Page 1

TSW-210

POWER SWEEPER ATTACHMENT

OWNER’S MANUAL

FOR USE ON TANAKA STRAIGHT SHAFT GRASS TRIMMERS

Page 2

OWNER’S MANUAL

TABLE OF CONTENTS

Foreword . . . . . . . . . . . . . . . . . . . . . . .2 Assembly Instructions . . . . . . . . . . . . .4-5

Safety Symbols . . . . . . . . . . . . . . . . . . .2 Operating Instructions . . . . . . . . . . . . . .6

Product Description . . . . . . . . . . . . . . . .2 Maintenance . . . . . . . . . . . . . . . . . . . . .7

Safety Instructions . . . . . . . . . . . . . . .3-4

FOREWORD

This Owner’s/Operator’s Manual is designed to familiarize the operator with the various features and

component parts of the equipment and to assist with the assembly, operation and maintenance of the

product.

It is essential that any operator of this product reads and understands the contents of this manual

before using the product.

Important safety instructions will be identified by the following safety symbol:

Failure to comply with the instructions in this manual may result in serious injury or death.

For additional assistance, contact any local authorized Tanaka dealer or contact Tanaka USA at 1-888-482-

6252.

MANUAL SAFETY SYMBOLS

Throughout this manual and on the product itself, you will find safety alerts and helpful information

messages preceded by symbols or key words. The following is an explanation of those symbols and key

words and what they mean to you.

This symbol accompanied by the words WARNING and DANGER calls attention to an act or

condition that can lead to serious personal injury to the operator or bystanders.

11

1

11

22

2

22

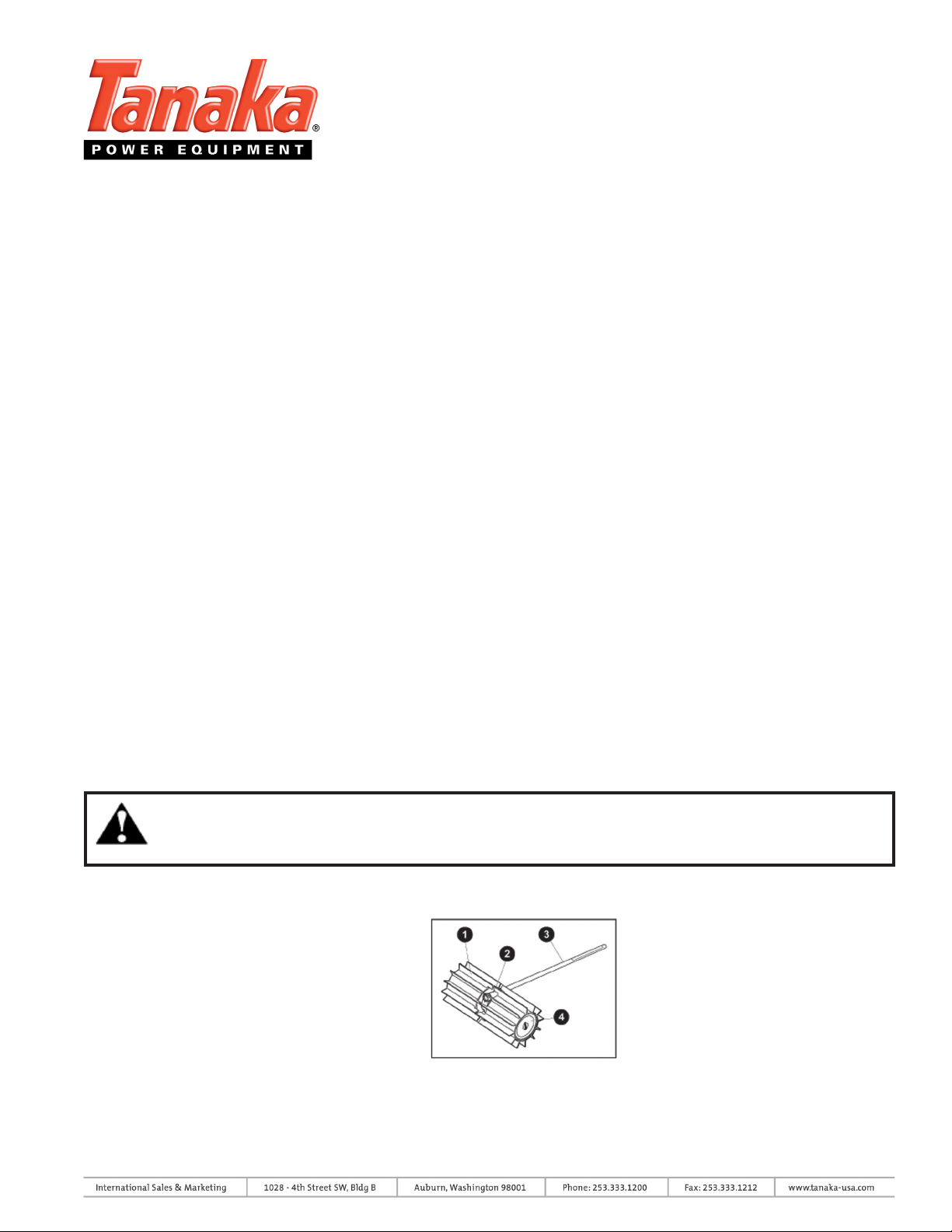

PRODUCT DESCRIPTION

1. Sweeper Belt

2. Gearcase

3. Outer Tube (Shown for reference only)

4. Sweeper Drum

- 2 -

44

4

44

Page 3

SAFETY INSTRUCTIONS

PRODUCT SAFETY

1. Read and understand this Owner’s/Operator’s Manual

before using this product. Be thoroughly familiar with the

proper use of this equipment.

2. Make sure the product is correctly assembled and

installed prior to use.

3. Never allow children to operate the product. Never

allow adults to operate the unit without first reading the

Owner’s/Operator’s Manual.

4. Never operate this product without proper guards or

other protective safety devices in place.

OWNER’S MANUAL

5. Before each use, inspect the product. Replace damaged parts. Make sure all fasteners are in place and

tightened securely.

6. If running problems or excessive vibration occur, stop immediately and inspect the unit for the cause. If

the cause cannot be determined, or is beyond your ability to correct, return the product to your servicing

dealer for repair.

7. Do not use this product for any job except that for which it is intended.

OPERATOR SAFETY

1. Never operate this product when you are tired, ill, or while under the influence of alcohol, drugs or

medication.

2. Always wear eye protection that complies with ANSI (American National Standards Institute) Z87-1.

3. Wear hearing protection.

4. Always wear heavy, long pants, boots and gloves. Do not wear loose clothing, jewelry, short pants,

sandals or go barefoot. Secure hair so it is above shoulder length.

5. To reduce risk of injury associated with inhalation of dust wear a face filter mask in dusty conditions.

6. Always operate with both hands firmly gripping the product.

7. Keep clear of the rotating belts and paddles at all times.

8. Never raise a moving attachment above waist level.

9. Do not put hands or feet near or under rotating parts. Keep clear at all times.

10. To reduce risk of injury associated with contact with a rotating part, stop engine before installing or

removing attachments.

- 3 -

Page 4

OWNER’S MANUAL

SAFETY INSTRUCTIONS

AWARENESS OF WORK ENVIRONMENT

1. Inspect your work area before you begin. Remove objects such as broken glass, nails, wire and rocks

which can become dangerous projectiles if thrown. Remove string, rope or similar materials which can

become entangled in the rotating drum.

2. Maintain a firm footing and balance while operating the product. Do not overreach.

3. Keep children, bystanders and animals outside a 50ft. (15m) radius surrounding the area of operation.

4. Use the product only in daylight or adequate artificial lighting.

5. Avoid prolonged operation in very hot or very cold conditions.

6. If contact is made with a hard object, stop the engine and inspect the sweepers and drums for damage.

ASSEMBLY INSTRUCTIONS

- 4 -

33

3

33

Page 5

OWNER’S MANUAL

INSTALLING THE GEARBOX SWEEPING ATTACHMENT

1. Make sure all the components are included in the box. The box should contain:

a. Gearbox (1)

b. Drum Assemblies (2)

c. Drum Axle (2)

d. Clevis Pin (2)

e. Hitch Pin (2)

f. Cotter Pin (2)

g. Shaft Protector (2)

h. Gearcase Spacer (1)

2. Slide the rubber sleeve drive shaft protector onto the drive shaft pipe housing. This sleeve will protect the

drive shaft pipe from repeated contact with the rubber paddles. The protector can be slid up the drive shaft pipe

housing during installation, but should be slid down to rest on top of the gear case before use.

3. Insert the end of the drive shaft housing into the gearcase and push it until it bottoms. The drive shaft tube

should go into the gearcase about 1 - 1.5 inches. If the drive shaft housing stops before bottoming, rotate it

until you feel the inner drive shaft splines engage the gearcase. Then push the drive shaft all of the way in.

4. All Tanaka trimmers use a locator screw to properly position the gear case, (in addition to the pinch bolt which

tightens the gear case to the shaft). Some trimmer models do not have the locator screw and hole in the correct

place for mounting the sweeper gear case. In this instance, an additional hole will need to be drilled. Insert the

shaft pipe all the way into the sweeper gear case, and mark the center of the locator bolt hole. Remove the drive

shaft pipe, and use the existing gear case hole to ensure you have the new hole properly centered (to ensure the

gear case is straight). Using a 6mm (3/8”) drill bit, drill the new locator hole in the drive shaft pipe.

5. Use a 4mm hex (Allen) wrench to tighten the gearcase positioning screw first, then the gearcase clamp screw.

6. Push one of the drum axles onto either of the two gearcase output shafts. If necessary, rotate the drum axle

until the clevis pin hole in the axle aligns with the matching hole in the gearcase output shafts.

7. Use a clevis pin and hitch pin to secure the drum axle to the shaft.

8. Slide the recessed end of a sweeper drum assembly over the installed axle, and then push the drum down the

axle until the cotter pin hole in the axle extends above the drum surface.

Important Note: The two drum assemblies are identical, but each drum must be

installed with the recessed end facing toward the gearcase.

9. Use a cotter pin to secure the drum assembly on the axle. The cotter pin is designed to fit tightly against the

outboard end of the drum, so you may need to compress the drum face slightly during installation. Spread the

ends of the cotter pin to secure.

10. Repeat steps 7 - 10 to install the remaining axle and drum assembly.

- 5 -

Page 6

OWNER’S MANUAL

OPERATING INSTRUCTIONS

BREAK-IN

The Power Sweeper operates best when the fins quickly slide or skim the surface being swept. New or

replacement sweeper belts will tend to grip or drag on hard surfaces, and should be fully broken in prior to

actual operation. Break in is accomplished by operating the product at full throttle for 3 - 5 minutes in

loose gravel or similar abrasive material.

Important Note: It is tiring and unnecessary to lift or hold the fins from the work surface

during operation.

Warning: Burn Danger. The gearcase will become very hot during normal operation.

OPERATING TECHNIQUES

Operate the product at or near full throttle with the sweeper fins

resting on the work surface.

CLEARING NARROW AREAS

When sweeping narrow areas such as sidewalks, the Power Sweeper can

be used to throw material

directly ahead of the operator.

CLEARING WIDER AREAS

Clearing wider areas may require sweeping at an angle to create

windrows to one side of the path being cleared. Windrows of lighter

materials can be combined into one main row or pile for eventual pick

up, while heavy or bulky material may need to be collected row by row.

CLEARING CORNERS

To pull debris from corners, reverse the sweeper drum rotation by

turning the powerhead over (throttle facing up).

Warning: Use lower throttle settings when reversing the

Sweeper to sweep corners as debris will be thrown

toward the operator in this position. Also be aware that

thrown debris may affect footing.

-6 -

Page 7

OWNER’S MANUAL

MAINTENANCE - 300 HOURS

GEARCASE LUBRICATION

The gearcase should be filled with 60cc (2.0 fl.oz.) of Mobil SHC634 Synthetic Gear Oil. A maximum of 75 80cc can be used, but never exceed 80cc. Operation with excessive oil level will result in high operating

temperatures. Do not overfill.

REPLACING THE GEARCASE OIL

Warning: Burn Danger. The gearcase will be extremely hot after use.

1. Disconnect the spark plug wire at the engine.

2. Remove the left hand drum and axle assembly (as viewed from the operating position). Wipe the

sideplate clean and remove four screws (it is not necessary to remove the gearcase from the outer tube).

3. Turn gearcase side plate to break the seal and lift the plate from the

gearcase.

Note: It may be necessary to use a heat gun to softenthe sealer

material.

4. Turn the gearcase to the left hand side and allow all used gearcase

oil to drain into a small container.

5. Place the gearcase on the right hand side and support so the outer

tube is parallel to the ground. Refill the gearcase with 60cc (2.0 fl.oz.)

of Mobil SHC634 Synthetic Gear Oil to the bottom of the chamfer on

the output gear. The correct oil depth is 5/8 inch (15.5mm). Do not

over fill.

6. Inspect the sideplate for damage and clean off all remaining liquid

gasket material with brake cleaner or acetone. Coat the outer sealing

flange of the sideplate with Loctite Ultragrey silicon sealant or

Threebond No. 1104 Liquid gasket.

7. Replace the cover and install the four sideplate screws. Tighten securely.

8. Reinstall the drum and axle assembly per the Assembly Instructions on page 4. Fill to this

level

- 7 -

Page 8

OWNER’S MANUAL

For more information on this product including a complete illustrated parts list,

go to www.tanaka-usa.com

Loading...

Loading...