Page 1

Owner’Owner’

Owner’

Owner’Owner’

s Mans Man

s Man

s Mans Man

ualual

ual

ualual

Model Numbers:

THB-2500,THB-2510,THB-2500,THB-2510,

THB-2500,THB-2510,

THB-2500,THB-2510,THB-2500,THB-2510,

TBL-4600,TBL-4610,TBL-505TBL-4600,TBL-4610,TBL-505

TBL-4600,TBL-4610,TBL-505

TBL-4600,TBL-4610,TBL-505TBL-4600,TBL-4610,TBL-505

BLBL

OO

BL

BLBL

WERSWERS

O

WERS

OO

WERSWERS

P/N 12626

Date 08-10-01

TBL-4600

THB-2510

ISM, Inc. • 1028 4th Street SW • Auburn, WA 98001 • Phone: (253) 333-1200 • Fax: (253) 333-1212

Supplier To The Outdoor Power Equipment Industry

www.tanakapowerequipment.com custsvc@tanaka-ism.com

Page 2

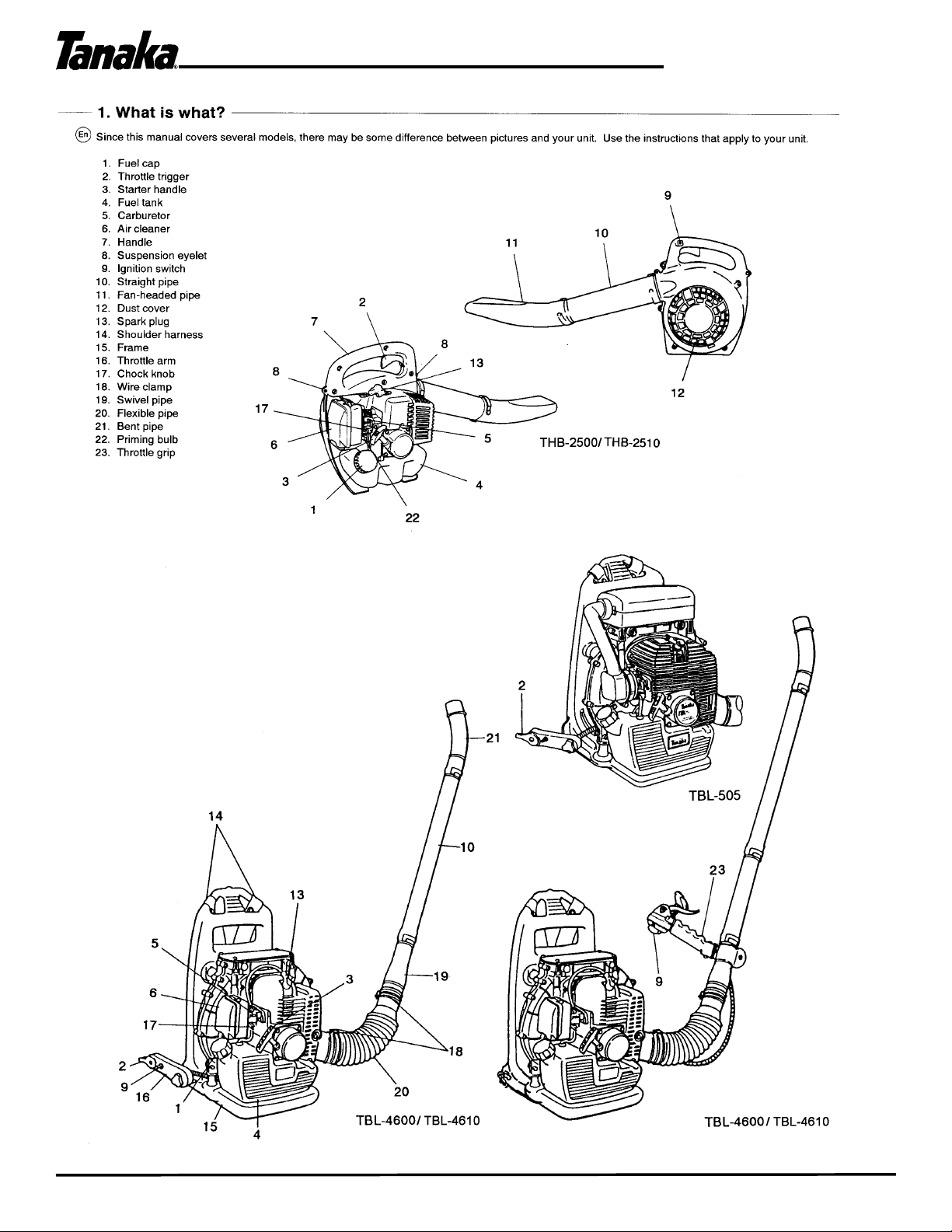

THB-2500/THB-2510/TBL-4600/4610,TBL-505

Owner’s Manual

Before using this unit:

• Read the operator’s manual carefully.

• Check that the blower is correctly assembled

• Start the unit and check the carburetor adjustment.

and adjusted.

See “Maintenance”.

The engine exhaust from this product

contains chemicals known to the State

of California to cause cancer, birth

defects and other reproductive harm.

WARNING

Always wear eye, head and ear protectors

when using this unit.

Read, understand and follow all warnings and

instructions in this manual and on the unit.

It is important that you read, fully understand and observe

the following safety precautions and warnings. Careless or

improper use of the unit may cause serious or fatal injury.

WARNING DANGER

Explains choke position. Upper sign indicates

choke closed and the lower fully open.

www.tanakapowerequipment.com 1 custsvc@tanaka-ism.com

Keep hands off from rotating fan. For vacuum,

vacuum pipe and bag must be in place. For

blower, dust cover must be securely installed.

Page 3

THB-2500/THB-2510/TBL-4600/4610,TBL-505

Owner’s Manual

www.tanakapowerequipment.com 2 custsvc@tanaka-ism.com

Page 4

THB-2500/THB-2510/TBL-4600/4610,TBL-505

2. Warnings and safety instructions.

Operator Safety

• IMPORTANT: A dust filter mask should be worn during

operation.

• Always wear a safety face shield or goggles. Always wear

heavy, long pants, boots and gloves. Do not wear loose

clothing, jewelry, short pants, sandals or go barefoot. Secure

hair so it is above shoulder length.

• Do not operate that tool when you are tired, ill or under the

influence of alcohol, drugs or medication.

• Never let a child or inexperienced person operate the

machine.

• Wear hearing protection.

• Never start or run the engine inside a closed room or

building. Breathing exhaust fumes can kill.

• Keep handles free of oil and fuel.

• Keep hands away from moving part or heated area.

• Do not grab or hold the unit by the blow pipe.

• When the unit is turned off, make sure the engine has

stopped before the unit is set down.

• When operation is prolonged, take a break from time to time

so that you may avoid possible whitefinger disease which is

Tool Safety

Never modify the tool in any way. Do not use the tool for any job

except that for which it is intended.

Fuel Safety

Antivibration systems do not guarantee that you will not sustain

whitefinger disease or carpal tunnel syndrome. Therefore, continual

and regular users should monitor closely the condition of their hands

and fingers. If any of the above symptoms appear, seek medical advice

immediately.

caused by vibration.

• Inspect the entire tool before each use. Replace damaged

parts. Check for fuel leaks and make sure all fasteners are in

place and securely fastened.

• Replace parts that are cracked, chipped or damaged in any

way before using the tool.

• Make sure the safety guard is properly attached.

• Keep others away when making carburetor adjustments.

• Use only accessories as recommended for this tool by the

manufacturer.

WARNING!

• Mix and pour fuel outdoors and where there are no sparks or

flames.

• Use a container approved for fuel.

• Do not smoke or allow smoking near fuel or the tool or while

using the tool.

• Wipe up all fuel spills before starting engine.

• Move at least 3 m (10 ft) away from fueling site before

starting engine.

• Stop engine before removing fuel cap.

• Empty the fuel tank before storing the tool. It is

recommended that the fuel be emptied after each use. If

fuel is left in the tank, store so fuel will not leak.

• Store tool and fuel in area where fuel vapors cannot reach

sparks or open flames from water heaters, electric motors or

switches, furnaces, etc.

WARNING!

Owner’s Manual

Blowing Safety

• Operate power equipment only at reasonable hours-not early

in the morning or late at night when people might be

disturbed. Comply with times listed in local ordinances. Usual

recommendations are 9:00 a.m. to 5:00 p.m., Monday

through Saturday.

• Never direct discharge of air toward bystanders nor allow

anyone near the area of operation. Use care in directing

discharge to avoid glass enclosures, automobiles, etc.

• Stay alert for uneven sidewalks, holes in terrain or other

unstable condition when using the tool.

• Take all possible precautions when leaving the tool

unattended such as stopping the engine.

• Never operate the tool without guards, blow pipes or other

protective device in place. (if so equipped.)

• Keep others including children, animals, bystanders and

helpers outside the 15 m (50ft) hazard zone. Stop the

engine immediately if you are approached.

• Always keep the engine on the right side of your body.

(Hand held blower only)

• Keep firm footing and balance. Do not over-reach.

• Keep all parts of your body away from the muffler.

Maintenance Safety

• Maintain the tool according to recommended procedures.

• Disconnect the spark plug before performing maintenance

except for carburetor adjustments.

• Keep others away when making carburetor adjustments.

• Use only genuine replacement parts as recommended by the

Transport and storage

If situations occur which are not covered in this manual, take care and

have good judgment. Contact your dealer if you need assistance.

Pay special attention to statements preceded by the following words:

Indicates a strong possibility of severe personal injury or loss of life, if

instructions are not followed.

CAUTION!

Indicates a possibility of personal injury or equipment damage, if

instructions are not followed.

NOTE!

Helpful information for correct function and use.

manufacturer.

• Carry the tool by hand with the engine stopped and the

muffler away from your body.

• Allow the engine to cool, empty the fuel tank, and secure the

tool before storing or transporting in a vehicle.

• Empty the fuel tank before storing the tool. It is

recommended that the fuel be emptied after each use.

If fuel is left in the tank, store so fuel will not leak.

• Store tool out of the reach of children.

• Clean the unit carefully and store it in a dry place.

• Make sure engine switch is off when transporting or storing.

WARNING!

www.tanakapowerequipment.com 3 custsvc@tanaka-ism.com

Page 5

Fi

THB-2500/THB-2510/TBL-4600/4610,TBL-505

g. 1

Owner’s Manual

3. Assembly procedures.

Blow pipes to main body (Fig. 1-1)

Inspect the main body and accessories,

Connect straight pipe (1) and other pipe(s)

securely. (See page 1)

Align groove (2) in straight pipe with projection (3) on blower housing (or another pipe) and slide the pipe onto the blower

housing (or another pipe).

Rotate the pipe clockwise to lock it into place, then tighten the clamp band (if so equipped, THB-2510).

NOTE! (TBL-4600, optional)

• Connect flexible pipe (2) to main body with clamp (1).

Finger-tighten the clamp.

• Connect swivel pipe (4) to flexible pipe with clamp (3).

• Install throttle grip (5) to swivel pipe so that the grip locates 2-3 cm away from projection (6) on swivel pipe.

• Finally, if direction of bent pipe does not match the direction of throttle grip, loosen knob (7) or wing bolt (8) (enclosed in

vinyl bag) and swivel the grip to your comfort. (Fig. 1 - 1 B)

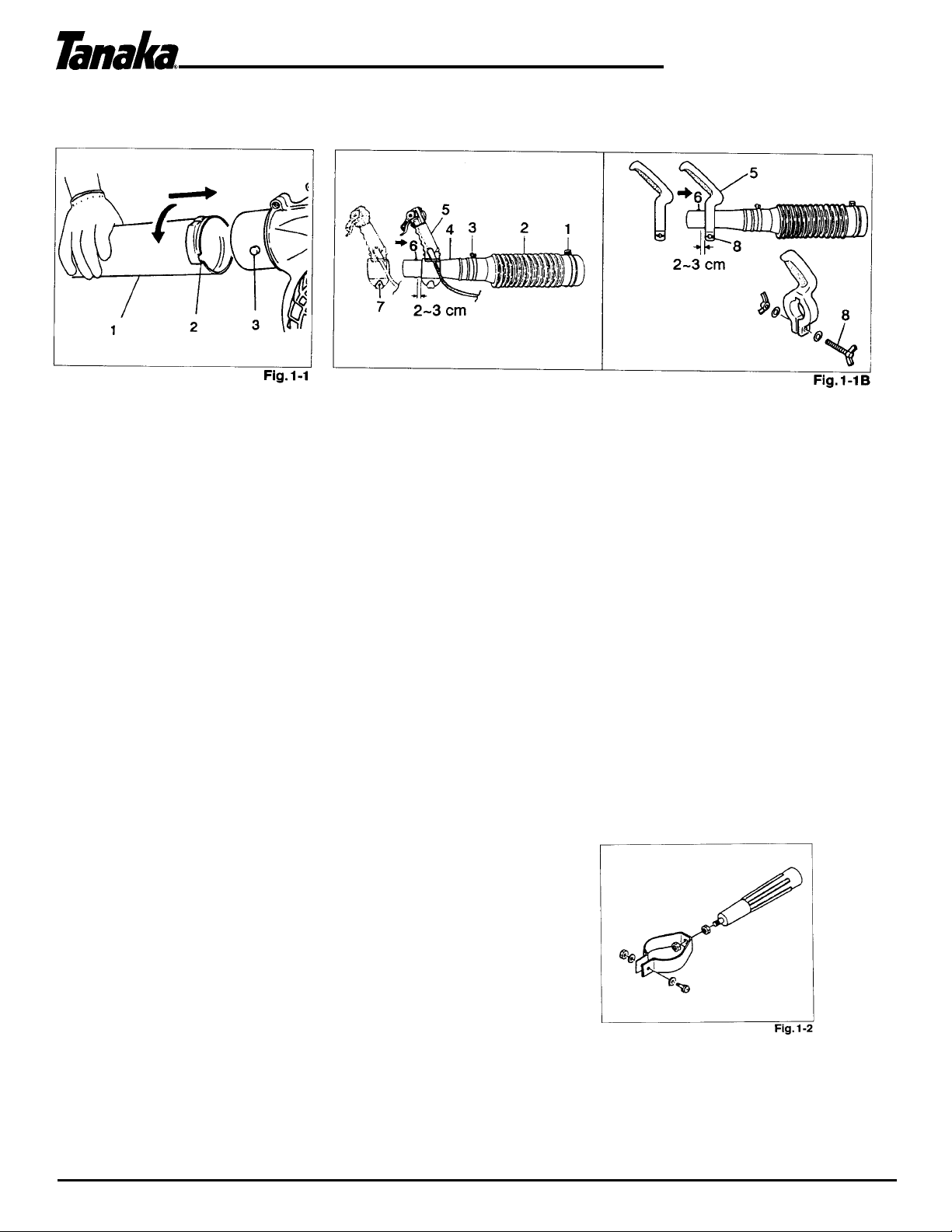

NOTE! (TBL-4600/4610/505, optional)

• Use flexible pipe with wire clamps.

• Install the pipe handle on swivel pipe or on straight pipe. Decide

location and direction to your comfort.

(Fig. 1-2)

NOTE! (THB-2510, optional)

Vacuum attachment is offered as an optional kit, which converts the hand-held blower into a vacuum cleaner. For installation,

see THV-200 vacuum manual.

www.tanakapowerequipment.com 4 custsvc@tanaka-ism.com

Page 6

THB-2500/THB-2510/TBL-4600/4610,TBL-505

Owner’s Manual

4. Operating procedures.

WARNING!

This unit is equipped with a two-stroke engine. Always run the engine on fuel, which is mixed with oil.

Provide good ventilation, when fueling or handling fuel.

Fuel

• Always use branded 89 octane unleaded gasoline.

• Use Tanaka two-cycle oil or a quality two-cycle oil at mixing ratio of 25-50:1 (Gasoline (A) : Oil (B)), only for the state of

California at 50: 1.

• Never use multi-grade oil (10 W/30) or waste oil.

• Always mix fuel and oil in a separate clean container.

Always start by filling half the amount of fuel, which is to be used. Then add the whole amount of oil. Mix (shake) the fuel

mixture.

Add the remaining amount of fuel.

Mix (shake) the fuel-mix thoroughly before filling the fuel tank.

Fueling

WARNING!

* Always shut off the engine before refueling.

*Slowly open the fuel tank, when filling up with fuel, so that possible over-pressure disappears.

Tighten the fuel cap carefully, after fueling.

*Always move the unit at least 3 m (10 ft.) from the fueling area before starting.

Before fueling, clean the tank cap area carefully, to ensure that no dirt falls into the tank.

Make sure that the fuel is well mixed by shaking the container, before fueling.

www.tanakapowerequipment.com 5 custsvc@tanaka-ism.com

Page 7

THB-2500/THB-2510/TBL-4600/4610,TBL-505

Owner’s Manual

Starting

CAUTION!

Do not start if the pipe is obstructed by the ground or any other object.

1 .Set ignition switch (1) to ON position.

(Fig. 2-2, 2B, 2C)

• Push priming bulb (4) several times so that fuel flows through return pipe (5) (if so equipped) (Fig. 2-3, 3B)

• Move throttle lever to a half-open position (2) and lock it with lock lever (4) (if so equipped), when it is hard to

start engine. (Fig. 2-2C)

Note! (TBL-4610)

Model TBL-4610 does not have an ignition switch.

To start or to stop the unit, ignore the switch operation from procedures in the manual. However, when

starting the unit, move throttle lever to START position.

2. Set choke lever to CLOSED position (4). Fig. 2-4, 4B

3. Pull recoil starter briskly, taking care to keep the handle in your grasp

and not allowing it to snap back. (Fig. 2-5, 5B)

4. When you hear the engine want to start, return choke lever to RUN

position (open). Then pull recoil starter briskly again.

NOTE!

If engine does not start, repeat procedures from 2 to 4.

5. After starting engine, allow the engine about 2-3 minutes to warm up

before subjecting it to any load.

www.tanakapowerequipment.com 6 custsvc@tanaka-ism.com

Page 8

THB-2500/THB-2510/TBL-4600/4610,TBL-505

Owner’s Manual

Operating blower (Fig. 2-6, 6B)

Adjust shoulder harness to fit your stature before operating unit. Back-pack unit in a correct way. (Fig. 2-6B)

WARNING!

Do not direct discharge of air toward people or pet.

1. The unit should be operated in a well ventilated area.

2. A low speed should be used to blow leaves and dry grass.

3. A medium speed should be used to clean wet leaves and grass.

4. A high speed should be used when moving gravel, dirt or other heavy materials.

CAUTION!

This blower has been designed and adjusted to be used with all blower pipes attached (See page 1). It must never be

operated without the straight pipe, and blow head.

Stopping (Fig. 2-7, 7B, 7C)

Decrease engine speed, and push ignition switch to stop position.

Note! (TBL-4610)

Model TBL-4610 does not have an ignition switch.

To stop the unit, move throttle lever to START position and run for a few minutes, then move the lever further to STOP

position.

www.tanakapowerequipment.com 7 custsvc@tanaka-ism.com

Page 9

5. Maintenance

THB-2500/THB-2510/TBL-4600/4610,TBL-505

Owner’s Manual

MAINTENANCE, REPLACEMENT, OR REPAIR OF THE EMISSION CONTROL DEVICES AND SYSTEM MAY BE

PERFORMED BY ANY NONROAD ENGINE REPAIR ESTABLISHMENT OR INDIVIDUAL.

Carburetor adjustment (Fig. 3-1, 1 B, IC)

In the carburetor, fuel is mixed with air. When the engine is test run at the factory, the carburetor is basically

adjusted. A further adjustment may be required, according to climate and altitude. The carburetor has one adjustment

possibility:

T = Idle speed adjustment screw.

Idle speed adjustment (T)

To adjust, turn IDLE Adjustment Screw (T) in (clockwise) to increase engine speed, out (counterclockwise) to

decrease engine speed.

Standard Idle rpm is 2500-3000rpm.

CAUTION!

The above adjusting procedure must be followed when adjustment is MADE or DAMAGE to engine will occur because of

the incorrect condition.

RECOMMENDATION:

CARBURETOR ADJUSTMENT NEEDS THE SKILL OF EXPERIENCED OR WELL TRAINED PEOPLE. IT IS RECOMMENDED TO

TAKE THE UNIT TO YOUR NEAREST DEALER.

www.tanakapowerequipment.com 8 custsvc@tanaka-ism.com

Page 10

THB-2500/THB-2510/TBL-4600/4610,TBL-505

Air filter

The air filter must be cleaned from dust and dirt in order to avoid:

• Carburetor malfunctions.

• Starting problems.

• Engine power reduction.

• Unnecessary wear on the engine parts.

• Abnormal fuel consumption.

Remove the air cleaner cover by pushing and pulling back the tab on the top. (Fig. 3-2)

Owner’s Manual

Cleaning the air filter

Clean the cleaner element every day or every 8 hours of operation. More frequent cleaning is recommended under

very dusty conditions. Wash the element in liquid detergent and water. Squeeze the element to remove the dirt. Press

the element in a dry rag until it is completely dry. Saturate the element in 2-cycle oil or the equivalent. Squeeze the

element to distribute the oil completely and to remove any excess oil. Replace the element and install the cover. (Fig.

3-2B, 2C)

Fuel filter (Fig. 3-3, 3B)

Drain all fuel from fuel tank and pull fuel filter line from tank. Pull filter element out of holder assembly and rinse

element in warm water with detergent.

Rinse thoroughly until all traces of detergent are eliminated. Squeeze, do not wring, away excess water and allow

element to air dry.

NOTE!

If element is hard due to excessive dirt buildup, replace it.

www.tanakapowerequipment.com 9 custsvc@tanaka-ism.com

Page 11

THB-2500/THB-2510/TBL-4600/4610,TBL-505

Owner’s Manual

Spark plug (Fig. 3-4)

The spark plug condition is influenced by:

• An incorrect carburetor setting.

• Wrong fuel mixture (too much oil in the gasoline)

• A dirty air filter.

• Hard running conditions (such as cold weather).

These factors cause deposits on the spark plug electrodes, which may result in malfunction and starting difficulties. If

the engine is low on power, difficult to start or runs poorly at idling speed, always check the spark plug first. If the

spark plug is dirty, clean it and check the electrode gap. Readjust if necessary. The correct gap is 0.6 mm (.024”). The

spark plug should be replaced after about 100 operation hours or earlier if the electrodes are badly eroded.

NOTE!

In some areas, local law requires using a resistor spark plug to suppress ignition signals. If this machine was originally

equipped with resistor spark plug, use same type of spark plug for replacement.

Muffler (Fig. 3-5, 5B,5C)

Remove the muffler and clean out any excess carbon from the exhaust port or muffler inlet every 100 hours of

operation.

Cylinder (Engine cooling) (Fig. 3-6, 6B)

The engine is air cooled, and air must circulate freely around engine and over cooling fins on cylinder head to prevent

overheating.

Every 100 Operating hours, or once a year (more often if conditions require), clean fins and external surfaces of engine

of dust, dirt and oil deposits which can contribute to improper cooling.

NOTE!

Do not operate engine with engine shroud or muffler guard removed as this will cause overheating and engine damage.

Spark arrestor

If your unit comes with spark arrestor screen and yet your local regulation requires use of spark arrestor for prevention

against a possible fire, please attach it to the muffler by removing muffler protector and other related parts.

(The spark arrestor meets the regulation of SAE J335-SEP90 and CSA CAN3-Z62. 1 -M77)

www.tanakapowerequipment.com 10 custsvc@tanaka-ism.com

Page 12

THB-2500/THB-2510/TBL-4600/4610,TBL-505

Owner’s Manual

Maintenance schedule

Below you will find some general maintenance instructions. For further information

please contact your service dealer.

Daily maintenance

• Clean the exterior of the unit.

• Check the dust cover for damage or cracks. Change the cover in case of impacts or

cracks. (Hand held blower only)

• Check that nuts and screws are sufficiently tightened.

Weekly maintenance

• Check the starter, especially cord and return spring.

• Clean the exterior of the spark plug.

• Remove it and check the electrode gap. Adjust it to 0.6 mm (.024”), or change the

spark plug.

• Clean the cooling fins on the cylinder and check that the air intake at the starter is

not clogged.

• Clean the air filter.

Monthly maintenance

• Rinse the fuel tank with gasoline.

• Clean the exterior of the carburetor and the space around it.

• Clean the fan and the space around it.

www.tanakapowerequipment.com 11 custsvc@tanaka-ism.com

Page 13

6. Specifications

THB-2500/THB-2510/TBL-4600/4610,TBL-505

Owner’s Manual

ANSI : Measured at 50 feet away from unit.

CEN : Measured at operator's ear.

NOTE : Equivalent noise level/vibration levels are calculated as the time-weighted energy total for noise/vibration levels

under various working conditions with the following time distribution : ½ idle, ½ full speed.

* All data subject to change without notice.

www.tanakapowerequipment.com 12 custsvc@tanaka-ism.com

Page 14

THB-2500/THB-2510/TBL-4600/4610,TBL-505

Declaration of conformity

Declaration de conformite

Owner’s Manual

Dichiarazione di conformita

We,

Nous,soussign6s,

Noi,

Der unterzeichnete,

Nosotros,

Tanaka Kogyo Co., Ltd., 3-4-29 Tsudanuma, Narashino, Chiba, Japan

Konformitiitserkliirung

Declaraci6n de conformidad

Konformitetsdeklaration

vi,

Declare under our sole responsibility that the product, power blower model THB-25 10, TBL-4600/4610/5O5

D6clarons sous notre seule responsabilitd que le produit en question, souffleuse mdcanique mod~le

Dichiariamo sotto la nostra unica responsabilita che it prodotto, it motosoffiatore modello

Erklarl unter, eigener Verantwortung, daB das Produkt, motorgeblase model]

Declaramos dajo nuestra Onica responsabilidad que el producto, soplador mecdnico modelo

Forklarar harmed pA eget ansvar att denna produkt, motordriven grdsmattsluftare modell

to which this declaration relates is in conformity with the essential safety requirements of directives.

laquelle se rapporte la pr6sente d6claration est conforme aux directives concernant les conditions de s6curit6

essentielles.

at quale questa dichiarazione si riferisce, ~ conforme ai requisiti di sicurezza essenziali delle direttive.

for das these Erklarung gilt, den wesentlichen Sicherheitsanforderungen der Directive entspricht.

que corresponde a esta declaracl6n, satisface la (s) siguiente (s) exigencia (s) de seguridad esencial (es) de las

directivas.

till vilken denna deklaration tillhor, uppfyller samtliga vasentliga sakerhetskrav f6reskrivna

1

ber6rda direktiv.

89/392/EEC, 91/368/EEC, 93/44/EEC, 93/68/EEC, EMC89/336/EEC

The following standards have been taken into consideration

Les normes suivantes ont 6t6 prises en consid6ration. Sono

stati presi in considerazione

nachfolgenden Standards wurden in Betracht gezogen. Se ban

tenido en consideraci6n las siguientes normas. Vi har tagit

hansyn till f6ljande standards.

Manufactured at: Chiba, Japan

Fait A:

Luogo:

Erstellt in:

Fabricado en:

Tillverkad av:

Signature:

Signature:

Firma:

Unterschrift:

Fimado:

Signatur:

Position:

Function:

Incarico:

Titel:

Cargo:

Befattning:

Sejii Tanaka

Vice president

Vice-pr6sident

Vicepresidente

Stellvertretender Vorsitzender

Vicepresidente

Vice President

1

seguenti standard. Die

Serial No. up from

No. de s6rie A partir de

Num. di serie da

Scrien-Nr. ab

No. de Serie de

Serienr fr. o.m.

IS03864, (EN-292-2)

v001001

en adelante

www.tanakapowerequipment.com 13 custsvc@tanaka-ism.com

Loading...

Loading...