Page 1

tams elektronik

Manual

Minitimer MT-1

"Time Switch"

Item 51-01015 | 51-01016 | 51-01017

Minitimer MT-2

"Delayed switching"

Item 51-01025 | 51-01026 | 51-01027

Minitimer MT-3

"Pulse delay"

Item 51-01035 | 51-01036 | 51-01037

tams elektronik

n n n

Page 2

tams elektronik

English MT-1 | MT-2 | MT-3

Contents

1. Getting started............................................................................3

2. Safety instructions.......................................................................5

3. Safe and correct soldering...........................................................7

4. Operation overview.....................................................................9

5. Technical specifications..............................................................12

6. Assembling the kit.....................................................................13

7. Performing a functional test.......................................................22

8. Connecting the MT-1.................................................................23

9. Connecting the MT-2.................................................................26

10. Connecting the MT-3.................................................................29

11. Check list for troubleshooting.....................................................32

12. Guarantee bond........................................................................34

13. EU Declaration of Conformity.....................................................35

14. Declarations concerning the WEEE directive................................35

Version 2.5 08/2021

© Tams Elektronik GmbH

All rights reserved, in particular the right of reproduction, distribution

and translation. Copies, reproductions and alterations in any form

require the written permission of Tams Elektronik GmbH. We reserve

the right to make technical changes.

Printing the manual

The formatting is optimised for double-sided printing. The standard

page size is DIN A6. If you prefer a larger display, printing on DIN A5 is

recommended.

Seite 2

Page 3

tams elektronik

!

MT-1 | MT-2 | MT-3 English

1. Getting started

How to use this manual

This manual gives step-by-step instructions for safe and correct

assembly of the kit and fitting and connecting of the ready-built

module, and operation. Before you start, we advise you to read the

whole manual, particularly the chapter on safety instructions and the

checklist for trouble shooting. You will then know where to take care

and how to prevent mistakes which take a lot of effort to correct.

Keep this manual safely so that you can solve problems in the future. If

you pass the kit or the ready-built module on to another person, please

pass on the manual with it.

Intended use

The minitimers MT-1, MT-2 and MT-3 are designed to be operated

according to the instructions in this manual in model building, especially

with model railways. Any other use is inappropriate and invalidates any

guarantees.

The minitimers MT-1, MT-2 and MT-3 should not be assembled or

mounted by children under the age of 14.

Reading, understanding and following the instructions in this manual

are mandatory for the user.

Caution:

The minitimer MT-3 contains integrated circuits. These are very

sensitive to static electricity. Do not touch components without first

discharging yourself. Touching a radiator or other grounded metal part

will discharge you.

Seite 3

Page 4

tams elektronik

English MT-1 | MT-2 | MT-3

Checking the package contents

Please make sure that your package contains:

one kit, containing the components listed in the parts list and one

PCB:

MT-1 page 17

MT-2 page 18

MT-3 page 19

or one ready-built module

or one ready-built module in a housing (complete unit).

Required materials

To assemble the kit you will need

a soldering iron with temperature control and a thin tip and a deposit

stand or a controlled soldering station

a scraper, rag or sponge

a heat-resistant pad

a small pair of side cutters and wire strippers

tweezers and flat-nose pliers if necessary

electronic solder (preferably 0.5 to 0.8 mm diameter)

For testing the module you need an electric light bulb.

In order to connect the module you need wire. Recommended

diameters: > 0,14 mm² for all connections.

In order to activate the circuit you need :

MT-1

push-button

e.g. push-button item no. 85-5212x, x=1,2,3,6,7

MT-2

switch

e.g. toggle switch 1xUm item no. 84-51510

MT-3

push-button

e.g. push-button item no. 85-5212x, x=1,2,3,6,7

Seite 4

Page 5

tams elektronik

MT-1 | MT-2 | MT-3 English

In order to connect the devices you possibly need a relay (see sections

8, 9 and 10):

MT-1 relay 12 V e.g. relay 1xUm 12 V, item no. 84-61010

MT-2 relay 5 V e.g. relay 2xUm 5 V, item no. 84-61020 and

protective diode 1N4148, item no.83-11100

MT-3 relay 12 V e.g. relay 1xUm 12 V, Art.-Nr. 84-61010

2. Safety instructions

Mechanical hazards

Cut wires can have sharp ends and can cause serious injuries. Watch

out for sharp edges when you pick up the PCB.

Visibly damaged parts can cause unpredictable danger. Do not use

damaged parts: recycle and replace them with new ones.

Electrical hazards

Touching powered, live components,

touching conducting components which are live due to malfunction,

short circuits and connecting the circuit to another voltage than

specified,

impermissibly high humidity and condensation build up

can cause serious injury due to electrical shock. Take the following

precautions to prevent this danger:

Never perform wiring on a powered module.

Assembling and mounting the kit should only be done in closed,

clean, dry rooms. Beware of humidity.

Only use low power for this module as described in this manual and

only use certified transformers.

Connect transformers and soldering irons only in approved mains

sockets installed by an authorised electrician.

Seite 5

Page 6

tams elektronik

English MT-1 | MT-2 | MT-3

Observe cable diameter requirements.

After condensation build up, allow a minimum of 2 hours for

dispersion.

Use only original spare parts if you have to repair the kit or the

ready-built module.

Fire risk

Touching flammable material with a hot soldering iron can cause fire,

which can result in injury or death through burns or suffocation.

Connect your soldering iron or soldering station only when actually

needed. Always keep the soldering iron away from inflammable

materials. Use a suitable soldering iron stand. Never leave a hot

soldering iron or station unattended.

Thermal danger

A hot soldering iron or liquid solder accidentally touching your skin can

cause skin burns. As a precaution:

use a heat-resistant mat during soldering,

always put the hot soldering iron in the soldering iron stand,

point the soldering iron tip carefully when soldering, and

remove liquid solder with a thick wet rag or wet sponge from the

soldering tip.

Dangerous environments

A working area that is too small or cramped is unsuitable and can cause

accidents, fires and injury. Prevent this by working in a clean, dry room

with enough freedom of movement.

Other dangers

Children can cause any of the accidents mentioned above because they

are inattentive and not responsible enough. Children under the age of

14 should not be allowed to work with this kit or the ready-built

module.

Seite 6

Page 7

tams elektronik

!

!

MT-1 | MT-2 | MT-3 English

Caution:

Little children can swallow small components with sharp edges, with

fatal results! Do not allow components to reach small children.

In schools, training centres, clubs and workshops, assembly must be

supervised by qualified personnel.

In industrial institutions, health and safety regulations applying to

electronic work must be adhered to.

3. Safe and correct soldering

Caution:

Incorrect soldering can coffe dangers through fires and heat. Avoid

these dangers by reading and following the directions given in the

chapter Safety instructions.

Use a soldering iron with temperature control, which you set to

approx. 300 °C.

Only use electronic solder with a flux.

Never use soldering water or soldering grease when soldering

electronic circuits. These contain an acid that destroys components

and conductor paths.

Insert the connecting wires of the components as far as possible

through the holes of the board without using force. The body of the

component should be close above the board.

Make sure that the polarity of the components is correct before

soldering them.

Solder quickly: soldering for too long can coffe pads or tracks to

become detached or even destroy components.

Hold the soldering tip on the soldering point in such a way that it

touches the component wire and the pad at the same time. Add (not

Seite 7

Page 8

tams elektronik

English MT-1 | MT-2 | MT-3

too much) solder simultaneously. As soon as the solder begins to

flow, remove it from the soldering point. Then wait a moment for the

solder to flow well before removing the soldering iron from the

soldering joint.

Do not move the component you have just soldered for about 5

seconds.

A clean, non-oxidised (scale-free) soldering tip is essential for a

perfect soldering joint and good soldering. Therefore, before each

soldering, wipe off excess solder and dirt with a damp sponge, a

thick damp cloth or a silicone wiper.

After soldering, cut off the connecting wires directly above the

soldering point with a side cutter.

After assembly, always check each circuit again to ensure that all

components are correctly inserted and polarised. Also check that no

connections or tracks have been accidentally bridged with tin. This

can lead not only to malfunction, but also to the destruction of

expensive components. You can re-liquefy excess solder with the

clean hot soldering tip. The solder then flows from the board to the

soldering tip.

Seite 8

Page 9

tams elektronik

MT-1 | MT-2 | MT-3 English

4. Operation overview

Minitimer MT-1 "Time Switch"

The minitimer MT-1 is designed for controlling operations in model

railways which are supposed to last for 1 to 100 seconds. The desired

switching time is set via a trimming potentiometer.

Examples of use: Automatic opening of the gate at a level crossing after

a certain time, automatic stop of trains at the platform for a certain

time.

The circuit is triggered by a positive switching pulse at the module´s

input, for instance via a key switch or a reed contact. Then the output

is grounded for the preset time.

Devices with a current up to 100 mA intended to be switched on can be

connected directly to the minitimer´s output. Devices with a higher

current or devices intended to be switched off, can be controlled via a

relay. It is also possible to switch over between two devices by

connecting a relay.

Minitimer MT-2 "Delayed switching"

The minitimer MT-2 switches on or off operations in model railways

with a time delay between 0 and 25 seconds. The desired time delay is

set via a trimming potentiometer.

Examples of use: Delay of a locomotive´s start after changing the

signal to "go" (= the engine driver´s reaction time).

The circuit is triggered by grounding the module´s input, e.g. via a

switch. The module´s output is grounded after the preset delay time

has elapsed, the connected device consequently is not switched on until

the delay time is over.

If the earth connection at the module´s input is interrupted, the

connected device is switched off with a time delay of approx. 1 second.

If the time passing between making and interrupting the earth

Seite 9

Page 10

tams elektronik

English MT-1 | MT-2 | MT-3

connection at the module´s input is shorter than the preset delay time,

the connected device stays off.

Devices with a current up to 100 mA intended to be switched on after a

certain delay time can be connected directly to the minitimer´s output.

Devices with a higher current or devices supposed to be switched off

can be controlled via a relay.

Minitimer MT-3 "Pulse delay"

The minitimer MT-3 transfers voltage changes with a time delay

between 0 and 60 seconds to a connected device on a model railway.

The desired time delay is set via a trimming potentiometer.

Examples of use: Delayed triggering of solenoid operated devices

(signals, points, bistable relay), delayed power cut-off in a rail section

after crossing a reed contact in order to release the contact.

The circuit is controlled by an IC saving the voltage changes´sequence

at the module´s input and transferring them with the preset time delay

between 0 and 60 seconds to the output. The time period between two

voltage changes at the module´s input can be as long as you like. The

IC can save up to seven voltage changes within the preset delay time.

With more than seven voltage changes within the preset delay time the

first saved voltage change will be overwritten.

Devices with a current up to 1.000 mA can be connected directly to the

minitimer´s output. Devices with a higher current or devices intended

to be switched invertedly can be controlled via a relay.

Seite 10

Page 11

tams elektronik

MT-1 | MT-2 | MT-3 English

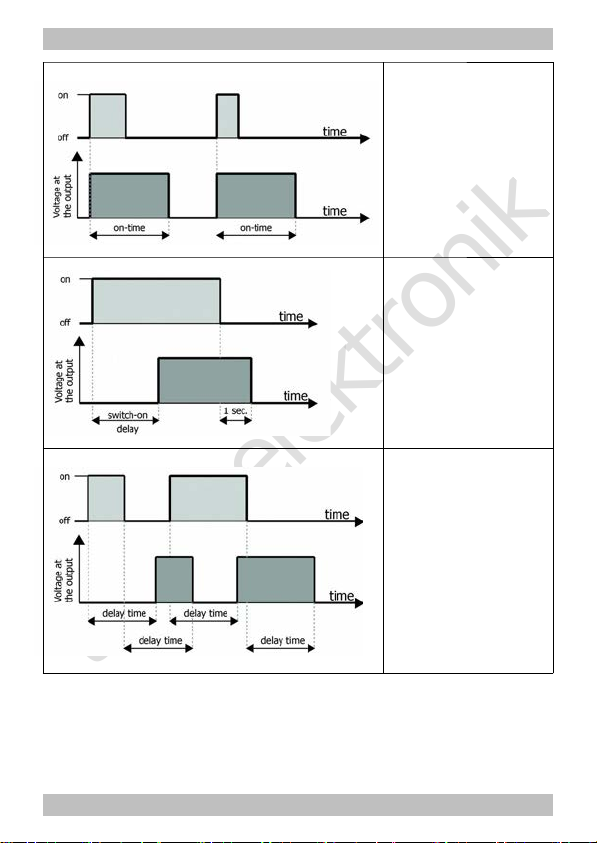

Minitimer MT-1

A = bridging the

switching inputs

B = voltage at the output

U = voltage

t = time

Δt = on-time

Minitimer MT-2

A = voltage at the input

B = voltage at the output

U = voltage

t = time

Δt = switch-on delay

Minitimer MT-3

A = voltage at the input

B = voltage at the output

U = voltage

t = time

Δt = delay time

Seite 11

Page 12

tams elektronik

English MT-1 | MT-2 | MT-3

5. Technical specifications

Supply voltage 12-18 Volt a.c. or d.c. voltage

Current consumption (without

connected devices) approx.

5 mA

Max. current at the output MT-1: 100 mA

MT-2: 100 mA

MT-3: 1.000 mA

Max. switching time (+ 20 %) MT-1: 100 seconds

MT-2: 25 seconds

MT-3: 60 seconds

Protected to

IP 00

Ambient temperature in use 0 ... +60 °C

Ambient temperature in storage -10 ... +80 °C

Comparative humidity allowed max. 85 %

Dimensions

of the PCB (approx.)

including housing (approx.)

48 x 52 mm

70 x 60 x 25 mm

Weight (approx.) assembled

board

including

housing

MT-1 17 g 34 g

MT-2 16 g 33 g

MT-3 19 g 36 g

Seite 12

Page 13

tams elektronik

MT-1 | MT-2 | MT-3 English

6. Assembling the kit

You can skip this part if you have purchased a ready-built module or device.

Preparation

Put the sorted components in front of you on your workbench.

The separate electronic components have the following special features

you should take into account in assembling:

Resistors

Resistors reduce current.

The value of resistors for smaller power ratings is indicated

through colour rings. Every colour stands for another

figure.

Carbon film resistors have 4 colour rings. The 4th ring

(given in brackets here) indicates the tolerance of the

resistor (gold = 5 %).

Value: Colour rings:

1 k brown - black - red (gold)

3,3 k orange - orange - red (gold)

4,7 k yellow - violet - red (gold)

5,6 k green - blue - red (gold)

10 k brown - black - orange (gold)

47 k yellow - violet - orange (gold)

330 k orange - orange - yellow (gold)

Seite 13

Page 14

tams elektronik

English MT-1 | MT-2 | MT-3

Trimm-potentiometers

Trimm-potentiometers (abrv. "trimm-pots") are resistors

which allow the value of resistance to be varied and that

way to be adapted to the particular demands. In the

middle they have a small slot into which a small

screwdriver can be put in order to vary the value of

resistance. The maximum value is printed on the housing.

Depending on the mounting situation trimmpots with a lying or a

standing package are used.

Ceramic capacitors

Among other things ceramic capacitors are used for

filtering interference voltages or as frequency determining

parts. Ceramic capacitors are not polarized.

Normally they are marked with a three-digit number which

indicates the value coded. The number 104 corresponds to

the value 100 nF.

Electrolytic capacitors

Electrolytic capacitors are often used to store energy. In

contrast to ceramic capacitors they are polarized. The

value is given on the package.

Electrolytic capacitors are available with different voltage

sustaining capabilities. Using an electrolytic capacitor with

a voltage sustaining capability higher than required is

always possible.

Seite 14

Page 15

tams elektronik

MT-1 | MT-2 | MT-3 English

Diodes and Zener diodes

Diodes allow the current to pass through in one direction

only (forward direction), simultaneously the voltage is

reduced by 0,3 to 0,8 V. Exceeding of the limit voltage

always will destroy the diode, and allow current to flow in

the reverse direction.

Zener diodes are used for limiting voltages. In contrast to "normal"

diodes they are not destroyed when the limit voltage is exceeded.

The diode type is printed on the package.

Light emitting diodes (LEDs)

When operated in the forward direction the LEDs light.

They are available in several different versions (differing in

colour, size, form, luminosity, maximum current, voltage

limits).

Light emitting diodes should always be connected via a

series resistor which limits the current and prevents failure.

Transistors

Transistors are current amplifiers which convert low signals

into stronger ones. There are several types in different

package forms available. The type designation is printed

on the component.

Transistors for a low power rating (e.g. BC types) have a

package in form of a half zylinder (SOT-package).

Transistors for a high power rating (e.g. BD types) have a

flat package (TO-package), which is in use in different

versions and sizes.

The three pins of bipolar transistors (e.g. BC and BD

types) are called basis, emitter and collector (abbreviated

with the letters B, E, C in the circuit diagram).

Seite 15

Page 16

tams elektronik

English MT-1 | MT-2 | MT-3

Integrated circuits (ICs)

Depending on the type, ICs fulfil various tasks. The most

common housing form is the so-called "DIL"-housing, from

which 4, 6, 8, 14, 16, 18 or more "legs" (pins) are

arranged along the long sides.

ICs are sensitive to damage during soldering (heat,

electrostatic charging). For that reason in the place of the

ICs IC sockets are soldered in, in which the ICs are

inserted later.

Microcontrollers

Microcontrollers are ICs, which are individually programmed for the

particular application. The programmed controllers are only available

from the manufacturer of the circuit belonging to it.

Terminal strips

Terminal strips are solder-in screw-type terminals. They provide a

solder-free and safe connection of the cables to the circuit, which can

still be separated any time.

Seite 16

Page 17

tams elektronik

MT-1 | MT-2 | MT-3 English

MT-1: PCB layout and parts list

Resistors R1, R2, R3, R4 3,3 k

R5, R6, R7 1 k

Trim pots R8 500 k

Capacitors C4 100 nF

Electrolytic capacitors C1, C2, C3 220 µF / 25 V

Diodes D2, D3 1N400x, x=2...7

Zener diodes D1 5V1

Transistors Q1, Q2, Q3 BC547B

Terminal strips X1 ... X6

Seite 17

Page 18

tams elektronik

English MT-1 | MT-2 | MT-3

MT-2: PCB layout and parts list

Resistors R1 10 k

R2 5,6 k

R3 1 k

R4, R5, R6 47 k

Trim pots R7 500 k

Diodes D1 1N400x, x=2...7

Electrolytic capacitors C1 100 µF/25 V

C2 470 µF/16 V

Transistors Q1, Q2 BC547B

Q3 BC557

Terminal strips X1, X2

Seite 18

Page 19

tams elektronik

MT-1 | MT-2 | MT-3 English

MT-3: PCB layout and parts list

Resistors R1, R2, R4, R6, R8 1 k

R3 4,7 k

R5 330 k

Trim pots R7 500 k

Diodes D1, D3, D4 1N4148

D5 1N400x, x=2...7

Zener diodes D2 ZD 5V1

LEDs D6

Capacitors C4 100 nF

Electrolytic capacitors C1, C2, C3 220 µF/25 V

Transistors T1 BD679

Micro-Controller / IC sockets IC1 PIC 12F508A

Terminal strips X1, X2

Seite 19

Page 20

tams elektronik

!

English MT-1 | MT-2 | MT-3

Assembly

Proceed according to the order given in the list below. First solder the

components on the solder side of the PCB and then cut the excess

wires with the side cutter. Follow the instructions on soldering in

section 3.

Caution:

Several components have to be mounted according to their polarity. When

soldering these components the wrong way round, they can be damaged

when you connect the power. In the worst case the whole circuit can be

damaged. At the best, a wrongly connected part will not function.

1. Resistors Mounting orientation of no importance.

2. Diodes, Zener

diodes

Observe the polarity!

The negative end of the diodes is marked with

a ring. This is shown in the PCB layout.

3. Ceramic

Capacitors

(MT-1 and MT-3 only)

Mounting orientation of no importance.

4. Transistors Observe the polarity!

The cross section of transistors for a low power

rating in SOT-packages is shown in the PCB

layout.

With transistors for a high power rating in TO

packages (e.g. BD types) the unlabelled back

side is marked in the PCB layout by a thick

line.

5. IC sockets

(MT-3 only)

Mount the sockets that way, the markings on

the sockets show in the same direction as the

markings on the PCB board.

Seite 20

Page 21

tams elektronik

MT-1 | MT-2 | MT-3 English

6. Electrolytic

capacitors

Observe the polarity! One of the two leads (the

shorter one) is marked with a minus sign.

7.

Terminal strips

Put together the terminal strips before

mounting them.

8. Trimmpotentiometers

The mounting orientation is preset by the

layout of the three pins.

9. Light emitting

diodes (LEDs)

(MT-3 only)

Observe the polarity!

With wired LEDs the longer lead is always the

anode (positive pole).

10. ICs in DILhousing

Insert the ICs into the soldered socket.

Do not touch the ICs without first discharging

yourself by touching a radiator or other

grounded metal parts.

Do not bend the "legs" when inserting them

into the sockets. Check that the markings on

the PCB, the socket and the IC show to the

same direction.

Performing a visual check

Perform a visual check after the assembly of the module and remove

faults if necessary:

Remove all loose parts, wire ends or drops of solder from the PCB.

Remove all sharp wire ends.

Check that solder contacts which are close to each other are not

unintentionally connected to each other. Risk of short circuit!

Check that all components are polarised correctly.

When you have remedied all faults, go on to the next part.

Seite 21

Page 22

tams elektronik

!

English MT-1 | MT-2 | MT-3

7. Performing a functional test

With all minitimers it is recommended to check function and switching

times before mounting them. Proceed according to the sections 8. (MT-

1), 9. (MT-2) or 10. (MT-3), but connect a lamp to the outputs for the

devices for the test.

Set the trimm pot as follows:

MT-1: left stop (= shortest possible switching time)

MT-2: middle position (= middle time delay)

MT-3: right stop (= shortest possible delay time)

Connect the minitimer to the power supply and trigger a switching

operation.

Caution:

If a component gets too hot, disconnect the mini-timer and power

supply from the mains immediately. Possible short circuit! Check the

assembly!

Seite 22

Page 23

tams elektronik

!

MT-1 | MT-2 | MT-3 English

8. Connecting the MT-1

Follow the connections diagrams fig. MT-1.1 and MT-1.2 and connect

the minitimer MT-1 as follows:

X1 device

(polarized device "-")

X2 device

(polarized device "+")

X3 transformer

(with direct voltage "+")

X4 transformer

(with direct voltage "^")

X5

X6

switching input

In order to trigger the minitimer MT-1 the switching input (connections

X5 and X6) has to be shunted, e.g. with a key switch. Then, the

connected device will be switched on for a time between 1 and 100

seconds and be switched off after this time.

Caution:

The power consumption of the connected device may not exceed

100 mA, otherwise the module will be destroyed. Devices with a

higher power consumption can be switched via a relay.

Setting the switching time

Set the desired switching time at the trimm pot R8. It is between 1 and

100 seconds (+ 20 %), depending on the settings. With some mounting

situations it makes sense to set the switching time while performing a

functional test with a lamp.

Connecting a relay

In order to switch a device with more than 100 mA power consumption

or to switch off a device you have to connect the device via a relay

(12 V). In order to switch over between two devices you will need a

relay (12 V).

Seite 23

Page 24

tams elektronik

English MT-1 | MT-2 | MT-3

Fig. MT-1.1:

MT-1: Connections

Seite 24

Page 25

tams elektronik

MT-1 | MT-2 | MT-3 English

Fig. MT-1.2:

MT-1: Connection of a device via a relay

Seite 25

Page 26

tams elektronik

English MT-1 | MT-2 | MT-3

9. Connecting the MT-2

Follow the connections diagrams fig. MT-2.1 and MT-2.2 and connect

the minitimer MT-2 as follows:

X1-1 device

(polarized device "+")

X1-2 device

(polarized device "-")

X2-1 switching input

X2-2 transformer

(with direct voltage "+")

X2-3 transformer / earth

(with direct voltage "^")

In order to trigger the minitimer MT-2 you have to connect the

switching input (connection X2-1) to earth (connection X2-3), e.g. with

a switch. After the set delay time the connected device will be switched

on. Approx. 1 second after interrupting the earth connection between

X2-1 and X2-3, the device will be switched off.

Setting the time delay

Set the desired delay time at the trimm pot R7. Please note: In case the

time passing between making and interrupting the earth connection

between X2-1 and X2-3 is shorter than the preset delay time, the

connected device stays off.

Connecting a relay

In order to switch a device with more than 100 mA power consumption or

to switch off a device you have to connect the device via a relay (5 V) and

an protective diode (e.g. 1N4148) as anti-surge diode. When operating

the module without an anti-surge diode it will be destroyed after

several switchings.

Seite 26

Page 27

tams elektronik

MT-1 | MT-2 | MT-3 English

Fig. MT-2.1:

MT-2: Connections

Seite 27

Page 28

tams elektronik

English MT-1 | MT-2 | MT-3

Fig. MT-2.2:

MT-2: Connection of a device via a relay

Seite 28

Page 29

tams elektronik

MT-1 | MT-2 | MT-3 English

10. Connecting the MT-3

Follow the connections diagrams fig. MT-3.1 and MT-3.2 and connect

the minitimer MT-3 as follows:

X1-1 device

(polarized device "+")

X1-2 device

(polarized device "-")

Remark: You can connect solenoid articles directly to the output.

X2-1 transformer / earth

(with direct voltage "^")

X2-2 transformer

(with direct voltage "+")

X2-3 switching input

After applying the voltage, the LED on the module will not be switched

on before the set delay time has passed, in order to check the set time

delay. After the set time has elapsed, the minitimer is operational,

indicated by the LED permanently lighting.

As a rule, the minitimer MT-3 is switched in series with other electronic

circuits generating voltage changes at it´s input (changes between

open and closed ground connection between the switching input X2-3

and the ground connection X2-1). The connected device will be

switched on and off to the rhythm of the voltage changes, however

with the set time delay.

Setting the time delay

Set the desired delay time at the trimm pot R7. Turning to the left will

increase the delay time.

Please note: When altering the time delay during operation without

disconnecting the module from the power supply, first all saved voltage

changes will be "worked off" before the new set time delay takes effect.

Connecting a relay

In order to switch a device with more than 1.000 mA power

consumption or to invert the signals you have to connect the device via

a relay (12 V).

Seite 29

Page 30

tams elektronik

English MT-1 | MT-2 | MT-3

Fig. MT-3.1:

MT-3: Connections

Seite 30

Page 31

tams elektronik

MT-1 | MT-2 | MT-3 English

Fig. MT-3.2:

MT-3: Connection of a device via a relay

Seite 31

Page 32

tams elektronik

!

English MT-1 | MT-2 | MT-3

11. Check list for troubleshooting

Parts are getting too hot and/or start to smoke.

Disconnect the system from the mains immediately!

Possible cause: one or more components are soldered incorrectly.

à In case you have mounted the module from a kit, perform a

visual check (à section 6.) and if necessary, remedy the faults.

Otherwise send in the module for repair.

The lamp connected for the functional test of the module does not

light.

Possible cause: one or more components are soldered incorrectly.

(MT-1: e.g. D2, MT-2: e.g. D1). à Alter the mounting direction.

Possible cause: The lamp is defective. à Check the lamp by

connecting it directly to the voltage supply.

MT-2 only: The module does not switch.

Possible cause: The length of time the input is connected to ground

is shorter than the selected time delay. à Reduce the time delay or

lengthen the time the input is connected to ground.

Seite 32

Page 33

tams elektronik

MT-1 | MT-2 | MT-3 English

Hotline: If problems with your module occur, our hotline is pleased to

help you (mail address on the last page).

Repairs: You can send in a defective module for repair (address on the

last page). In case of guarantee the repair is free of charge for you.

With damages not covered by guarantee, the maximum fee for the

repair is the difference between the price for the ready-built module

and the kit according to our valid price list. We reserve the right to

reject the repairing of a module when the repair is impossible for

technical or economic reasons.

Please do not send in modules for repair charged to us. In case of

warranty we will reimburse the forwarding expenses up to the flat rate

we charge according to our valid price list for the delivery of the

product. With repairs not covered by guarantee you have to bear the

expenses for sending back and forth.

Seite 33

Page 34

tams elektronik

English MT-1 | MT-2 | MT-3

12. Guarantee bond

For this product we issue voluntarily a guarantee of 2 years from the

date of purchase by the first customer, but in maximum 3 years after

the end of series production. The first customer is the consumer first

purchasing the product from us, a dealer or another natural or juristic

person reselling or mounting the product on the basis of selfemployment. The guarantee exists supplementary to the legal warranty

of merchantability due to the consumer by the seller.

The warranty includes the free correction of faults which can be proved

to be due to material failure or factory flaw. With kits we guarantee

the completeness and quality of the components as well as the function

of the parts according to the parameters in not mounted state. We

guarantee the adherence to the technical specifications when the kit

has been assembled and the ready-built circuit connected according to

the manual and when start and mode of operation follow the

instructions.

We retain the right to repair, make improvements, to deliver spares or

to return the purchase price. Other claims are excluded. Claims for

secondary damages or product liability consist only according to legal

requirements.

Condition for this guarantee to be valid, is the adherence to the

manual. In addition, the guarantee claim is excluded in the following

cases:

if arbitrary changes in the circuit are made,

if repair attempts have failed with a ready-built module or device,

if damaged by other persons,

if damaged by faulty operation or by careless use or abuse.

Seite 34

Page 35

tams elektronik

MT-1 | MT-2 | MT-3 English

13. EU Declaration of Conformity

This product fulfils the requirements of the following EU

directives and therefore bears the CE marking.

2001/95/EU Product Safety Directive

2015/863/EU on the restriction of the use of certain hazardous

substances in electrical and electronic equipment (RoHS)

2014/30/EU on electromagnetic compatibility (EMC Directive).

Underlying standards:

DIN-EN 55014-1 and 55014-2: Electromagnetic compatibility -

Requirements for household appliances, electric tools and similar

electrical appliances. Part 1: Emitted interference, Part 2: Immunity to

interference

To maintain electromagnetic compatibility during operation, observe

the following measures:

Only connect the supply transformer to a professionally installed and

fused earthed socket.

Do not make any changes to the original components and follow the

instructions, connection and assembly diagrams in this manual exactly.

Only use original spare parts for repair work.

14. Declarations concerning the WEEE directive

This product complies with the requirements of the EU

Directive 2012/19/EC on Waste Electrical and Electronic

Equipment (WEEE).

Do not dispose of this product in (unsorted) municipal waste, but

recycle it.

Seite 35

Page 36

tams elektronik

n

n

n

Information and tips:

n

http://www.tams-online.de

n

n

n

n

Warranty and service:

n

Tams Elektronik GmbH

n

Fuhrberger Straße 4

DE-30625 Hannover

n

fon: +49 (0)511 / 55 60 60

fax: +49 (0)511 / 55 61 61

n

e-mail: modellbahn@tams-online.de

n

n

Loading...

Loading...