Page 1

tams elektronik

E D C

Central unit for

digital system EasyControl

Version "Basic" item no. 40-02007

Version "Basic-R" item no. 40-02017

Version "V24" item no. 40-02037

Version"Booster" item no. 40-02057

Version"Booster-R" item no. 40-02067

Manual

tams elektronik

n n n

Page 2

tams elektronik

RedBox English

Seite 2

Page 3

tams elektronik

English RedBox

Contents

1. Getting started................................................................................................................5

2. What is EasyControl?.......................................................................................................7

2.1. Components............................................................................................................7

2.2. EasyNet...................................................................................................................7

2.3. Digital formats.........................................................................................................9

3. Components for the digital system EasyControl................................................................11

3.1. Central unit............................................................................................................11

3.2. Booster.................................................................................................................12

3.2.1. Breaking distance booster ("Breaking booster")..............................................12

3.2.2. Seperating driving and switching...................................................................13

3.3. Non-central control devices.....................................................................................14

3.4. PC, tablet and smartphone.....................................................................................15

3.4.1. Overview PC- and WLAN interfaces of the central unit versions.......................16

3.4.2. Control software...........................................................................................16

3.5. Adapters for other bus systems...............................................................................17

3.6. S88 modules..........................................................................................................17

3.7. DCC programming track.........................................................................................18

4. Connecting external components and the power supply to the RedBox..............................19

4.1. EasyNet interface...................................................................................................20

4.2. XpressNet interface................................................................................................23

4.3. PC interfaces.........................................................................................................24

4.4. WLAN interface......................................................................................................25

4.4.1. Connecting Android devices to the WLAN interface of the RedBox...................25

4.5. External boosters...................................................................................................26

4.6. Integrated booster (versions "Booster" and "Booster-R" only)...................................28

4.6.1. Connecting voltage supply and rails...............................................................29

4.6.2. Configurating the integrated booster..............................................................30

4.6.3. Driving and switching separately with one RedBox..........................................31

4.7. S88 feedback modules...........................................................................................32

4.8. Programming track.................................................................................................33

4.9. Power supply for control devices.............................................................................33

5. Adjusting parameters of the digital control......................................................................35

6. Operation......................................................................................................................39

6.1. Switching on / off...................................................................................................39

6.2. Plug and play.........................................................................................................39

6.3. LED displays on the front side.................................................................................40

6.4. LED displays on the rear side (versions "Booster" and "Booster-R" only)....................40

Seite 3

Page 4

tams elektronik

RedBox English

7. Update..........................................................................................................................41

8. Check list for troubleshooting.........................................................................................42

8.1. Errors occurring while starting up............................................................................42

8.2. Errors occurring while setting parameters................................................................42

8.3. Errors occurring while operating..............................................................................42

8.4. Errors occurring during software update..................................................................43

9. Technical Specifications..................................................................................................44

9.1. RedBox..................................................................................................................44

9.2. Integrated Booster (Versions "Booster" and "Booster-R")..........................................45

10. Background information.................................................................................................46

10.1.Motorola-Format....................................................................................................46

10.2.DCC-Format...........................................................................................................47

10.3.m3........................................................................................................................49

10.4.s88.......................................................................................................................49

10.5.RailCom.................................................................................................................50

10.6.Boosters................................................................................................................51

11. The asterisks **.............................................................................................................52

12. Guarantee bond.............................................................................................................53

13. EU declaration of conformity...........................................................................................54

14. Declarations conforming to the WEEE directive................................................................54

© 06/2018 Tams Elektronik GmbH

All rights reserved. No part of this publication may be reproduced or transmitted in any form or

by any means, electronic or mechanical, including photocopying, without prior permission in

writing from Tams Elektronik GmbH.

Subject to technical modification.

Seite 4

Page 5

tams elektronik

English RedBox

1. Getting started

Checking contents

Please make sure that your package contains:

RedBox

power pack (12 V AC / 1,6 A)

cable to connect a DCC programming track

versions "Booster" and "Booster-R" only:

3 short-circuit jumpers

2 plug-in parts for terminal strips

compact disc containing manual, USB-driver (Tams-ID) and demo software

Required auxiliary devices

For operating the digital control you need auxiliary devices (not included in the scope of

delivery):

for versions "Basic", "Basic-R" and "V24": at least one external booster and an appropriate

power supply

for versions "Booster" and "Booster-R": one transformer or power supply unit. Hint: The

required output depends on the rail voltage set for the integrated booster. ( à section 4.6.1.

"Connecting voltage supply and rails")

one input and display device:

one EasyControl device with software version from 2.0

(e.g. LokControl, HandControl, HandControl 2) or

a PC with control software or software CV-Navi or

an Android smartphone or tablet with app "EasyControl Android" and a Raspberry Pi

with WLAN router (e.g. wControl)

Seite 5

Page 6

tams elektronik

RedBox English

Saftey instructions

The RedBox should only be used in concordance with these instructions to control digital model

railroad layouts. It is not suitable for use by children under 14. Incorrect use and nonobservance of the manul can be dangerous. In particular there is a risk of electric shock through

contact with metal parts under power, especially when an incorrect voltage is used, or when

operated in a too humid or wet environment. Therefore the following precations should be

observed:

Wiring should only be carried out when the control is disconnected.

Only operate indoors in a dry environment.

Only use proprietry transformers with the correct voltage.

Only connect the transformer in an authorised manner to the house power supply.

Use adequetly thick cable for all wiring. Too thin a cable can overheat.

If the layout is exposed to condensation, allow at least two hours for drying out.

Use only original spare parts if you have to repair the kit or the ready-built module.

Seite 6

Page 7

tams elektronik

English RedBox

2. What is EasyControl?

EasyControl is a digital control for your model railroad layout, which is assembled from different

components. This modular design principle allows you to adjust it to various demands and

differently sized model railway layouts.

2.1. Components

It consists of at least

one digital central unit RedBox (available since 09-2016) or MasterControl (available from

2005 to 2016)

one external booster (not required with RedBox versions "Booster" and "Booster-R")

one external control device (not required with MasterControl)

In addition to your central unit RedBox or MasterControl you can use more than 60 additional

control devices or adapters in one digital control. The following devices are suitable:

EasyControl devices (e.g. LokControl, HandControl, HandControl 2)

digital control devices for bus systems of other manufacturers (e.g. XpressNet)

PC

mobile Android terminal devices (e.g. smartphone, tablet)

DECT-teleohones

digital central units of other manufacturers for Motorola- and/or DCC-format

à section 3. Components for digital control system EasyControl

2.2. EasyNet

External control devices or adapters and the central units RedBox or MasterControl communicate

via the data bus EasyNet. They can be plugged in or out at any time to the EasyNet, even during

operation (plug and play). As a bus line for the EasyNet patch cables with RJ 45 connectors ar

used.

One additional control device or adapter can be connected directly to the EasyNet interface of

the RedBox or the MasterControl. You need a junction (e.g. wye junction or BusControl), if you

want to connect more than one additional device (as far as the device concerned does not have

two RJ 45 connectors, like SniffControl or PhoneControl).

Seite 7

Page 8

tams elektronik

RedBox English

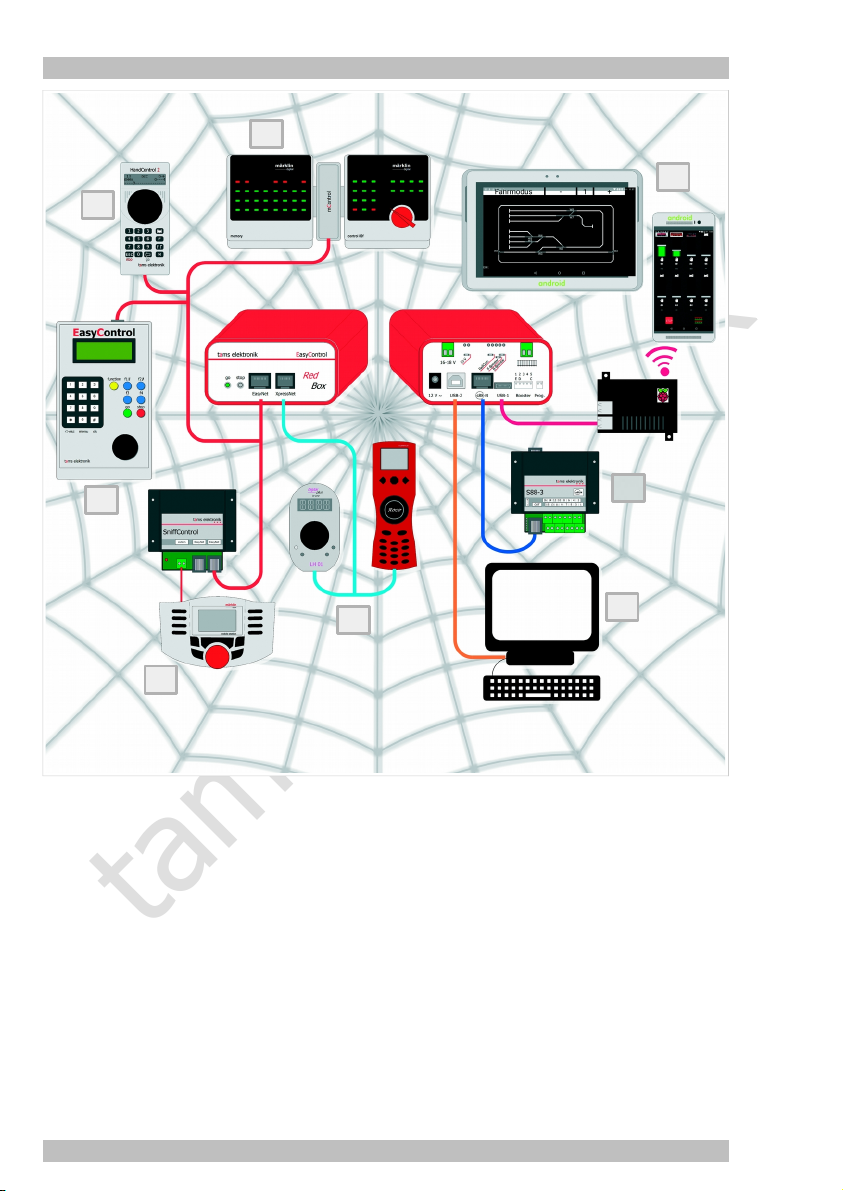

3

6

1

1

4

2

Examples of external control devices and feedback modules to be connected to a

RedBox:

1. EasyControl control devices (e.g. LokControl, HandControl 2)

2. Digital central units of other manufacturers for Motorola- and/or DCC-format (e.g. Maerklin

Mobile Station): connection via SniffControl

3. Older digital control devices for Maerklin Control Unit: connection via mControl

4. Digital control devices for XpressNet (e.g. Lenz LH01, Roco Multimaus)

5. PC

6. mobile Android terminal devices via Raspberry Pi with WLAN router (e.g. wControl). Hint:

The versions "Basic-R" and "Booster-R" have an integrated Raspberry Pi with WLAN router,

there is no need for an additional wControl.

7. s88-feedback modules

7

5

Seite 8

Page 9

tams elektronik

English RedBox

2.3. Digital formats

EasyControl is a multi protocol control system and capable to control vehicle and accessory

decoders of any manufactures compatible with these formats:

Motorola I ("old" Motorola format)

Motorola II ("new" Motorola format)

DCC (complying to NMRA and RCN standards)

Moreover you can use the m3-format to control vehicle decoders designed for mfx-format.

Feedback data sent in mfx-format cannot be analysed by the digital system EasyControl.

EasyControl allows to operate vehicles with Motorola, DCC or mfx decoders in parallel.

You make the setting for whether operating solenoid accessory decoders in the Motorola or DCC

format either

commonly for all connected decoders or

seperately for a group of four decoders.

à Section 10. Background information

RailCom

EasyControl supports the feedback standard RailCom. EasyControl devices, mobile terminal

devices and the PC allow you to enter commands to read out the CV values of decoders

compatible to RailCom. In order to collect and analyse feedback data, you need special RailCom

detectors.

à Section 10. Background information

Decoder addresses , speed levels, switchable functions

Depending on the data format you have the following possibilities for controlling vehicle and

accessory decoders:

Motorola DCC m3

Vehicle decoder addresses 255 10.239 16.384

Amount of speed levels 14 or 27 14, 28 or 128 128

Functions

Accessory decoder addresses 1.020 2.040 –-

function (light)

f1 bis f4

f0 to f28

or to 32.768

f0

f1 to f15

Seite 9

Page 10

tams elektronik

RedBox English

27 speed levels with the Motorola format

As a standard, the Motorola format supports 14 speed levels. EasyControl additionally offers two

methods to extend those speed levels to 27.

Speed level mode 27a: Some decoders (e.g. Maerklin 6090x and Maerklin mfx decoders) support

27 speed levels using the so called interspeed levels. To reach an interspeed level you switch to

a higher speed level and immediately switch back. A power failure will cause the loss of this

speed information data. Your MasterControl simulates those 27 speed levels and shows them in

the display. The MasterControl creates the interspeed levels by regularly switching to a higher

speed level for a short time. This ensures that the speed levels are correctly set even after a

power failure. Normally, the change between speed levels is not visible.

Speed level mode 27b: Using free bit combinations in the function’s double bit helps realizing

proper 27 speed levels. The decoder must support this (e.g. locomotive decoders of Tams

Elektronik and ESU). When controlling locomotive decoders that only support 14 speed levels or

the speed level mode 27a with speed level mode 27b, only every second set speed level actually

changes speed.

Programming modes in the DCC format

RedBox and MasterControl have connections for a programming track which allows to read out

and programm DCC vehicle decoders.

The programming modes to be used and the paremeters to be set depends on the particular

decoder (see decoders´s manual). EasyControl supports programming and reading data in the

following DCC programming types:

CV-programming – byte wise and bitwise

Register and Page programming

Main track programming (POM)

à Section 10. Background information

Programming of mfx vehicle decoders

When setting vehicles with mfx decoders onto the programming track, you can

read out the UID

and program the address

Programming of Motorola vehicle decoders

It is not possible to program Motorola vehicle decoders on the programming track, as this

method is not intended for use with the Motorola format. For that reason you have to program

Motorola decoders according to the manufacturer specifications on the main track.

à Section 10. Background information

Seite 10

Page 11

tams elektronik

English RedBox

3. Components for the digital system EasyControl

3.1. Central unit

As a central unit you can use either a RedBox or a MasterControl (with function "central unit").

The central units RedBox and Master Control

send control instructions to every kind of decoder on your layout,

check for components plugged into the EasyNet,

poll for data and control instructions from components of the EasyControl,

send data to components of the EasyControl,

receive feedback data of s88 modules and transfer them to the PC,

are the interfaces between computer(s) and model railroad layout.

Database for system parameters

RedBox and MasterControl have an integrated database to store all parameters relevent for the

digital system:

booster configuration (short circuit polarity, short circuit sensitivity)

output of commands for accessory decoders at the booster outputs

standard data format for vehicle decoders

switching times for solenoid decoders (minimum/maximum)

RailCom support

number of connected s88 modules

length of signal pause for Motola vehicle decoders

Locomotive database

RedBox and MasterControl have an integrated database to store parameters you apply to a

locomotive’s address, which are:

data format

amount of speed levels

(locomotive’s) name. Example: A locomotive of type BR 89 is assigned address "89" and the

name "EMMA". When applying names to locomotive addresses, you can find a locomotive by

looking for it´s name in the database.

Entering and modifying data

In order to display, enter and modify the system parameters or the data of vehicle decoders,

you need:

MasterControl or

LokControl, HandControl or HandControl 2 (software version 2.0 or higher) or

PC with software CV-Navi or control software supporting EasyControl or

Raspberry Pi (or wControl) and Android smartphone or tablet with app "EasyControl Android"

With the central unit RedBox you cannot display, enter or modify system parameters.

Seite 11

Page 12

tams elektronik

RedBox English

3.2. Booster

Each central unit needs at least one booster. With larger layouts you normally need several

boosters, connected to separate sections of the layout. The required number of boosters

depends on the power requirements of the layout and the amount of current the booster can

provide.

Booster outputs

RedBox: one output for the connection of external boosters (either Maerklin compatible or

DCC conform)

MasterControl: two outputs for the connection of external boosters (either Maerklin

compatible or DCC conform). As both interfaces have to be programmed in common, you

have to use boosters of the same type for both outputs. It is recommended to use boosters

identical in construction.

Integrierted booster

The versions "Booster" and "Booster-R" of the RedBox have an integrated 2.5 A booster (in

addition to the booster output). This is sufficient for operating a small layout (up to nominal size

H0).

MasterControl and the versions "Basic", "Basic-R" and "V24" of the RedBox do not have

integrated boosters. With these central units you have to connect at least one external booster.

3.2.1. Breaking distance booster ("Breaking booster")

Besides the standard booster output, the MasterControl has a second booster output ("breaking

booster"), which can be used to control all breaking distances on your layout. Every Maerklin**compatible booster or booster for the DCC system can be used as breaking booster. As both

interfaces have to be programmed in common, you have to use boosters of the same type for

both outputs. It is recommended to use boosters identical in construction.

The integrated booster of the RedBox (versions "Booster" and "Boster-R") can be configurated

for use as breaking booster.

As soon as one of the locomotives enters a breaking distance, the booster receives a stop signal,

no matter which speed was set. All other data such as the status of the decoder functions and

the driving direction are still sent by the central unit.

Seite 12

Page 13

tams elektronik

English RedBox

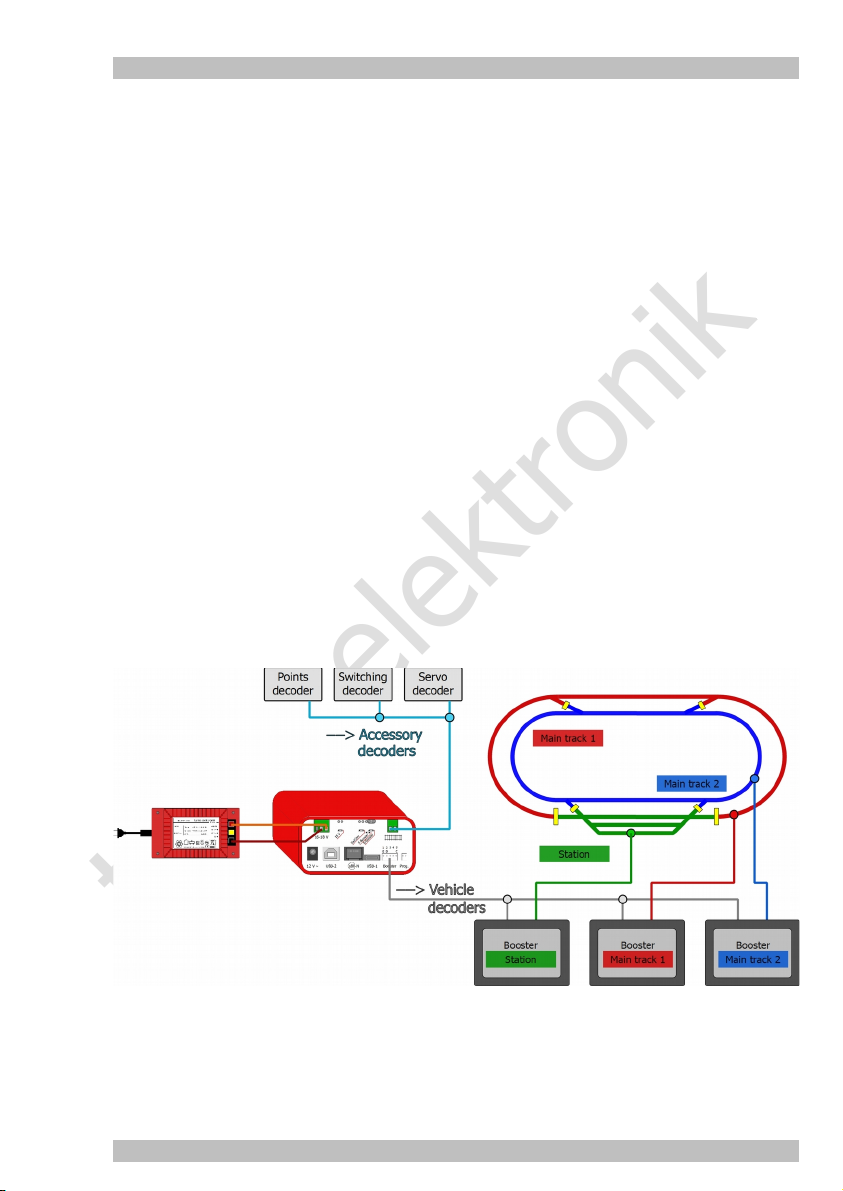

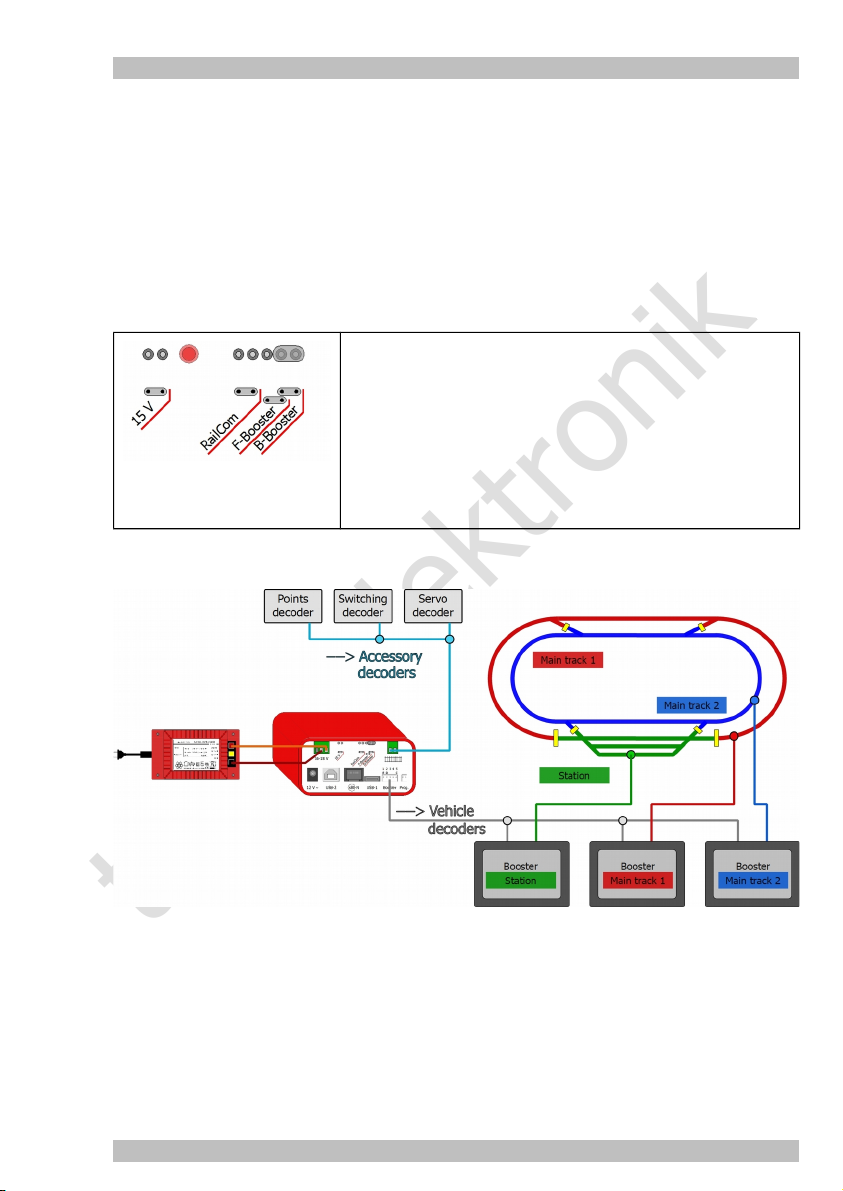

3.2.2. Seperating driving and switching

As a standard, the commands to control the vehicle decoders are sent continuously via the

central unit´s booster output, whereas the commands to control the accessory decoders are

sent only when required. For that purpose the transmission of vehicle decoder commands is

interrupted shortly, to transfer the accessory decoder commands during the resulting cutout.

In PC controlled (larger) layouts, this kind of data transfer can cause problems, e.g. when

vehicle decoders receive stop commands too late and this results in locomotives passing stop

signals. Usually two central units are used to solve this problem. They control vehicle and

accessory decoders separately (and are controlled by the PC software accordingly).

With MasterControl and RedBox you can switch off the transmission of accessory decoder

commands at the booster output. Then, only vehicle decoder commands will be transferred and

the delay caused by the transmittsion of accessory decoder commands is excluded.

That way, MasterControl and RedBox (versions "Booster" and "Booster-R") allow to control

vehicle and accessory seperately with one central unit.

MasterControl: Controlling the vehicle decoders via the standard booster output (accessory

decoder commands switched off) and controlling the accessory decoders via the breaking

distance booster output.

RedBox versions "Booster" and "Booster-R": Controlling the vehicle decoders via the booster

output for external boosters (accessory decoder commands switched off) and controlling the

accessory decoders via the integrated booster.

There is no need for adapting the control software. You have to register only one central unit for

this application.

Figure: Seperating driving and switching with one RedBox (versions "Booster" or "Booster-R).

The integrated booster controls the accessory decoders, digital commands for the vehicles

decoders are sent via the external boosters only.

Seite 13

Page 14

tams elektronik

RedBox English

3.3. Non-central control devices

Non-central control devices (such as external devices for the system EasyControl, XpressNet

devices or central units of other manufacturers) offer the possibility to control your model

railroad from different spots and / as well as together with others. They can be plugged in or out

at any time to the EasyNet, even during operation. An EasyNet can handle more than 60 noncentral control units, adapters or similar.

When connecting non-central control devices to the EasyNet, restrictions concerning the

controllable digital formats are cancelled. As an example vehicle decoders designed for Motorola

or mfx format can be controlled with pure DCC devices. In case the decoder´s amount of speed

levels set int the locomotive data base does not correspond to the amount which can be set at

the non-central device, the central unit converts the speed levels internally. The number of

switchable functions and selectable addresses corresponds to the device´s hardware

specification.

You can only use one RedBox or MasterControl (function "control unit") in one digital control. If

required, you can use one or several (additional) MasterControls as non-central control devices,

when operated by a modified software.

Seite 14

Page 15

tams elektronik

English RedBox

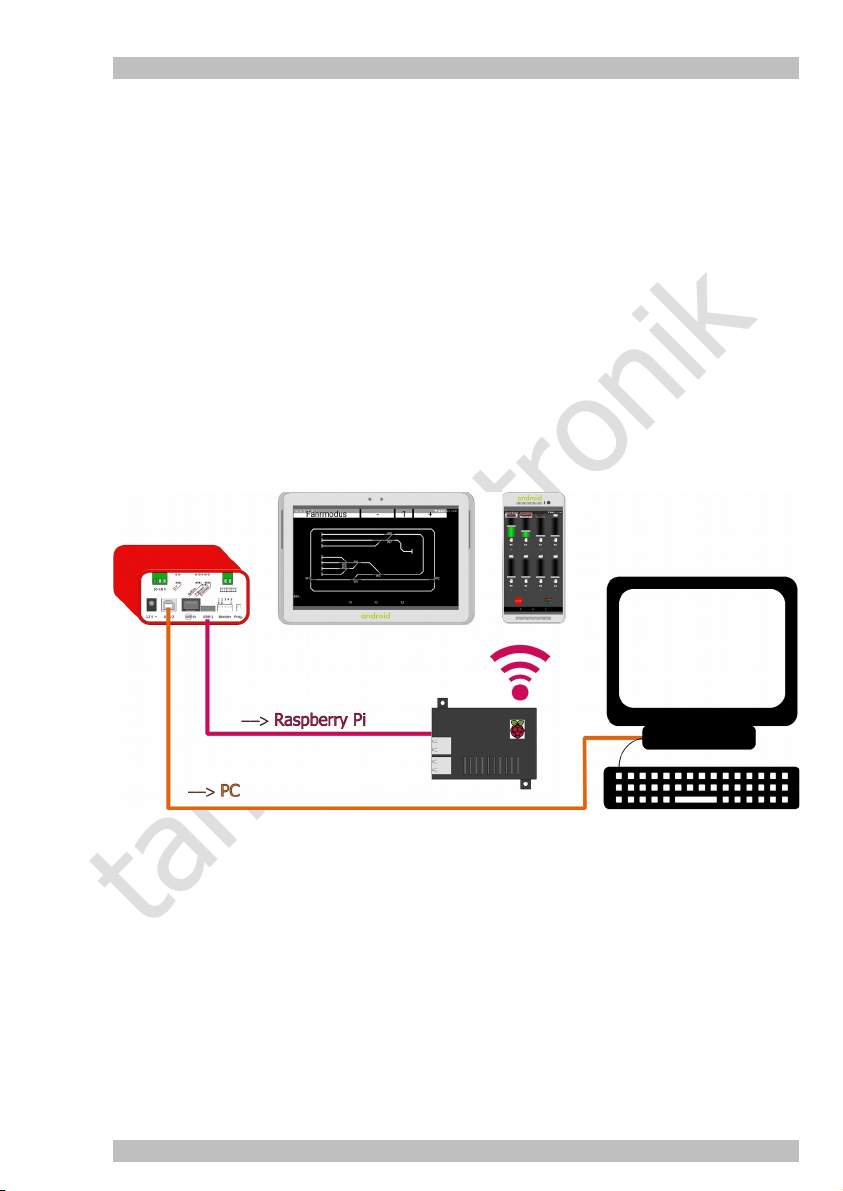

3.4. PC, tablet and smartphone

The versions "Basic", "Booster" and "V24" of RedBox as well as MasterControl have each two

interfaces for the (simultaneous) connection of two computers. The versions "Basic-R" and

"Booster-R" of the RedBox have one PC-interface each.

You can integrate up to 32 mobile Android terminal devices (tables, smartphones) into the digital

system EasyControl for use as wireless control devices. You can establish the WLAN connection

with:

customary single-board computer Raspberry Pi 3 with integrated WLAN or Raspberry Pi 2 and

additional WLAN-router

wControl (item no. 40-09957). wControl consists of a single-board computer Raspberry Pi 3

model B and a micro SD-card preconfigured for use as WLAN interface in the system

EasyControl.

RedBox versions "Basic-R" or "Booster-R" with integrated single-board computer Raspberry

Pi 3.

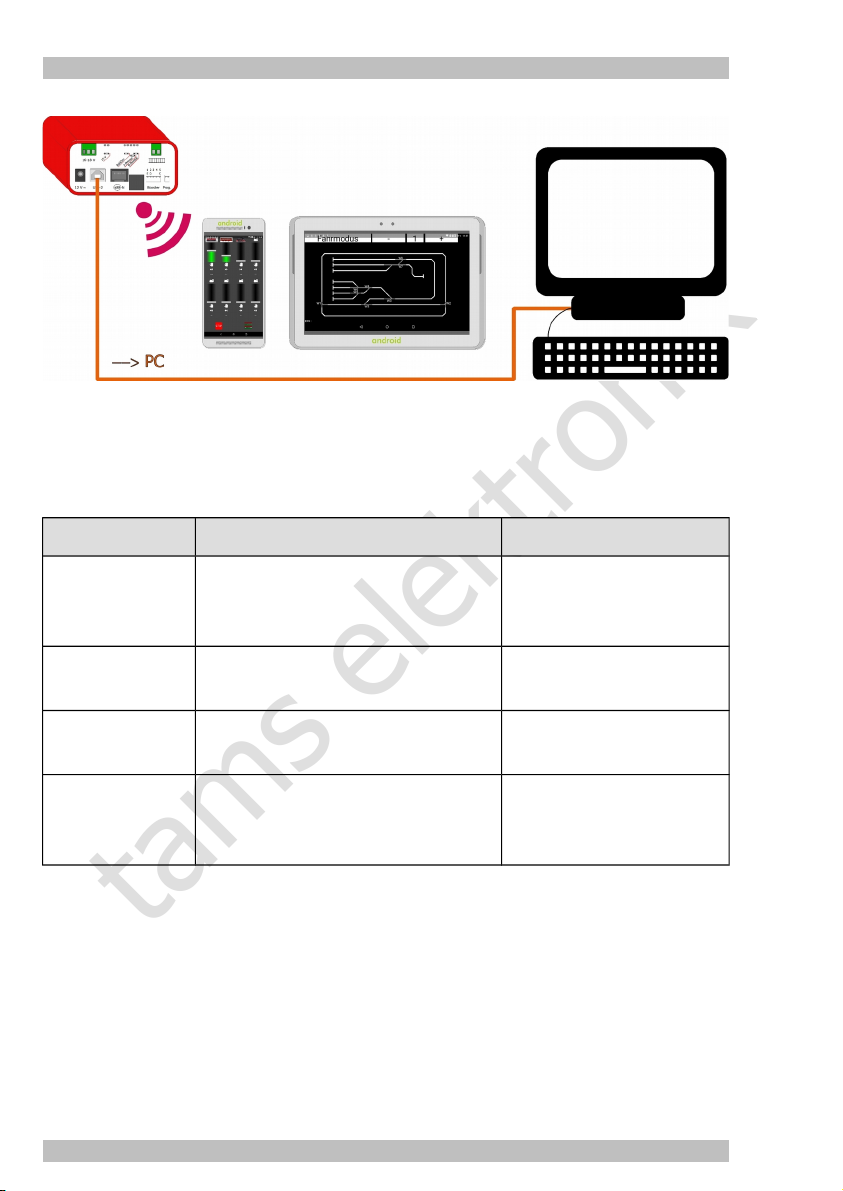

Figure: Integrating PC and mobile terminal devices (here: via an external WLAN interface

wControl)

Seite 15

Page 16

tams elektronik

RedBox English

Figure: Integrating PC and mobile terminal devices (here: via the integrated WLAN interface of

the RedBox version "Booster-R")

3.4.1. Overview PC- and WLAN interfaces of the central unit versions

PC interfaces WLAN interfaces

MasterControl one serial interface

(baud rate adjustable)

one USB interface with SiLabs identifier

RedBox "Basic"

RedBox "Booster"

RedBox "Basic-R"

RedBox "Booster-R"

RedBox "V24" one serial interface

USB-1 type Mini-B with Tams identifier

USB-2 type B with SiLabs identifier

USB-2 type B

with SiLabs identifier

(baud rate adjustable)

one USB interface with Tams identifier

external WLAN interface

required

external WLAN interface

required

integrated Raspberry Pi 3

preconfigured for EasyControl

external WLAN interface

required

3.4.2. Control software

Every software, which supports the Märklin** 6050 or P50X protocol is able to control your

RedBox or MasterControl.

In order to use a tablet or smartphone as a wireless control device, you have to install an app on

your mobile terminal device.

Seite 16

Page 17

tams elektronik

English RedBox

3.5. Adapters for other bus systems

Digital devices of other manufacturers using other bus systems than EasyNet for data transfer

can be integrated into the system EasyControl and used for controlling and switching vehicle and

accessory decoders. Your RedBox has an integrated XpressNet interface for the connection of up

to 16 XpressNet devices.

There are different adapters available for the connection of devices of other manufacturers:

Device to be connected Adapter

DECT telephones PhoneControl

XpressNet devices of all manufactureres XNControl

Hint: Your RedBox has an integrated XpressNet interface for

the connection of up to 16 XpressNet devices.

Motorola and DCC digital control devices

of all manufactureres

Older digital control devices for the Maerklin**

Control Unit (item no. 6020 and 6021)

SniffControl

mControl

Hinwes: mControl replaces Maerklin** Control Unit item no.

6020 or 6021.

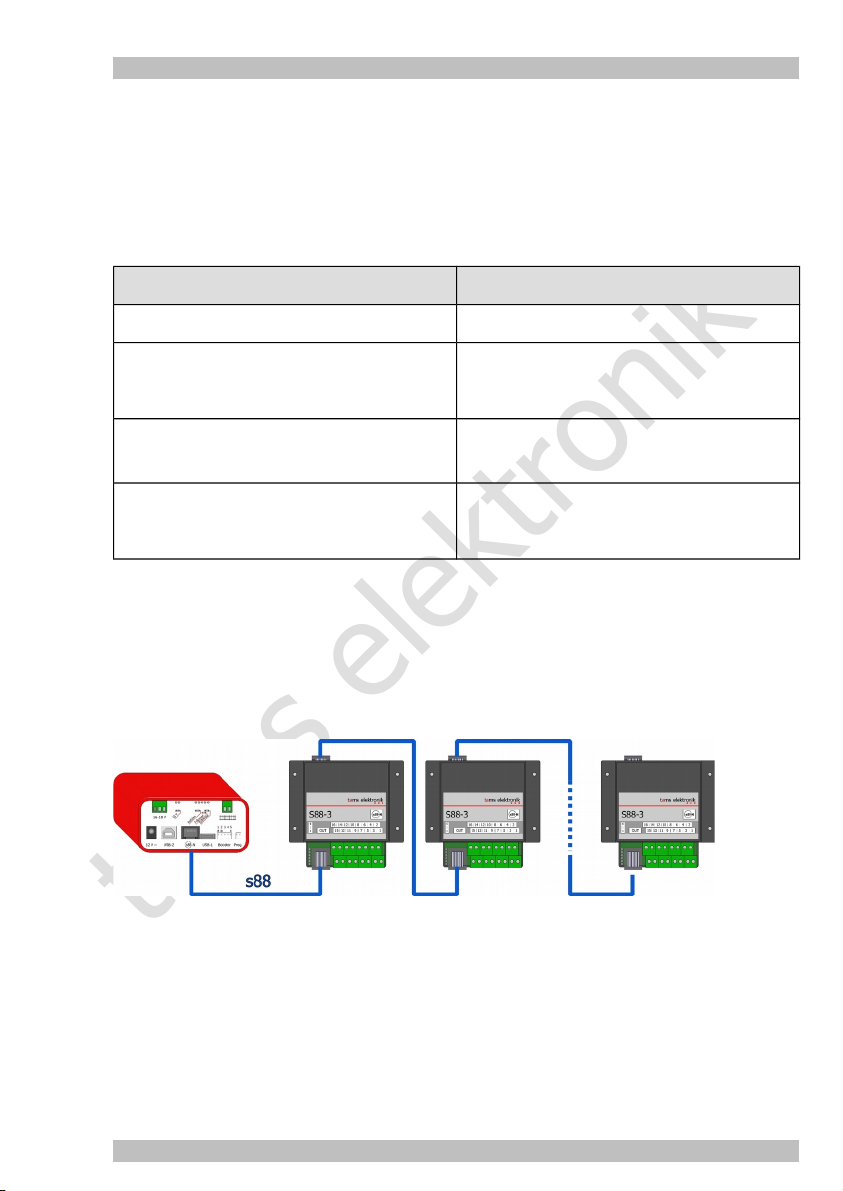

3.6. S88 modules

You can connect up to 52 s88 feedback devices or s88-compatible modules with 832 contacts to

one RedBox or MasterControl. Modules of all manufacturers can be integrated.

The RedBox has a s88 interface according to standard s88-N (for the connection of a patch

cable), the MasterControl a 6-pole interface.

Figure: Connecting s88 modules (max. 52 with 832 contacts)

Seite 17

Page 18

tams elektronik

RedBox English

3.7. DCC programming track

RedBox and MasterControl have a connection for a DCC programming track. Every common rail

can be used for that.

For the decoders of vehicles set onto the programming track you can

in DCC format: read out and program the CVs

in m3 format (for mfx decoders): program the address and read out the UID

Seite 18

Page 19

tams elektronik

English RedBox

4. Connecting external components and the power supply to the RedBox

RedBox | Front side

RedBox "Basic" | Rear side RedBox "Basic-R" | Rear side

RedBox "Booster" | Rear side RedBox "Booster-R" | Rear side

RedBox "V24" | Rear side

Seite 19

Page 20

tams elektronik

RedBox English

4.1. EasyNet interface

You can integrate more than 60 non-central control devices or adapters for devices of other

manufacturers into the digital system via the EasyNet interface on the front side of your RedBox.

Any (RJ 45) Ethernet patch cable (used in Computer networks) will work. Please also read the

manual of your control device or adapter.

You can connect one device or adapter directly to the EasyNet interface of your RedBox. You

need a distributor (Y-distributor for Ethernet patch cables or BusControl) when using more than

one additional device. Exceptions are devices with two EasyNet interfaces, e.g. SniffControl,

XNControl.

The power supply of the RedBox is sufficient to supply four additional devices. When connecting

more devices, you need a BusControl and an additional AC power pack.

EasyControl devices

Please note, that all EasyControl devices must have the same software version as the RedBox to

prevent malfunction of data transfer between the devices.

Other manunfacturer´s digital controls and DECT telephones

Adapters, connected to the EasyNet interface of your RedBox, allow to integrate all Motorola

and/or DCC central units made by other manufacturers, and digital devices for other bus

systems into the digital system, and to use them as external control devices.

Restrictions of digital central units concerning the usable digital formats are overcome, e.g. you

can control vehicle decoders designed for Motorola or mfx format with pure DCC devices. In

case the number of speed levels defined for a decoder in the locomotive data base does not

correspond to the number of speed levels to be set at the device, the RedBox converts the

speed levels internally.

Please note, that with some devices the input options are restricted (e.g. number of switchable

functions, length of locomotive addresses, input of accessory decoder commands).

Seite 20

Page 21

tams elektronik

English RedBox

Device to be connected Adapter

DECT telephone PhoneControl

XpressNet devices from all manufacturers, e.g.

Roco** Lokmaus 2 and 3, Multimaus (not

Lokmaus 1)

handheld controllers by Lenz**

handheld controllers by Massoth**

Motorola and DCC digital central units from all

manufacturers

Older digital devices for digital Control Unit by

Märklin** (item no. 6020 and 6021), e.g.

Keyboard (item no. 6040)

Memory (item no. 6043)

Control panel Control 80 (item no. 6035)

and 80F (item no. 6036)

Infra Control 80 f (item no. 6070)

XNControl

Hint: The RedBox has an integrated XpressNet interface for

the connection of a maximum of 16 XpressNet devices.

Hint: As a power supply for the connected devices you need a

DC or AC power pack (e.g. item no. 70-09110).

SniffControl

mControl

Hint: The mControl replaces Märklin** Control Unit item no.

6020 or 6021.

Hint: As a power supply for the connected devices you need a

DC or AC power pack (e.g. item no. 70-09110).

Figure: Connecting EasyControl devices and DECT telephones (from left to right):

LokControl

MasterControl (with software "MC-Control")

HandControl 2

DECT telephone (via PhoneControl)

Seite 21

Page 22

tams elektronik

RedBox English

Figure: Connecting other manunfacturer´s digital controls to the EasyNet interface (from left to

right):

Märklin Mobile Station or other Motorola- and/or DCC-central units via SniffControl

Digital devices for Märklin Control Unit 6020 and 6021 via mControl: The Märklin** Control

Unit is replaced by mControl and RedBox..

Hint: SniffControl has two EasyNet interfaces. For that reason there is no need for an extra

distributor to connect an additional device.

Seite 22

Page 23

tams elektronik

English RedBox

4.2. XpressNet interface

The XpressNet interface on the front side of the RedBox allows to connect a maximum of 16

XpressNet devices directly to the RedBox(e.g. Roco** Lokmaus 2 and 3, Roco** Multimaus,

handheld controllers by Lenz** and Massoth**) and to use them as external control devices.

Restrictions of the devices concerning the usable digital formats are overcome, e.g. you can

control vehicle decoders designed for Motorola or mfx format with pure DCC devices. In case the

number of speed levels defined for a decoder in the locomotive data base does not correspond

to the number of speed levels to be set at the device, the RedBox converts the speed levels

internally.

Please note, that with some devices the input options are restricted (e.g. number of switchable

functions, length of locomotive addresses, input of accessory decoder commands).

Figure: Connecting XpressNet devices

Direct connection of a maximum of 16 XpressNet devices via the XpressNet interface.

As an alternative or an addition, XpressNet devices can be connected via a XNControl

connected to the EasyNet interface.

Seite 23

Page 24

tams elektronik

RedBox English

4.3. PC interfaces

Depending on the version, your RedBox has:

"Basic", "Booster" and "V24": two galvanically isolated PC interfaces, for parallel connection of

two computers.

"Basic-R" and "Booster-R" with integrated WLAN interface: one USB interface

By means of a PC you can

make software updates for the RedBox

set parameters for the RedBox (e.g. with software CV-Navi)

control the layout (with a suitable PC software)

Versions with two USB- interfaces: RedBox "Basic" and "RedBox "Booster"

USB-1: type Mini-B with Tams identifier

USB-2: type B with SiLabs identifier

There are no specifications according to the assignment of computer(s) to the two interfaces.

Preferably you should connect a computer not operated by Windows or a Raspberry Pi to the

interface USB-1.

When using interface USB-1 for a computer operated by Windows, you have to install a driver

software from the CD on your computer before the first use. In case it is not possible to install a

driver software with Tams identifier for this computer, you should use interface USB-2. Normally,

the driver software for this interface will be installed autamatically when used for the first time

(from Windows 7).

Versions with one USB-interface: RedBox "Basic-R" and "RedBox "Booster-R"

The versions "Basic-R" and "Booster-R" have one USB interface (USB-2) of type B with SiLabs

identifier. Normally, the driver software for this interface will be installed autamatically, when

used for the first time (from Windows 7).

Serial interface: RedBox "V24"

The version "V24" of the RedBox has a serial interface and an USB interface with Tams

identifier. The serial interface is for use with control software controlling the interfaces COM1

and COM2 only, and or for use with PCs not providing an USB interface.

Seite 24

Page 25

tams elektronik

English RedBox

4.4. WLAN interface

Integrating mobile terminals

You can simultaneously operate a maximum of 32 Android smartphones or tablets in one system

EasyControl. If you want to use mobile terminals as wireless control devices with the versions

"Basic", "Booster" and "V24" of the RedBox you need an extra WLAN Interface:

a commercial single-board computer Raspberry Pi 2 and an extra WLAN router or

a commercial single-board computer Raspberry Pi 3 with integrated WLAN router or

an interface "wControl" (item no. 40-09957) with preconfigured Raspberry Pi 3

You should preferably connect the WLAN interface to the interface USB-1 of the RedBox.

The versions "Basic-R" and "Booster-R" of the RedBox have an integrated WLAN interface.

Required software ("app")

You need the app "EasyControl Android" for the mobile terminal(s) which can be downloaded

from the Google Playstore (free trial version, price for the full version: 5,99 € | status: 12/2016).

4.4.1. Connecting Android devices to the WLAN interface of the RedBox

The Versions "Basic-R" and "Booster-R" have an integrated WLAN interface which has been

preconfigured for operation in the EasyNet.

Switching on

Within one minute after switching on the power supply for the RedBox "Basic-R" or "Booster-R"

the WLAN is available.

Connecting a mobile terminal with the wControl

Activate on your smartphone or tablet the list with available WLAN networks under "settings".

Connect you mobile terminal to the network "EasyControl_Android" and enter the following

password for this network:

EasyControl

Pay attention to the upper and lowercase letters when entering the password.

Hint: Your smartphone or tablet automatically restores the connection to the latest chosen

WLAN when restarted.

Downloading the control software

Download the software from the Google Playstore.

The IP-Adresse of the WLAN (192.168.42.1) is preset in the software EasyControl Android. In

case the setting has been overwritten, you have to enter it manually.

Seite 25

Page 26

tams elektronik

RedBox English

4.5. External boosters

To use the version "Basic", "Basic-R" or "V24" you need to connect at least one booster to the

booster interface of the RedBox. Every Märklin**-compatible booster or booster for the DCC

system can be used. Please observe the booster manual.

Please note: Both types of boosters differ regarding short circuit polarity. Yet to be able to use

both types of boosters, the short circuit polarity can be set in the system configuration of the

RedBox. As this setting applies to all connected boosters, only one type of booster may be

connected to your RedBox. Generally, it is recommended to use identically constructed boosters

for supplying the different sections of a circle, in order to avoid problems when crossing the

separations between sections.

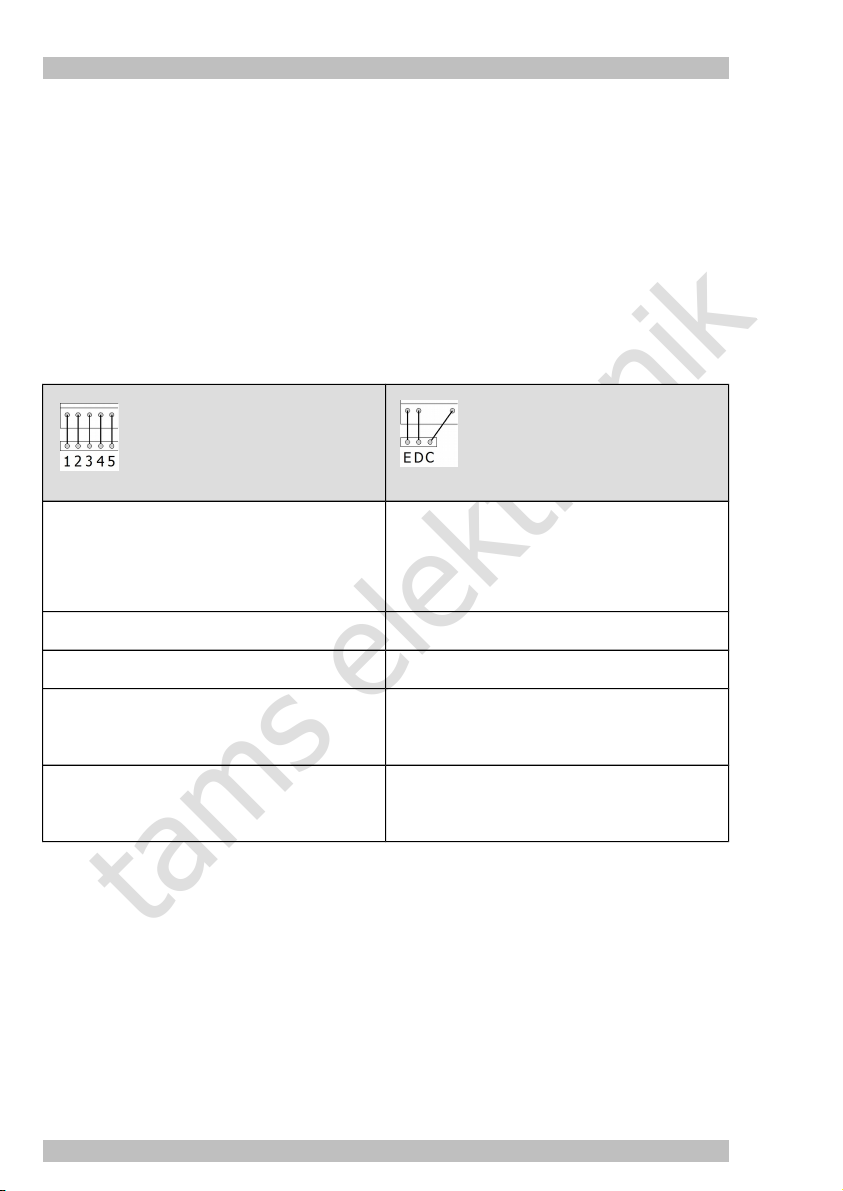

Pin assignment of the booster interface

Märklin**-compatible

booster interface

1 Short circuit feedback.

When the booster detects a short circuit (or in otherwords a

too high current consumption), it reports this to the central

unit. Thereupon the central unit switches off the booster and

displays a short circuit.

2 Ground D Ground

3 no function

4 Booster "on / off"

= output signal for switching on and off Märklin-compatible

boosters

5 Data

= output signal (track signal) for controlling vehicle and

accesory decoders

Special features of the RedBox versions "Booster" and "Booster-R"

The integrated booster and the interface for the connection of external boosters are completely

separated. When using the integrated booster exclusively for supplying a separate layout part,

as braking booster or for controlling accessory decoders, you can use Märklin compatible or DCC

boosters as external boosters (exactly as with the version "Basic", "Basic-R" and "V24").

When using external boosters as a supplement for the integrated booster (supplying several

booster sections of the same layout), you should use boosters B-3 (item no. 40-19327), as these

boosters are identically constructed as the integrated booster. With other booster types, short

circuits or interferences with data transfer possibly occur when crossing the separations between

booster sections.

E Short circuit feedback.

When the booster detects a short circuit (or in otherwords a

too high current consumption), it reports this to the central

unit. Thereupon the central unit switches off the booster and

displays a short circuit.

C Data

= output signal (track signal) for controlling vehicle and

accesory decoders

Booster interface

for DCC system

Seite 26

Page 27

tams elektronik

English RedBox

Figure: Supplying several booster

sections of one layout. As a supplement

for the booster integrated in the

versions "Booster" or "Booster-R" two

boosters B-3 are used.

Seite 27

Page 28

tams elektronik

RedBox English

4.6. Integrated booster (versions "Booster" and "Booster-R" only)

Attention:

!

Be careful to allow the air to flow unhindered through the ventilation slits in the housing of the

RedBox, otherwise the integrated booster possibly overheats. Risk of fire! Make sure to keep

distance to other devices, walls, and similar when connecting your RedBox.

Technical specification of the integrated booster

Supply voltage Separate transformer or separate switching power supply, output

voltage depending on the set track voltage

Track voltage set

15 V 12 - 15 V 17 - 18 V

19 V 16 - 18 V 21 – 22 V

Output voltage 15 or 19 volts digital voltage (regulated)

Power consupmtion max. 48 watt

Maximum output current 2,5 A

Data formats

Feedback log RailCom (RailCom cutout can be switched off)

Output signal symmetrical

LED display

A LED on the rear side of the RedBox shows the operating mode of the integrated booster.

→ Section 6.3.: LED display on the rear side

DCC, Motorola

mfx (vehicle decoder commands only)

Output voltage of the transformer

AC voltage DC voltage

Seite 28

Page 29

tams elektronik

English RedBox

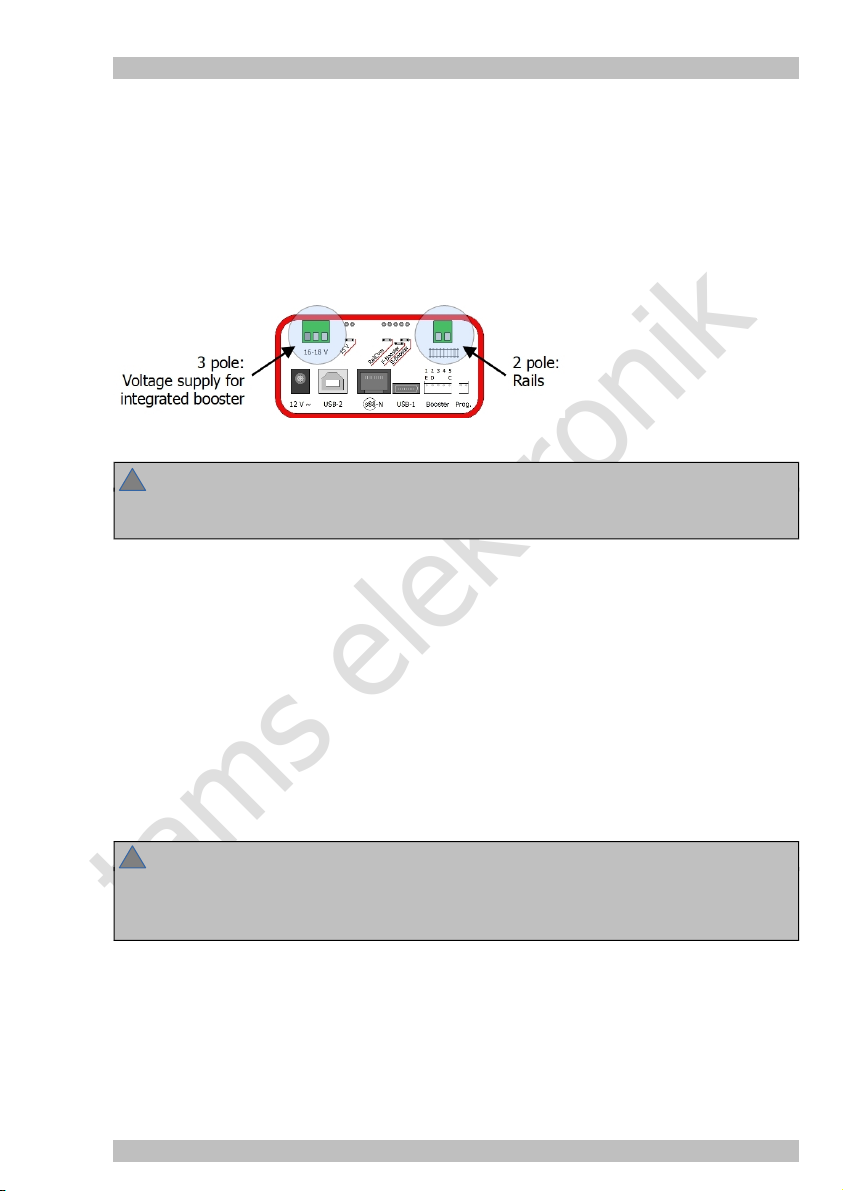

4.6.1. Connecting voltage supply and rails

There are plug-in type terminals for connecting voltage supply and rails on the rear sides of the

versions "Booster" and "Booster-R". Insert the connecting cables into the plug-in parts (included

in delivery), tighten the screws and insert them into the socket parts on the rear side of your

RedBox.

Voltage supply (transformer or power supply unit): 3 pole, connection "16-18 V"

Rails: 2 pole, connection "rails"

Attention:

!

Do not interchange the connections for voltage supply and rails. In this case, your RedBox

probably will be damaged when put into operation!

Recommended cable cross sections

Voltage supply: minimum 0.75 mm²

Rail connection: minimum 1.5 mm²

Voltage supply for the integrated booster

For the integrated booster a separate voltage supply is required:

a.c. transformer with an output voltage of

12 - 15 V (with 15 V track voltage) or

16 - 18 V (with 19 V track voltage)

power supply unit with a set voltage of

17 - 18 V (with 15 V track voltage) oder

21 - 22 V (with 19 V track voltage)

Attention:

!

The output voltage of transformer or power supply unit should not exceed the specified values

as the booster has to dissipate the surplus voltage as heat. The integrated booster possibly

overheats. Risk of fire!

Connection to the rails

You should connect the two rail connections of the integrated booster to the two rails (with 2 rail

systems) or one rail and the middle conductor (with 3 rail systems). The booster current should be

fed into the rails every 2 to 3 m, as the resistances at the track pieces´ transistions are quite high.

In case the distances are too long, problems with reporting short circuits or the vehicles´power

supply possibly occur.

Seite 29

Page 30

tams elektronik

RedBox English

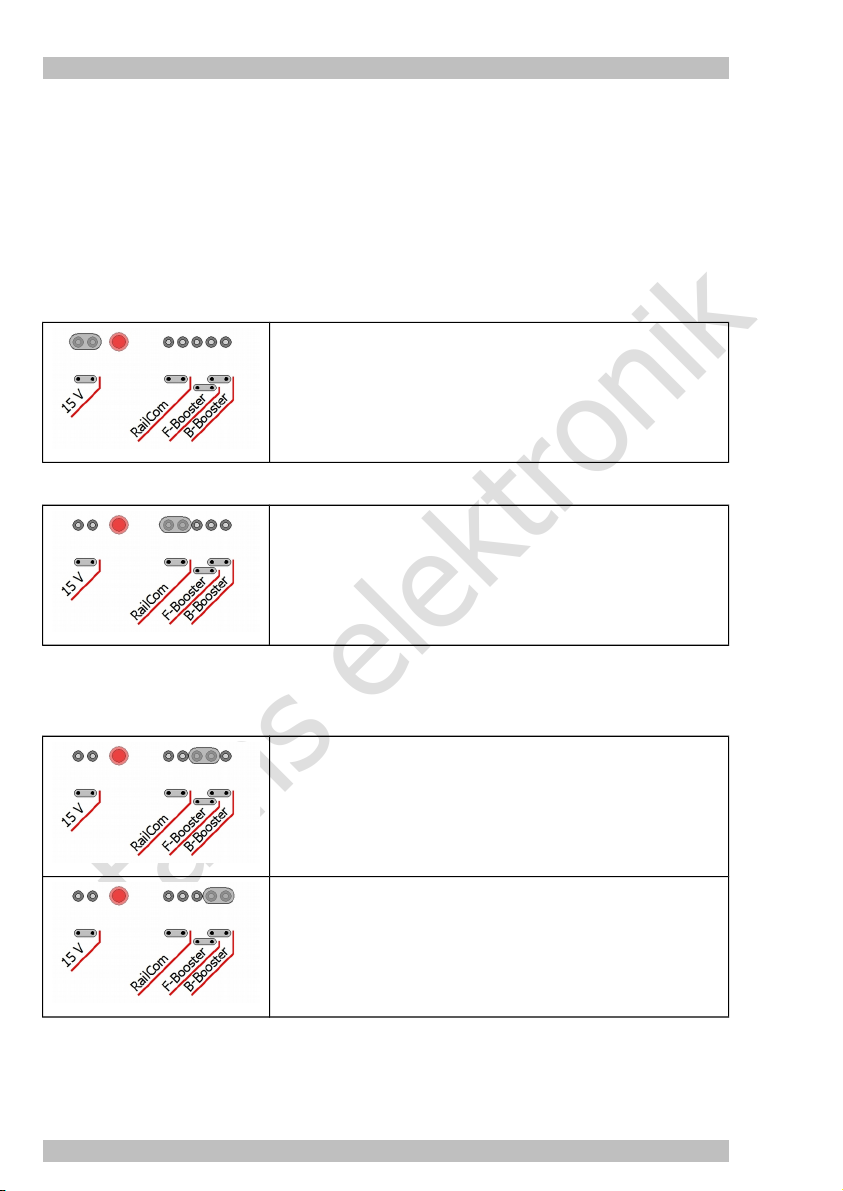

4.6.2. Configurating the integrated booster

On the rear side of your RedBox there are several pin headers, you can bypass with jumpers or

not to make settings:

15 V: setting the track voltage

RailCom: RailCom cutout on or off

F-Booster and B-Booster: Using the integrated booster as standard booster ("driving booster")

or as breaking booster

Setting the track voltage

Jumper set: 15 V (regulated)

Jumper not set: 19 V (regulated)

RailCom® cutout on / off

Jumper set: RailCom cutout switched on

Jumper not set: RailCom cutout switched off

Recommendation: If not using RailCom as feedback system,

you should switch off the RailCom cutout (jumper not set).

Choosing standard or breaking booster

You have to insert the jumper either ro F-Booster or B-Booster. When the jumper is not set, the

booster has no function, as a display the LED flashes.

Jumper set to F-Booster:

Use of the integrated booster as "standard booster" (driving

booster). At the booster output "normal" digital commands are

available to control vehicle and accessory decoders.

Jumper set to B-Booster:

Use of the integrated booster as "breaking booster". At the

booster output digital commands are available to control

vehicle and accessory decoders. For the vehicle decoders is

sent speed level "0" – regardless of the actually set value.

Seite 30

Page 31

tams elektronik

English RedBox

4.6.3. Driving and switching separately with one RedBox

You can configurate the integrated booster (for use as driving or breaking booster) that way,

sending digital commands to control accessory decoders will be suppressed. In doing so, you

prevent the transfer of vehicle commands being interrupted by sending commands for accessory

decoders. You need a PC (with program CV-Navi or control software) to set your RedBox to this

use.

Please note: The settings made for use as "standard booster" (driving booster) apply to all

external boosters as well. Basically, 4 different settings are possible. For most uses the following

setting makes sense:

Jumper set to B-Booster

+ no accessory commands to driving booster

This is the standard setting when sending commands for

vehicle and accessory decoders separately. The integrated

booster controls and supplies the accessory decoders, external

boosters are used to control and supply the vehicle decoders.

With this setting, it is possible to use the integrated booster as

a breaking booster as well.

Example of use: The integrated booster controls and supplies the accessory decoders. At the

interface for external boosters the accessory decoder commands are suppressed. The external

boosters tranfer driving commands for vehicle decoders only.

Seite 31

Page 32

tams elektronik

RedBox English

4.7. S88 feedback modules

You can connect a maximum of 52 s88 feedback modules or s88 compatible modules (with a

maximum of 832 contacts). It is possible to connect feedback modules with connections

according to the standard s88-N directly by using patch cables with RJ 45 connectors. In order

to connect previous modules with 6 pole pin connectors to your RedBox, you need an adapter

s88-A-SR or s88-A-BR. Please observe the manual for your s88 module!

à Section 11: Background information

Attention:

!

There are s88 feedback modules with RJ 45 connectors available which do not comply with the

standard s88-N. You should not connect these modules to your RedBox. When put into

operation, the RedBox and/or connected modules possibly are damaged.

Figure: Connection s88 modulen (max. 52 with 832 contacts)

Seite 32

Page 33

tams elektronik

English RedBox

4.8. Programming track

You can use the programming track

to read out and program vehicles decoders for the DCC format

to program the addresses of vehicles decoders for the mfx format and to read out their UID

Please have a look into the decoder´s manual to find out which programming modes can be

used and which parameters can be set.

Please not: It is not possible to program pure Motorola vehicle decoders on the programming

track, as this format does not provide this programming mode. Motorola decoders have to be

programmed on the main track according to the manufacturer´s specifications.

In order to make settings for the decoder on the programming track you need:

a piece of rails, which you connect to the programming track connection "Prog" of your

RedBox by means of the included connecting cable

an EasyControl device with software status 2.0 or higher (e.g.. LokControl, HandControl,

HandControl 2) or

a PC with software CV-Navi or a control software supporting the programming of decoders or

a mobile Android device (smartphone, tablet) with app "EasyControl Android", connected viy

a Raspberry Pi to the RedBox

Attention:

!

When integrating the programming track into your layout (e.g. as siding) you have to make

sure that both rails are disconnected from the rest of your layout.

If not, the connection for the programming track possibliy will be damaged!

Moreover, you would program every DCC decoder on your model railway.

4.9. Power supply for control devices

The power for your RedBox is supplied by an AC power pack (included in the scope of supply).

One AC power pack can handle the central unit and up to four additional control units. To use

more, a separate AC power pack can be connected to the BusControl.

Connect the power pack to the connection "12 V ~" on the rear side of the RedBox and the

power socket. As soon as the RedBox is ready for operation, the red LED on the front side lights

up.

Hint: The power pack supply the RedBox and up to four additional control units only, but not the

booster integrated in the versions "Booster" or "Booster-R". For supplying the integrated booster

(and rails) you need a transformer or a power supply unit.

→ Section 4.5.: Integrated booster

Seite 33

Page 34

tams elektronik

RedBox English

Seite 34

Page 35

tams elektronik

English RedBox

5. Adjusting parameters of the digital control

You can combine EasyControl with different types of devices. In the system parameters, you

have to define which types of devices (booster, decoders, etc.) you use, to ensure error-free

control of the devices.

Your RedBox does not allow to display, enter or edit the system parameters. For that purpose

you can use:

EasyControl devices (e.g. MasterControl, LokControl, HandControl, HandControl 2): The

devices must have a software version from 2.0. The manuals from version 07/2018 which are

available for free download on our homepage, give further information how to proceed.

PC (with software CV-Navi or control software with EasyControl support)

mobile Android smartphone or tablet with app "EasyControl Android" and Raspberry Pi

Setting duration of the signal pause in the Motorola format

These settings only apply to vehicle decoders in the Motorola format. It’s recommended to set

the signal pause to 1.5 ms. Only if problems with Motorola I decoders occur in operation mode,

should you change the setting to 4.025 ms.

Default value Possible settings

short

Configuring the boosters

The settings of both the booster type (Motorola or DCC) and the short circuit polarity apply to all

connected (external) boosters.

Default value Possible settings

DCC booster

Short circuit polarity

= 100 ms

short (= 1.5 ms)

long (= 4.025 ms)

DCC (conform) booster: short circuit polarity = "negative"

MM-(kompatible) booster: short circuit polarity = "positive"

Value range: AUS, 5, 10, 15, ... 1000 ms

Hint: The lower the set value, the faster the short circuit detection reacts and

booster outputs are switched off. Please note: A high value can cause "welding" in

case of a short circuit (especially in combination with a powerful booster).

Seite 35

Page 36

tams elektronik

RedBox English

Setting standard data format for vehicle decoders

This setting will be set as standard for the programming of all locomotive and function decoders.

Default value Possible settings

DCC format, 28 speed levels DCC format, 28 speed levels

Motorola format, 14 speed levels

You have to alter the settings in the locomotive data base if you want to control specific vehicle

decoders with a different format or number of speed levels. Make changes in the data base

with an EasyControl device: using the locomotive menu

with a PC: using the program "CV-Navi" or a control software

with a smartphone or tablet and a Raspberry Pi: using the app "EasyControl Android"

RailCom support

Default value Possible settings

++ Accessory

Booster options (for versions "Booster" and "Booster-R" only)

It is possible to suppress the output of accessory decoder commands individually for driving and

breaking booster, for none of them, or for both boosters. When using the integrated booster to

control accessory decoders ("switching") and the external booster(s) to control vehicle decoders

("driving"), you have to

off (0): The Railcom support is switched off.

Tailbits (1): There will be left space for the RailCom cutout

during data transfer.

+ IdNotify (2):The central unit sends regularly it´s

identification (in addition to Tailbits).

++ Accessory (3): The central unit sends regularly a point

command, to allow the points decoders sending feedback

signal (in addition to Tailbits and IdNotify).

put the jumper on "B-Booster"

adjust the booster option to "no accessory commands for driving booster"

Default value Possible settings

--- --no accessory commands for driving booster

no accessory commands for breaking booster

no accessory commands for driving and breaking booster

Hint: Normally, "no accessory commands for driving booster" is the only appropriate

setting.

Seite 36

Page 37

tams elektronik

English RedBox

Setting the number of s88 modules

Default value Possible settings

0 Value range: 0, 1, 2, 3….52

Setting switching time of solenoid accessory decoders

The setting applies to all solenoid accessory decoders.

Default value Possible settings

minimum switching time:

100 ms

maximum switching time:

5.0 s

Setting interface baud rate (version "V24" only)

Default value Possible settings

57600 Baud

Value range: 0, 50, 100, 150 ... 1000 ms

Hint: When setting a certain minimum switching time, you can switch points by

quickly tapping the function key, although the points need a longer switching time.

Value range: 0.1 , 0.2 , 0.3, 0.4 ... 25.5 s

Hint: By setting a certain maximum switching time, you can prevent damages at the

points caused by too long switching times.

Value range: 1200, 2400, 4800, 9600, 14400, 19200, 38400,

57600

Hints:

When using the serial interface, this value has to be set according to your PC

interface configuration.

The USB interface is 57600 and can’t be changed.

Seite 37

Page 38

tams elektronik

RedBox English

Seite 38

Page 39

tams elektronik

English RedBox

6. Operation

6.1. Switching on / off

Switching on your RedBox

After switching on the power supply for your RedBox, the connected booster(s) first have no

power, meaning that your track also has no power. The red LED in the "stop"-button is

illuminated.

Push the button "go" to switch on the boster(s). The green LED in the "go"-button is illuminated.

Switching off your RedBox

You can switch off all boosters by pressing "stop". If for instance two trains are about to crash,

you can stop the operation of your model railroad. Please note: The current speed levels and

function statuses are not discarded! As soon as you start operation again by pressing "go" all

active locomotives start moving as before.

Attention! Some locomotive decoders have additional power buffers, which can support a

locomotive when power is cut. Before operating such a decoder, please check how much

energy is stored and which of the locomotives is able to move without power, otherwise cutting

power to the booster(s) might not prevent a crash.

6.2. Plug and play

You can establish or interrupt connections of external devices or adapters to the EasyNet at any

time – even during ongoing operation (plug and play).

Seite 39

Page 40

tams elektronik

RedBox English

6.3. LED displays on the front side

The two buttons "go" and "stop" have an integrated red or rather red LED. The LEDs show the

operating mode of your RedBox.

red off

green off

red permanently on

green off

red off

green permanently on

red fast flashing A booster has reported a short circuit. As a consequent, the

green off

red slow flashing The update mode has been started for the RedBox.

green off

red

green

alternating

flashing

The RedBox has not been connected to the power supply.

The RedBox has been swithed on.

All boosters are switched off.

The RedBox has been swithed on. .

All boosters have been swithed on

RedBox has switched off the track power.

After having eliminated the short circuit, you have to push "go"

in order to restart operation.

In order to return to standard operation, you have to switch off

the RedBox (shortly interrupt the power supply).

Hint: Do not finish the update mode, after the software transfer has been started.

The update mode has been started for the external devices.

In order to return to standard operation, you have to switch off

the RedBox (shortly interrupt the power supply).

6.4. LED displays on the rear side (versions "Booster" and "Booster-R" only)

The LED on the rear side shows operating modes or issues encountered for the integrated

booster.

off RedBox and boosters are switched off.

permanently on RedBox and boosters are switched on.

slow flashing

(approx. once per second)

The booster does not receive signals from the central unit.

Please check,

if the central unit has been set to "stop".

if the jumper has been set to B-Booster or F-Booster. If not,

insert the jumper.

fast flashing A short circuit has occured at the track output, whereupon the

RedBox has switched off the track voltage.

After having eliminated the short circuit, you have to push "go"

in order to restart operation.

Seite 40

Page 41

tams elektronik

English RedBox

7. Update

Your RedBox and other EasyControl devices are state-of-the-art products, which are constantly

improved and adapted to occurring changes. To benefit from this development, you can update

the devcies to the newest software version.

Please note: All EasyControl devices used in one digital control system must have the same

software version! Otherwise malfunction of data transfer between the devices might occur.

You can download the most recent version of the software (firmware) for free from our

homepage (area "Download"). In order to perform the update, you need

a PC running Microsoft Windows or Linux and internet access

an USB cable (or when using the version "V24" a serial cable)

Software "CV-Navi", which you can download from our hoemage for free

If you cannot or do not want to perform the update yourself, you can send us your RedBox to

update it. In case you use further EasyControl devices together with your RedBox, you have to

send them in for update as well. The update is free of charge, we only charge the return

expenses according to our valid price list.

Software-Update for your RedBox

First, download the firmware (i.e. the software running the RedBox) from our homepage on your

PC. You find the firmware under:

www.tams-online.de/download/firmware

Then, switch off the RedBox. Simultaneously pressing "stop" and "go" switch the power back on,

while holding both keys. The red LED on the front side of the RedBox flashes and the green LED

is off.

Now please connect the MasterControl to your PC and execute the update application.

Please note: Always connect the MasterControl to your PC before executing the update

application. Otherwise your PC might have difficulties detecting the interface.

Follow the instructions of the update application.

Seite 41

Page 42

tams elektronik

RedBox English

8. Check list for troubleshooting

8.1. Errors occurring while starting up

After switching on track power, the locomotive responds to switching on / off its functions,

but not to turning a control device´s speed control knob.

Possible reason: The integrated booster (versions "Booster" and "Booster-R") has been

configurated as breaking booster and always sends a "0" as speed level. à Alter the

integrated booster´s configuration by putting the jumper on "F-Booster".

When switching on the booster by pressing "go", your RedBox switches off immediately, the

red LED in the "stop"-button flashes quickly.

Possible reason: The short circuit polarity settings of the booster(s) are wrong. à Change the

short circuit polarity settings.

Versions "Booster" and "Booster-R": After switching on the RedBox and pushing the "go"-

button the green LED in the "go-button" and the red LED of the integrated booster on the

rear side are illuminated. Nevertheless, the locomotives do not respond to turning a control

device´s speed control knob.

Possible reason: The power supply for the booster (transformer, switching power-supply)

have not been connected properly or not been switched on. à Check the booster´s power

supply.

8.2. Errors occurring while setting parameters

When programming a DCC decoder an error is displayed.

Possible reason: You’ve choosen a programming method not supported by the decoder.

à See the manual of the decoder for supported programming methods.

You cannot test all s88 modules, although their connection is ok.

Possible reason: The setting for the amount of s88 modules is wrong. à Change the setting

for the amount of s88 modules.

8.3. Errors occurring while operating

A locomotive does not respond to driving or function commands, although you entered the

right address.

Possible reason: The decoder is assigned a wrong format. à Change the data format.

A locomotive with DCC decoder immediately drives fast, although in speed level 1.

Possible reason: The decoder only supports 14 or 28 speed levels, but is assigned 128 ones.

à Change the amount of speed levels.

You can’t switch on / off lights on a locomotive with DCC decoder and / or when accelerating,

the lights flicker.

Possible reason: The speed level settings of both decoder and and in the locomotive data

base do not match. à Change the speed level settings of the decoder or in the data base.

Seite 42

Page 43

tams elektronik

English RedBox

When accelerating a locomotive with a Motorola decoder, only every second speed level

increases the locomotive’s speed.

Possible reason: The locomotive decoder was assigned speed level "27 a" or "27 b", but the

locomotive decoder only supports 14 speed levels. à Change the amount of speed levels in

the locomotive data base.

In operation mode, locomotives with Motorola I decoders are causing problems: They do not

respond to driving or function commands or have an odd driving behaviour.

Possible reason: The duration of the signal pause is set inaccurately. à Change the duration

of the signal pause.

The two locomotives in double traction move in opposite directions.

Possible reason: Before establishing a double traction, you did not set the driving direction for

both locomotives. à Repeat the creation of the double traction.

The points cannot be switched.

Possible reason: The point format is wrong. à Change the points format.

The RedBox does not respond to software commands of a connected PC.

The connection between MasterControl and PC is bad. à Check your cable. Also check, if the

right COM port is set in the software.

Possible reason (version "V24" only): The baud rate has been set faultily. à Alter the baud

rate.

8.4. Errors occurring during software update

After the software update, the RedBox won’t start.

Possible reason: You updated using the wrong software file, for instance an update for the

LokControl. à Update again.

While updating, the progress bar jumps back (often).

This is not an error. The update application checks continuously, if the data transferred is

correct. If this is not the case, it repeats the transfer.

Hotline

If problems with your device occur, our hotline is pleased to help you (mail address on the last

page).

Repairs

You can send in a defective device for repair (address on the last page). In case of guarantee

the repair is free of charge for you. With damages not covered by guarantee, the maximum fee

for the repair is 50 % of the current sales price according to our valid price list. We reserve the

right to reject the repairing of a module when the repair is impossible for technical or economic

reasons.

Please do not send in devices for repair charged to us. In case of warranty we will reimburse

the forwarding expenses up to the flat rate we charge according to our valid price list for the

delivery of the product. With repairs not covered by guarantee you have to bear the expenses

for sending back and forth.

Seite 43

Page 44

tams elektronik

RedBox English

9. Technical Specifications

9.1. RedBox

Motorola-I and –II

Data formats

Power supply 12 volts AC

Power consumption (without consumer) approx. 200 mA

Interfaces for the connection of

external control devices

PC interfaces

(galvanically isolated)

Other interfaces

Maximum amount of s88 modules

Vehicle decoder addresses

Speed levels

Functions

Accessory decoder addresses

DCC (corresponding to NMRA-and RCN-standard)

m3 (for driving mfx decoders)

EasyNet (RJ 45)

XpressNet (RJ 12)

Versions "Basic", "Basic-R", "Booster", "Booster-R":

USB-1 type Mini-B with Tams identifier

USB-2 type B with SiLabs identifier

Version "V24":

one serial interface (baud rate adjustable)

one USB interface with Tams identifier

Booster (optionally compatible with Märklin or DCC

conform)

DCC programming track

s88 feedback module (corresponding to standard s88-N)

Power supply

52 s88 or s88 compatible modules

(832 contacts)

Motorola: 255 (1 – 255)

DCC: 10239 (1 – 10239)

m3: 16384

Motorola: 14 or 27 (a or b)

DCC: 14, 28 or 128

m3: 128

Motorola: function, f1 to f4

DCC: f0 to f28 resp. f32768

m3: f0, f1 to f15

Motorola: 1020 (1 – 1020)

DCC: 2040 (1 – 2040)

m3: ---

Seite 44

Page 45

tams elektronik

English RedBox

Protection IP 00

Ambient temperature while operating 0 - + 60 °C

Ambient temperature in storage - 10 to + 80 °C

Comparative humidity allowed max. 85 %

Dimensions (approx.) 95 x 135 x 45 mm

Version "Basic" 160 g

Version "Basic-R" 172 g

Weight (approx.)

9.2. Integrated Booster (Versions "Booster" and "Booster-R")

Version "Booster" 215 g

Version "Booster-R" 217 g

Version "V24" 170 g

Supply voltage

Output voltage 15 or 19 volts digital voltage (regulated)

Power consumption max. 48 watt

Maximum output current 2,5 A

Data formats

Feedback log RailCom (RailCom cutout can be switched off)

Output signal symmetrical

16 - 18 volts AC voltage or

17 – 22 volts DC voltage

DCC, Motorola

mfx (vehicle decoder commands only)

Seite 45

Page 46

tams elektronik

RedBox English

10. Background information

10.1. Motorola-Format

Märklin** originally introduced the Motorola format, using Chips from Motorola, hence the name.

First, only 80 addresses could be used, later this was extended to 255.

Data transfer in the Motorola format

Data is transferred in so called packets, which are sent with pauses in between. This kind of

data transfer results in DC power on the track. Hence, locomotives without decoder start moving

as soon as they are put on the track.

The previously developed Motorola I format relies on sending packets on two different

frequencies: One data packet contains the address information, the 14 speed level data, and the

status of one function and is continuously sent. A theoretically possible 15th speed level is used

to switch driving directions. The information about the state of additional functions is sent in the

second packet. This is only sent, if the status changes.

The later developed Motorola II format relies on sending one packet continuously: This packet

contains the address and the speed levels as well as additional information about the status of

the four functions and the absolute driving direction. The Motorola II format allows only 14

speed levels as well. In the meantime, decoders have become available, which support 27 speed

levels by adding additional “half levels” in between the existing speed levels.

Compatibility of both Motorola formats

Regardless which of the two Motorola format the decoder receives, it can change the speed

level, the driving direction and the function “light” correctly. To be able to use the four additional

functions, it must be controlled using the appropriate format.

Driving solenoid accessory decoders for the Motorola format

The information to switch solenoid accessory decoders (points und switching decoders) is sent in

the same second data packet in the Motorola I format as the information of the four additional

functions. In the Motorola II format, this second packet only contains information to drive

solenoid accessory decoders. This data packet is only sent, when the status of solenoid

accessory decoders changes.

With 80 addresses this adds up to 80 x 4 = 320, with 255 to 255 x 4 = 1020 addresses.

When calling address from a control unit, it must distinguish between locomotive and solenoid

accessory decoders, in order to control both. It depends on the control unit how this is done.

Seite 46

Page 47

tams elektronik

English RedBox

10.2. DCC-Format

The DCC format was developed by LENZ** and later declared as standard by the NMRA

(National Model Railroad Association). Meanwhile the RailCommunity (Association of

Manufacturers of Model Railcroad Products) maintains and advances this standard.

Data transfer in the DCC format

In the DCC format, data is transferred continuously and thus there is no DC power on the track.

Hence, different to Motorola formats, locomotives without decoders do not automatically start

moving when put on the track. It is possible to control one decoderless locomotive from the

central unit in DCC layouts, because the analog driving signals are laid over the digital signals.

Nonetheless, this feature is not recommended, as it tends to damage the engine electrics. This is

the reason why it is not supported in EasyControl.

Possibilities of the DCC format

The DCC format features up to 10239 addresses, up to 28 (or 32768) functions and up to 128

speed levels as well as an absolute driving direction. How may addresses, functions and speed

levels can actually be used depends on component limits such as the limits of decoders or the

central unit.

CV programming

Today’s CV programming allows you to set a decoders properties by setting the so-called

configuration variables (CV variables). The meaning of each variable is clearly defined by the

NMRA. Each variable has 8 bits and can contain the values of 0 to 255. To be able to use

extended addresses, one address uses two CV variables. The values can be transferred bitwise

or bytewise. Bitwise transfer only makes sense if each bit has its’ own property (e.g. CV# 29). In

the table in ssection 10.2. you can find the most commonly used CV variables and their possible

values.

Page programming and register programming

Before CV programming, there was register programming and page programming.

The possibilities to set the decoder properties are limited when page programming is used.

There are only 8 registers to program (primary address, Vstart, acceleration rate, deceleration

rate, configuration data, manufacturer version No., manufacturer ID). The possible values of the

register variables are analog to those of the CV variables.

Page programming offers the same possibilities as CV programming. The properties of the

decoder are set in register variables. 4 registers make one page. The pages are adjacent

(register 1 to 4 on Page 0, register 5 to 8 on page 1, and so on) so a register can be accessed

directly while programming.

Seite 47

Page 48

tams elektronik

RedBox English

Configuration variables for the DCC format (exert)

CV# CV name Value

(Default value)

1 Primary address 0 ... 127

(3)

2 Vstart 0 ... 255

(-)

3 Acceleration rate 0 ... 255

(-)

4 Deceleration rate 0 ... 255

(-)

5 Vhigh 0 ... 255

(0)

6 Vmid 1 ... 255

(1)

7 Manufacturer

version No.

8 Manufacturer ID e.g. 62 In this case: Tams Elektronik GmbH

9 Total PWM period 0 ... 255

17 + 18Extended address 1 ... 10239

19 Consist address 0 ... 127

29 Configuration data#10 ... 255

33 – 46Output Loc. FL(f),

FL(r), F1-F12

1 ... 255 This is the version number of the decoder’s internal

(0)

(-)

(-)

(-)

0 ... 255

(-)

Explanations

The primary address contains a value between 1 and

127. Is the CV#1 equal to 0, the decoder switches to

analog mode.

Defines the current powering the engine at minimum

speed.

Defines the duration of the pause while switching up

to the next higher speed level.

Defines the duration of the pause while switching

down to the next lower speed level.

Defines the current powering the engine at maximum

speed.

Defines the current powering the engine at moderate

speed.

software.

The current powering the electric motors is facilitated

by switching on / off the power. The interval

between those power peeks is called PMW period. By

altering the PMW period, the individual running

characteristics of an electric motor are changed.

Defines the address between 1 and 10239, if the

decoder is set to extended addresses.

Defines the alternate (second) address of the

decoder.

Defines main properties of the decoder: Driving

direction, amount of speed steps, switching to analog

operation, additional feedback while in programming

mode, choice of the speed table, primary addresses

or extended addresses.

Contains a matrix indication of which function inputs

control which Digital Decoder outputs.

Seite 48

Page 49

tams elektronik

English RedBox

CV# CV name Value

(Default value)

49 – 64Manufacturer

Unique

67 – 94Speed Table

(only in 28 speed

steps mode)

0 ... 255

(-)

0 ... 255

(-)

Explanations