused SCSI ID for your DLT VS160 Internal Drive. The

factory default SCSI ID is 5. If the drive’s factory default SCSI

ID is not being used by another device on the same SCSI bus,

you do not need to change the SCSI ID.

Note: If you plan to attach the drive to a narrow (50-pin) SCSI

bus, you can only use IDs 0 through 7.

Locate the SCSI ID jumpers on the rear panel of the drive as

shown in Figure 2-5.

68-pin high-density

SCSI Connector

SCSI ID Jumper Block

Power Connector

Figure 2-5: SCSI ID Jumper Block Location

To set the SCSI ID on your DLT VS160 Internal Drive, use the

supplied jumpers to select the desired SCSI ID as shown in the

following table:

SCSI ID 0 1 2 3 4 5* 6 7

Jumper

Block

SCSI ID 8 9 10 11 12 13 14 15

Jumper

Block

Table 1: Setting the SCSI ID Jumper Block

* Factory default SCSI ID

2.4.3.2 When to Use Termination

If your DLT VS160 Internal Drive is the only SCSI device on

the selected server other than the SCSI host adapter, or it is

the last physical device on the SCSI bus (at the end of the SCSI

cable), it must be terminated. If another SCSI device is the last

device on the SCSI bus, confirm that it is properly terminated

Tandberg DLT VS160 Installation and Operations Manual 2-11

Page 18

Tandberg Data Installing Your Tandberg DLT VS160 Drive

and do not terminate your DLT VS160 Internal Drive.

Regardless of which device is used to terminate the SCSI bus,

that device must have power applied and be turned on for

proper termination to occur.

To terminate your DLT VS160 Internal Drive, install an active

Low-Voltage Differential/Single-Ended (LVD/SE) cable-end or

inline terminator on the SCSI cable you intend to use with your

DLT VS160 Internal Drive as shown in Figure 2-6. You can use

a cable-end terminator as shown in Figure 2-6 or an inline

terminator, whichever is most convenient.. See the terminator's

instructions for more information.

Terminator SCSI Ribbon Cable

Figure 2-6: Installing the Terminator

2-12 Tandberg DLT VS160 Installation and Operations Manual

Page 19

Tandberg Data Installing Your Tandberg DLT VS160 Drive

Note: If the SCSI cable that came with your SCSI host adapter

already has a terminator built into it, do not use another

terminator. An example of such a cable is shown in Figure 2-7.

SCSI Ribbon Cable

Supplied with SCSI

Host Adapter

Terminator

Figure 2-7: SCSI Ribbon Cable with Terminator Built-in

2.4.4 Installing your DLT VS160 Internal Drive

This is the final installation stage, which requires that you

install your DLT VS160 Internal Drive in the host server or

workstation and attach the SCSI and power cables.

To install your DLT VS160 Internal Drive, follow these steps:

1. Shut down the operating system and turn off the selected

server or workstation. Turn off all attached accessory

devices, such as printers and other SCSI devices. Remove

the power cables from the host server or workstation and all

attached accessories. Failure to follow these instructions

may result in damage to your DLT VS160 Internal Drive or

other devices.

Tandberg DLT VS160 Installation and Operations Manual 2-13

Page 20

Tandberg Data Installing Your Tandberg DLT VS160 Drive

Do not move on to step 2 until you have shut down

the operating system and turned off the server or

workstation that is to be the host for your DLT

VS160 Internal Drive. Turn off all attached

accessory devices, such as printers and other SCSI

devices. Remove the power cables from the host

server or workstation and all attached accessories.

2. Remove the cover from the host server or workstation as

described in the server’s or workstation’s manuals.

Figure 2-8: Remove Server/Workstation Cover

2-14 Tandberg DLT VS160 Installation and Operations Manual

Page 21

Tandberg Data Installing Your Tandberg DLT VS160 Drive

3. Locate an available 5¼-inch drive bay and remove the front

cover from the drive bay as described in the server’s or

workstation’s manuals.

4. Slide your DLT VS160 Internal Drive into the open drive

bay.

Figure 2-9: Install Drive in an Open Drive Bay: Tower, 2U

server shown

Note: Install a SCSI host adapter in the selected server or

workstation now, if necessary. For more information on SCSI

host adapter requirements, see page 2-1.

Tandberg DLT VS160 Installation and Operations Manual 2-15

Page 22

Tandberg Data Installing Your Tandberg DLT VS160 Drive

Note: If your SCSI host adapter already has a ribbon cable

with an open 68-pin, high-density connector, you can use the

existing cable instead of the cable supplied with your DLT

VS160 internal drive.

5. Locate the SCSI ribbon cable in the accessories package.

Attach one end of the SCSI ribbon cable to the SCSI

connector on the rear panel of your DLT VS160 Internal

Drive. The SCSI connectors are keyed, preventing improper

connection.

Note: If the supplied SCSI cable does not fit the connector on

your SCSI host adapter, you either have an incompatible SCSI

host adapter or you need to purchase a cable adapter. Contact

Tandberg Data or your SCSI host adapter manufacturer for

information.

Note: Refer to page 2-11 to determine if you need to use an

LVD/SE terminator with the SCSI cable.

6. Attach the other end of the SCSI ribbon cable to the SCSI

host adapter, aligning the colored stripe on the ribbon cable

with pin 1 on the SCSI host adapter’s connector.

2-16 Tandberg DLT VS160 Installation and Operations Manual

Page 23

SCSI Cable (Shown

with Terminator

Installed)

Tandberg Data Installing Your Tandberg DLT VS160 Drive

7. Locate an available power cable in the host server or

workstation and attach it to the power connector on the rear

panel of your DLT VS160 Internal Drive. The connectors

are keyed, preventing improper connection.

Power Cable

Figure 2-10: Attach SCSI and Power Cables to your DLT VS160

Internal Drive

Tandberg DLT VS160 Installation and Operations Manual 2-17

Page 24

Tandberg Data Installing Your Tandberg DLT VS160 Drive

8. Secure your DLT VS160 Internal Drive with the

appropriate mounting screws, either in the sides or bottom

of the drive sled, as appropriate for the server or

workstation chassis. Figure 2-11 shows the drive without

the power and SCSI cables attached for clarity.

Figure 2-11: Secure DLT VS160 Internal Drive in Installation

Bay (Side Mounting Screws Shown)

Note: Some servers and workstations require mounting rails

for internal devices. Contact your server or workstation

manufacturer for information.

9. Replace the cover on the server or workstation.

10. Attach the power cables to the server or workstation and all

attached accessories.

11. Turn on the host server or workstation and allow its

operating system to start.

12. Refer to page 3-2 to learn about your DLT VS160 Internal

Drive’s self-test and initialization features.

2-18 Tandberg DLT VS160 Installation and Operations Manual

Page 25

Tandberg Data Installing Your Tandberg DLT VS160 Drive

2.5 Installing the Device Drivers

Note: The device drivers required if you intend to use native

operating system backup applications can be found at

www.tandberg.com. Commercial backup applications generally

provide all necessary device driver support.

2.5.1 Microsoft® Windows NT® 4.0:

1. Make sure that you are logged on to the server or

workstation with Administrator privileges.

2. Download the required drivers from www.tandberg.com

3. Click the Start button, point to Settings, then click

Control Panel.

4. Double-click the Tape Devices icon.

5. Click the Drivers tab.

6. Click the Add button.

7. Click the Have Disk button.

8. Type the path to the driver you downloaded in step 2.

9. Click the DLT1VS Tape NT entry and click the OK button.

10. When the New SCSI Tape Device Found dialog box appears,

click its OK button.

11. Type the path to the driver you downloaded in step 2 and

click the Continue button.

12. Click the OK button in the Tape Devices dialog box.

13. Restart the server or workstation.

14. After the server or workstation restarts, log on with

Administrator privileges, click the Start button, point to

Settings, click Control Panel, double-click the Tape

Devices icon, and make sure the DLT VS160 drive device

driver is loaded. If the device driver is not loaded, repeat the

installation beginning at step 1.

2.5.2 Microsoft® Windows® 2000:

1. Make sure that you are logged on to the server or

workstation with Administrator privileges.

2. Download the required drivers from www.tandberg.com

Tandberg DLT VS160 Installation and Operations Manual 2-19

Page 26

Tandberg Data Installing Your Tandberg DLT VS160 Drive

3. Right-click the My Computer icon on the Windows

desktop, click Manage, then click Device Manager.

4. The DLT VS160 drive should be listed under the "? Other

Devices" item as "QUANTUM VS160 SCSI Sequential

Device."

5. Right-click the QUANTUM VS160 SCSI Sequential

Device listing, click Uninstall, and then click the OK

button to confirm that you want to remove the device.

6. Click the Action button in the upper-left corner of the

Computer Management dialog box or right-click anywhere

in the right-hand pane of the dialog box.

7. Click Scan for Hardware Changes. Windows 2000 now

scans for the DLT VS160 drive. The DLT VS160 drive

appears under "? Other Devices" again.

8. Right-click the QUANTUM VS160 SCSI Sequential

Device listing and click Properties.

9. Click the Reinstall Driver button.

10. When the Upgrade Device Driver Wizard appears, click the

Next button.

11. Click Display a list... and then click the Next button.

12. Click the Tape Drives item in the list. You may have to

scroll down to see this item.

13. Click the Have Disk button, type the path to the driver you

downloaded in step 2, and click the OK button.

14. Click the DLT VS Tape Drive entry and click the Next

button.

15. Click the Next button to install the driver.

16. Click the Finish button.

17. Close the Device Properties dialog box.

The drive now appears in Device Manager under Tape Drives,

listed as "DLT VS Tape Drive," and is ready to use.

2-20 Tandberg DLT VS160 Installation and Operations Manual

Page 27

3 Using Your Tandberg DLT

VS160 Drive

3.1 Chapter Overview

This chapter explains how to use your Tandberg DLT VS160

Drive. It describes the front panel LEDs and controls, how to

load, eject, and care for tape cartridges, and how to use the

cleaning cartridge.

3.2 Front Panel Controls and Indicators

This section explains how to use the front-panel controls and

indicators.

Ready LED Clean LED Unload/Eject Button

External Power LED Fault LED Cartridge Door Media LED

Figure 3-1: DLT VS160 Front Panel

Note: The front panel controls and indicators are in the same

locations on both the internal and external drives. The internal

drive does not have a Power LED.

3.2.1 Key to Indicators

This section describes what each front panel indicator means

and the circumstances under which one or more indicators are

illuminated or blinking.

Tandberg DLT VS160 Installation and Operations Manual 3-1

Page 28

Tandberg Data Using Your Tandberg DLT VS160 Drive

3.2.1.1 Indicator Activity During Power-On Self-Test (POST)

Every time you turn on or reset the drive, it conducts a PowerOn Self-Test (POST). This test ensures that the drive is

working properly and is ready to use. While POST is in

progress, watch the front panel LEDs to see the progress and

results of the test. During POST, the following actions take

place:

The LEDs illuminate one at a time, from left to right,

•

starting with the Ready LED, next the Fault LED, and

finally the Clean LED, at approximately one second

intervals

About four seconds later, the Media LED illuminates

•

Each LED signals a different part of the POST process

•

All LEDs then turn off momentarily

•

If a cartridge is not loaded, the Ready LED illuminates and

•

POST is complete, the entire process taking approximately

eight seconds

If a cartridge is loaded, the Ready LED flashes while the

•

drive mounts the cartridge, a process that can take several

minutes depending upon the position of the media in the

tape path

As POST completes, the drive makes a slight buzzing noise

•

for several seconds. This noise is normal and should be

ignored

The drive is now ready to use.

3-2 Tandberg DLT VS160 Installation and Operations Manual

Page 29

Tandberg Data Using Your Tandberg DLT VS160 Drive

3.2.1.2 Indicator Activity During Normal Operation: Ready LED

When your DLT VS160 Drive is in use, the Ready LED

indicates the three states detailed in Table 2. The Ready LED

operates independently of the other three LEDs.

Ready LED

Drive Status

Activity

Off No power to the drive

On Power is on; no cartridge loaded or a loaded cartridge is idle with no tape

motion

Blinking The drive is loading a cartridge or a loaded cartridge has tape motion

indicating read, write, seek, rewind, calibration, or other cartridge activity

Table 2: Ready LED Activity and Drive Status

3.2.1.3 Indicator Activity During Normal Operation: Fault/Clean/Media LEDs

The Fault, Clean, and Media LEDs indicate the status of the

drive. Note that the LEDs can indicate more than one of the

indicated operating conditions simultaneously. For example:

If cleaning is required while a DLT1 format cartridge is

•

loaded, both the Clean and Media LEDs are on.

If an internal write/read diagnostic fails as a result of a

•

permanent write error, both the Fault and Clean LEDs

blink slowly.

Tandberg DLT VS160 Installation and Operations Manual 3-3

Page 30

Tandberg Data Using Your Tandberg DLT VS160 Drive

Table 3 describes what each front panel indicator means.

Indicator Activity Operating Condition

Fault

Clean

Media

Slow Blink (1x per second) User initiated write/read diagnostic failed

Fast Blink (3x per second) Servo or mechanism error

On Internal firmware error

Slow Blink (1x per second) Calibration error or permanent write/read error

Medium Blink (2x per second) Cleaning in progress

On Cleaning required: 250 tape motion hours

exceeded since last cleaning

Slow Blink (1x per second) Unsupported format, or damaged or unsupported

cartridge type inserted into drive

On DLT1 (VS80) format DLTtape™ IV cartridge

loaded

Table 3: Fault/Clean/Media LED Activity and Drive Status

See Chapter 4, Troubleshooting, for more details on error

conditions.

3.2.2 Unload/Eject Button Features

The Unload/Eject button provides features in addition to

unloading and ejecting a cartridge. To activate one of these

features, press and hold the Unload/Eject button for the

amount of time specified in Table 4. Release the Unload/Eject

button when the desired LED sequence is displayed.

If you do nothing for 15 seconds after accessing any of the

additional features that require an action, such as loading a

cartridge, the drive returns to normal operating mode.

Note: The Unload/Eject button features indicated by an

asterisk (*) in Table 4 overwrite all data on the cartridge loaded

in the drive. Use extreme caution when accessing these

features to avoid loss of important data.

3-4 Tandberg DLT VS160 Installation and Operations Manual

Page 31

Tandberg Data Using Your Tandberg DLT VS160 Drive

LED Status

Ready Fault Clean Media

On N/A N/A N/A 0-6 Normal unload/eject function

Blinking Off Off Off 6-9 Reserved

Blinking Blinking Off Off 9-12 Enter code update mode

Blinking Blinking Blinking Off 12-15 Reserved

Blinking Blinking Blinking Blinking 15-18 Reserved

On Off Off Off 18-21 Revert to normal operating mode

On On Off Off 21-24 Write/read diagnostic mode*

On On On Off 24-27 Reserved*

On On On On 27-30 Emergency reset

Off Off Off Off 30+ Revert to normal operating mode

Button

Hold Time

(seconds)

Feature Description

Table 4. Unload/Eject button features

3.2.2.1 Unload/Eject Button Feature Description

Normal Unload/Eject

When you release the button, the drive unloads and ejects the

cartridge.

Enter Code Update Mode

When you release the button, the drive is ready to accept a code

update cartridge. Insert a code update cartridge within 15

seconds to initiate an automatic code update. If you do not load

a code update cartridge within 15 seconds, the drive returns to

normal operating mode.

Write/Read Diagnostic Mode

Note: This mode overwrites all data on the cartridge in the

drive. Use extreme caution when using this feature to avoid

loss of important data.

When you release the button, the drive initiates an internal

write/read diagnostic. The diagnostic requires that you first

load a cartridge that is blank or does not contain valuable data.

When the diagnostic begins, the drive writes and then reads

approximately 400MB of data and then unloads and ejects the

cartridge. The process takes about two minutes. If the

diagnostic test detects no errors, the drive returns to normal

operating mode. If an error occurs, the appropriate LEDs

illuminate.

Tandberg DLT VS160 Installation and Operations Manual 3-5

Page 32

Tandberg Data Using Your Tandberg DLT VS160 Drive

Emergency Reset

When you release the button, the drive performs a hard reset,

behaving as if it had been turned off and then on. A standard

POST then takes place.

Revert to Normal Operating Mode

When you release the button, the drive returns to normal

operation.

3.3 Using Cartridges

Your Tandberg DLT VS160 Drive reads and writes Tandberg

DLTtape VS1 Media cartridges (Tandberg Data part

number 432637). Your DLT VS160 Drive can read – but not

write – DLTtape™IV cartridges previously written using the

DLT1/VS80 format.

Note: Your Tandberg DLT VS160 Drive automatically ejects

any other cartridge types and any cartridges whose format it

cannot read. Make sure all cartridges that you want to use for

writing are Tandberg DLTtape VS1 Media cartridges part

number 432637.

3.3.1 Loading a Cartridge

Loading a cartridge into your DLT VS160 Drive is fast and

easy. After the drive completes POST, insert the DLTtape VS1

Media cartridge into the cartridge slot, oriented as shown in

Figure 3-2, and push the cartridge gently into the drive until it

stops.

Figure 3-2: Loading a Tandberg DLTtape VS1 Cartridge

The Ready LED blinks while the drive loads the cartridge.

When the cartridge is ready to use, the Ready LED is steadily

illuminated. If the cartridge is a DLTtape™IV written using

3-6 Tandberg DLT VS160 Installation and Operations Manual

Page 33

Tandberg Data Using Your Tandberg DLT VS160 Drive

the DLT1/VS80 format, the Media LED is also steadily

illuminated

3.3.2 Unloading a Cartridge

Caution: Remove the cartridge from your DLT VS160 Drive

before turning off the tabletop drive or the host server or

workstation for an internal drive. Leaving a cartridge in the

drive when power is off can result in cartridge and drive

damage and may cause data loss because the

header/catalog data may not be properly written before

the drive loses power. When you remove the cartridge from

the drive, return the cartridge to its storage case to prolong

cartridge life.

To unload a cartridge from your DLT VS160 Drive, follow these

steps:

1. Press the Unload/Eject button or use your backup software

to unload the cartridge. The Ready LED blinks while the

drive rewinds the tape.

2. When the drive has rewound the tape, it unloads the

cartridge.

Figure 3-3: Unloading a Tandberg DLTtape VS1 Cartridge

3. Remove the cartridge from the drive.

4. Return the cartridge to its storage case to prolong cartridge

life.

Tandberg DLT VS160 Installation and Operations Manual 3-7

Page 34

Tandberg Data Using Your Tandberg DLT VS160 Drive

3.3.3 Cartridge Write-Protect Switch

All tape cartridges have a write-protect switch to prevent

accidental erasure of data. Before loading a tape cartridge into

your DLT VS160 Drive, make sure the write-protect switch on

the front of the cartridge is positioned as desired.

Indicator

Write-Protect

Switch

Write

Protected

Write Enabled

Figure 3-4: DLTtape VS1 Write-Protect Switch

Slide the switch to the right to write-protect the cartridge.

The "locked" icon appears on the switch indicating that the

cartridge is write-protected.

Slide the switch to the left to allow your DLT VS160 Drive to

write data to the cartridge. The "unlocked" icon appears on the

switch. The indicator on the top of the cartridge also points to

the appropriate icon, indicating the write-protect status of the

cartridge.

3.3.4 Caring for your Cartridges

To ensure the longest possible life for all of your Tandberg

DLTtape VS1 Media cartridges, follow these guidelines:

Do not drop or strike a cartridge. Excessive shock can

•

displace the tape leader, making the cartridge unusable and

possibly damaging your DLT VS160 Drive.

Store your tape cartridges in their storage cases.

•

3-8 Tandberg DLT VS160 Installation and Operations Manual

Page 35

Tandberg Data Using Your Tandberg DLT VS160 Drive

Do not expose your tape cartridges to direct sunlight or

•

sources of heat, including portable heaters and heating

ducts.

The operating temperature range for your tape cartridges is

•

50° F to 104° F (10° C to 40° C). The storage temperature

range is 60° F to 90°F (16° C to 32° C).

If a tape cartridge has been exposed to temperatures

•

outside the ranges specified above, stabilize the cartridge at

room temperature for the same amount of time it was

exposed to extreme temperatures, up to 24 hours.

Store your tape cartridges in a dust-free environment in

•

which relative humidity is always between 20% and 80%

(noncondensing). The ideal storage relative humidity is

40%, ± 20%.

Do not place tape cartridges near sources of electromagnetic

•

energy or strong magnetic fields, such as computer

monitors, electric motors, speakers, or X-ray equipment.

Exposure to electromagnetic energy or magnetic fields can

destroy data on cartridges.

Place identification labels only in the slide-in slot on the

•

front of the cartridge.

Never use any type of adhesive labels on tape cartridges.

•

3.3.5 Using the Cleaning Cartridge

(Tandberg Data Part Number 432246)

When the Clean LED is on, your DLT VS160 Drive's read/write

head needs to be cleaned. See Chapter 4, Troubleshooting for

other conditions that may indicate drive cleaning is necessary.

Follow the instructions on page 3-6 to load the cleaning

cartridge. Cleaning typically takes several minutes, during

which the Clean LED blinks.

Caution: Use only approved cleaning cartridges(part

number 432246) in your DLT VS160 Drive. Use of any

other type of cleaning cartridge can damage the read/write

head in your drive. If you attempt to load any other type of

cleaning cartridge, your DLT VS160 Drive prevents damage by

ejecting the cartridge after approximately 25 seconds without

allowing the cleaning tape to come into contact with the

read/write head.

Tandberg DLT VS160 Installation and Operations Manual 3-9

Page 36

Tandberg Data Using Your Tandberg DLT VS160 Drive

Figure 3-5: DLT VS Cleaning Cartridge

Each cleaning cartridge has a useful life of 20 cleanings. The

cleaning cartridge includes a label with 20 small boxes printed

on it. Always place a check mark in a box each time you use the

cartridge to clean the drive. Replace the cleaning cartridge

when all boxes are checked.

When the cleaning cartridge has cleaned the read/write head,

the Clean LED turns off and the drive ejects the cleaning

cartridge.

Note: If any LEDs blink or if the Clean LED is illuminated

again when you insert another cartridge immediately after

cleaning, see Table 3 on page 3-4 for more information.

3-10 Tandberg DLT VS160 Installation and Operations Manual

Page 37

4 Troubleshooting

This chapter provides troubleshooting information for your

DLT VS160 Drive.

4.1 Obtaining Drivers and

Firmware Upgrades

If the tape backup software does not detect the tape drive or to

obtain the latest operating system drivers and/or firmware

upgrades, see the Tandberg support website at:

www.tandberg.com

4.2 Troubleshooting the Drive

This section provides troubleshooting information for specific

drive conditions.

4.2.1 Power-On Self-Test (POST) and Drive

Connectivity Failure

Every time you turn on or reset the drive, it conducts a PowerOn Self-Test (POST). This test ensures that the drive is

working properly and is ready to use. While POST is in

progress, watch the front panel LEDs to see the progress and

results of the test. See Chapter 3 for details on normal LED

activity during POST.

A successful POST always finishes with a solid Ready LED.

POST takes approximately eight seconds with no tape loaded

and up to several minutes with a tape loaded, depending on the

position of the media in the tape path. When a tape is loaded,

other expected LED indications may exist. See Chapter 3 for

details. Any unexpected LED indications during POST may

indicate a failure. Use the information in Table 5 and Table 6 to

troubleshoot the drive. If the condition persists, contact

Tandberg Technical Support.

Page 38

Tandberg Data

Symptom Problem Solution

None of the drive’s

LEDs illuminate.

Media LED: Slow blink Unsupported format,

Media LED:

Illuminated

Clean LED: Slow blink Calibration error or

The drive is not

receiving power.

unsupported cartridge

type, or damaged

cartridge.

A DLT1 (VS80) format

DLTtape™ IV

cartridge is loaded.

permanent write/read

error.

Check the drive’s power cable. If a tabletop

drive, check the power cable connections.

Plug the power cable into a different power

outlet.

Loading an unsupported cartridge, such as

a DLTtape™III, an SDLT cartridge, or an

incompatible cleaning cartridge, damaged

media, a DLTtape™ IV cartridge that is

either blank or was written using an

unsupported format such as DLT4000,

DLT7000 or DLT8000, or an unsuccessful

buckle operation causes this condition. The

drive ejects the cartridge. Inspect cartridge

and confirm format, type, and integrity. If

repeatable with a known-good cartridge,

replace drive or call Tandberg Technical

Support.

Your DLT VS160 Drive can read, but not

write, this cartridge. If attempting to read, no

action is required. Because this cartridge

cannot be written, if you attempt a write

operation, your backup application should

return a "Write Protected" message.

The drive cannot read the calibration tracks

on the tape or has encountered a

permanent write or read error. If the failure

is the result of a calibration error, the drive

ejects the cartridge. If the failure is the

result of a permanent read/write error, the

drive does not eject the cartridge. Try a

known-good cartridge. If condition persists

with a particular cartridge, discard or

degauss that cartridge. If repeatable with a

known-good cartridge, try cleaning the

drive. If cleaning does not help, replace the

drive or contact Tandberg Technical

Support.

Clean LED:

Illuminated

Fault LED: Slow blink User initiated

Cleaning required. 250

tape motion hours

exceeded since last

cleaning.

write/read diagnostic

failed.

4-2 Tandberg DLT VS160 Installation and Operations Manual

Drive continues to function, although

increased soft error rates may be

encountered. Clean the drive at your

earliest convenience. LED indication

remains until drive is cleaned.

Eject tape, power cycle or reset drive. Try

diagnostic again with a different, knowngood tape.

Note: This feature overwrites any data

currently on the cartridge. Confirm that the

Page 39

Tandberg Data

Symptom Problem Solution

selected cartridge does not contain

important data.

If this condition persists with a known-good

cartridge, contact Tandberg Technical

Support.

Fault LED: Fast blink Servo or mechanical

error.

Fault LED: Illuminated Internal firmware error. Power cycle or reset the drive. Try the

Other LED Indications Unspecified. If you encounter any LED indications that

Power cycle or reset the drive. Try the

operation again with a known-good

cartridge. If condition persists, contact

Tandberg Technical Support.

operation again with a known-good

cartridge. If condition persists, contact

Tandberg Technical Support.

are not covered in this manual, contact

Tandberg Technical Support.

Table 5: Troubleshooting Errors Indicated by Front Panel LEDs

Table 6 helps you troubleshoot other drive and connectivity

problems.

Symptom Problem Solution

The host server or

workstation does not

recognize your DLT

VS160 Drive.

The drive’s SCSI ID

might not be unique.

Regardless of the number of SCSI devices

attached to the server or workstation that is

to be the host for your DLT VS160 Drive,

each must have a unique SCSI ID. Check

the SCSI IDs on all other SCSI devices on

the selected server, including the SCSI host

adapter, and select an unused SCSI ID for

your DLT VS160 Drive.

Note: If you attach the drive to a narrow

(50-pin) bus, you can only use SCSI IDs 0

through 7.

The SCSI host

adapter might be

incorrectly configured.

The SCSI cable might

be loose.

Tandberg DLT VS160 Installation and Operations Manual 4-3

Check the SCSI host adapter configuration.

Refer to the SCSI host adapter manuals for

instructions.

Check both ends of the SCSI cable, both for

the external and internal drives.

Page 40

Tandberg Data

Symptom Problem Solution

The SCSI terminator

might be loose or

missing.

The SCSI bus might

be improperly

terminated.

1. Make sure an active Low-Voltage

Differential/Single-Ended (LVD/SE)

terminator is properly seated on the

open SCSI connector on the rear panel

of the external drive or on the last

device on the SCSI bus.

2. Make sure an active LVD/SE terminator

is in place on the SCSI ribbon cable for

the internal drive.

1. If your DLT VS160 Drive is the last or

only device on the SCSI bus, make sure

the drive is properly terminated.

2. If your DLT VS160 Drive is not the last

or only device on the SCSI bus, check

all SCSI cable connections and make

sure the last device on the SCSI bus is

terminated.

3. Make sure termination is set properly on

the SCSI host adapter.

4. If you attach the drive to a narrow (50pin) SCSI bus, you must use a

customer-supplied 68-pin to 50-pin

adapter that terminates the unused 18

pins. These adapters are sometimes

labeled "high-byte termination."

The SCSI terminator

might not be at the

end of the SCSI bus or

more than two

terminators might be

present on the SCSI

bus.

The SCSI host

adapter might be in a

defective expansion

slot.

5. Regardless of which device is used to

terminate the SCSI bus, it must have

power applied and be turned on for

proper termination to occur.

Make sure the terminators are placed only

at each end of the SCSI bus — normally

one at the host adapter and one on the last

device on the bus. However, if both internal

and external devices are attached to the

same SCSI host adapter, the adapter may

be positioned in the middle of the SCSI bus

and should not be terminated. In that case,

the SCSI devices on each end of the bus

must be terminated.

Move the SCSI host adapter to a different

expansion slot.

4-4 Tandberg DLT VS160 Installation and Operations Manual

Page 41

Tandberg Data

Symptom Problem Solution

There are fatal or

nonfatal errors for

which you cannot find

the cause.

The SCSI bus might

be too long.

The SCSI bus might

be improperly

terminated.

Make sure the total length of the SCSI bus

does not exceed the ANSI SCSI standard of

19 feet (6 meters) for a Single-Ended (SE)

bus, 40 feet (12 meters) for a Low-Voltage

Differential (LVD) SCSI bus with multiple

devices, or 82 feet (25 meters) for an LVD

SCSI bus with a single device. If you attach

the drive to an SE bus or if there are any SE

devices attached to the bus, the bus is

limited to the maximum cable lengths of an

SE bus.

1. If your DLT VS160 Drive is the last or

only device on the SCSI bus, make sure

the drive is properly terminated. Make

sure only the last device is terminated.

2. If your DLT VS160 Drive is not the last

or only device on the SCSI bus, check

all SCSI cable connections and make

sure the last device on the SCSI bus is

terminated.

3. Make sure termination is set properly on

the SCSI host adapter.

4. If you attach the drive to a narrow (50pin) SCSI bus, you must use a

customer-supplied 68-pin to 50-pin

adapter that terminates the unused 18

pins. These adapters are sometimes

labeled "high-byte termination."

The backup

application does not

recognize the drive.

5. Regardless of which device is used to

terminate the SCSI bus, it must have

power applied and be turned on for

proper termination to occur.

The AC power source

may not be properly

grounded (DLT VS160

External Drive only).

Application not

compatible or

improper device

drivers installed.

Tandberg DLT VS160 Installation and Operations Manual 4-5

1. Plug your DLT VS160 External Drive's

power cable into a power outlet on the

same circuit as the host server.

2. Plug your DLT VS160 External Drive’s

power cable into a different power

outlet.

If the operating system recognizes the

drive, but not the backup application,

confirm that you are using a compatible

backup application. Also confirm that you

have the proper device drivers, if

necessary, installed. See the Tandberg

support website at www.tandberg.com to

obtain the latest operating system drivers

and/or firmware upgrades.

Page 42

Tandberg Data

Symptom Problem Solution

The drive cannot write

data to or read data

from a cartridge.

Cartridge or drive

problem.

1. Make sure that the cartridge is writeenabled. Move the write-protect switch

to the write-enabled position.

2. If you are attempting to write data,

make sure you are using a DLTtape

VS1 Media cartridge.

3. Make sure that the cartridge has not

been exposed to harsh environmental

or electrical conditions and is not

physically damaged in any way.

4. Many backup applications do not read

or write to cartridges that were created

using a different backup application. In

this case, you may have to perform an

erase, format, or label operation on the

cartridge using your backup application.

5. Make sure you understand any data

protection or overwrite protection

schemes that your backup application

may be using, any of which could

prevent you from writing to a given

cartridge.

6. Retry the operation with a different,

known-good cartridge.

7. Clean the tape drive.

4-6 Tandberg DLT VS160 Installation and Operations Manual

Page 43

Tandberg Data

Symptom Problem Solution

The drive is not

backing up data

efficiently.

Network, cartridge,

SCSI bus, backup

data set, or backup

application problem.

1. Check the network bandwidth from the

host server. If you are backing up data

over a network, compare to a local-only

backup for relative backup speed

indication.

2. Make sure that the drive is on its own

SCSI bus and not daisy-chained to

another tape drive or to the hard drive

being backed up.

3. Clean the tape drive.

4. Try a new cartridge. A marginal

cartridge can cause performance

problems due to bad spots on the tape

requiring retries.

5. Make sure that the data is being

compressed. See your backup

application user documentation for

details.

6. Check the size of the files in the backup

set. Small file size can impact

performance.

7. Confirm that the backup application is

using block sizes of at least 32KB, and

preferably 64KB. See your backup

application user documentation for

details.

Tandberg DLT VS160 Installation and Operations Manual 4-7

Page 44

Tandberg Data

Symptom Problem Solution

The drive does not

eject a cartridge.

Timing or drive

problem.

Allow sufficient time for the drive to

complete any operations, such as POST,

reset, load, unload, rewind, etc. Worst case

is when powering up or resetting the drive

with the tape positioned at the physical end

of the media. Recovery from this state could

take several minutes.

Allow sufficient time for the backup

application to release any hold it may have

on the drive. Worst case could be several

minutes. Confirm that the backup

application is not set to prevent media

removal.

Try a software eject, using your backup

application, allowing sufficient time for the

command to execute.

If the drive still does not eject the cartridge,

power down the drive and remove all

connectors except power from the rear of

the tape drive. Apply power to the drive and

allow it to complete POST. Press the

Unload/Eject button, allowing sufficient time

for the command to execute.

See If the Drive Becomes Unresponsive for

instructions on performing an emergency

reset to eject the cartridge.

The drive repeatedly

rejects a cartridge.

Cartridge or drive

problem.

Table 6: Drive and Connectivity Troubleshooting

If the drive still does not eject the cartridge,

contact Tandberg Technical Support.

The DLT VS160 Tape Drive rejects any

unsupported cartridge, such as a

DLTtape™ III, an SDLT cartridge, an

incompatible cleaning cartridge, damaged

media, a DLTtape™ IV cartridge that is

either blank or was written using an

unsupported format such as DLT4000,

DLT7000 or DLT8000, as well as any

cartridge that causes an unsuccessful

buckle operation. Inspect the cartridge and

confirm format, type, and integrity. If

repeatable with a known-good cartridge, try

cleaning the drive. If cleaning does not help,

replace the drive or contact Tandberg

Technical Support.

4-8 Tandberg DLT VS160 Installation and Operations Manual

Page 45

Tandberg Data

4.2.2 If the Drive Becomes Unresponsive

On rare occasions, the drive may become unresponsive. If this

should happen, use this procedure to reset the drive and unload

the cartridge:

1. Press and hold the Unload/Eject button for approximately

27 seconds until all four LEDs are steadily illuminated (not

blinking).

2. Release the Unload/Eject button while all four LEDs are

steadily illuminated. The drive initiates a device reset, then

performs a POST.

3. Upon completion of POST, press and release the

Unload/Eject button as soon as the Ready LED begins to

blink and/or you hear tape motion. The drive attempts to

eject the cartridge as soon as the device reset is complete

and the drive completes a mid-tape load. This may take

several minutes, depending on the where the media is

positioned in the tape path

4. If you do not press the Unload/Eject button again as

indicated in Step 3, the cartridge in the drive is ready to use

after the drive resets and loads the cartridge.

4.2.3 Drive Makes Noises During System Startup

During system startup, the computer accesses the tape drive

and retensions any tape cartridge in the drive to prepare the

drive for operation. The noise and vibration associated with this

activity are normal for this technology and do not indicate a

problem with the drive.

4.2.4 Drive Failures During Backup or Restore Operations

If you experience drive failures during backup or restore

operations, check each of the following conditions:

Make sure you are using the correct type of tape cartridge.

•

Make sure tape cartridge is not write-protected.

•

Remove and reinsert the tape cartridge.

•

Try a different tape cartridge, preferably a new one.

•

Clean the tape drive read/write head.

•

Verify drive settings in the system setup program.

•

Tandberg DLT VS160 Installation and Operations Manual 4-9

Page 46

Tandberg Data

Check all cable connections

•

4.2.5 Tape-Backup Software Errors

If your tape backup software experiences errors, check each of

the following conditions:

DMA conflicts during backup or compare operations.

•

Media unreadable.

•

See the User's Operating Guide supplied with your tape

•

backup software application for more information.

4-10 Tandberg DLT VS160 Installation and Operations Manual

Loading...

Loading...